Variable-focus lens and method of manufacturing the same

A lens and focal length technology, applied in the direction of lens, instrument, installation, etc., can solve the problems of complicated lens manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

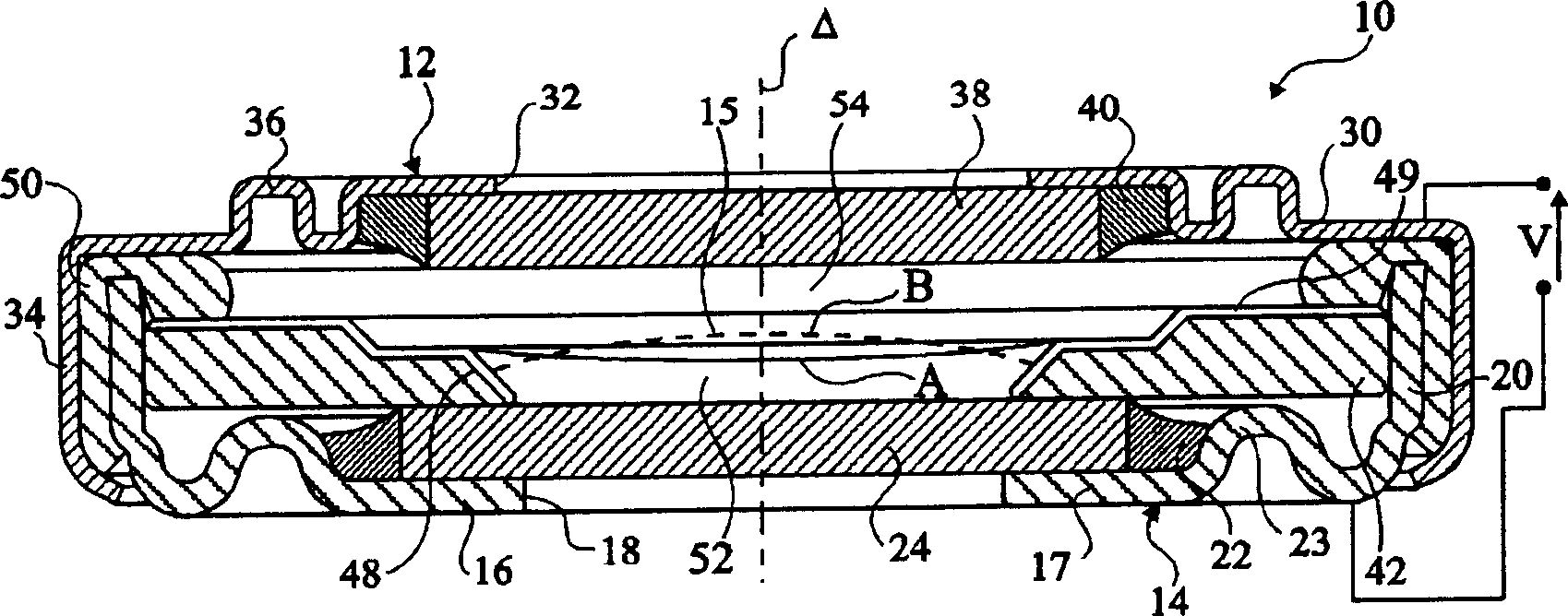

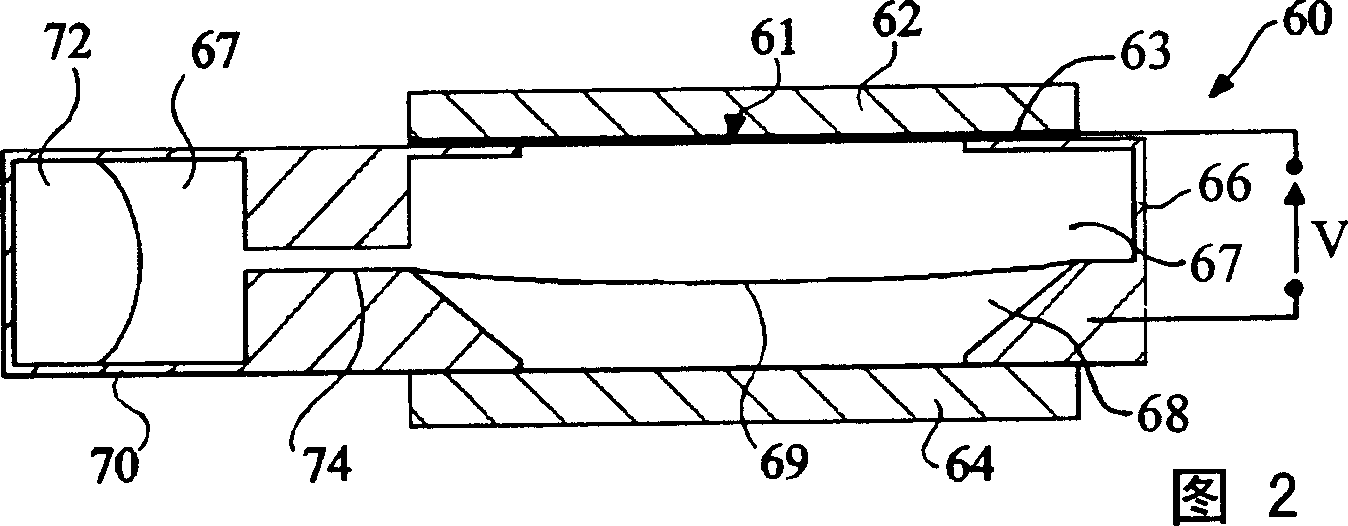

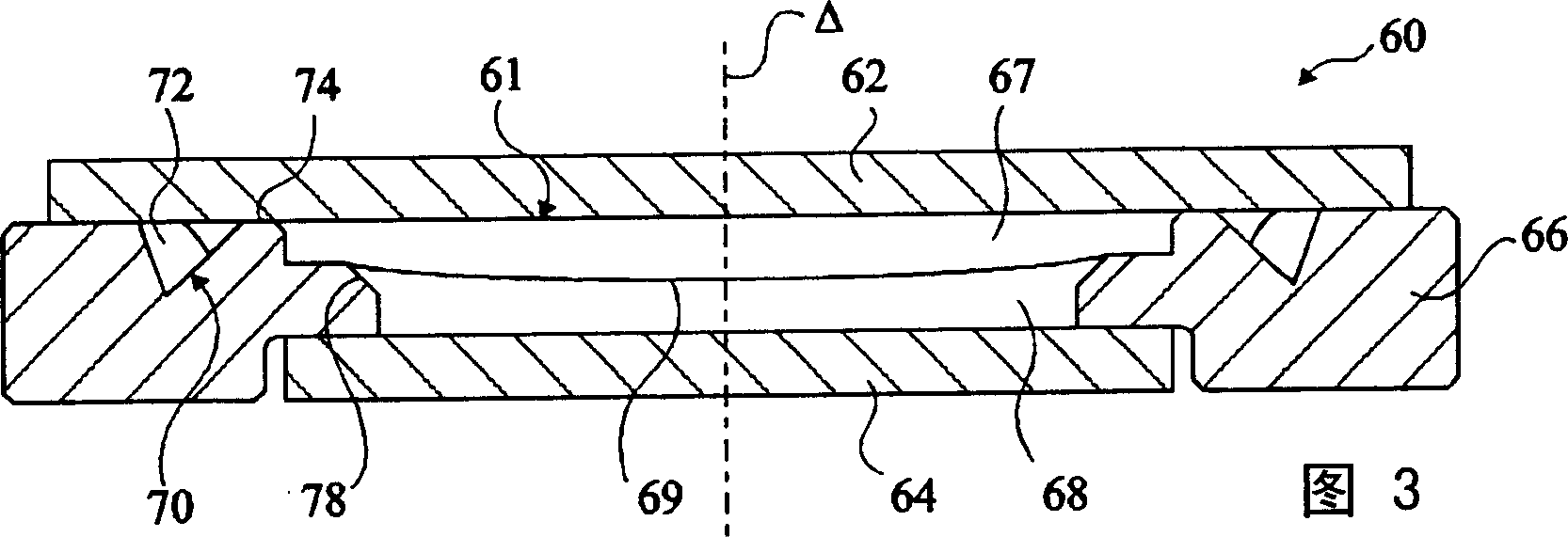

[0024] For the sake of clarity, the same reference numerals are used to designate the same elements in the various figures.

[0025] The invention involves the intentional introduction of a volume of gas into contact with one of the liquids contained in the lens, but taking care to prevent said volume of gas from being present in the area through which light passes. Restricting means are used to prevent the volume of gas from moving into the light path. When the temperature changes, the liquid contained in the lens expands, and this expansion is compensated by said volume of gas, which is very compressible in nature, thereby limiting the variation of the internal pressure of the lens. The gas may be, for example, air, an inert gas or a mixture of several inert gases, or, alternatively or in combination, the vapor of one of the liquids contained in the lens.

[0026] According to the invention, said volume of gas may comprise, for example, one or more gas bubbles contained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com