Modular drive wheel and modular robot containing it

A technology of modularization and driving wheels, which is applied in the direction of motor vehicles, transportation and packaging, etc. It can solve the problems of inconvenient maintenance and inability to quickly replace robots, etc., and achieve the effects of quick replacement, universality, and improved assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

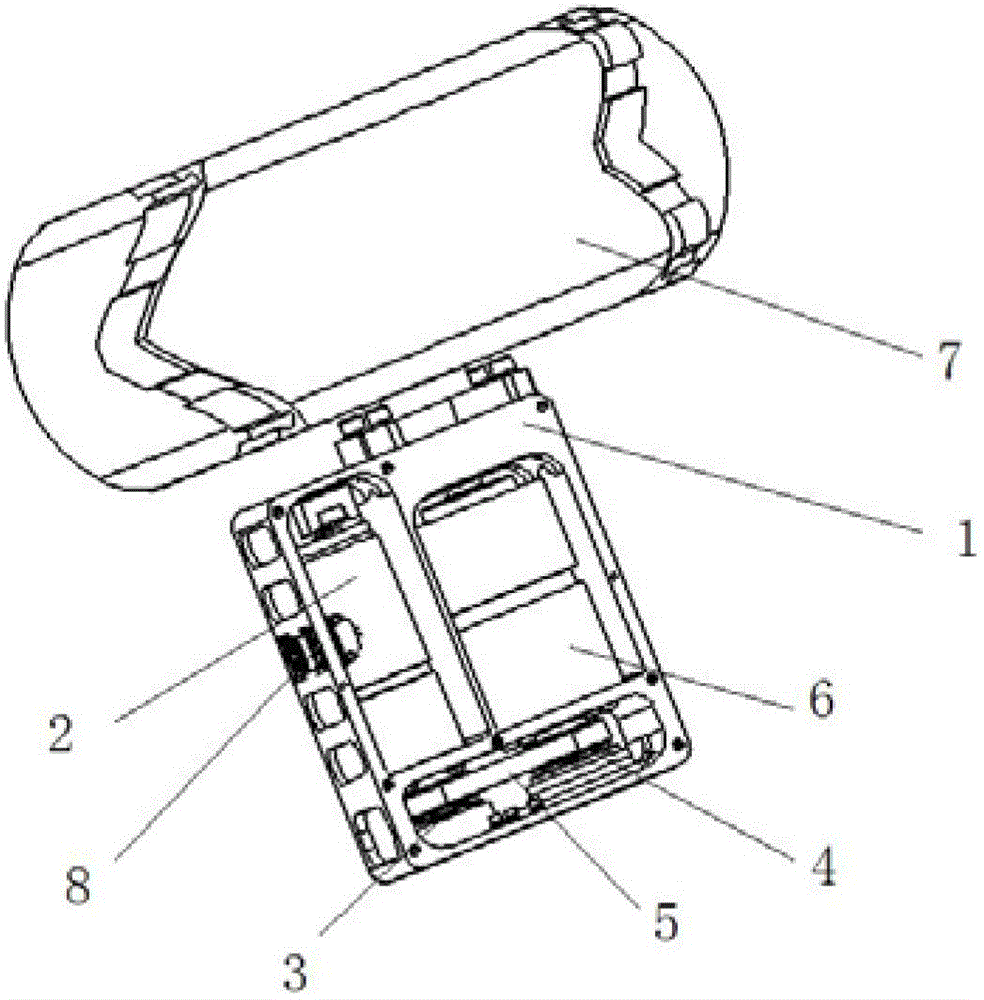

[0021] Such as figure 1 As shown, the modular drive wheel in the present embodiment includes a packing box 1, and a motor 2, a speed reducer 6 and a synchronous wheel set are arranged in the packing box 1, and the synchronous wheel set includes a first pulley 3, a The second pulley 4 and the transmission belt 5 connecting the first pulley 3 and the second pulley 4 . The first pulley 3 is connected to the output shaft of the motor 2 through an auxiliary reducer (not shown in the figure), the second pulley 4 is fixed on the input shaft of the reducer 6, and the output shaft of the reducer 6 is connected from the packaging box 1 The sidewall of the tire passes through, and is connected with a tire 7 by a bearing shaft (not shown in the figure). The motor 2 in this embodiment is a commercially available 350W hollow cup carbon br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com