Heavy-load RGV system for flexible production line

A technology of trolleys and all-in-one machines, applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems that the arm span is difficult to meet the production needs and is limited, so as to improve operability, large operability, and turnover small torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

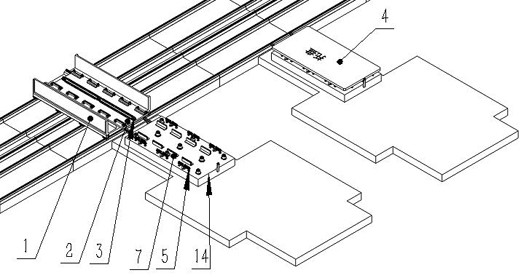

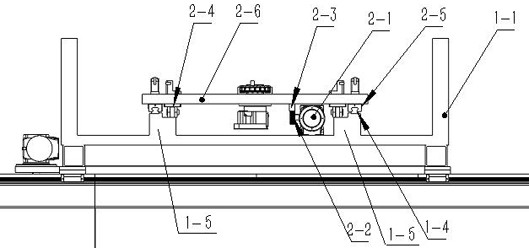

[0028] Such as Figure 1 to Figure 12 As shown, this embodiment includes a trolley base assembly 1, an extension assembly 2, a chain transmission assembly 3, a tray assembly 4, a hydraulic lift assembly 5, an extension guide limit assembly 6, a lift guide limit assembly 7, and a zero point positioning unit 8 , the end surface limit assembly 9 including the buffer, four ground rails 12, the linear guide rail I10 fixed on the ground rails 12, the ground rail racks 11 located in the center circumference of the four ground rails and parallel to the ground rails 12 and opposite One or more machine tool workbenches 14 on which the ground rail 12 is arranged vertically.

[0029] The trolley base assembly 1 includes a trolley base 1-1, an integrated motor and reducer I1-2, a plurality of sliders I1-3 and a gear I. Slide blocks I1-3 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com