Power conveying device and power conveying method

A technology of power transmission device and output shaft, applied in the direction of transmission device, transmission device parts, gear transmission device, etc., can solve the problems of extremely high processing technology requirements, poor structural impact resistance, limited application scope, etc., and achieve reliable technology, The effect of small clearance and extended start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

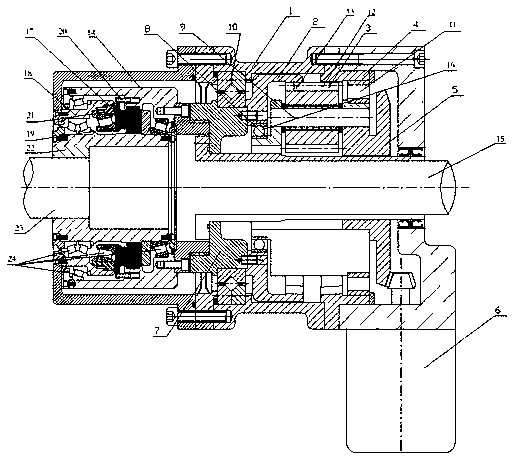

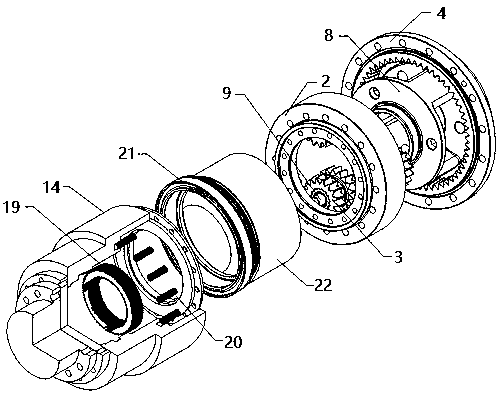

[0043] The use method and principle of the power transmission device 30 of the present invention are as follows: the drive mechanism 6 drives the transmission structure 5, the planet carrier 8, the planetary pin 9 between the transmission structure 5 and the planetary carrier 8, and the planetary pin 9 is provided with The single-thickness planetary gear 3 rotates coaxially. Since the single-thickness planetary gear 3 meshes with the fixed second thickening ring gear 4 through the gear structure provided on the surface, the single-thickness planetary gear 3 rotates around the planetary pin 9, because the single-thickened planetary gear 3 also meshes with the first thickened ring gear 2 through the gear structure provided on the surface, so that the first thickened ring gear 2 rotates, and in turn The first thickened ring gear 2 drives the output shaft housing 14 on the outside of the thickened planetary gearbox output shaft 23 to rotate, and the output shaft housing 14 drives t...

Embodiment 2

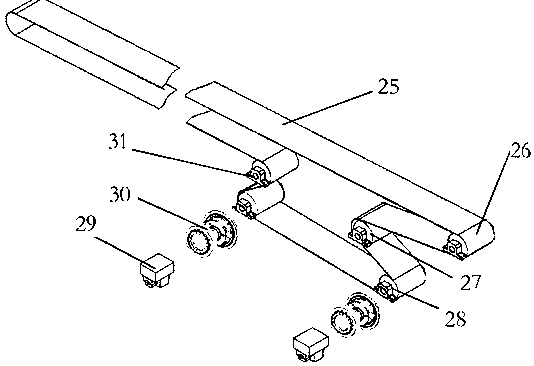

[0045] see image 3 , is a schematic diagram of applying the power transmission device 30 of the present invention to a bulk material conveyor. The conveyor belt 25 is wound and arranged on several driving rollers. The output shaft 23 of the power transmission device 30 is connected, and the input end of the power transmission device 30 is connected with the drive motor 29. The several drive rollers are arranged symmetrically on the left and right sides of the conveyor belt 25. Taking the right side as an example, when conveying The right side of the belt 25 is provided with a first driving roller 26, the left side of the first driving roller 26 is provided with a second driving roller 27, and the right side of the second driving roller 27 is provided with a third driving roller 28. The first driving roller 26 , the second driving roller 27 and the third driving roller 28 are arranged in a W shape.

[0046] The technical solution of the present invention realizes the effects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com