Reducer assembly and vehicle

A reducer and assembly technology, which is applied in the field of supporting components of the vehicle transmission system, can solve the constraints of the overall structural strength and reliability of related components, abnormal noise of gear meshing transmission and related matching components, and changes in the axial structural stiffness of differentials. Improve the overall structural strength and work reliability, ensure rigidity, and ensure structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the present invention is to provide a reducer assembly, which can provide reliable structural support and protection for the internal differential assembly, avoid structural deformation of the assembly, and ensure the overall structural rigidity and reliability of the equipment; at the same time , providing a vehicle using the above speed reducer assembly.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

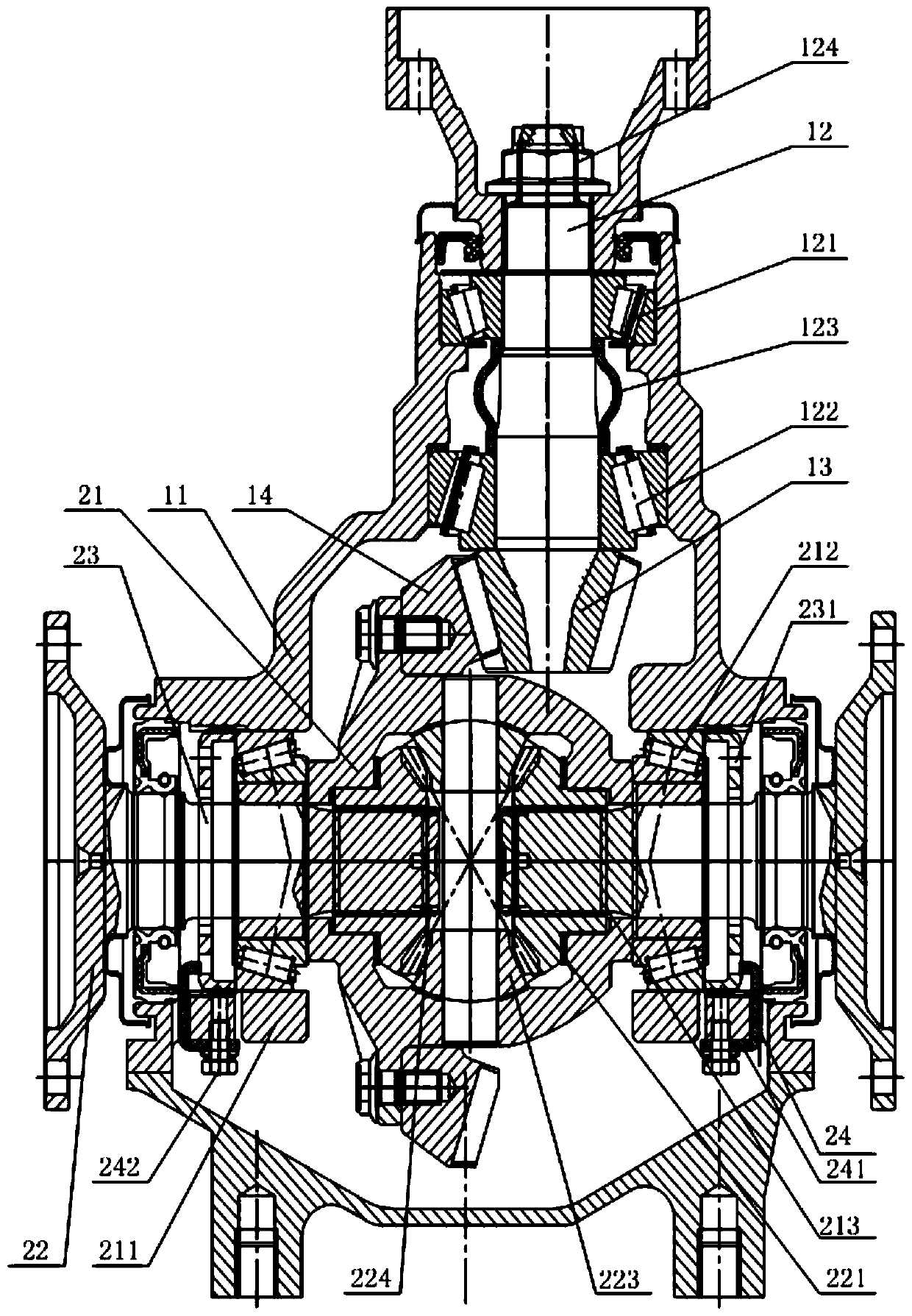

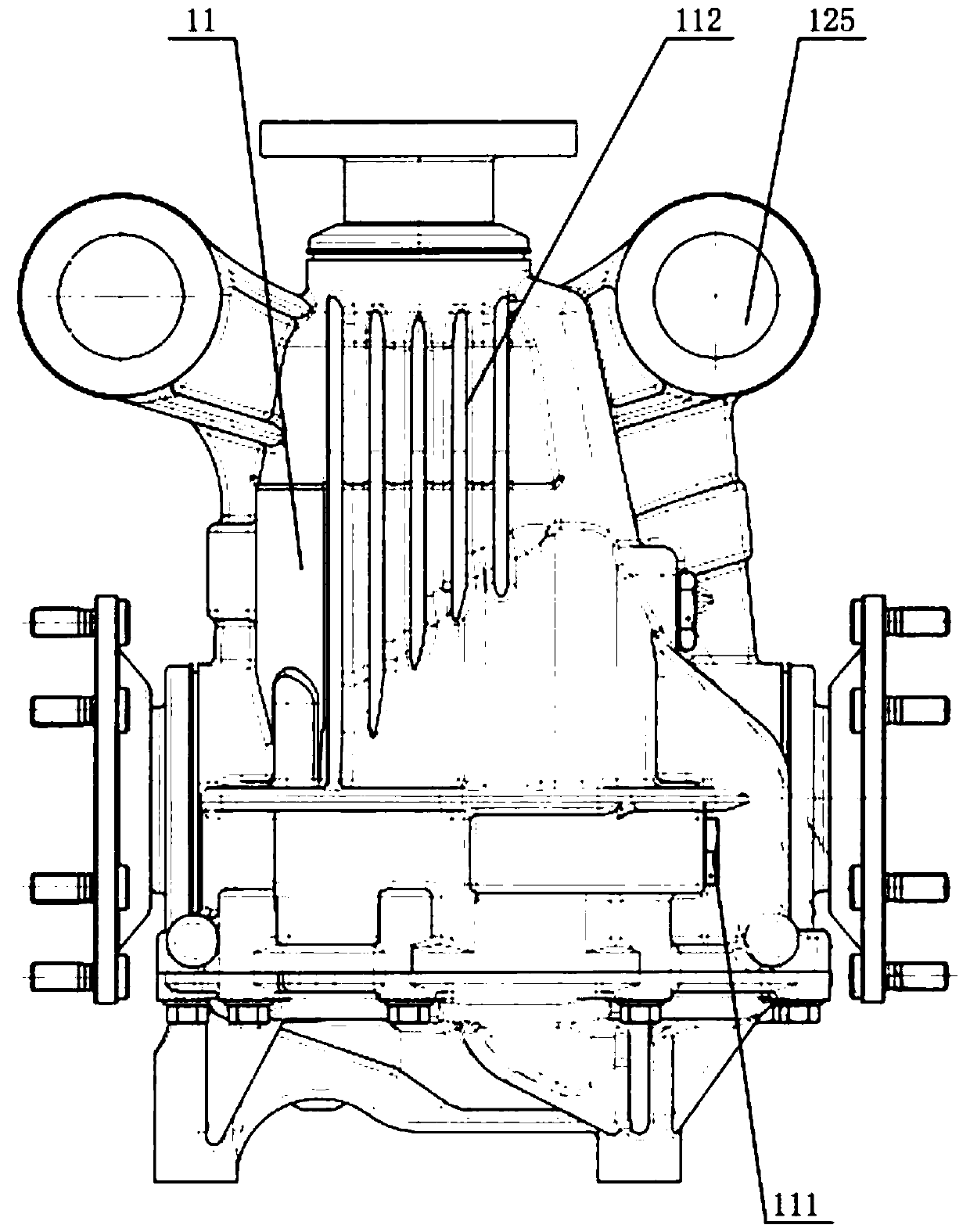

[0024] Please refer to figure 1 with figure 2 , figure 1 A cross-sectional view of the internal structure of the reducer assembly provided for a specific embodiment of the present invention; figure 2 for figure 1 Bottom view of the external structure.

[0025] In a specific embodiment, the reducer assembly provided by the present invention includes a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com