Pull type clutch assembly test tool

A technology for testing tooling and clutches, which is applied in the field of clutches, can solve the problems of lack of test tooling for pull-type clutch cover assemblies and insufficient testing methods, and achieve the effects of increasing pressure, improving detection results, and reducing tooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figure 1-6 As shown, a pull clutch assembly test fixture, including:

[0032] Base 5;

[0033] The clutch assembly fixed bracket, the clutch assembly fixed bracket is arranged on the base, including the lower fixed bracket 4 and the limit piece 3 arranged above the lower fixed bracket, the lower fixed bracket 4 is provided with four connecting rods 41 and six The fixed end 42, the lower fixed bracket 4 is connected with the limiter 3 through the connecting rod 41, and the center of the limiter 3 is provided with a detection through hole 31;

[0034] The detection part, when performing the clutch assembly test, the clutch assembly is fixed between the lower fixing bracket and the limiter through the fixed end, the detection part is placed on the clutch assembly, and is located in the detection through hole, and the limiter The center point of is on the axis of the clutch assembly.

[0035] When testing the clutch assembly, install the test tool on the testing...

Embodiment 2

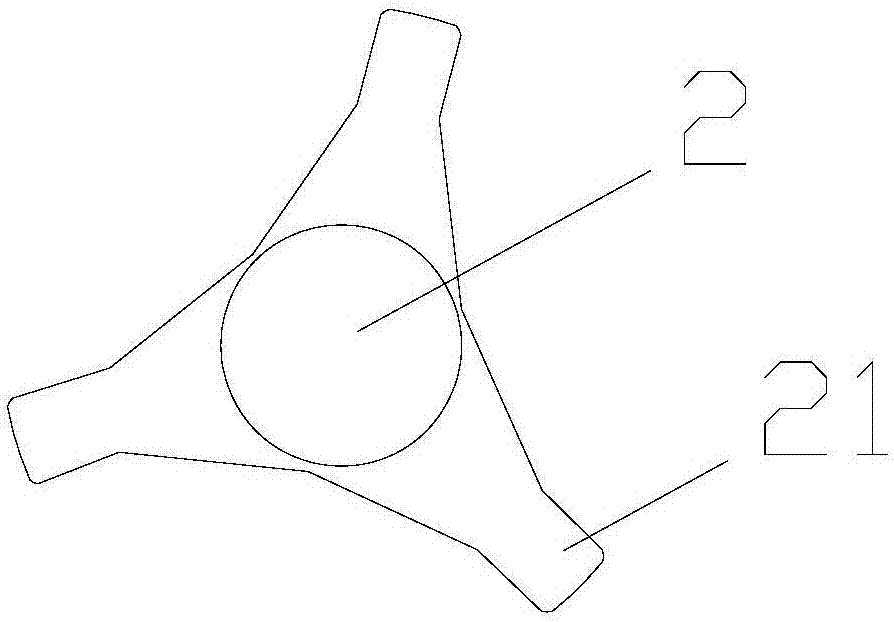

[0042] Compared with Embodiment 1, the detection part in this embodiment is different from that in Embodiment 1. The detection part is used to detect the big end of the diaphragm spring, and other parts are the same as in Embodiment 1. Such as Figure 7 , 8 As shown, the detection part is disc-shaped, and three protrusions 21 are uniformly arranged on the outer periphery of the detection part 2 along its radial direction. The detection part is used to detect the strength of the large end of the diaphragm spring of the clutch assembly. For a pull clutch, during the period of time when the clutch pedal is not stepped on during the driving phase of the vehicle, the large end of the diaphragm spring presses the pressure plate to ensure that the driven plate and The flywheels are close together, so the large end of the diaphragm spring is under pressure for a long time, so the strength of the large end of the diaphragm spring needs to meet the requirements. During the test, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com