Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Ensure structural rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

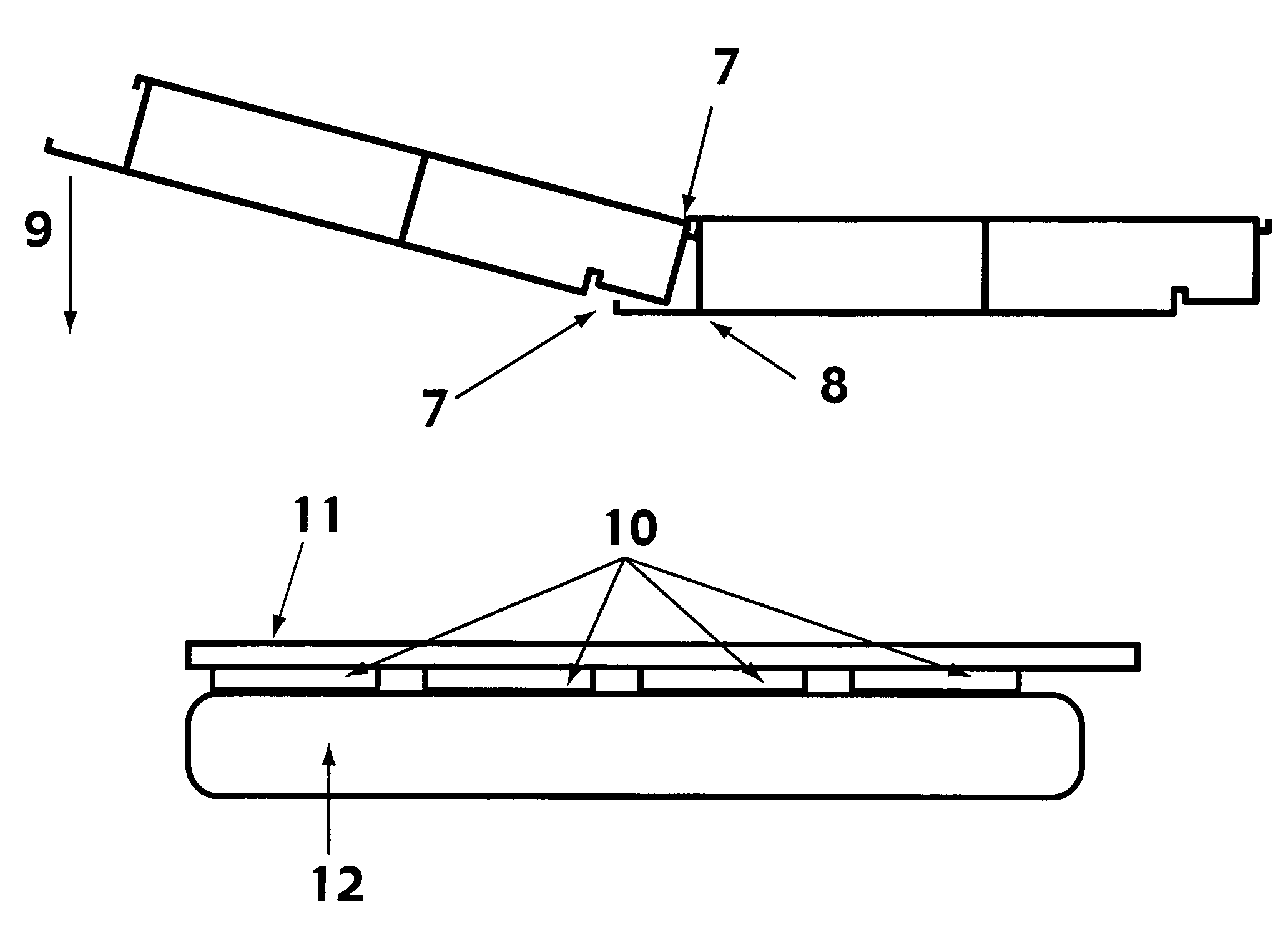

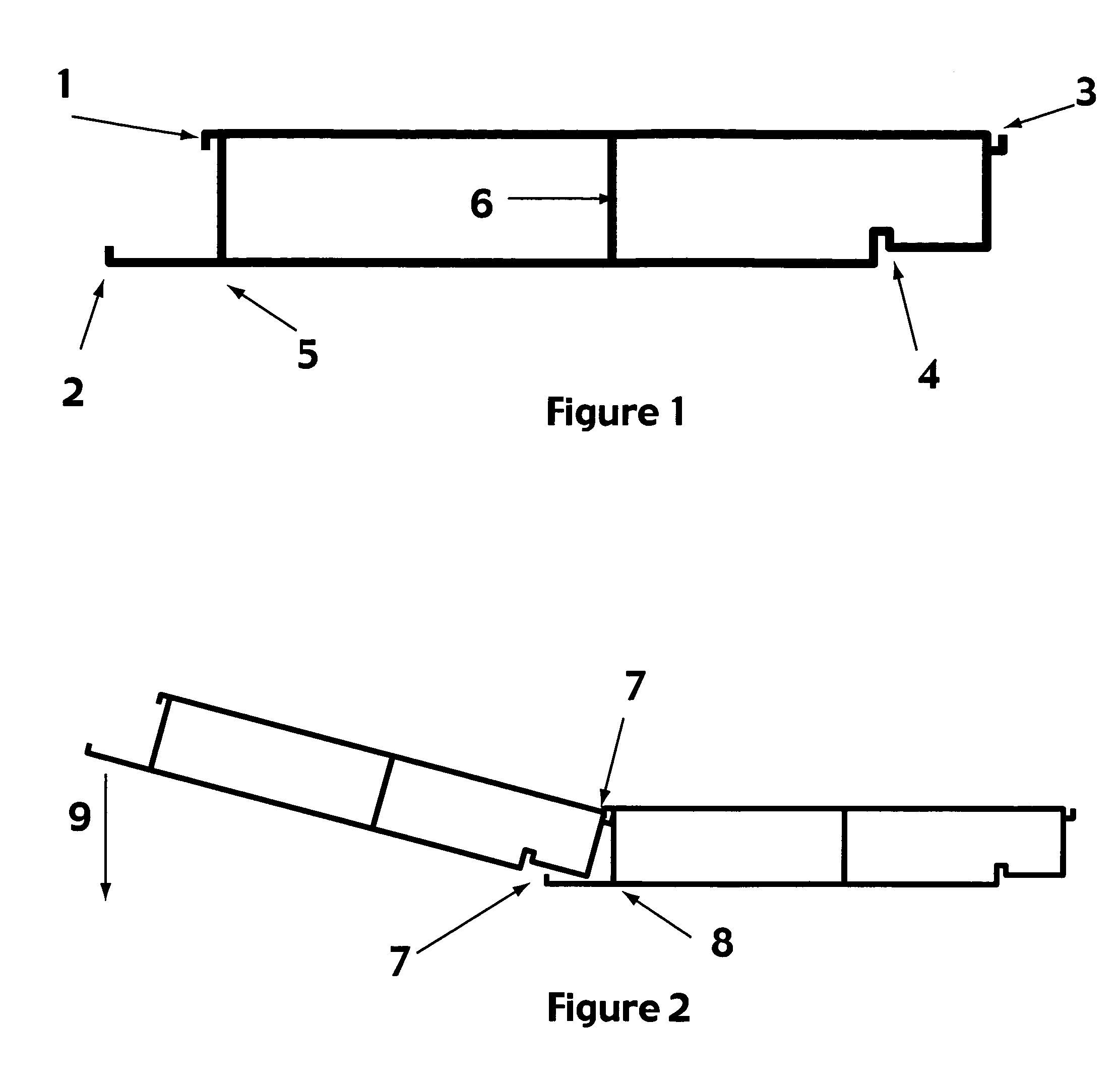

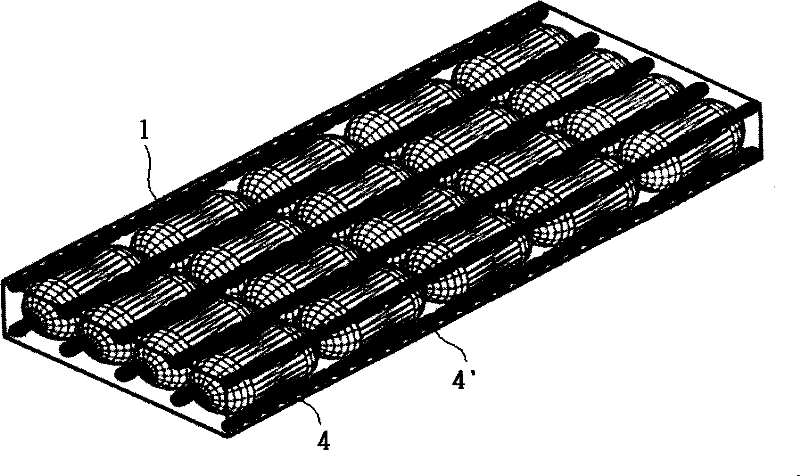

Modular deck structure of a pontoon boat

ActiveUS7188576B2Easy to manufactureEasy to assembleNon-magnetic metal hullsHull decksMarine engineeringModularity

A modular snap-tight interlocking deck and process for constructing a pontoon boat with said deck is described. The modular deck includes lightweight planks that snap together using a tongue-in-groove design. Once joined, the planks are inseparable and form a rigid, flat, watertight surface.

Owner:XPRESS BOATS

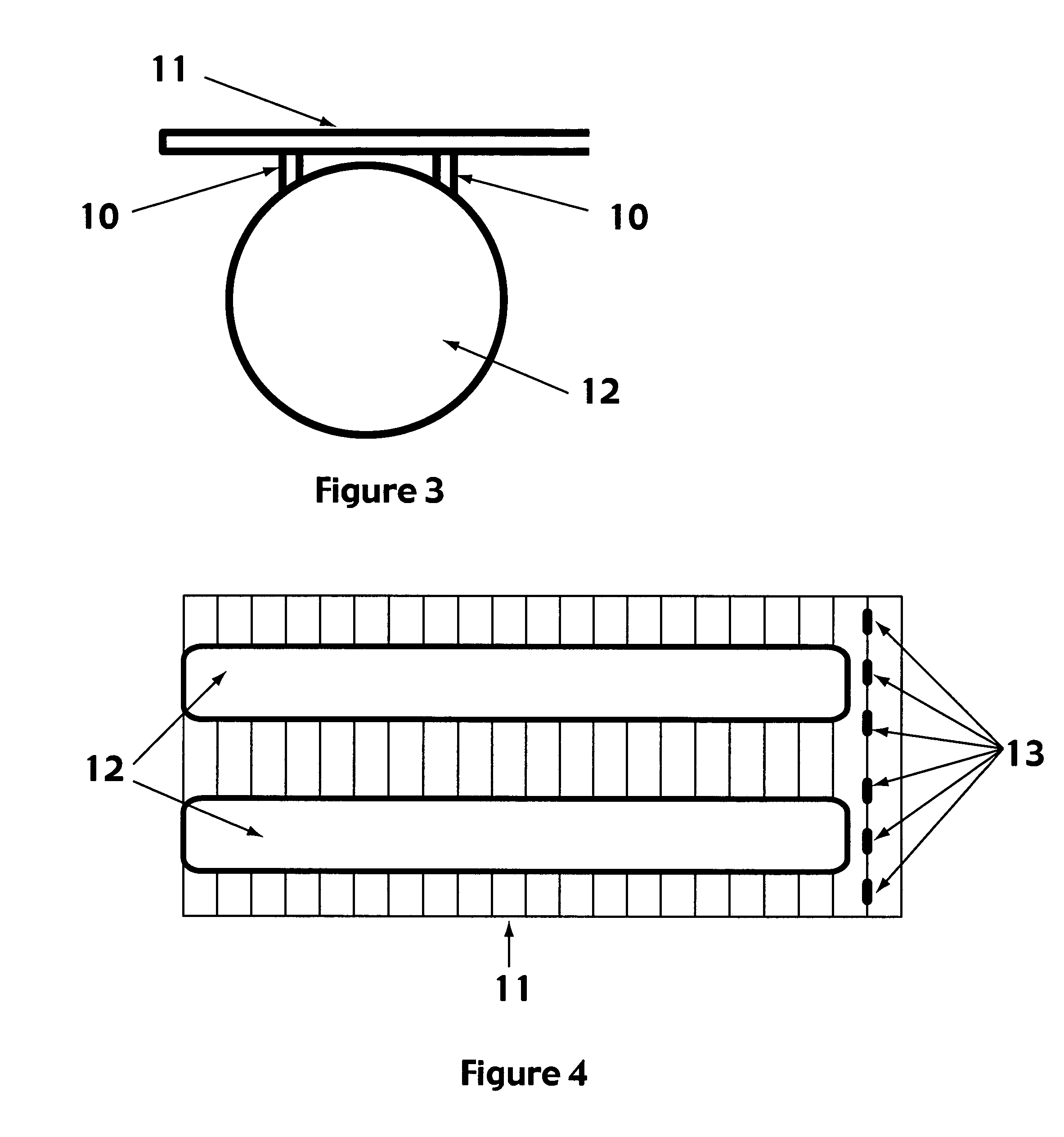

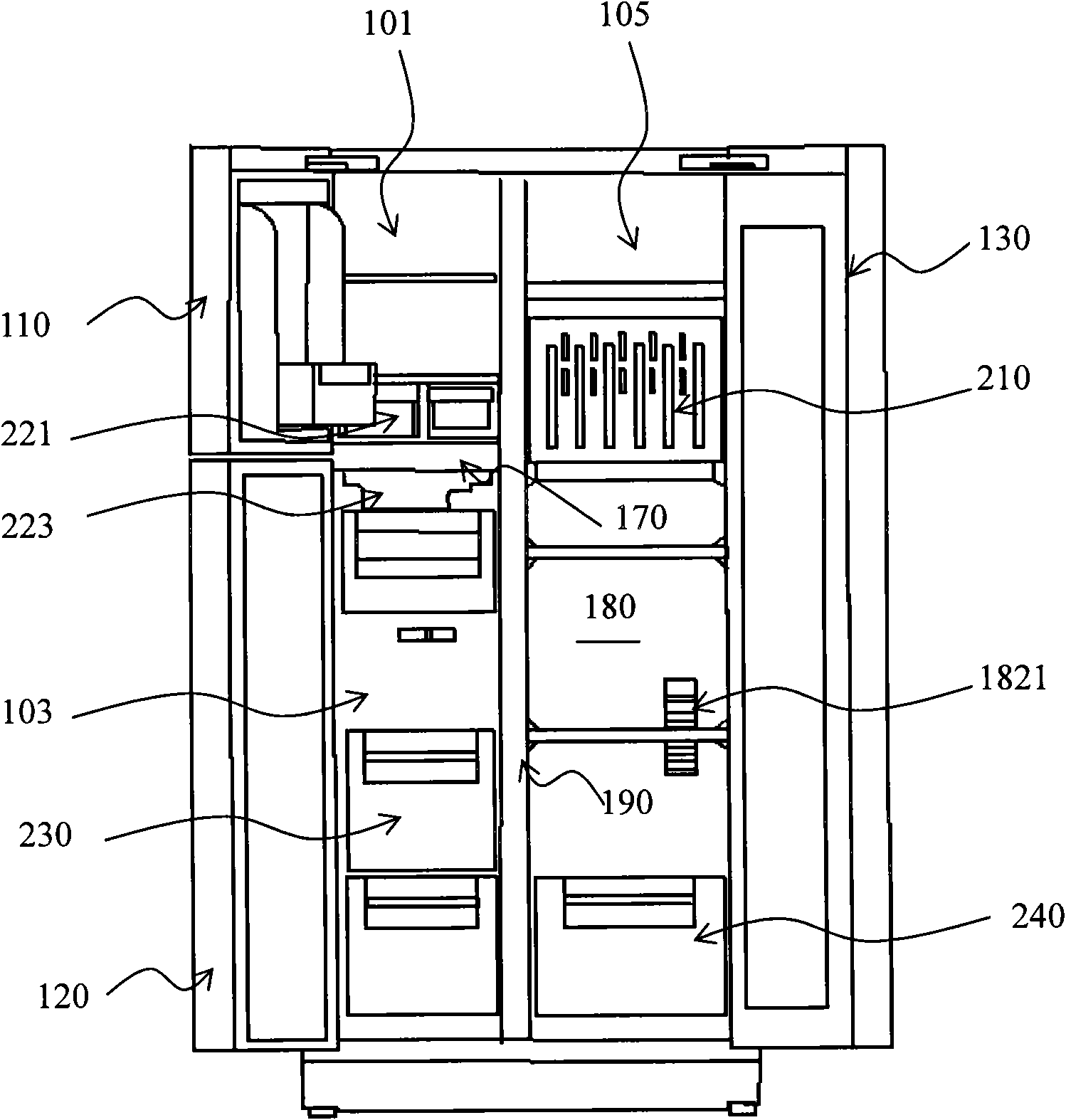

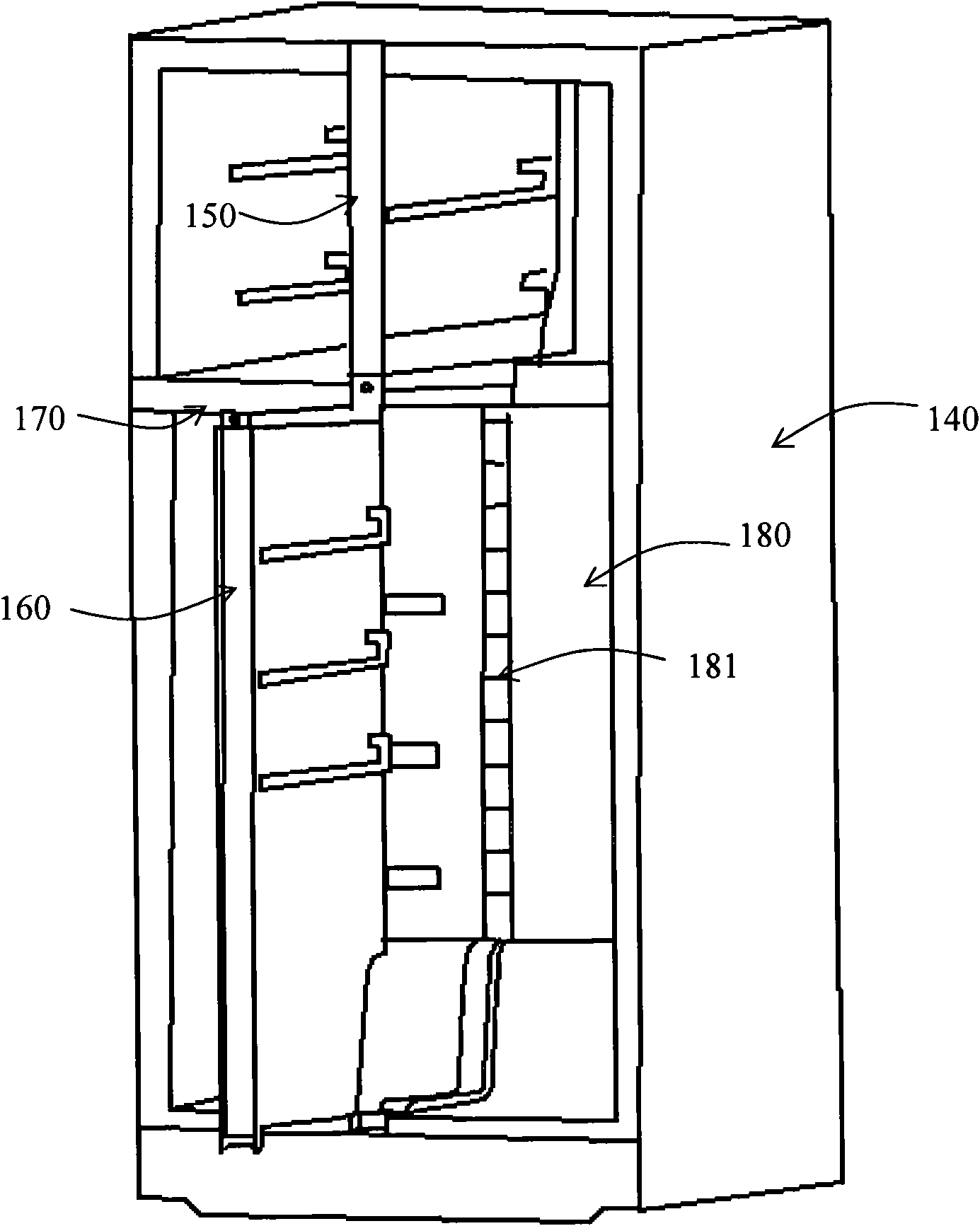

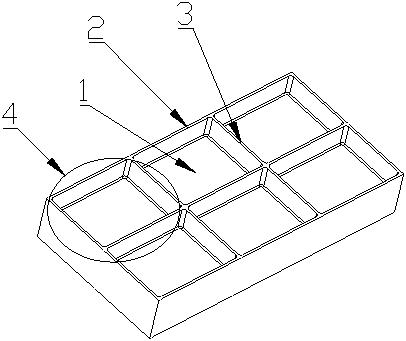

Refrigeration equipment and case manufacturing method thereof

ActiveCN101603761AEnsure structural rigidityEnsure structural stabilityLighting and heating apparatusDomestic refrigeratorsInterior spaceFoaming agent

The invention discloses refrigeration equipment comprising a case, wherein the case is internally provided with a liner and a partition to divide the inner space of the case into a plurality of chambers, and the partition is a prefabricated partition and is connected with the liner in an embedding way. The invention also provides a case manufacturing method of the refrigeration equipment, comprising the following steps: preassembling the case; placing the prefabricated partition into the case to enable the prefabricated partition to be connected with the liner of the case in an embedding way; and filling a foaming agent into the case and enabling the foaming agent to enter the prefabricated partition to carry out case foaming. The prefabricated partition is arranged in the liner of the case of the refrigeration equipment, and the prefabricated partition is connected with the liner in an embedding way, therefore, the inner space of the case can be flexibly divided to obtain the plurality of chambers. Meanwhile, because the liner can still an integral structure, the structure rigidity and the stability of the liner are ensured.

Owner:HAIER GRP CORP +1

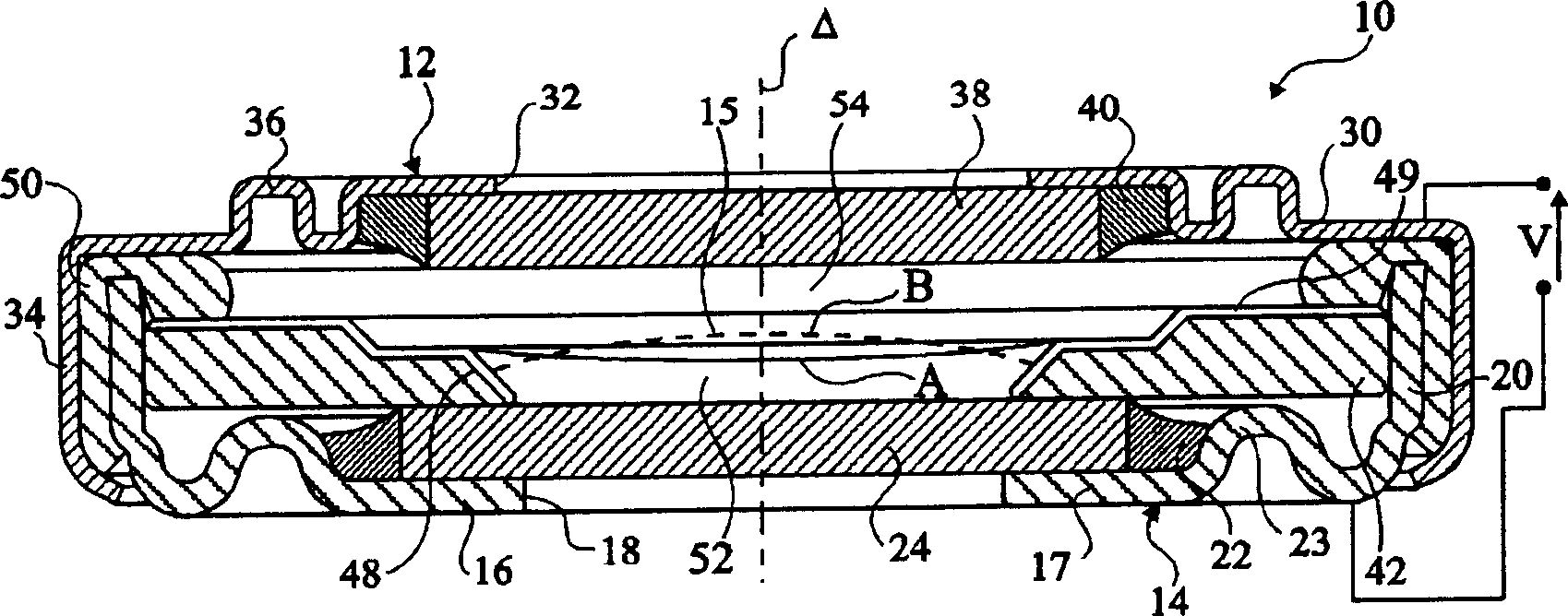

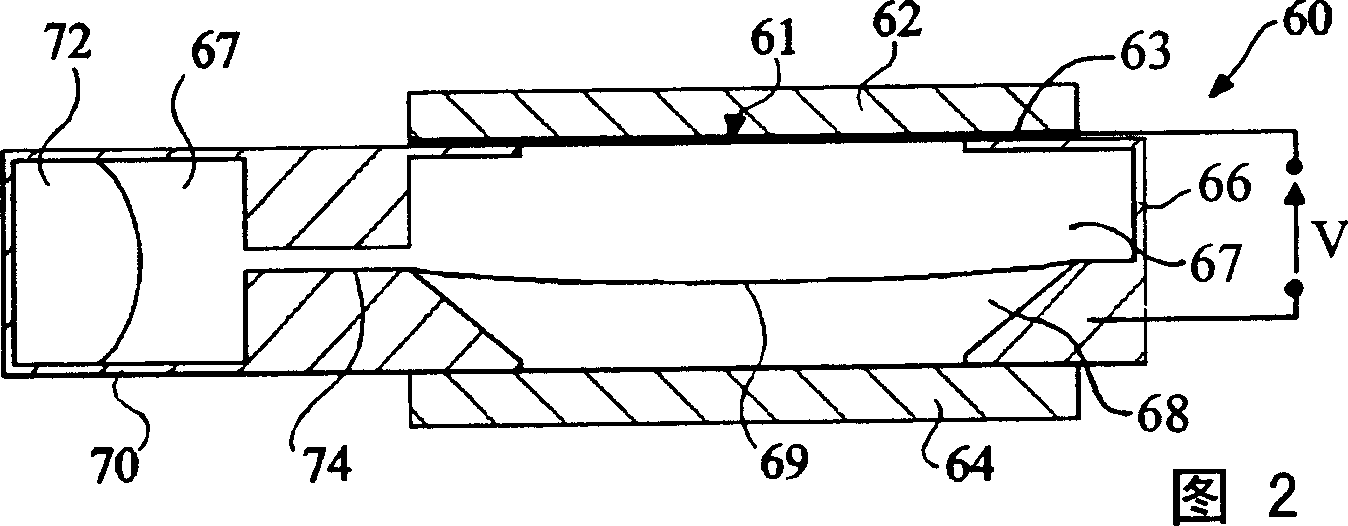

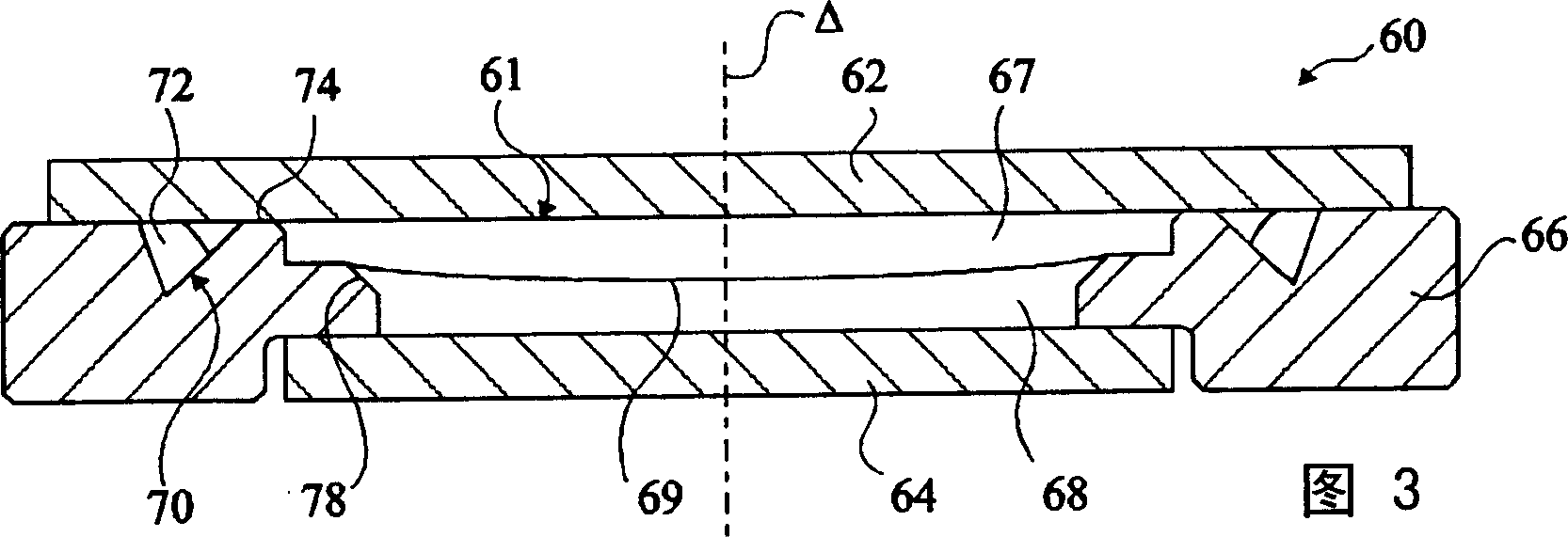

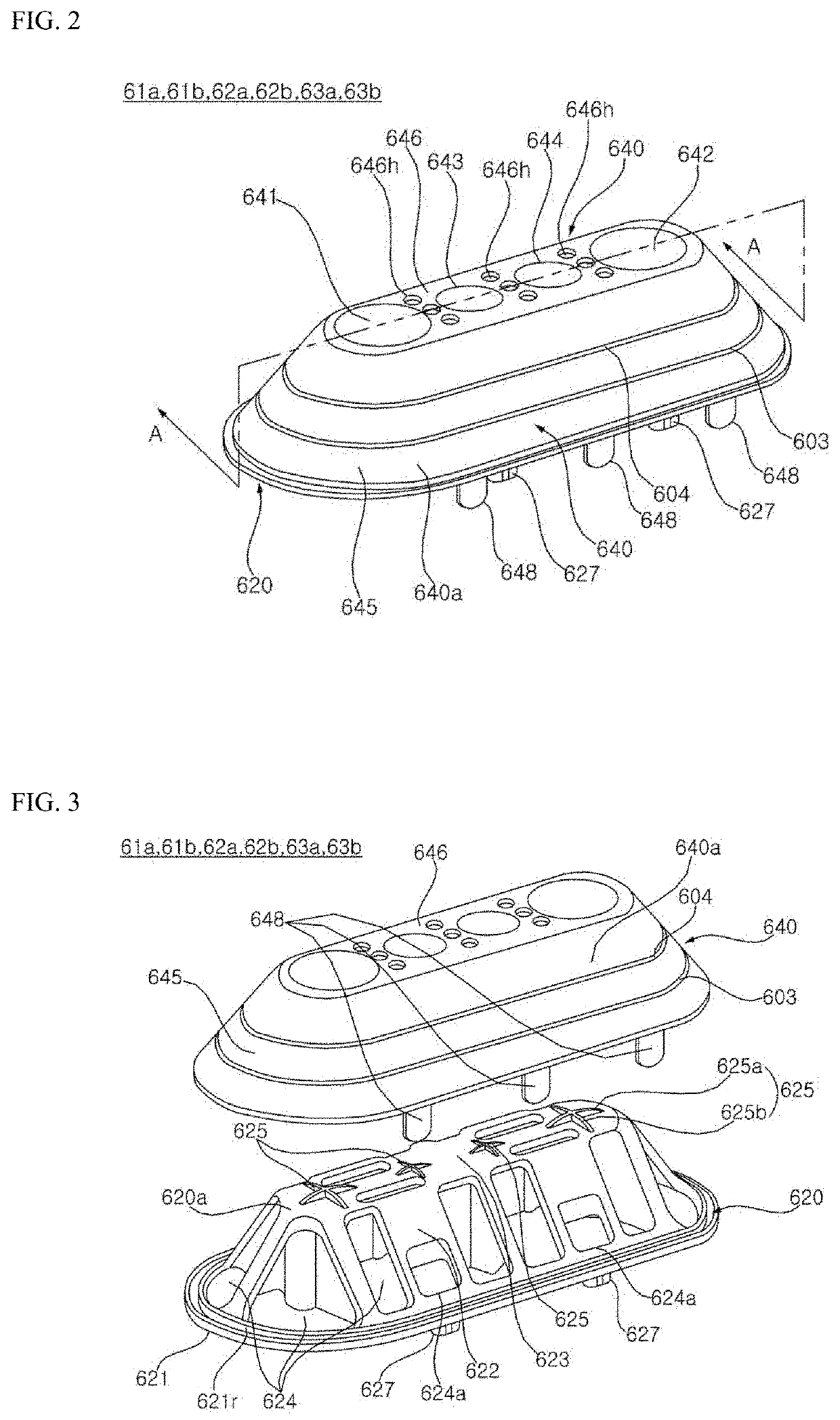

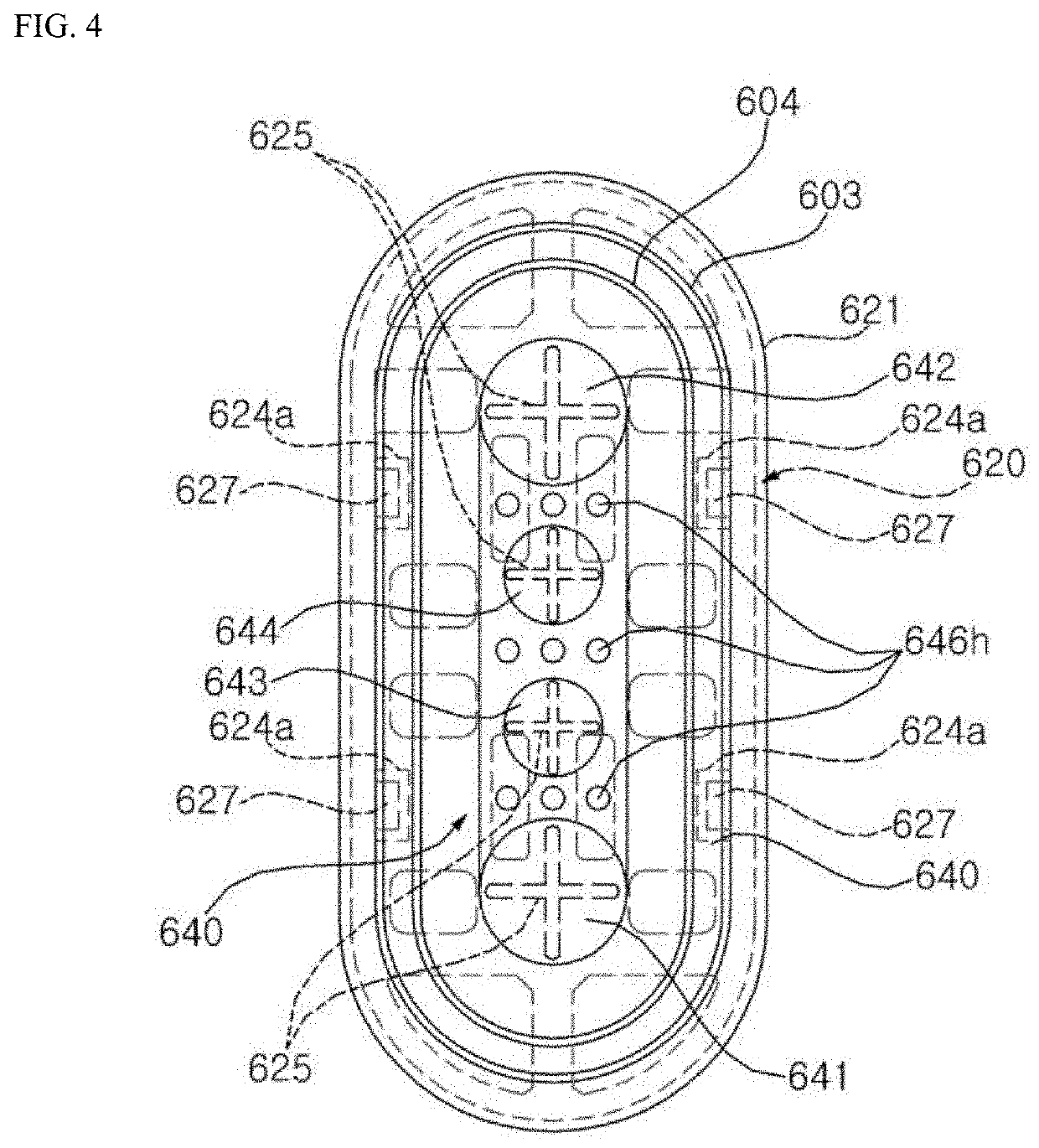

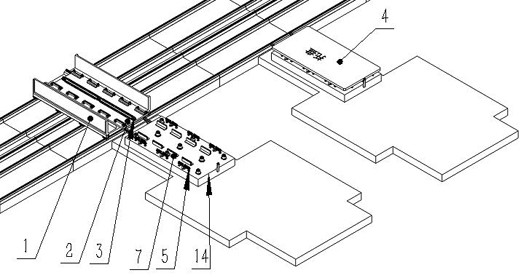

Variable-focus lens and method of manufacturing the same

InactiveCN1885066AEasy to manufactureEnsure structural rigidityMountingsLensOptical axisRefractive index

The invention relates to a variable-focus lens (60) for focussing light rays in light paths passing through the lens along an optical axis (Delta). The lens comprises an arrangement of first and second immiscible liquids (67, 68) that have different refractive indices and are in contact over a moveable refractive optical interface (69), a volume of gas (72) in contact with one of said liquids, and a retention measure (70, 74) for keeping the volume of gas away from the light paths of the light rays passing through the lens for focussing.

Owner:VARIOPTIC SA

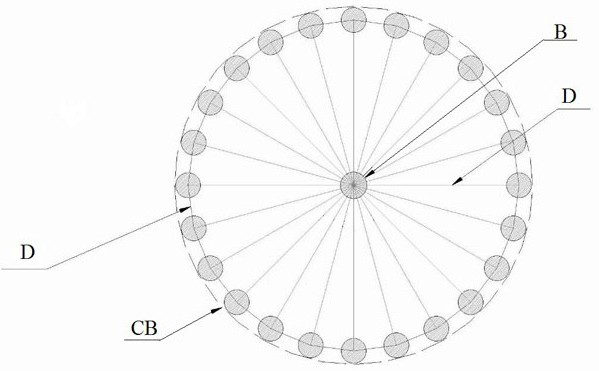

Method and device for causing a ship to dive by using additional buoyancy

The present invention provides a method and device for launching a ship using additional buoyancy, wherein, in order to keep the ship balanced during launching, the additional buoyancy is applied to the inside or outside of the ship instead of adding ballast to the ship. The method includes: placing a buoyant body of a size determined by the weight and buoyancy of the partially constructed ship on the bottom surface of the ship or on the side of the ship; fixing the buoyant body on the hull to generate additional buoyancy Maintaining the balance of the hull during launching; loading water into the dock to launch partially built and fully built boats; transporting fully built boats out of the dock; draining the dock to dock partially built boats bottom of the dock; and separating the buoy from the partially constructed hull.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

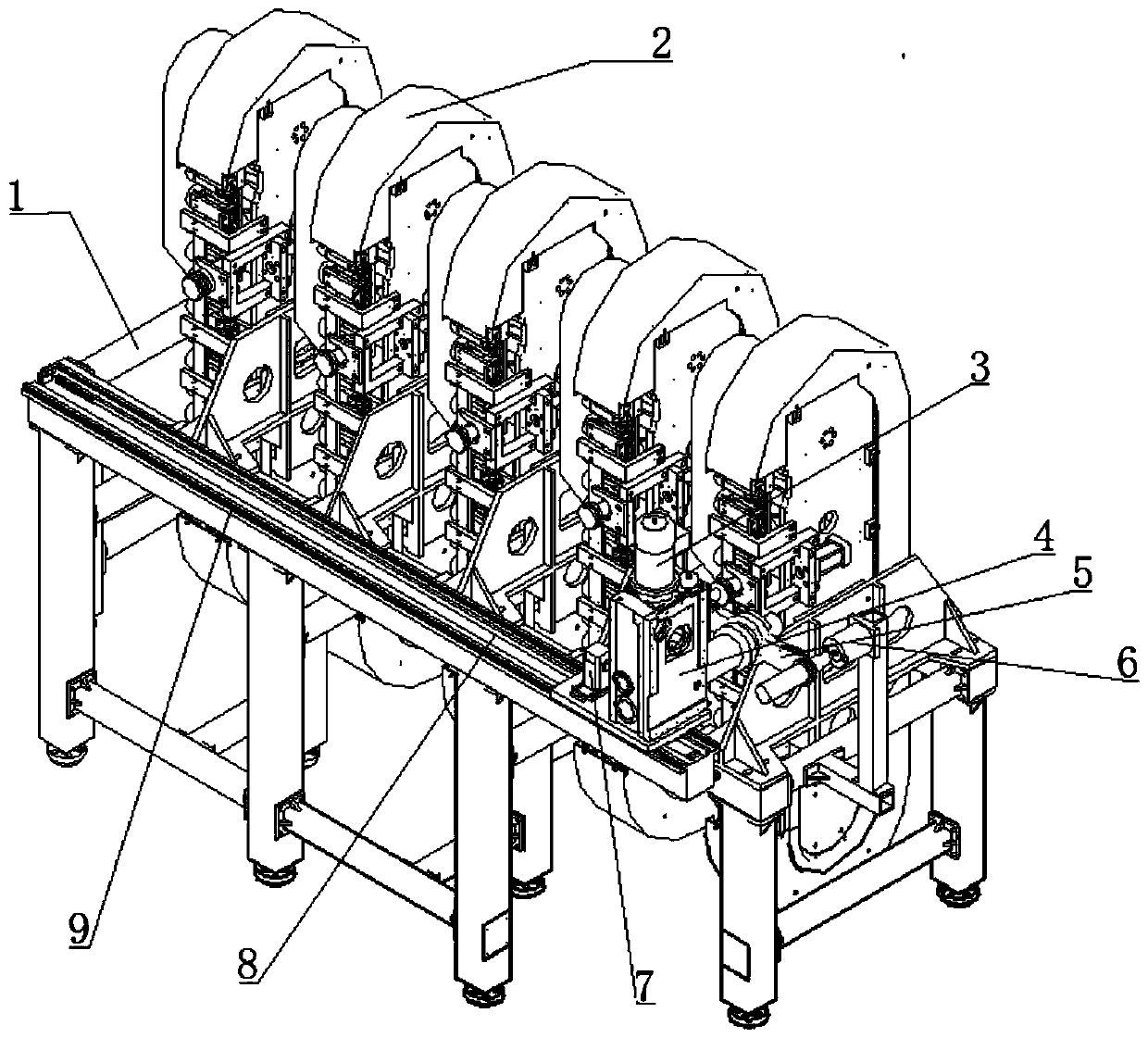

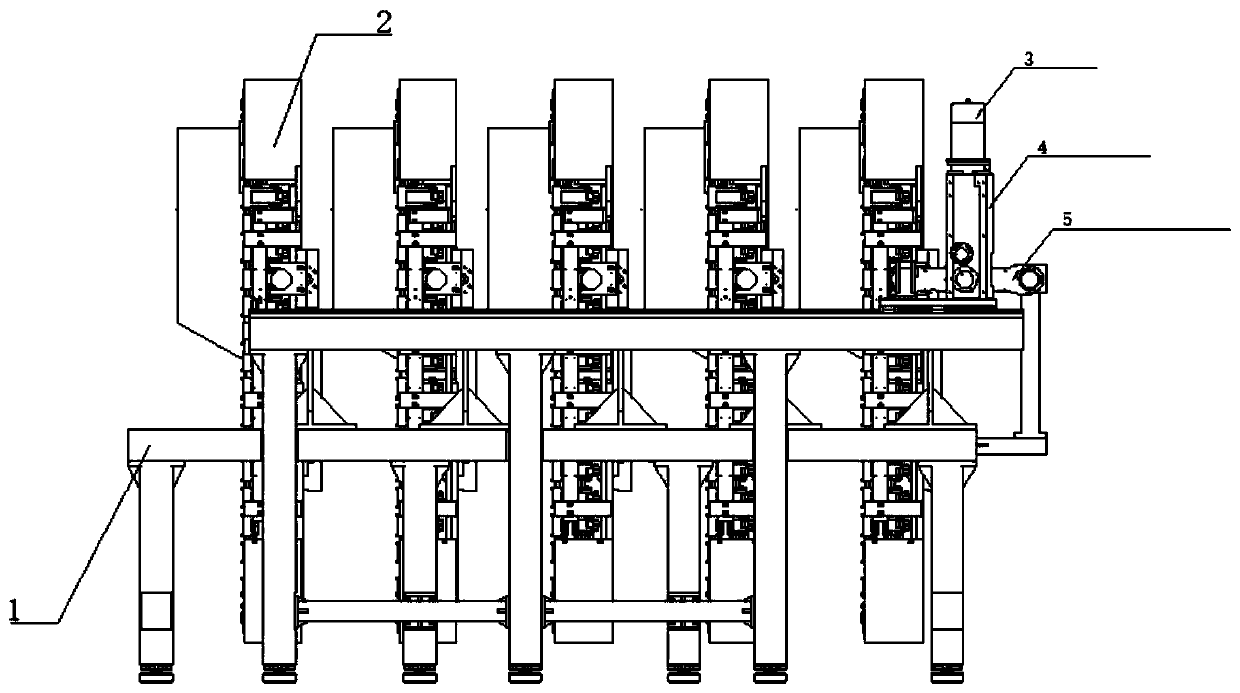

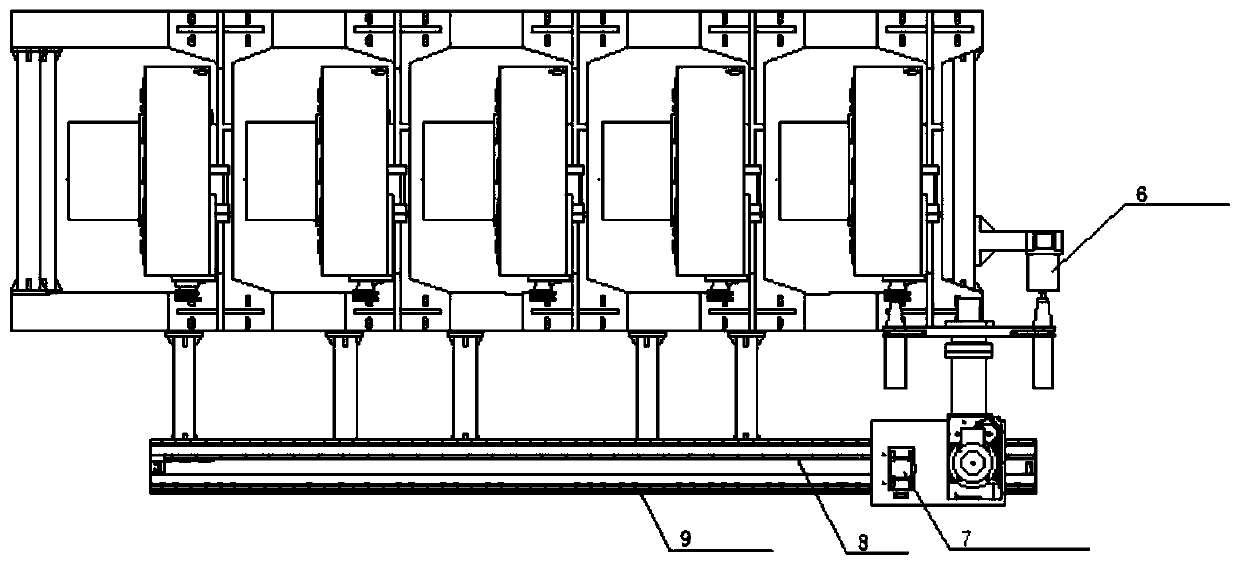

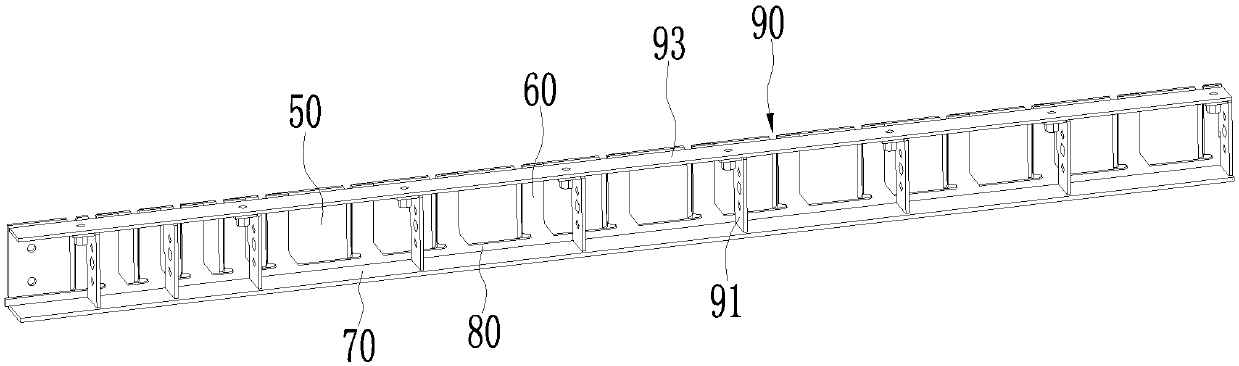

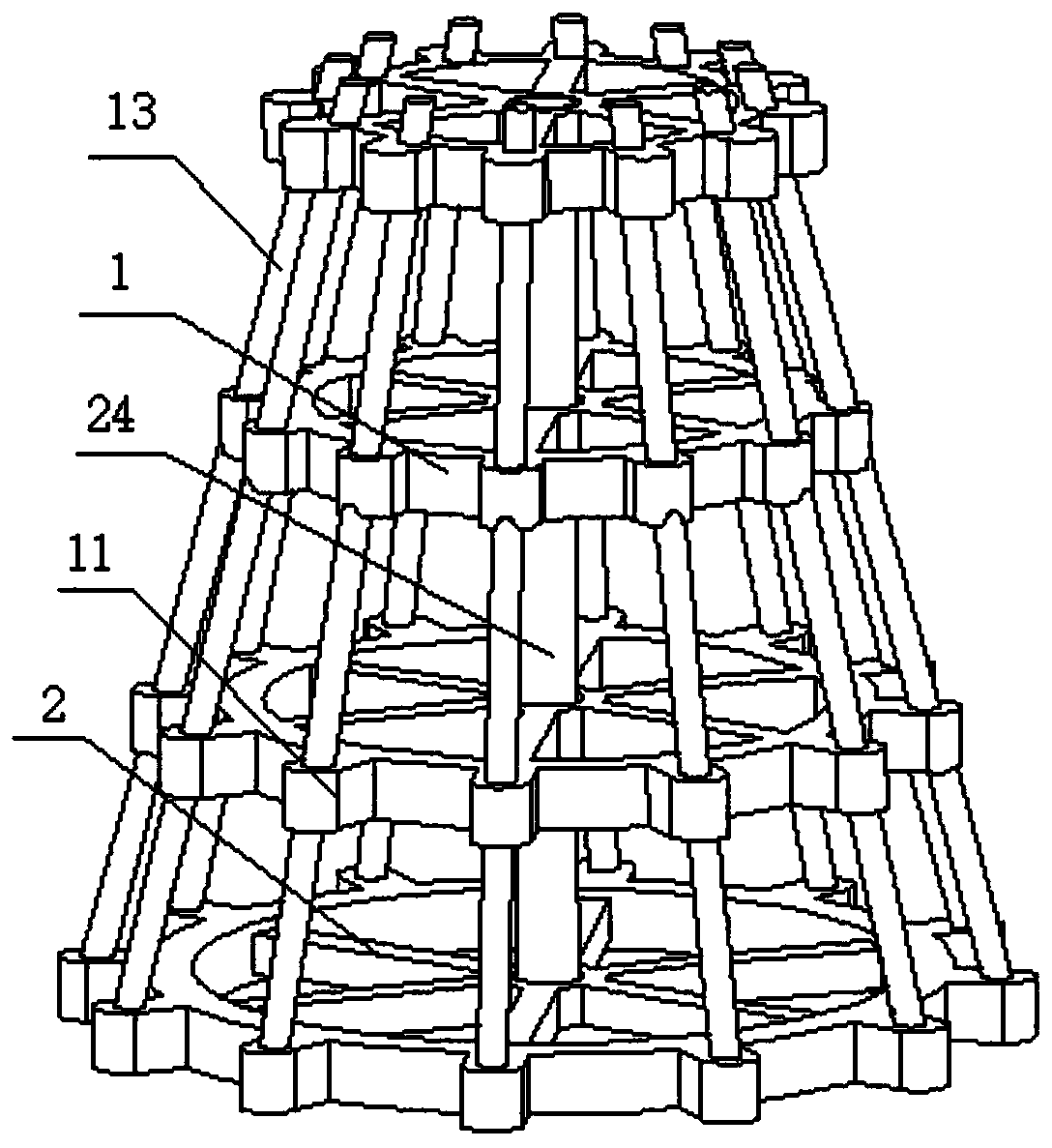

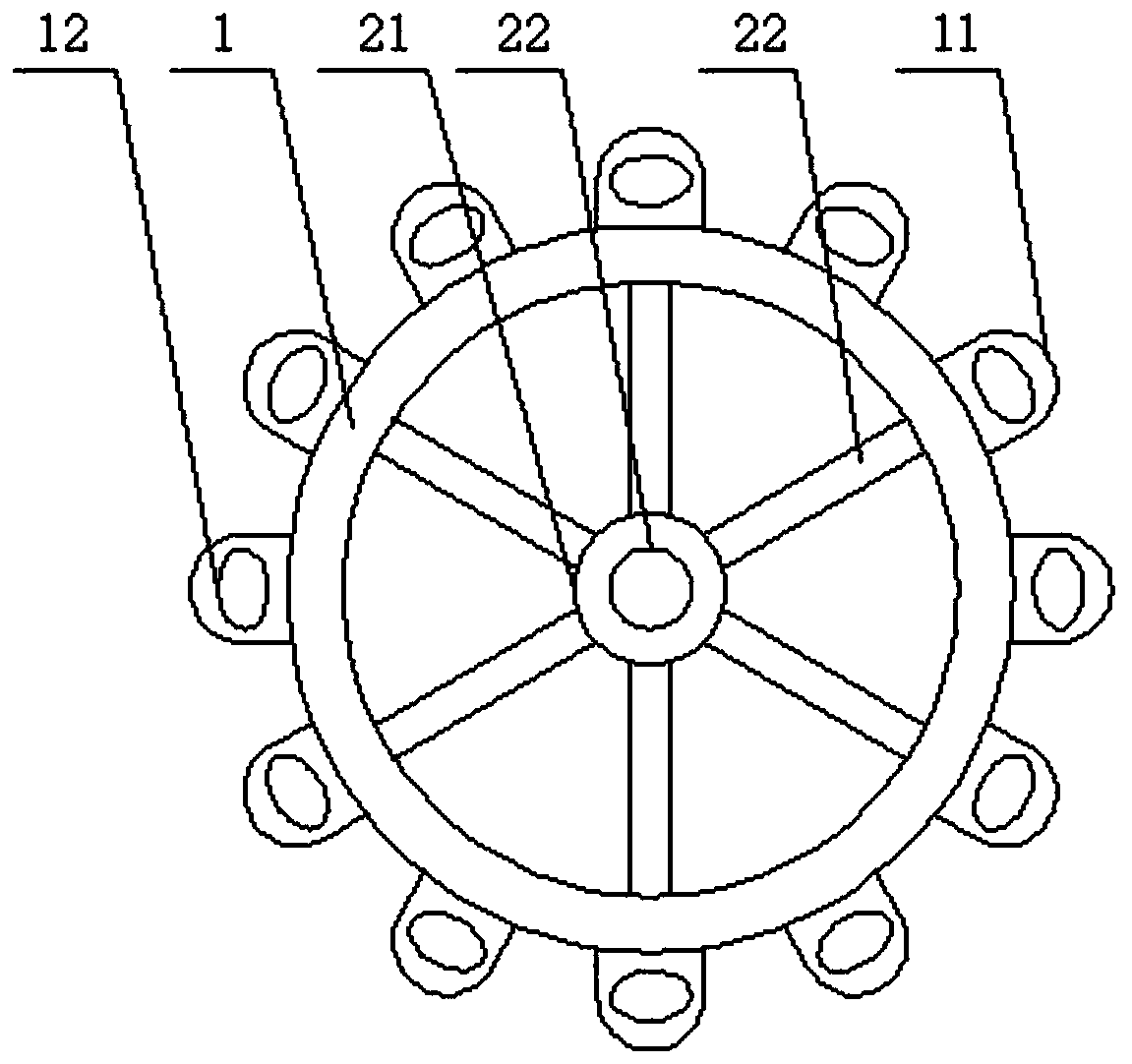

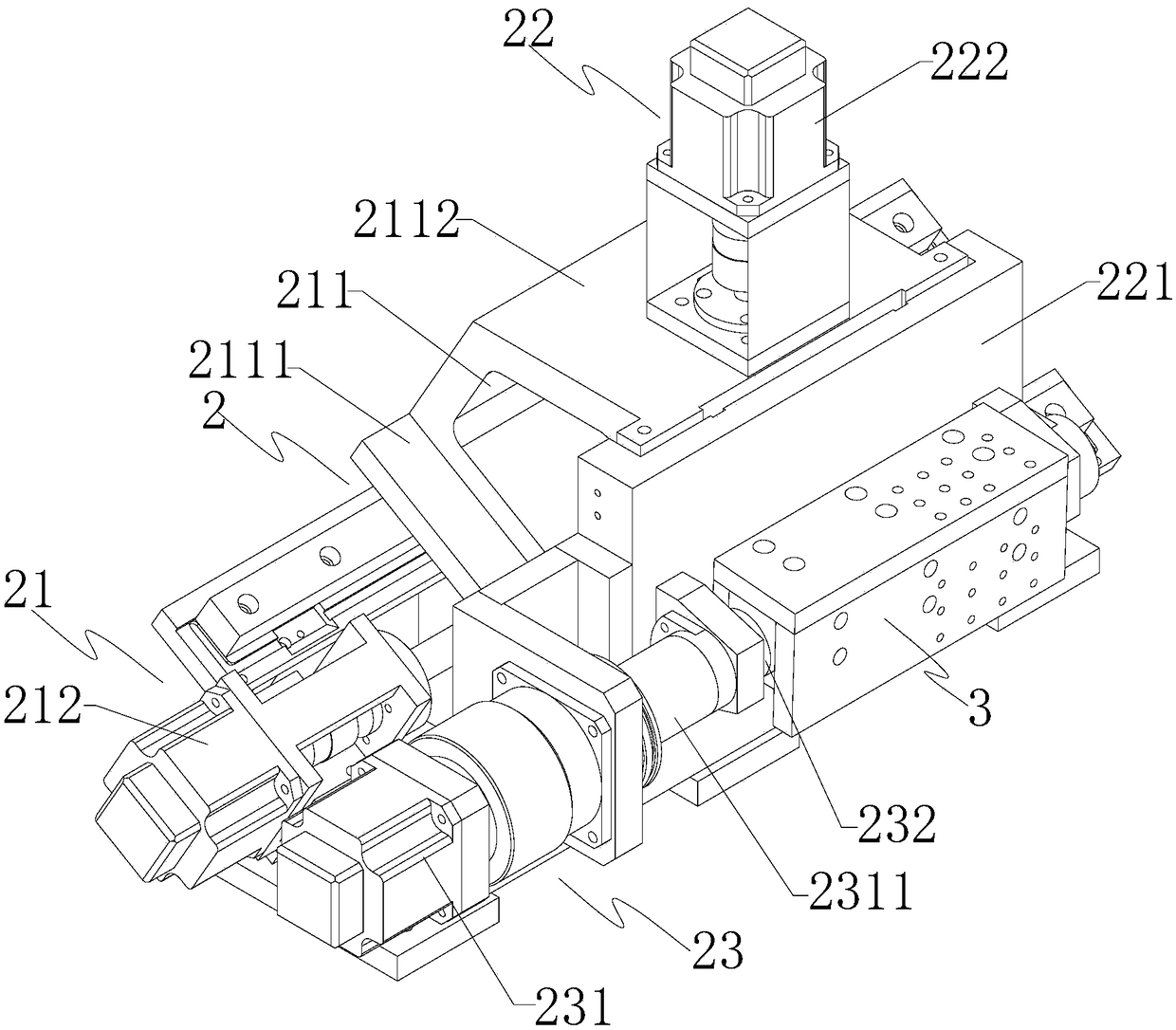

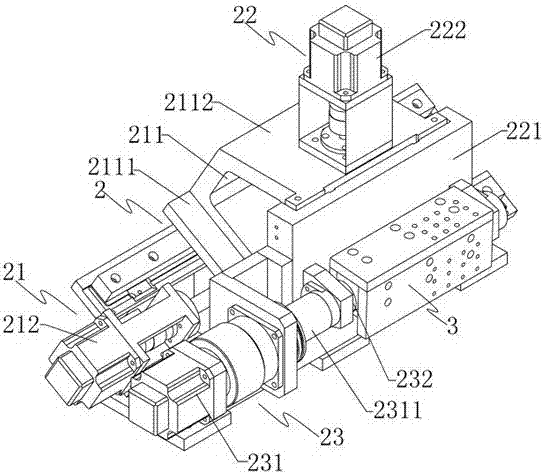

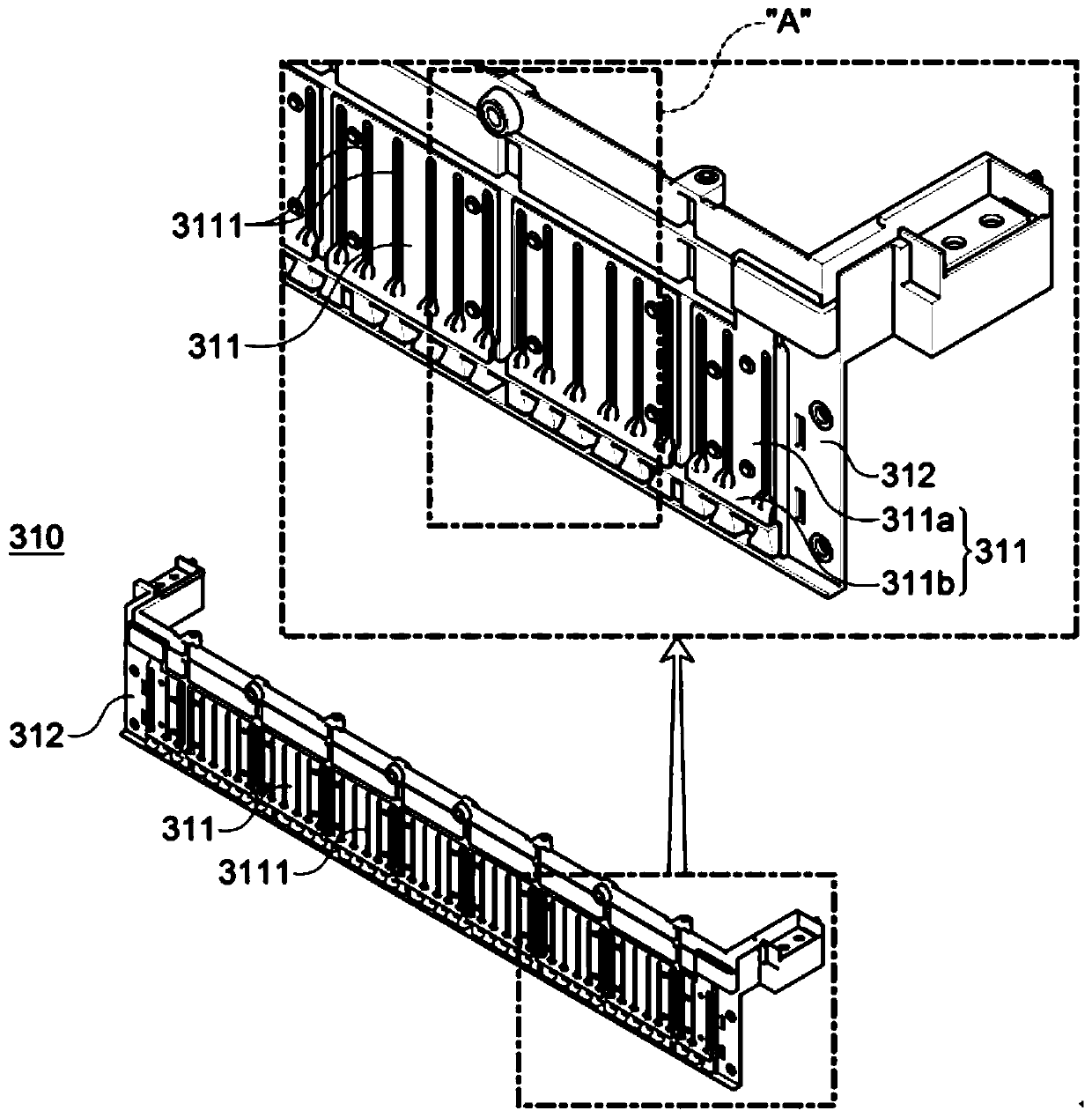

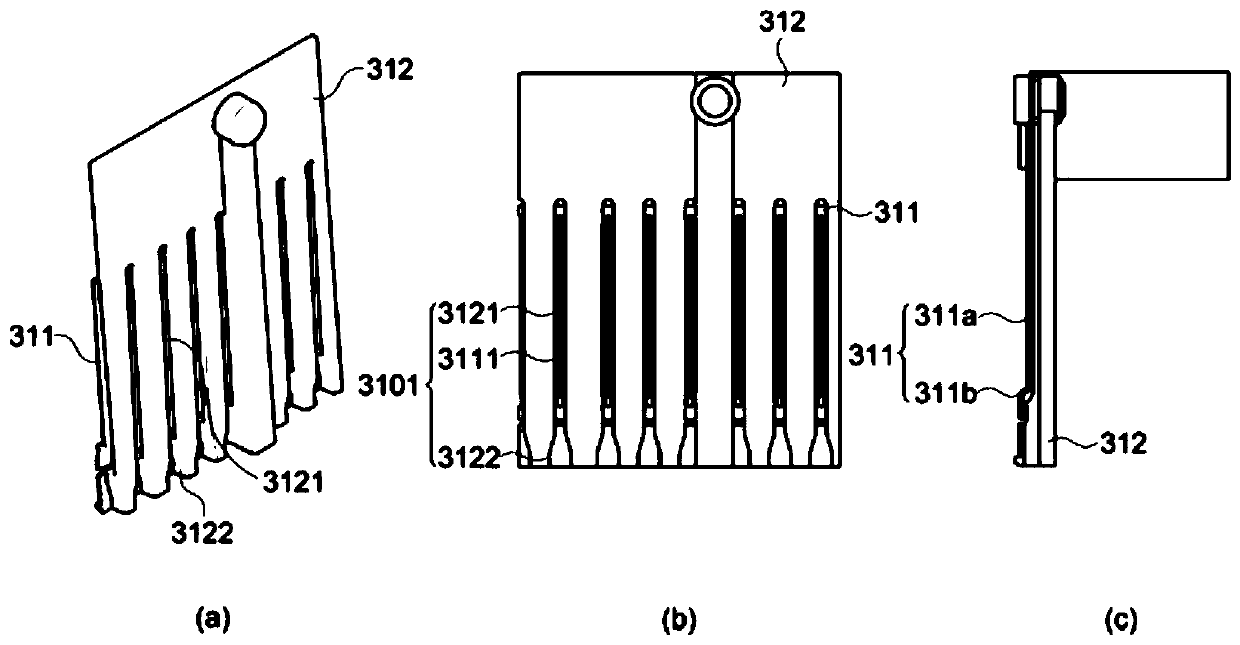

Modular structure chain type tool magazine and automatic tool change control method

InactiveCN110064955ASolve large capacityReasonable structural designPositioning apparatusMetal-working holdersElectric machineryChain type

The invention provides a modular structure chain type tool magazine and an automatic tool change control method; the modular structure chain type tool magazine compriess a machine frame, a main controller, a linear mechanism, an ATC automatic tool change mechanism, an ATC translation motor and a virtual main shaft, wherein the ATC automatic tool change mechanism comprises an ATC motor and a cutterarm driven by the ATC motor to change the tool; a plurality of sub-module tool magazines are arranged on the machine frame in the movement direction of the ATC automatic tool change mechanism on thelinear mechanism; an independent servo motor, a sensing mechanism and a unit controller are arranged in each sub-module tool magazine; the unit controllers in the sub-module tool magazines are connected with a main controller circuit through a bus interface and a field bus respectively; and each submodule tool magazine is independently controlled by the main controller. With reasonable structure design, the tool magazine provided by the invention can solve the problem of large capacity of the tool magazine effectively under the condition of ensuring transmission stability, precision and structural rigidity; and the tool change efficiency is effectively improved.

Owner:CHANGZHOU DESU MACHINERY

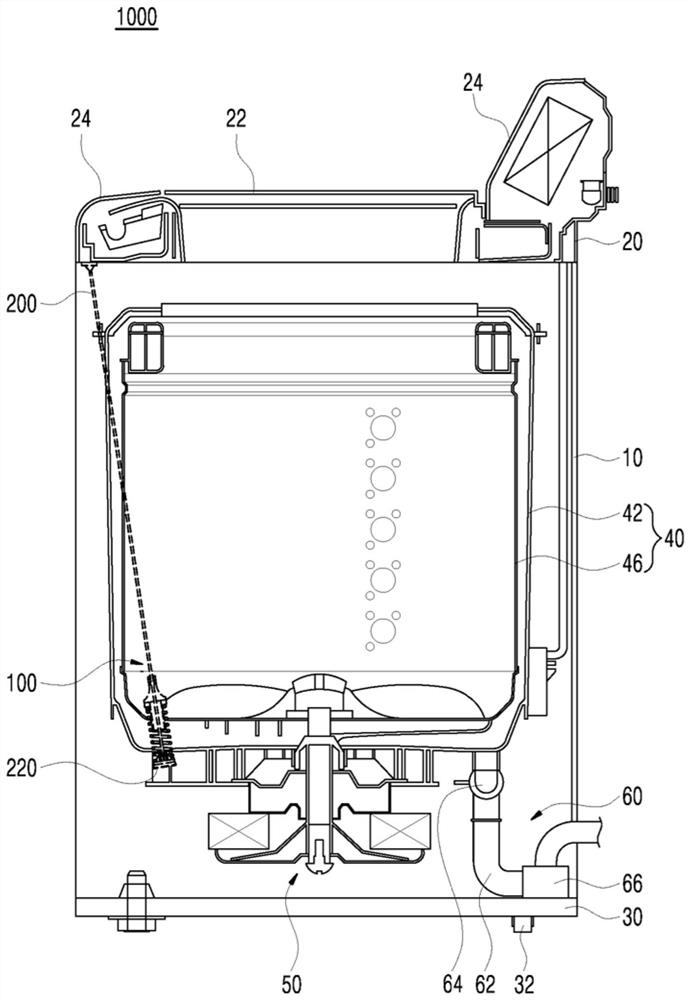

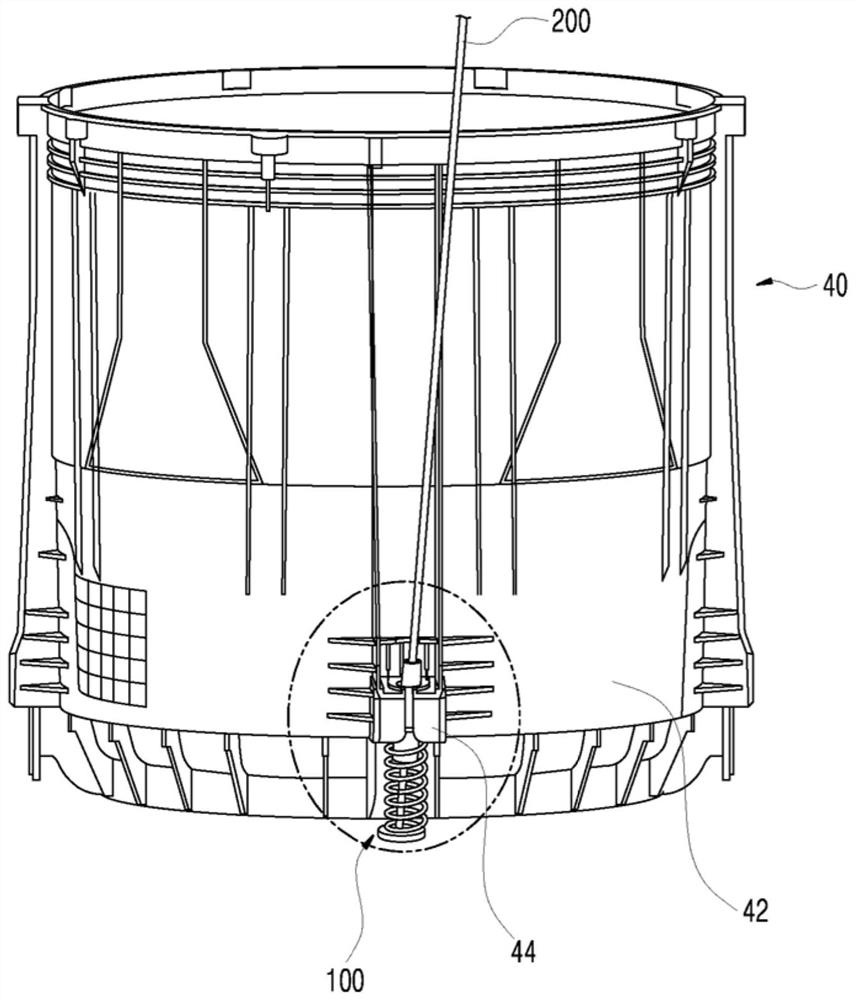

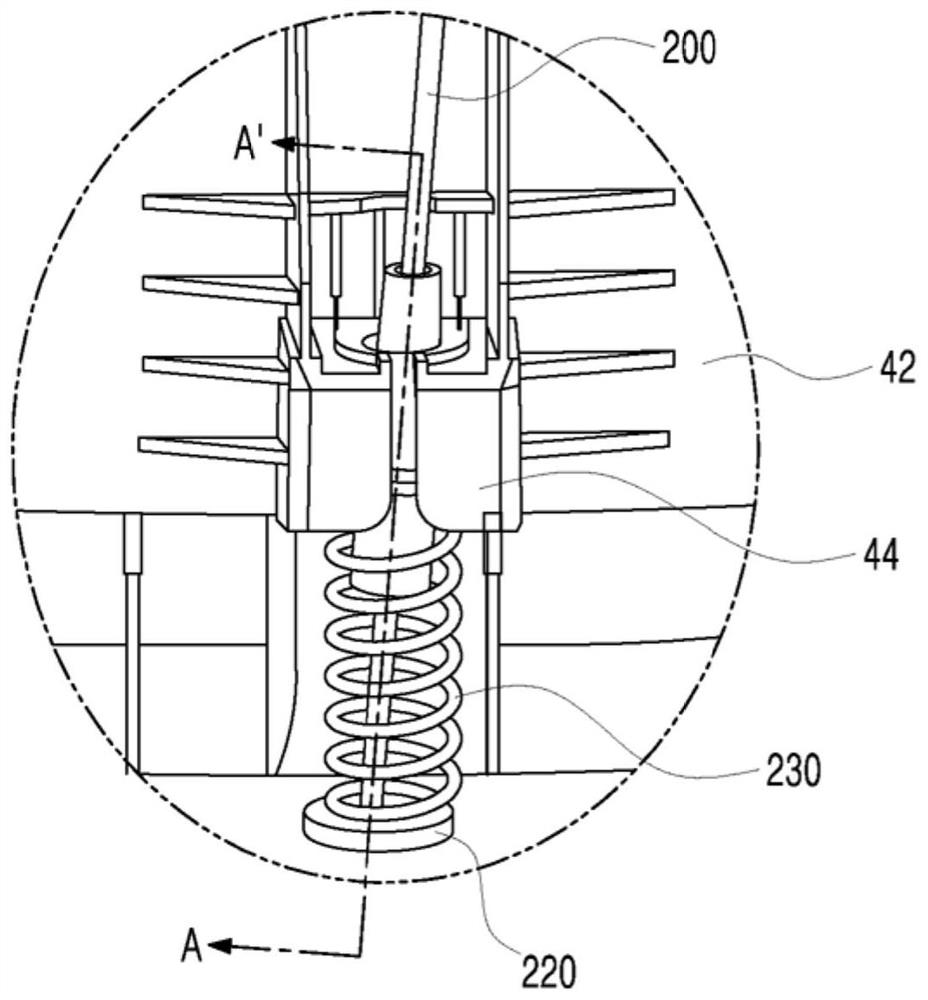

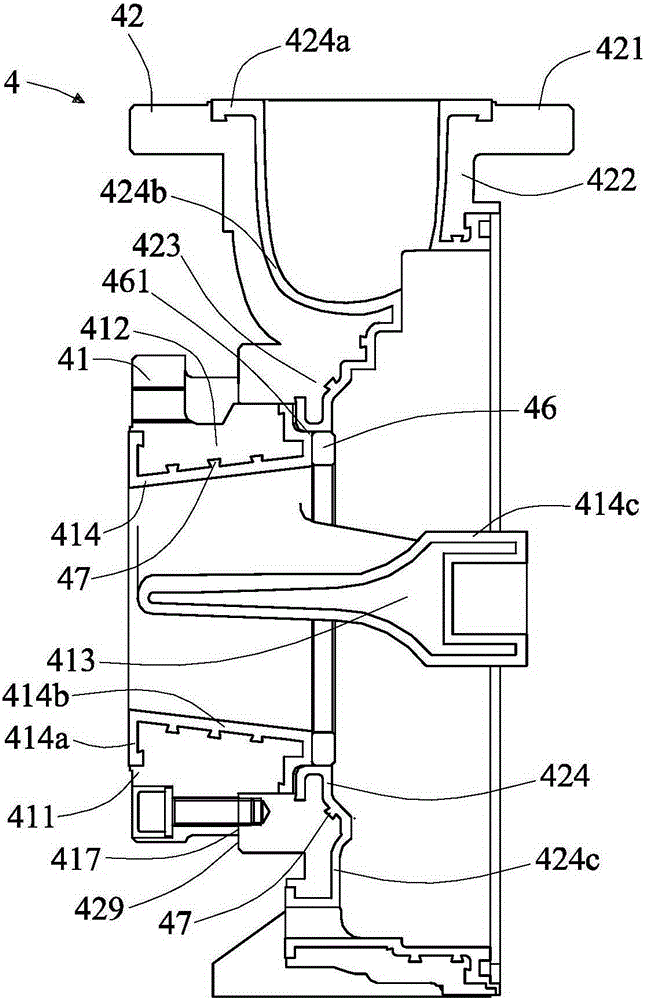

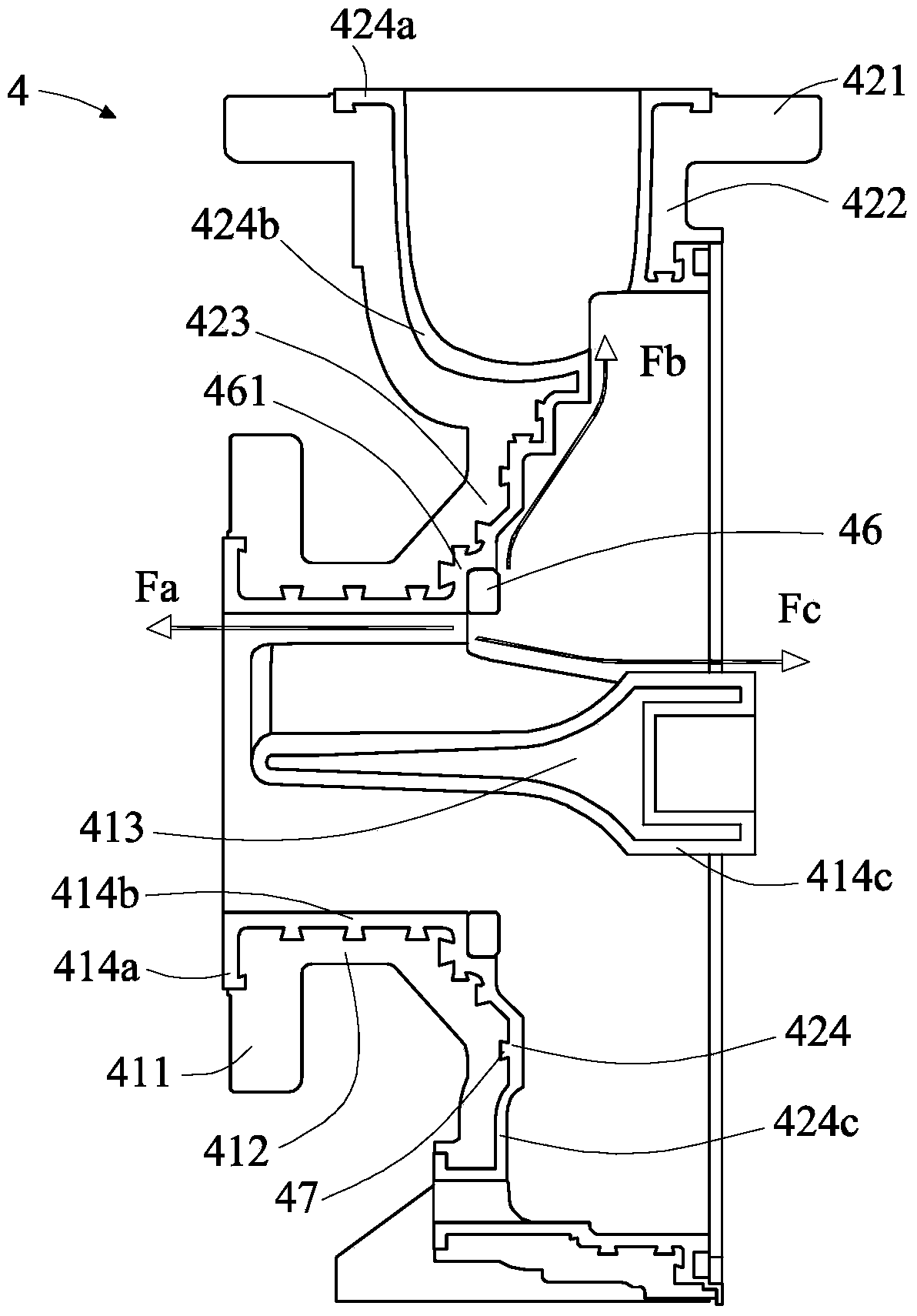

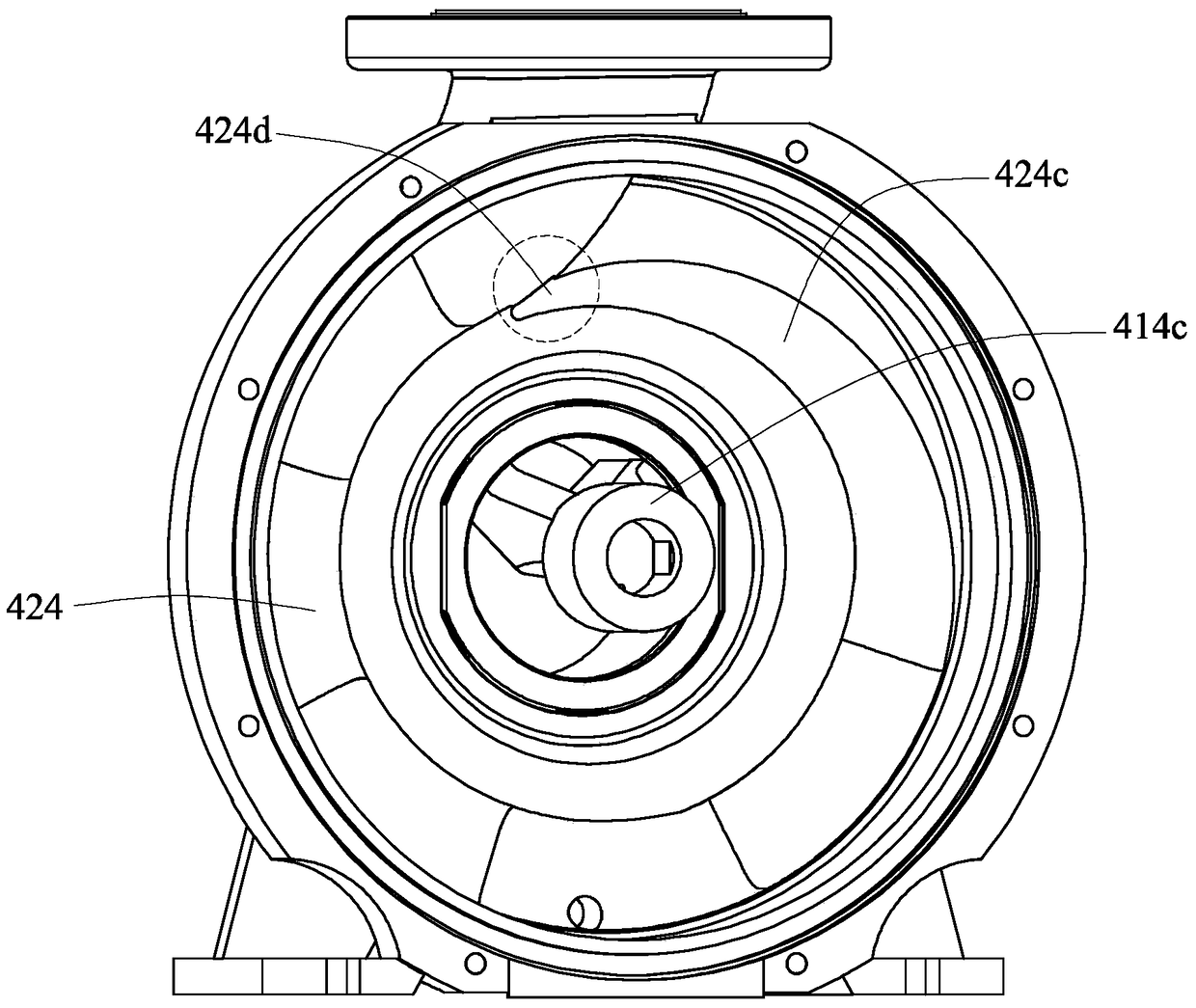

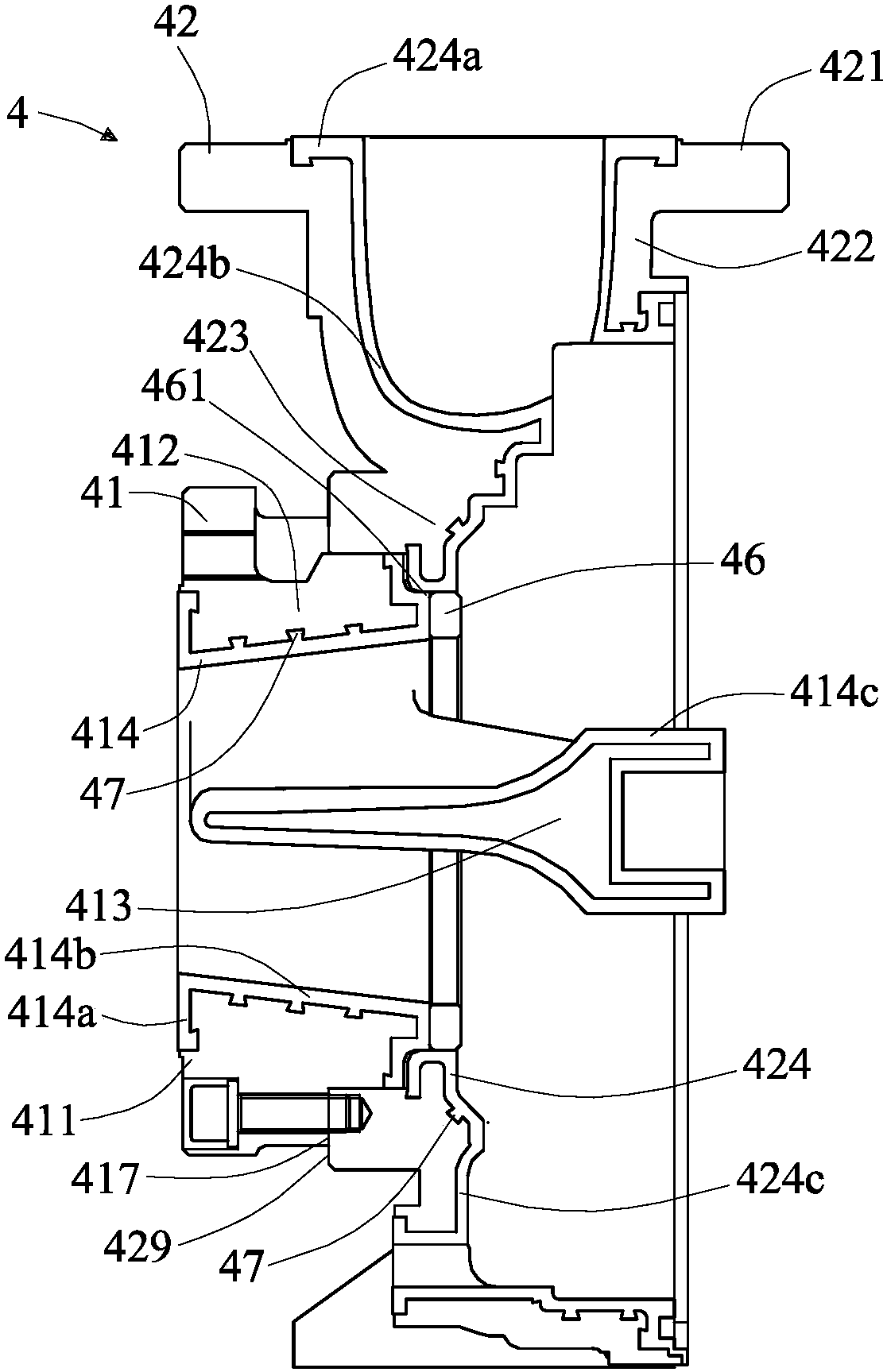

Suspension assembly and clothes treating apparatus including the same

PendingCN112442848AReduce performanceEnsure structural rigidityOther washing machinesTextiles and paperInterior spaceStructural engineering

Owner:LG ELECTRONICS INC

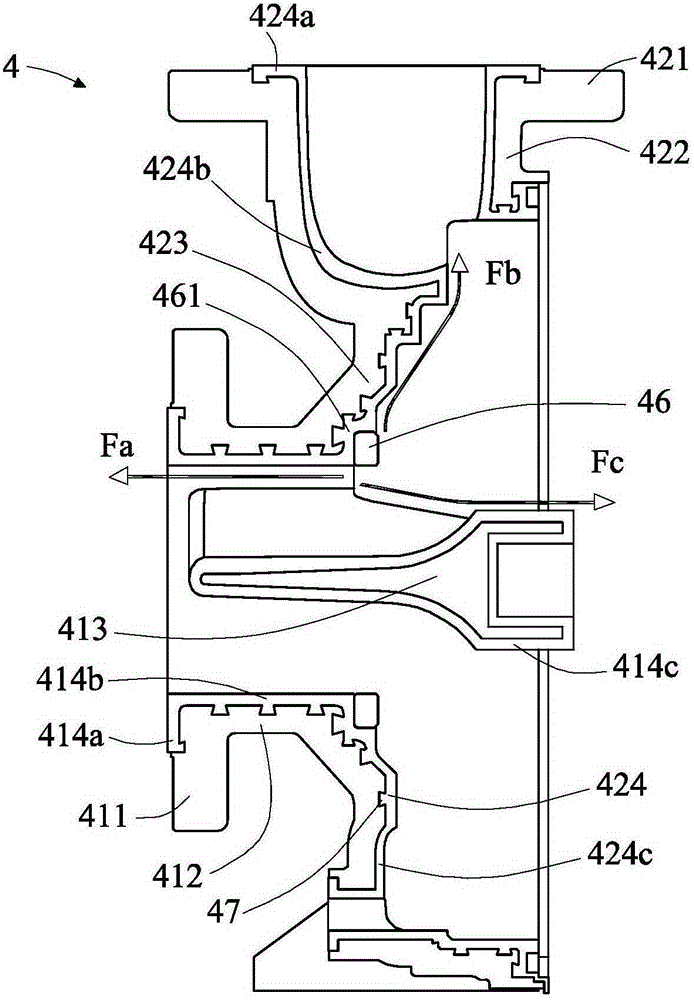

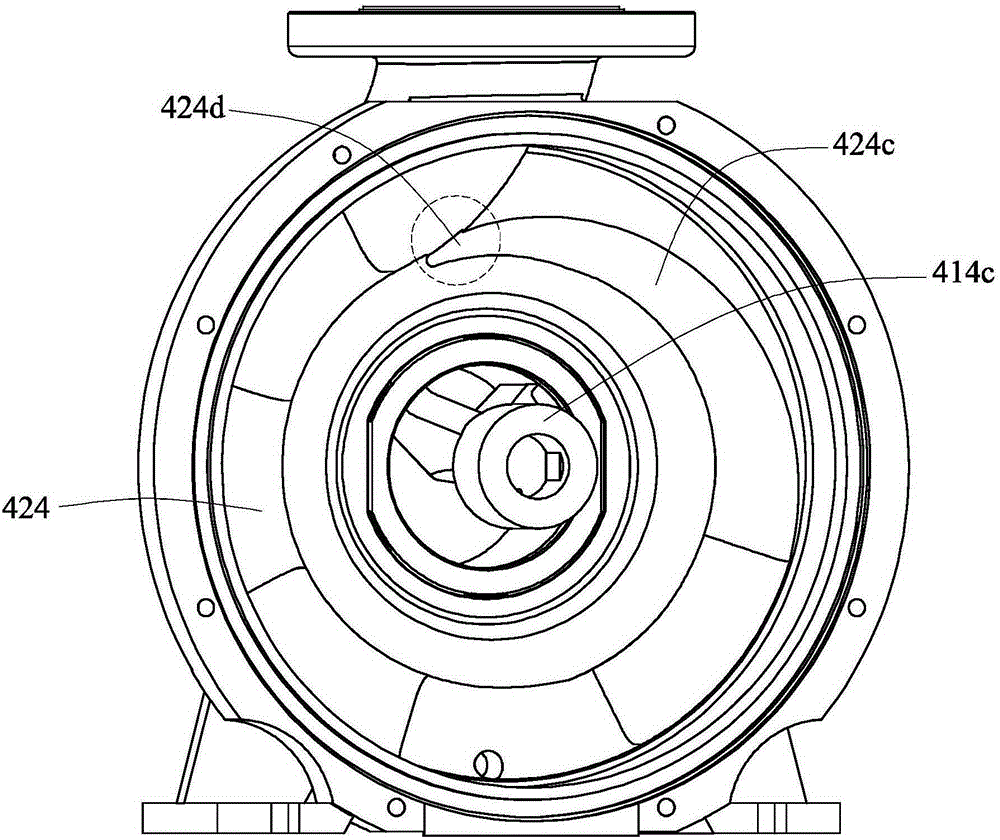

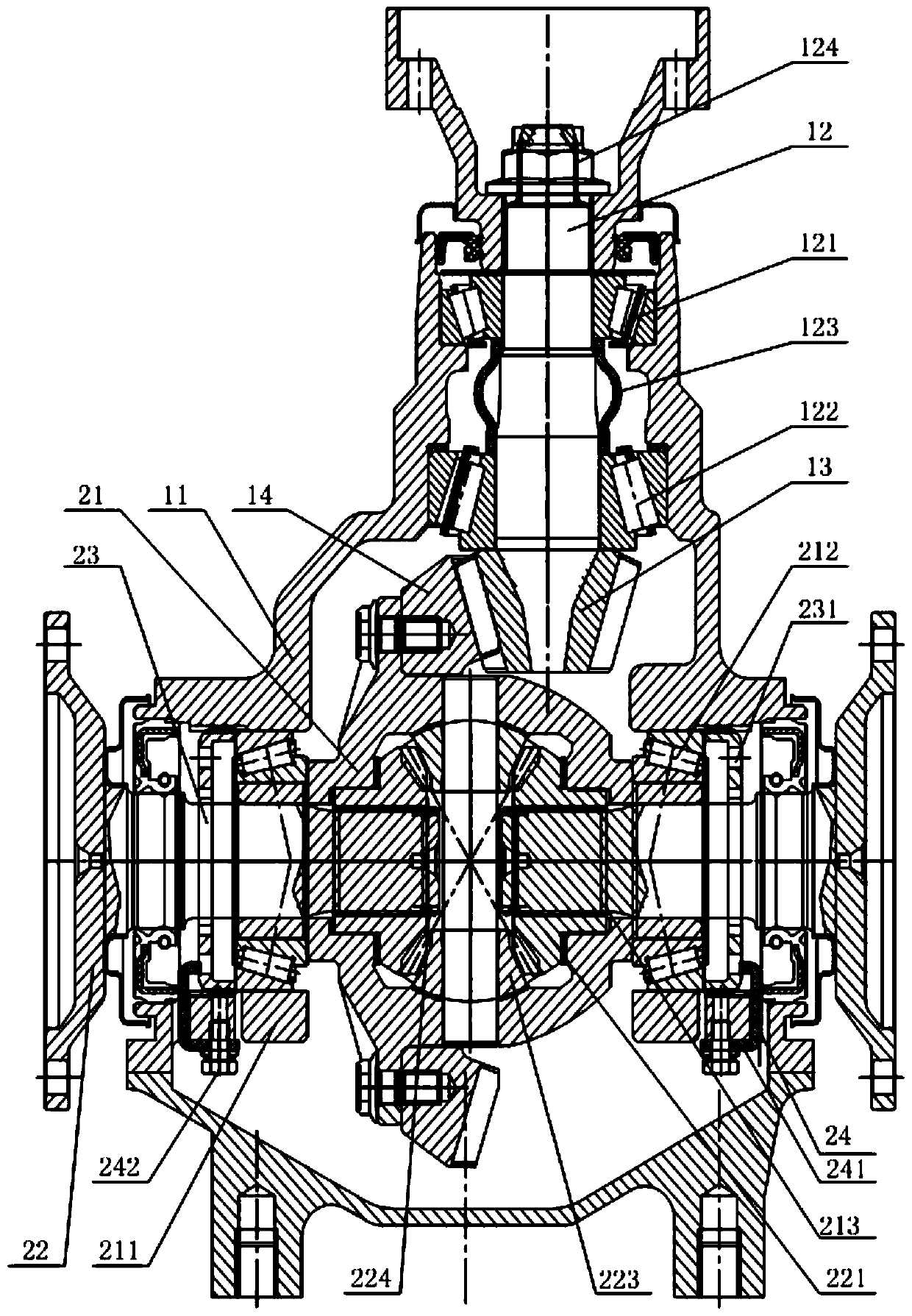

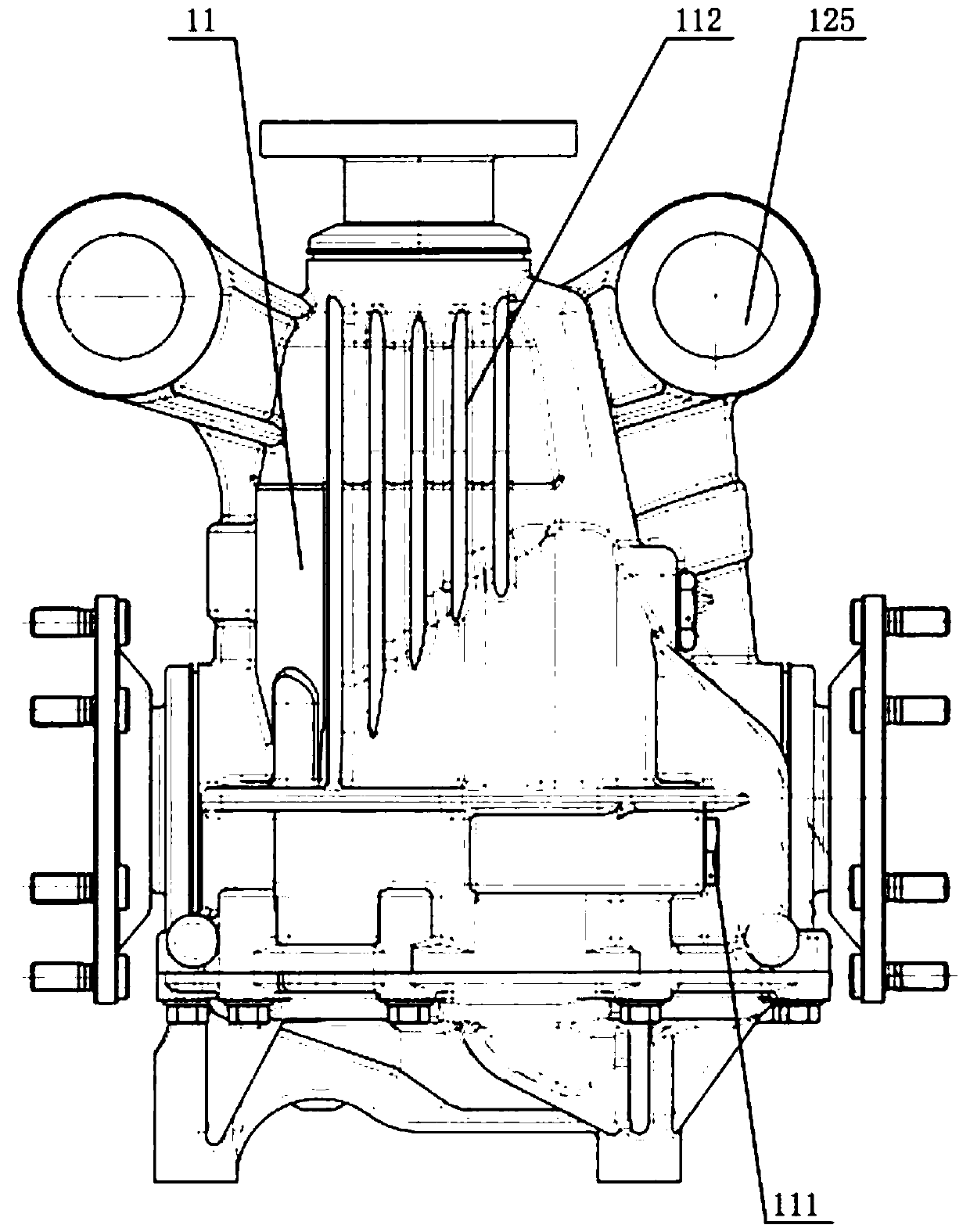

PFA lining pump shell structure

ActiveCN106246598ASmall sizeReduce variance ratioPump componentsPumpsManufacturing cost reductionImpeller

The invention discloses a PFA (Polyfluoroalkoxy) lining pump shell structure and aims at improving the production efficiency, reducing the manufacturing cost and the production reject ratio, making the improvement especially for a metal lining PFA pump shell structure, reducing the pump shell production cost and increasing the manufacturing yield. A metal shell lining PFA pump is used for conveying high-corrosivity chemical liquid, a metal shell is used for resisting the pump pressure and the piping load, and a PFA lining serves as a liquid receiving material to resist corrosion of liquid chemical. According to the improvement key point of the pump shell structure, the production bad factors of injection molding are reduced through the structure change, and the pump shell structure is characterized in that inlet shell lining PFA serves as a pumping inlet; scroll shell lining PFA is used for containing an impeller, collecting liquid generated after impeller acting and discharging the liquid through an outlet, and an inlet shell and a scroll shell are independently produced and then combined to form an integral pump shell so as to reduce the residual stress of injection molding.

Owner:ASSOMA

High-strength polypropylene plastic

InactiveCN108822401AEnsure structural stabilityEnsure structural rigidityPolymer scienceOrganic solvent

The invention discloses a high-strength polypropylene plastic which comprises the following substances in parts by weight: 70-90 parts of a polypropylene resin, 20-40 parts of an organic solvent, 20-30 parts of a compounded plastic, 10-20 parts of a filling agent, 10-20 parts of propylene glycol and 5-10 parts of silicon dioxide. According to the high-strength polypropylene plastic, the filling agent is put into a polypropylene base material, and the filling agent is dispersed in the organic solvent, so that the filling agent can be uniformly dispersed in the polypropylene plastic, and the structural stability and the rigidity of the polypropylene plastic can be ensured; in addition, due to addition of nano silicon dioxide in the polypropylene plastic disclosed by the invention, the structural rigidity of the polypropylene plastic is further improved.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

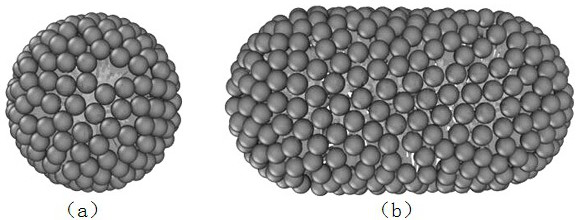

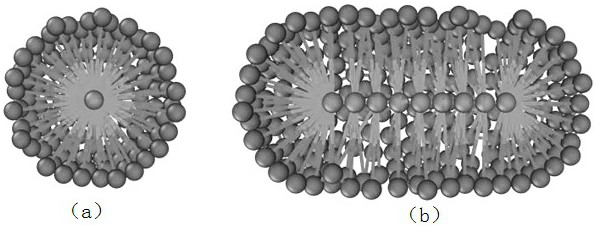

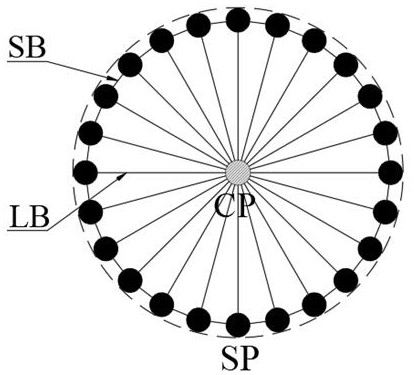

General force field rodlike nanoparticle coarse graining model and establishment method thereof

PendingCN114566225AKinetic performance unchangedControl lengthDesign optimisation/simulationComputational theoretical chemistryNanoparticleNanochemistry

The invention provides a general force field rodlike nanoparticle coarse graining model and an establishment method thereof, and belongs to the technical field of nanometer chemical calculation. The model is divided into a central bead cluster and outer-layer cylindrical shell-shaped beads, the outermost-layer beads arranged at the two ends are hemispherical spherical shells, and the outermost-layer beads arranged at the middle section are cylindrical shell-shaped beads; two types of beads are defined in a used force field, the molar mass and potential action parameters are assigned, and a central bead cluster and the outermost beads are connected through keys, so that it is guaranteed that deformation and collapse do not occur during molecular dynamics simulation, and the overall property is kept unchanged; the whole coarse graining model only has the outermost layer of beads and the central bead cluster, so that the number of the beads is greatly reduced, the accuracy of molecular dynamics calculation can be ensured, meanwhile, the calculation amount is greatly reduced, the calculation speed is increased, and the waste of calculation power is avoided.

Owner:TAIYUAN UNIV OF TECH

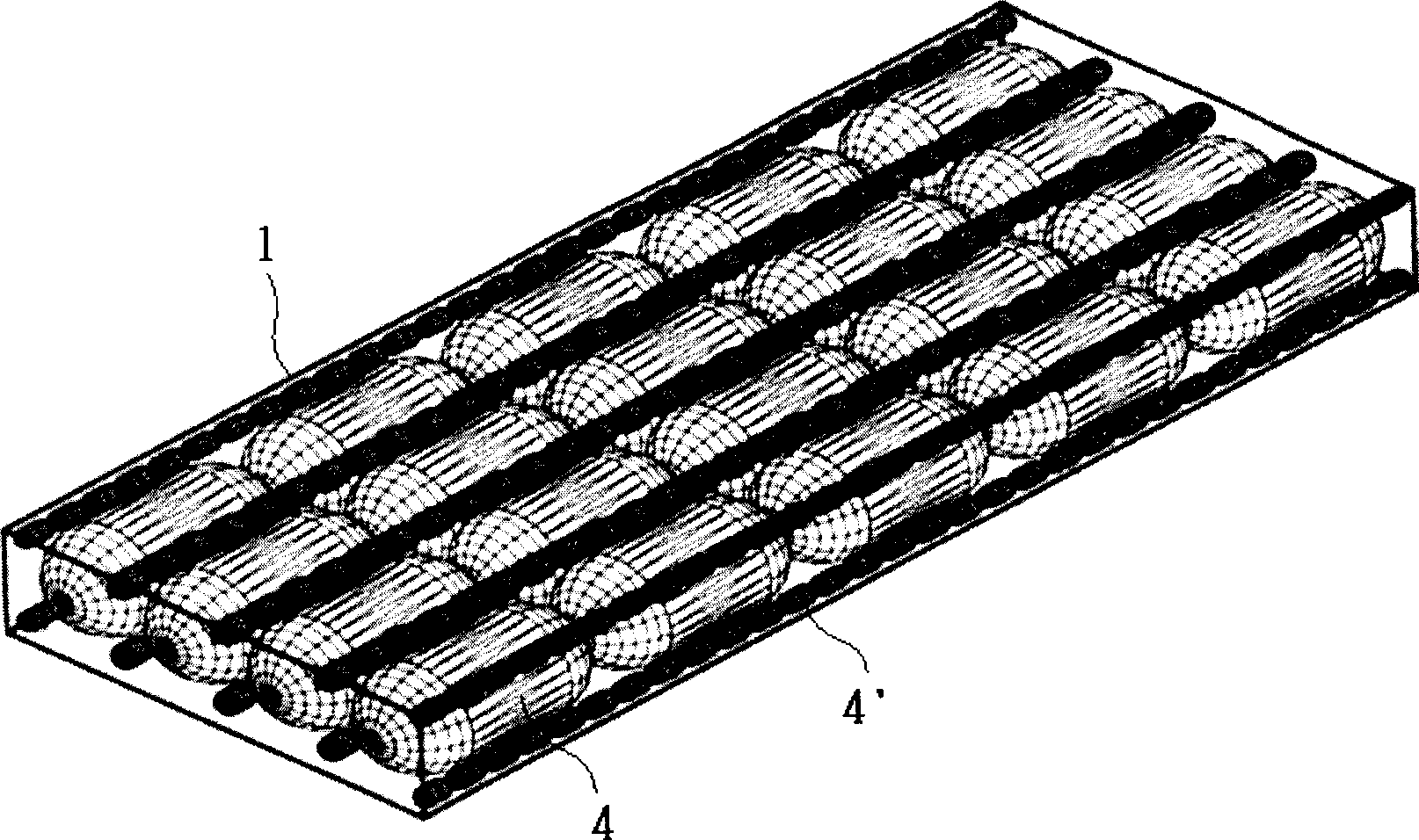

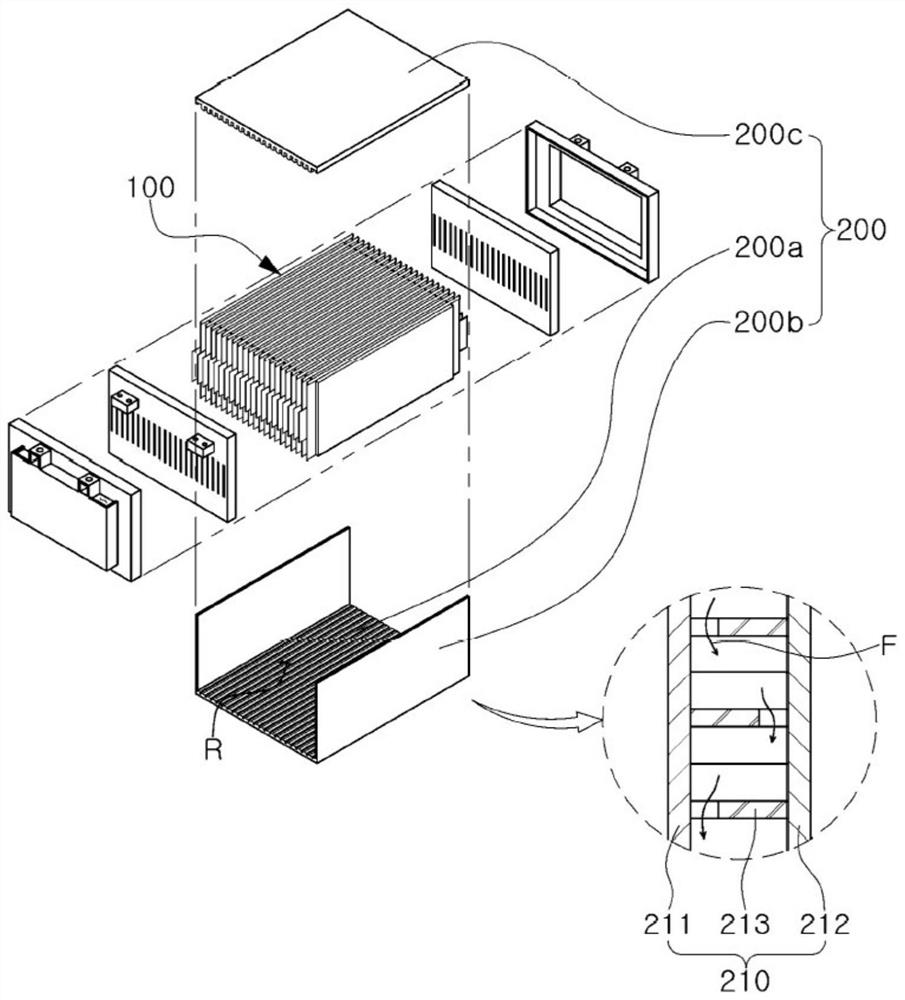

Battery module

PendingCN113363644AImprove the continuous explosion problemPrevent heat from spreadingBattery isolationSecondary cellsInterior spaceThermodynamics

The invention relates to a battery module. The battery module according to the invention includes: a plurality of secondary battery cells; and a housing unit having an internal space in which the plurality of secondary battery cells are accommodated and including a plate member extending a flame or gas path.

Owner:SK ON CO LTD

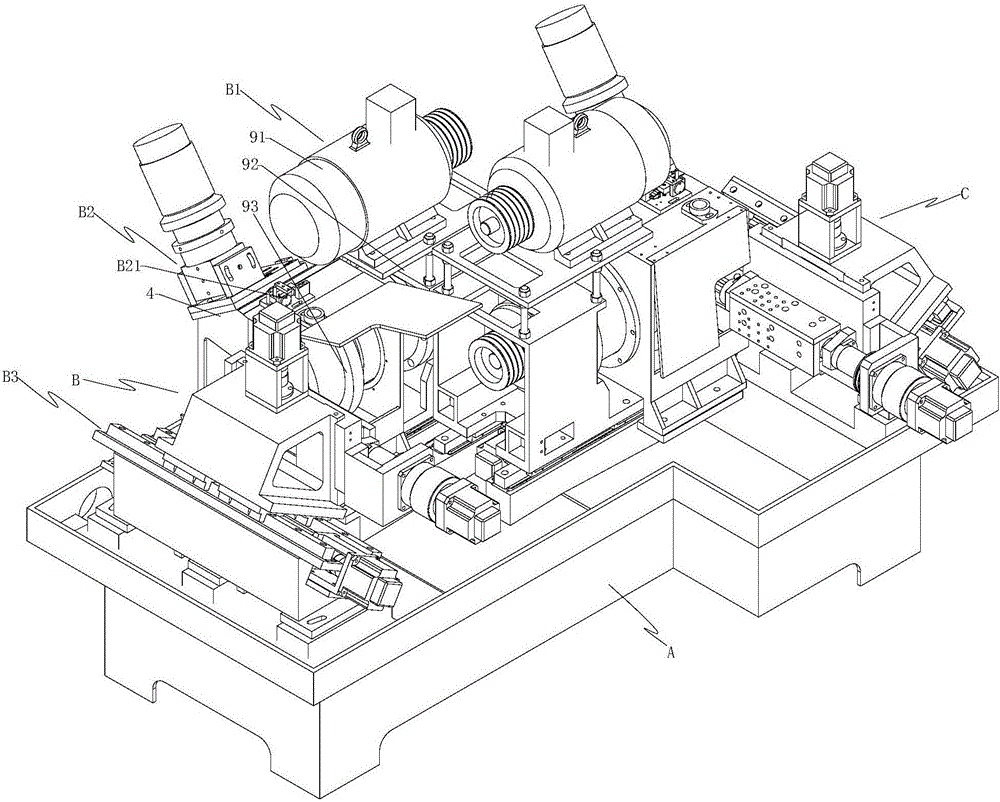

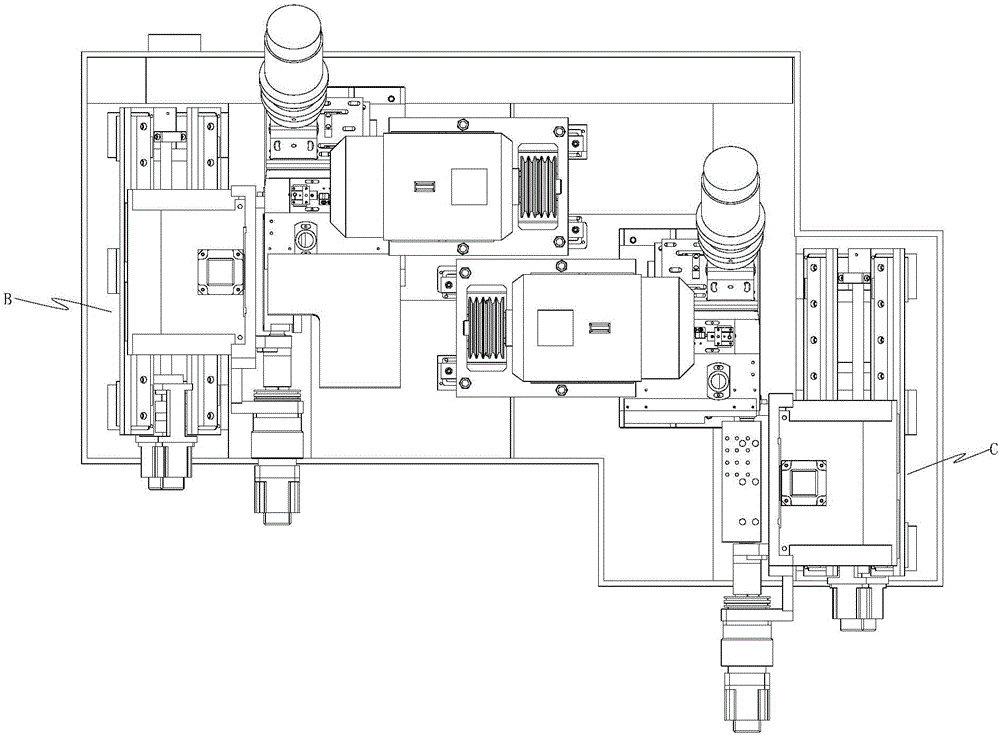

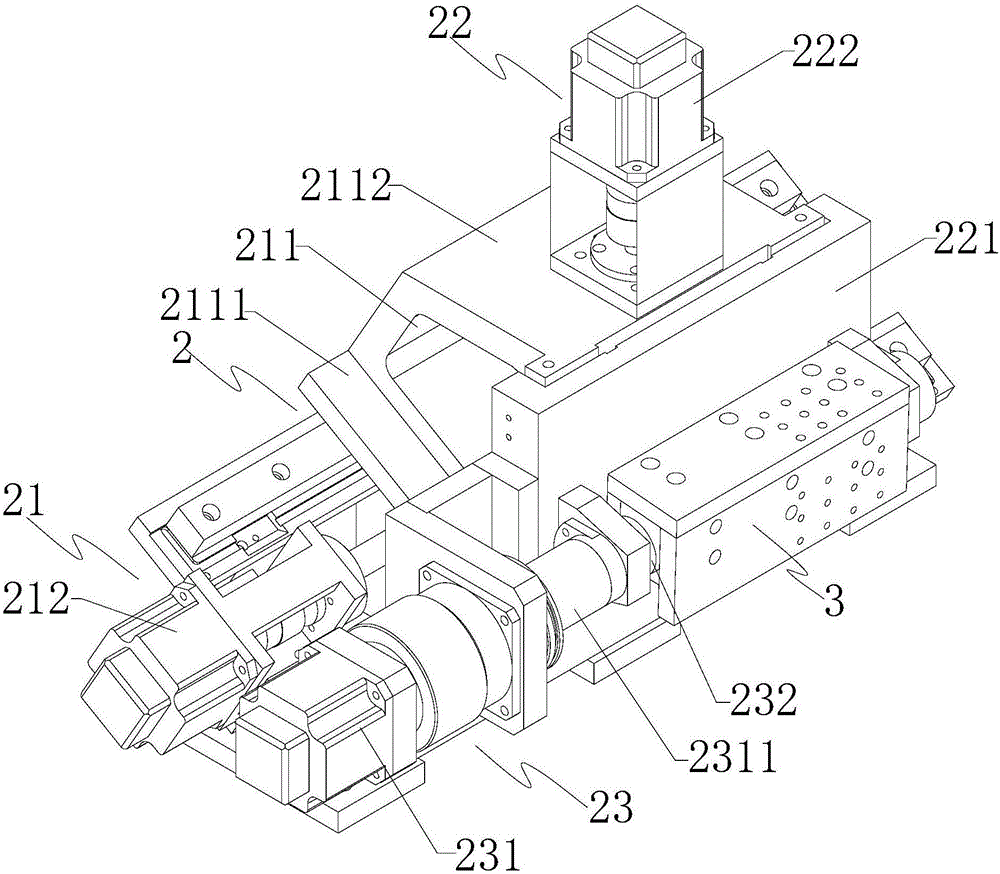

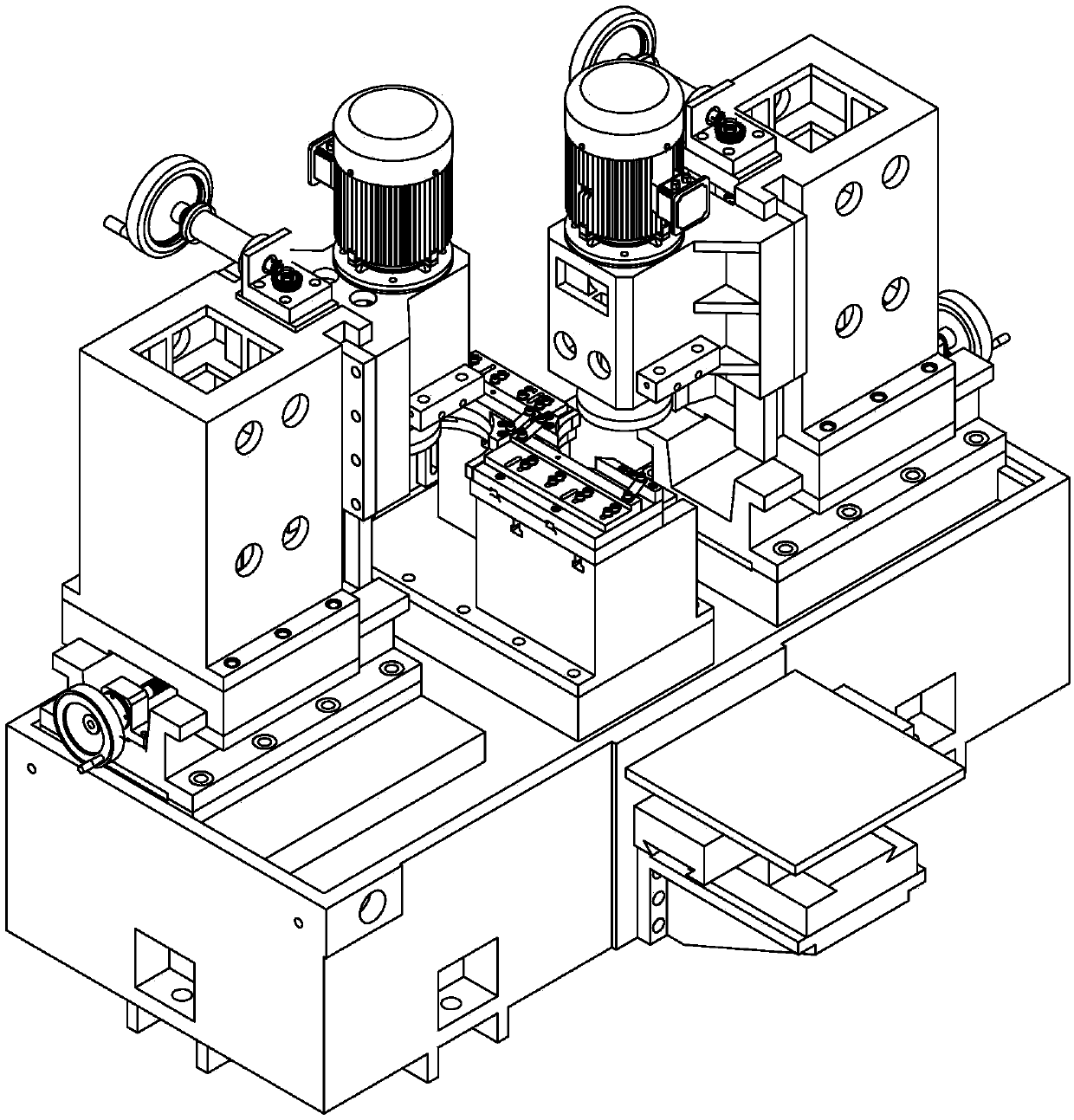

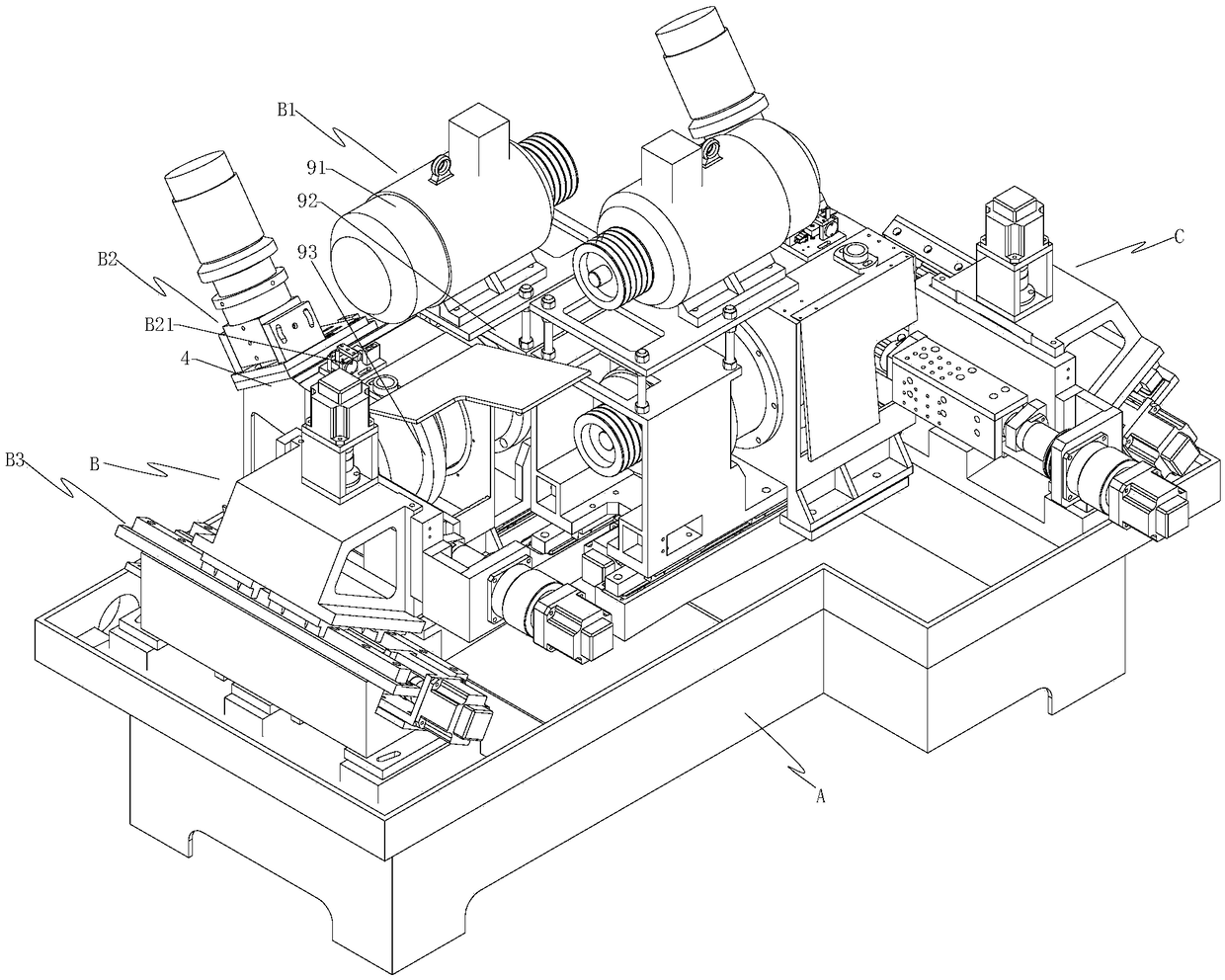

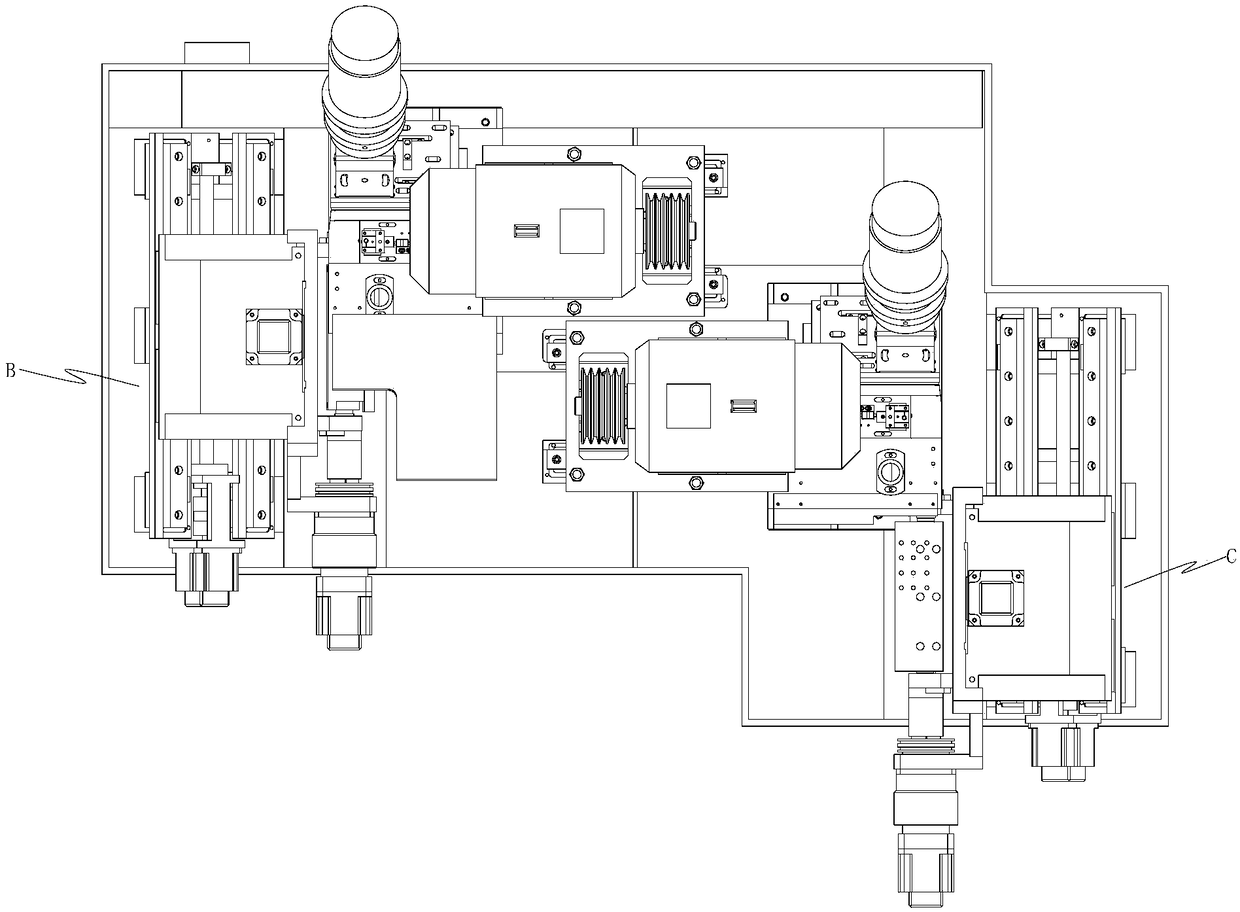

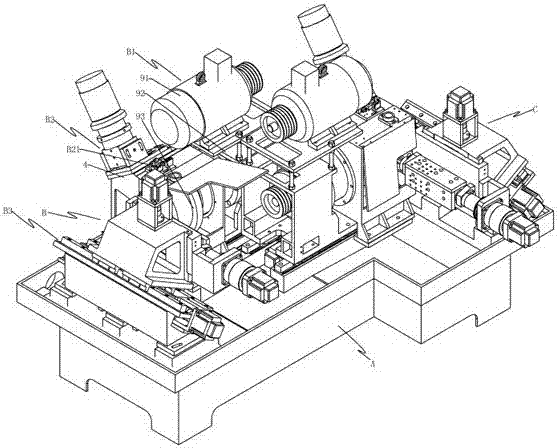

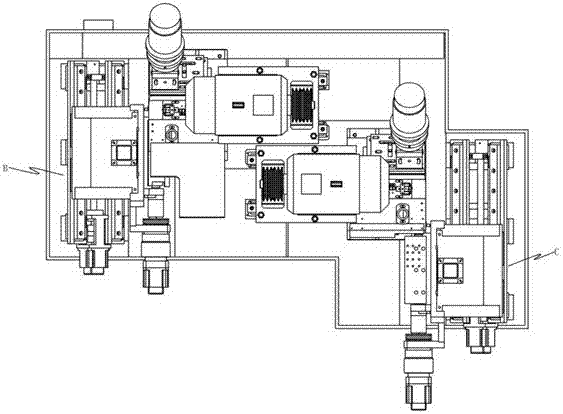

Double-station numerical control end face grinding machine device

ActiveCN106541306ACompact structureOptimize the structure of the whole machineGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention discloses a double-station numerical control end face grinding machine device. The double-station numerical control end face grinding machine device comprises a machine frame. The machine frame is provided with a first station end face grinding machine and a second station end face grinding machine, wherein the first station end face grinding machine comprises a first abrasion wheel device used for grinding workpieces, a first abrasion wheel automatic repair device used for repairing abrasion wheels, and a first three-axis linkage tool rest device used for fixing the workpieces; and the second station end face grinding machine and the first station end face grinding machine are identical in structure. The double-station structure is adopted, the structure is compact, the whole machine structure of equipment is optimized, the using performance of the equipment is improved, the production efficiency is improved, and the labor cost and production cost are reduced.

Owner:阳江市阳东区国浩机械制造有限公司

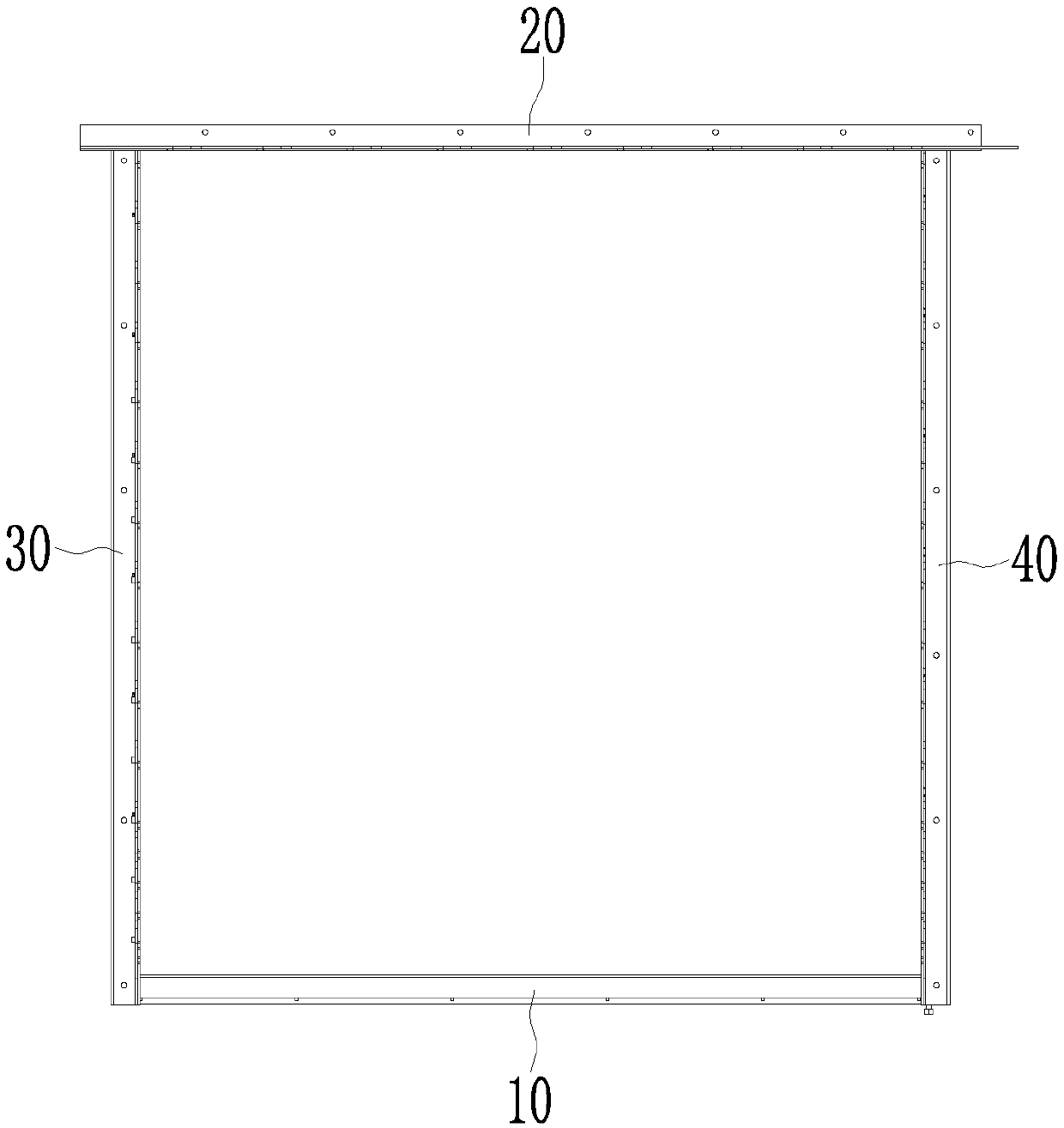

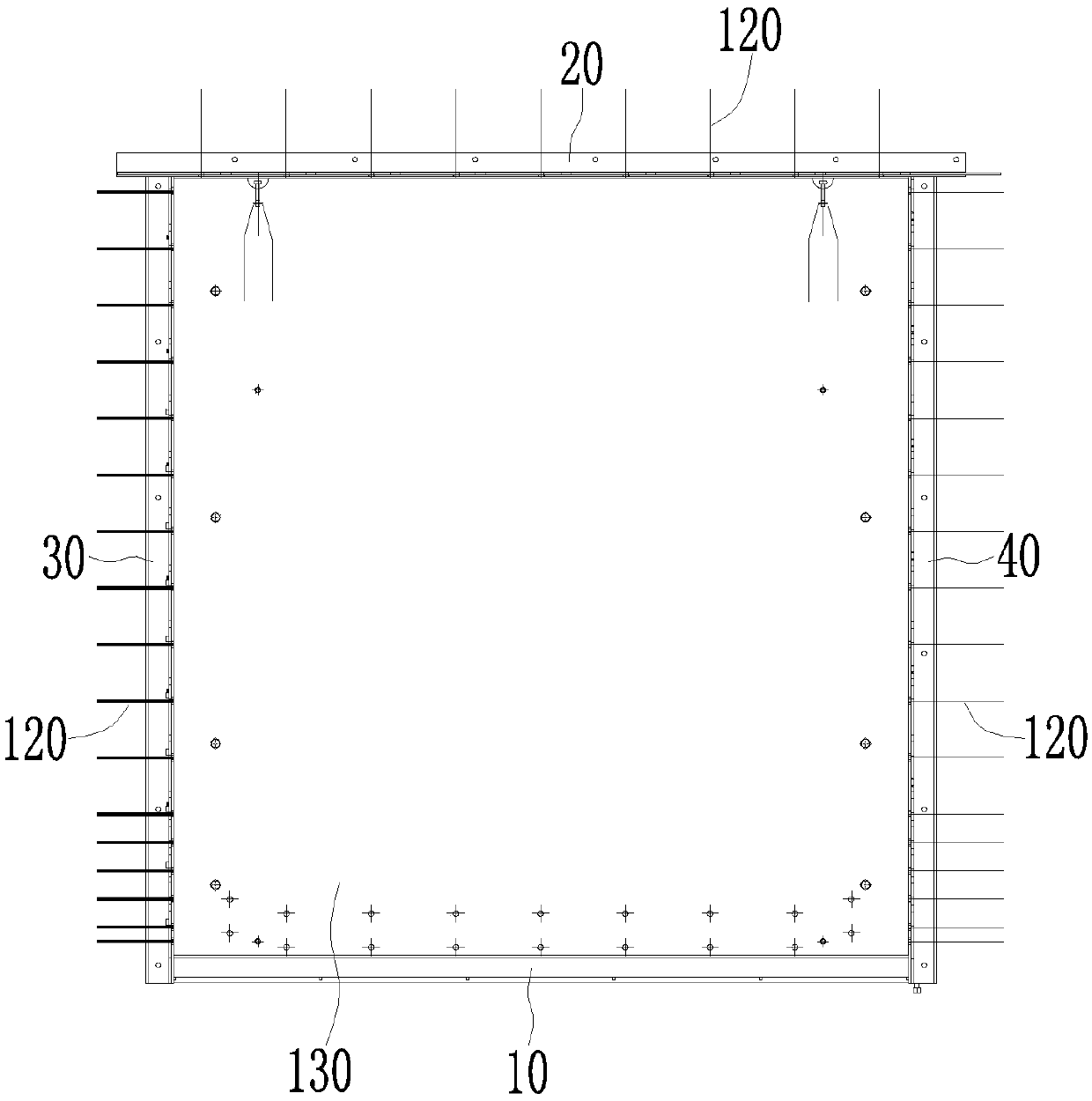

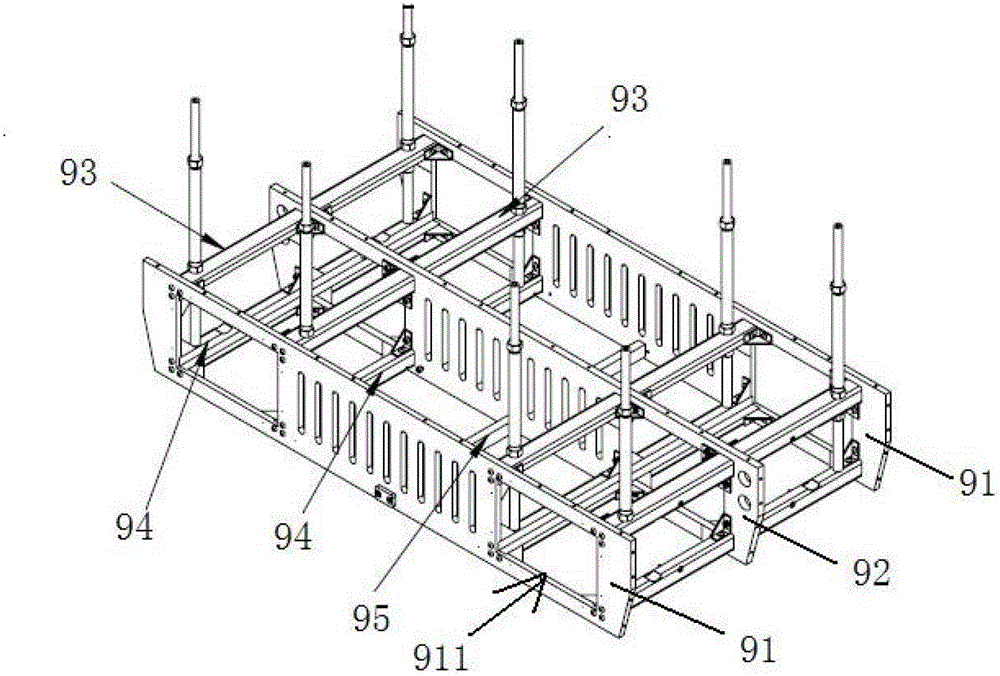

Stretching-out rebar prefabricated part forming mold and using method thereof

InactiveCN109514710AOptimized molding process stepsGuaranteed structural strengthMouldsRebarUltimate tensile strength

The invention discloses a stretching-out rebar prefabricated part forming mold and a using method thereof. The stretching-out rebar prefabricated part forming mold comprises a bottom side mold, a topside mold, a left side mold and a right side mold, wherein the top side mold and the bottom side mold are oppositely arranged in an spaced mode; the left side mold and the right side mold are oppositely arranged in an spaced mode; one end of the bottom side mold is detachably connected with the left side mold through fasteners, and the other end of the bottom side mold is detachably connected withthe right side mold through fasteners; the end, away from the bottom side mold, of the left side mold is detachably connected with one side of the top side mold through fasteners; and the end, away from the bottom side mold, of the right side mold is detachably connected with one side of the top side mold through fasteners. The connection structure can ensure the high overall structural strengthand rigidity of the mold, meanwhile, the assembling technology is simple and easy to implement, during mold disassembling, the fasteners can be freely unscrewed as required, the corresponding side mold can be dismantled conveniently, the situation that a traditional mold needs to be disassembled in a certain disassembling-assembling sequence is avoided, the flexibility is higher, the operability is high, and the production efficiency is advantageously improved.

Owner:GUANGDONG LIANCHENG RESIDENTIAL EQUIP INFORMATION TECH CO LTD

Milling method for double-sided frame part

ActiveCN113441765AGuaranteed processing strengthEnsure structural rigidityMilling equipment detailsPositioning apparatusStructural engineeringUltimate tensile strength

The invention discloses a milling method of a double-sided frame part. The method comprises the following steps: S1, roughly milling the upper surface and the lower surface of a blank to respectively obtain a frame surface A and a frame surface B, and enabling the process allowance of the frame surface B to be greater than the process allowance reserved by the frame surface A; S2, performing unstressed clamping, performing finish milling on the frame surface A, and machining to the theoretical size without the process allowance; and S3, performing finish milling on the frame surface B, using the top faces of ribs and edge strips of the frame surface A subjected to finish milling in the step S2 for positioning, and when a web plate is machined, milling the web plate from inside to outside by adopting axial milling without layering and taking the center of the sash of the frame surface B as the starting point. According to the method, the ribs and the edge strips of the frame surface A subjected to finish milling are used as positioning references for positioning, and an additional clamp is not needed; large process allowance is reserved when the frame surface B is obtained through rough milling, and the machining strength of the finish-milling frame surface is guaranteed; and axial milling is adopted, layering is avoided, machining is conducted from inside to outside in sequence, the problem that in the prior art, web plate machining vibrates and the web plate is damaged is solved, and the overall machining stability of the web plate is guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

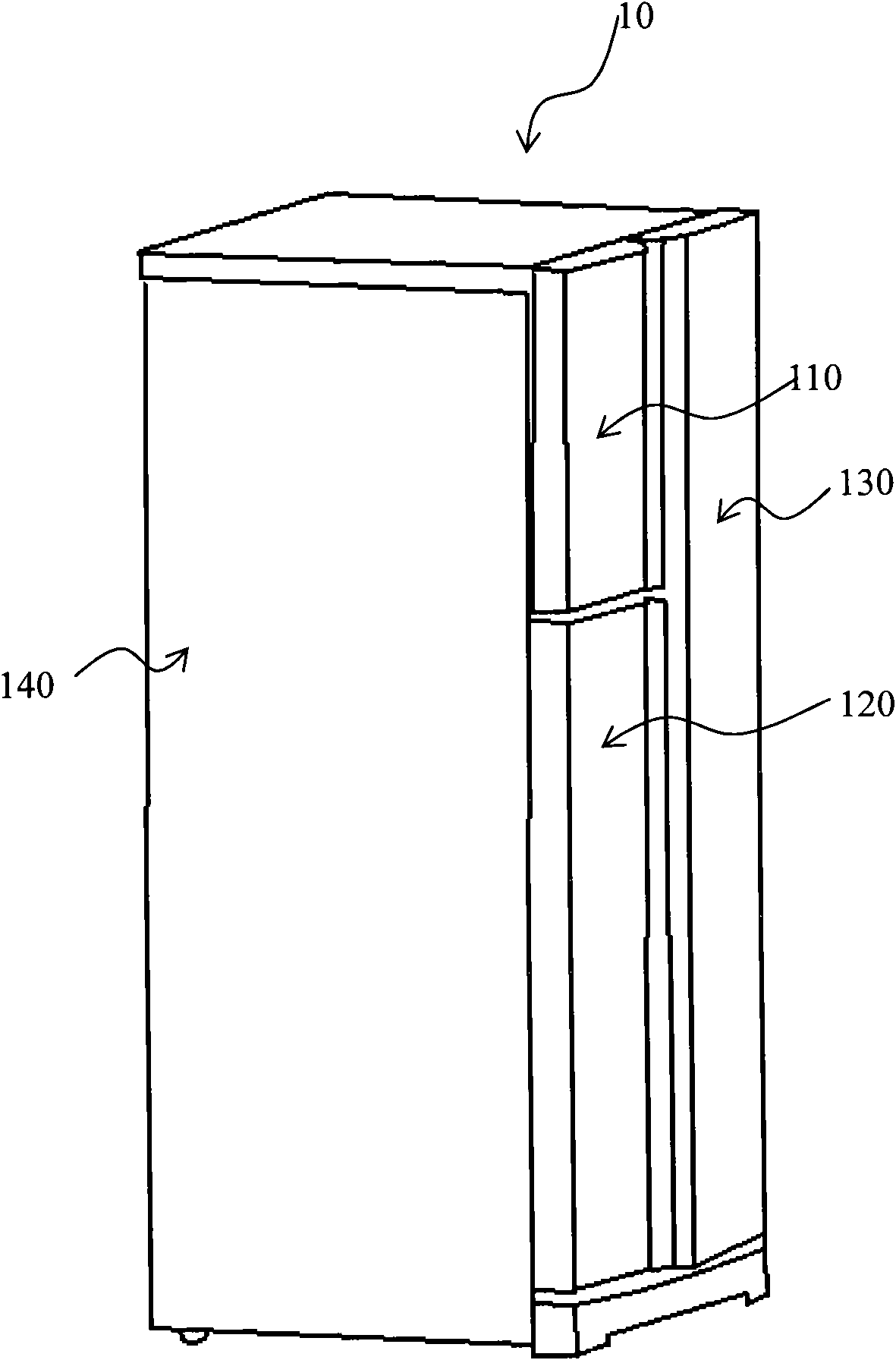

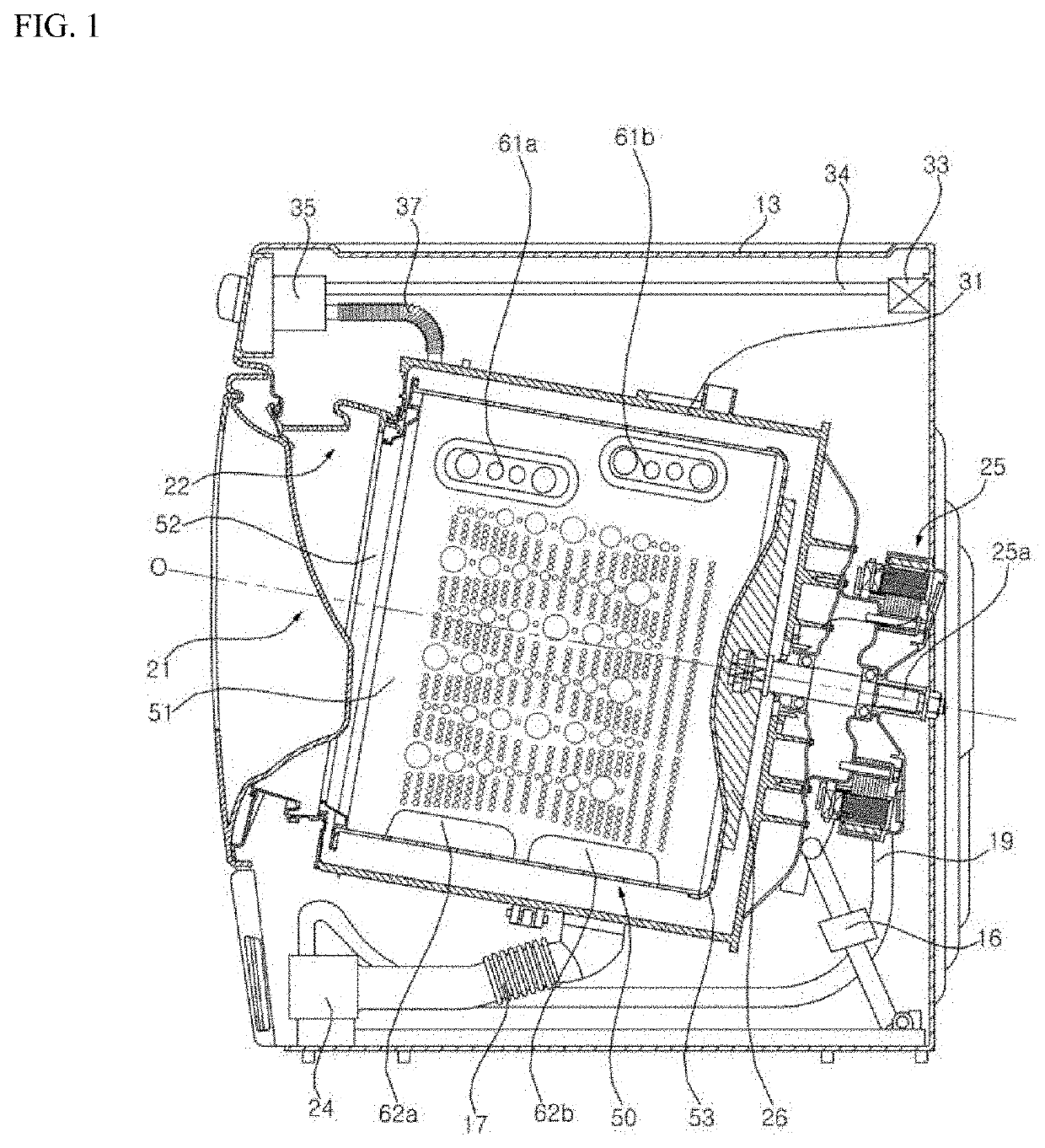

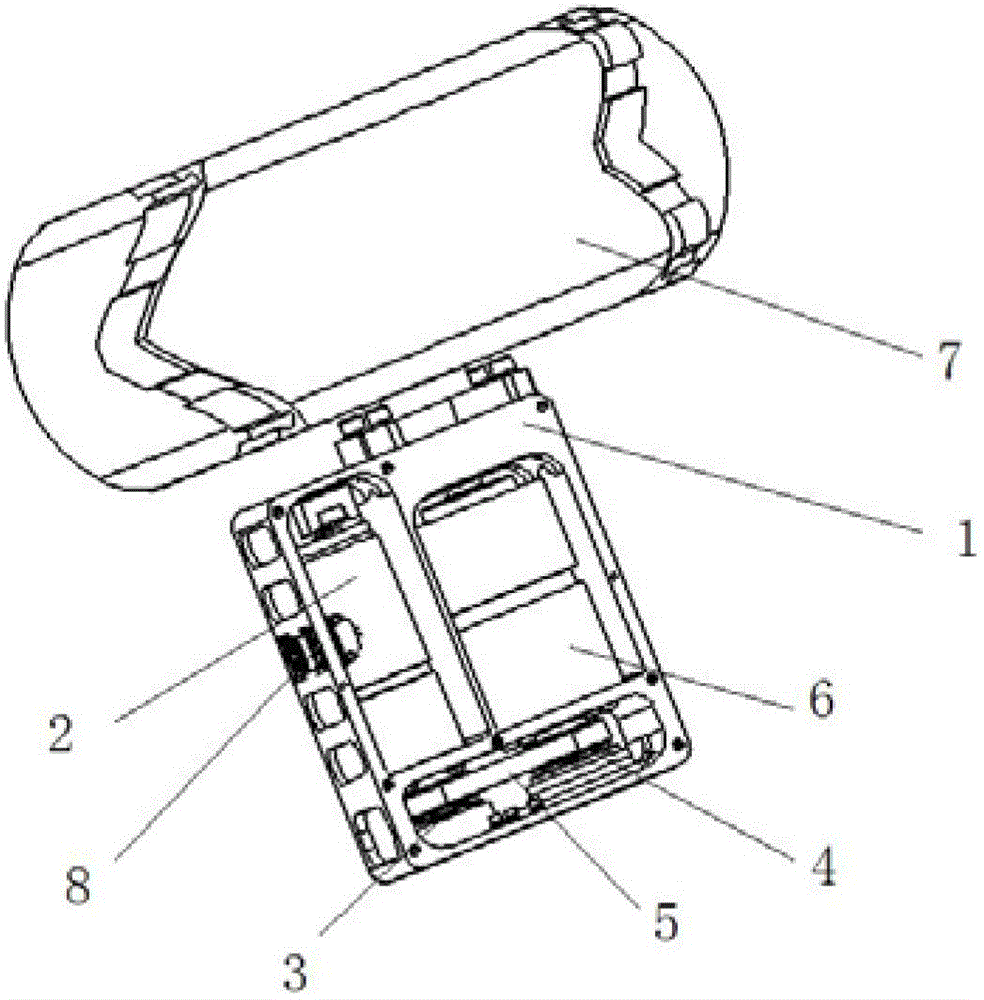

Laundry treating apparatus

InactiveUS20200248363A1High rigidityImprove fastening forceOther washing machinesWashing machine with receptaclesLaundryRotational axis

A laundry treating apparatus according to the present disclosure includes a drum having a mounting slot and being configured to receive laundry and rotate about a predetermined rotation axis extending in a front-rear direction, and a lifter disposed on an inner circumferential surface of the drum and extending in the front-rear direction. The lifter includes a lifter frame installed on the inner circumferential surface of the drum, and a frame cover coupled to the lifter frame and protruding radially inward from the inner circumferential surface of the drum. The lifter frame has a catching protrusion protruding from an inner surface of the lifter frame and having a shape that is symmetrical based on a center in a plan view.

Owner:LG ELECTRONICS INC

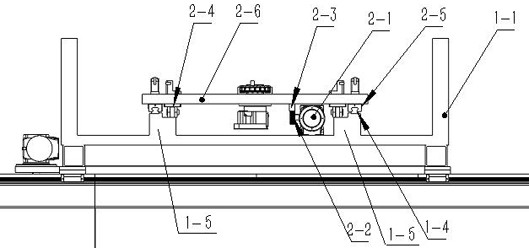

Heavy-load RGV system for flexible production line

PendingCN114229369AReduced precision requirementsStructural overhang is shortConveyor partsMechanical conveyorsGear wheelLap joint

The invention discloses a heavy-load RGV trolley system for a flexible production line. A trolley base body assembly is connected to a ground rail through a linear guide rail and a sliding block and is driven by a motor and driven by a gear and a rack to walk in the direction of the ground rail; the extending assembly is connected to the trolley base body through a linear guide rail and a sliding block, horizontally extends out in the direction perpendicular to a ground rail through motor driving and gear and rack transmission, and is in lap joint with a machine tool workbench. The chain transmission assembly achieves rotation of a dragging pin on a chain through transmission of a motor and a chain wheel fixed to the extending assembly. A tool and a workpiece are arranged on the upper portion of the tray assembly, and a guide mechanism is arranged at the bottom of the tray assembly. The machine tool workbench is provided with a zero point positioning unit, a hydraulic lifting assembly and a lifting guide limiting assembly. Hydraulic cylinders of the hydraulic lifting assemblies operate synchronously to enable blind rivets at the bottom of the tray to be stably disengaged from the zero point or fall into zero point positioning holes. According to the automatic feeding and discharging device, automatic feeding and discharging can be achieved for parts large in appearance size and heavy in weight.

Owner:BAODING XIANGYANG AVIATION PRECISION MACHINERY

Mounting type communication rod and communication method

The invention discloses a mounting type communication rod and a communication method. The mounting type communication rod comprises a connecting ring, wherein a fixed block is fixedly welded with theouter surface of the connecting ring; an inclined through hole is formed in the fixed block; an inclined support rod is fixedly mounted on the inner surface of the inclined through hole; transverse mounting holes are formed in the two ends of the inclined support rod; mounting screws are fixedly mounted on the inner surfaces of the transverse mounting holes; the outer surfaces of the mounting screws are fixedly connected with the outer surface of the fixed block; a spoke plate is fixedly welded with the inner surface of the connecting ring; a middle plate is fixedly connected with the other end of the spoke plate; a middle threaded hole is formed in the inner center of the middle plate; and the central axis of the middle threaded hole is consistent with that of the connecting ring. Throughthe connecting ring structure with gradually changed diameters, the external fixed block is combined to mount the inclined support rod, so that the using convenience and stability can be greatly improved to ensure safety.

Owner:WEIFANG ENG VOCATIONAL COLLEGE

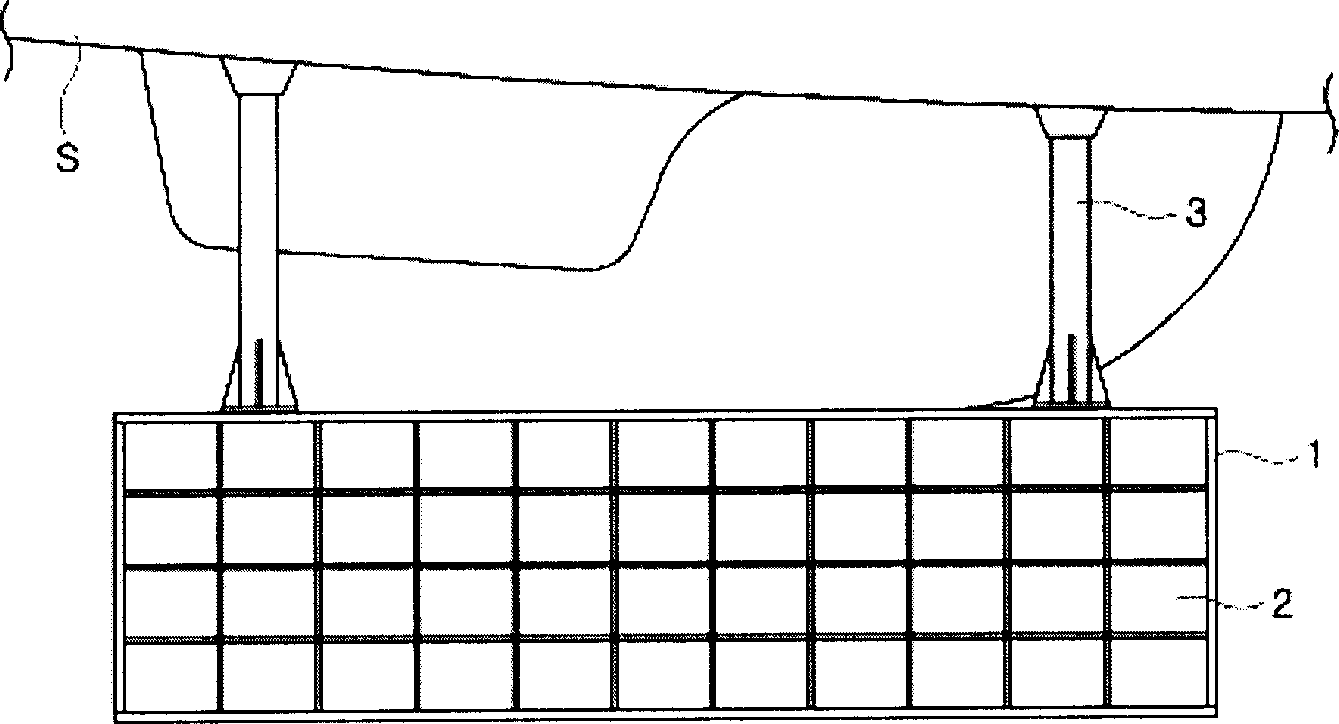

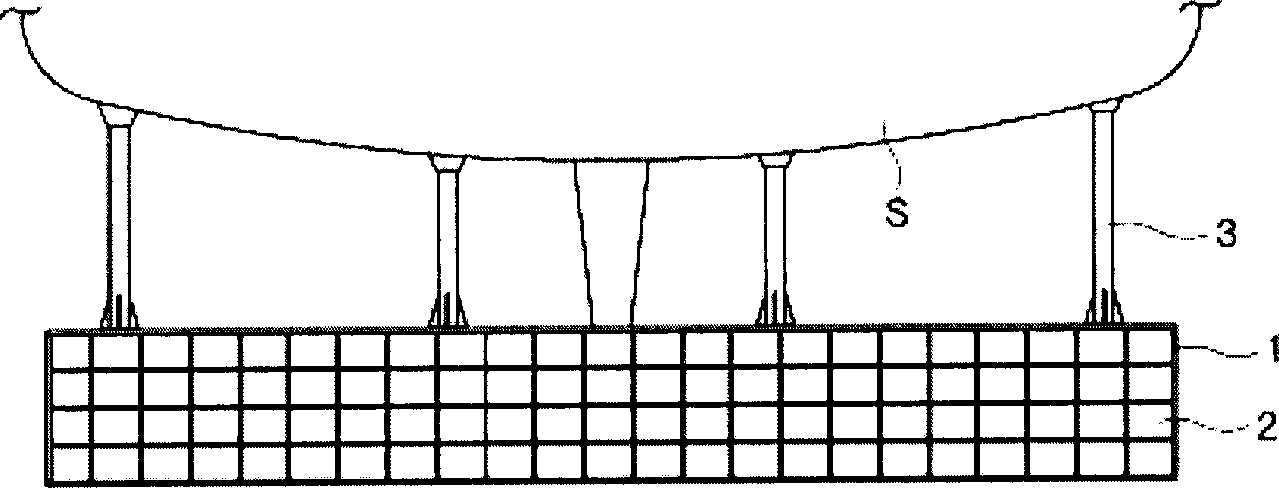

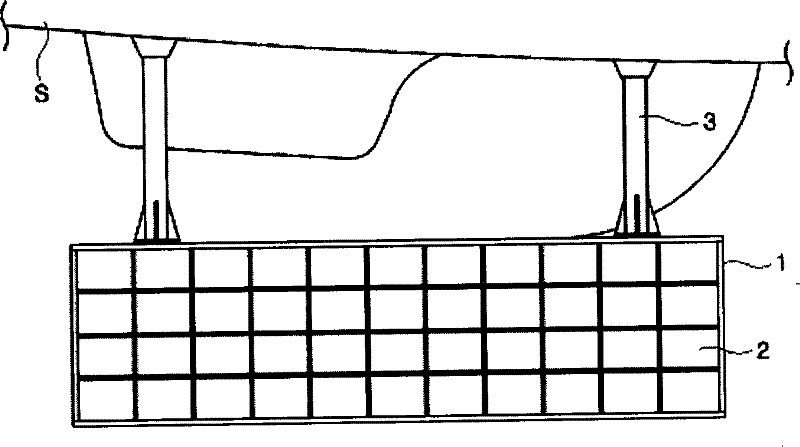

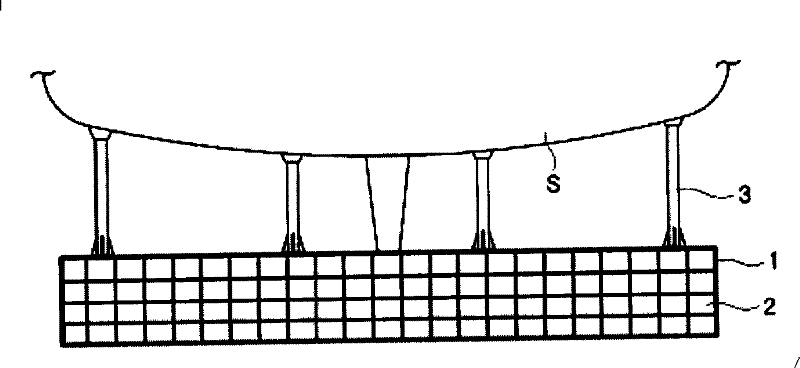

Method and device for causing a ship to dive by using additional buoyancy

InactiveCN1891569BAvoid damageEnsure structural rigidityDry-dockingSlipwaysMarine engineeringBuoyancy function

The launching method by additional buoyancy of the vessel S comprises the steps of: arranging a floating body 2 with magnitude determined by the weight or buoyancy of a partially constructed vessel S on a bottom or side surface of the vessel S; fixing the vessel S and the floating body 2 and generating additional buoyancy to maintain the balance of the vessel S during launching; filling water in a dock and launching the partially constructed vessel S and a completely constructed vessel; pulling the completely constructed vessel out of the dock; letting the water out of the dock and sinking the partially constructed vessels in the dock again; and separating the partially constructed vessel S from the floating body .

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

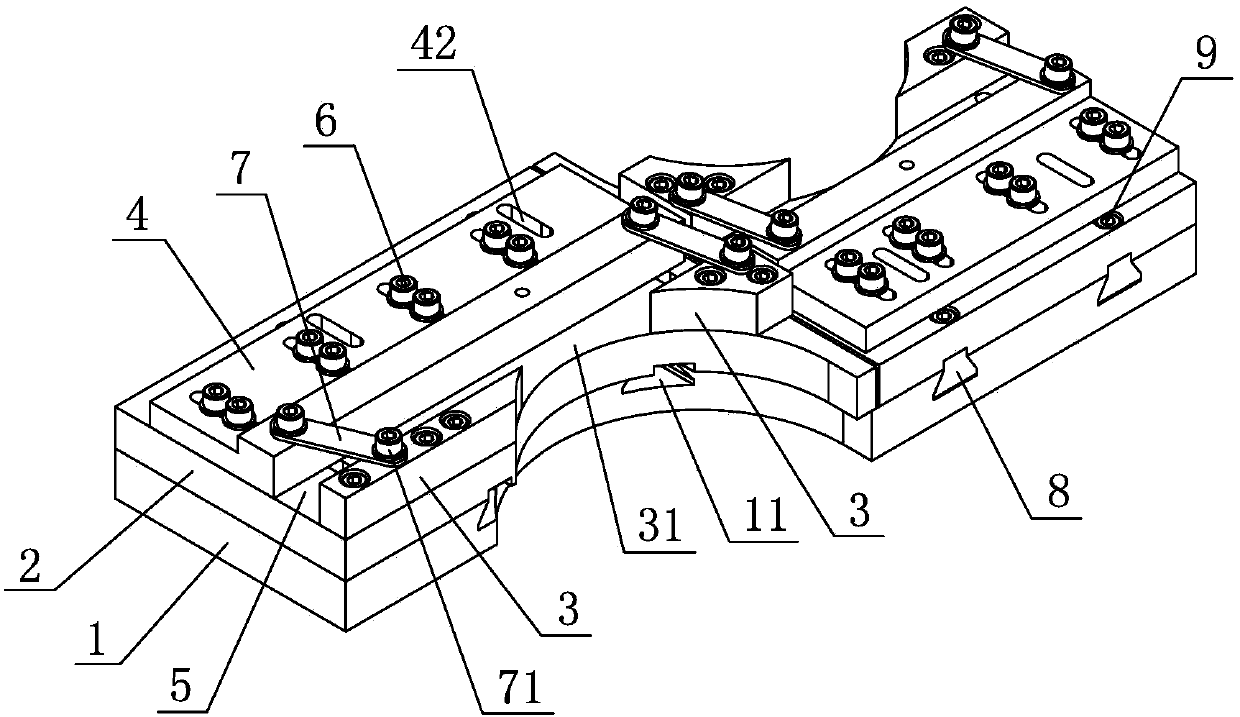

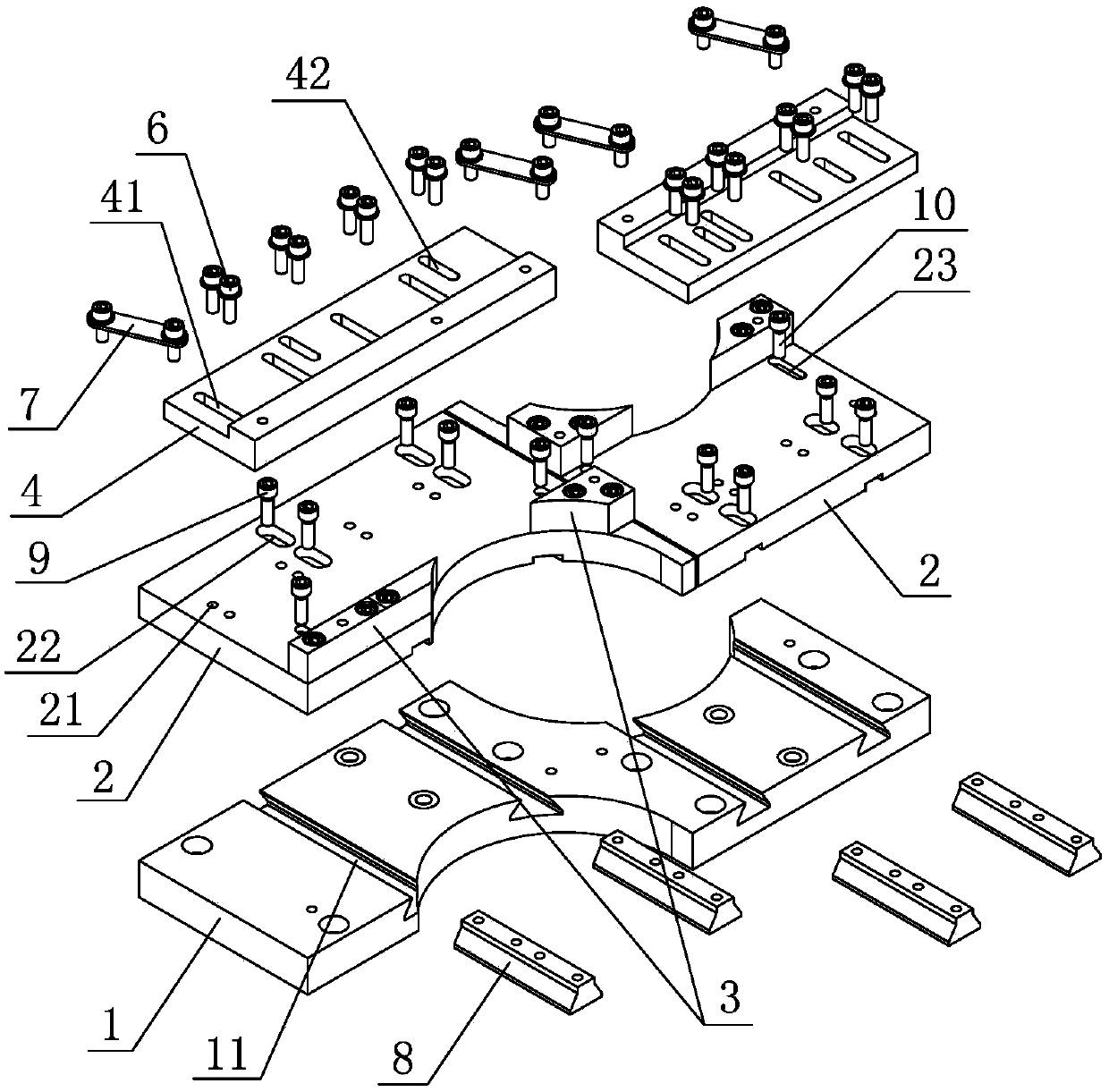

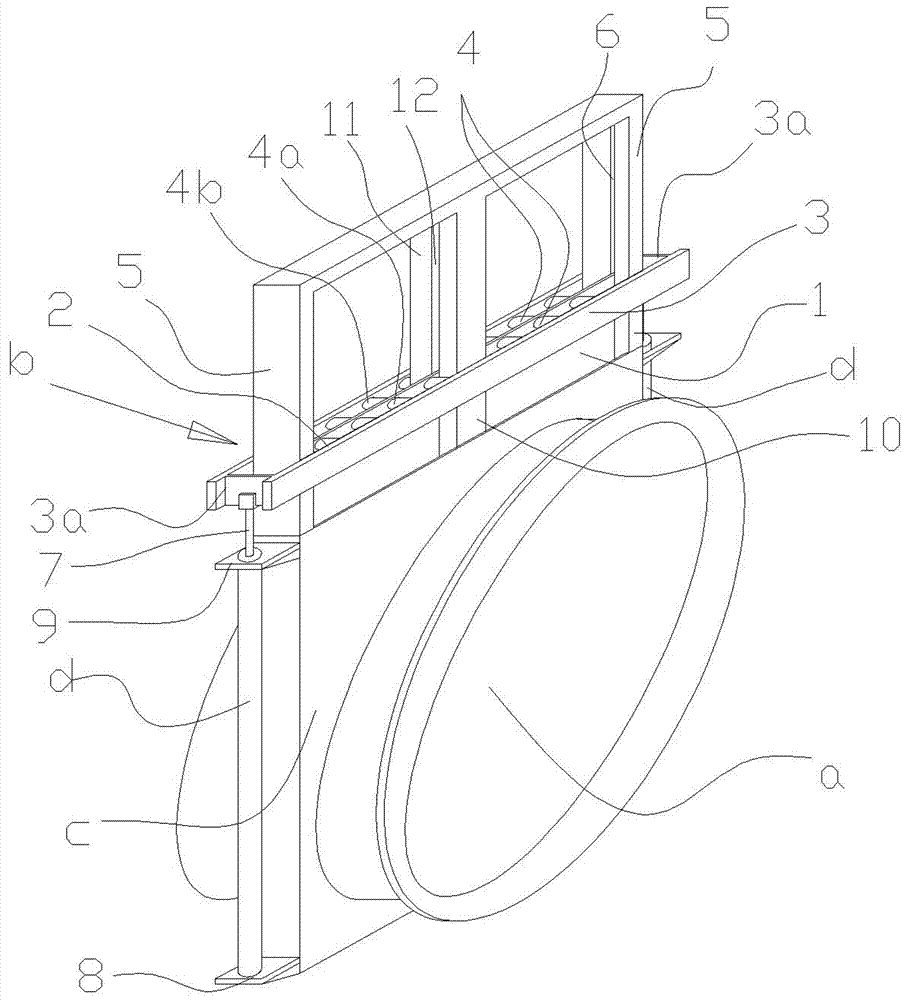

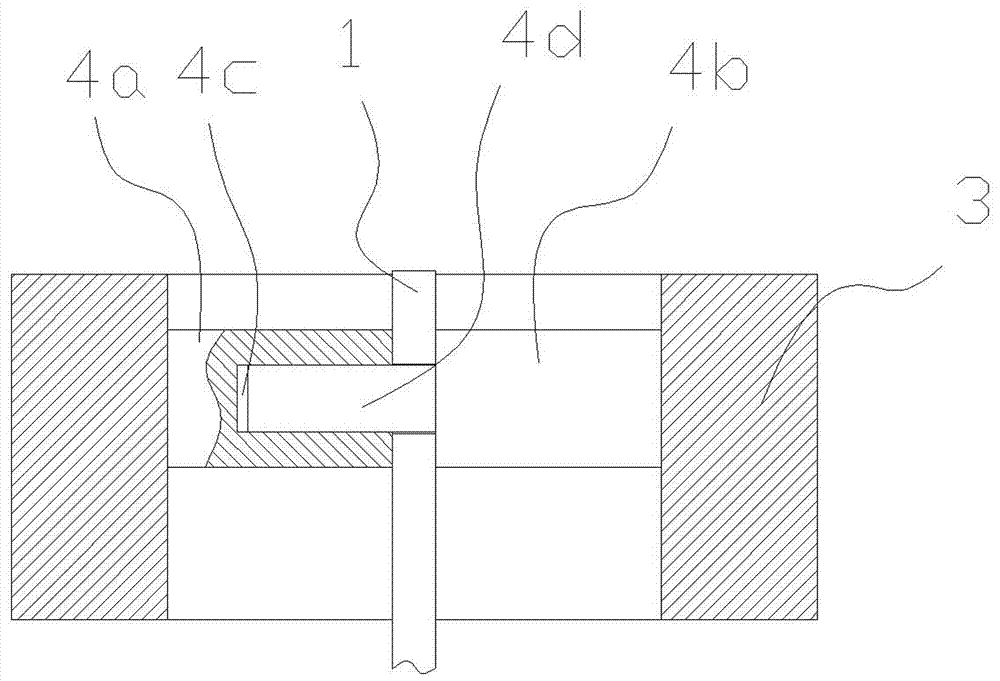

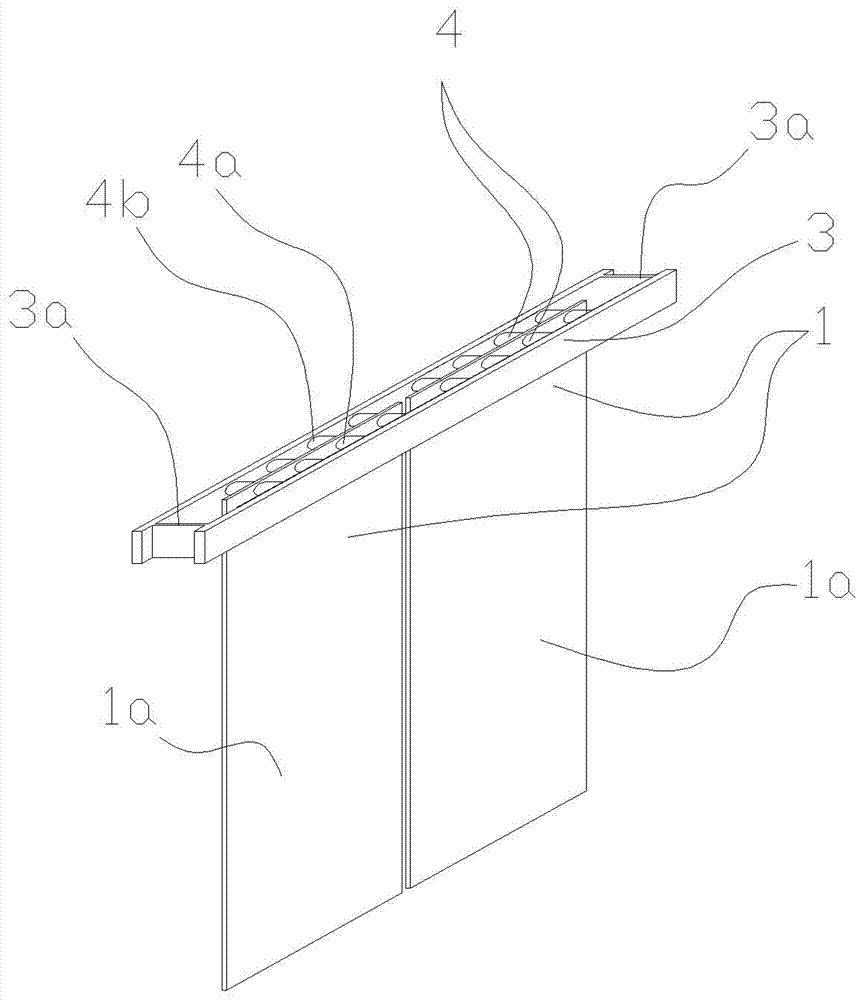

A universal fixture with convenient adjustment

ActiveCN106112607BEnsure structural rigidityGuaranteed flatnessPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a convenient-to-adjust universal fixture which comprises at least two groups of butted fixture assemblies, wherein mounting slots for mounting parts to be machined or special fixtures are formed in the fixture assemblies; the convenient-to-adjust universal fixture is characterized by further comprising a reference plate fixedly mounted on a machine tool workbench; the fixture assemblies are arranged on the reference plate; the mounting slots on the fixture assemblies are butted successively along the axial direction; fixture transverse position adjustment mechanisms are arranged between the fixture assemblies and the reference plate; and the adjustment directions of the transverse position adjustment mechanisms for the fixture assemblies are perpendicular to the axial directions of the mounting slots. The convenient-to-adjust universal fixture has the advantages that the fixture transverse position adjustment mechanisms are arranged between the fixture assemblies and the reference plate, so that the positions, in the transverse direction of the reference plate, of the fixture assemblies can be adjusted, and the mounting slots, used for mounting the parts to be machined or the special fixtures, on the multiple groups of fixture assemblies can be axially butted precisely; and furthermore, the convenient-to-adjust universal fixture is convenient and quick for adjustment, and is high in adjustment precision and efficiency.

Owner:宁波鑫其精密磁钢有限公司

A Structural Improvement of Pneumatic Ram Door

ActiveCN105588134BSafe and reliable lifeAvoid safety hazardsChimneysEngineeringUltimate tensile strength

An improved structure of a pneumatic gate valve comprises the gate valve arranged on a flue, and an air cylinder arranged on a main frame to drive the gate valve to move. The improved structure of the pneumatic gate valve is characterized by comprising a plate-shaped gate valve body and a gate clamp. The gate clamp comprises a framework and a plurality of pairs of columnar bodies arranged on the inner side of the framework. Each pair of columnar bodies comprise the female columnar body and the male columnar body. The upper end of the plate-shaped gate valve body is arranged between the female columnar body and the male columnar body of each pair of columnar bodies and clamped and fixed by the female columnar bodies and the male columnar bodies. Compared with the prior art, the improved structure of the pneumatic gate valve has the advantages that through grooves do not need to be formed in machine frames on two sides, the strength and rigidity of the whole main frame structure are guaranteed, deformation of the main frame is prevented, the strength of the gate valve is not affected, the occupied space is small, assembly is easy, maintenance is convenience, and safety is good.

Owner:FOSHAN SAINDI ENVIRONMENTAL PROTECTION TECH CO LTD

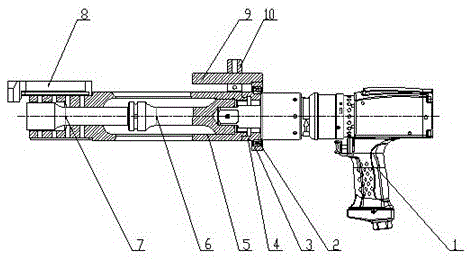

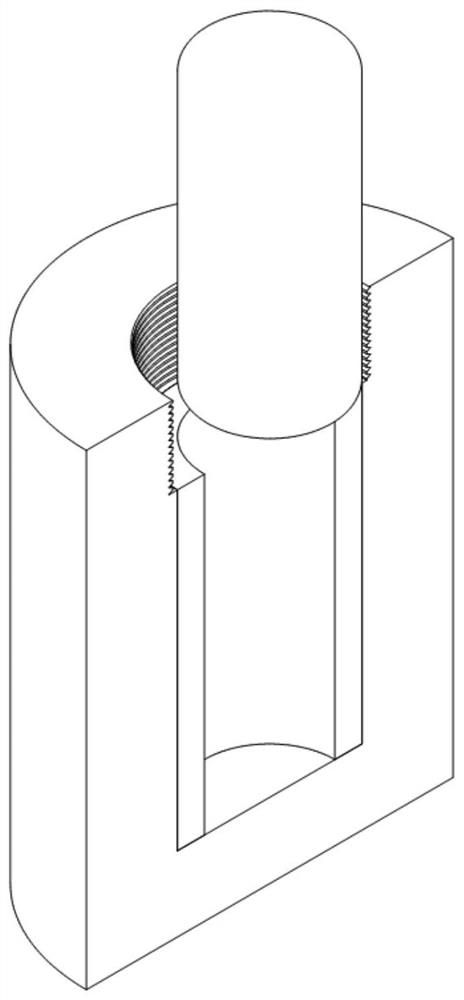

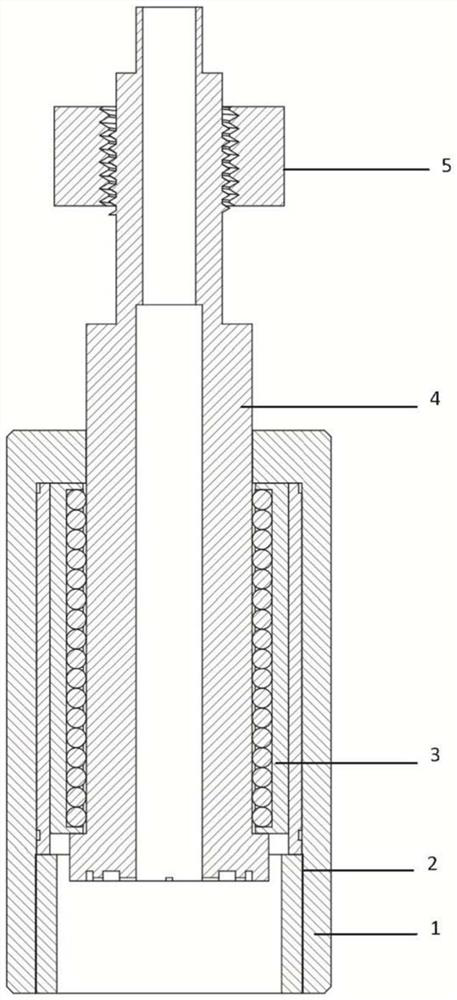

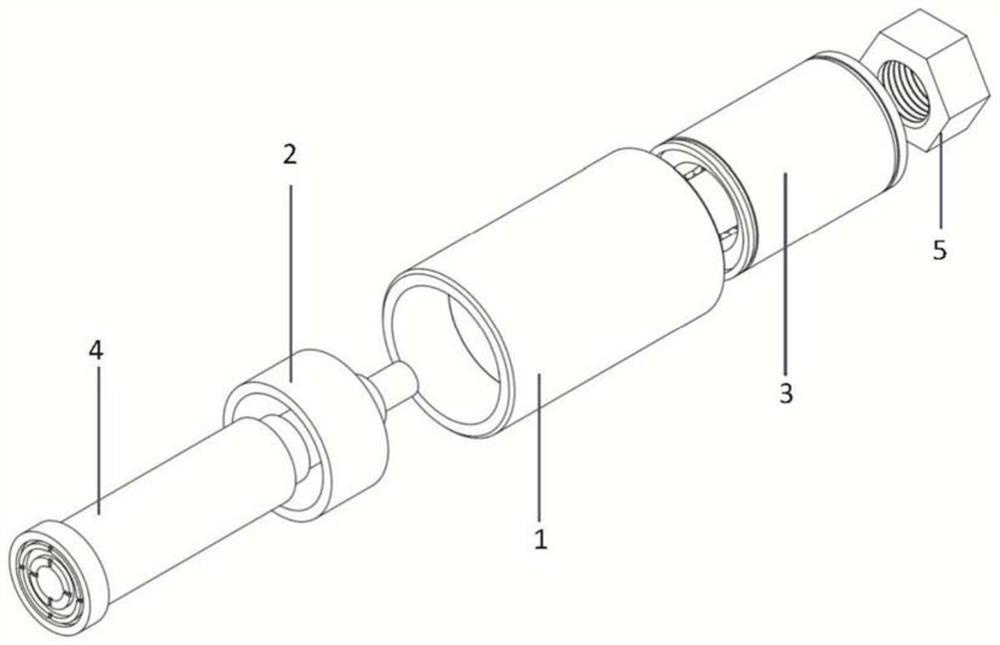

A kind of tightening and lengthening transition mechanism

The invention relates to the technical field of assembling, in particular to a tightening and lengthening transition mechanism. The tightening and lengthening transition mechanism comprises a tightening device and a tightening shaft on the tightening device. The tightening and lengthening transition mechanism further comprises a sleeve, a transition sleeve and a counter force transition sleeve, wherein the sleeve is used for assembling a fastener, one end of the transition sleeve is fixedly connected with the sleeve, the other end of the transition sleeve is fixedly connected with the tightening shaft, the counter force transition sleeve is arranged outside the sleeve and the transition sleeve, one end of the counter force transition sleeve is connected with the tightening device, and a counter force block is arranged above the other end of the counter force transition sleeve. The tightening and lengthening transition mechanism is small in size, low in weight, simple in structure, convenient to maintain, safe and reliable, the fastener is conveniently and accurately assembled, and use by an operator is protected and is convenient.

Owner:安徽唐古拉工业技术有限公司

Tightening and lengthening transition mechanism

The invention relates to the technical field of assembling, in particular to a tightening and lengthening transition mechanism. The tightening and lengthening transition mechanism comprises a tightening device and a tightening shaft on the tightening device. The tightening and lengthening transition mechanism further comprises a sleeve, a transition sleeve and a counter force transition sleeve, wherein the sleeve is used for assembling a fastener, one end of the transition sleeve is fixedly connected with the sleeve, the other end of the transition sleeve is fixedly connected with the tightening shaft, the counter force transition sleeve is arranged outside the sleeve and the transition sleeve, one end of the counter force transition sleeve is connected with the tightening device, and a counter force block is arranged above the other end of the counter force transition sleeve. The tightening and lengthening transition mechanism is small in size, low in weight, simple in structure, convenient to maintain, safe and reliable, the fastener is conveniently and accurately assembled, and use by an operator is protected and is convenient.

Owner:安徽唐古拉工业技术有限公司

Reducer assembly and vehicle

PendingCN110397707AAvoid phenomena such as stress deformationEnsure structural rigidityToothed gearingsGear lubrication/coolingStructural deformationReduction drive

The invention discloses a reducer assembly. An input shaft is arranged at one end of a reducer shell of the reducer assembly, an outer bearing and an inner bearing sequentially sleeve the input shaft,and a driving gear and a driven gear are meshed with the downstream of the input shaft in sequence; a differential is arranged in the reducer shell, two half-shaft gears are arranged coaxially in a differential shell, a planetary gear shaft is arranged between the two half-shaft gears, planetary gears meshed with the half-shaft gears are coaxially arranged on the planetary gear shaft, half shaftscoaxially inserted into the corresponding half-shaft gears are arranged on the two sides of the reducer shell respectively, bearing covers sleeve the outer walls of the two sides of the differentialshell, and differential bearings are coaxially embedded between the bearing covers and the differential shell. The reducer assembly can provide reliable structural support and protection for the internal differential assembly, so that structural deformation of the assembly is avoided, and the overall structural rigidity and reliability of the equipment are ensured. The invention further disclosesa vehicle adopting the reducer assembly.

Owner:LIUZHOU WULING MOTORS +1

Double-station CNC face grinder device

ActiveCN106541306BCompact structureOptimize the structure of the whole machineGrinding carriagesGrinding drivesNumerical controlEngineering

The invention discloses a double-station numerical control end face grinding machine device. The double-station numerical control end face grinding machine device comprises a machine frame. The machine frame is provided with a first station end face grinding machine and a second station end face grinding machine, wherein the first station end face grinding machine comprises a first abrasion wheel device used for grinding workpieces, a first abrasion wheel automatic repair device used for repairing abrasion wheels, and a first three-axis linkage tool rest device used for fixing the workpieces; and the second station end face grinding machine and the first station end face grinding machine are identical in structure. The double-station structure is adopted, the structure is compact, the whole machine structure of equipment is optimized, the using performance of the equipment is improved, the production efficiency is improved, and the labor cost and production cost are reduced.

Owner:阳江市阳东区国浩机械制造有限公司

A method for establishing a coarse-grained model of pigment carbon black based on martini force field

ActiveCN112768007BKinetic performance unchangedEnsure structural rigidityDesign optimisation/simulationComputational theoretical chemistryNanochemistryMaterials science

The invention provides a method for establishing a coarse-grained model of pigment carbon black based on Martini force field, which belongs to the technical field of nanometer chemical calculation; specifically, the coarse-grained model of spherical pigment carbon black is divided into a central bead and an outermost spherical shell-shaped bead. , define two types of beads in the Martini force field, assign molar mass and potential action parameters, and use bond connections on the connection between the central bead and the outermost spherical shell to ensure that the molecular dynamics simulation can be unchanged. It is small and does not collapse; since the entire coarse-grained model only has the outermost spherical shell-shaped beads and the central bead, which greatly reduces the number of beads, it can ensure the accuracy of molecular dynamics calculations while greatly reducing the amount of calculation, improving the The speed of calculation also avoids the waste of calculation.

Owner:TAIYUAN UNIV OF TECH

A high-temperature-resistant suction cup top post for installation of high-temperature radioactive sources

ActiveCN110773977BRealize the mechanized operation of installationEnsure structural rigidityGripping headsMetal working apparatusInsulation layerSilica gel

The invention relates to a high-temperature resistant sucker top column for installing a high-temperature radioactive source. The sucker top column comprises a hollow sucker top column body and a protective disc assembly, wherein the hollow sucker top column body can extend into an inner cavity of the protective disc assembly and can axially move relative to the protective disc assembly; and the bottom surface of the hollow sucker top column body and the upper surface of a workpiece form a sealing surface, and the inner side of the inner cavity of the protective disc assembly and the side surface of the workpiece form a sealing surface. The sucker top column has the following beneficial effects that a silica gel sucker is not adopted, the rigidity of the whole structure is ensured by a vacuum suction mode, the high temperature of the radioactive source can be borne, and the mechanical operation of the installation of the radioactive source is realized; and a limiting protective disc isadopted, thus it is ensured that the radioactive source is coaxial with a carbon-carbon cylinder heat insulation layer (high-temperature radioactive source cladding), and incapability of positioningdue to deviation is prevented.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Novel double-station numerical control end surface grinding machine

InactiveCN106985022ACompact structureOptimize the structure of the whole machineGrinding feed controlAbrasive surface conditioning devicesNumerical controlGrinding wheel

The invention discloses a novel dual-station numerical control end face grinder, which includes a frame, and the frame is provided with a first station end face grinder and a second station end face grinder, wherein: the first station end face grinder includes There is a first grinding wheel device for grinding the workpiece, a first grinding wheel automatic dressing device for dressing the grinding wheel, and a first three-axis linkage tool holder device for fixing the workpiece; the structure of the second station end face grinder is the same as that of the first The station face grinder is the same. The invention adopts a double-station structure, has a compact structure, optimizes the overall structure of the equipment, improves the performance of the equipment, increases the production efficiency, and saves labor costs and production costs.

Owner:阳江市阳东区国浩机械制造有限公司

Modular drive wheel and modular robot containing it

The invention discloses a modularized drive wheel and a modularized robot with the same. The modularized drive wheel comprises a first seal box. A motor, a reducer and a synchronous wheel group are disposed in the seal box. The synchronous wheel group comprises a first pulley, a second pulley and a transmission belt which connects the first pulley and the second pulley. An output shaft of the motor is connected with the first pulley. An input shaft of the reducer is connected with the second pulley. An output shaft of the reducer extends to the outside of the seal box and is connected with a tire through a load-bearing shaft. The modularized robot comprises the modularized drive wheel and a chassis support. The modularized wheel is fixed on the chassis support. The modularized wheel is compact in structure, universal and convenient in rapid replacement, maintenance or upgrading. The chassis support of the modularized robot is firm in structure and good in structural rigidity, large load can be borne, the modularized wheel inserted to the chassis support is independent of the chassis support and can be replaced and maintained independently, and assembling speed is increased.

Owner:SHANGHAI XPARTNER ROBOTICS

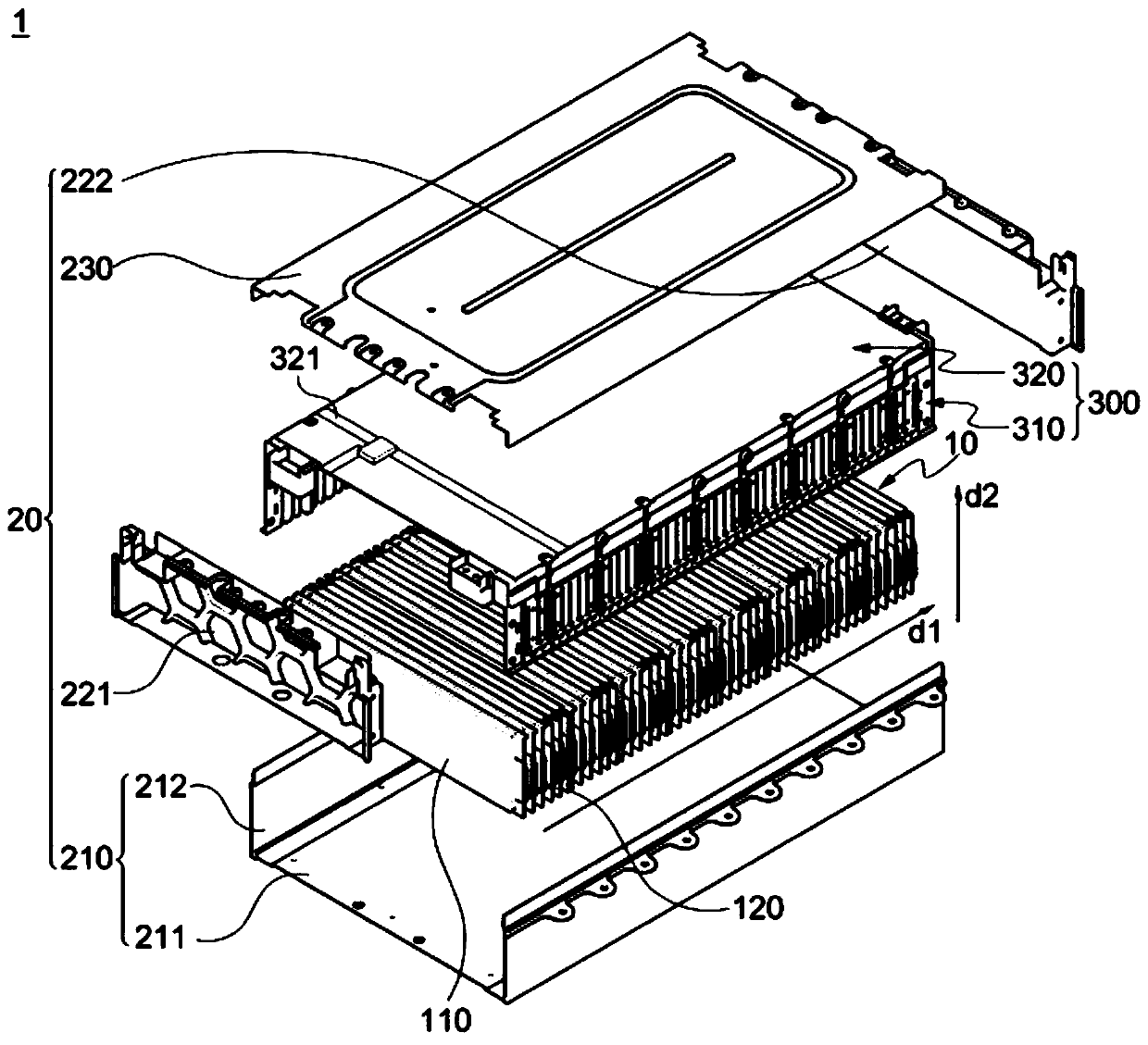

Battery module and manufacturing method thereof

ActiveCN111554840AEasy to fixEasy to assembleAssembling battery machinesFinal product manufactureElectrical batteryElectrical connection

The present invention provides a battery module, and the battery module includes a battery stack formed by stacking a plurality of battery cells respectively including electrode tabs on each other; and bus bar assemblies located on sides of the battery stack, from which the electrode tabs are drawn out, to electrically connect the plurality of battery cells to each other through a plurality of electrode tabs, wherein each of the bus bar assemblies includes a plurality of openings configured to hold the plurality of electrode tabs, and each of the plurality of openings includes an insertion portion formed by opening one side thereof so that the electrode tab is slidely inserted in a direction perpendicular to a direction in which the electrode tabs are drawn out.

Owner:SK ON CO LTD

structure of pfa lined pump casing

ActiveCN106246598BSmall sizeReduce variance ratioPump componentsPumpsImpellerManufacturing cost reduction

The invention discloses a PFA (Polyfluoroalkoxy) lining pump shell structure and aims at improving the production efficiency, reducing the manufacturing cost and the production reject ratio, making the improvement especially for a metal lining PFA pump shell structure, reducing the pump shell production cost and increasing the manufacturing yield. A metal shell lining PFA pump is used for conveying high-corrosivity chemical liquid, a metal shell is used for resisting the pump pressure and the piping load, and a PFA lining serves as a liquid receiving material to resist corrosion of liquid chemical. According to the improvement key point of the pump shell structure, the production bad factors of injection molding are reduced through the structure change, and the pump shell structure is characterized in that inlet shell lining PFA serves as a pumping inlet; scroll shell lining PFA is used for containing an impeller, collecting liquid generated after impeller acting and discharging the liquid through an outlet, and an inlet shell and a scroll shell are independently produced and then combined to form an integral pump shell so as to reduce the residual stress of injection molding.

Owner:ASSOMA

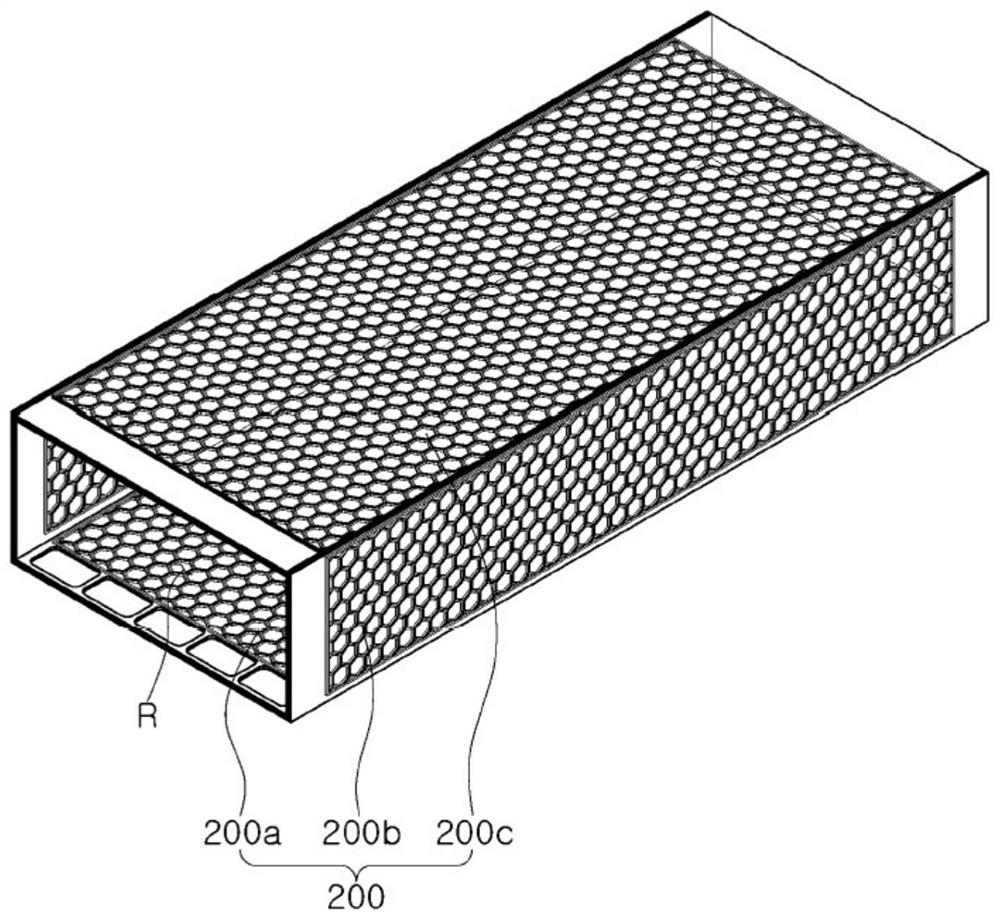

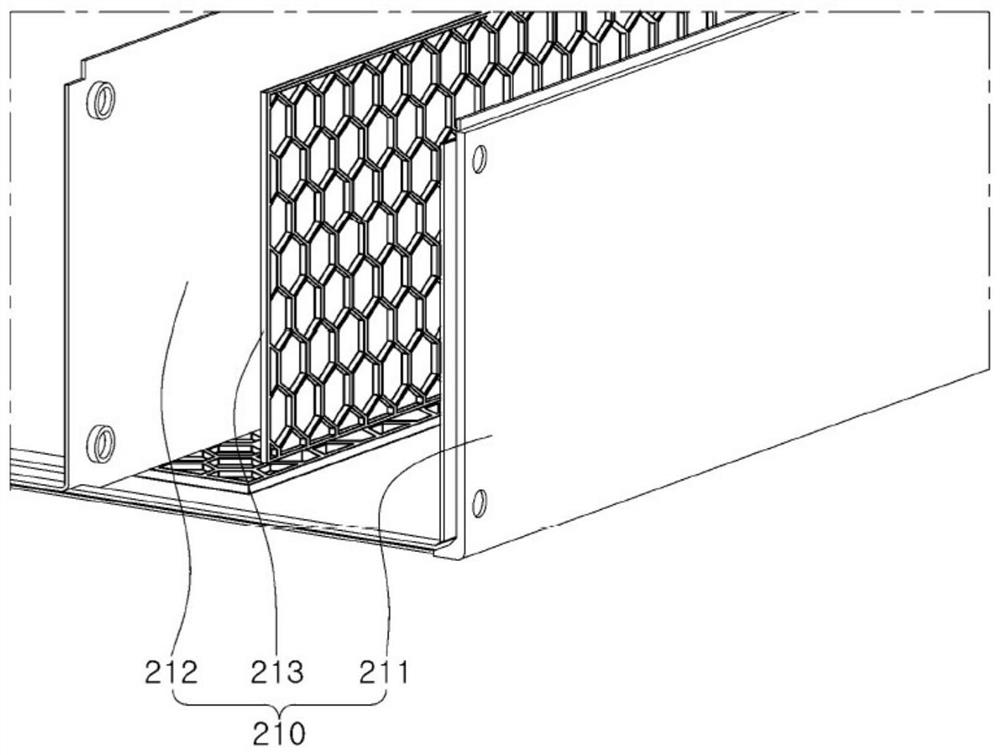

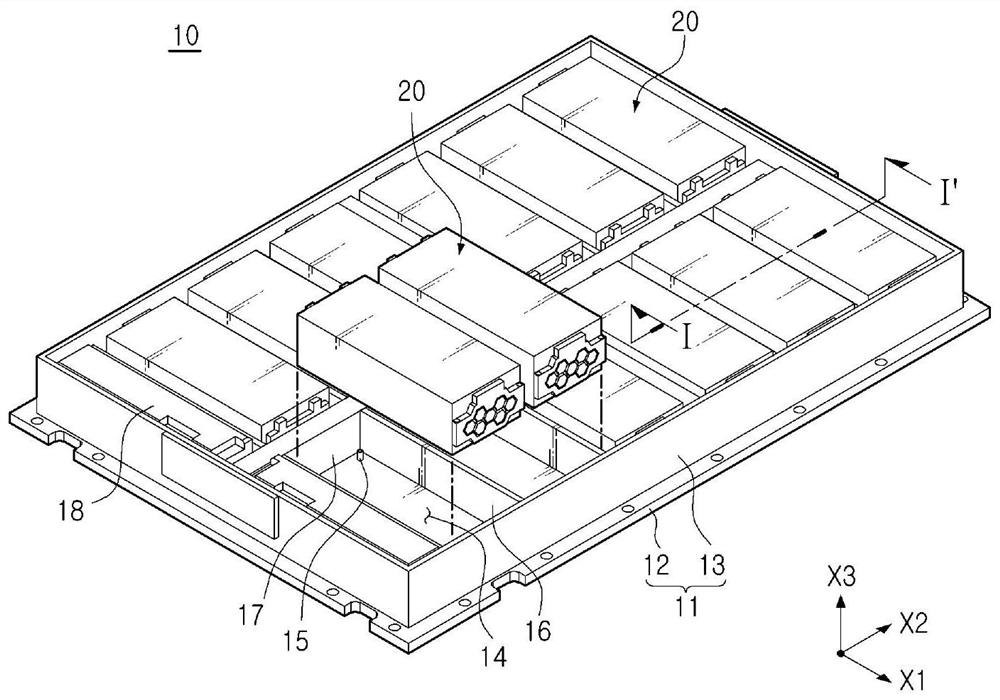

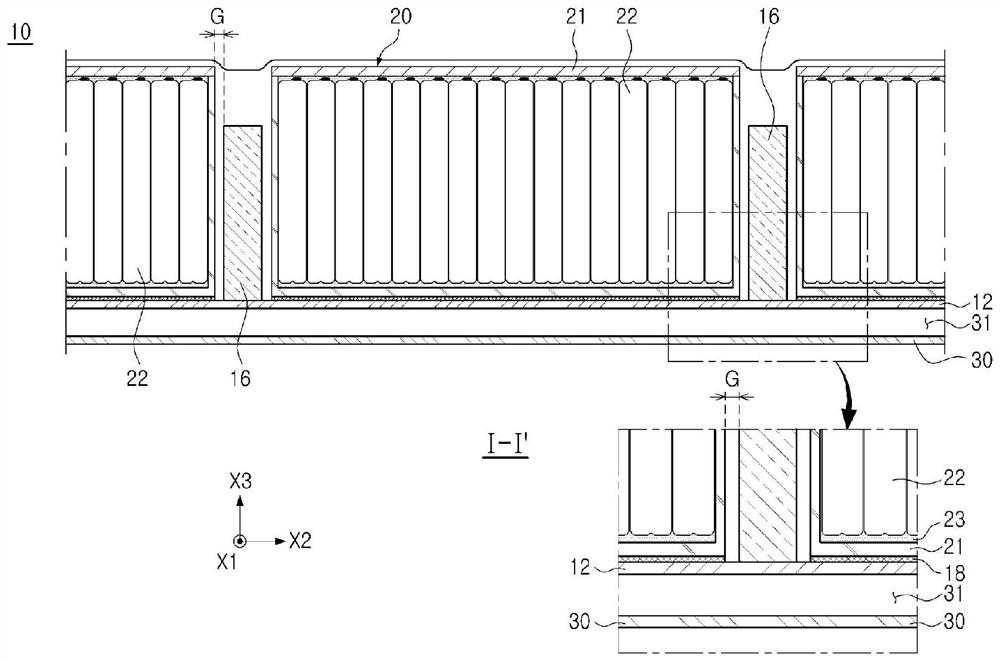

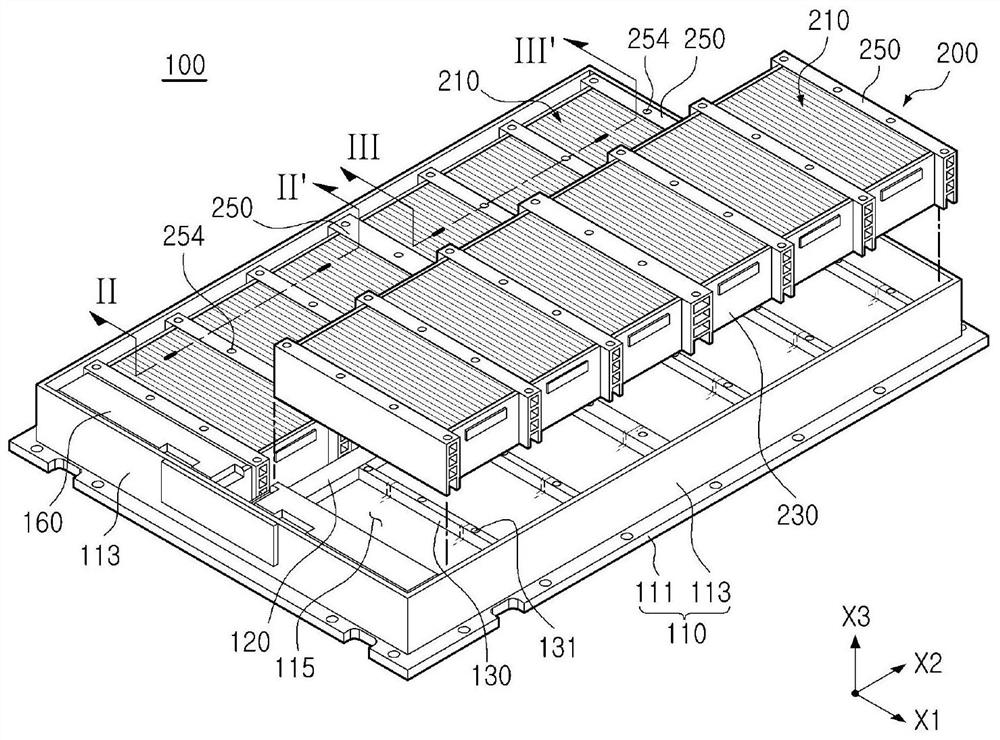

Battery pack

PendingCN114006122ADiversified installationIncrease energy densitySecondary cellsCell component detailsThermodynamicsMechanical engineering

The invention provides a battery pack for increasing energy density and having excellent heat dissipation performance. The battery pack (100) includes a plurality of cell stack units (210), each stack unit including a stack of a plurality of battery cells (220), a partition wall member (250) disposed between the cell stack units (210) adjacent to each other, and a pack housing (110) accommodating the plurality of cell stack units (210) and a plurality of partition wall members (250). The cell stack unit (210) and the partition wall member (250) are accommodated in the pack housing (110) while side surface of the cell stack unit (210) and a side surface of the partition wall member (250) are in contact with each other, and the partition wall member (250) is fixed to a bottom surface (112) of the pack housing (110).

Owner:SK ON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com