Numerical control high-speed carving and milling machine of bridge type elevated cross beam moving gantry

A beam, high-speed technology, applied in the field of machine tools, can solve the problems of inaccurate feed of each axis, and achieve the effects of compact structure, improved stability, and improved kinematic rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

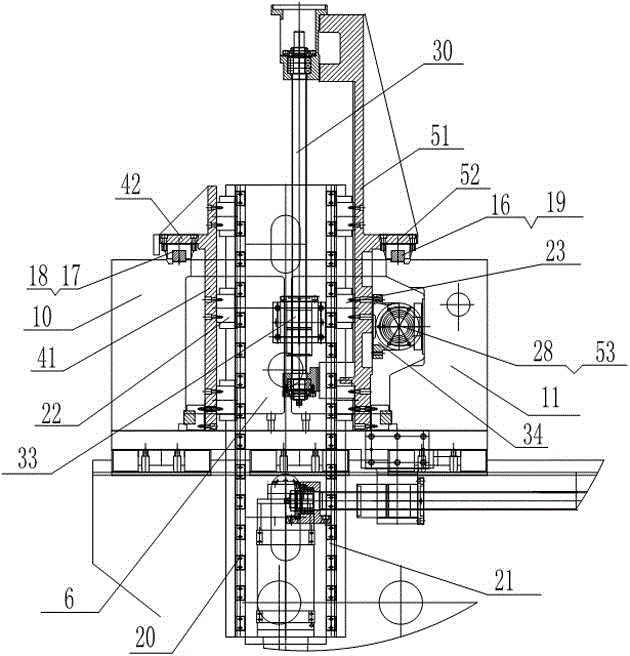

[0047] Such as figure 1 , figure 2 , image 3 with Figure 4 The CNC bridge-type elevated crossbeam mobile gantry high-speed engraving and milling machine shown includes a base 1, a left wall 2, a right wall 3, a beam, a front slide, a rear slide, a ram 6 and a spindle 7; the base 1 A workbench 8 is arranged on the top, the left wall 2 and the right wall 3 are arranged on the base 1 in parallel and the workbench 8 is located between the left wall 2 and the right wall 3, and the crossbeam is composed of a front crossbeam 10 and a rear crossbeam 11, the cross-section of the front cross beam 10 is "one" shape, the rear cross beam 11 is "Π" shape and the opening faces forward, and one end of the front cross beam 10 is fixed to one end of the rear cross beam 11.

[0048] The two ends of the beam are respectively arranged on the left wall 2 and the right wall 3, and form a horizontal movement pair with the left wall 2 and the right wall 3 respectively; the front sliding seat and...

Embodiment 2

[0060] Such as Figure 5 with Image 6As shown, the difference between this embodiment and Embodiment 1 is that the dual-drive engraving and milling is realized in the up and down direction. Compared with Embodiment 1, the structural difference is that the base 1, the left wall 2, the right wall 3, the Except for the guide rail 12, the right guide rail 13 and the workbench 8, the remaining components are two sets with the same structure. The specific structure is that two beams are slidably installed on the left guide rail 12 and the right guide rail 13, and the sliding methods are the same as those in the first embodiment. , not detailed here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com