Filter press filter plate handle with braking function and braking method thereof

A filter press filter plate and handle technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as affecting work efficiency, inability to achieve braking, and filter plate dumping, etc., to improve work efficiency and structure. Novel design to ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

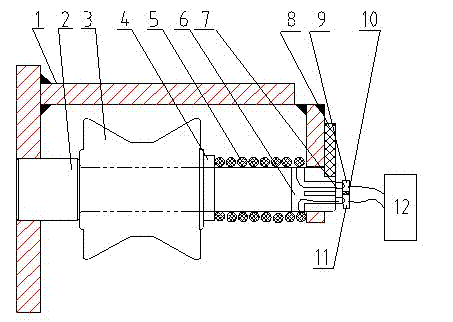

[0009] Embodiment 1: with reference to attached figure 1 . A filter plate handle of a filter press with a braking function, which includes a handle-type roller frame 1, and the trapezoidal groove-type metal roller 3 is located in the roller frame 1 through the electromagnetic roller shaft 2 below the handle-type roller frame 1, and the electromagnetic roller Axis 2 takes power through the conductive strip, and the power supply terminal of the conductive strip is connected to the power controller.

[0010] Described electromagnetic roller shaft 2 is made of positioning shaft and roller shaft, and the diameter of positioning shaft is larger than the diameter of roller shaft, and purpose is used for the limit of metal roller 3.

[0011] One end of the electromagnetic roller shaft 2 has a three-way wire channel 6, the coil 5 is wound on the roller shaft 2 and is located on one side of the metal roller 3, and the two ends of the coil 5 are respectively connected to the two power c...

Embodiment 2

[0015] Embodiment 2: On the basis of Embodiment 1, a method for braking the filter plate handle of a filter press with a braking function, the metal roller 3 wheel surfaces in the handle on both sides of the filter plate are located on the main beam guide rail, when When the power controller 12 instructs the filter plate to move, the two conductive strips 9 and 11 are non-conductive. The electromagnetic roller shaft 2 is energized to generate magnetic force and attract the metal roller 3 so that it cannot rotate, thereby achieving the purpose of braking the filter plate. The magnitude of the suction force of the electromagnetic roller shaft 2 is controlled by the magnitude of the coil current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com