A Structural Improvement of Pneumatic Ram Door

A technology of structural improvement and pneumatic gate, which is applied in exhaust gas device, combustion product treatment, combustion method, etc., can solve the problems of weak structure, inconvenient maintenance, difficult assembly, etc. Few, easy to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

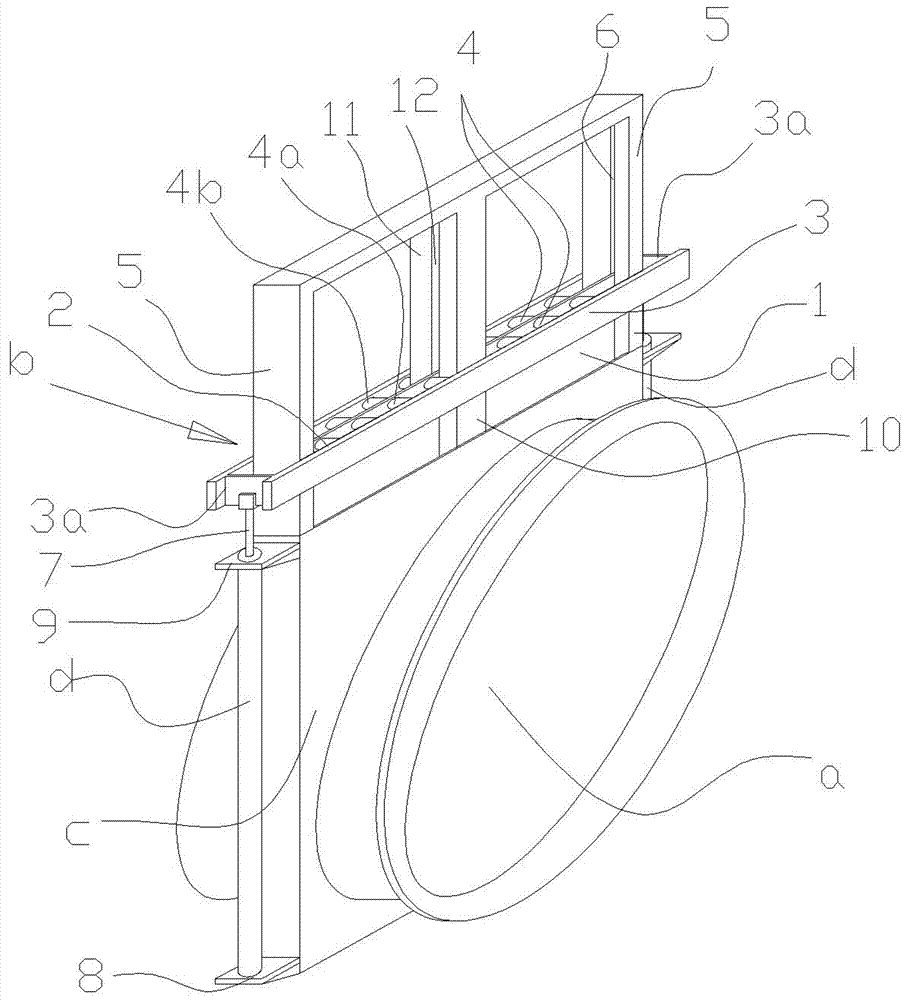

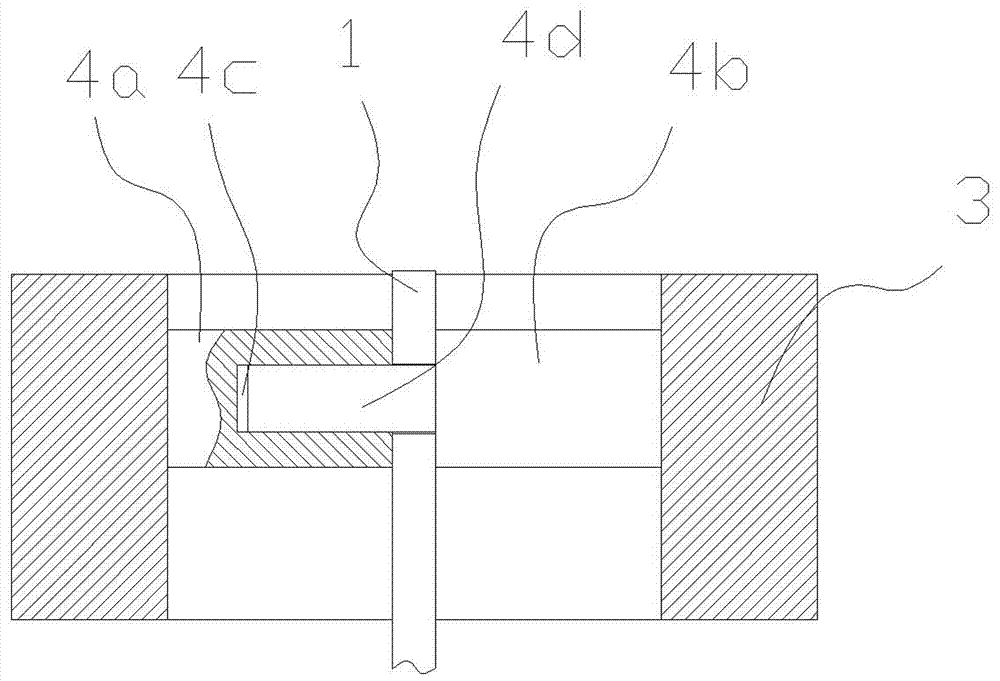

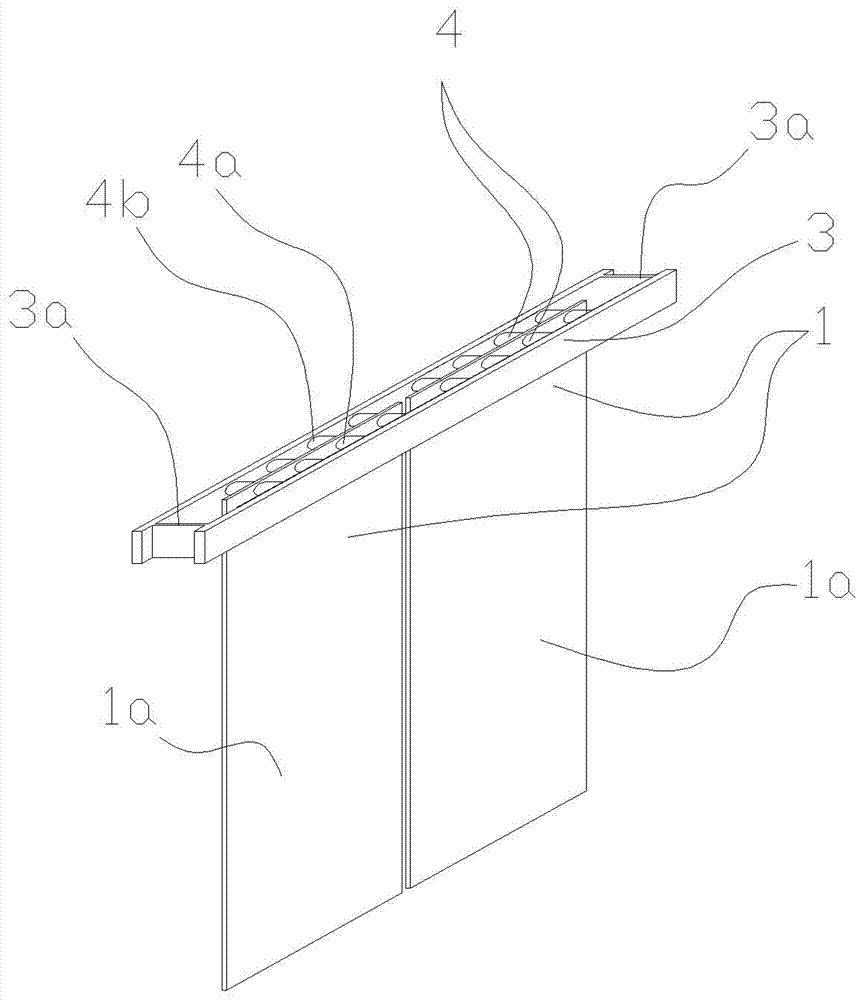

[0015] Such as figure 1 As shown, the present invention includes a ram door b arranged on the flue a, a cylinder d arranged on the main frame c to drive the ram door b to move, and the feature is that the ram door b includes a plate-shaped ram body 1, The splint clamp 2, the splint clamp 2 includes a rectangular frame 3, several pairs of pillars 4 arranged on the inside of the frame 3, each pair of pillars 4 includes a female pillar 4a, a male pillar 4b, and a plate gate body. The upper end of 1 is arranged between the female column 4a and the male column 4b of each pair of columns 4 and is clamped and fixed by the female column 4a and the male column 4b, and the two ends of the frame-like frame 3 float out of the flue a, The columnar racks 5 on both sides of the main frame c on the flue a are respectively guided through the two ends 3a of the frame-like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com