Splitting and core-pulling method for die-casting die

A die-casting mold and mold technology, which is applied in the field of core-pulling of die-casting molds, can solve the problems of blockage or retreat of the slider, and achieve the effect of solving the blockage or retreat and small contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

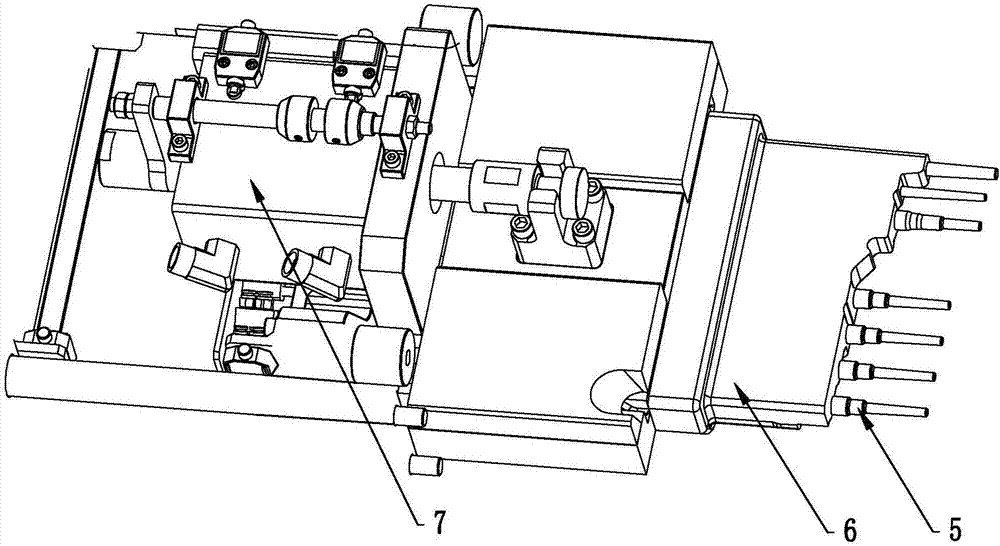

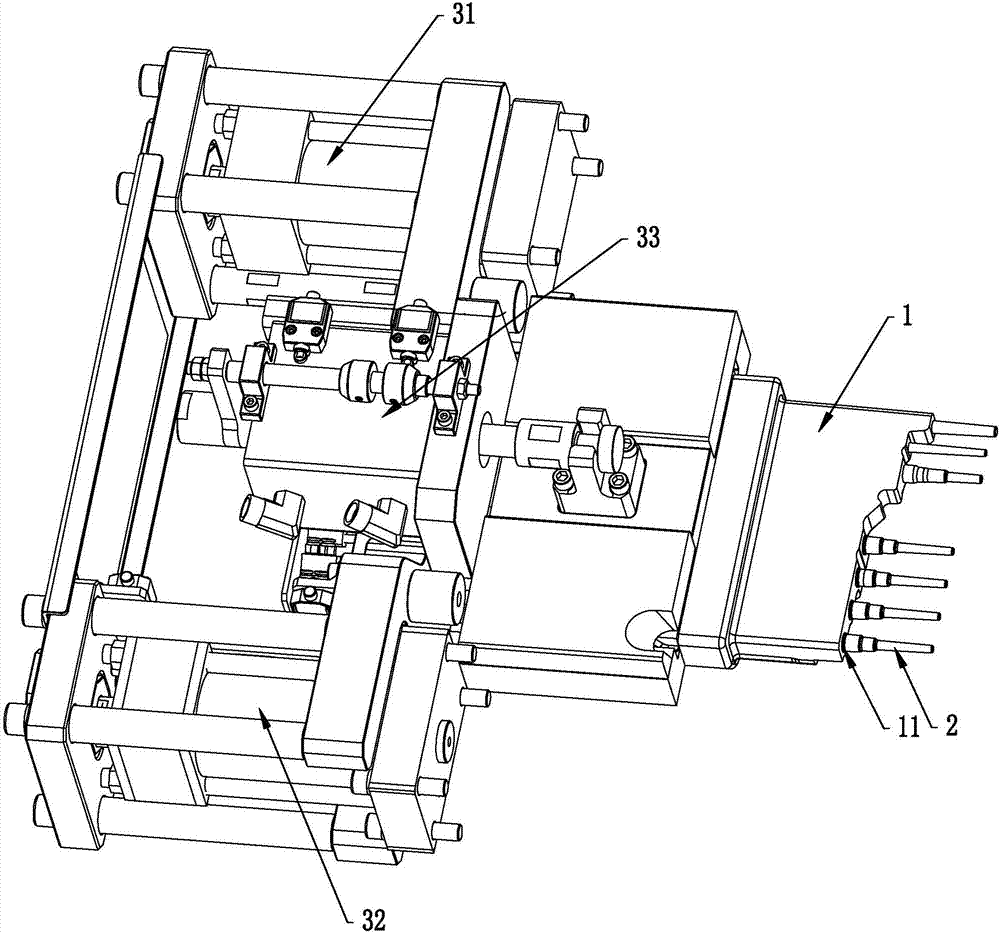

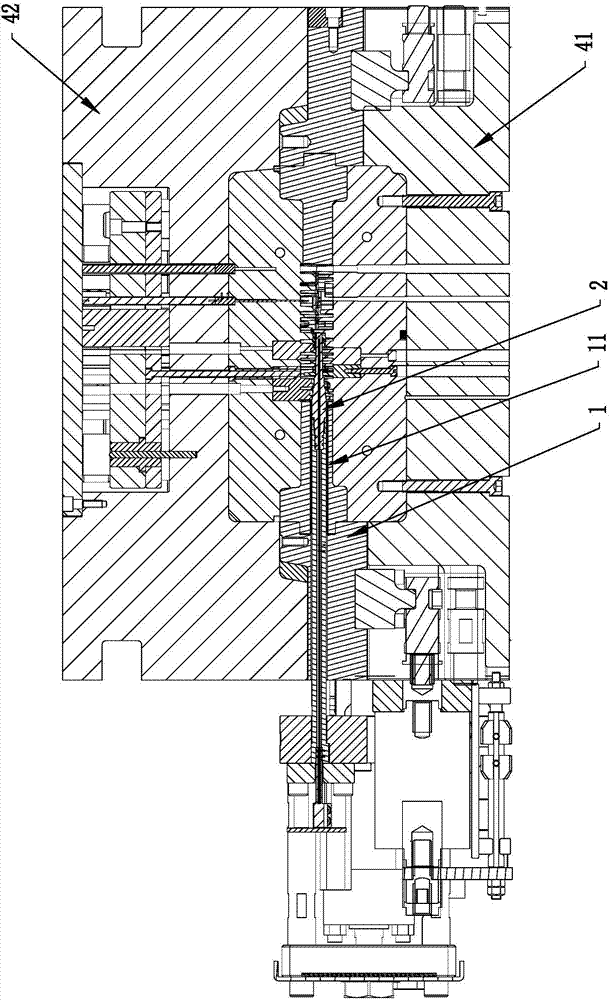

[0020] Such as Figure 2-4 The die-casting mold split core-pulling method shown, the mold used includes a fixed mold 41 and a movable mold 42 arranged with each other, and a number of fixed mold inserts and movable mold inserts are distributed and fixed in the fixed mold 41 and the movable mold 42, The core-pulling pins 2 continue to pass through the fixed mold insert and the movable mold insert after passing through the slide block 1 .

[0021] refer to figure 2 The core-pulling mechanism includes a slider 1, a core-pulling needle 2 and several driving cylinders. The cylinders in this embodiment are all hydraulic cylinders, and the core-pulling needle 2 and the slider 1 are respectively driven by different cylinders. The core-pulling needle 2 and the sliding Blocks 1 respectively have left and right movement strokes, and the moving direction of core-pulling pin 2 is parallel to its axis, and core-pulling pin 2 is slidably connected with slider 1 .

[0022] The working step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com