Flow path switching valve

A flow path switching and valve body technology, applied in multi-port valves, valve devices, engine components, etc., can solve problems such as stuck, insufficient piston concentricity, and achieve the effect of solving stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

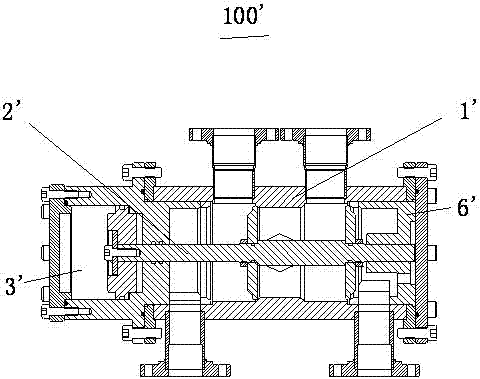

[0025] see figure 2 and image 3 As shown, a flow path switching valve 100 provided by the present invention includes: a valve body 1 having a valve chamber 10; a valve core 2 movably arranged in the valve chamber 10; a piston driving device 3 installed in the valve chamber 10; The first end of the valve body 1, the piston driving device 3 includes an end blind plate 31, which seals the end of the piston driving device 3; the piston drives the valve body 32, one end is fixedly connected to the end blind plate 31, and the other end is connected to the valve body. The body flange 11 is connected; the piston positioning seat 33 is fixedly installed between the piston-driven valve body 32 and the valve body flange 11, and limits the movement stroke of the piston 4; the piston 4 moves along the inner wall of the piston-driven valve body 32 and Connected with the valve core 2 through the ball joint 5; the bushing 6 is installed on the second end of the valve body 1 and has a guide...

specific Embodiment 2

[0030] see Figure 6 and Figure 7 As shown, the main structure of the flow path switching valve 200 in Embodiment 2 of the present invention is the same as that in Embodiment 1. For the understanding of the main structure, please refer to Embodiment 1, and the same parts also use the same reference numerals, which will not be repeated here.

[0031] The main difference of this embodiment is that the ball head 51 is set separately from the valve core 2 . The advantage of this is that the piston pressing plate 42 may not be provided with a mounting groove communicating with the central through hole and extending radially to form a lateral opening, only the central through hole 421 needs to be provided, and the piston pressing plate 42 is set into the connecting ball of the valve core 2 After the parts of the head 51 (with the second diameter), they are constrained together by axial bolts (not shown) to complete the assembly. The piston-driven valve body 32 and the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com