Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Efficient and economical process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

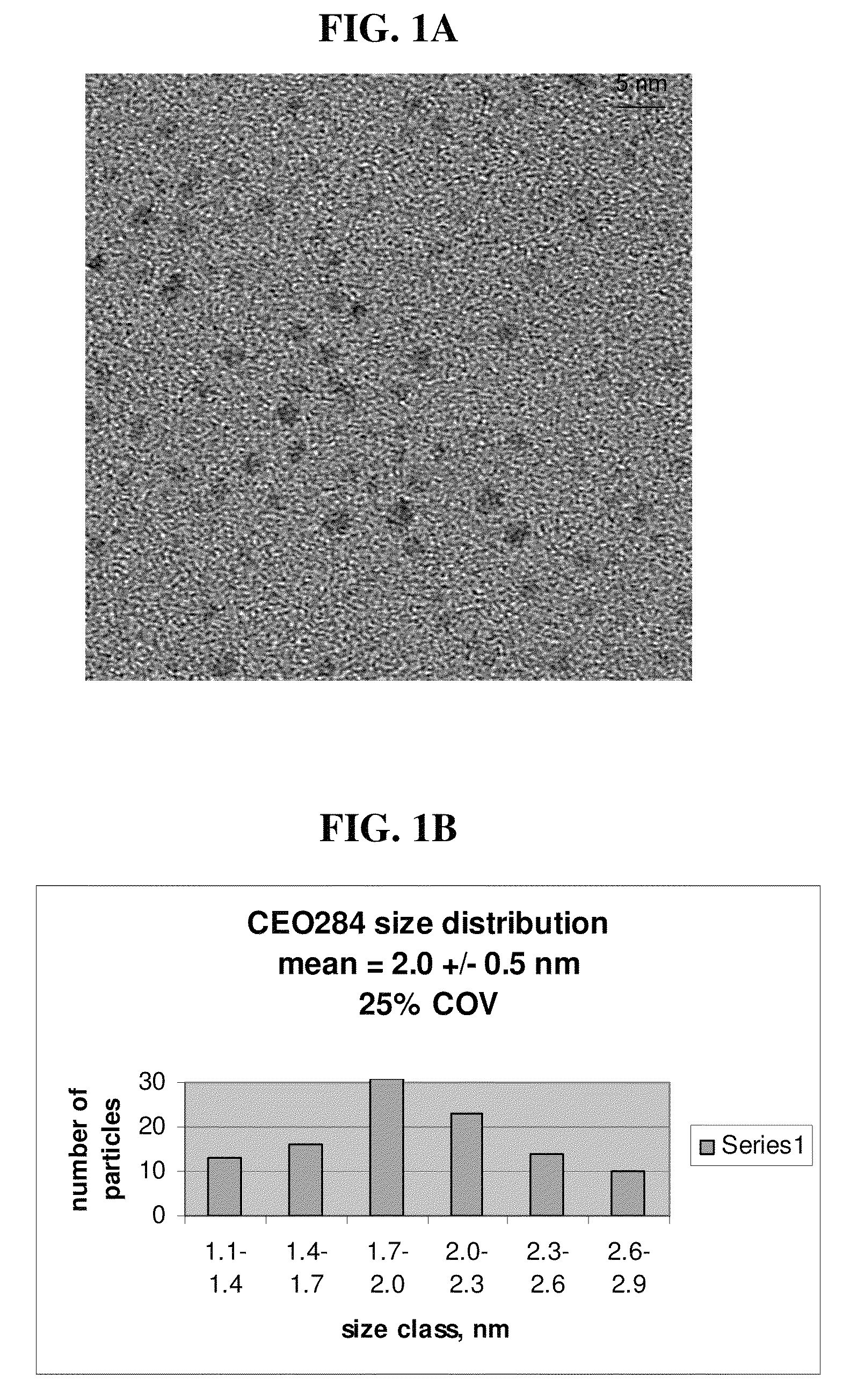

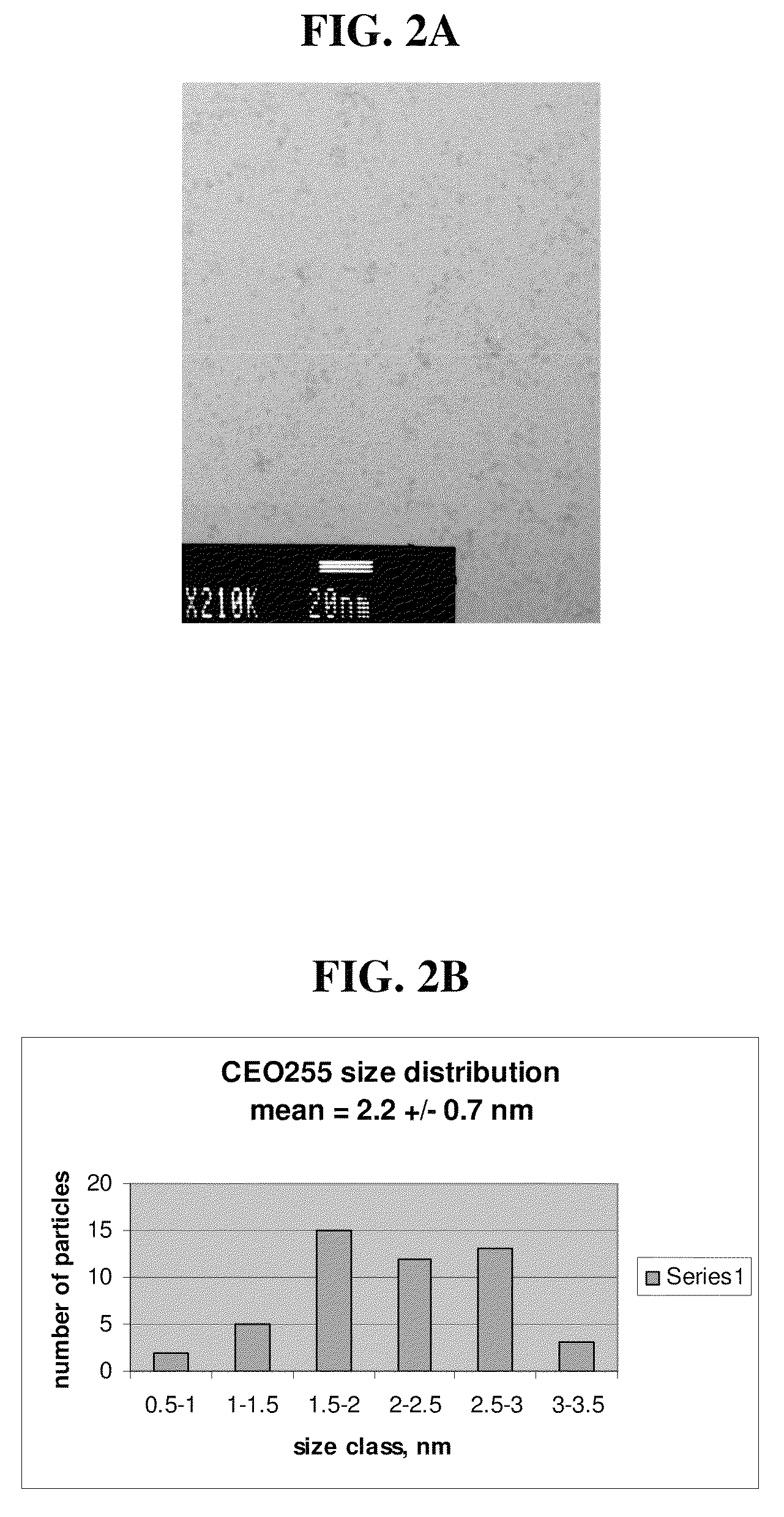

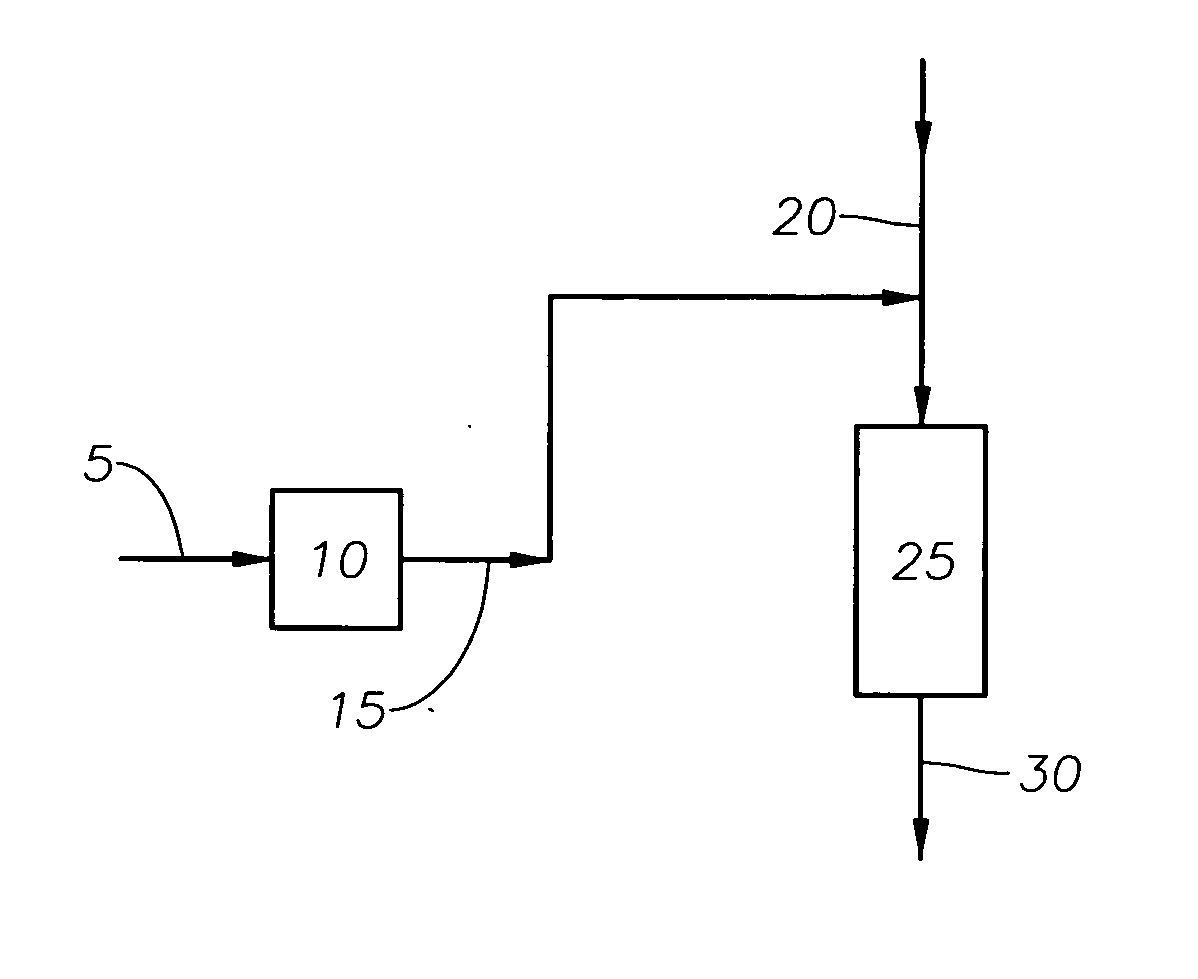

Process for Solvent Shifting a Nanoparticle Dispersion

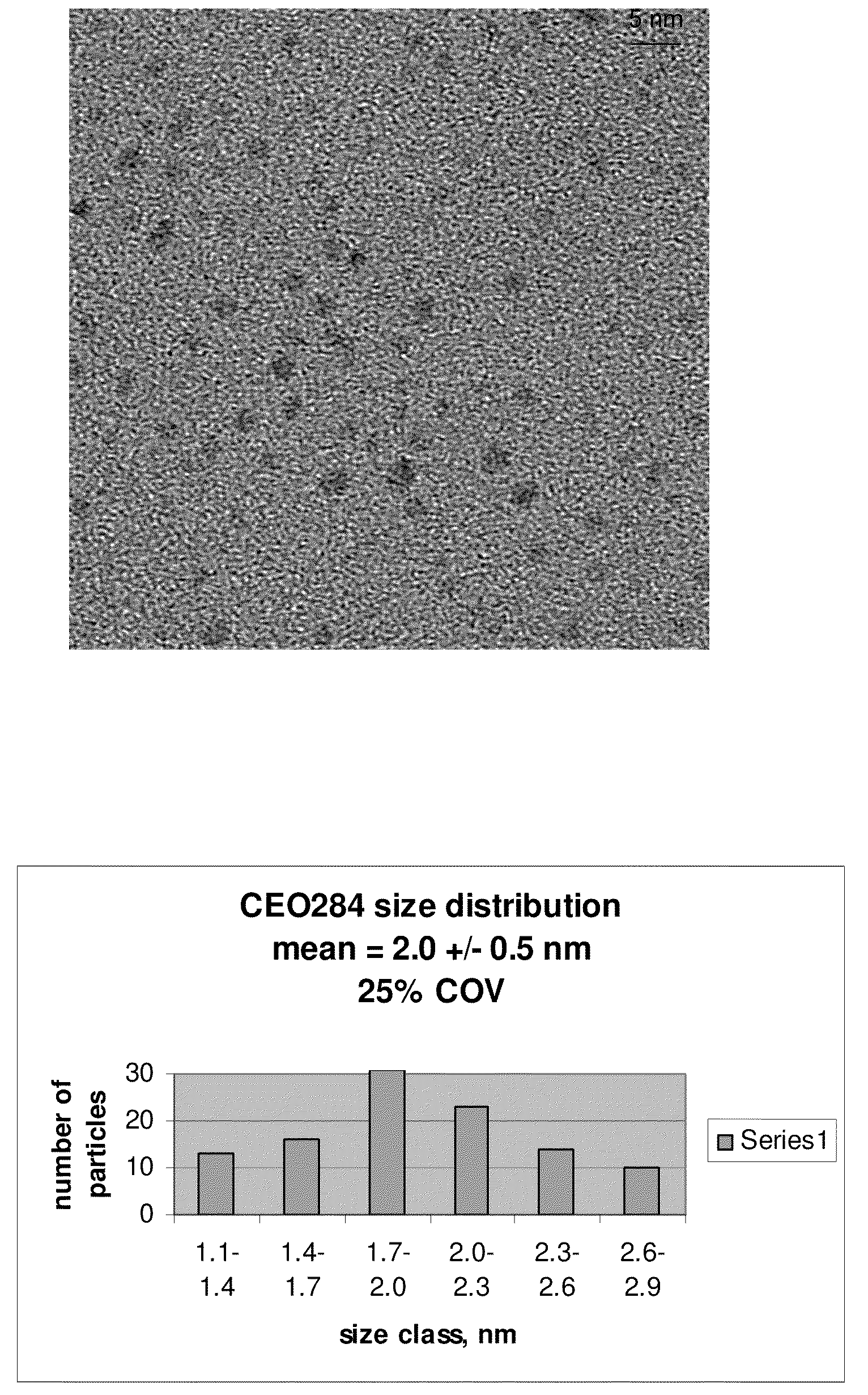

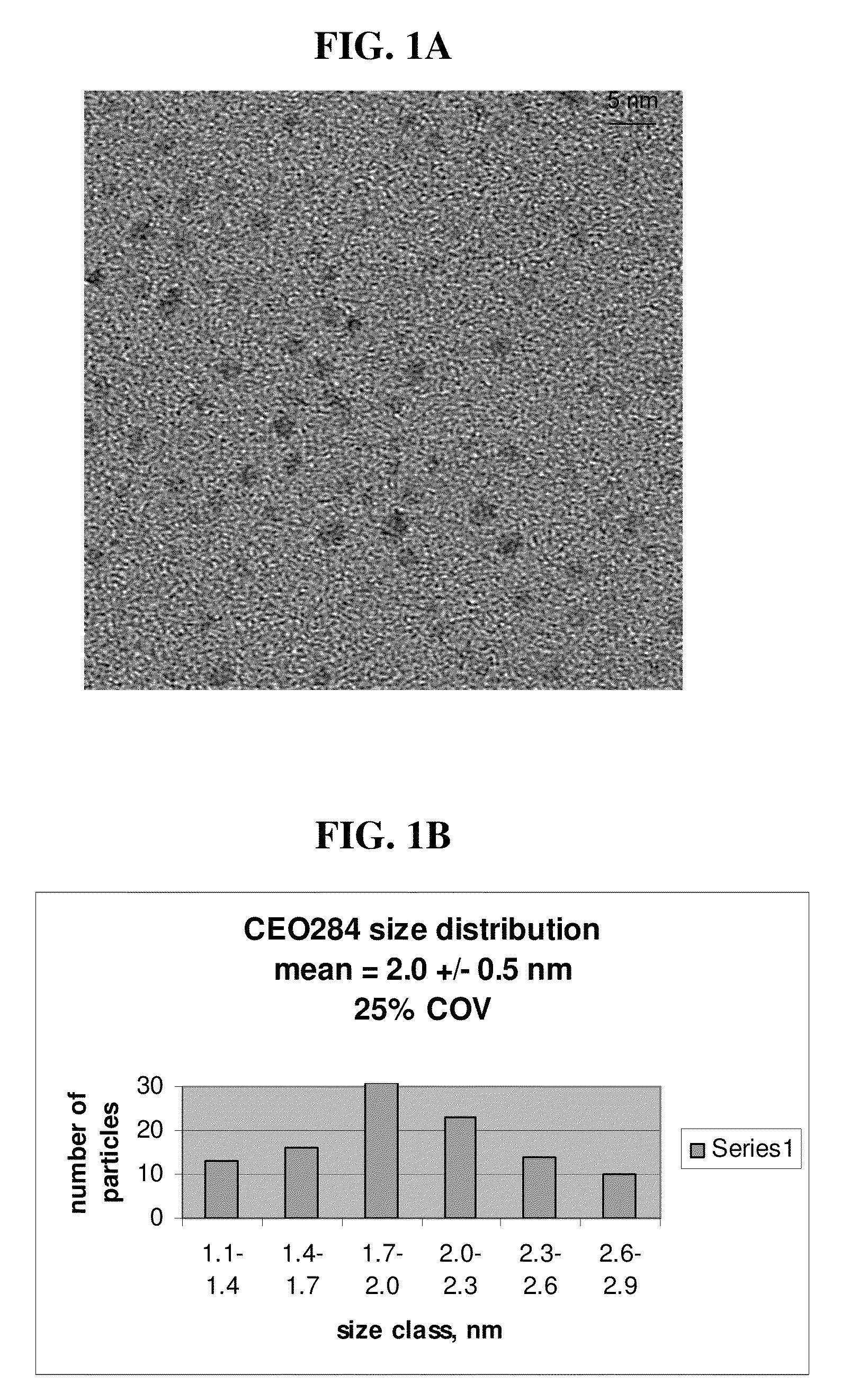

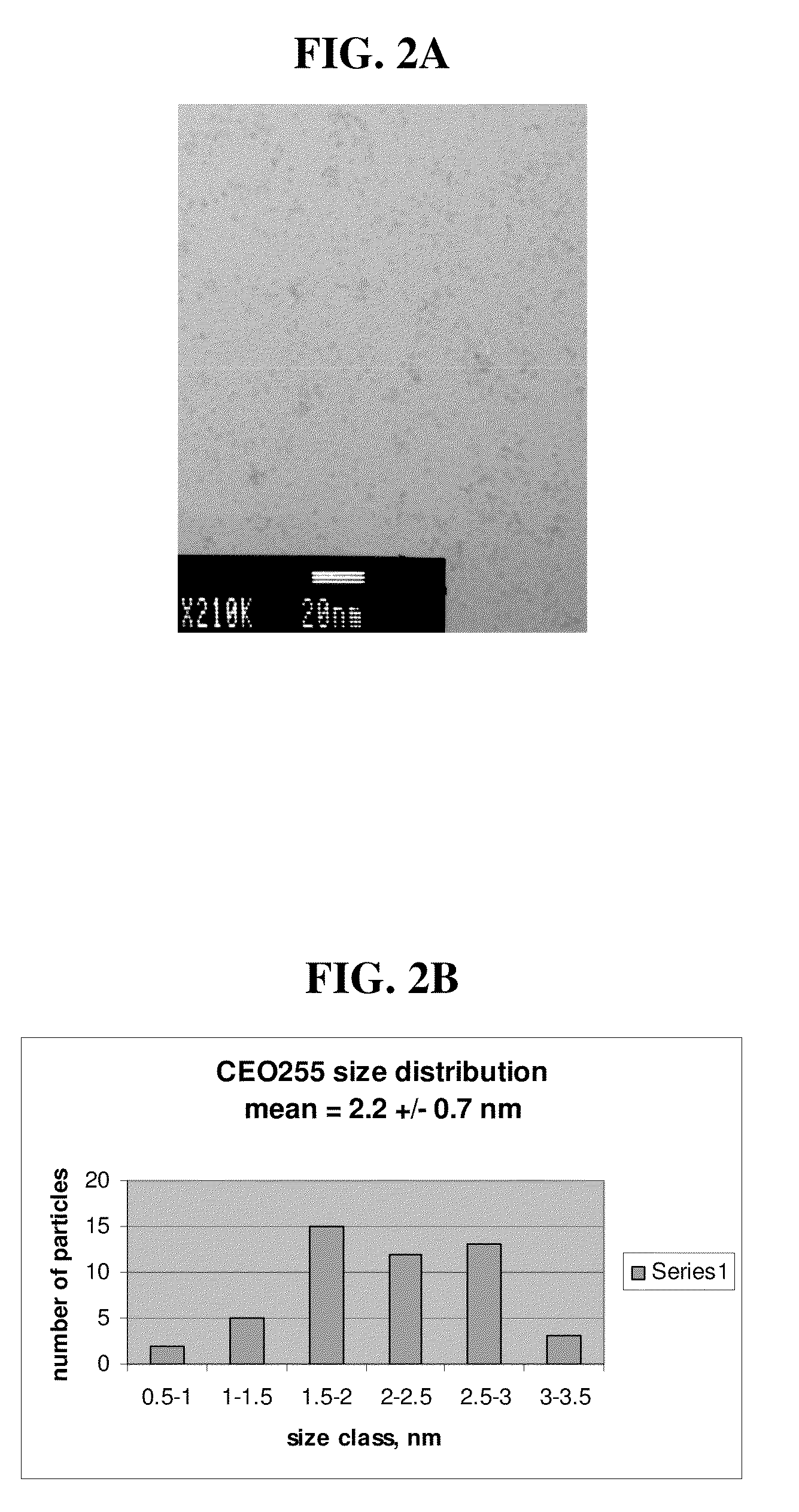

ActiveUS20100152077A1Less polar phaseEfficient and economical processSolvent extractionTransportation and packagingSolventNanometre

A process for replacing the continuous phase of a nanoparticle dispersion with a less polar phase, includes filtering the dispersion through a semi-permeable membrane filter to remove the continuous phase, and introducing a less polar phase.

Owner:CERION

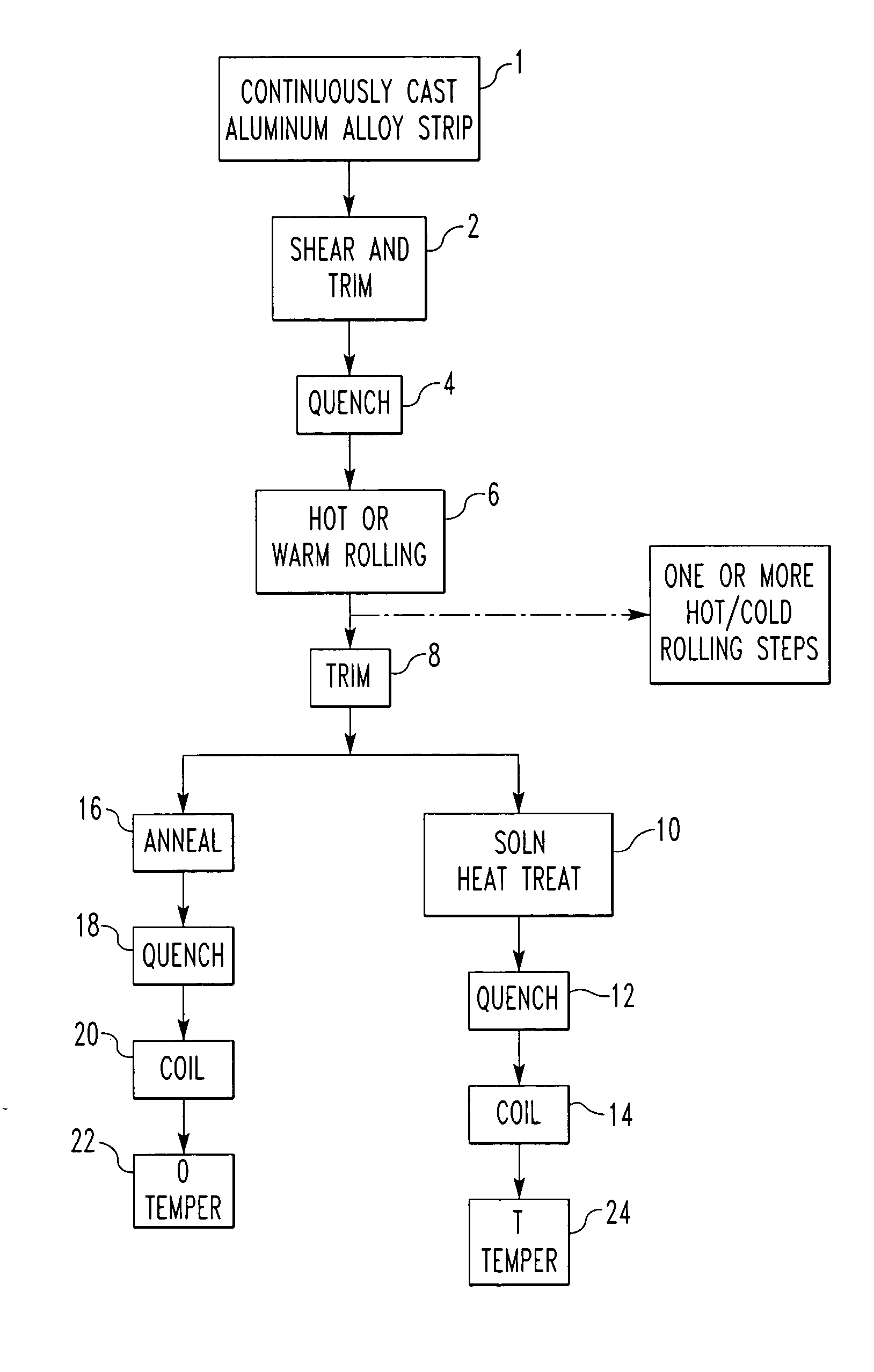

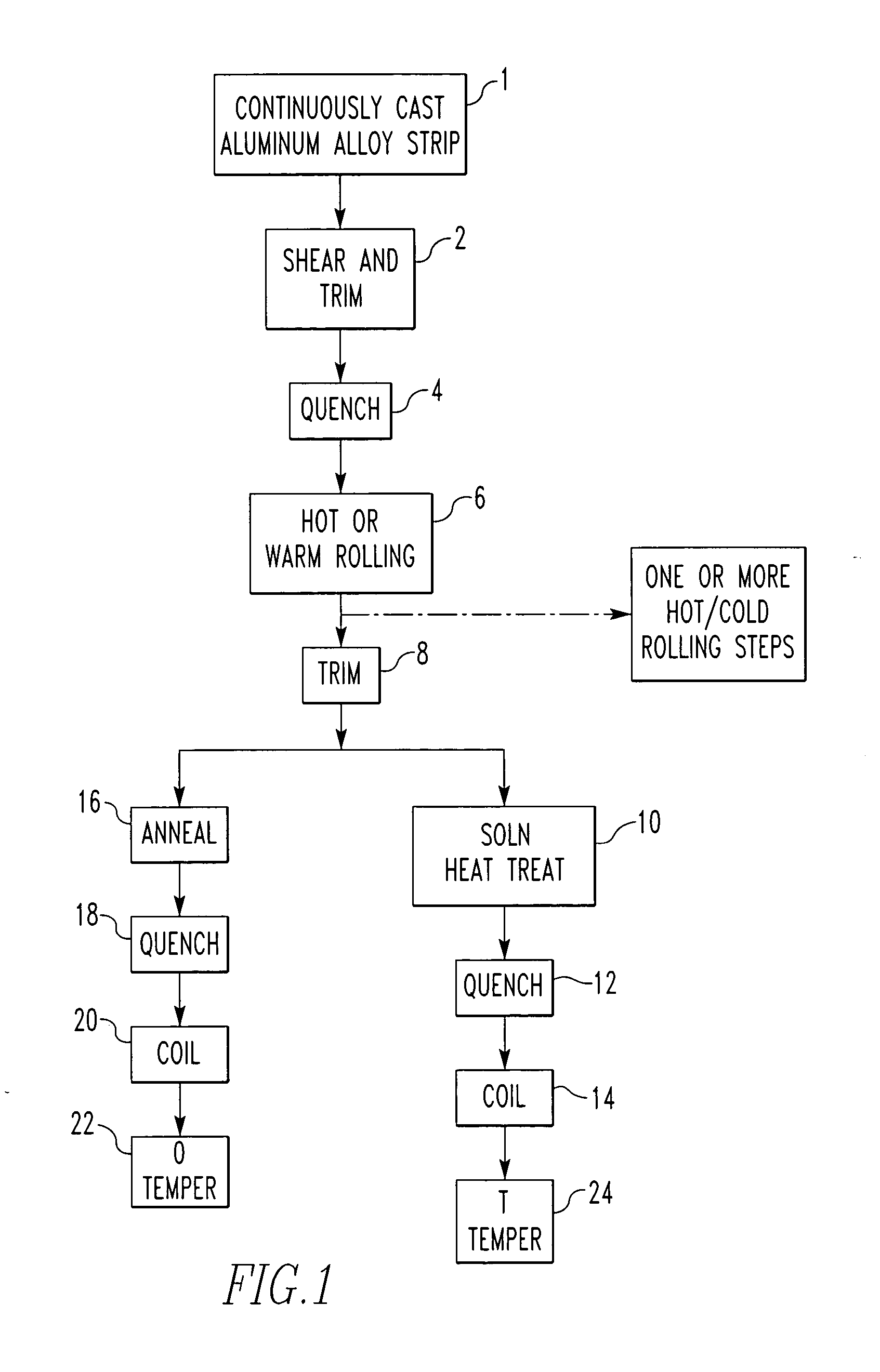

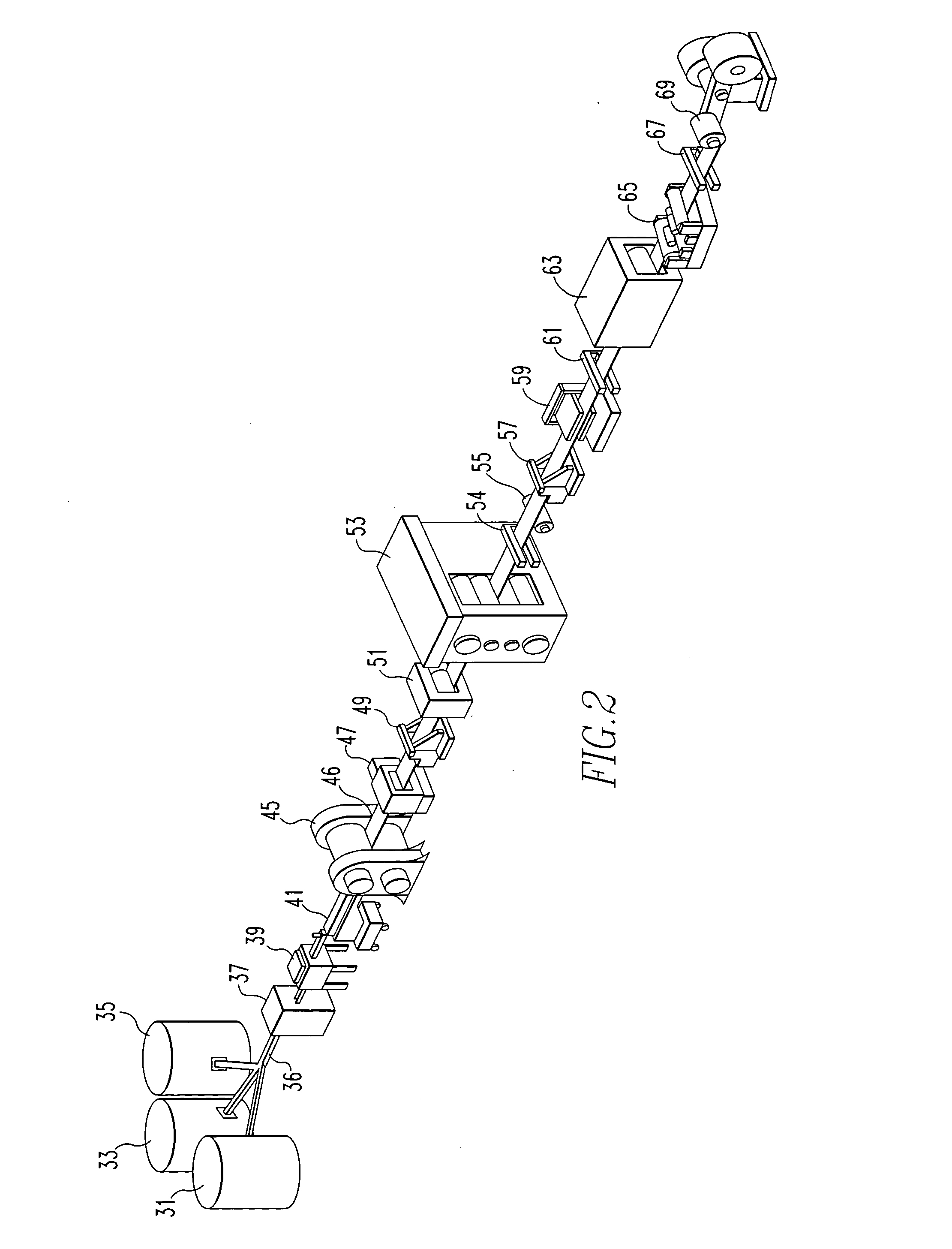

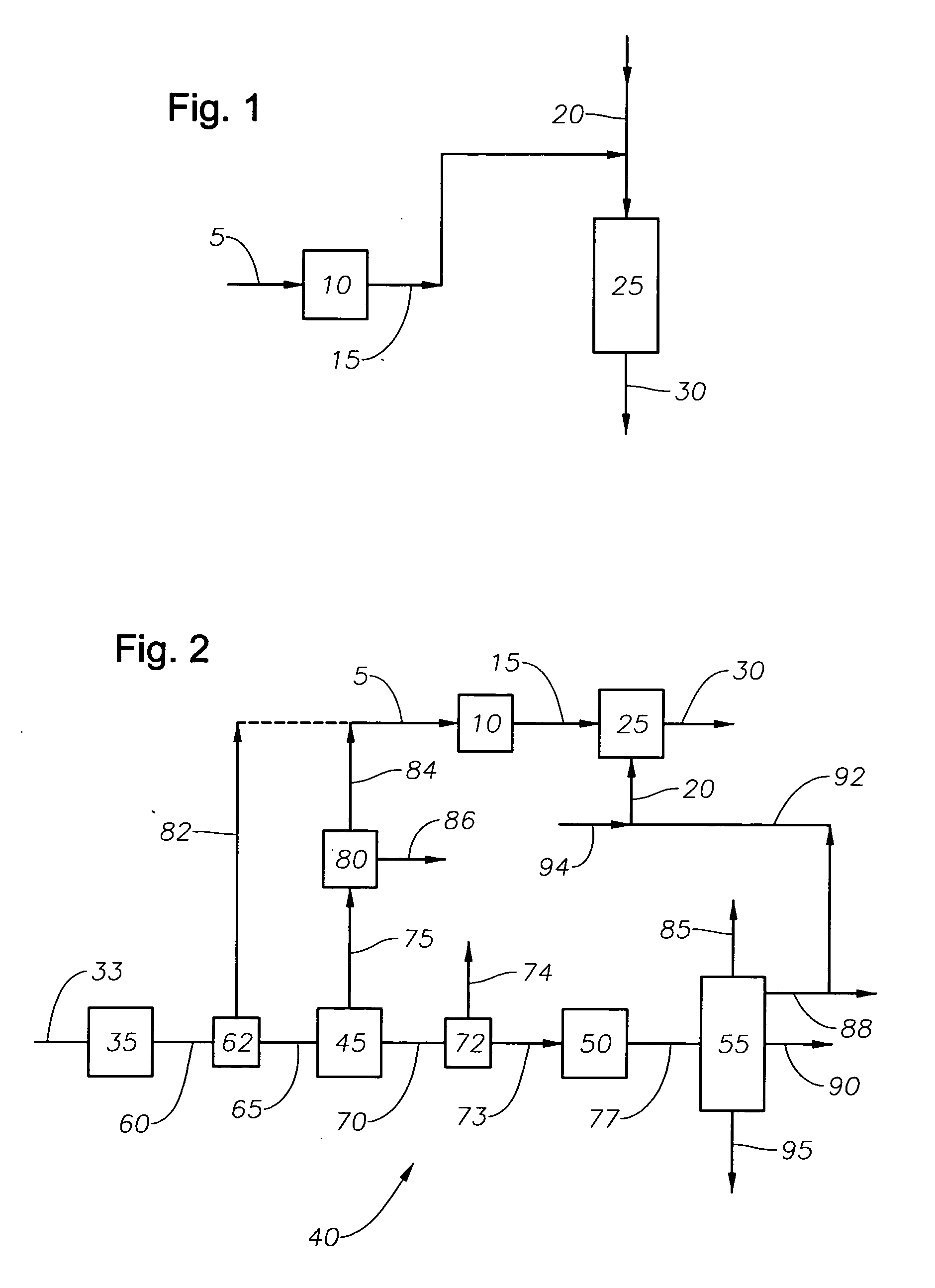

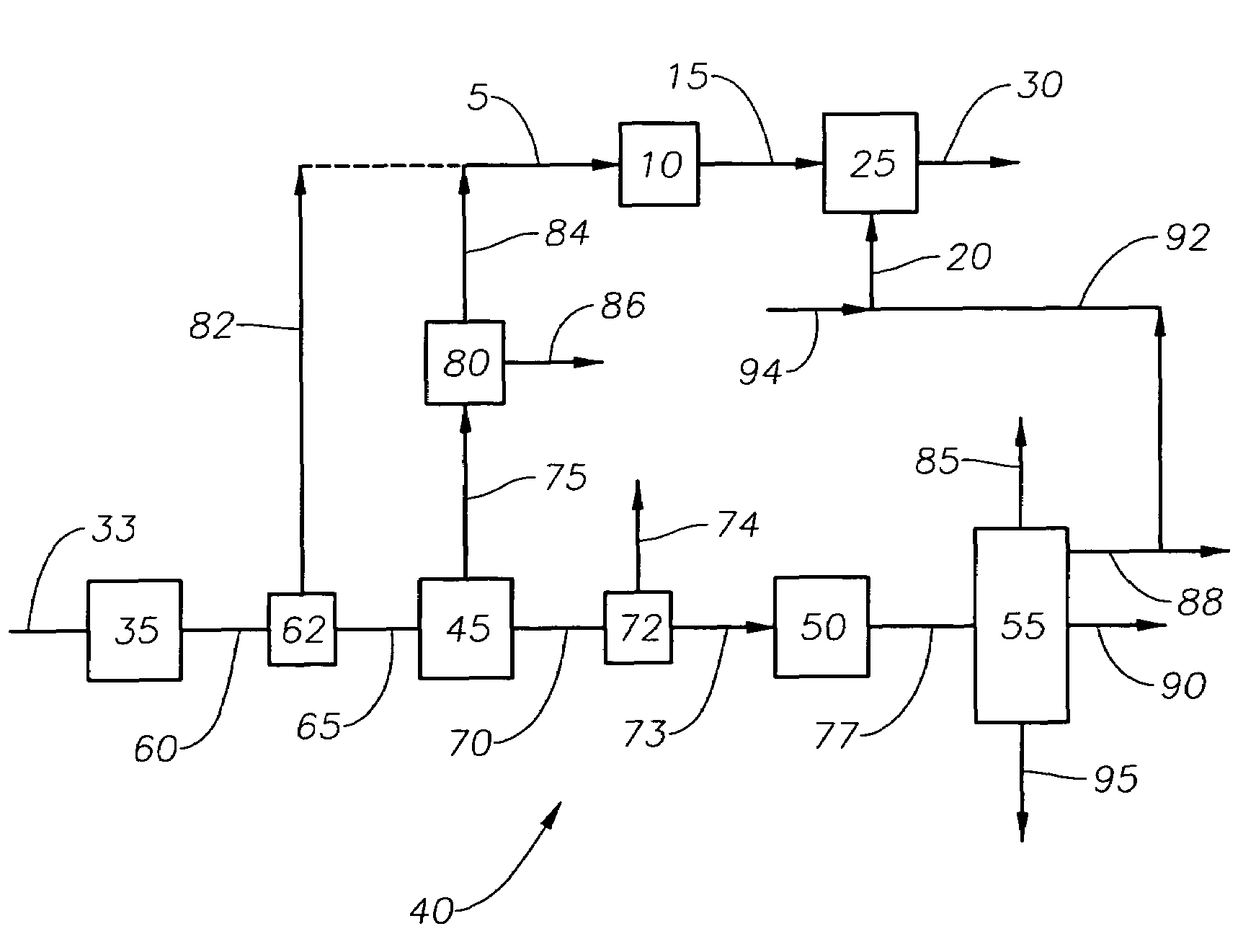

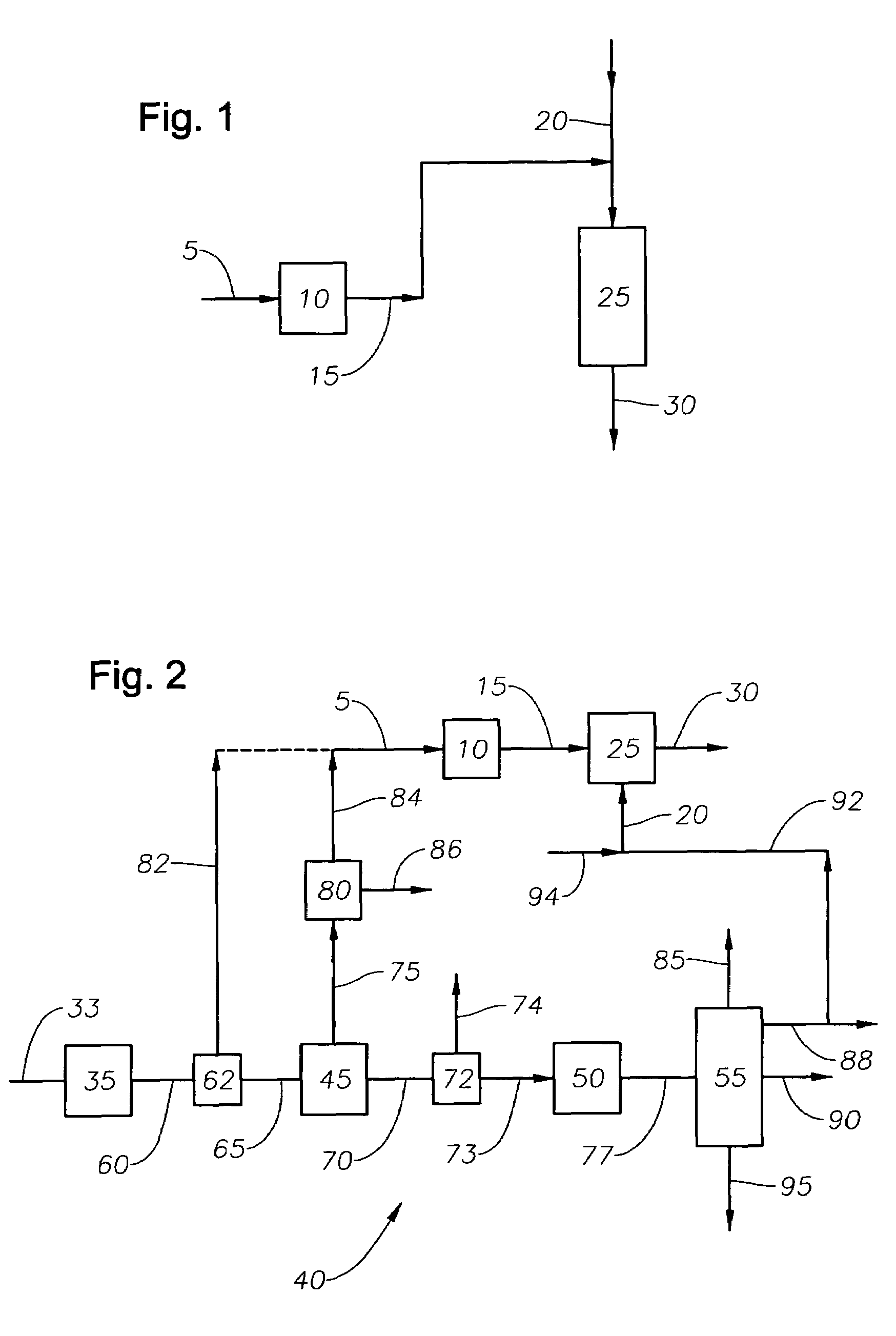

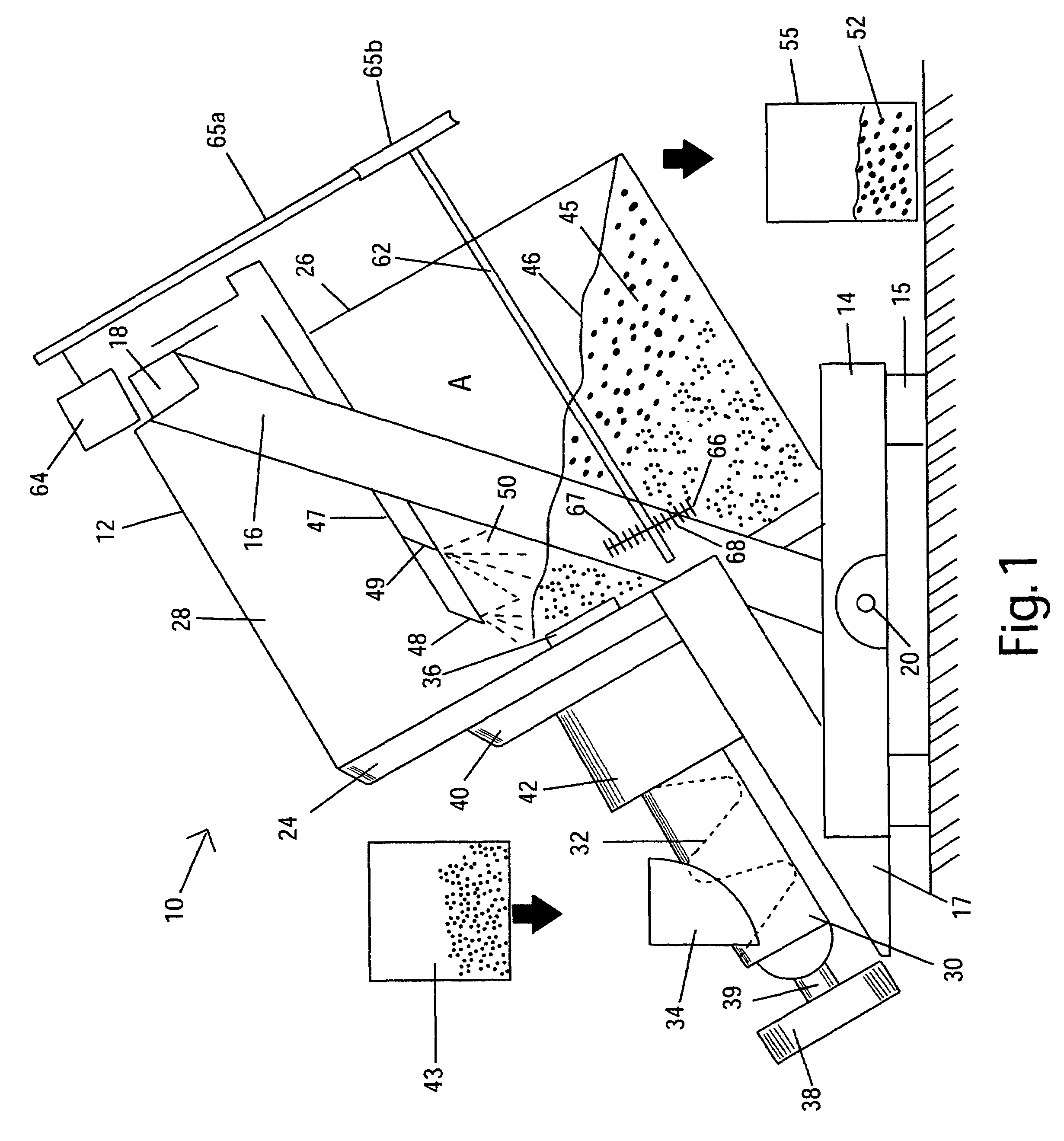

In-line method of making heat-treated and annealed aluminum alloy sheet

A method of making aluminum alloy sheet in a continuous in-line process is provided. A continuously-cast aluminum alloy strip is optionally quenched, hot or warm rolled, annealed or heat-treated in-line, optionally quenched, and preferably coiled, with additional hot, warm or cold rolling steps as needed to reach the desired gauge. The process can be used to make aluminum alloy sheet of T or O temper having the desired properties, in a much shorter processing time.

Owner:ARCONIC TECH LLC

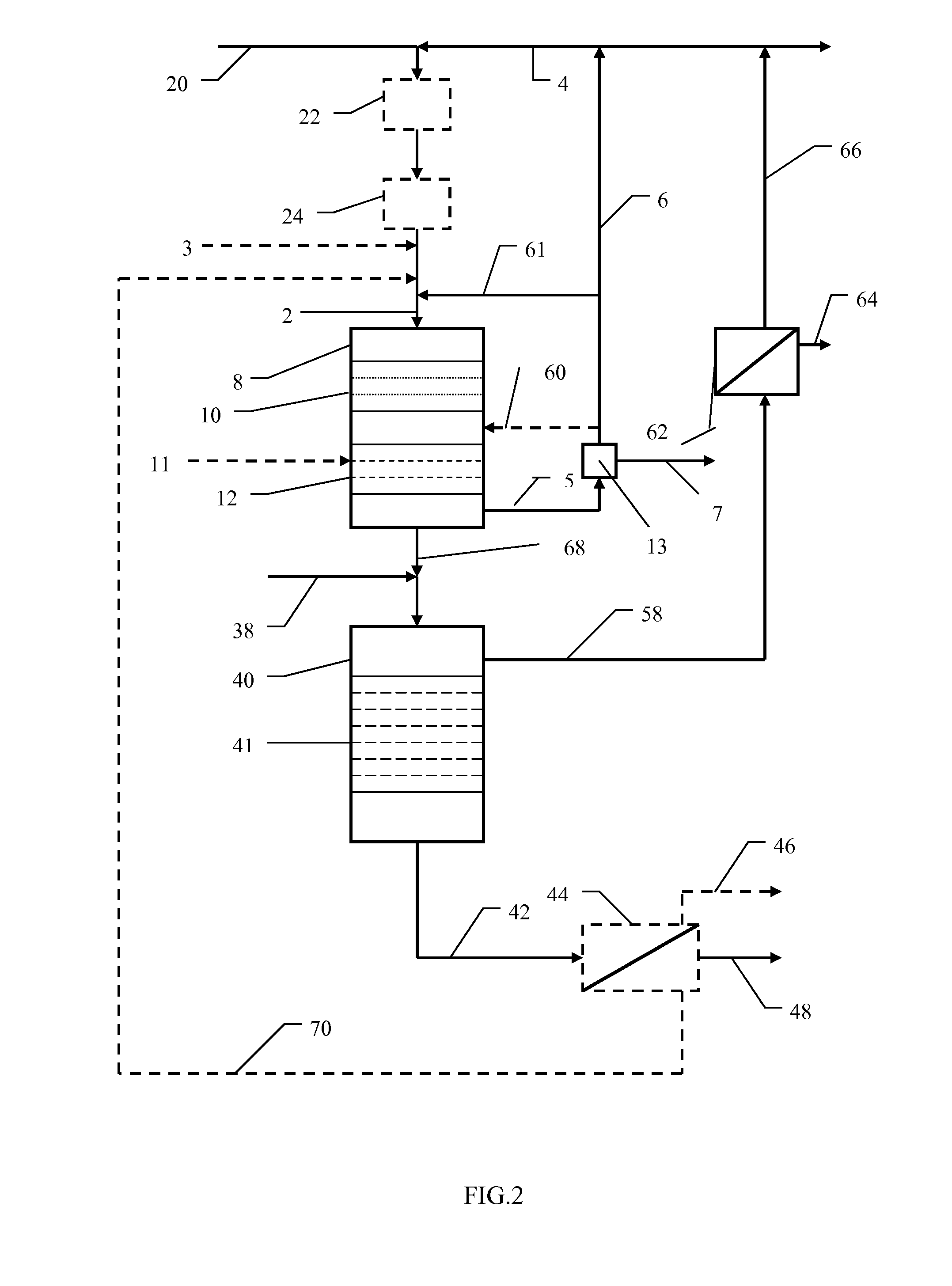

Separation of components from a multi-component hydrocarbon stream which includes ethylene

ActiveUS20120199467A1Improve economicsEfficient and economical processDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionChemistryMulti phase

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Process for solvent shifting a nanoparticle dispersion

ActiveUS8679344B2Less polar phaseEfficient and economical processSolvent extractionTransportation and packagingNanoparticles dispersionSolvent

A process for replacing the continuous phase of a nanoparticle dispersion with a less polar phase, includes filtering the dispersion through a semi-permeable membrane filter to remove the continuous phase, and introducing a less polar phase.

Owner:CERLON ENTERPRISES LLC

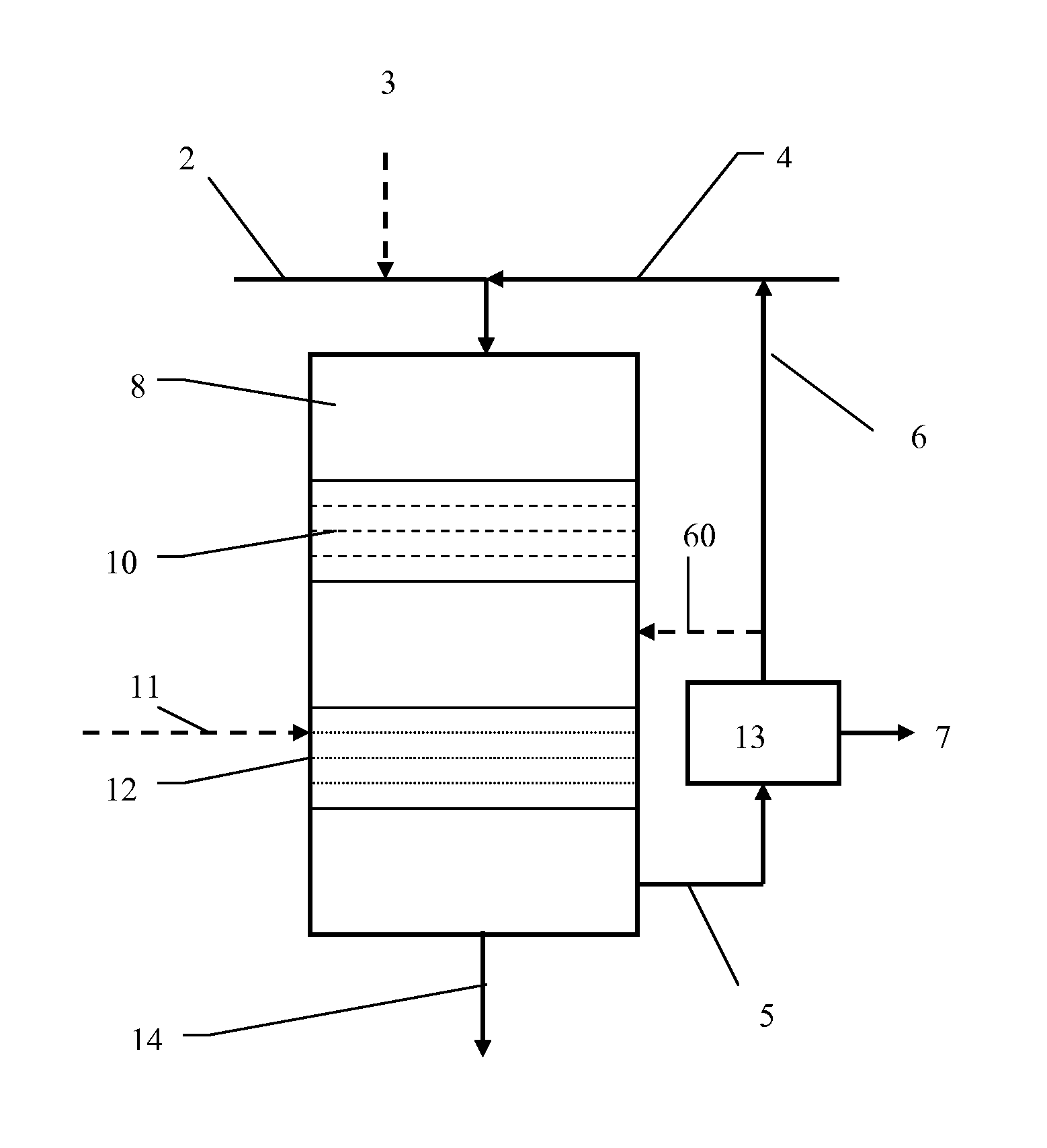

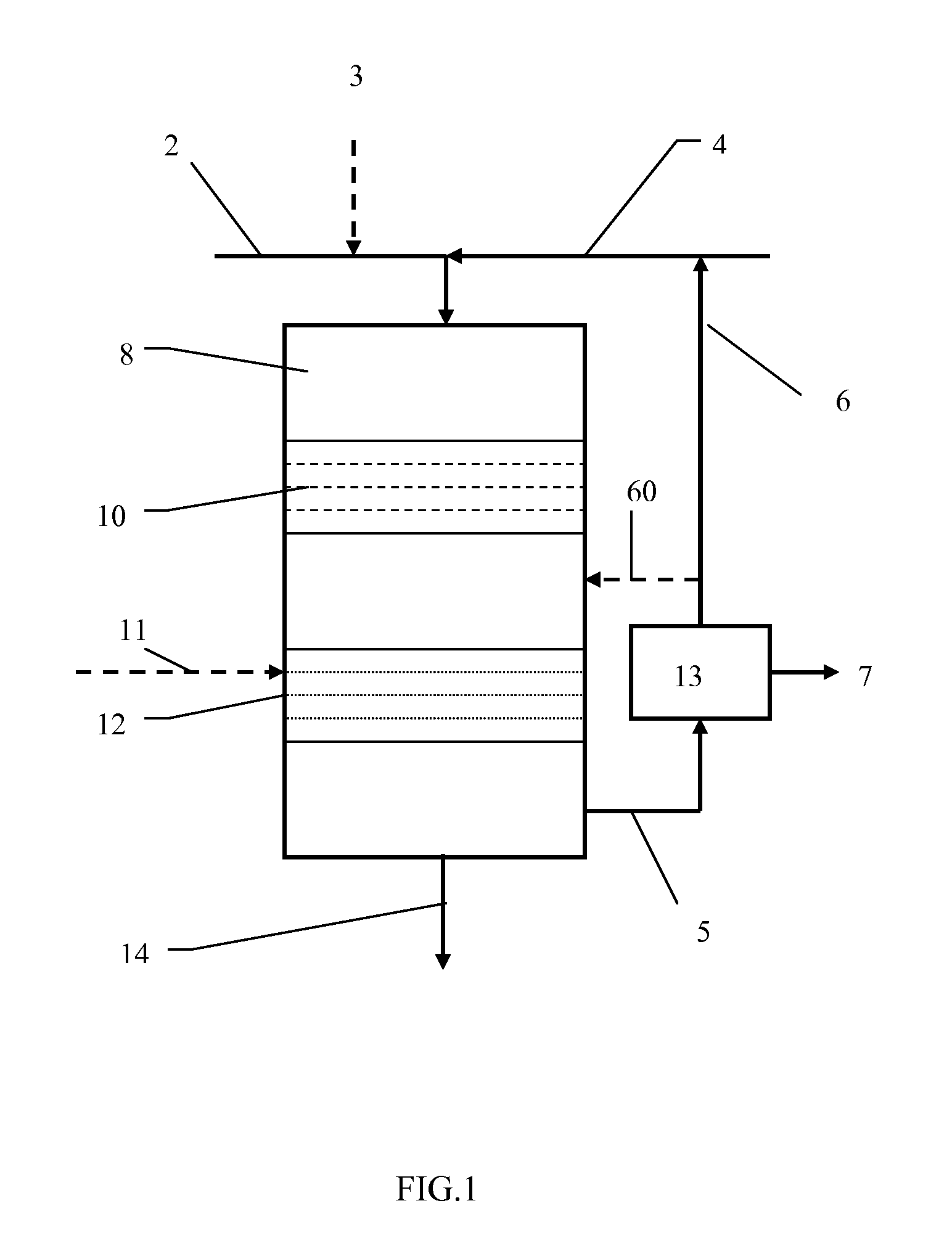

Olefin production from steam cracking using process water as steam

ActiveUS20050187415A1Low production costImprove efficiencyThermal non-catalytic crackingHydrogen/synthetic gas productionOxygen compoundNaphtha

The invention includes a process for making olefins. In one embodiment, the process comprises producing steam from a process water comprising organic compounds, wherein the process water comprises at least a portion of a product water from a hydrocarbon synthesis process; feeding the steam comprising some organic compounds and a light hydrocarbons feedstream into a steam cracker under cracking promoting conditions so as to crack with said steam some of the light hydrocarbons and some of the organic compounds from the steam to produce a cracker effluent comprising at least one olefin. In some embodiments, the light hydrocarbons feedstream comprises a naphtha cut. In alternate embodiments, the light hydrocarbons feedstream comprises a hydrocarbon fraction derived from a hydrocarbon synthesis reactor. In preferred embodiments, the process water and light hydrocarbons feedstream are at least in part derived from a Fisher-Tropsch synthesis, and the organic compounds comprise oxygenates.

Owner:PHILLIPS 66 CO

Process and apparatus for producing fuel from a biological origin through a single hydroprocessing step in the presence of a niw catalyst

ActiveUS20130067801A1Simple one-stepEfficient and economical processBiofuelsSolid fuelsHydrogenEngineering

The present invention relates to a process for producing mixture of fuel components, which process comprises providing a feed of biological origin; subjecting said feed of biological origin and a hydrogen gas feed to a single step of hydroprocessing in the presence of a catalyst system comprising dewaxing catalyst to form a mixture of fuel components. The present invention relates also to an apparatus for producing a mixture of fuel components from a feed of biological origin. The invention relates also to the use of the fuel components.

Owner:UPM-KYMMENE OYJ

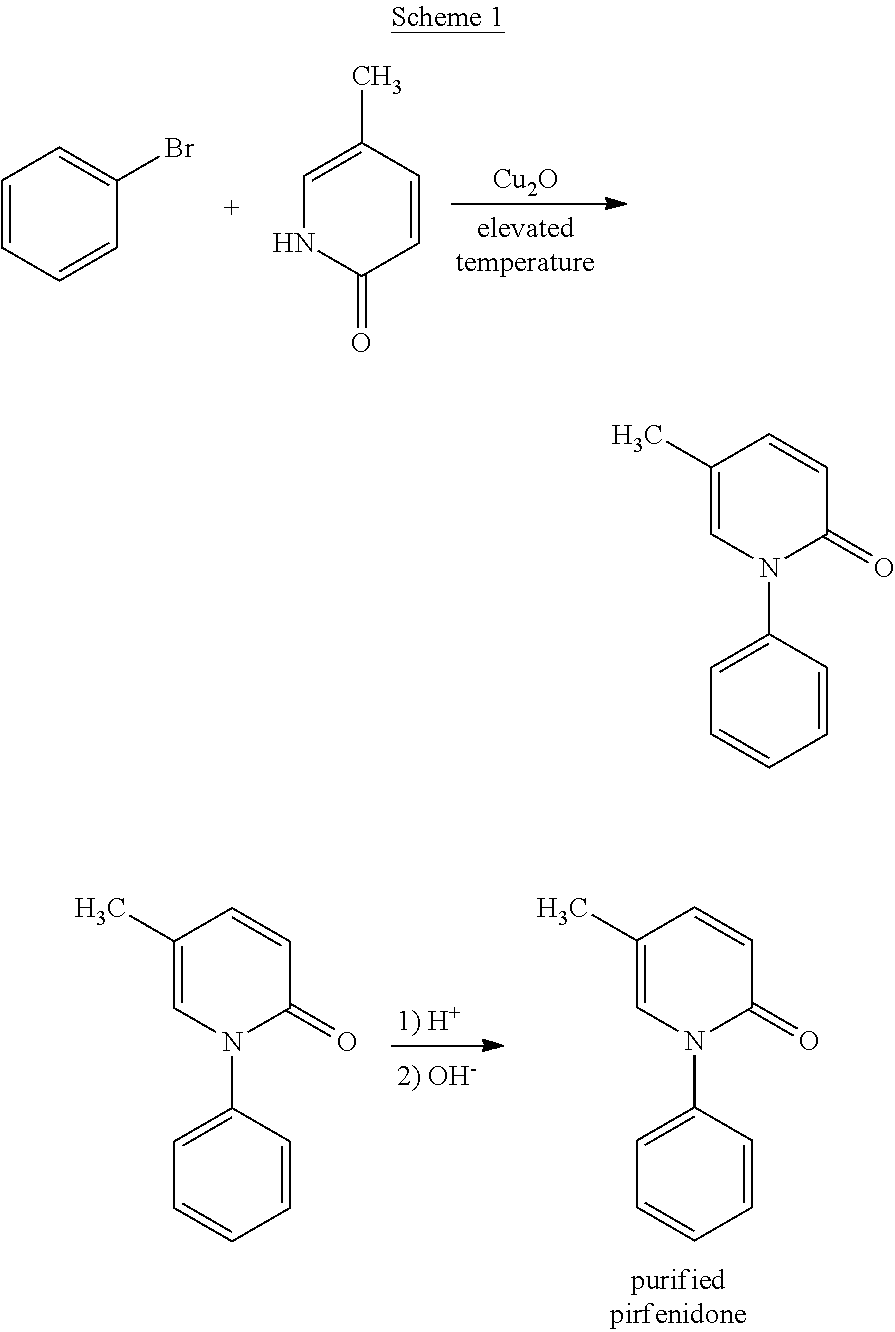

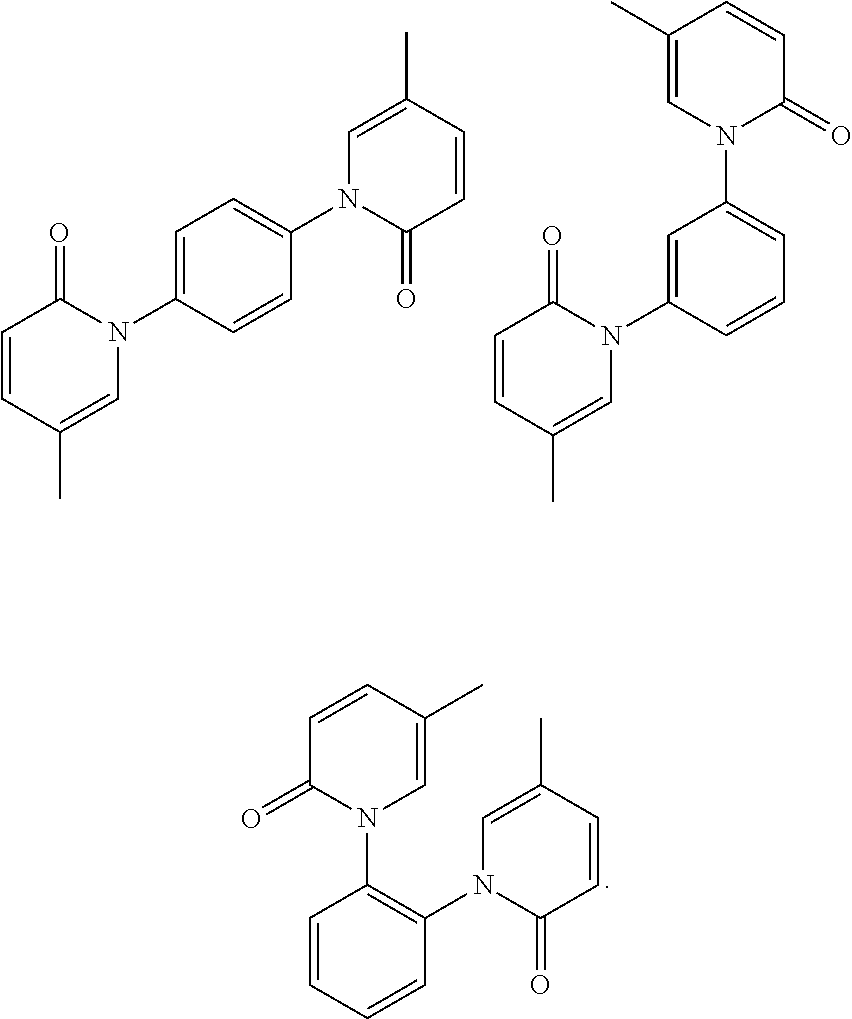

Method for Synthesizing Pirfenidone

ActiveUS20120016133A1Avoid insufficient purityEfficient and economical processOrganic active ingredientsBiocideAcetic acidRetention time

A process for synthesizing pirfenidone from bromobenzene having less than about 0.15% by weight dibromobenze is disclosed. Also disclosed are processes of synthesizing pirfenidone without using ethyl acetate or n-butanol, and pirfenidone having controlled levels of ethyl acetate, n-butanol, di(5-methyl-2-pyridinone)benzenes, and other impurities having specified retention times. Also disclosed are formulated dosage forms including the disclosed pirfenidone.

Owner:ZACH SYST SPA +2

Method for treating metal-contaminated water and soil

InactiveUS7029202B2Efficient and economical processStabilizing the metal contaminants in soilsWaste water treatment from quariesSolid waste disposalFiltrationTreated water

A method for removing metal contaminants from water uses lignin derivatives, such as lignosulfonates and kraft lignin, a coagulant, such as a metal salt, and a pH-increasing composition. The lignin derivative is dispersed in the contaminated water, the coagulant is added and the pH is adjusted as required to cause flocculation. A sludge is formed that contains the metals and that is separated from the treated water by filtration. Related methods are used to reduce the leachable metal content of contaminated soils. The invention also provides a composition for stabilizing the metal contaminants in soil, comprising lignin derivatives, a coagulant and a composition for increasing the pH. The mixture is blended with the contaminated soil, reducing its leachable metal content.

Owner:NORAM ENG & CONSTRS

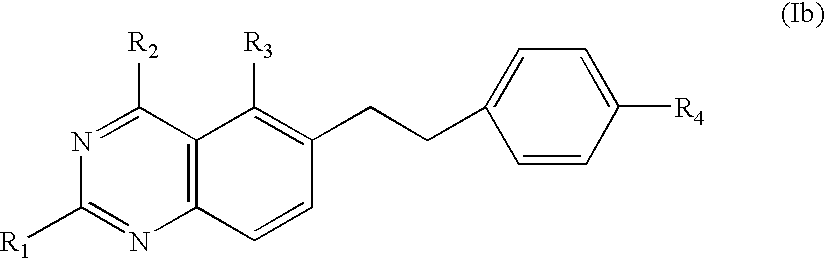

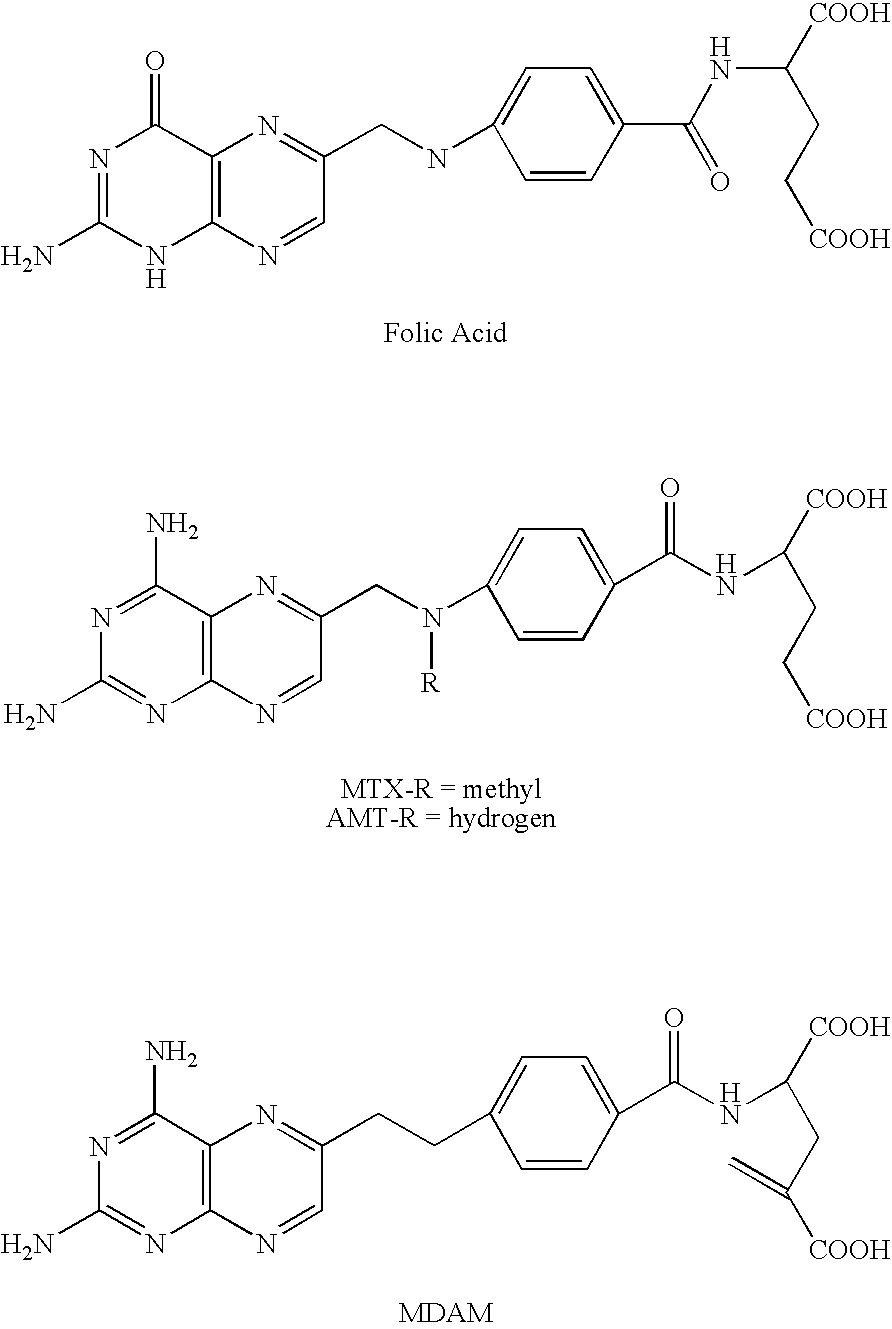

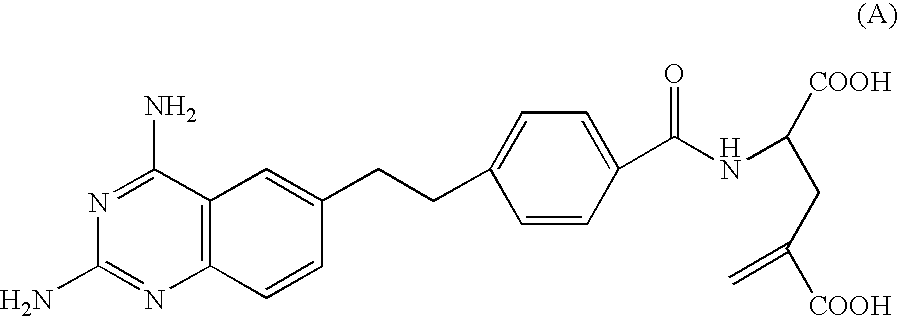

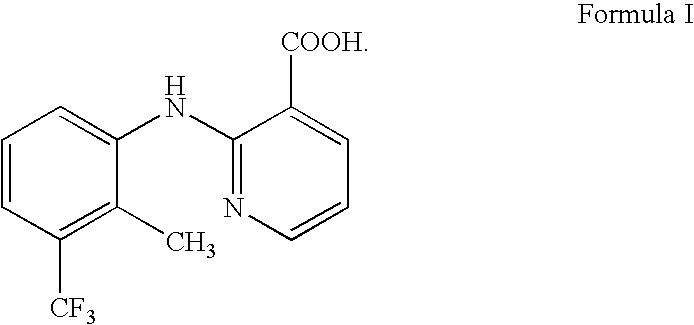

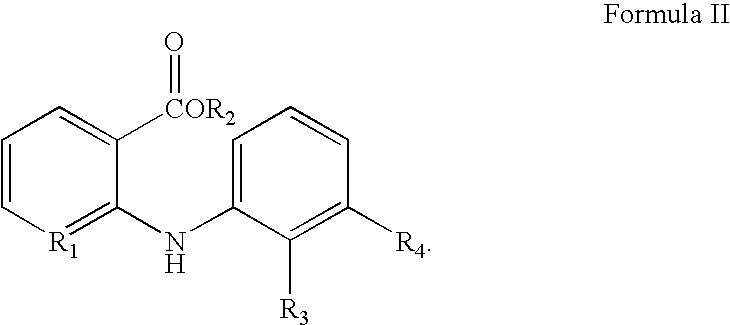

Process for synthesizing 6-quinazolinyl-ethyl-benzoyl and related antifolates

InactiveUS7060825B2Efficient and economicalEfficient and economical processOrganic chemistryBulk chemical productionBenzoic acidTriethylphosphite

The invention claimed herein relates to an improvement in a process for synthesizing a compound of formula Ib:wherein R1 and R2 are each individually amino or N-alkyl substituted amino; hydroxy; alkoxy; keto; lower alkyl; or a nitrogen or oxygen protecting group;R3 is hydrogen; hydroxy; alkoxy; trifluoromethyl alkoxy; halo; sulfhydryl or alkylthio;R4 is —C(O)—X;X is hydroxy; alkoxy; or an amino acid residue;in which process a 2-amino-5-nitro-benzonitrile starting reagent is cyclized to form 2,4-diamino-6-nitro-quinazoline, which is converted to 2,4,6-triamino-quinazoline, which is converted to 2,4-diamino-6-cyano-quinazoline, which is converted to 2,4-diamino-6-formyl-quinazoline;in which the improvement includes:reacting an R4-p-benzoic acid alkylene moiety with triethyl phosphite to form a 4-R4-carbonyloxyalkyl-phenyl-alkyldiethylphosphite; andreacting the 2,4-diamino-6-formyl-quinazoline with the 4-R4-carbonyloxyalkyl-phenyl-alkyldiethylphosphite to form the compound of formula Ib.

Owner:BIONUMERIK PHARMA INC

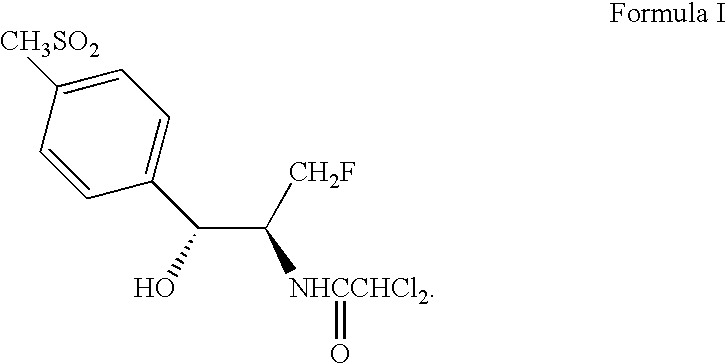

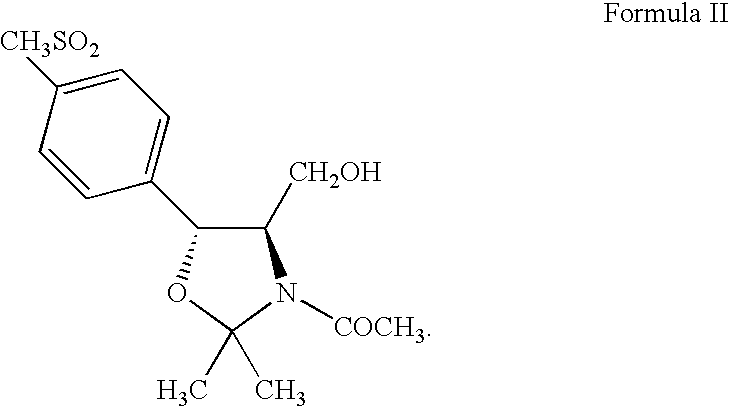

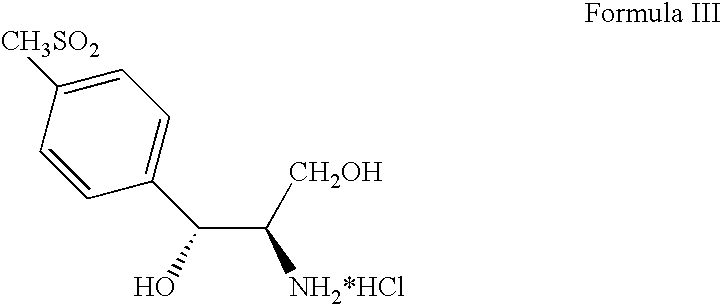

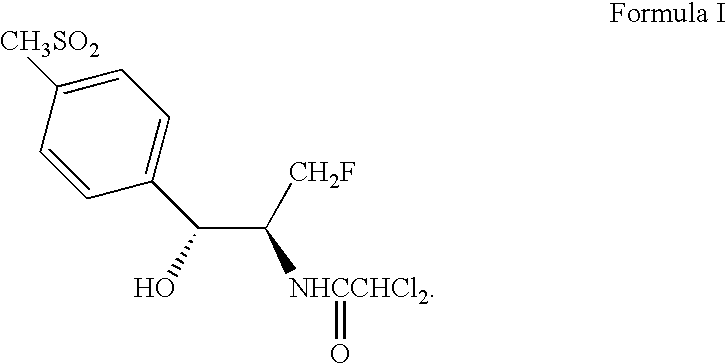

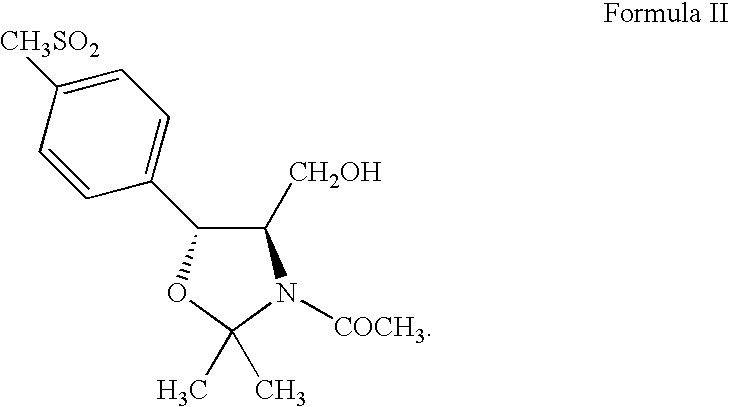

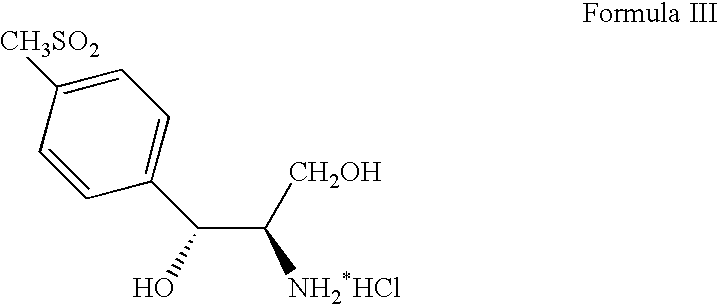

Process for preparing oxazolidine protected aminodiol compounds useful as intermediates to Florfenicol

InactiveUS20070055067A1Low costIncrease productionOrganic chemistryOrganic compound preparationOxazolidine ECombinatorial chemistry

An improved method of preparing oxazolidine protected aminodiol compounds is disclosed. These compounds are useful intermediates in processes for making Florfenicol.

Owner:SCHERING PLOUGH ANIMAL HEALTH +2

Olefin production from steam cracking using process water as steam

ActiveUS7235172B2Low production costImprove efficiencyThermal non-catalytic crackingHydrogen/synthetic gas productionNaphthaOrganic compound

The invention includes a process for making olefins. In one embodiment, the process comprises producing steam from a process water comprising organic compounds, wherein the process water comprises at least a portion of a product water from a hydrocarbon synthesis process; feeding the steam comprising some organic compounds and a light hydrocarbons feedstream into a steam cracker under cracking promoting conditions so as to crack with said steam some of the light hydrocarbons and some of the organic compounds from the steam to produce a cracker effluent comprising at least one olefin. In some embodiments, the light hydrocarbons feedstream comprises a naphtha cut. In alternate embodiments, the light hydrocarbons feedstream comprises a hydrocarbon fraction derived from a hydrocarbon synthesis reactor. In preferred embodiments, the process water and light hydrocarbons feedstream are at least in part derived from a Fisher-Tropsch synthesis, and the organic compounds comprise oxygenates.

Owner:PHILLIPS 66 CO

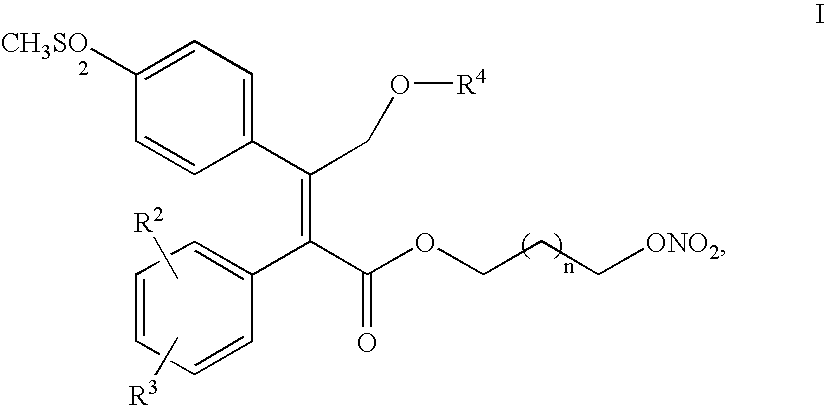

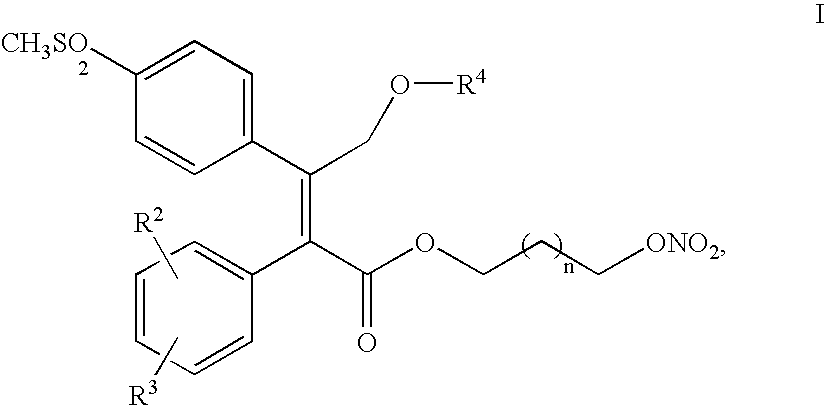

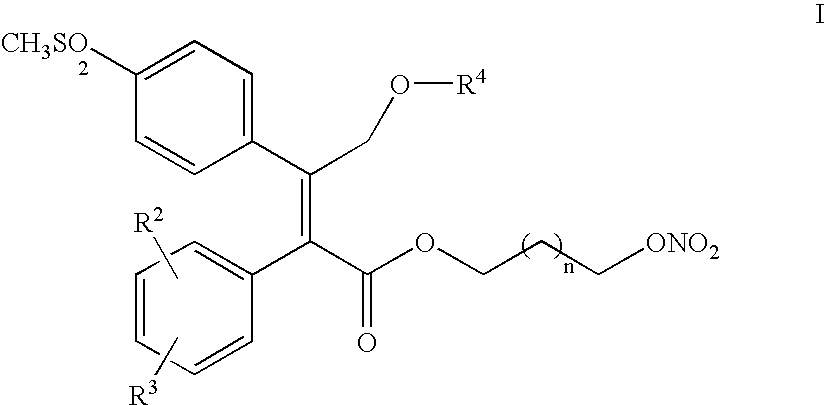

Process for making nitric oxide releasing prodrugs of diaryl-2-(5H)-furanones as cyclooxygenase-2 inhibitors

InactiveUS20050192346A1Reduce riskEfficient and economical processBiocideOrganic compound preparationDiseaseFuran

The invention encompasses a novel process for making compounds of Formula I which are prodrugs of cyclooxygenase-2 selective inhibitors that convert in vivo to diaryl-2-(5H)-furanones and also liberate nitric oxide in vivo. As such, the compounds made by the present invention may be co-dosed with low-dose aspirin to treat chronic cyclooxygenase-2 mediated diseases or conditions, effectively reduce the risk of thrombotic cardiovascular events and potentially renal side effects and at the same time reduce the risk of GI ulceration or bleeding. The present invention describes an efficient and economical process for the preparation of 2,3-disubstituted (2Z)-4-acetoxybut-2-enoate derivatives that is useful for the production of kilogram quantities of material for preclinical and clinical use.

Owner:SHI YAO JUN +4

Process for preparing ester oxazolidine compounds and their conversion to Florfenicol

ActiveUS7786329B2Low costIncrease productionOrganic chemistryOrganic compound preparationMedicinal chemistryFlorfenicol

A process for preparing ester oxazolidine compounds is disclosed. These compounds are useful intermediates in processes for making Florfenicol.

Owner:INTERVET INC

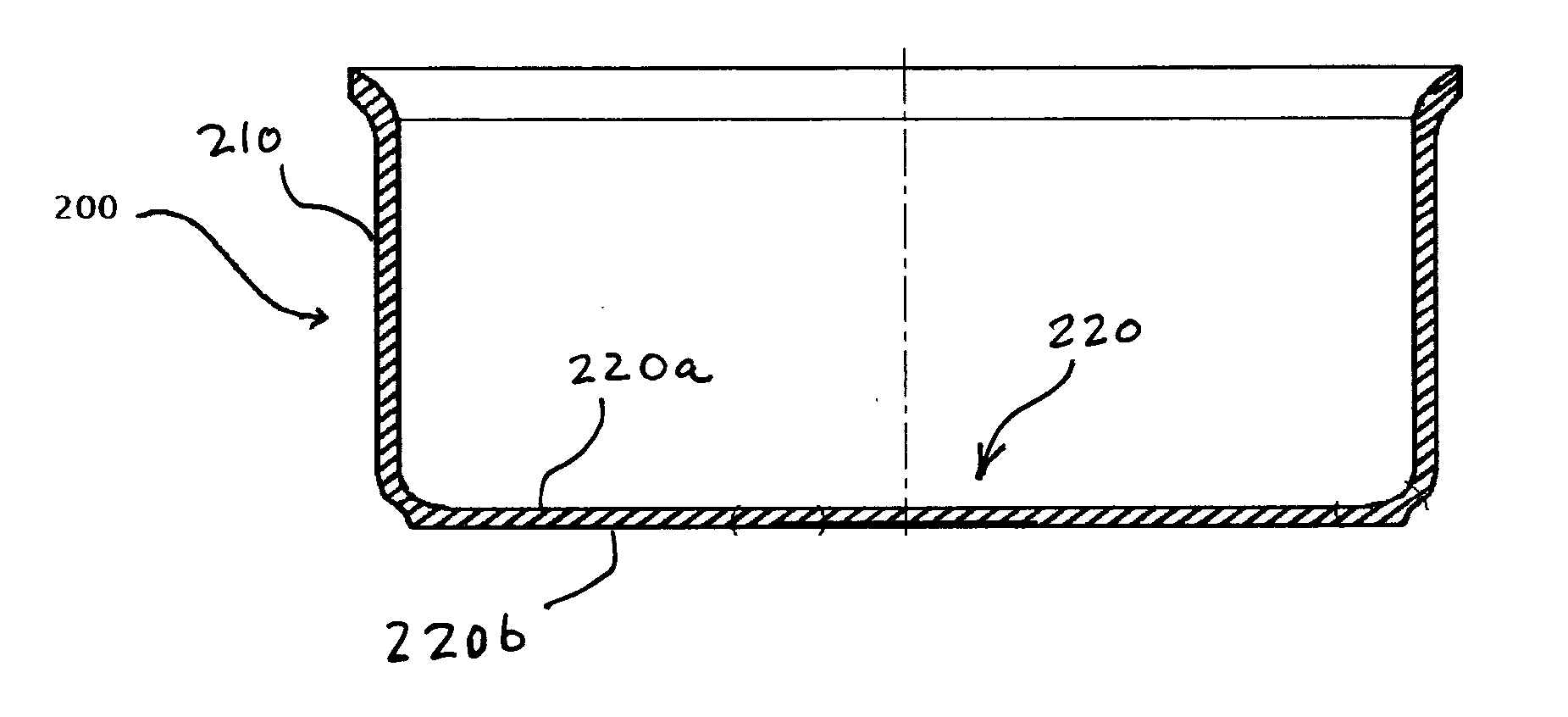

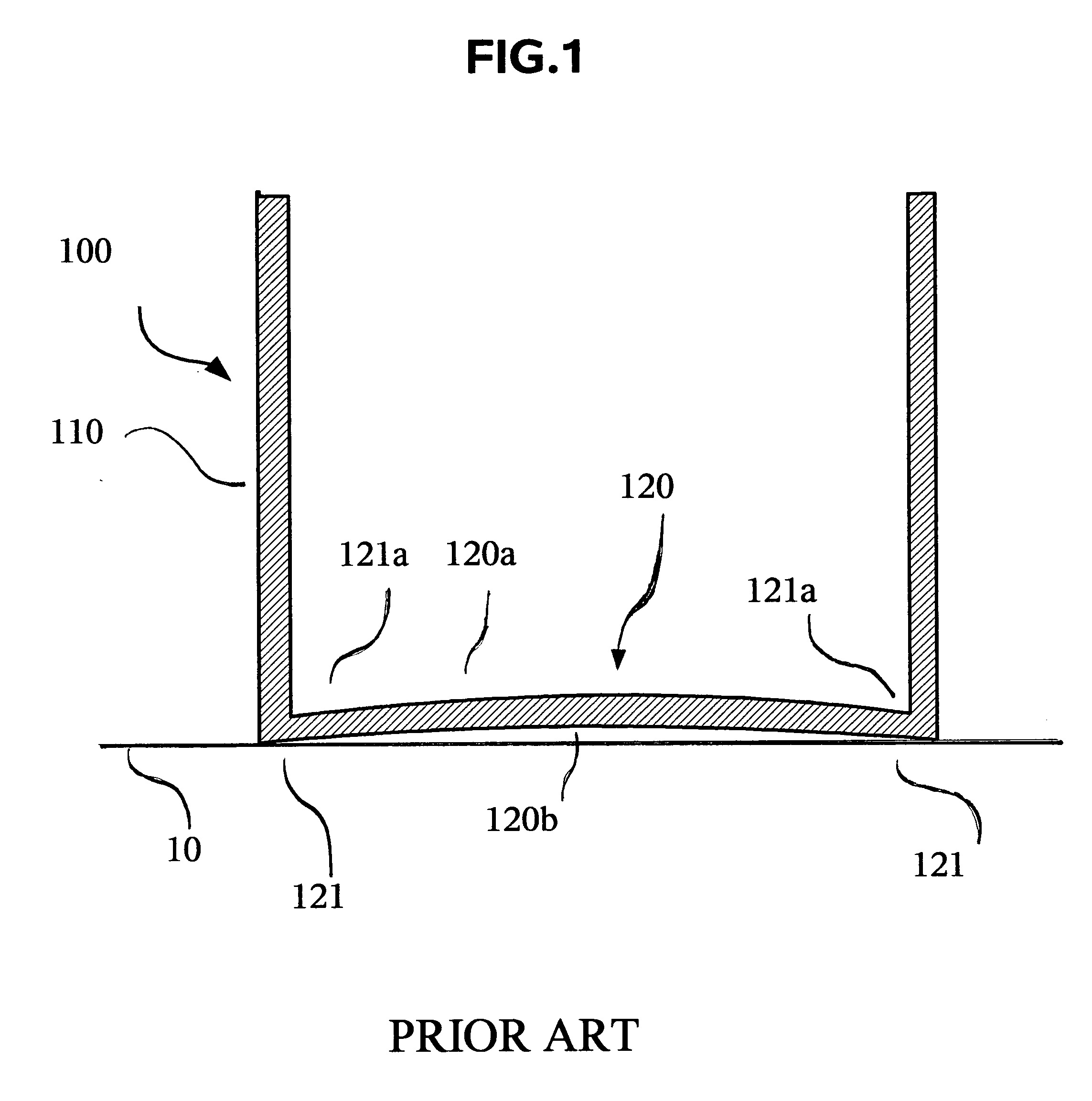

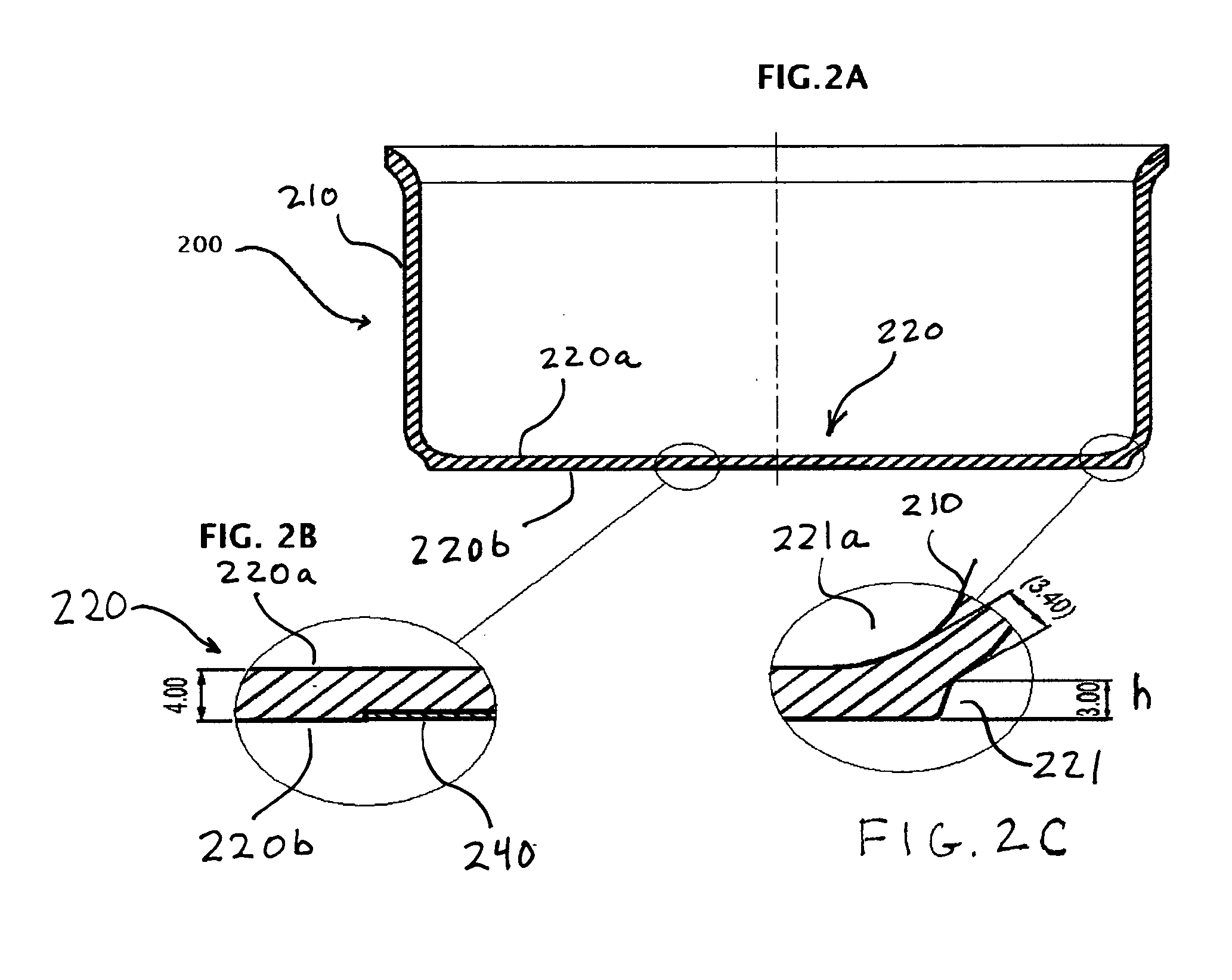

Cookware with flat interior surface

ActiveUS20070051731A1Efficient and economical processBaking vesselsMetal working apparatusCookerEngineering

An article of cookware is fabricated by a combination of a deep drawing a metal sheet or laminate to form a fluid retaining preform and then using an impact bonding process to attach a medallion to the outside bottom surface of preform. In another aspect, the impact bonding process alternatively provides a means to achieve a slightly concave exterior bottom surface, while maintaining a substantially flat and / or slightly concave interior bottom surface to minimize the use of cooking oil.

Owner:MEYER INTPROP

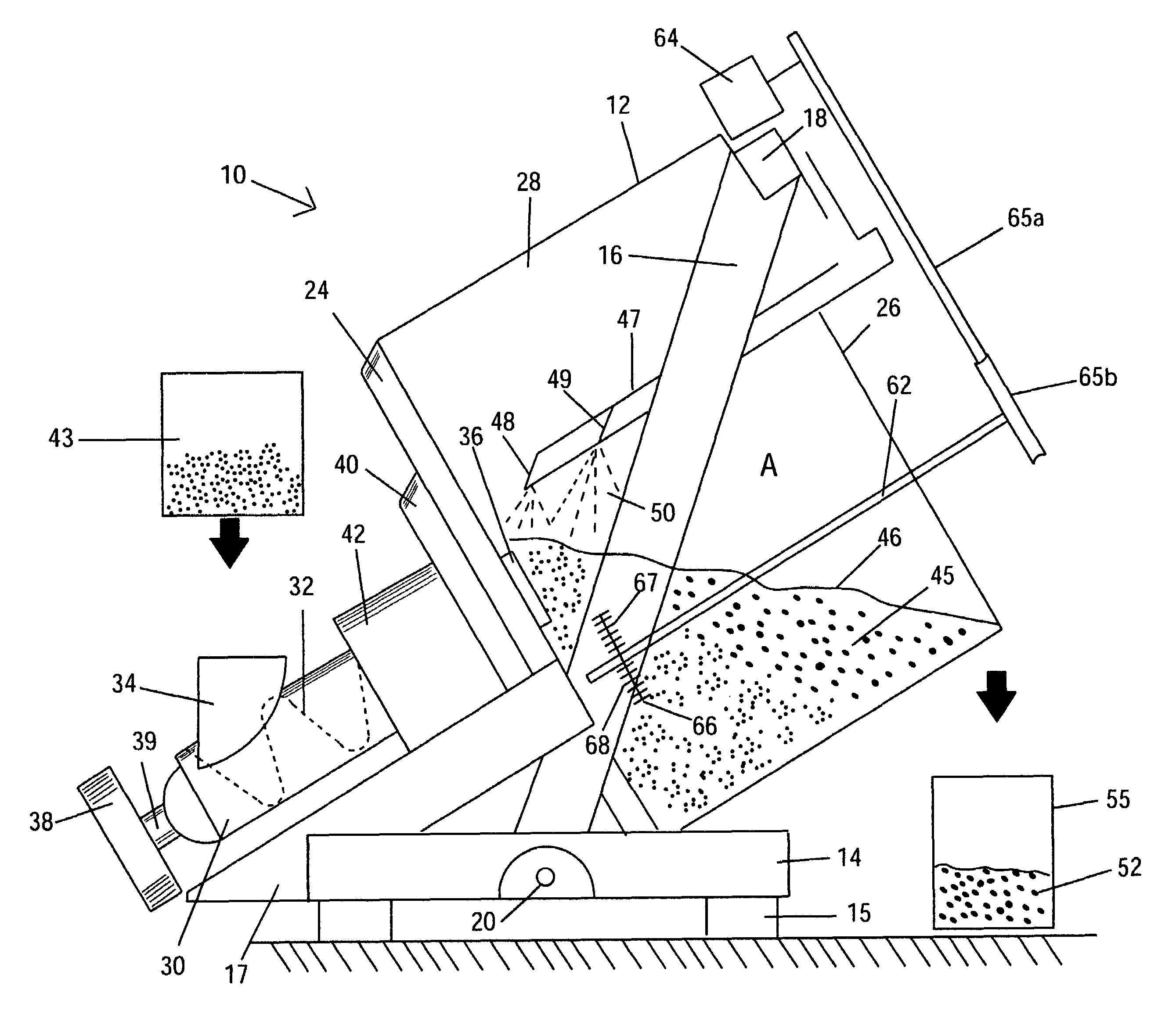

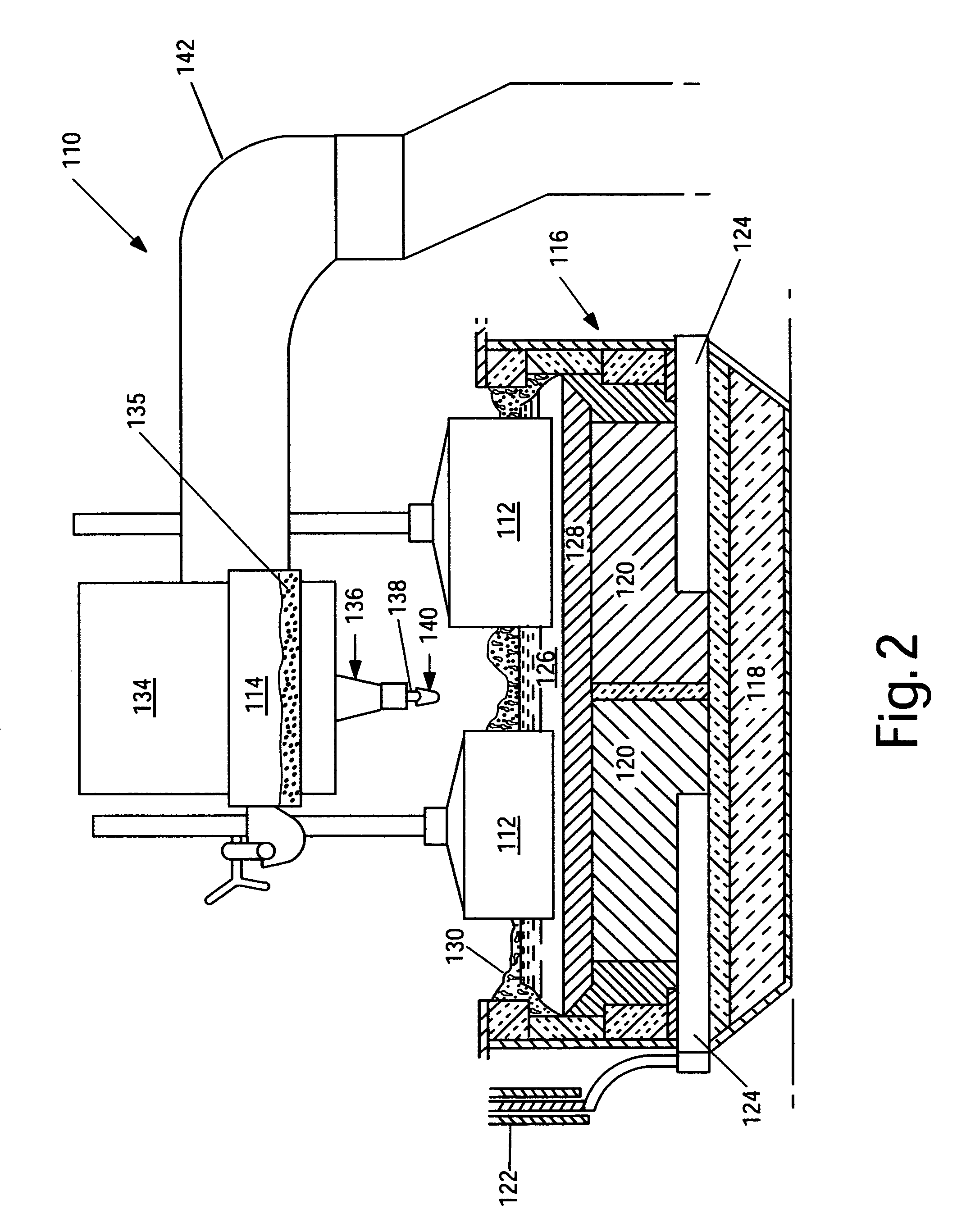

Agglomerating alumina dust for aluminum production

InactiveUS7625413B1Efficient and economical processConducive to agglomerationRotary drum furnacesPhosphatic fertiliser granulation/pelletisationElectrolysisMolten salt

Alumina-containing dust is agglomerated into granules by mixing the dust with an organic binder to form a mixture; feeding the mixture into a rotating drum; adding water to the mixture while the drum is rotating; stirring the mixture with a rotor hastening agglomeration of the dust particles into granules; collecting moist granules from an open end of the drum; and drying the moist granules. Granules produced by the process are suitable feedstock material for production of aluminum by electrolysis of alumina in a cell containing a molten salt bath, anodes, and a cathode.

Owner:REED JR THOMAS J

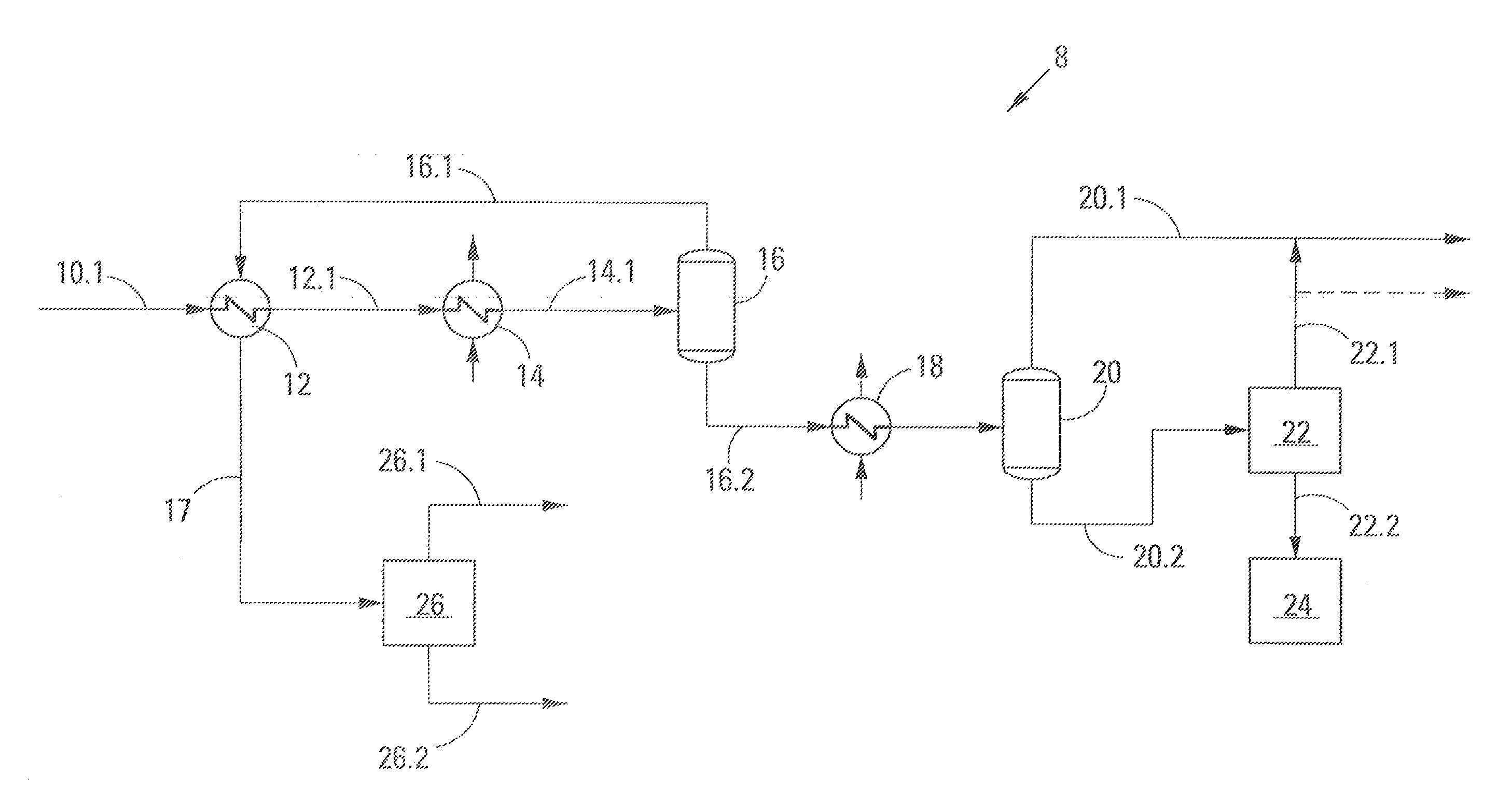

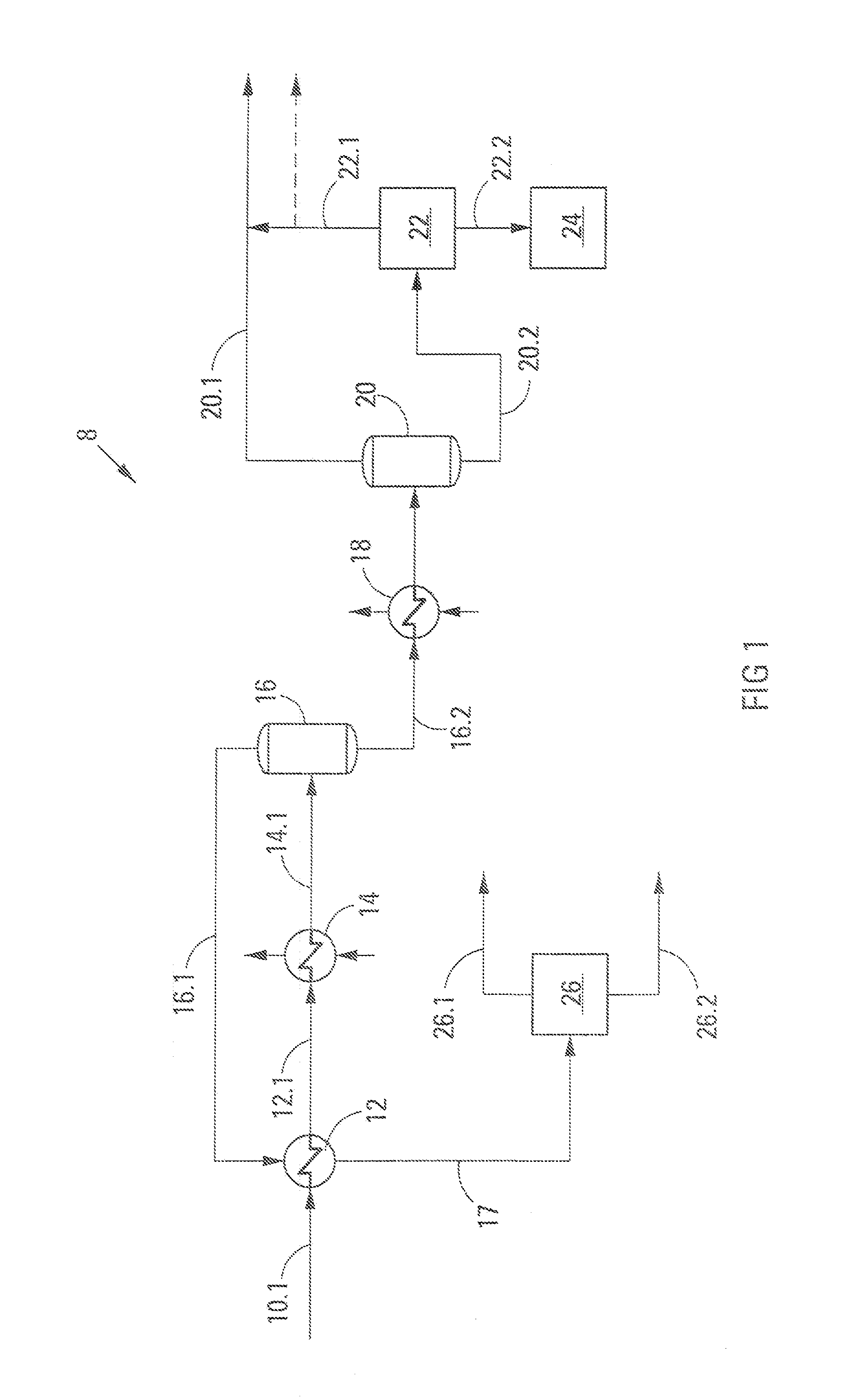

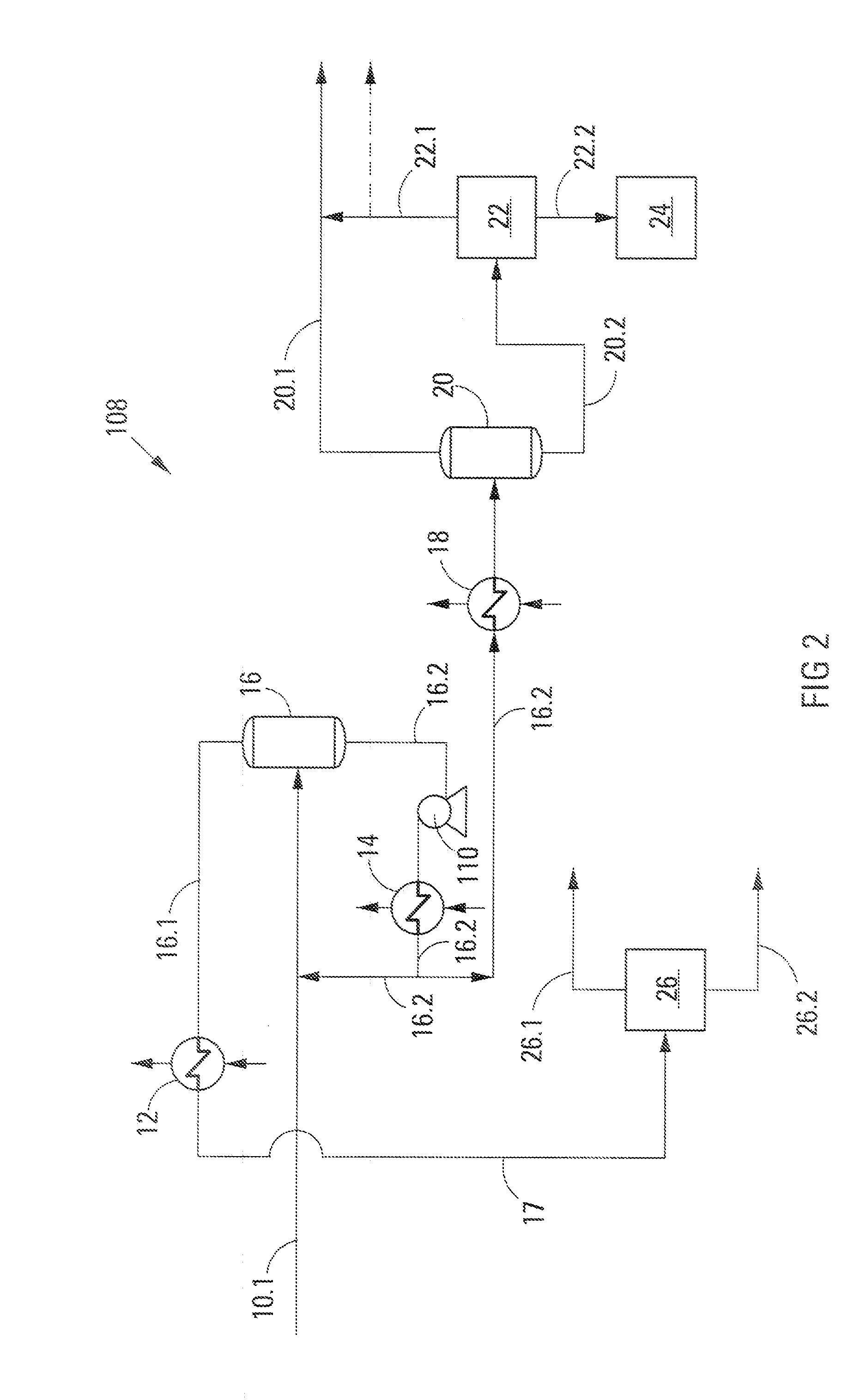

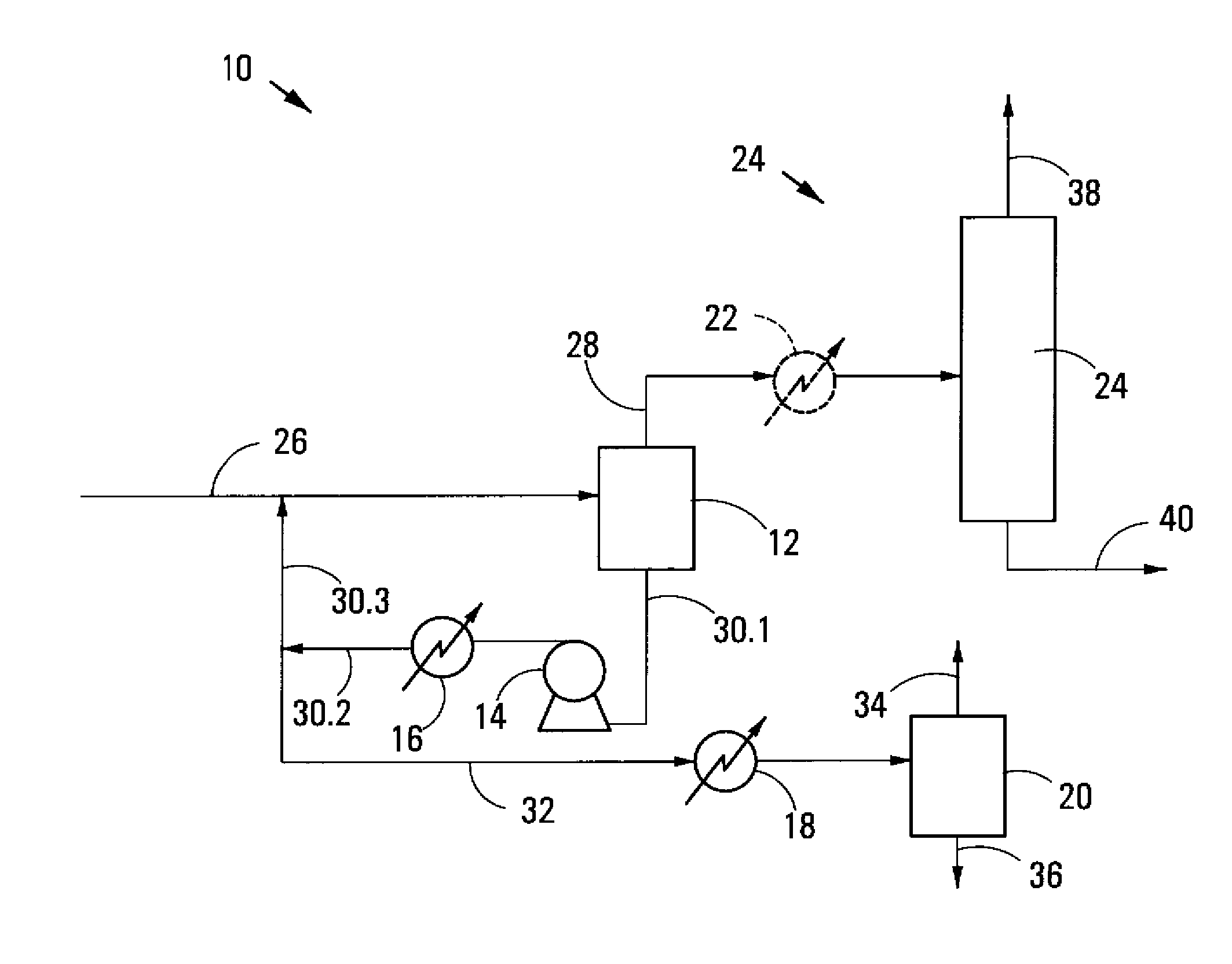

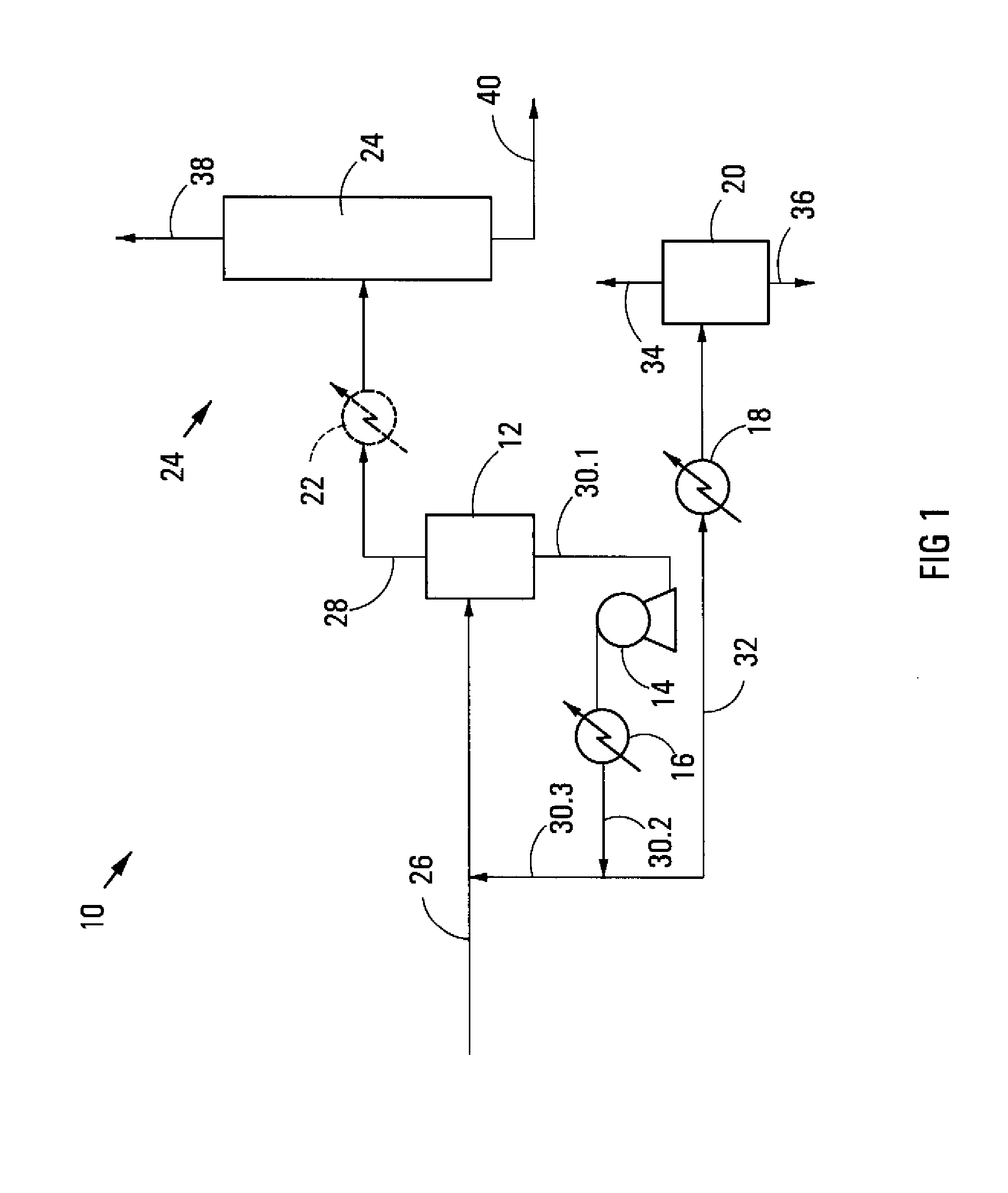

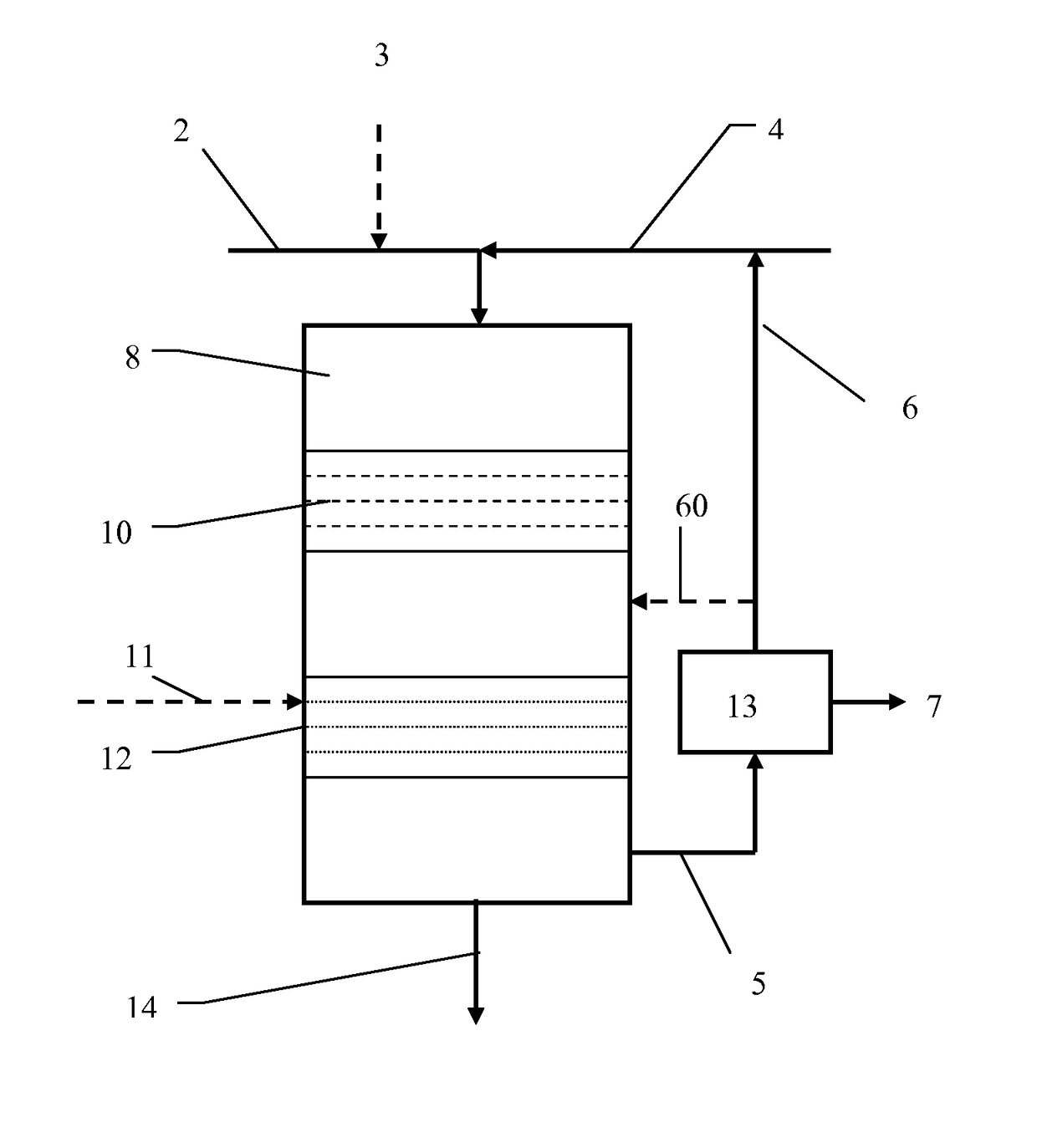

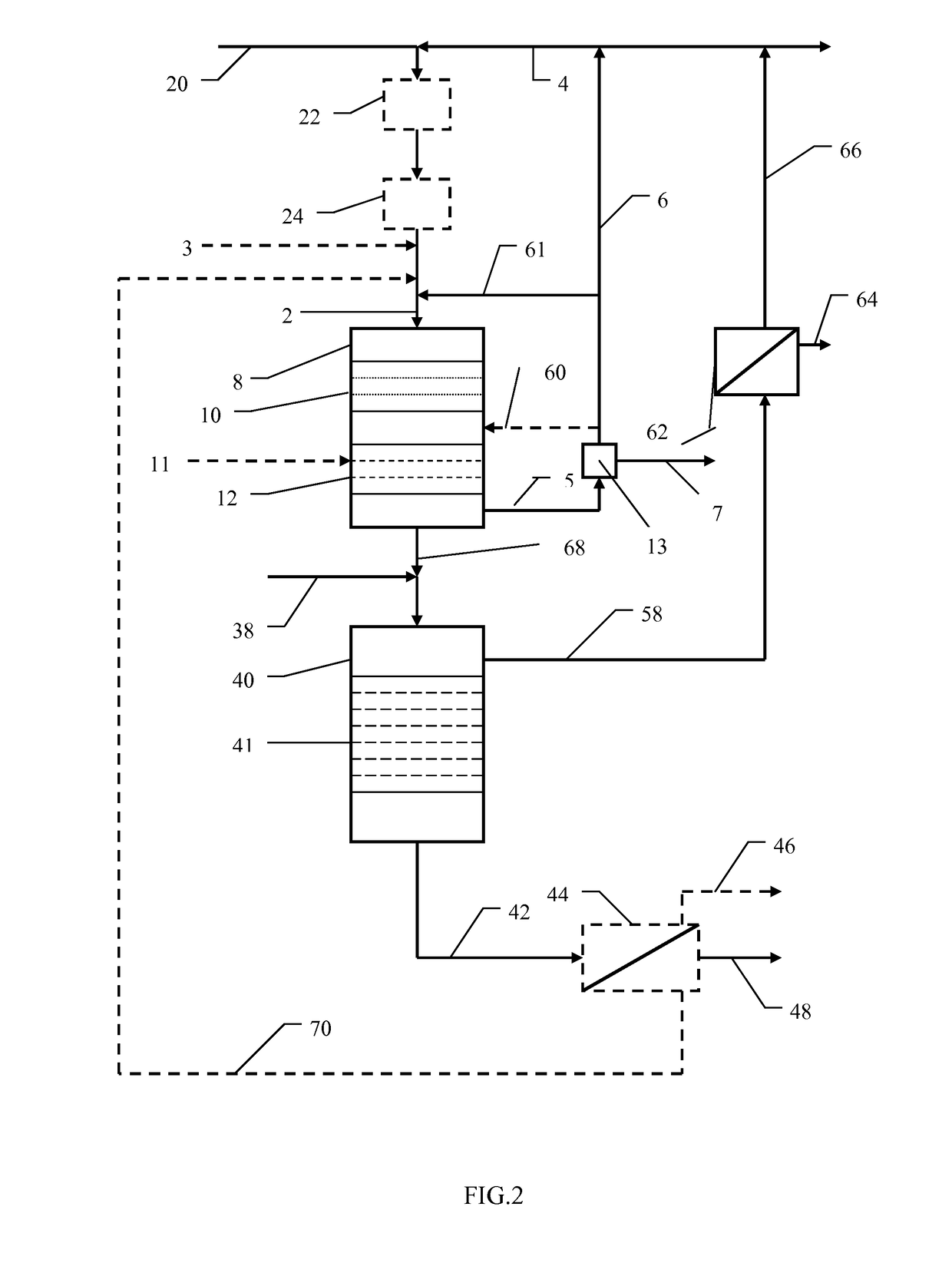

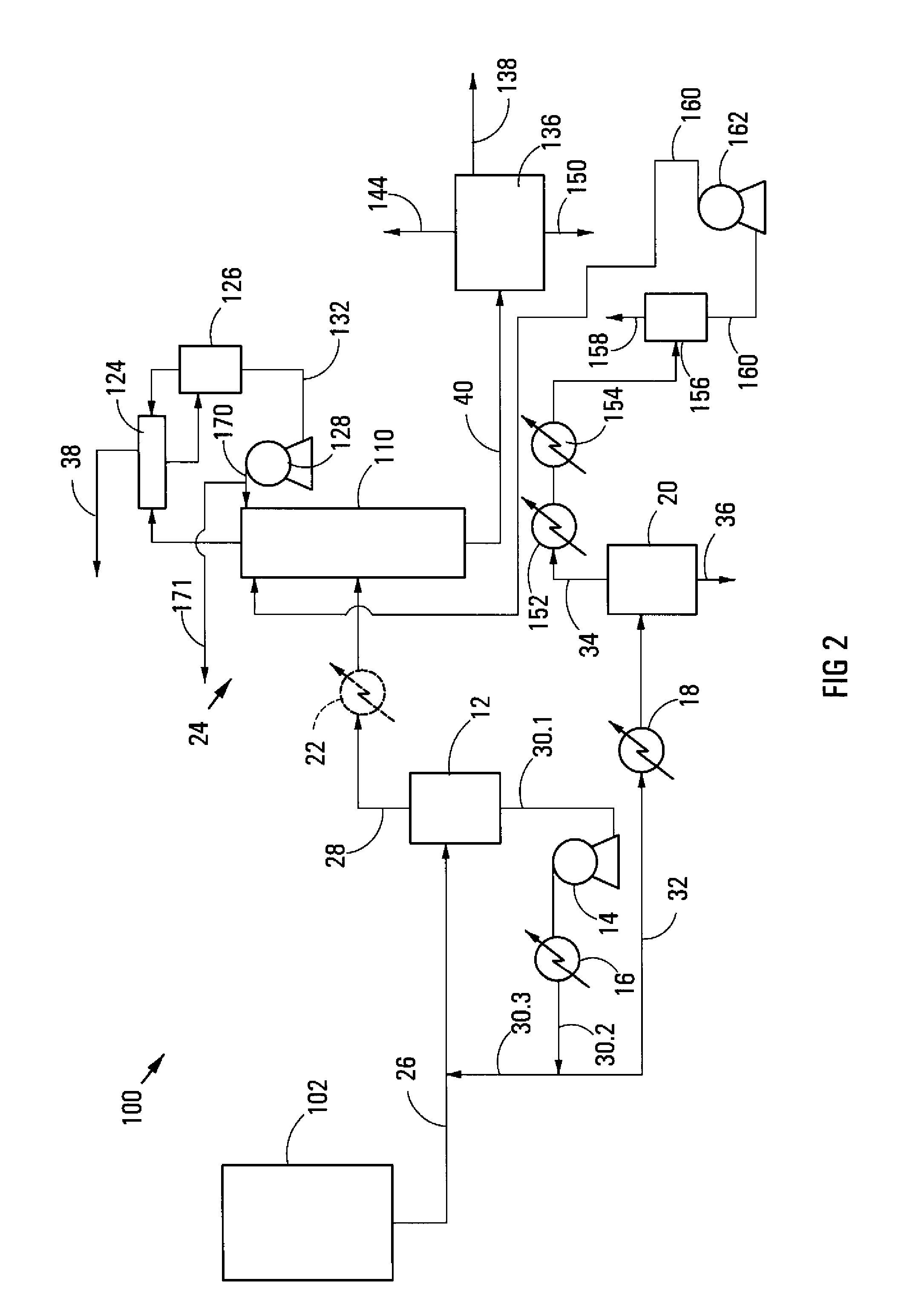

Separation of components from a multi-component hydrocarbon stream

ActiveUS20150133707A1Lower cost of capitalReduce operating costsCatalystsHydrocarbon preparation catalystsChemistryHigh pressure

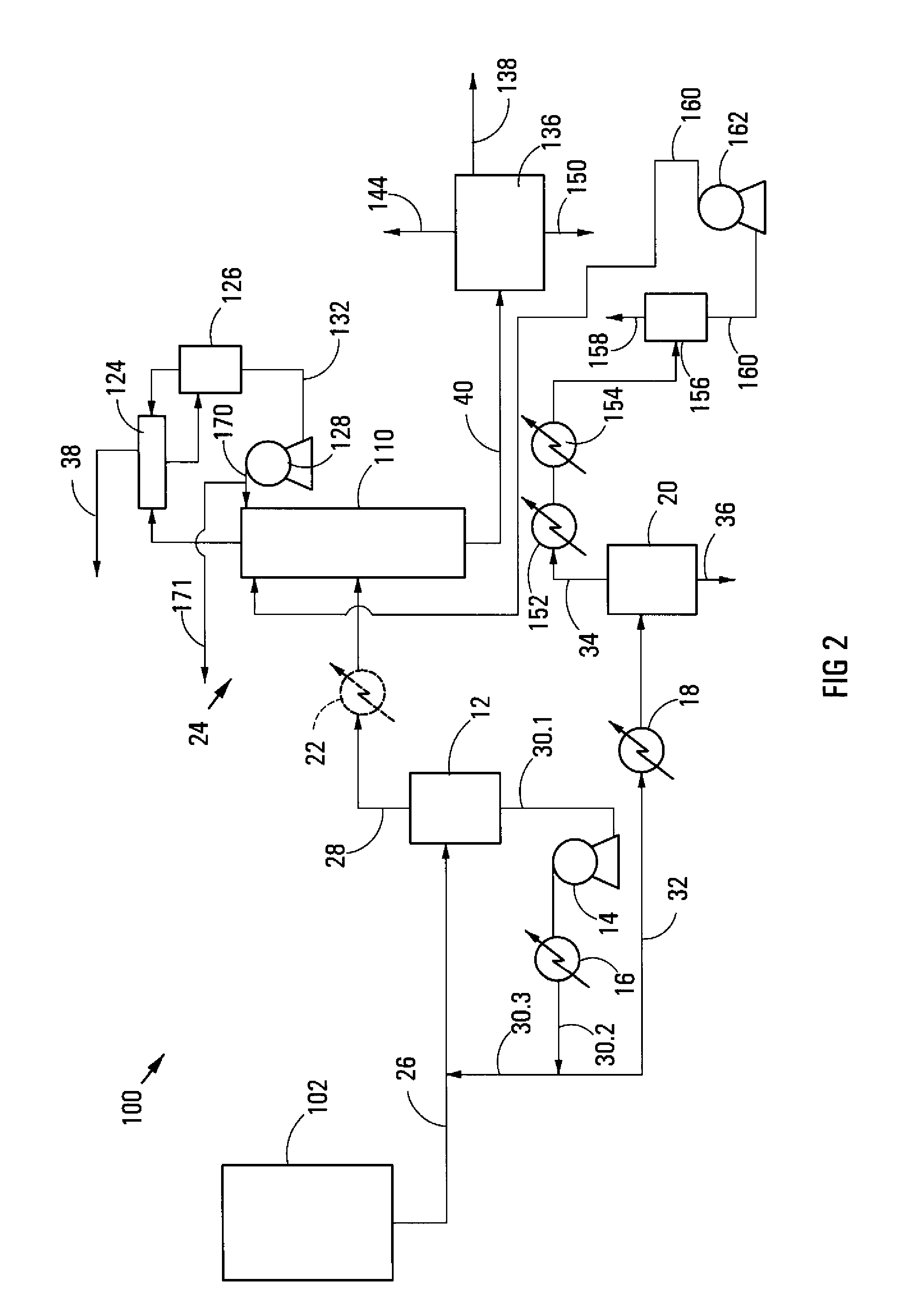

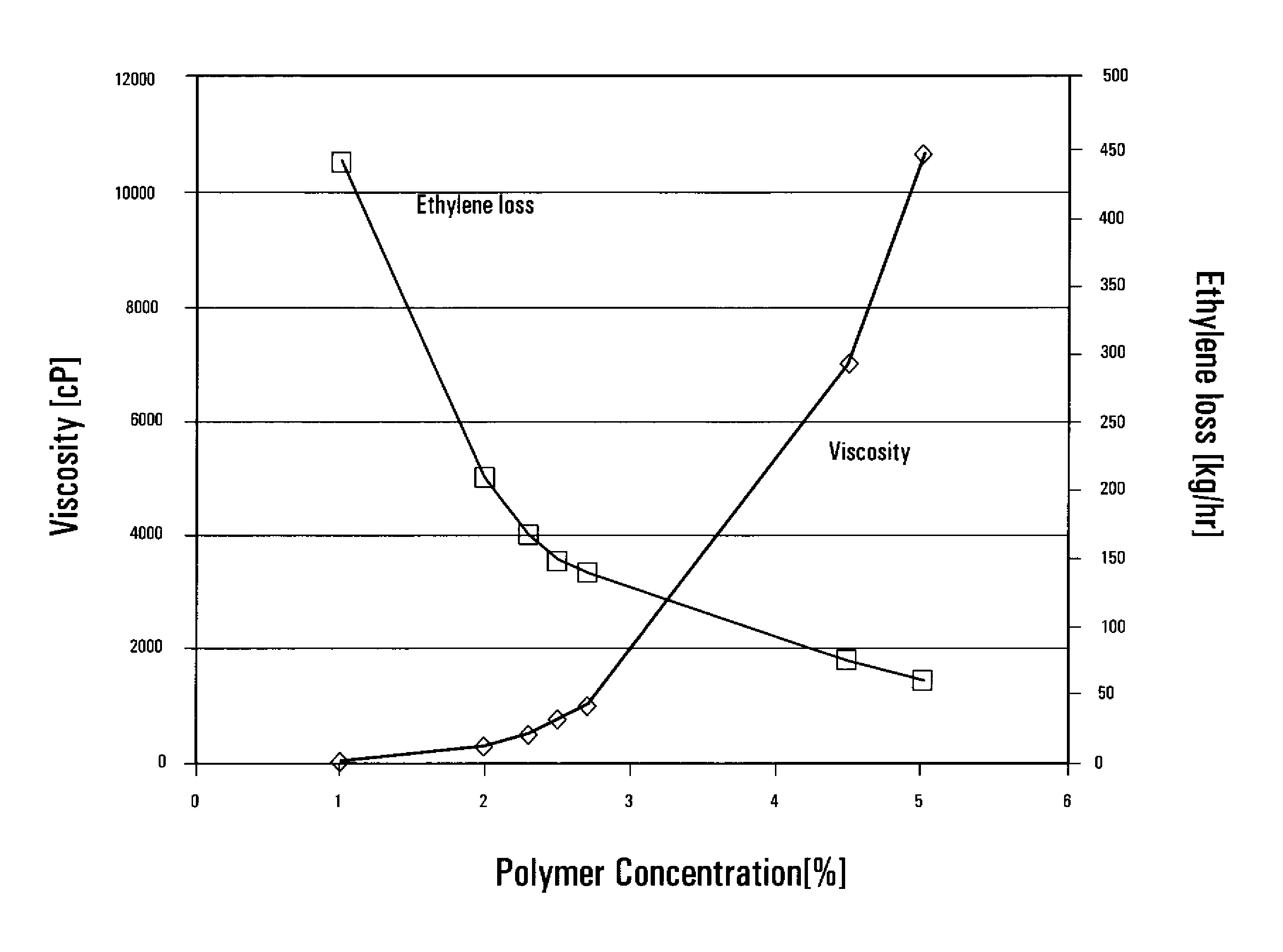

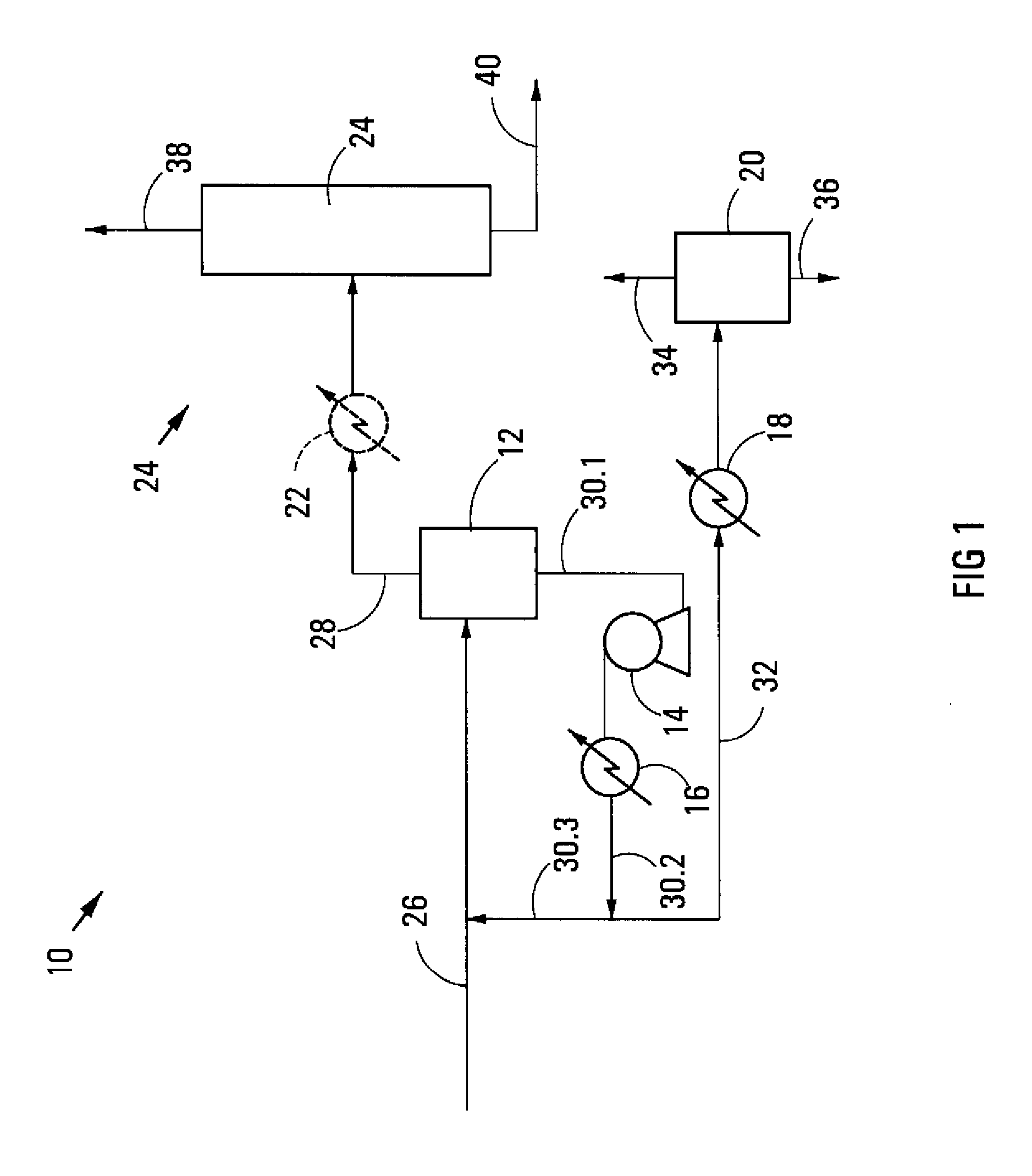

A process (10) to separate a multi-component hydrocarbon stream (26) comprising ethylene, at least one polymer and other components includes flashing the multi-component hydrocarbon stream in a first flash stage (12) from an elevated pressure of more than 30 bar(a) and an elevated temperature in the range of 150° C. to 185° C. to a flash pressure in the range of 10 bar(a) to 30 bar(a), producing a first ethylene-containing vapour overheads product (28) at a pressure in the range of 10 bar(a) to 30 bar(a) and a first flash stage bottoms product (30.1) which includes some ethylene, the at least one polymer and some of the other components. The flash pressure and the elevated temperature of the multi-component hydrocarbon stream (26) are selected such that the first flash stage bottoms product (30.1) has a concentration of the at least one polymer of less than 5% by mass to render the viscosity of the first flash stage bottoms product (30.1) at the temperature of the first flash stage bottoms product (30.1) in the first flash stage (12) at less than 1000 cP at a shear of 1 per second. At least a portion of the first flash stage bottoms product (30.1) is heated to a temperature in excess of 150° C. to form a heated first flash stage bottoms product (30.2). A recycle portion (30.3) of the heated first flash stage bottoms product (30.2) is combined with the multi-component hydrocarbon stream (26), which is at a temperature less than 150° C. before combination with the recycle portion (30.3), thereby to heat the multi-component hydrocarbon stream (26) to the elevated temperature in the range of 150° C. to 185° C. At least a portion (32) of the first flash stage bottoms product and the first ethylene-containing vapour overheads product (28) are withdrawn from the first flash stage (12).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

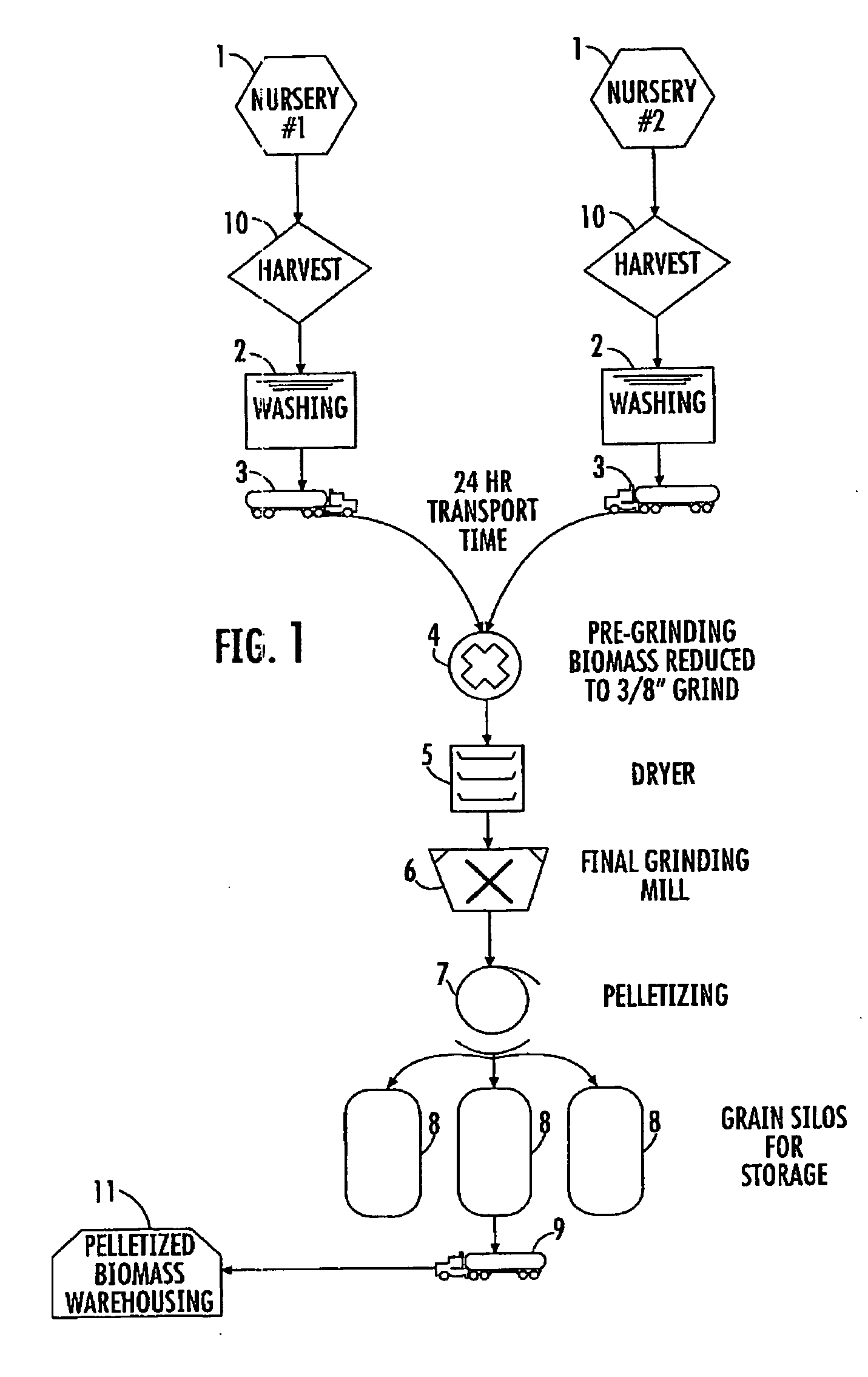

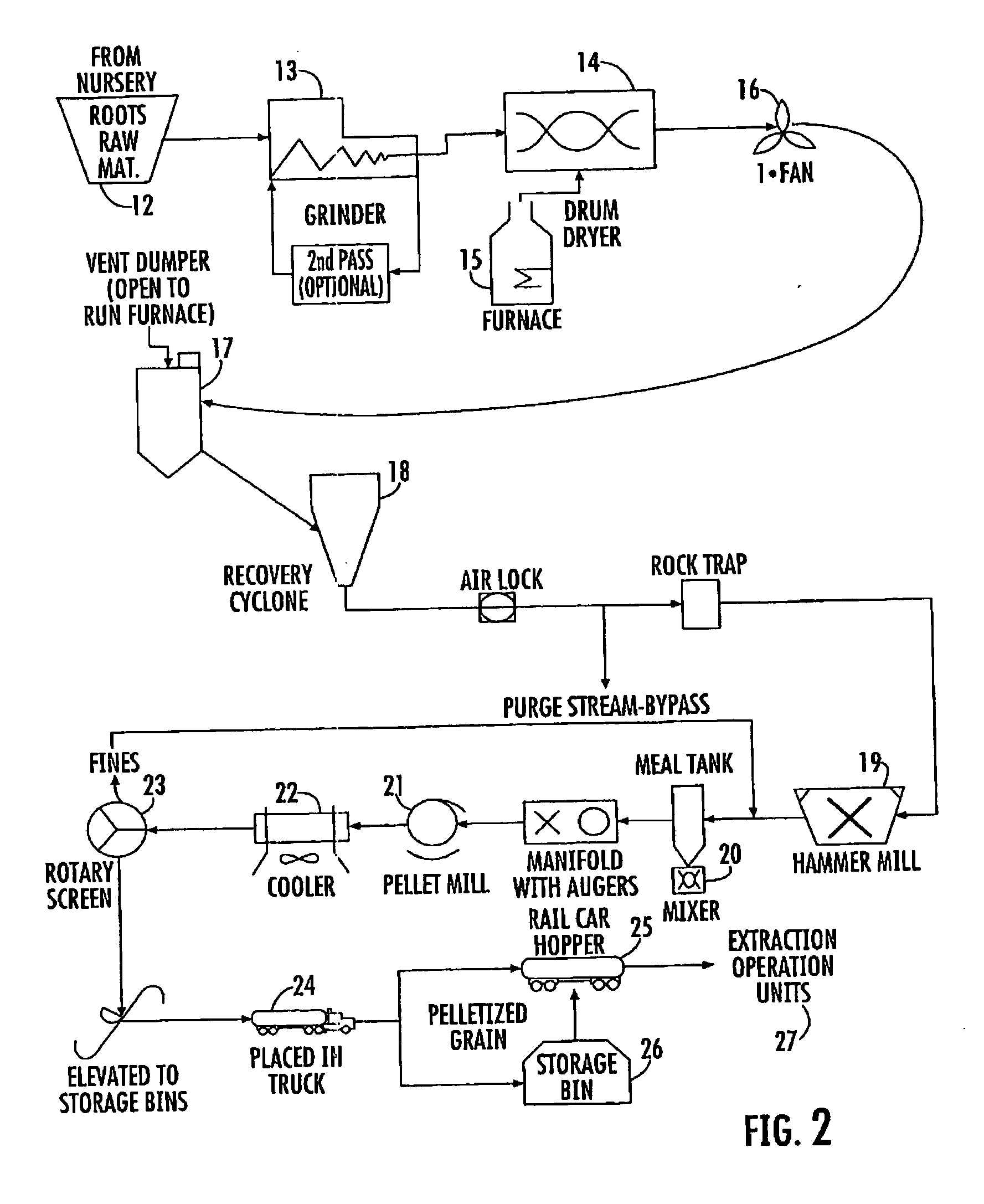

Harvesting and pelletizing yew biomass for extraction of taxanes and other natural products

InactiveUS20060127510A1Efficient and economicalEfficient and economical processBiocideOrganic chemistryNatural productTree material

A process for harvesting yew biomass and a process of making Yew pellets from Yew tree material is disclosed herein. The process for harvesting comprising the steps of (i) harvesting the tops or roots of the Yew tree; (ii) washing the harvested material; (iii) drying the harvested material; and (iv) grinding the harvested material into a fine powder. The process for making Yew pellets comprising the steps of (i) adding from about 1% to about 20% w / w water to the Yew tree material; and (ii) compressing the Yew tree material in a die to form a pellet whereby the resulting pellet has a final moisture content of less than 10% by weight. The yew pellets produced herein are suitable for extracting taxane molecules from the pellets.

Owner:PHYTON HLDG

Process for Recovering Flunixin From Pharmaceutical Compositions

InactiveUS20100331376A1Efficient and economical processReducing solvent volumeBiocidePowder deliveryMedicineFlunixin

Owner:INTERVET INC

Process and apparatus for producing fuel from a biological origin through a single hydroprocessing step in the presence of a NiW catalyst

ActiveUS9790439B2Simple one-stepEfficient and economical processBiofuelsSolid fuelsHydrogenEngineering

Owner:UPM-KYMMENE OYJ

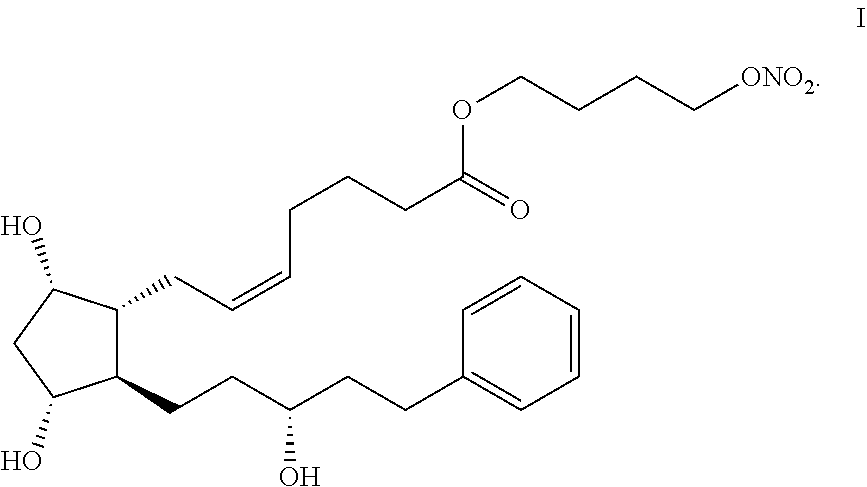

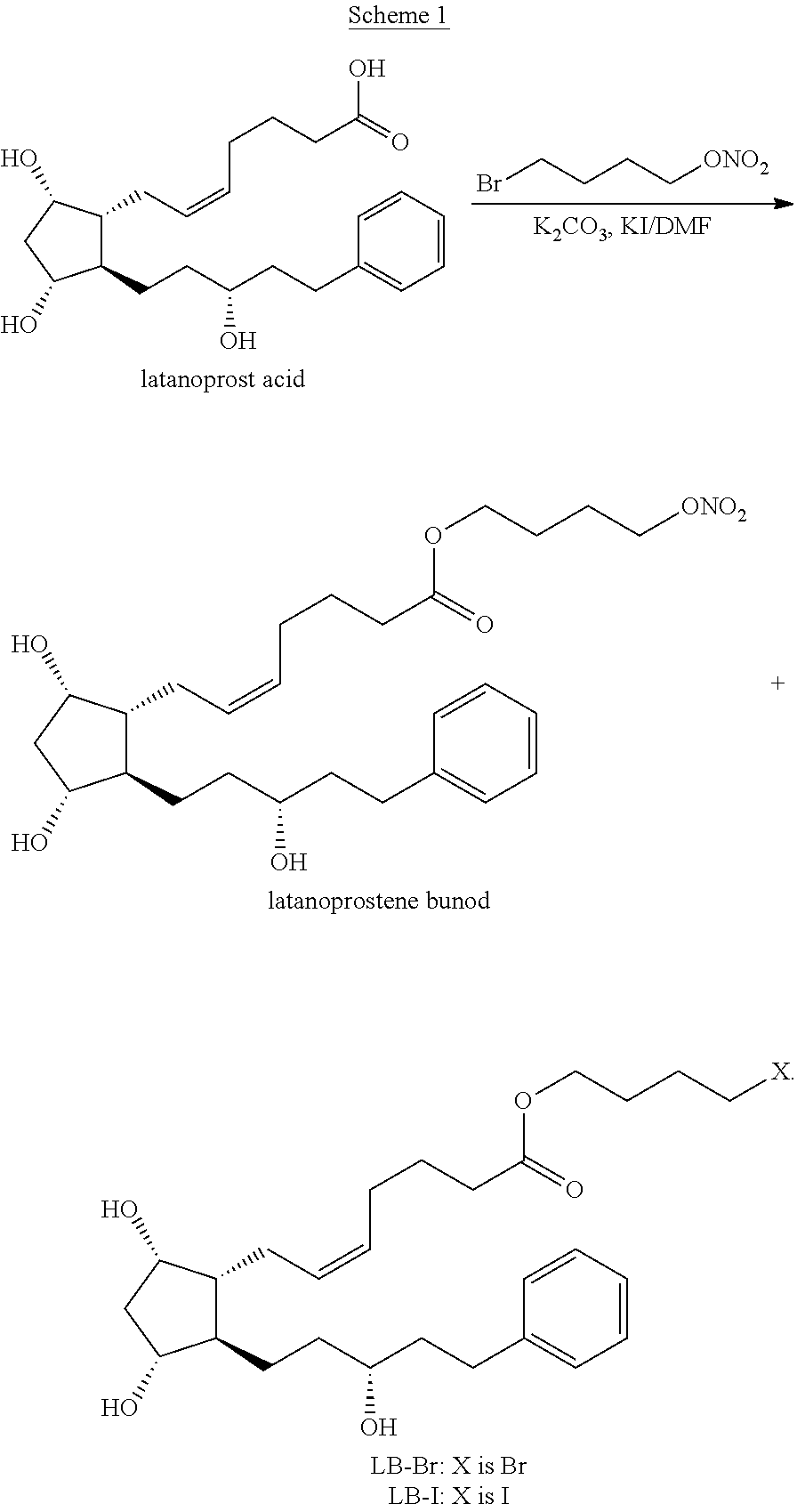

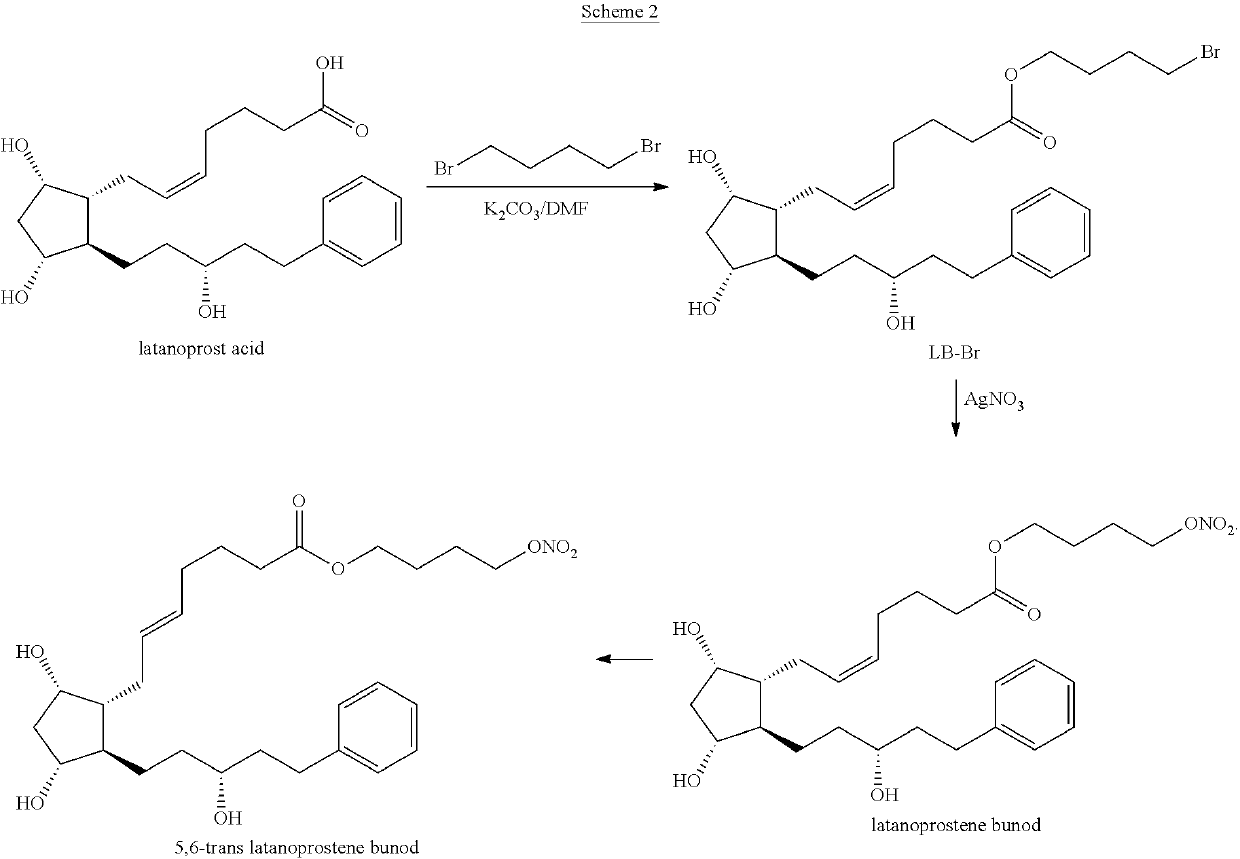

Process for the preparation of latanoprostene bunod and intermediate thereof and compositions comprising the same

ActiveUS20220024849A1Efficient and economical processAvoid easy removalOrganic active ingredientsGroup 4/14 element organic compoundsLatanoprostOrganic chemistry

Owner:CHIROGATE INT

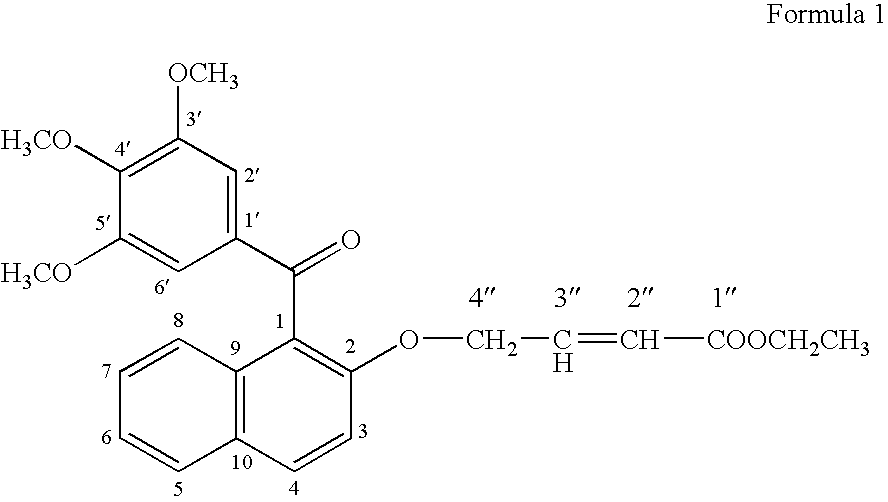

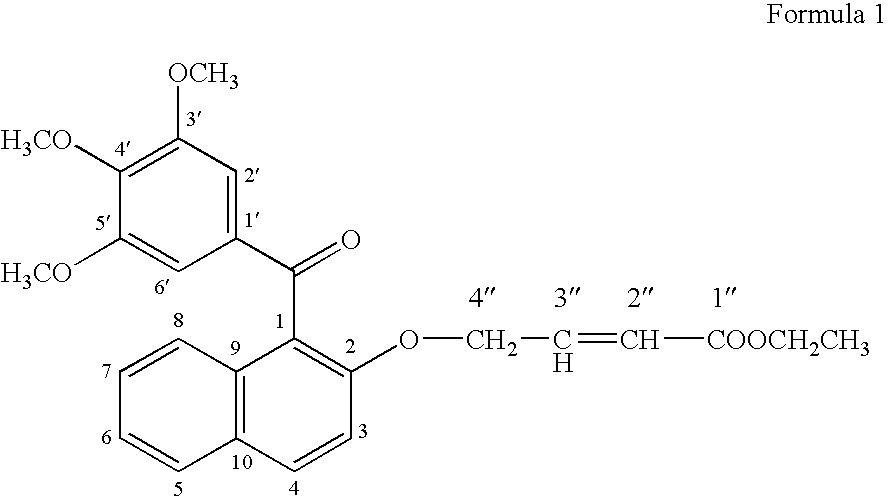

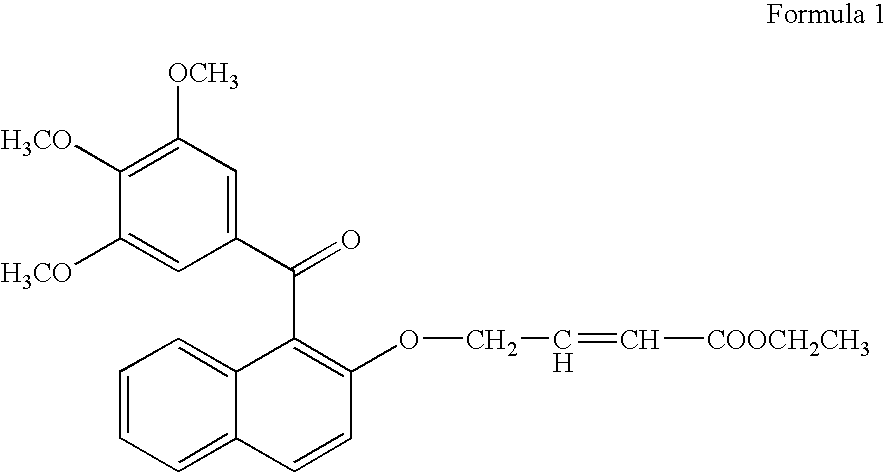

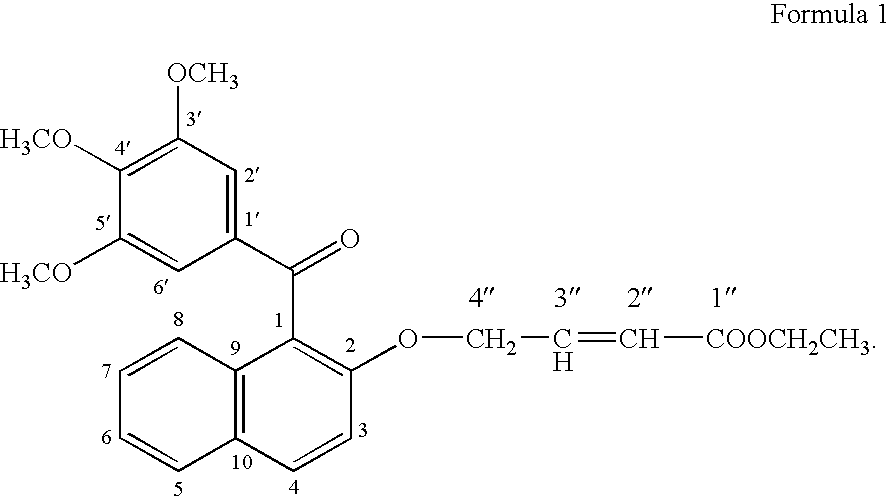

Gallic acid derivative and process of preparing the same

InactiveUS20050181950A1Efficient and economical processHigh yieldBiocideOrganic compound preparationGrowth plantBiological activity

This invention provides a plant growth regulatory activity of a new biologically active synthetic molecule methanone-(3′,4′,5′-trimethoxy) phenyl, 1-naphthyl, 2-O-4″-ethyl but-2″-enoate. More particularly, the invention relates to the potent plant growth promoting activity of a gallic acid derivative having a structure represented by Formula 1 and a molecular formulae C26H26O7. This invention also provides a novel process for preparation of said molecule from a naturally occurring compound and testing it for growth regulating activity using Bacopa test system developed at CIMAP (Khanuja et al., 2001).

Owner:COUNCIL OF SCI & IND RES

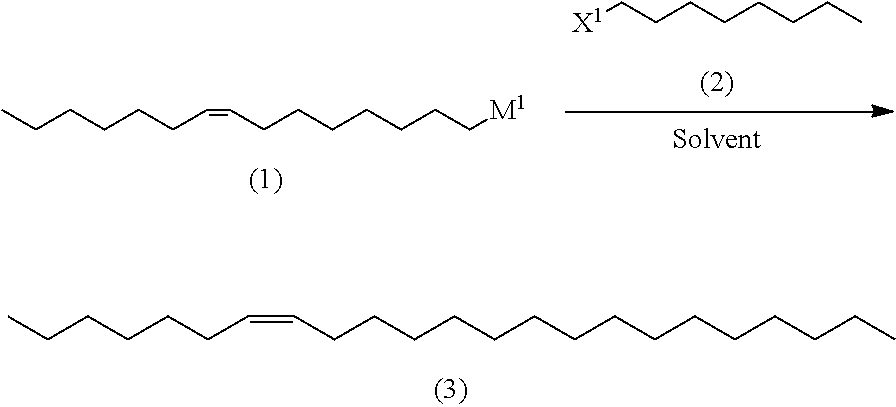

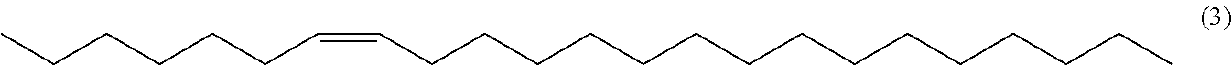

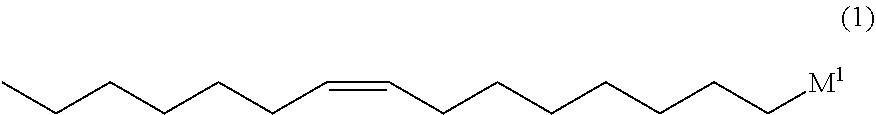

Process for preparing (7Z)-7-tricosene

ActiveUS20200361836A1Easily separateEfficient and economical processCatalystsHydrocarbon preparation catalystsCarbeneCombinatorial chemistry

The present invention provides a process for preparing (7Z)-7-tricosene of the following formula (3): the process comprising a step of subjecting a nucleophilic reagent, (8Z)-8-pentadecenyl compound of the following general formula (1), wherein M1 represents Li, MgZ1, CuZ1 or CuLiZ1, wherein Z1 represents a halogen atom or an (8Z)-8-pentadecenyl group, to a coupling reaction with a 1-halooctane compound of the following general formula (2), wherein X1 represents a halogen atom, to produce (7Z)-7-tricosene (3).

Owner:SHIN ETSU CHEM CO LTD

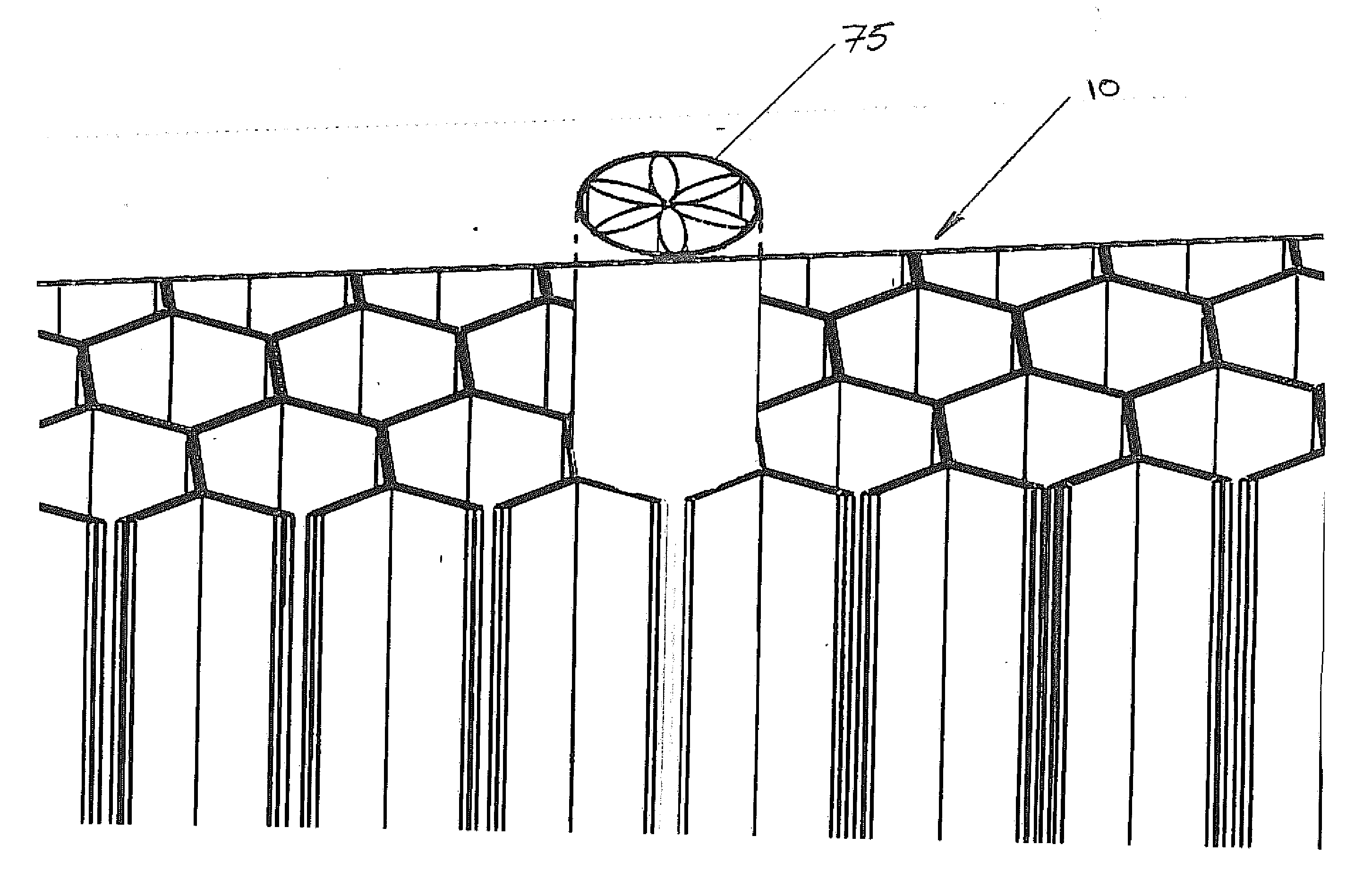

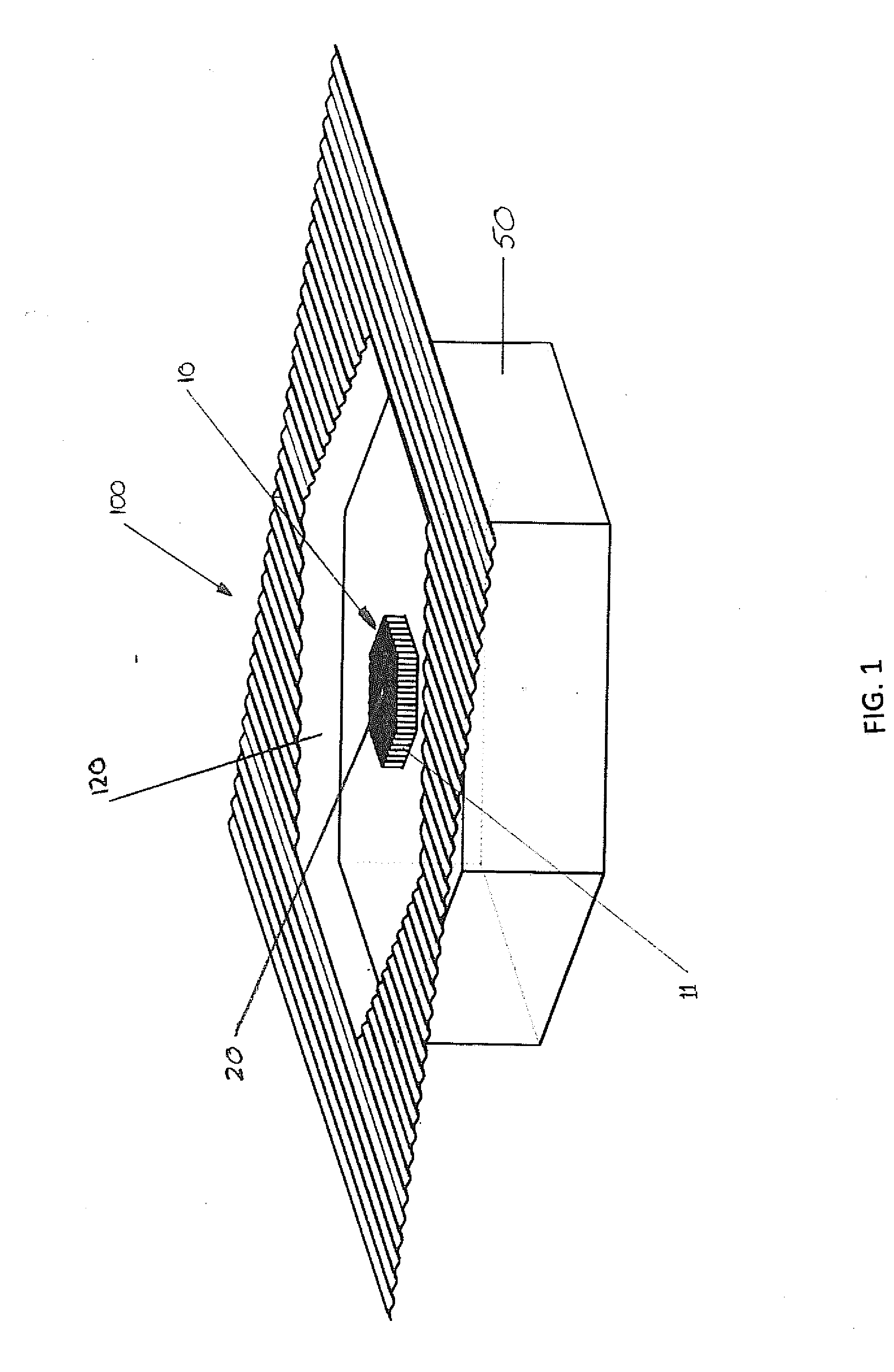

Low Profile Solar Energy Conversion System

InactiveUS20120235411A1Efficient and economical processEfficient economical processSolar heating energySolar heat devicesElectricityAir movement

A novel cost effective low profile structure that converts and stores solar radiation into heat and electricity for controlled utilization. The inventive material incorporates a large insulated vault or chamber of substantial thermal mass connected to a series of inlet passages and to a solar collector assembly. As solar radiation is collected by the solar collector assembly a temperature gradient is created between the collector and the air that is within the vault resulting in air being drawn out of the chamber and through the collector assembly. This air movement is utilized to rotate turbines that are coupled to the inlet passages generating electricity. The hot air is also captured and utilized. The system provides for an efficient, economical process of harnessing and utilizing solar energy by capitalizing on not only on its thermal nature, but its motive nature as well.

Owner:HUNKA ROBERT

Free-flowing, solid, high active alkyl ether sulfates

ActiveUS10287531B2Efficient and economical processEase of mass productionInorganic/elemental detergent compounding agentsSurface-active detergent compositionsIndustrial scaleALKYL ETHER SULFATE

The present invention relates to free flowing, solid, high active alkyl ether sulfates and process for manufacturing such solid alkyl ether sulfates at processing temperature of 80° C. and above on an industrial scale. The solid alkyl ether sulfates have improved flow properties, improved appearance, and improved solubility.

Owner:GALAXY SURFACTANTS LTD

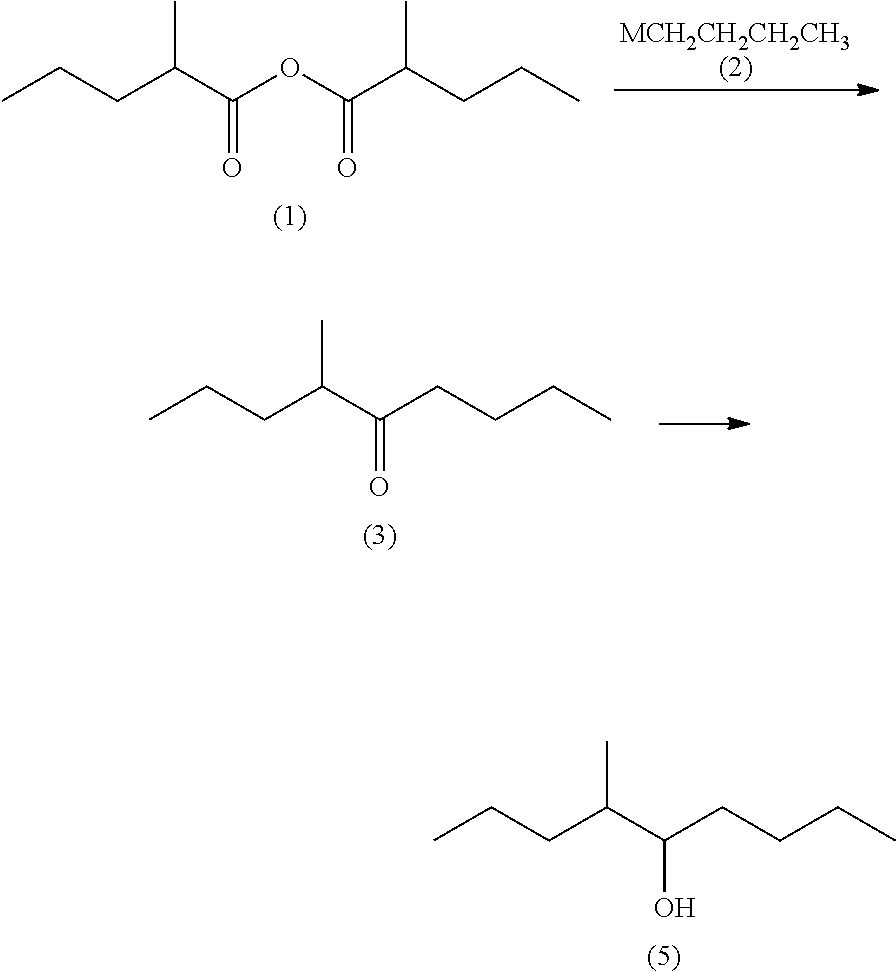

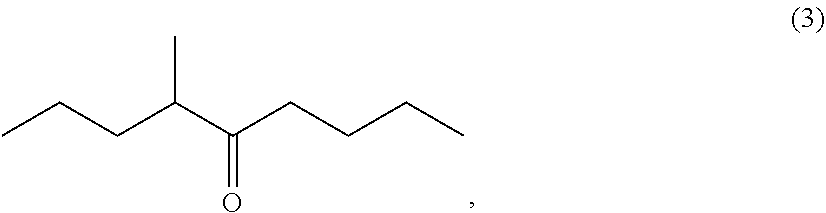

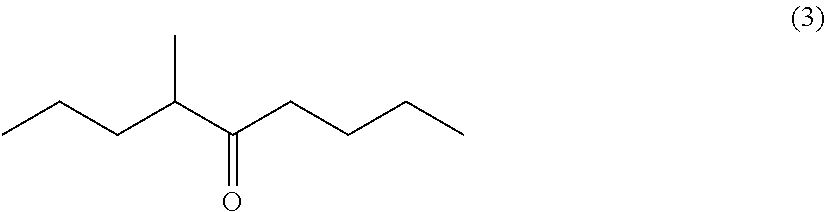

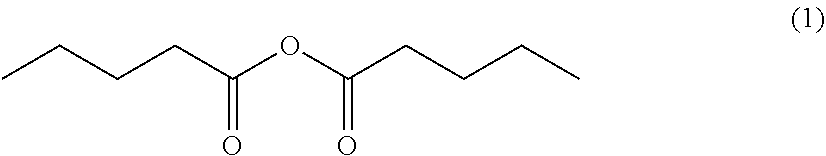

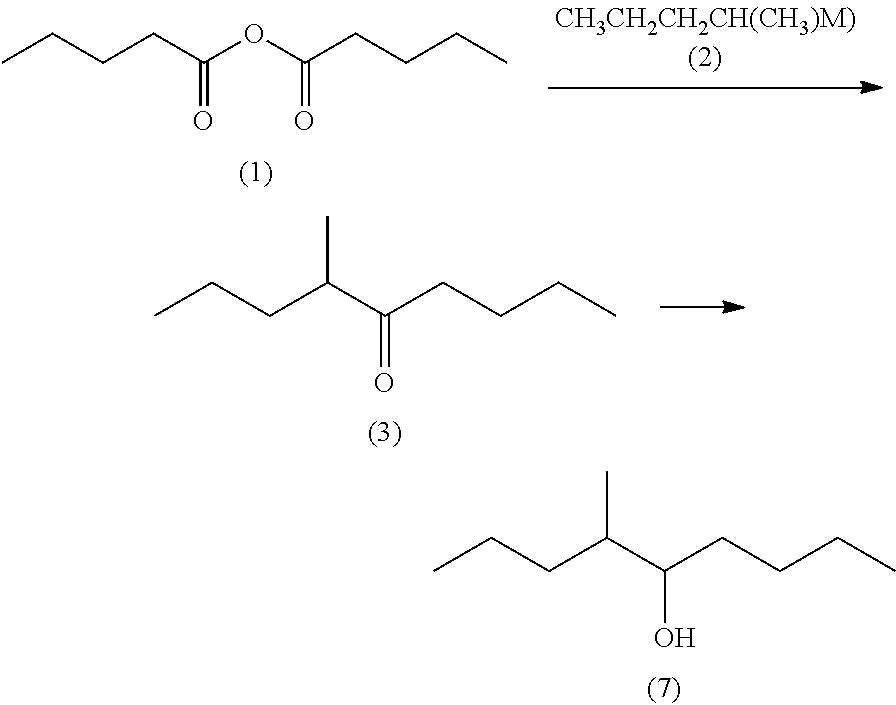

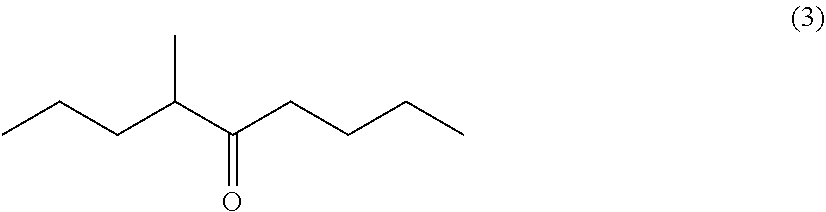

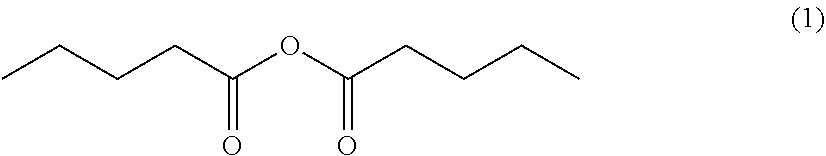

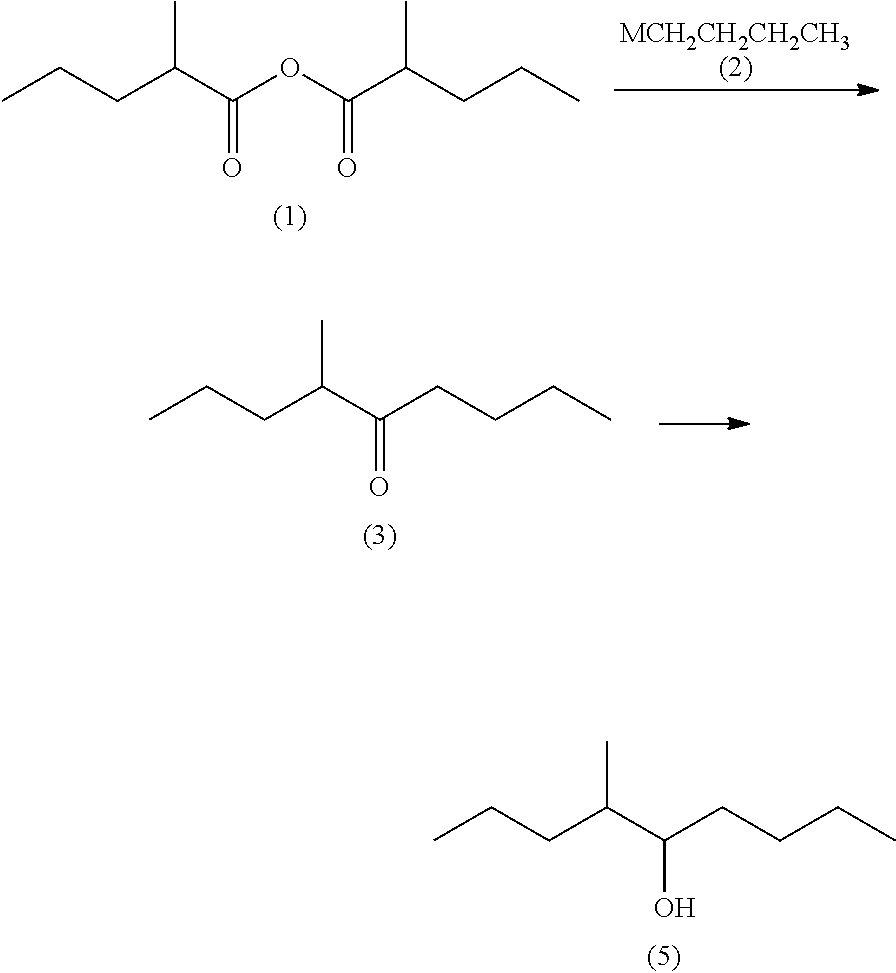

Processes for preparing 4-methyl-5-nonanone and 4-methyl-5-nonanol

ActiveUS20200199052A1Efficient and economical processHigh yieldOrganic compound preparationOrganic chemistry methodsHalogenCombinatorial chemistry

The present invention provides a process for preparing 4-methyl-5-nonanone of the following formula (3): the process comprising at least a step of subjecting 2-methylpentanoic anhydride of the following formula (1) and an n-butyl nucleophilic reagent of the following general formula (2) in which M represents Li, MgZ1, or ZnZ1, wherein Z1 represents a halogen atom or an n-butyl group, to a nucleophilic substitution. reaction Coproduce 4-methyl-5-nonanone (3), as well as a process for preparing 4-methyl-5-nonanol of the following formula (5), the process comprising at least steps of preparing 4-methyl-5-nonanone; and subjecting the obtained 4-methyl-5-nonanone and a reducing agent to a reduction reaction to produce 4-methyl-5-nonanol (5).

Owner:SHIN ETSU CHEM IND CO LTD

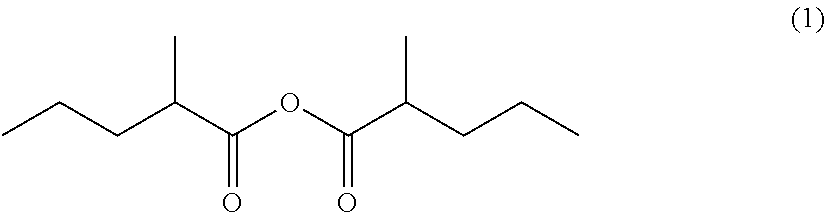

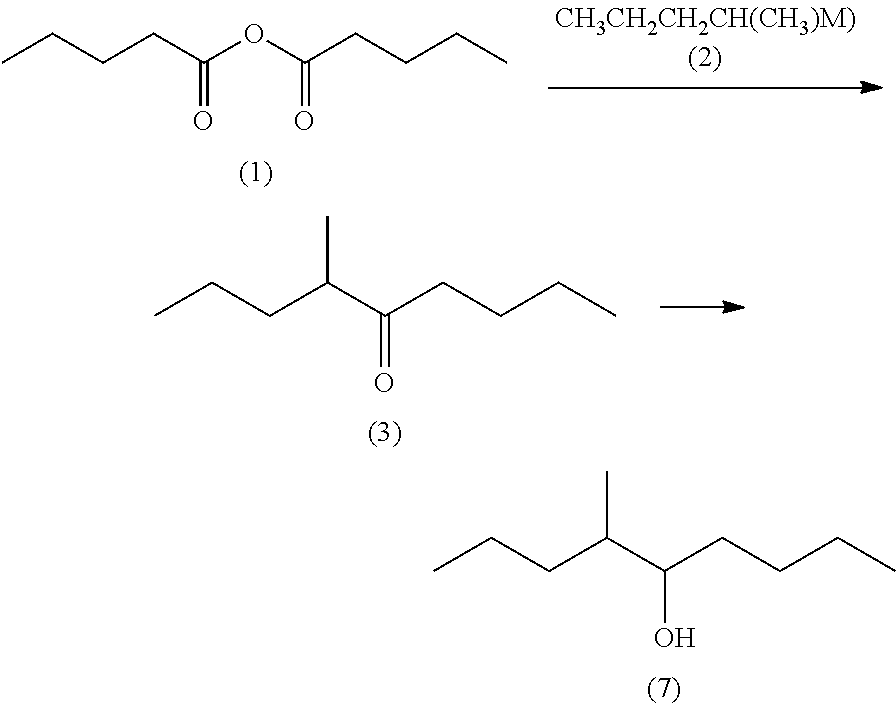

Processes for preparing 4-methyl-5-nonanone and 4-methyl-5-nonanol

ActiveUS10882806B2Efficient and economical processHigh yieldLithium organic compoundsOrganic compound preparationHalogenCombinatorial chemistry

The present invention provides a process for preparing 4-methyl-5-nonanone of the following formula (3), the process comprising at least a step of subjecting pentanoic anhydride of the following formula (1) and a 2-pentyl nucleophilic reagent of the following general formula (2), in which M represents Li, MgZ1, or ZnZ1, wherein Z1 represents a halogen atom or a 2-pentyl group, to a nucleophilic substitution reaction to produce 4-methyl-5-nonanone (3), as well as a process for preparing 4-methyl-5-nonanol of the following formula (7), the process comprising at least steps of preparing 4-methyl-5-nonanone and subjecting the obtained 4-methyl-5-nonanone and a reducing agent to a reduction reaction to produce 4-methyl-5-nonanol (7).

Owner:SHIN ETSU CHEM IND CO LTD

Separation of components from a multi-component hydrocarbon stream

ActiveUS9399179B2Efficient and economical processLow costCatalystsHydrocarbon preparation catalystsHigh pressureViscosity

A process (10) to separate a multi-component hydrocarbon stream (26) comprising ethylene, at least one polymer and other components includes flashing the multi-component hydrocarbon stream in a first flash stage (12) from an elevated pressure of more than 30 bar(a) and an elevated temperature in the range of 150° C. to 135° C. to a flash pressure in the range of 10 bar(a) to 30 bar(a), producing a first ethylene-containing vapor overheads product (28) at a pressure in the range of 10 bar(a) to 30 bar(a) and a first flash stage bottoms product (30.1) which includes some ethylene, the at least one polymer and some of the other components. The flash pressure and the elevated temperature of the multi-component hydrocarbon stream (26) are selected such that the first flash stage bottoms product (30.1) has a concentration of the at least one polymer of less than 5% by mass to render the viscosity of the first flash stage bottoms product (30.1) at the temperature of the first flash stage bottoms product (30.1) in the first flash stage (12) at less than 1000 cP at a shear of 1 per second. At least a portion of the first flash stage bottoms product (30.1) is heated to a temperature in excess of 150° C. to form a heated first flash stage bottoms product (30.2). A recycle portion (30.3) of the heated first flash stage bottoms product (30.2) is combined with the multi-component hydrocarbon stream (26), which is at a temperature less than 150° C. before combination with the recycle portion (30.3), thereby to heat the multi-component hydrocarbon stream (26) to the elevated temperature in the range of 150° C. to 185° C. At least a portion (32) of the first flash stage bottoms product and the first ethylene-containing vapor overheads product (28) are withdrawn from the first flash stage (12).

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Processes for preparing 4-methyl-5-nonanone and 4-methyl-5-nonanol

ActiveUS20200199053A1Efficient and economical processHigh yieldLithium organic compoundsOrganic compound preparationHalogenCombinatorial chemistry

The present invention provides a process for preparing 4-methyl-5-nonanone of the following formula (3), the process comprising at least a step of subjecting pentanoic anhydride of the following formula (1) and a 2-pentyl nucleophilic reagent of the following general formula (2), in which M represents Li, MgZ1, or ZnZ1, wherein Z1 represents a halogen atom or a 2-pentyl group, to a nucleophilic substitution reaction to produce 4-methyl-5-nonanone (3), as well as a process for preparing 4-methyl-5-nonanol of the following formula (7), the process comprising at least steps of preparing 4-methyl-5-nonanone and subjecting the obtained 4-methyl-5-nonanone and a reducing agent to a reduction reaction to produce 4-methyl-5-nonanol (7).

Owner:SHIN ETSU CHEM IND CO LTD

Processes for preparing 4-methyl-5-nonanone and 4-methyl-5-nonanol

ActiveUS10882805B2Efficient and economical processHigh yieldOrganic compound preparationOrganic chemistry methodsHalogenCombinatorial chemistry

The present invention provides a process for preparing 4-methyl-5-nonanone of the following formula (3): the process comprising at least a step of subjecting 2-methylpentanoic anhydride of the following formula (1) and an n-butyl nucleophilic reagent of the following general formula (2) in which M represents Li, MgZ1, or ZnZ1, wherein Z1 represents a halogen atom or an n-butyl group, to a nucleophilic substitution. reaction Coproduce 4-methyl-5-nonanone (3), as well as a process for preparing 4-methyl-5-nonanol of the following formula (5), the process comprising at least steps of preparing 4-methyl-5-nonanone; and subjecting the obtained 4-methyl-5-nonanone and a reducing agent to a reduction reaction to produce 4-methyl-5-nonanol (5).

Owner:SHIN ETSU CHEM IND CO LTD

Gallic acid derivative and process of preparing the same

InactiveUS7135590B2Efficient and economical processHigh activityBiocideOrganic compound preparationGrowth plantGallic acid ester

This invention provides a plant growth regulatory activity of a new biologically active synthetic molecule methanone-(3′,4′,5′-trimethoxy) phenyl, 1-naphthyl, 2-O-4″-ethyl but-2″-enoate. More particularly, the invention relates to the potent plant growth promoting activity of a gallic acid derivative having a structure represented by Formula 1 and a molecular formulae C26H26O7. This invention also provides a novel process for preparation of said molecule from a naturally occurring compound and testing it for growth regulating activity using Bacopa test system developed at CIMAP (Khanuja et al., 2001)

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com