Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Effectively “vaporized”" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

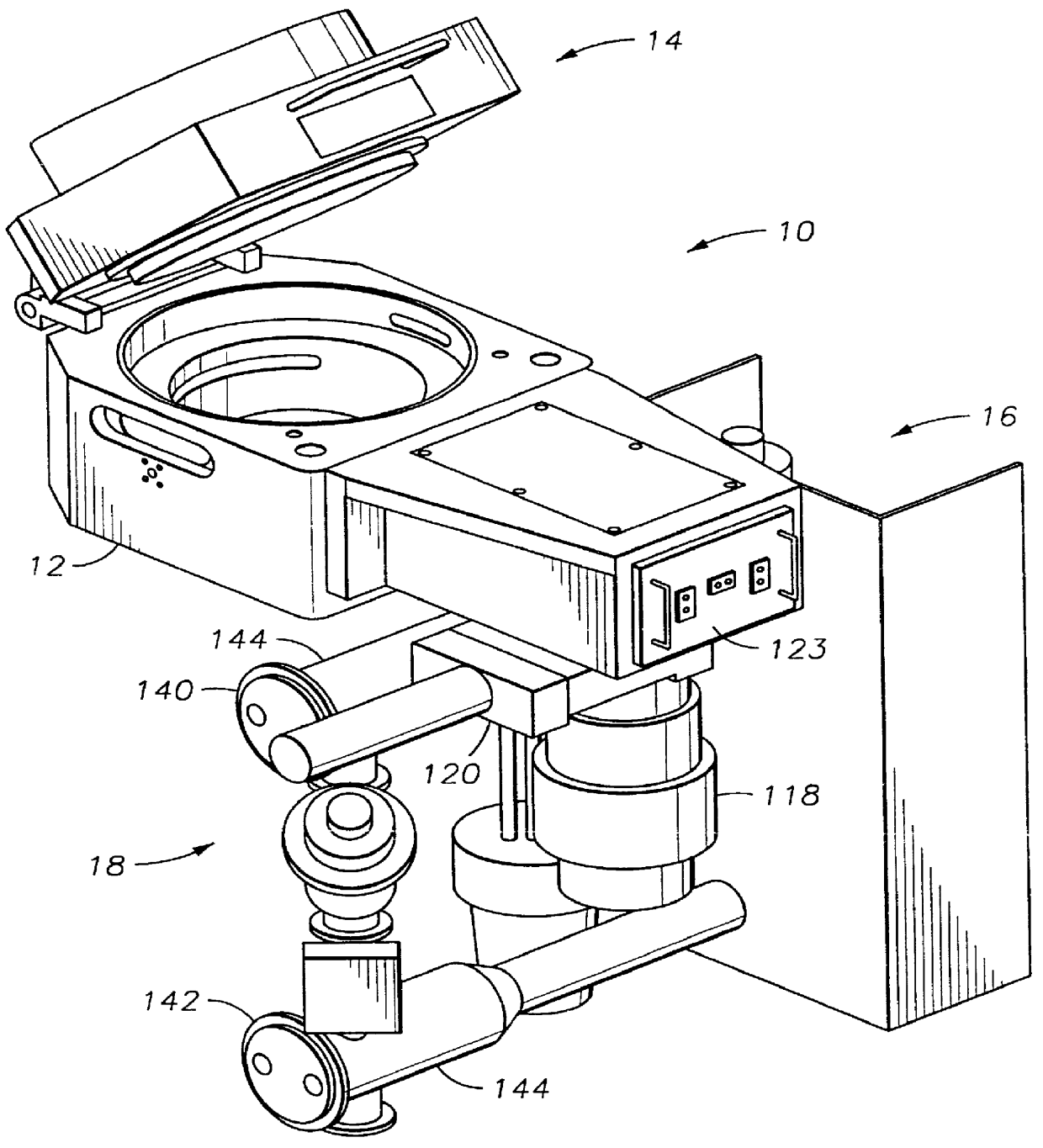

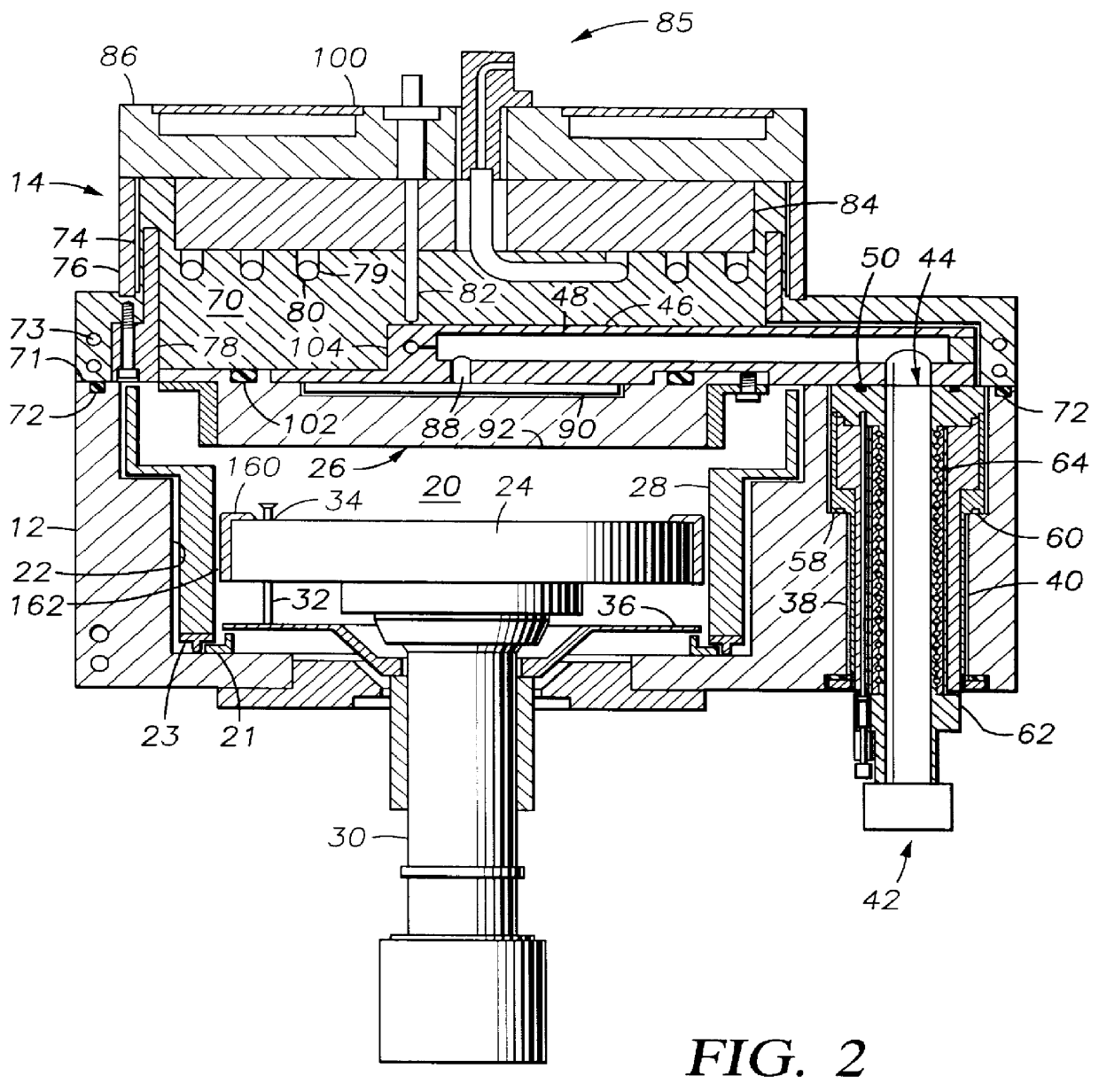

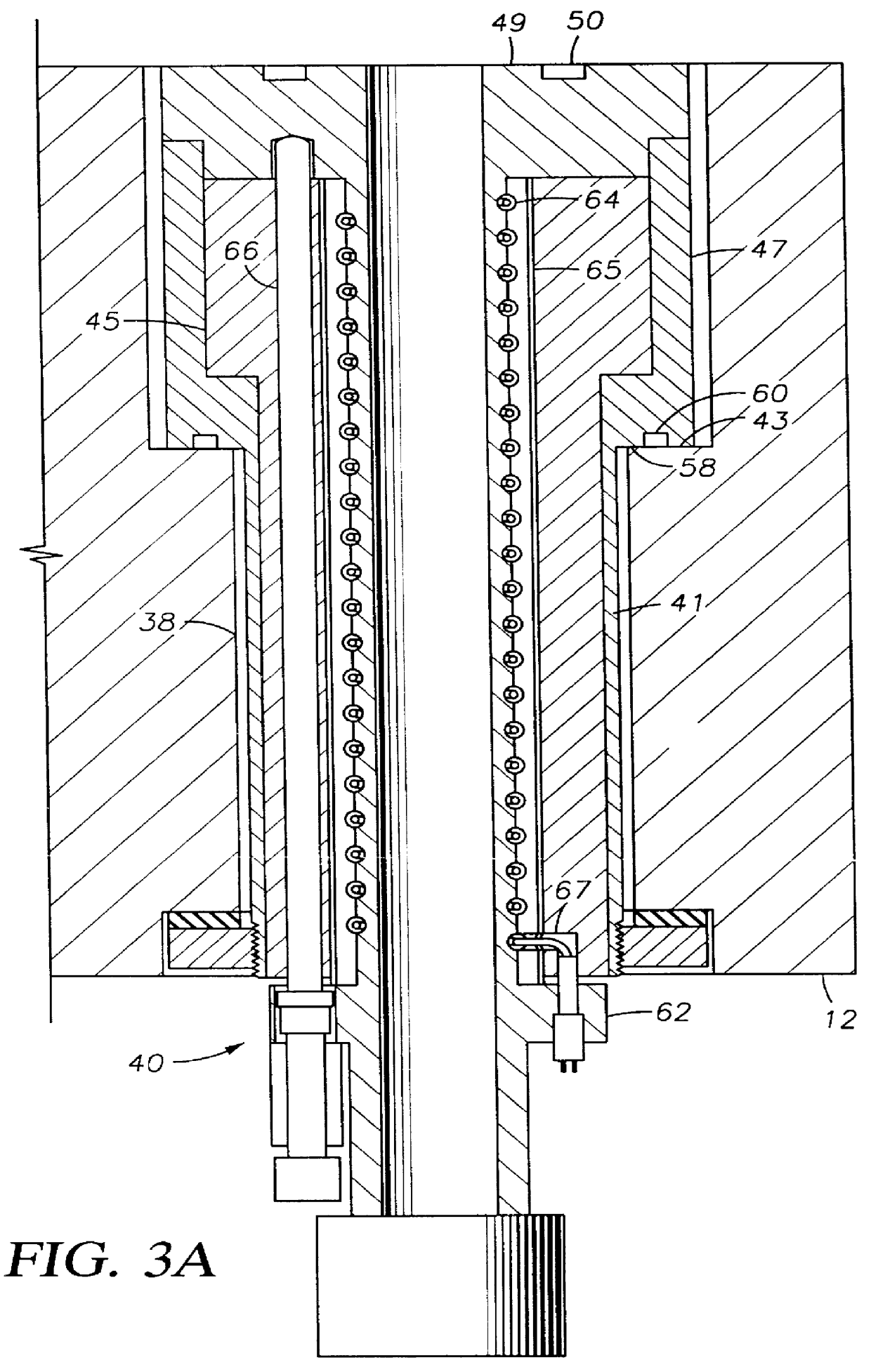

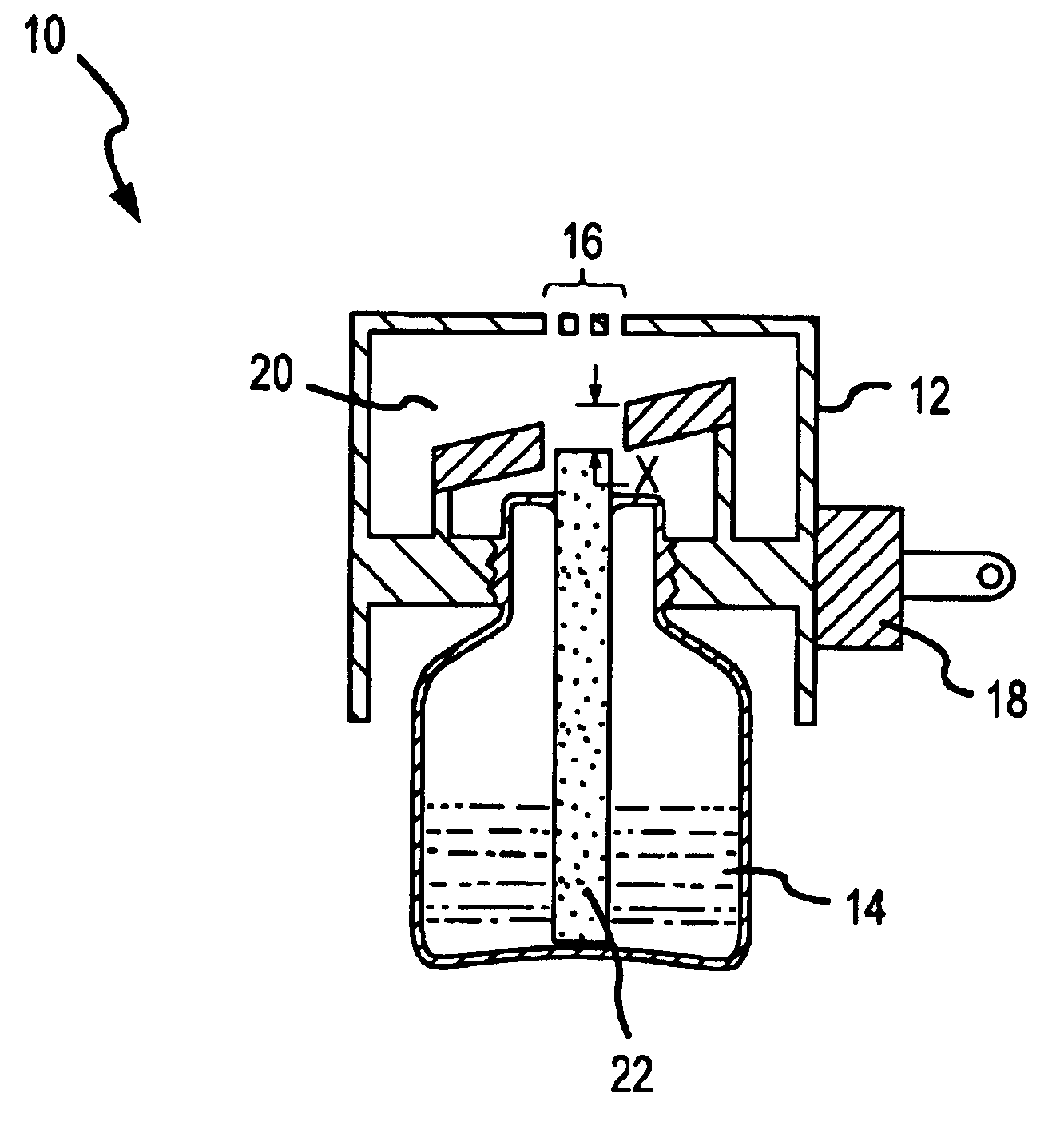

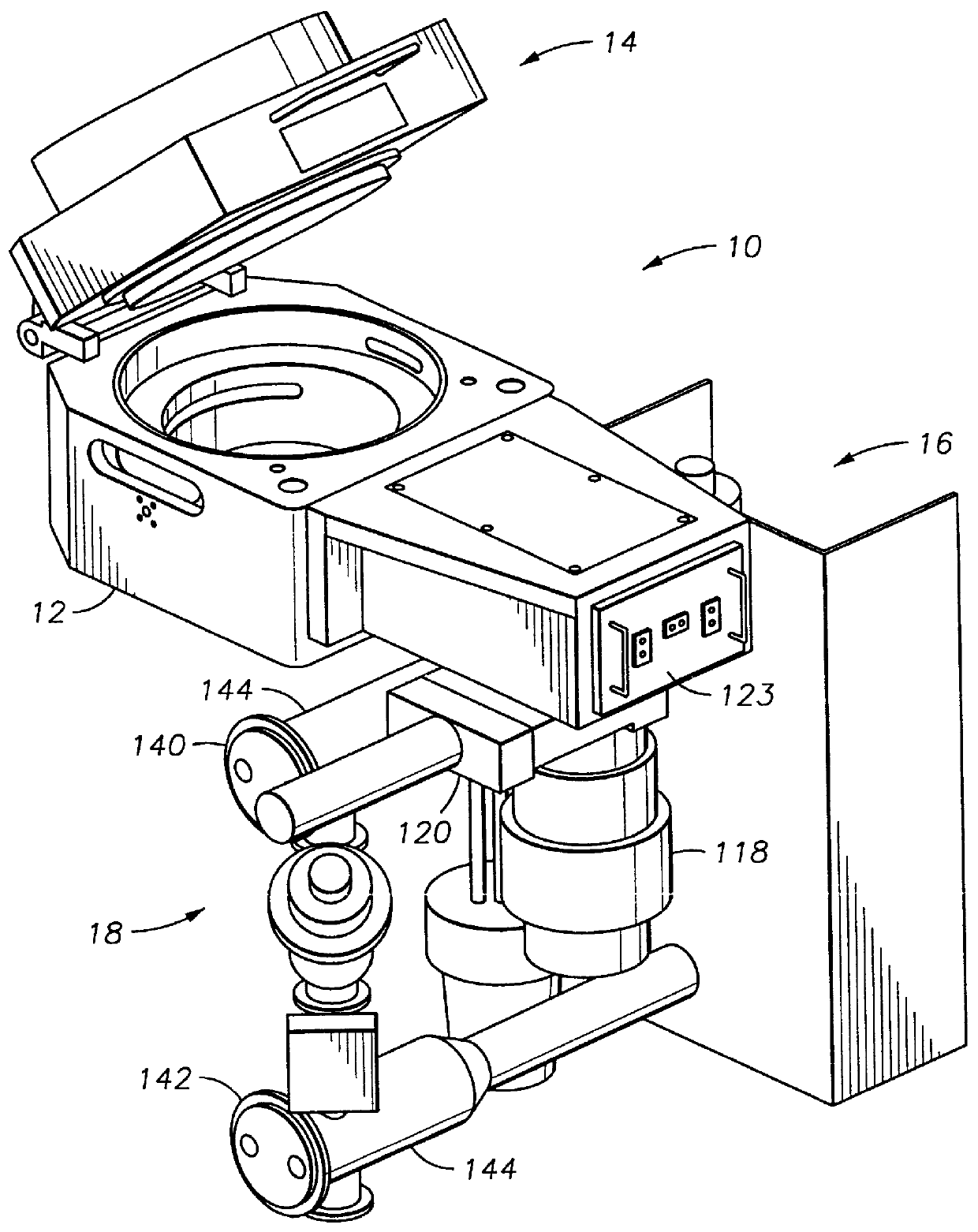

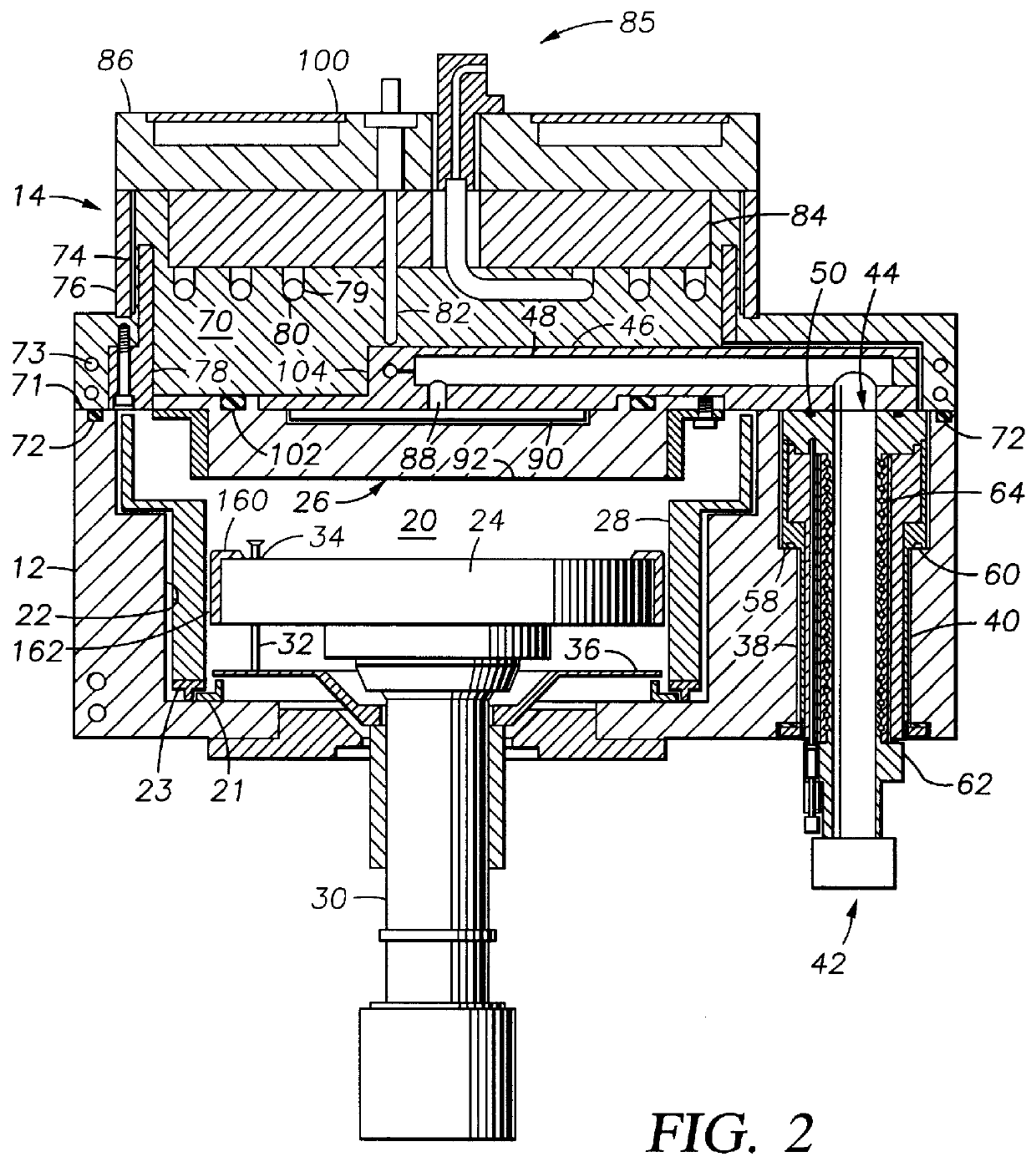

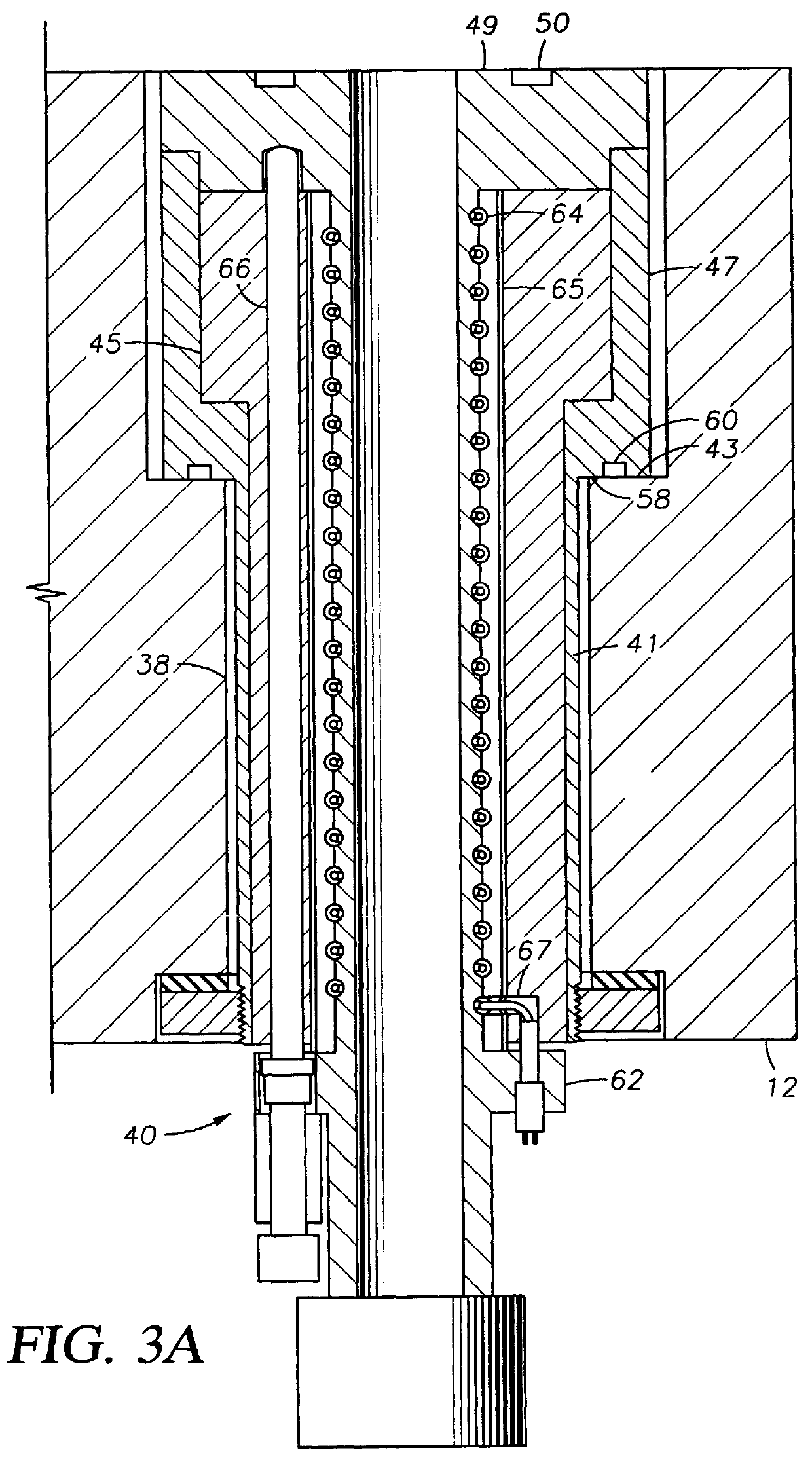

Temperature controlled chamber liner

InactiveUS6099651APrevent unwanted condensationPrevent decomposition and condensationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringTitanium oxide

The invention relates to an apparatus and process for the vaporization of liquid precursors and deposition of a film on a suitable substrate. Particularly contemplated is an apparatus and process for the deposition of a metal-oxide film, such as a barium, strontium, titanium oxide (BST) film, on a silicon wafer to make integrated circuit capacitors useful in high capacity dynamic memory modules.

Owner:APPLIED MATERIALS INC

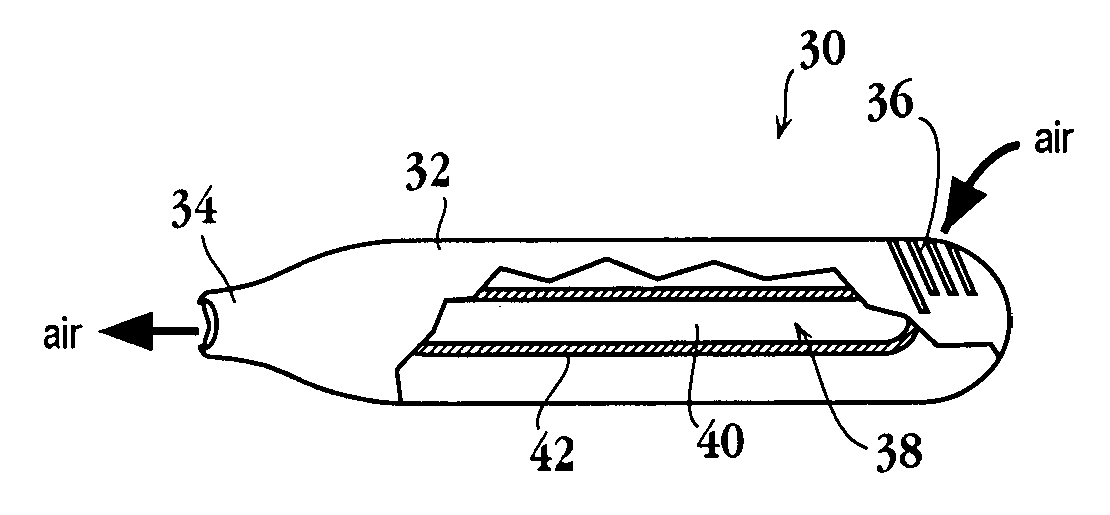

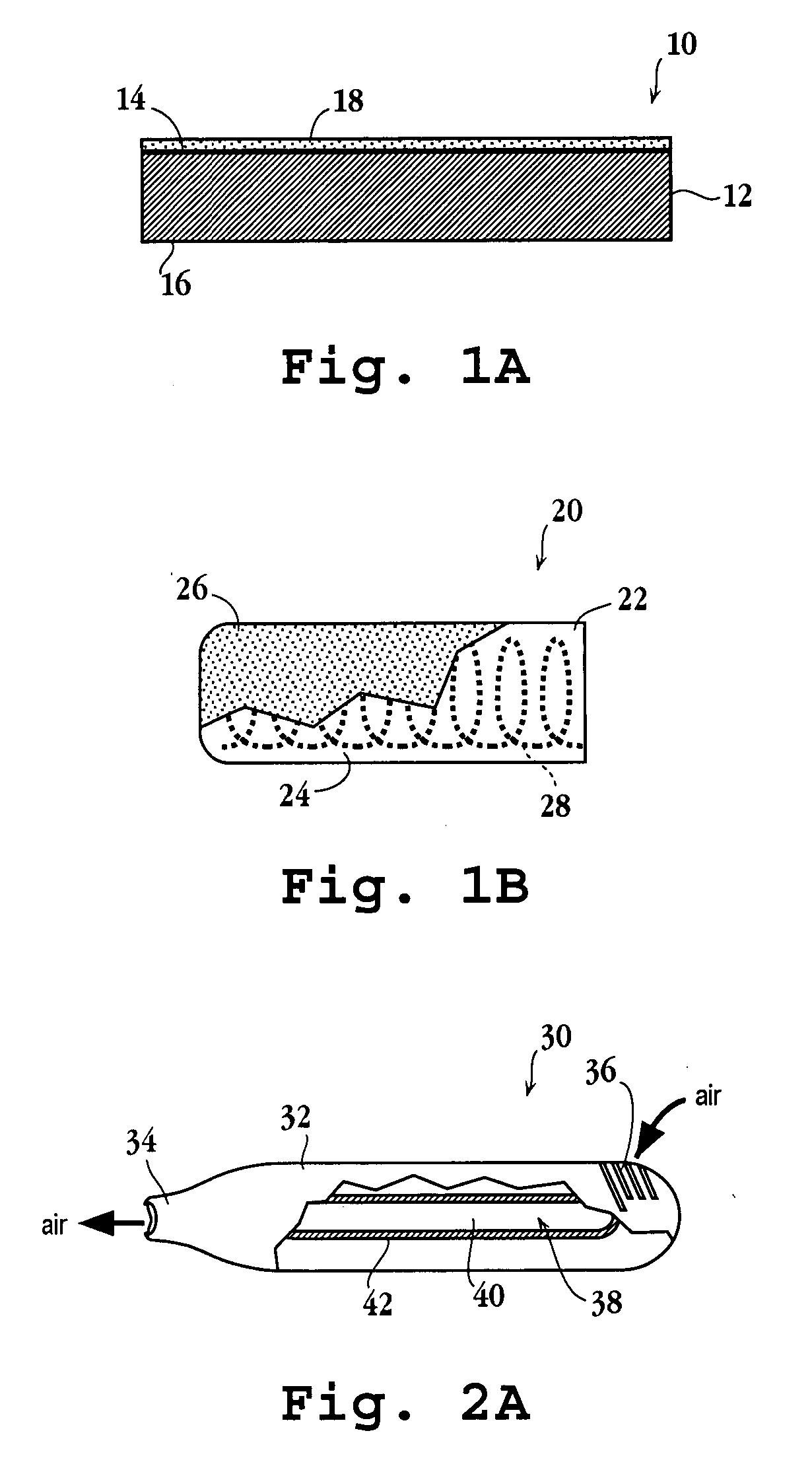

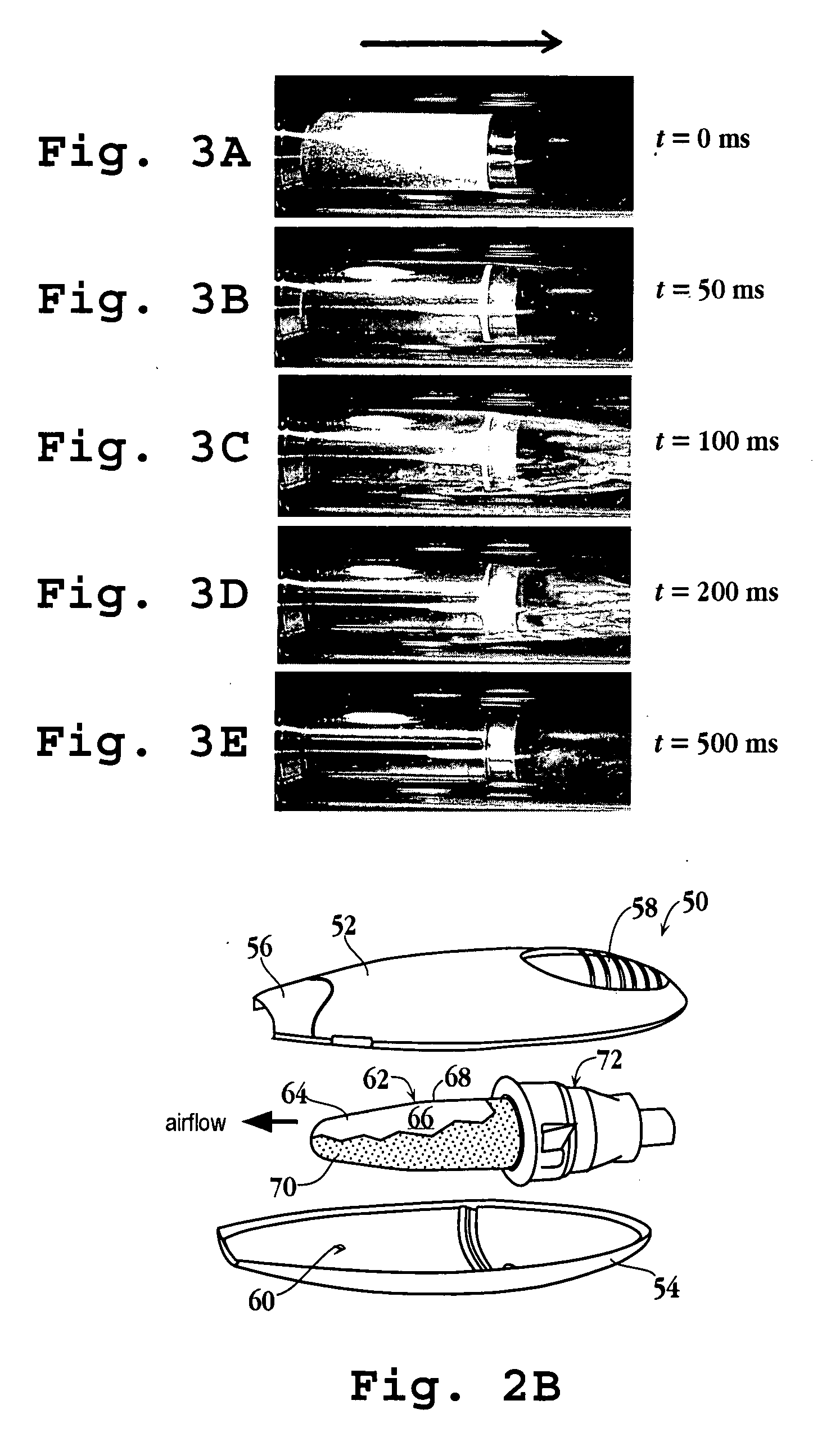

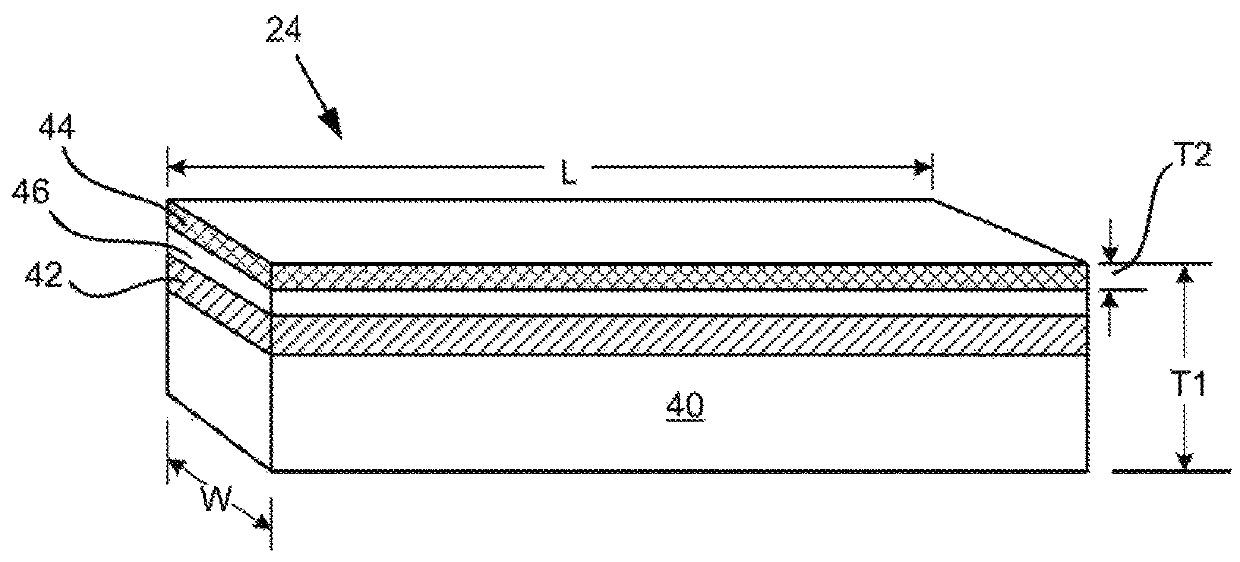

Thin-film drug delivery article and method of use

InactiveUS20070031340A1Reduce the amount requiredFast evaporationRespiratorsPowder deliveryDrug aerosolMedicine

An article for use in an aerosol device, for producing an aerosol of a drug composition is disclosed. The article includes a heat-conductive substrate having a surface with a selected surface area, and a drug composition film on the substrate surface having a selected film thickness of between 0.05 and 20 μm. The film thickness is such that an aerosol formed by vaporizing the drug composition by heating the substrate and condensing the vaporized compound contains 10% or less drug-degradation product and at least 50% of the total amount of drug composition contained in the film. The selected substrate surface area is such as to yield an effective human therapeutic dose of the drug aerosol. Also disclosed are methods of making and using the article.

Owner:ALEXZA PHARMA INC

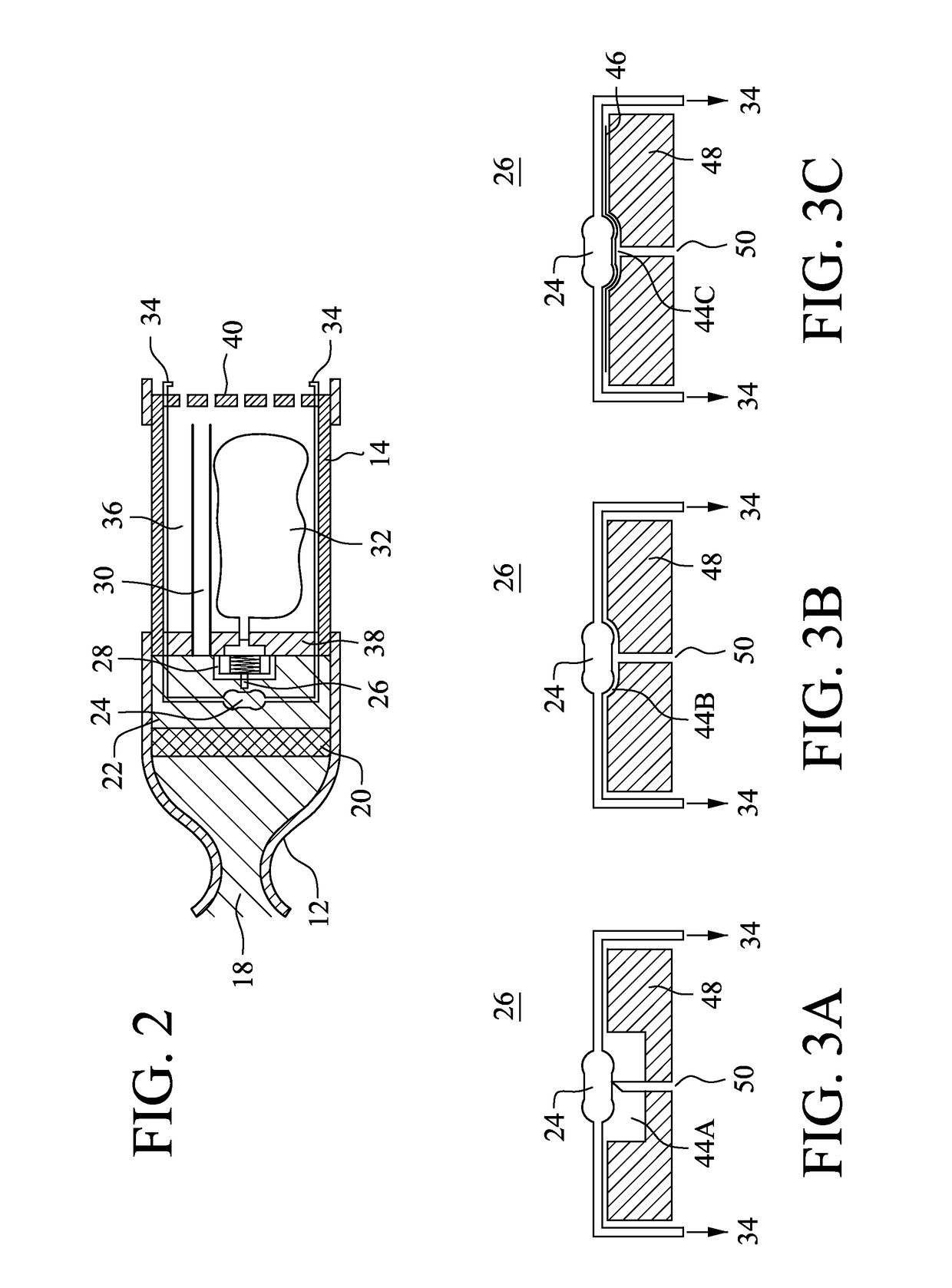

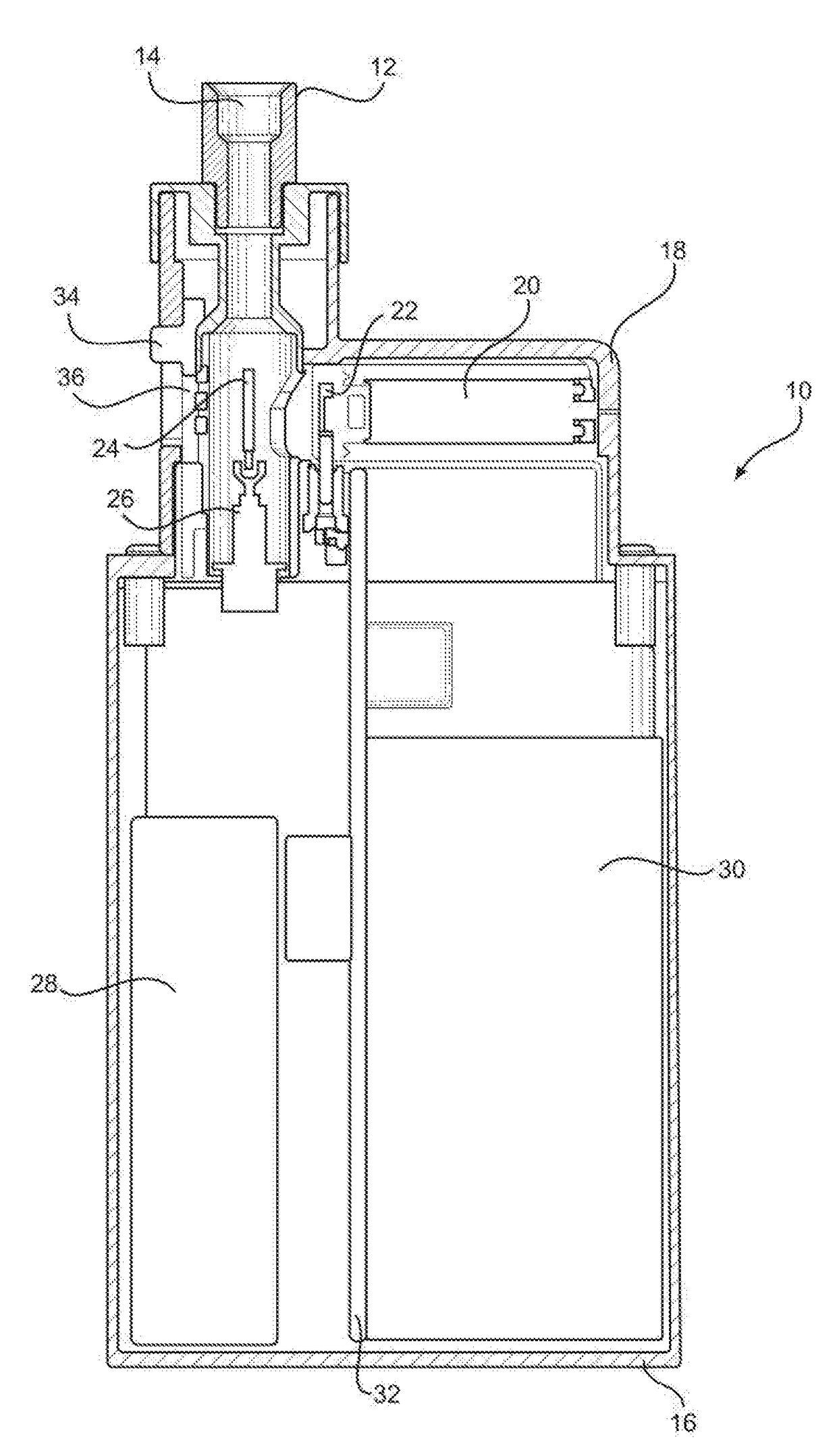

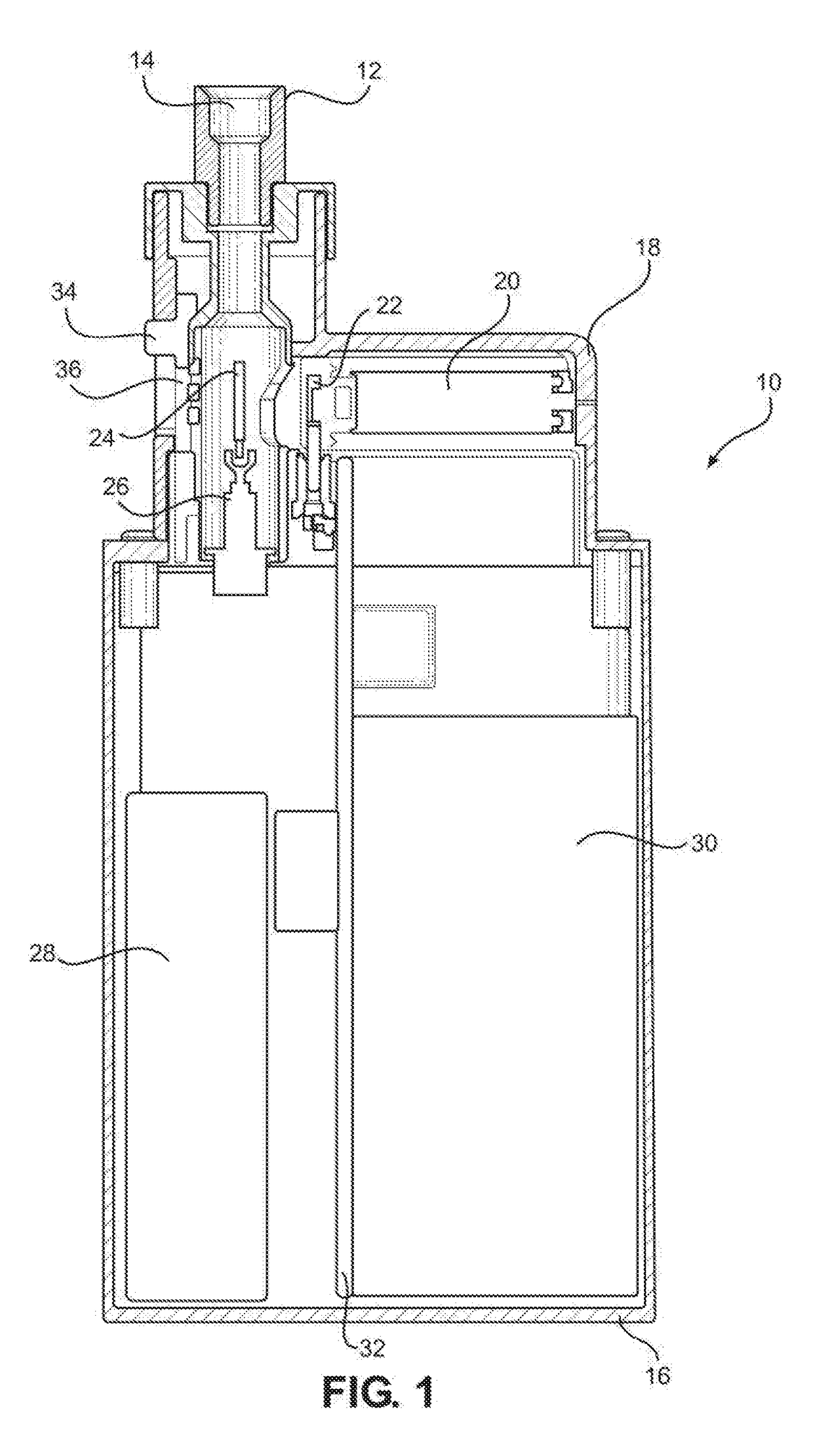

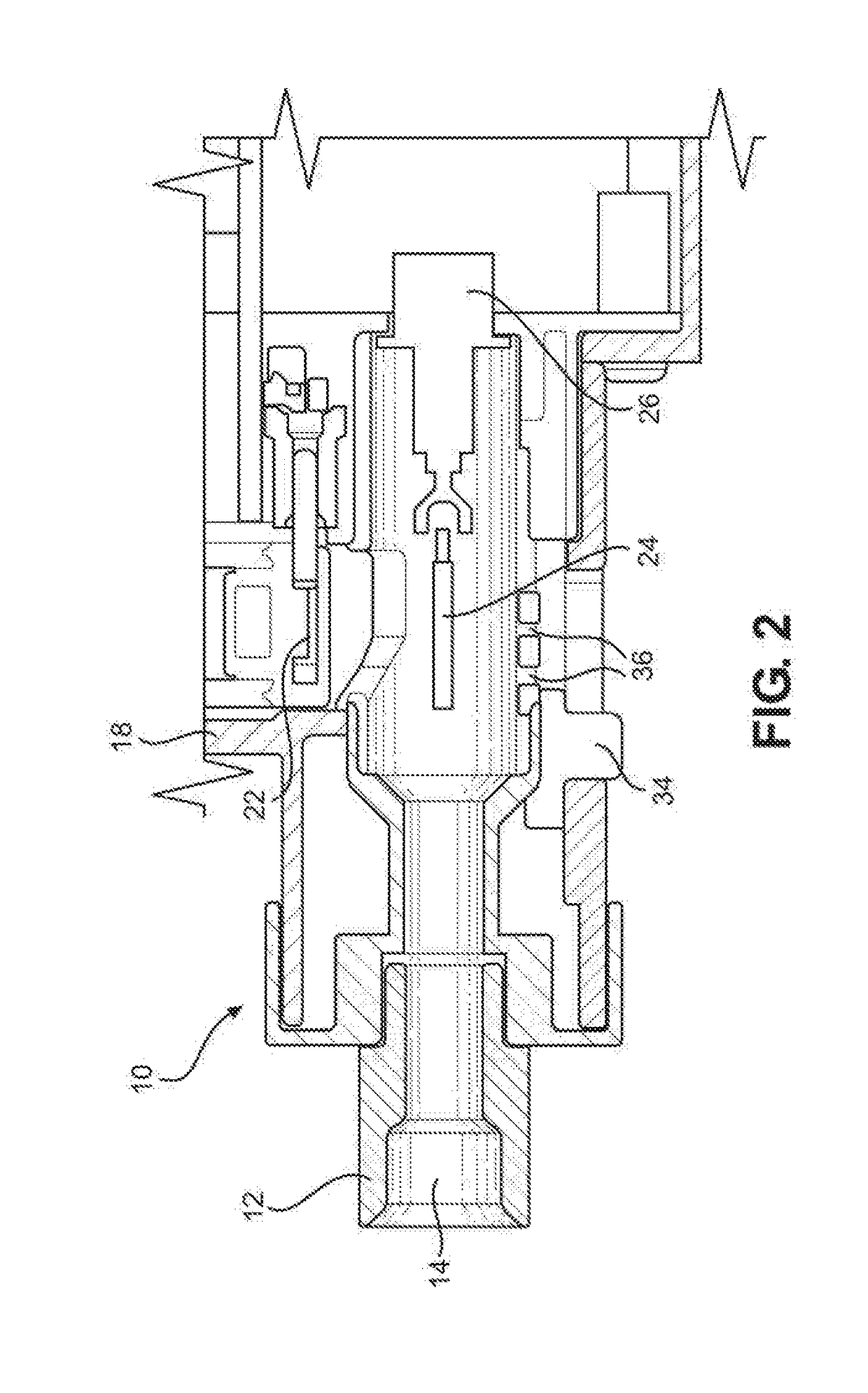

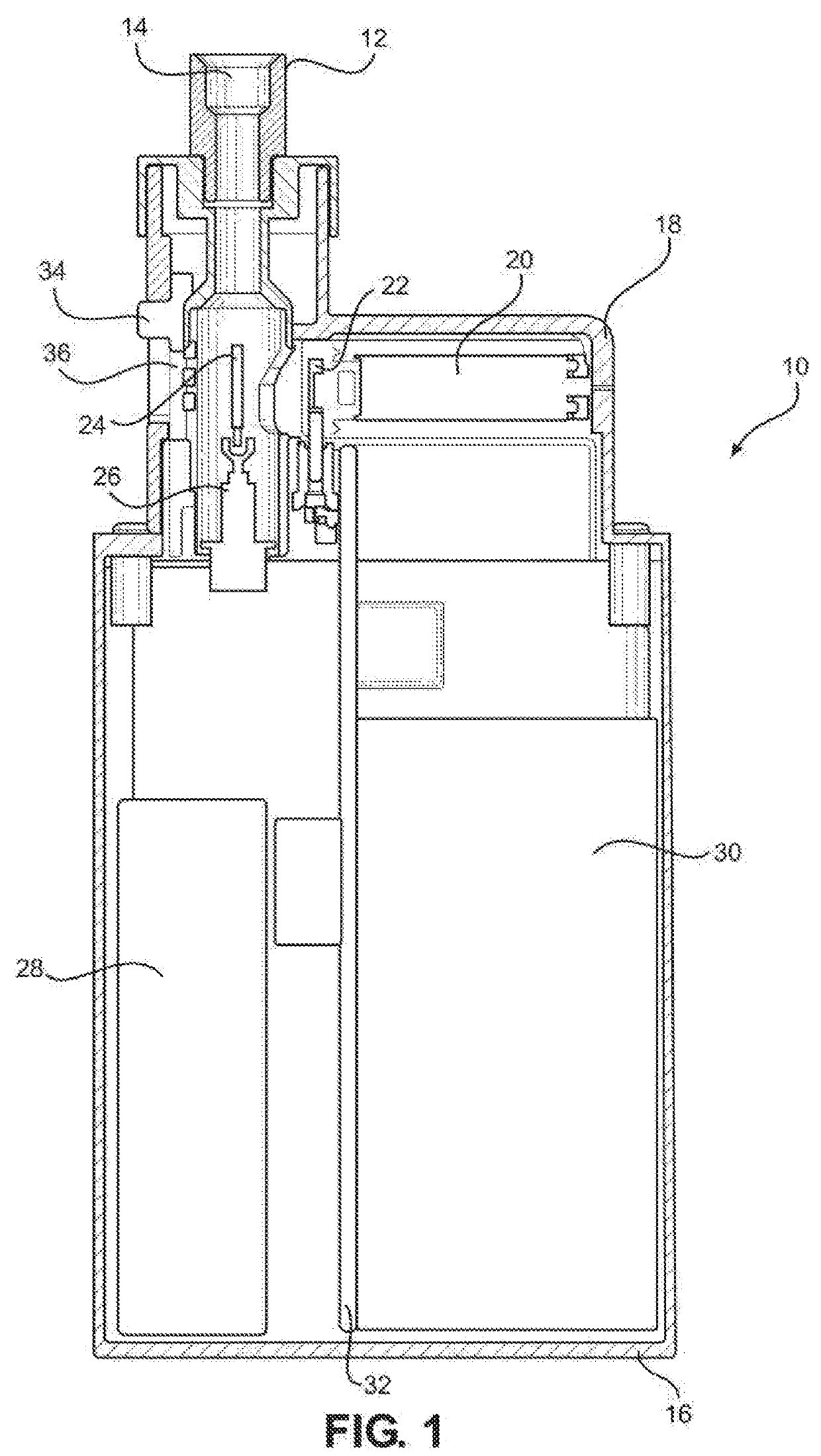

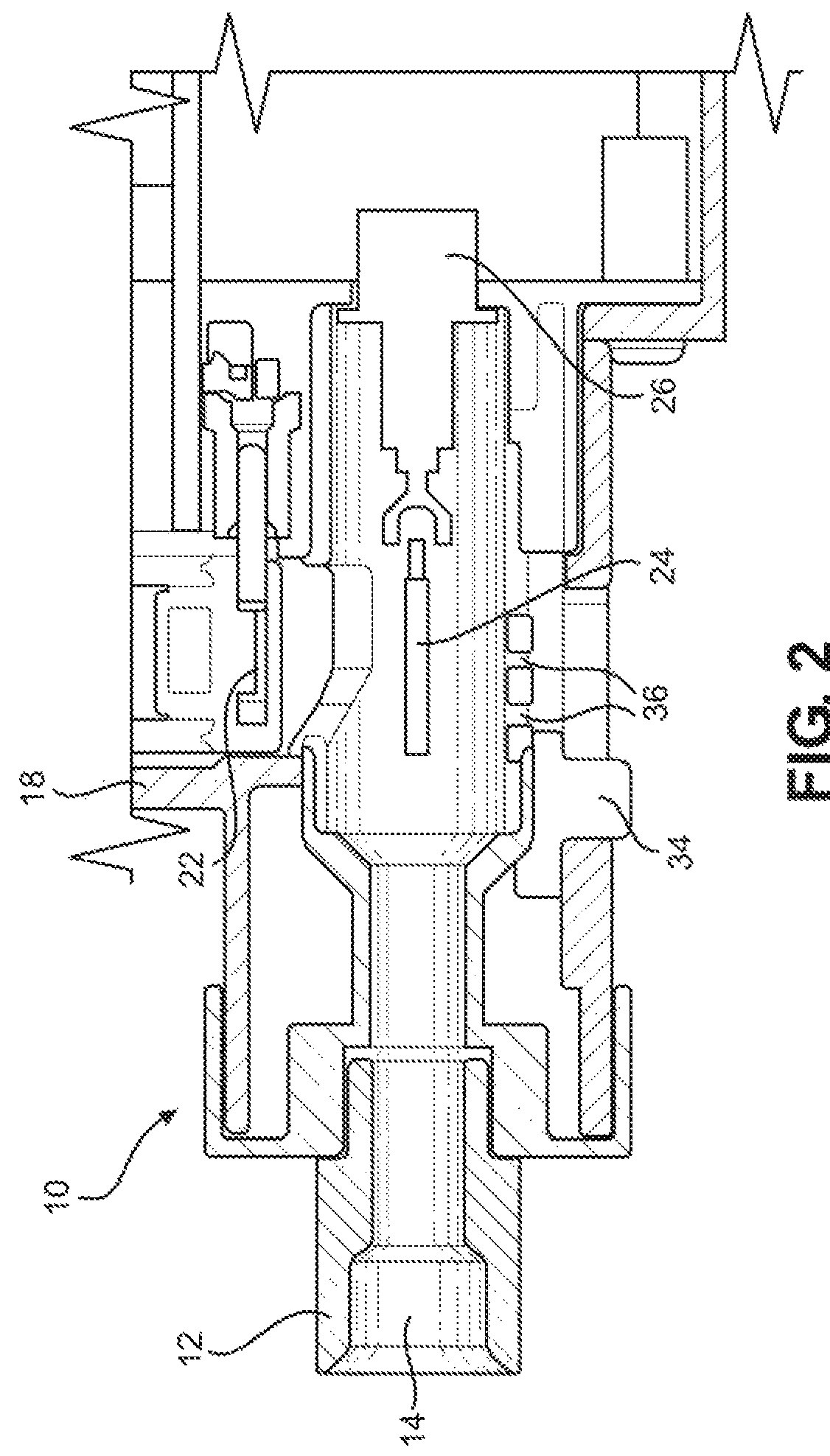

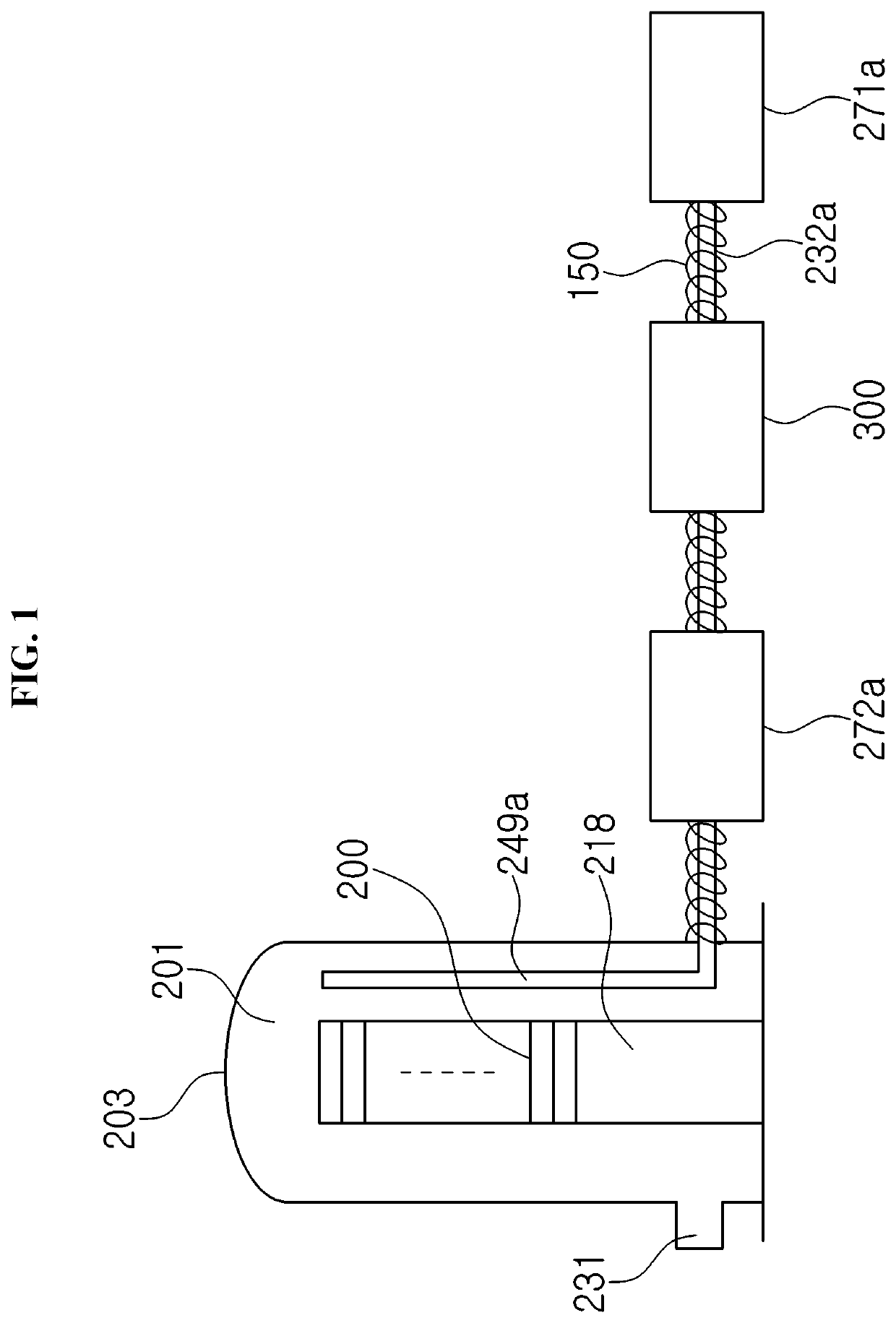

Personal vaporizer with liquid supply by suction

ActiveUS9642397B2Effectively “vaporized”Increase temperatureSteam generation heating methodsElectric heatingSuction forceEngineering

A personal vaporizer including a pressure-induced liquid transport device that allows a user to draw liquid from a liquid reservoir through applying a suction force on the mouthpiece. The amount of liquid drawn is proportional to the pressure induced, and proportional to the amount of vaporization a user may desired.

Owner:WESTFIELD GROUP

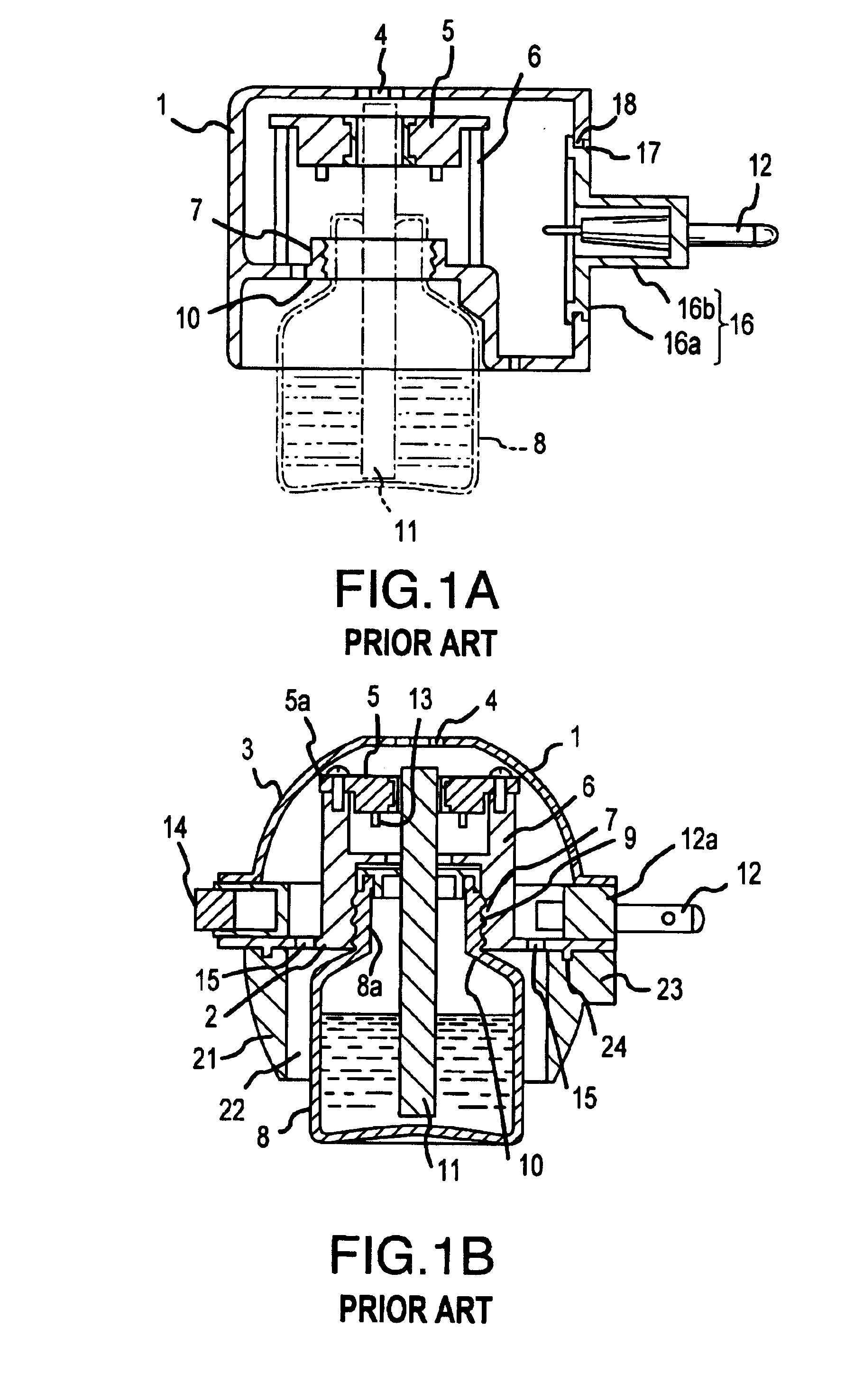

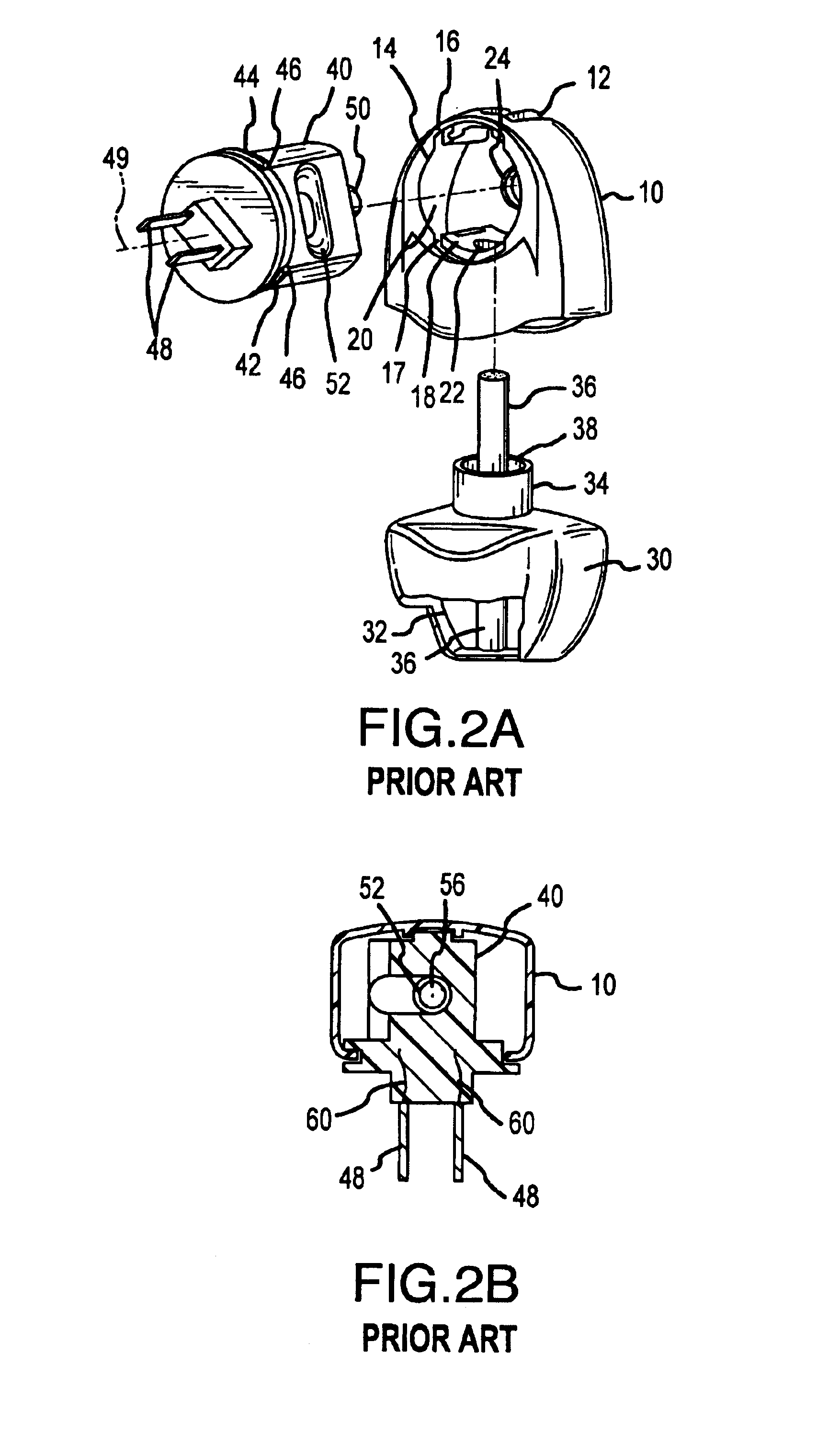

Method and apparatus for positioning a wick material in a vapor-dispensing device

InactiveUS6889003B2Facilitates effective fragrance vapor deliveryEfficient deliveryRespiratorsLighting and heating apparatusEvaporationBiomedical engineering

The present invention achieves advancement in the art by providing a method and apparatus for selective positioning of a wick material in a vapor-dispensing device that facilitates effective fragrance vapor delivery while offering significant advantages in manufacture, assembly, product performance, and product safety. In one embodiment, the wick is suitably selected and positioned such that sufficient surface area of the wick material is suitably exposed to the heating unit to enable effective evaporation of a vaporizable liquid, but the wick height relative to the heating element minimizes the amount of surface area of the wick in proximity to the heating element. Additionally, the positioning can reduce the need for protective overcaps and other apparatus for protecting the wick.

Owner:HENKEL KGAA

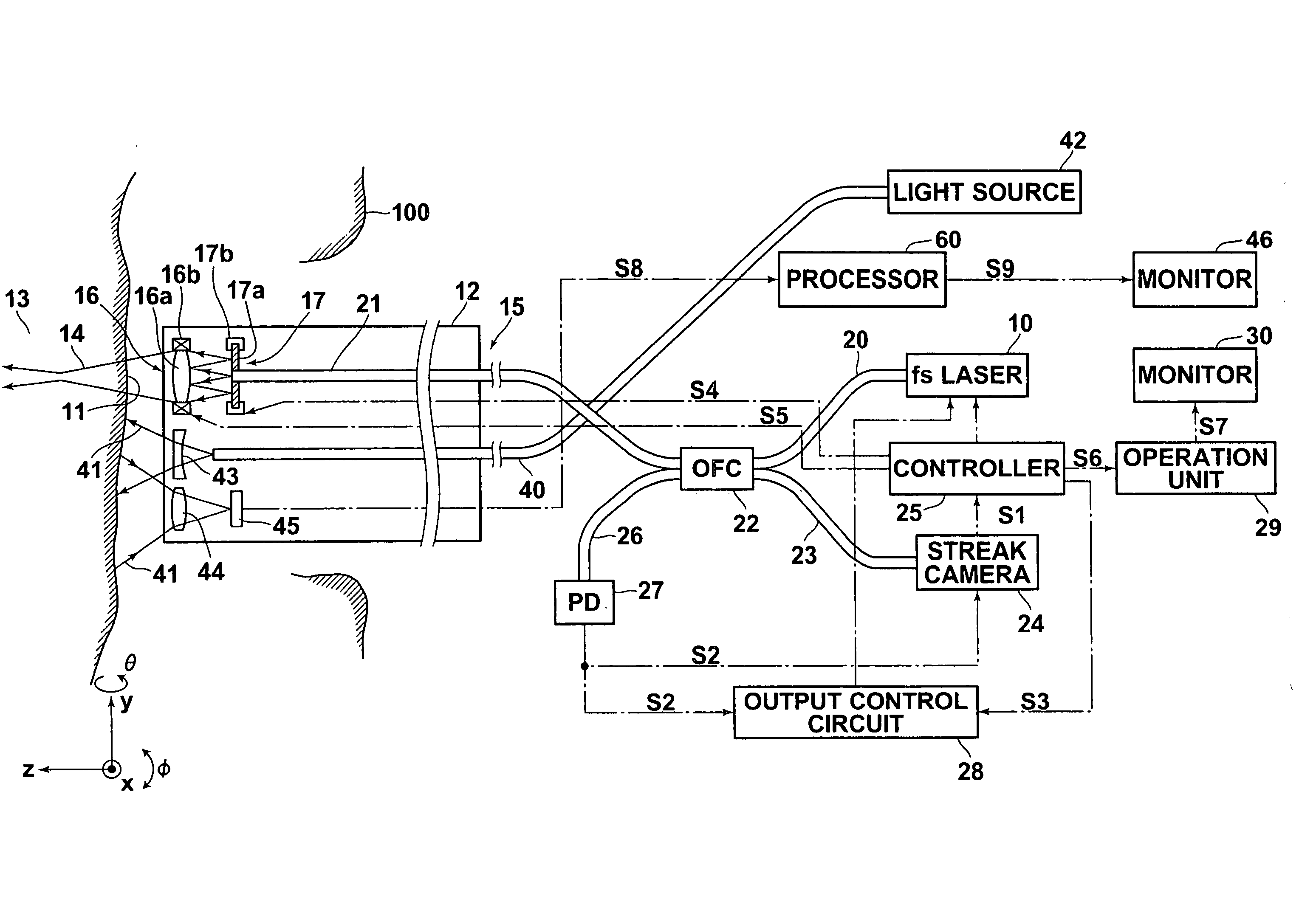

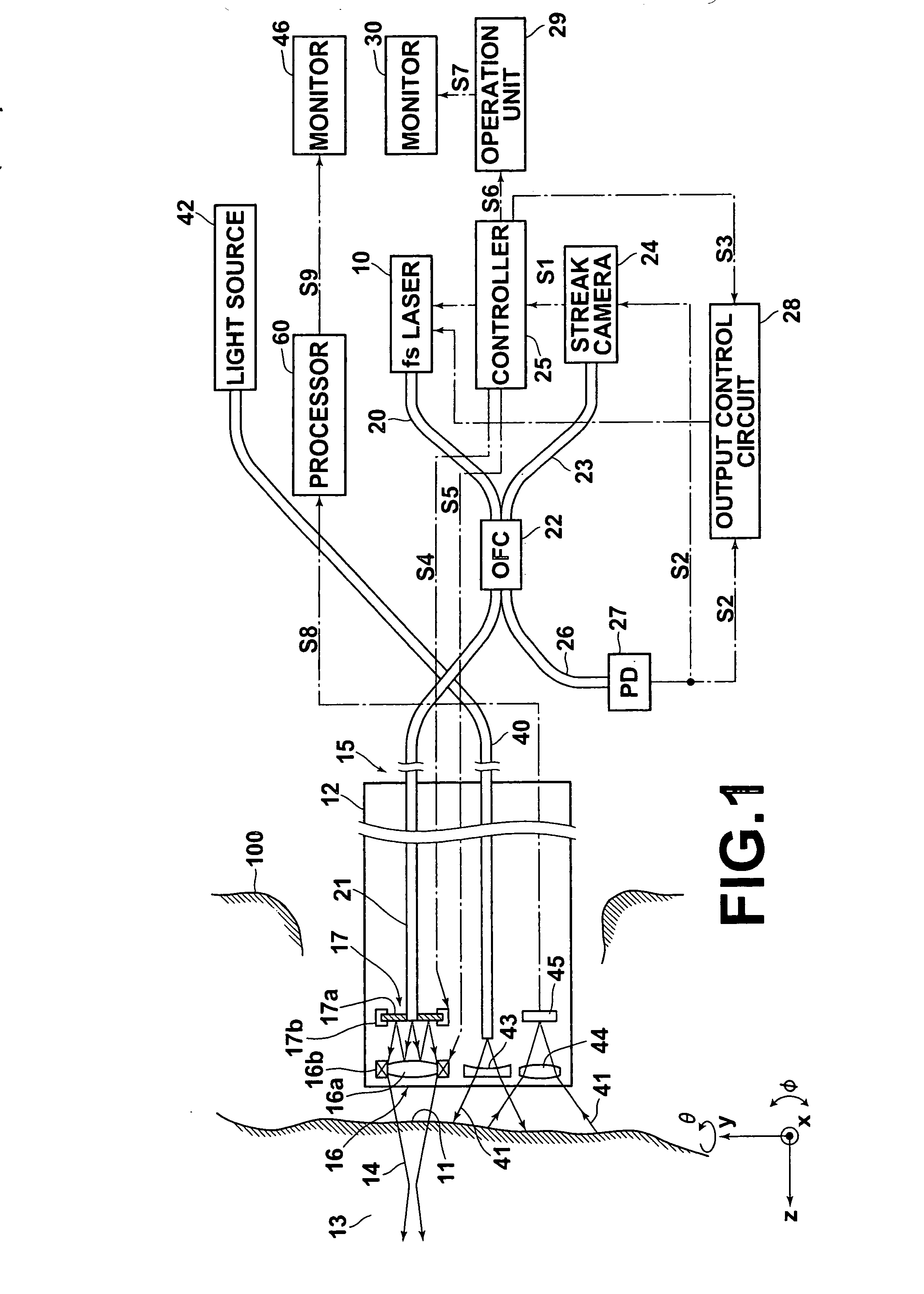

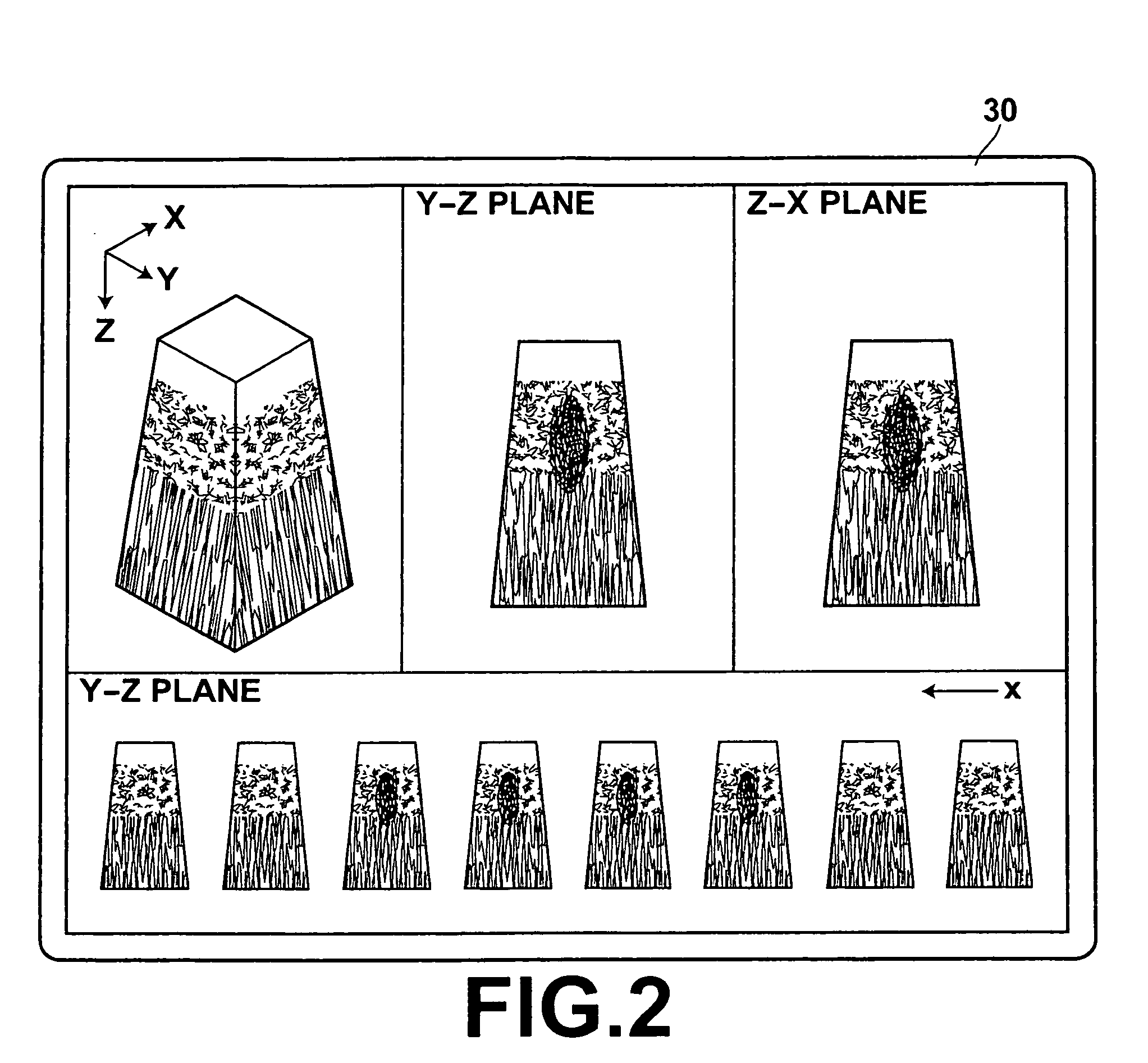

Optical diagnosis and treatment apparatus

InactiveUS20070027391A1Short pulse widthHigh temporal resolution light detectionCatheterSurgical instrument detailsTherapeutic DevicesTomographic image

An optical diagnosis and treatment apparatus includes a pulsed light source, an illumination optical system for illuminating a region of a living body through a guide tube, a light condensing means for condensing pulsed light, an optical scan means for two-dimensionally scanning the region, a light detection means for detecting the pulsed light reflected from the region, an operation means for reconstructing, based on an output from the light detection means, a tomographic image of the region, an image display means for displaying the tomographic image based on an output from the operation means and a light intensity switching means for switching the intensity of the pulsed light at least between two levels. The two levels are a level at which vaporization of living body tissue due to multi-photon absorption occurs at a convergence position of the pulsed light and a level at which vaporization does not occur.

Owner:FUJI PHOTO OPTICAL CO LTD

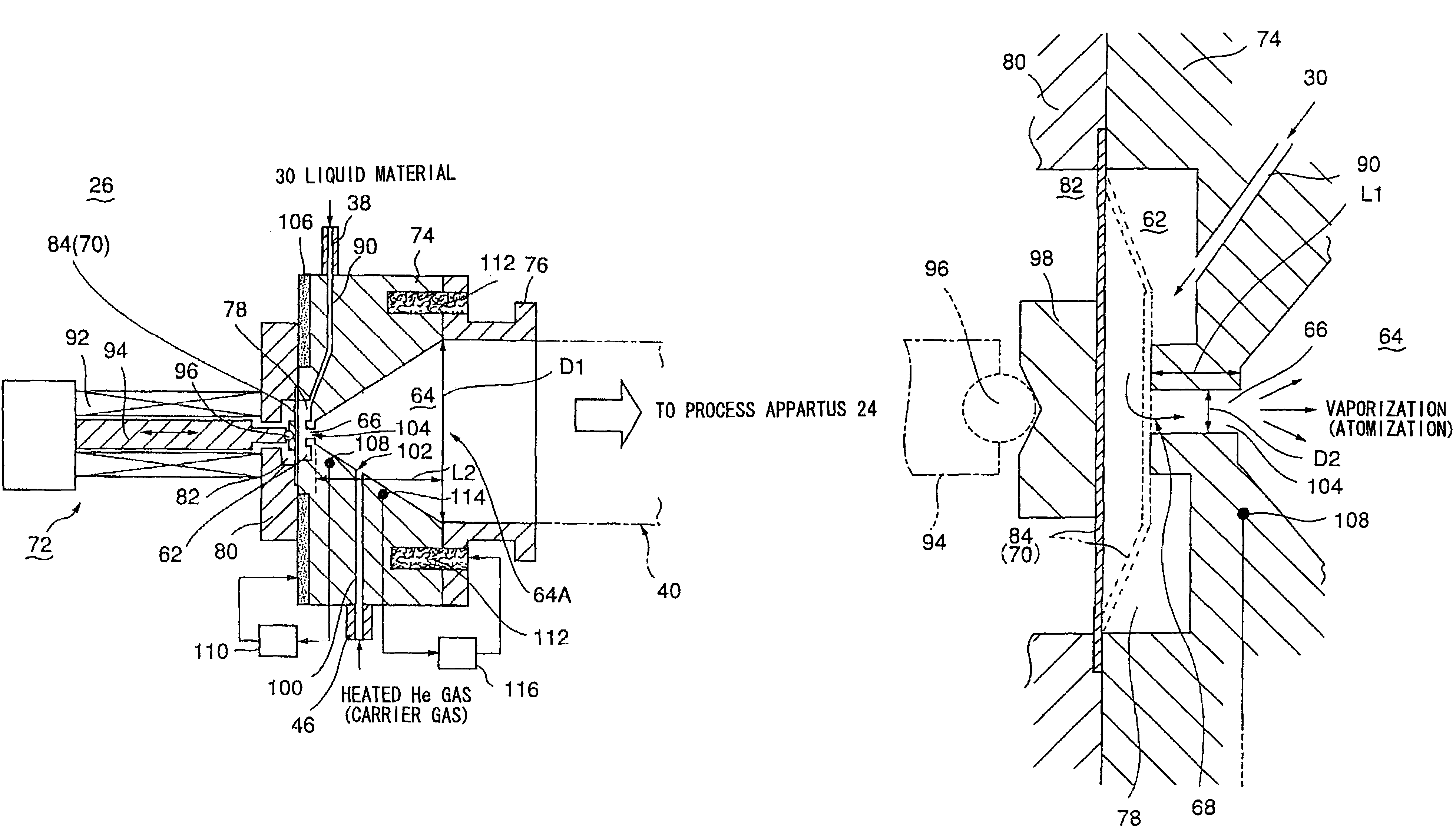

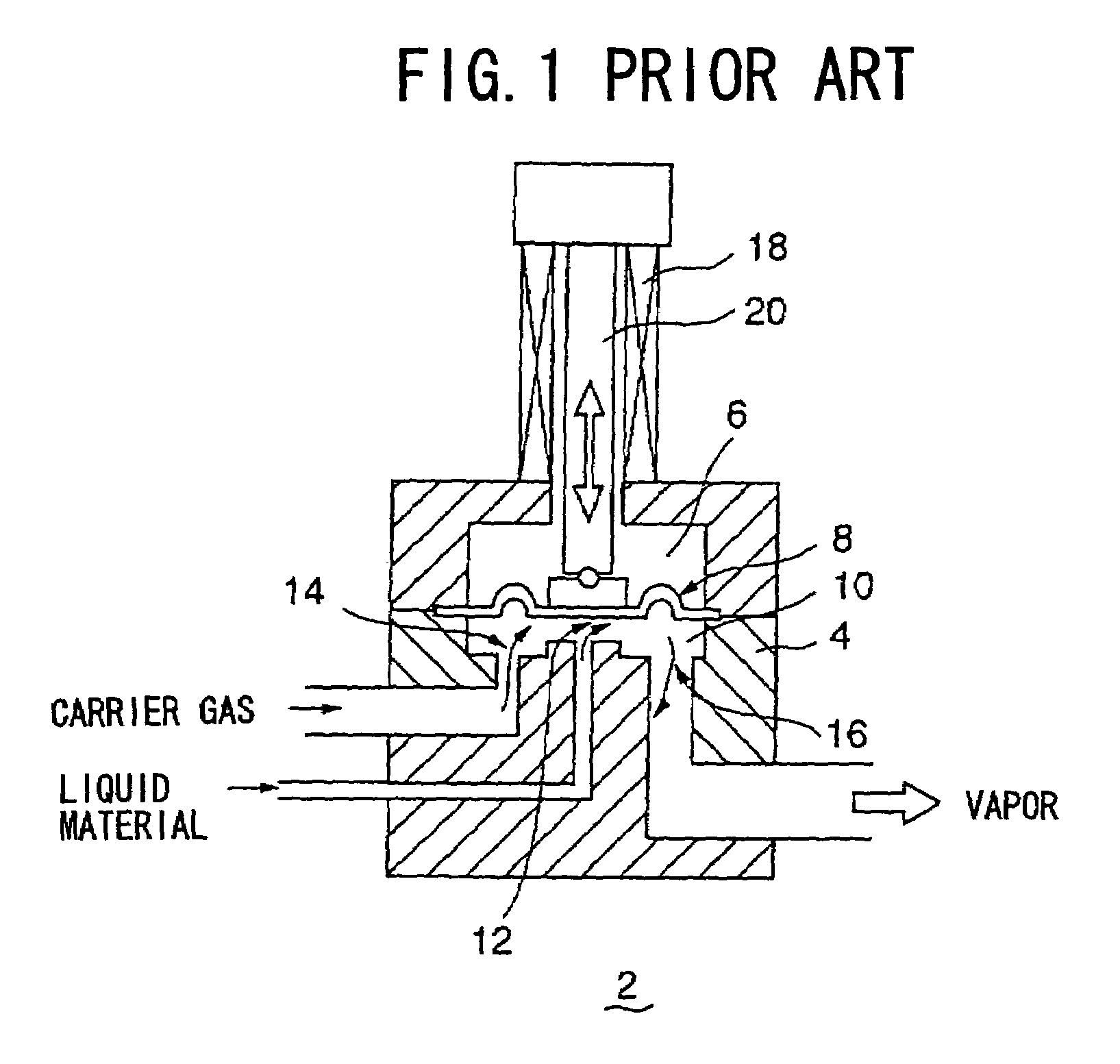

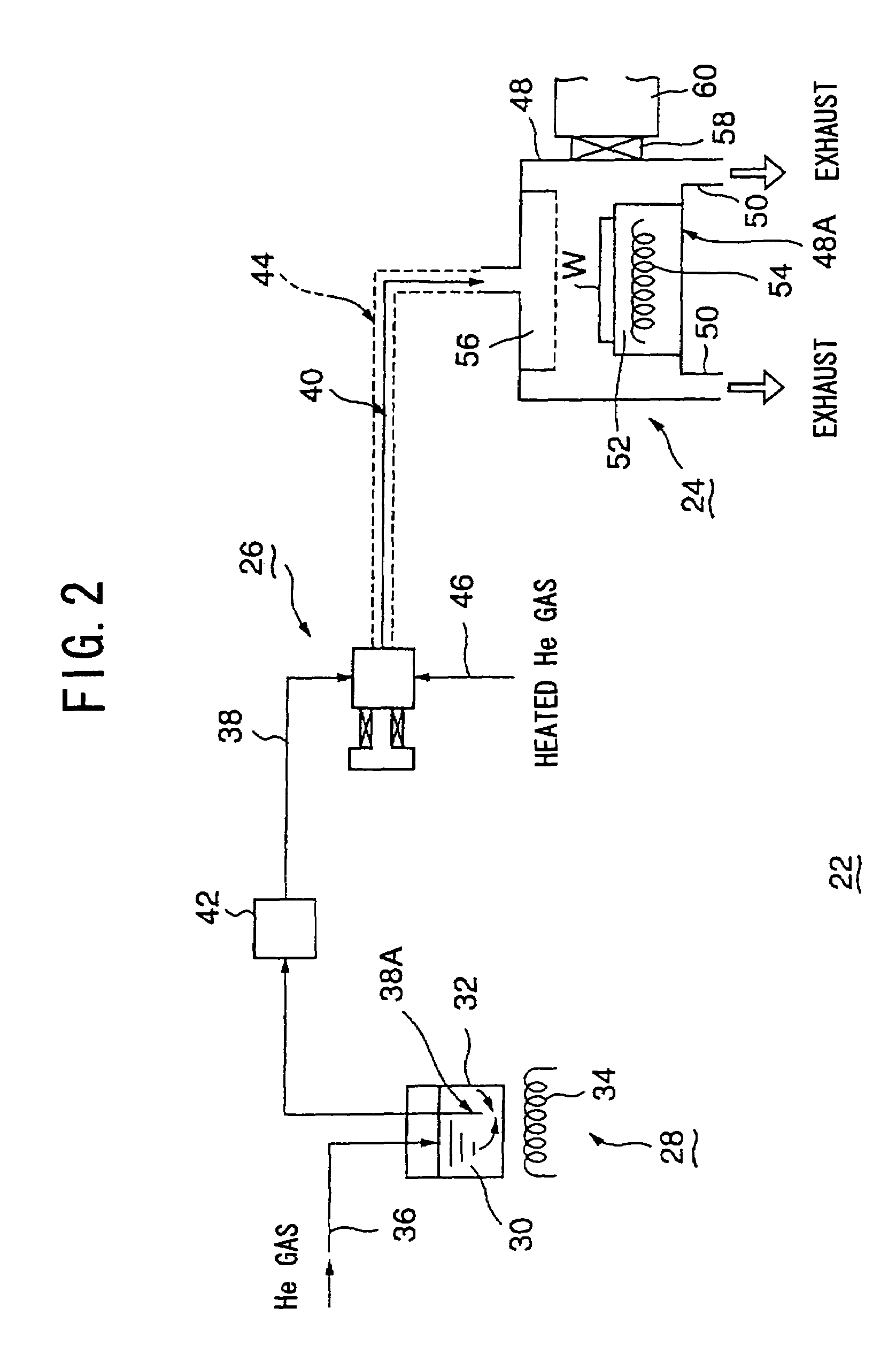

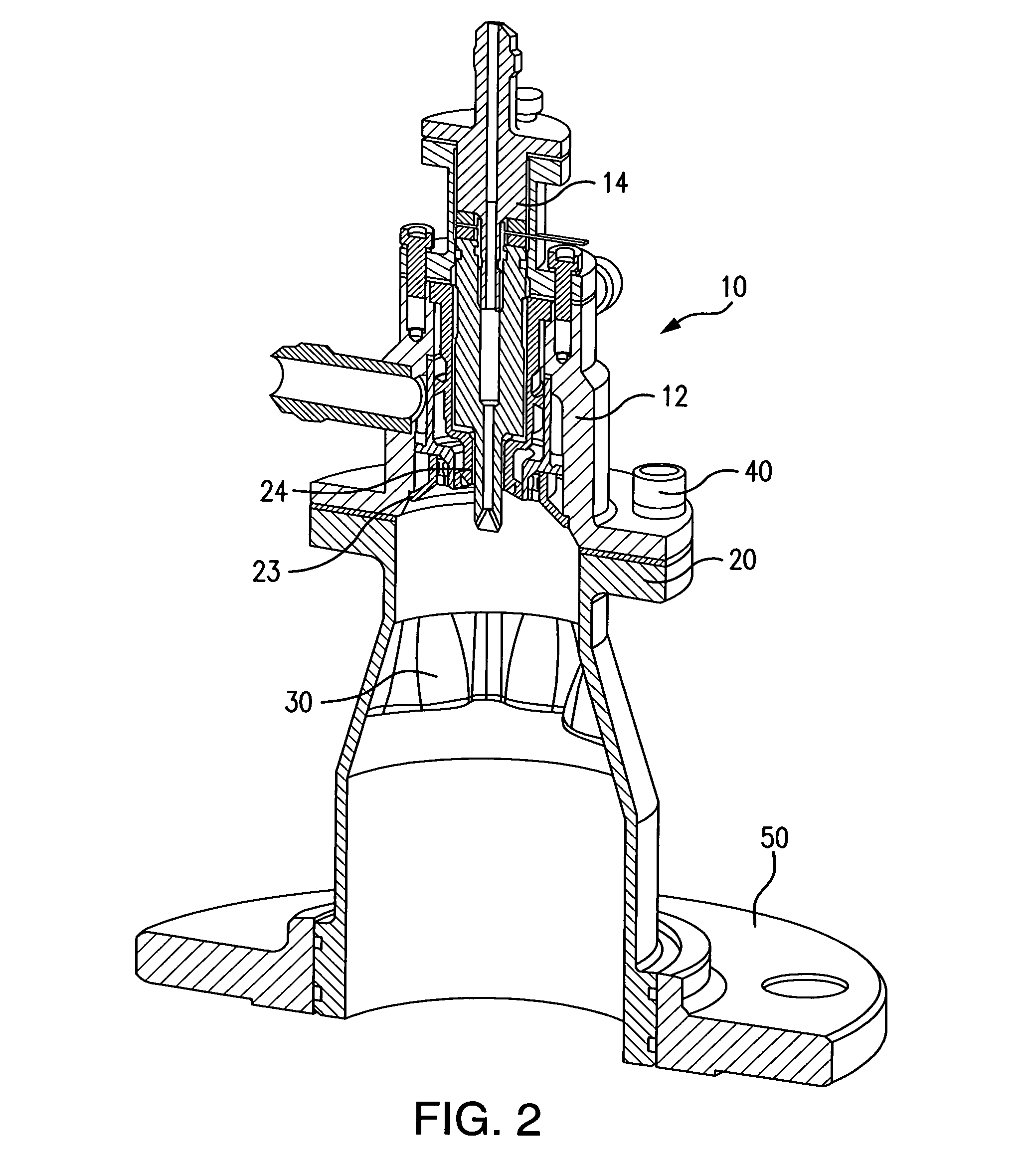

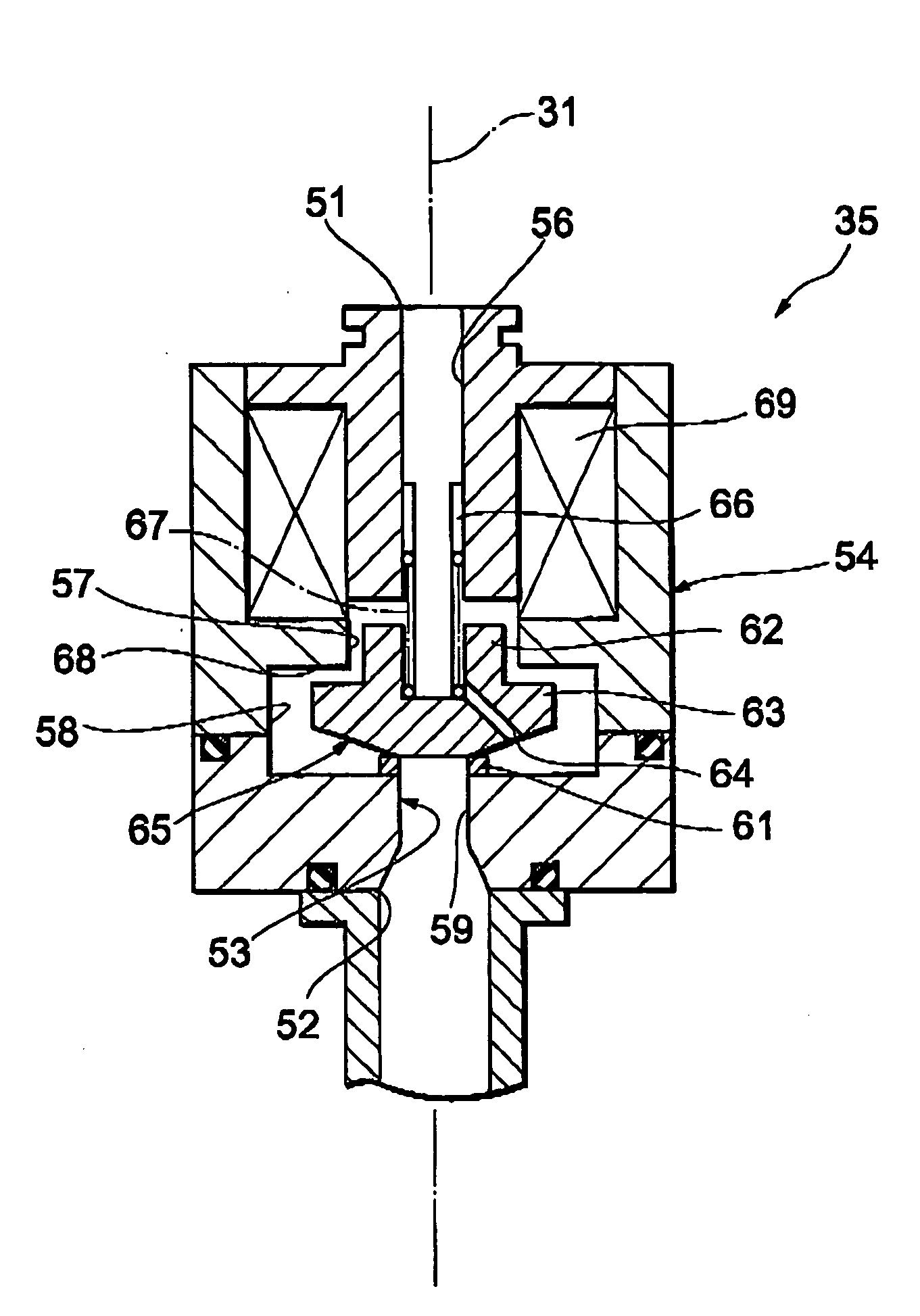

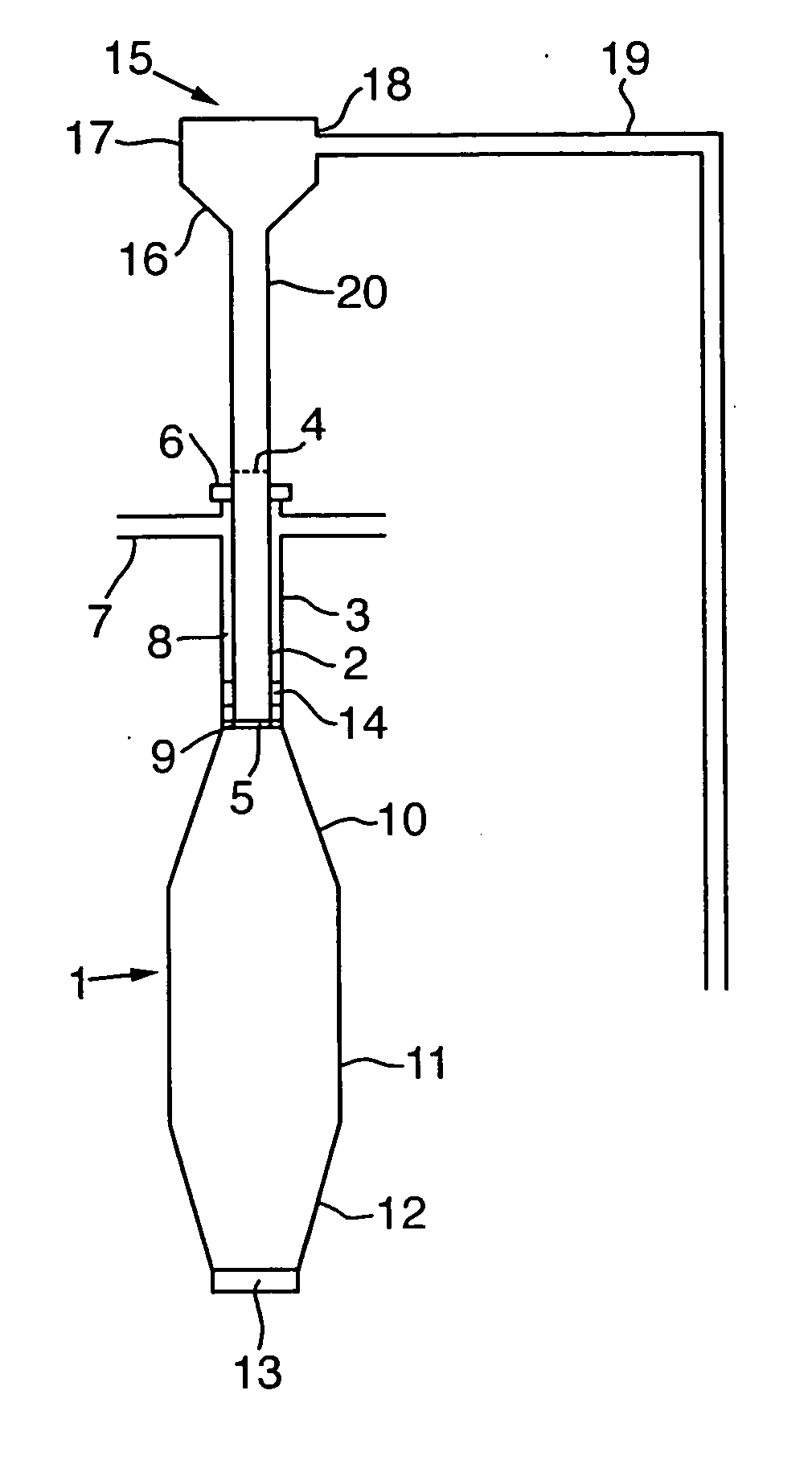

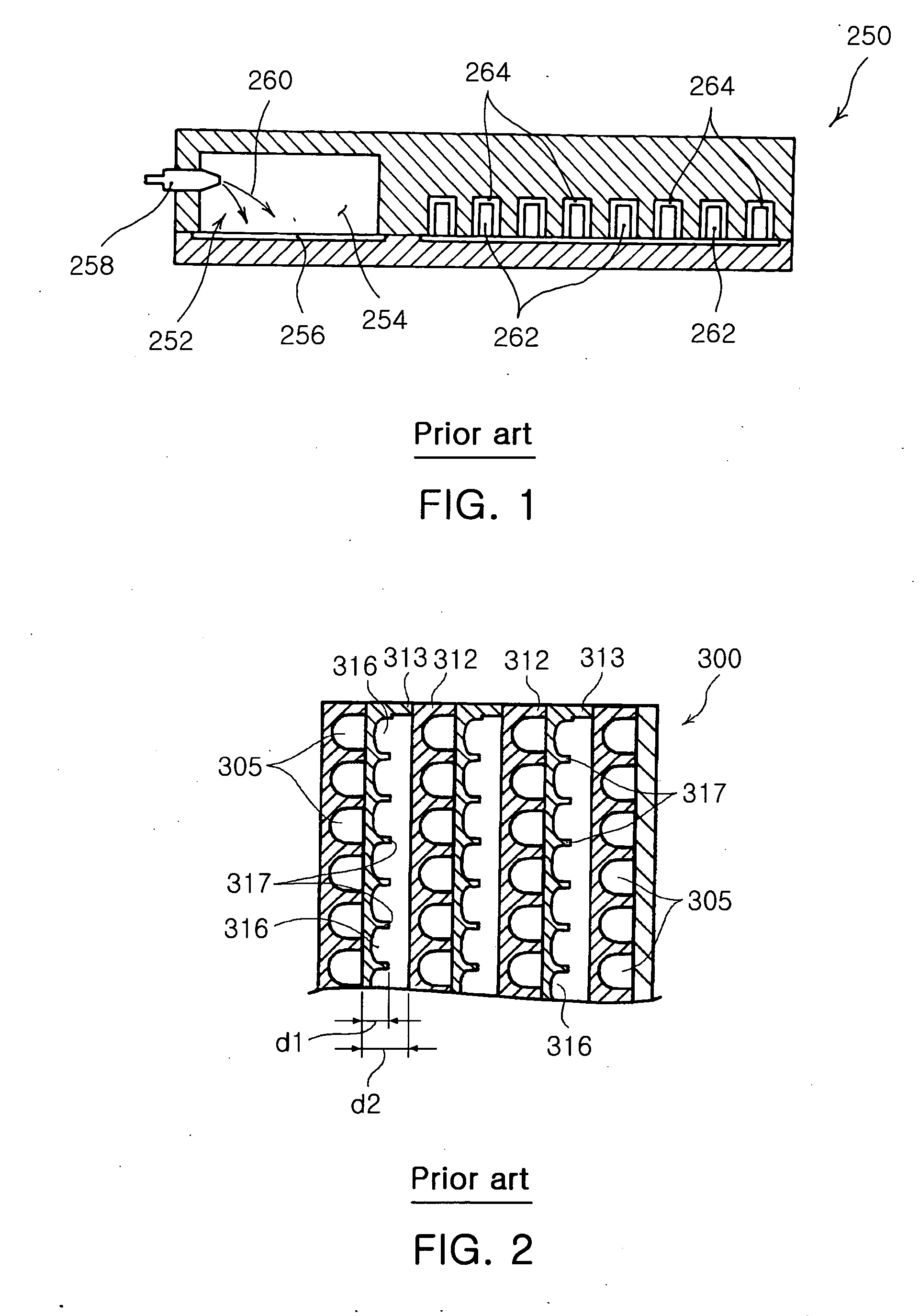

Semiconductor manufacturing system having a vaporizer which efficiently vaporizes a liquid material

InactiveUS7332040B1Obviates problemMaterial efficiencyFunctional valve typesEngine diaphragmsEvaporatorEngineering

A vaporizer can efficiently vaporize a liquid material under a depressurized atmosphere. The liquid material is temporarily stored in a liquid storing chamber, and is supplied to a vaporizing chamber set in the depressurized atmosphere via a small aperture. An inlet of the liquid storing chamber is opened or closed by a valve body, which is moved by an actuator controlling a degree of opening of the valve body.

Owner:TOKYO ELECTRON LTD

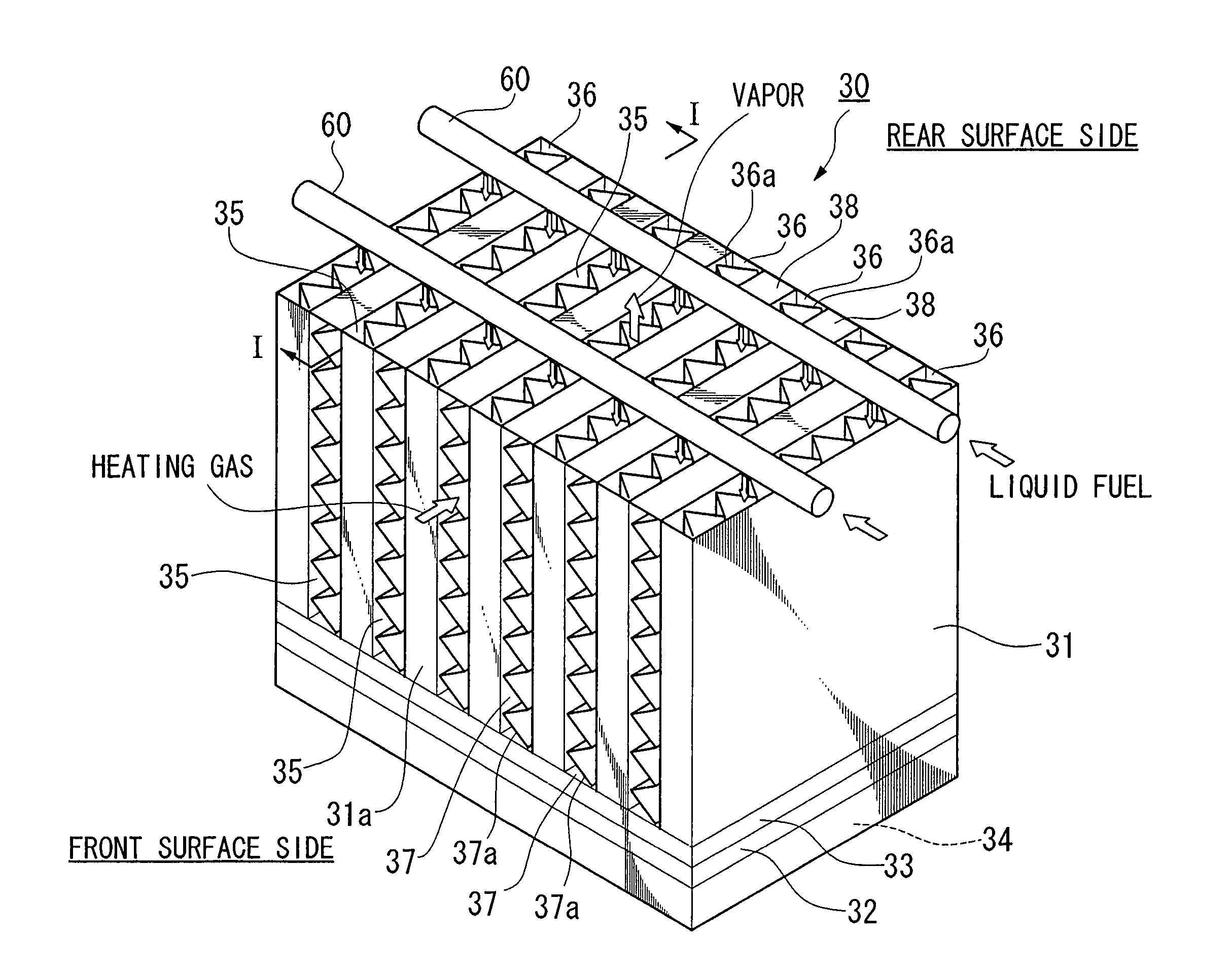

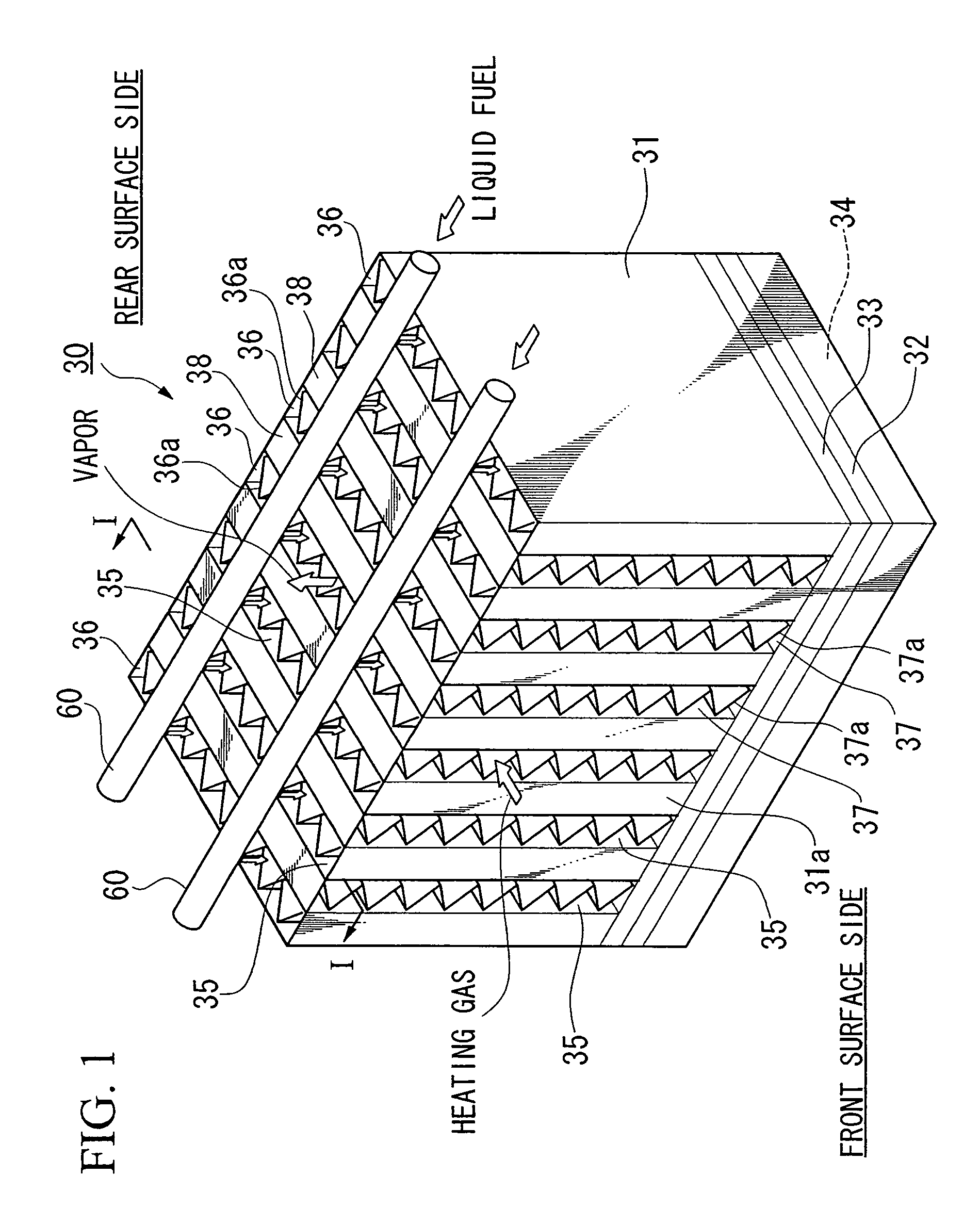

Vaporizer that vaporizes a liquid to generate vapor

InactiveUS7490580B2Efficient use ofImprove responseLiquid fuel feeder/distributionBoiler water tubesLiquid fuelVaporization

A vaporizer generates vapor by vaporizing a liquid. In particular, a vaporizer generates fuel vapor that is used for reforming fuel by vaporizing a liquid fuel that contains a hydrocarbon. This vaporizer includes a heating gas direct movement flow path along which a heating gas flows by moving directly in a horizontal direction; vaporization flow paths that are positioned such that they can exchange heat with the heating gas direct movement flow path, and that vaporizes liquid fuel; a fuel supply pipe that supplies the liquid fuel to the vaporization flow paths; and a vapor flow path that is positioned in an upstream portion on the heating gas direct movement flow path from the vaporization flow paths and that heat fuel vapor that is discharged from the vaporization flow paths. Fuel vapor that is generated on the vaporization flow paths circulates upwards in the direction of gravity along the vaporization flow paths, and subsequently is discharged from a top portion of the vaporization flow paths and is introduced into the vapor flow path. The fuel vapor then circulates in the direction of gravity along the vapor flow path.

Owner:HONDA MOTOR CO LTD

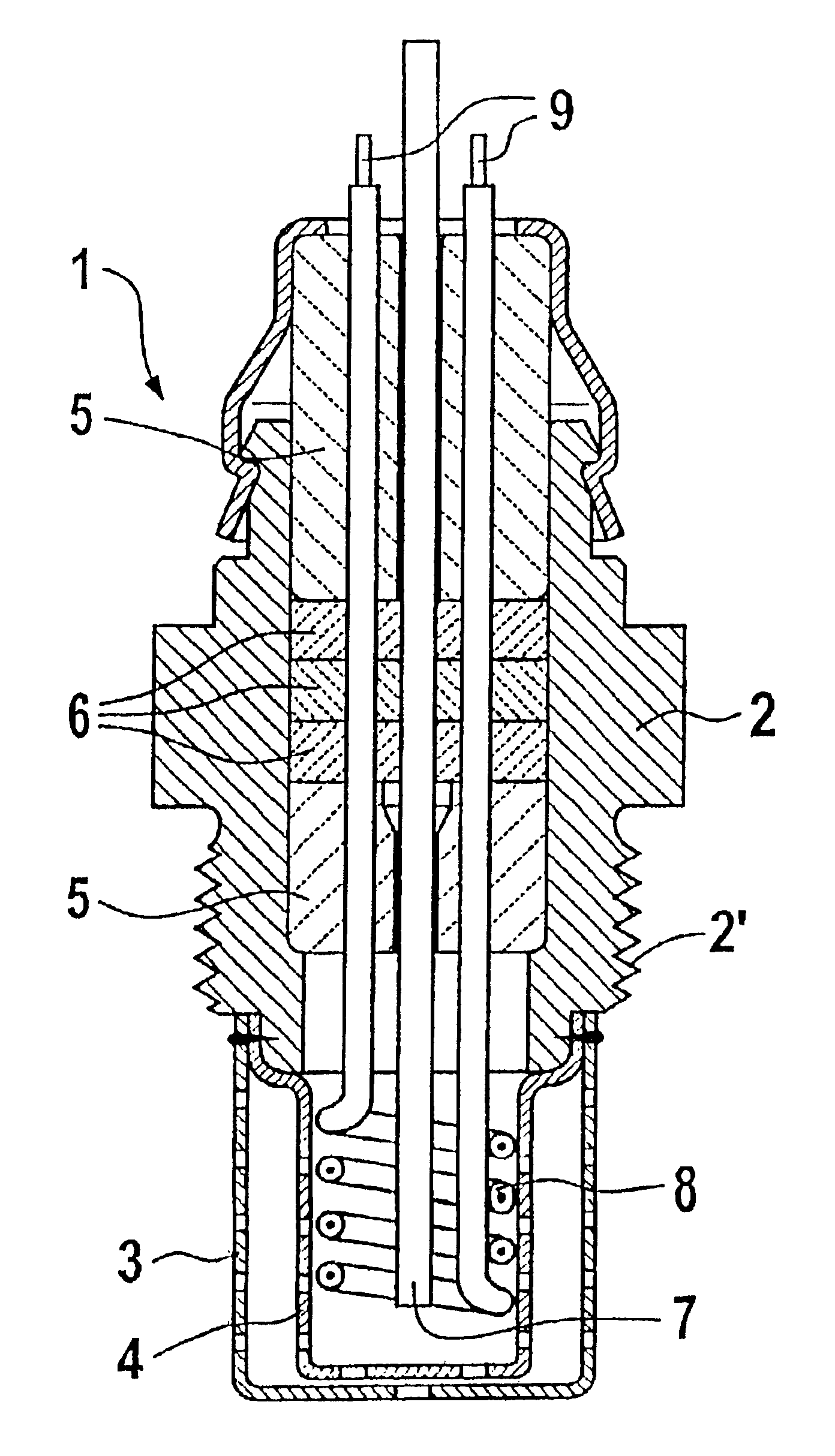

Measuring sensor for gases

InactiveUS6849238B2Reduce droplet streamFacilitate vaporization workAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationEngineeringLambda

The measuring sensor, particularly a lambda probe, has a ceramic sensor member retained at a high temperature during measuring operation. It is shielded from water droplets, carried along in the gas to be analyzed, by a heated protective housing, permeable for the gas to be analyzed, by which water droplets carried along in the direction of the sensor member are evaporated before reaching the sensor member. In this way, the water droplets are unable to cause any shock-like temperature drops at spots on the surface of the sensor member or material flaking.

Owner:ROBERT BOSCH GMBH

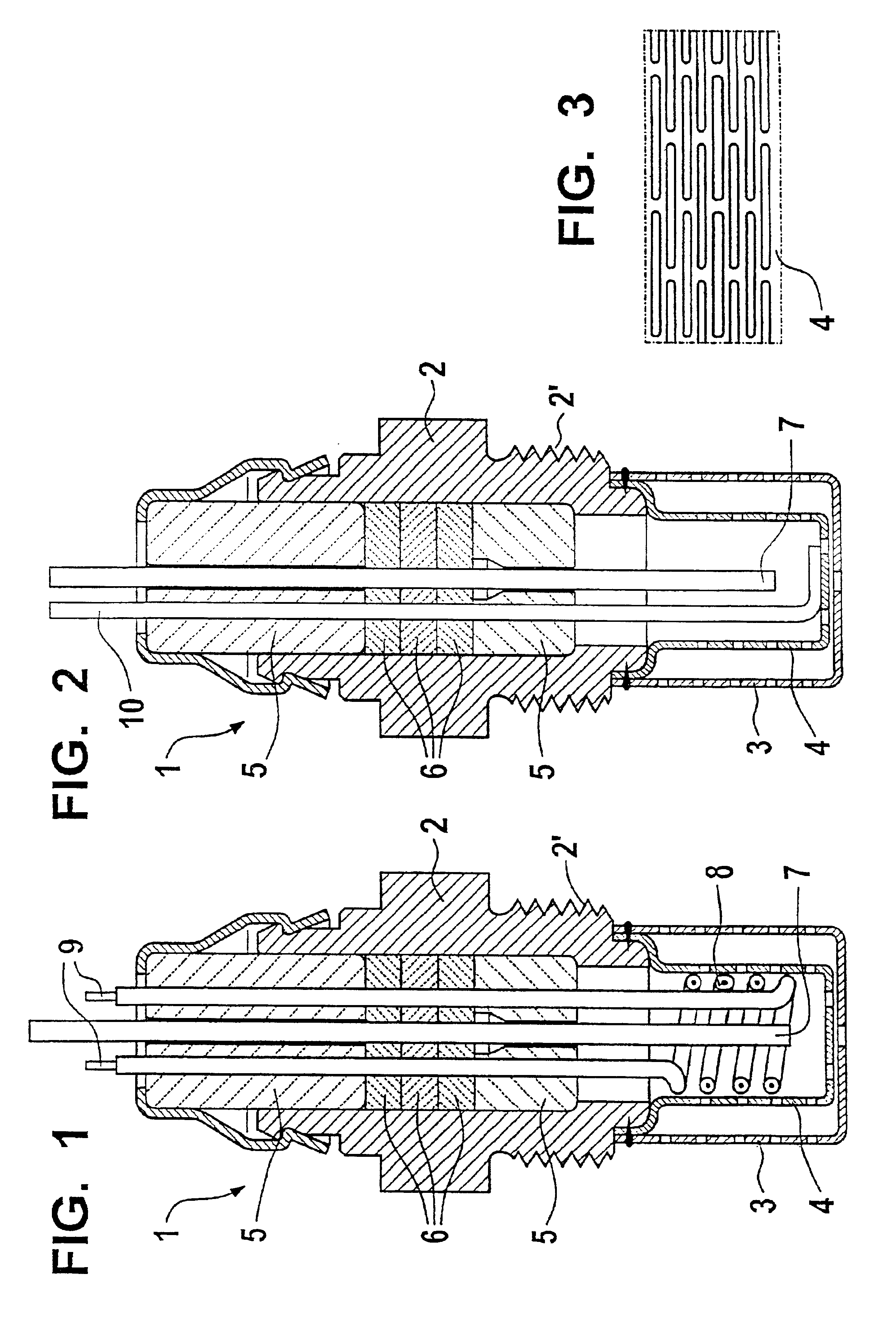

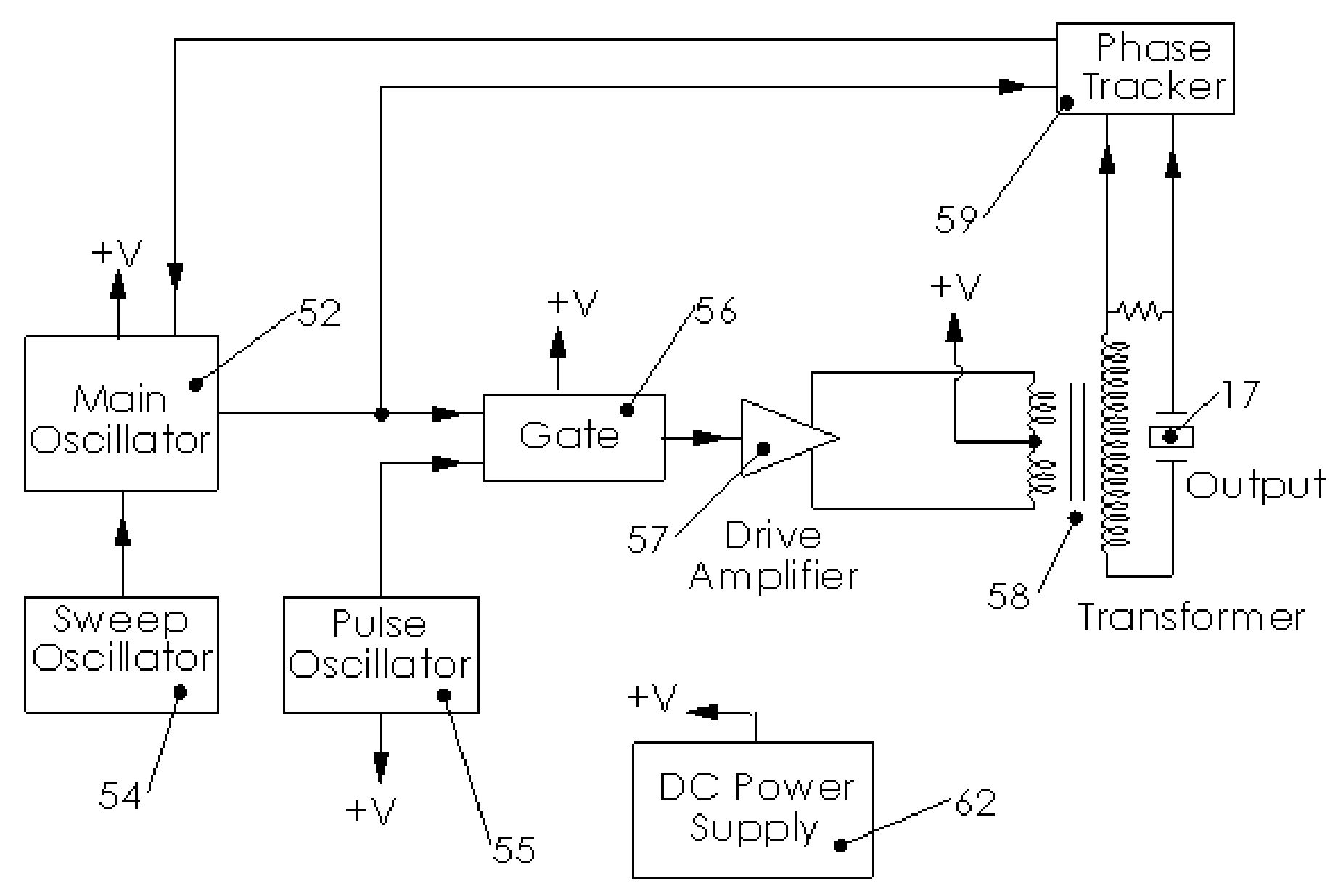

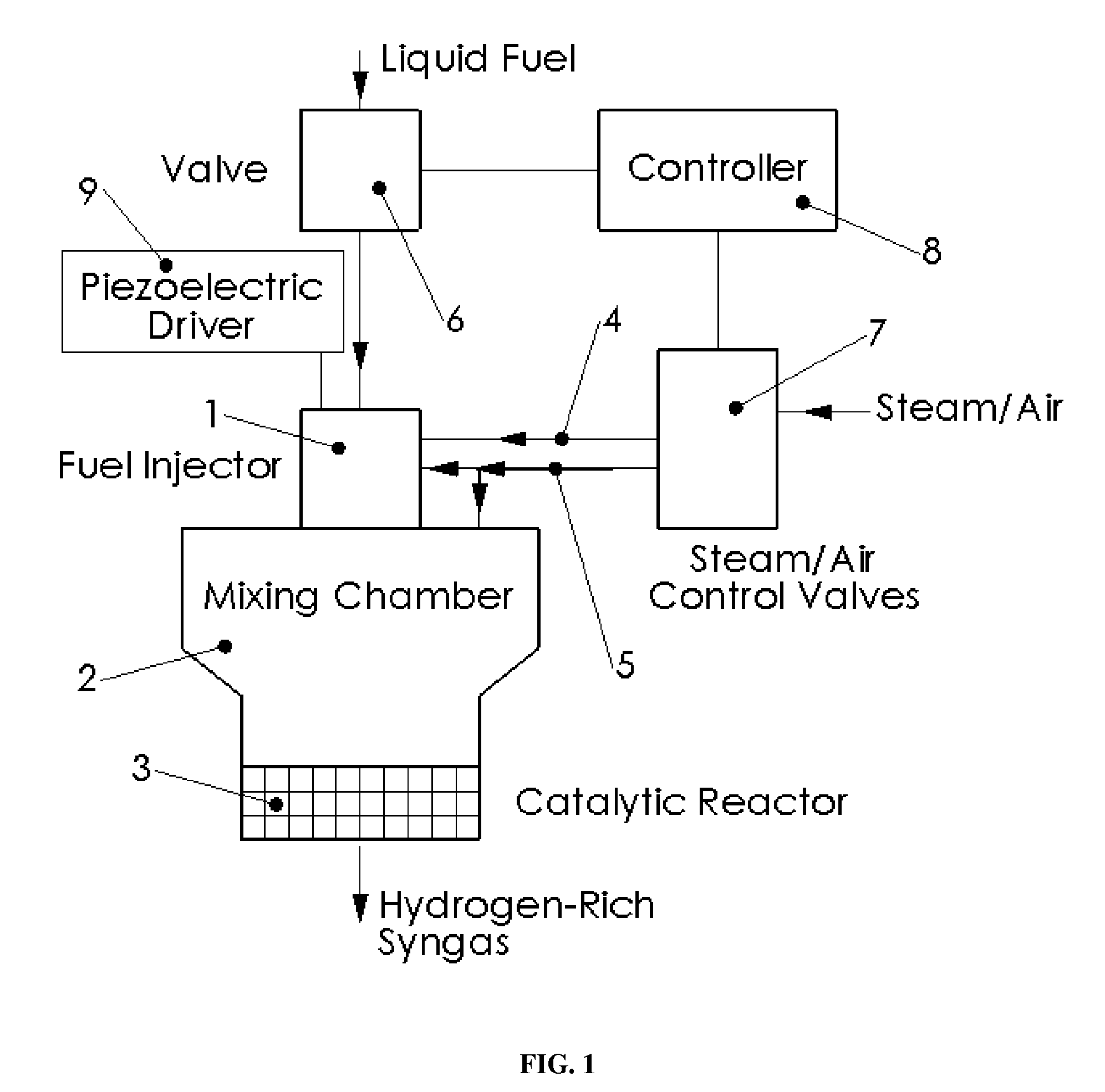

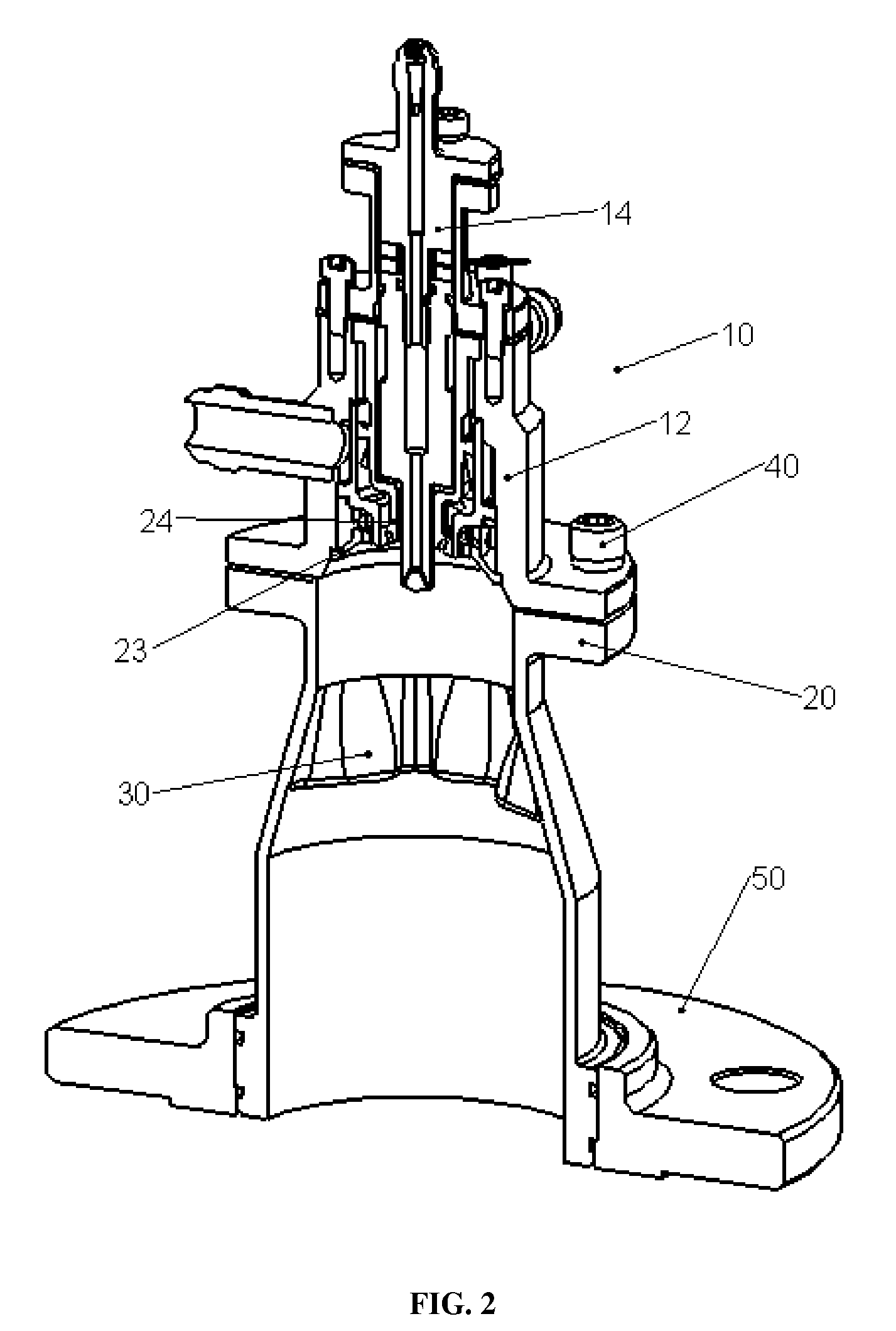

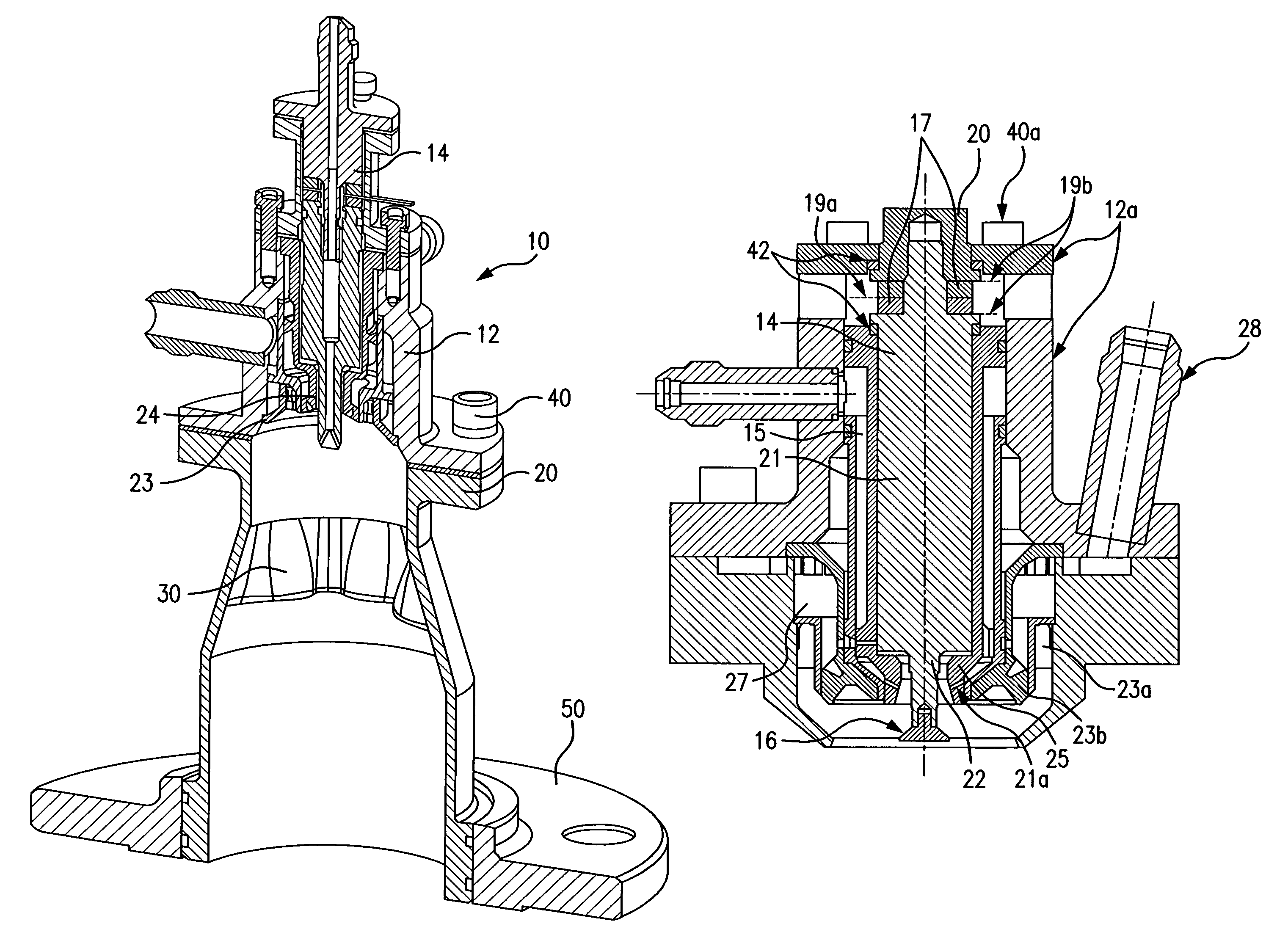

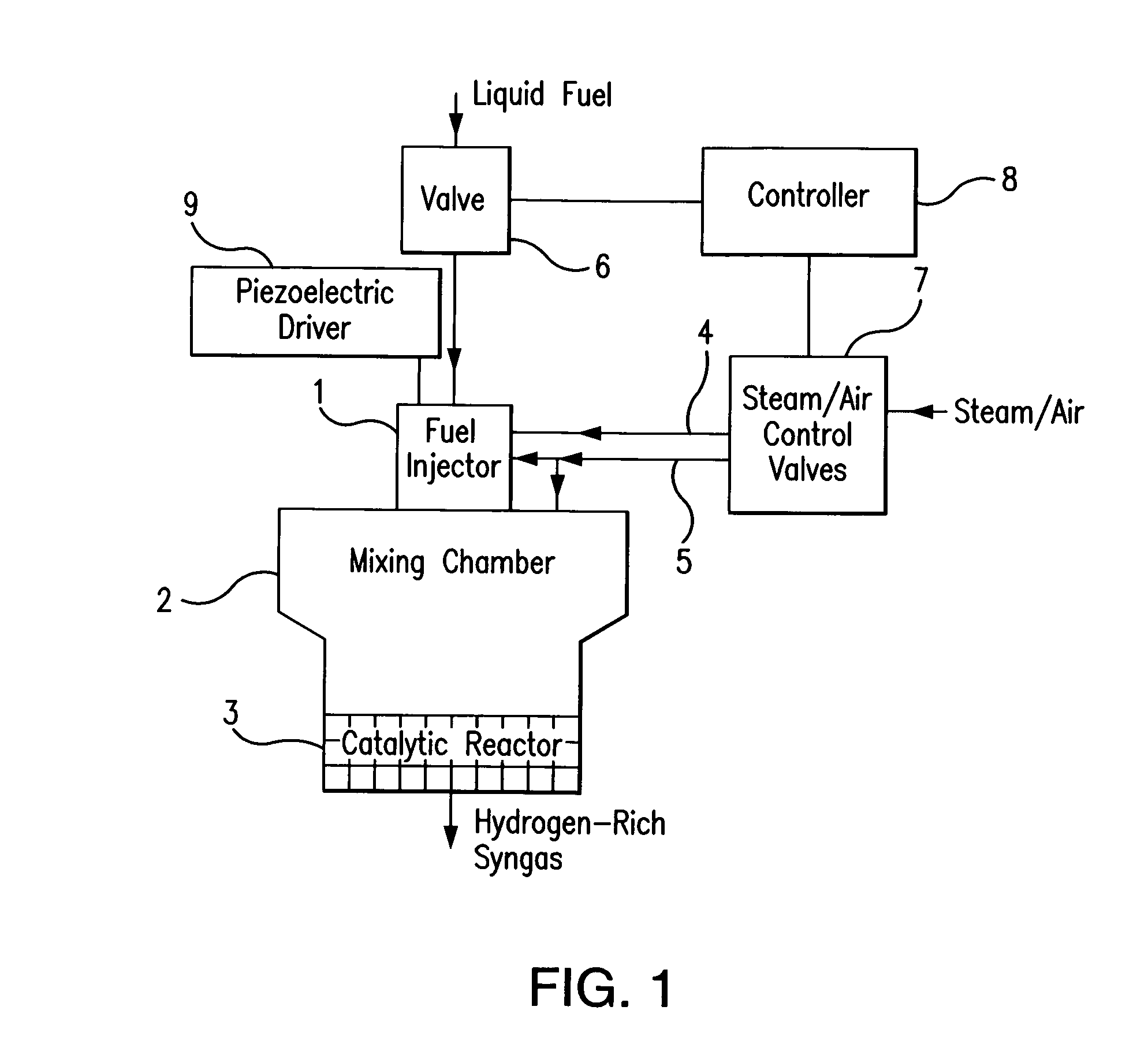

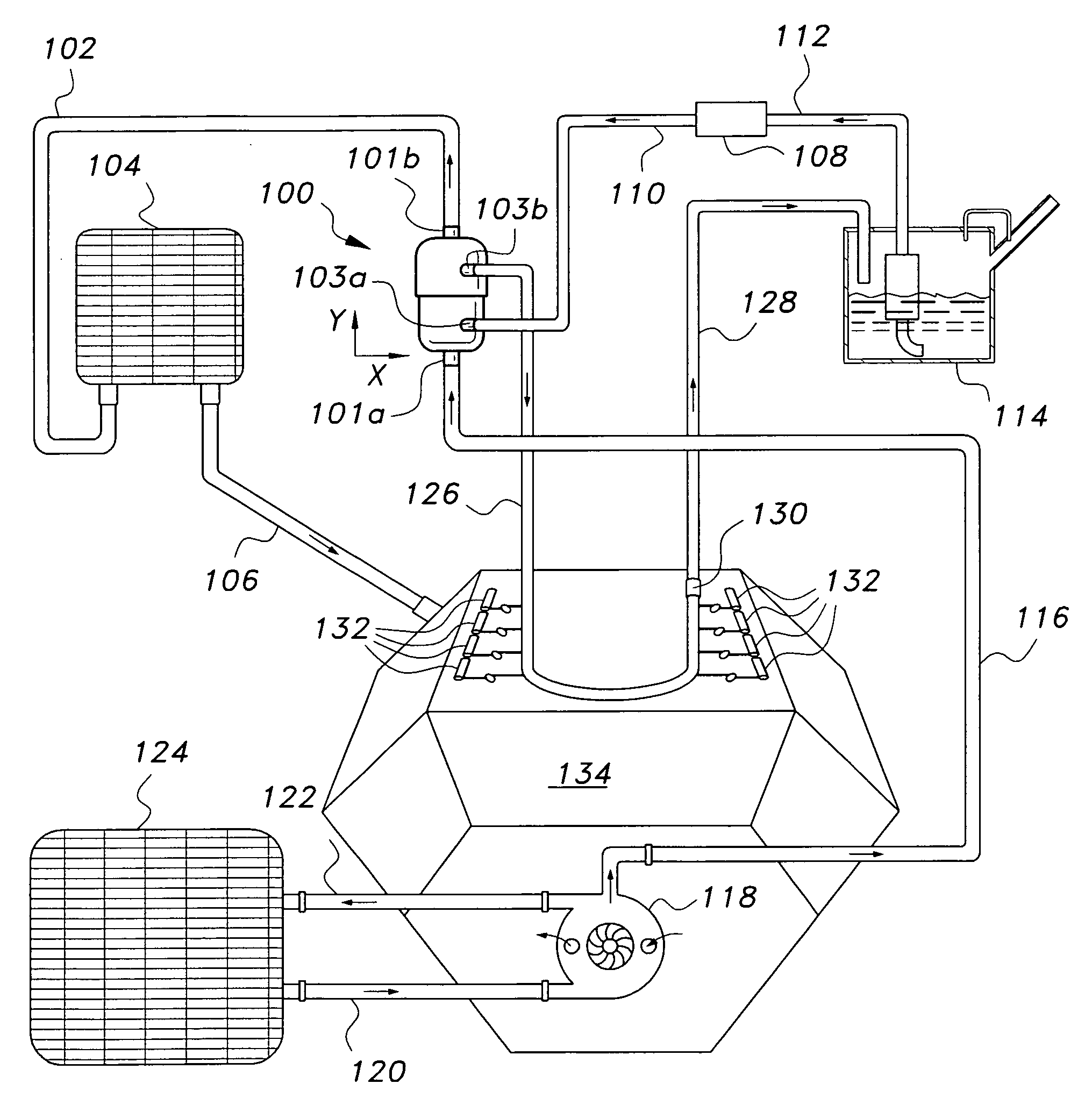

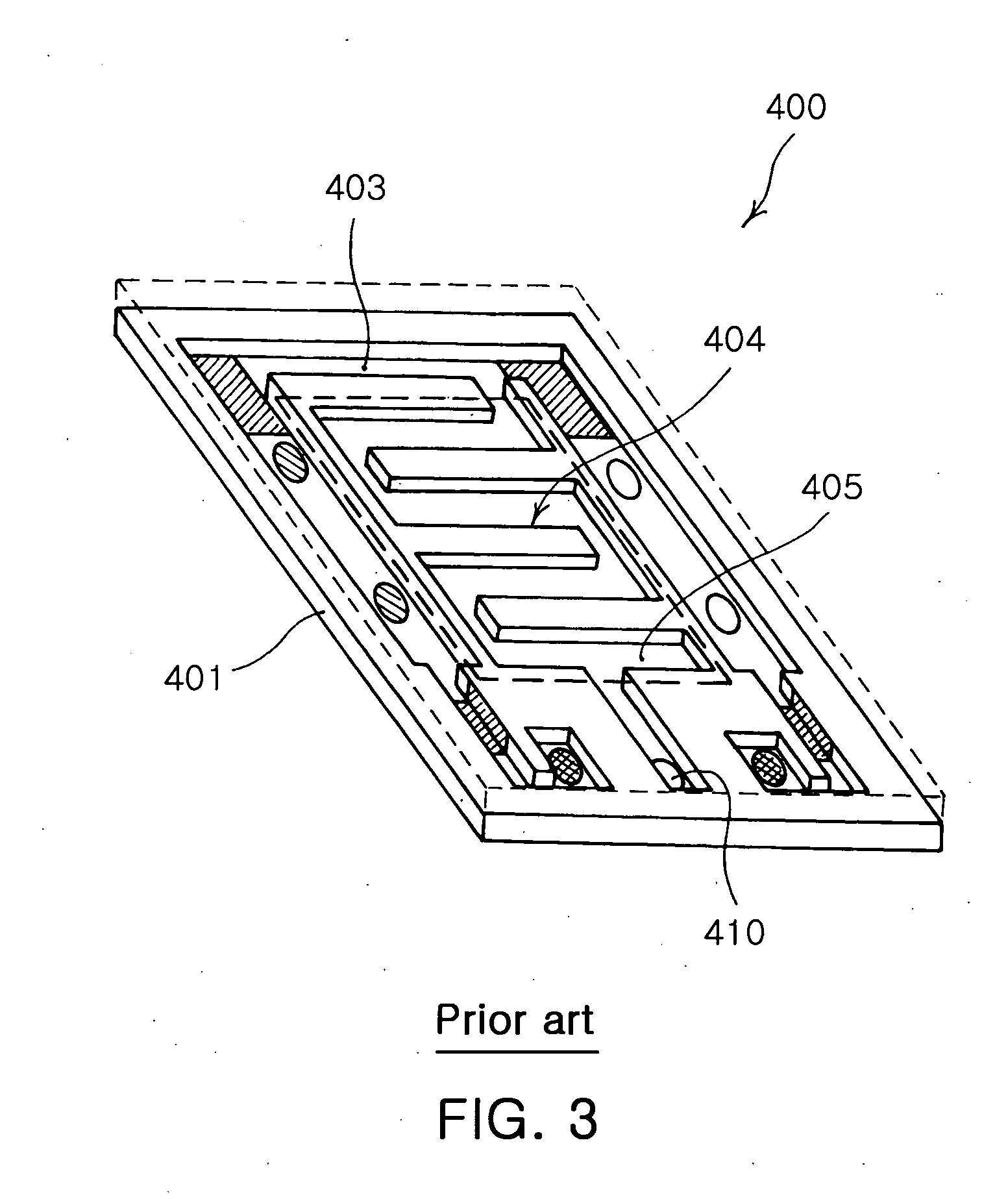

Fuel injection and mixing systems having piezoelectric elements and methods of using the same

ActiveUS20080121736A1Well mixedImprove uniformityInternal combustion piston enginesSpace heating and ventilationElectricityFuel cells

A fuel injection and mixing system is provided that is suitable for use with various types of fuel reformers. Preferably, the system includes a piezoelectric injector for delivering atomized fuel, a gas swirler, such as a steam swirler and / or an air swirler, a mixing chamber and a flow mixing device. The system utilizes ultrasonic vibrations to achieve fuel atomization. The fuel injection and mixing system can be used with a variety of fuel reformers and fuel cells, such as SOFC fuel cells.

Owner:DELAVAN

Fuel injection and mixing systems having piezoelectric elements and methods of using the same

ActiveUS8074895B2Effectively “vaporized”Prevent dropletInternal combustion piston enginesSpace heating and ventilationElectricityFuel cells

A fuel injection and mixing system is provided that is suitable for use with various types of fuel reformers. Preferably, the system includes a piezoelectric injector for delivering atomized fuel, a gas swirler, such as a steam swirler and / or an air swirler, a mixing chamber and a flow mixing device. The system utilizes ultrasonic vibrations to achieve fuel atomization. The fuel injection and mixing system can be used with a variety of fuel reformers and fuel cells, such as SOFC fuel cells.

Owner:DELAVAN

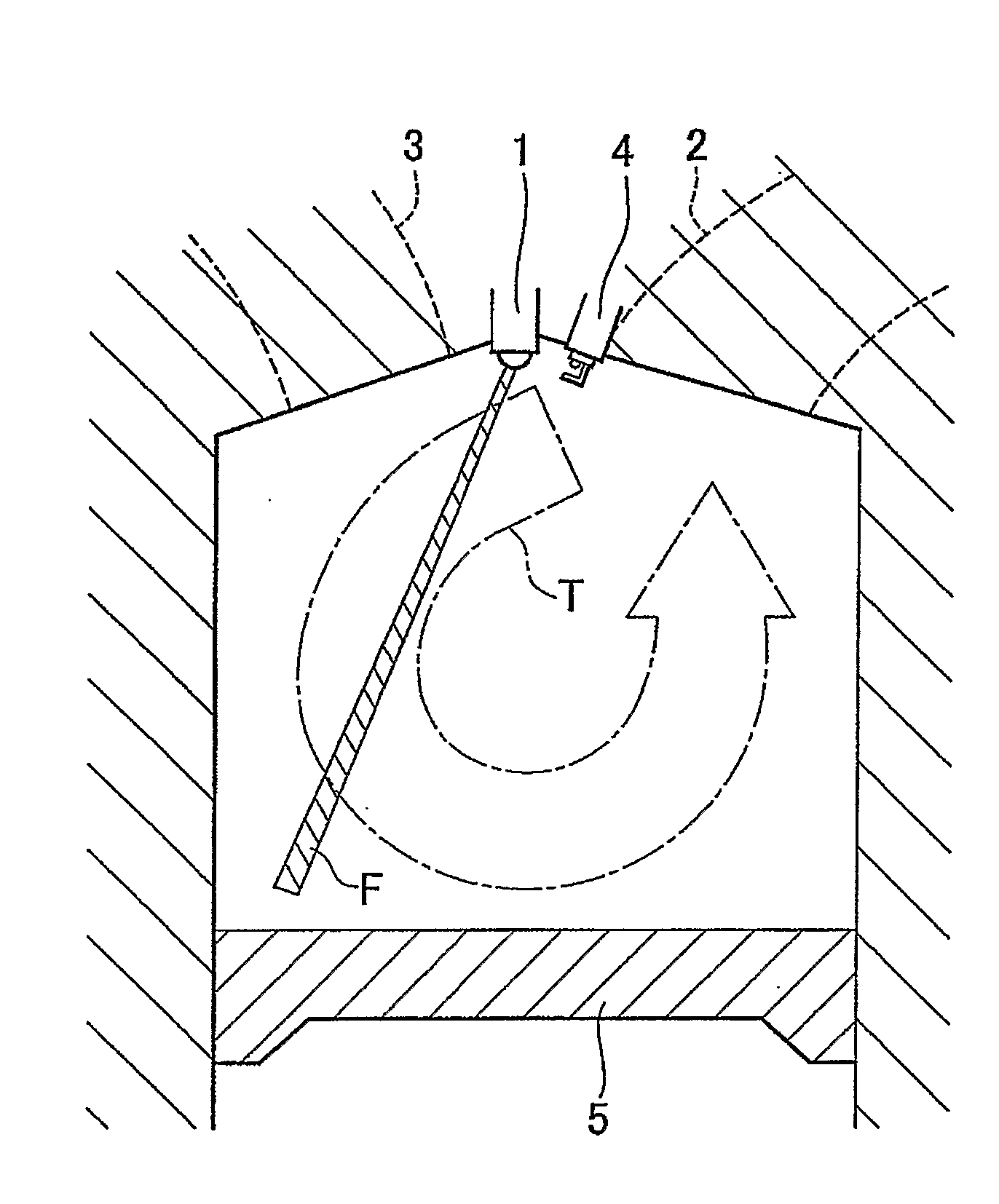

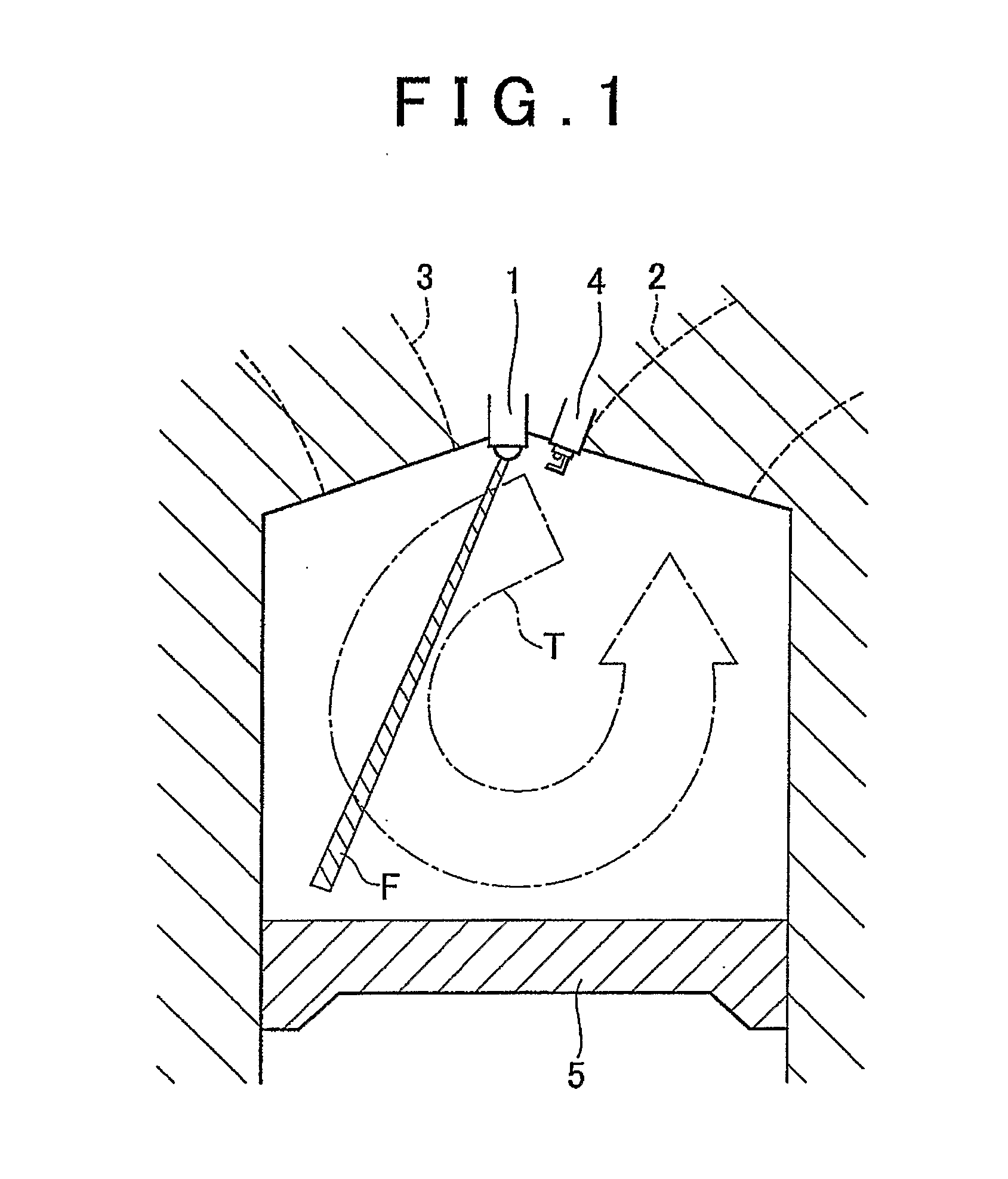

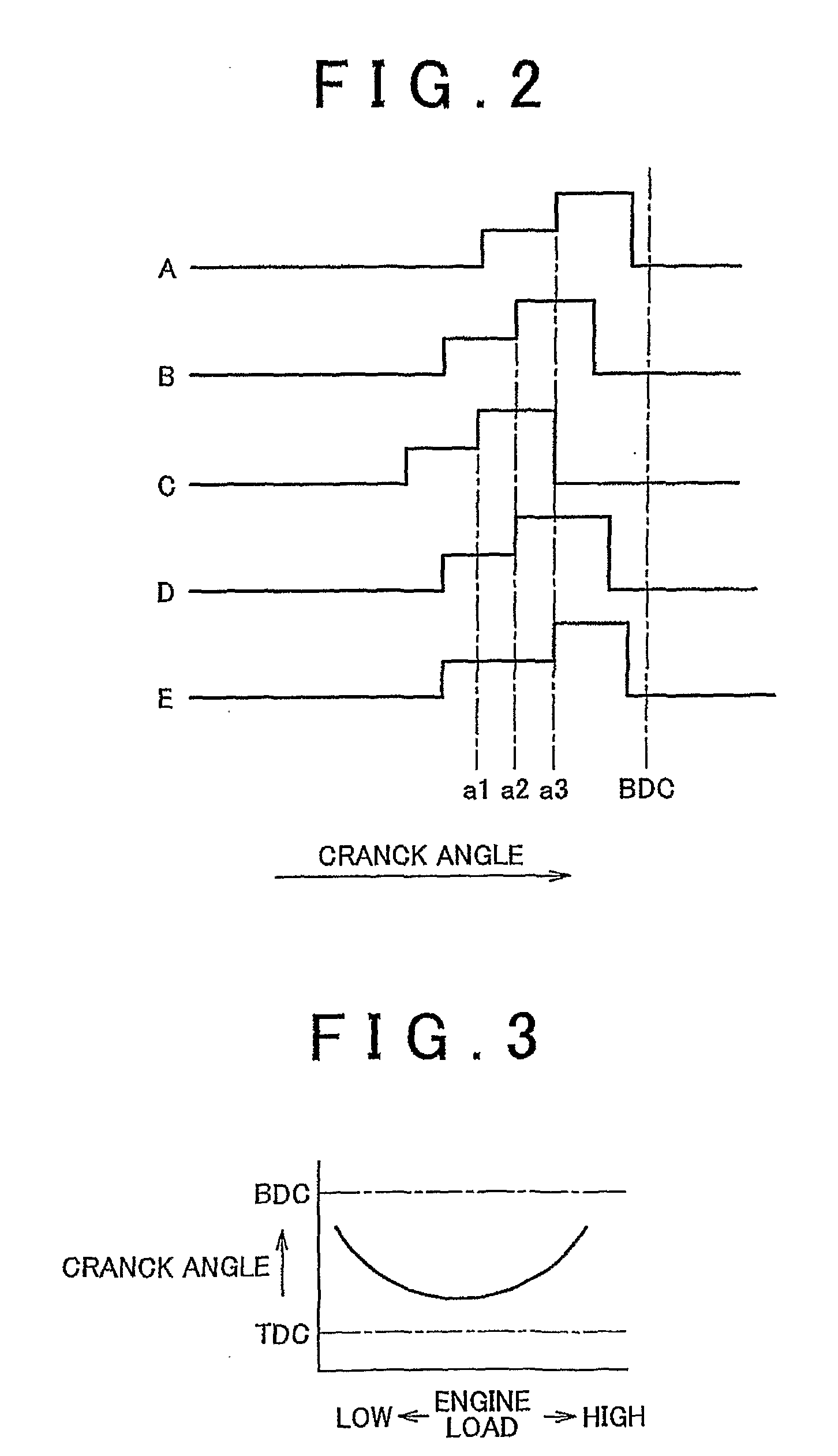

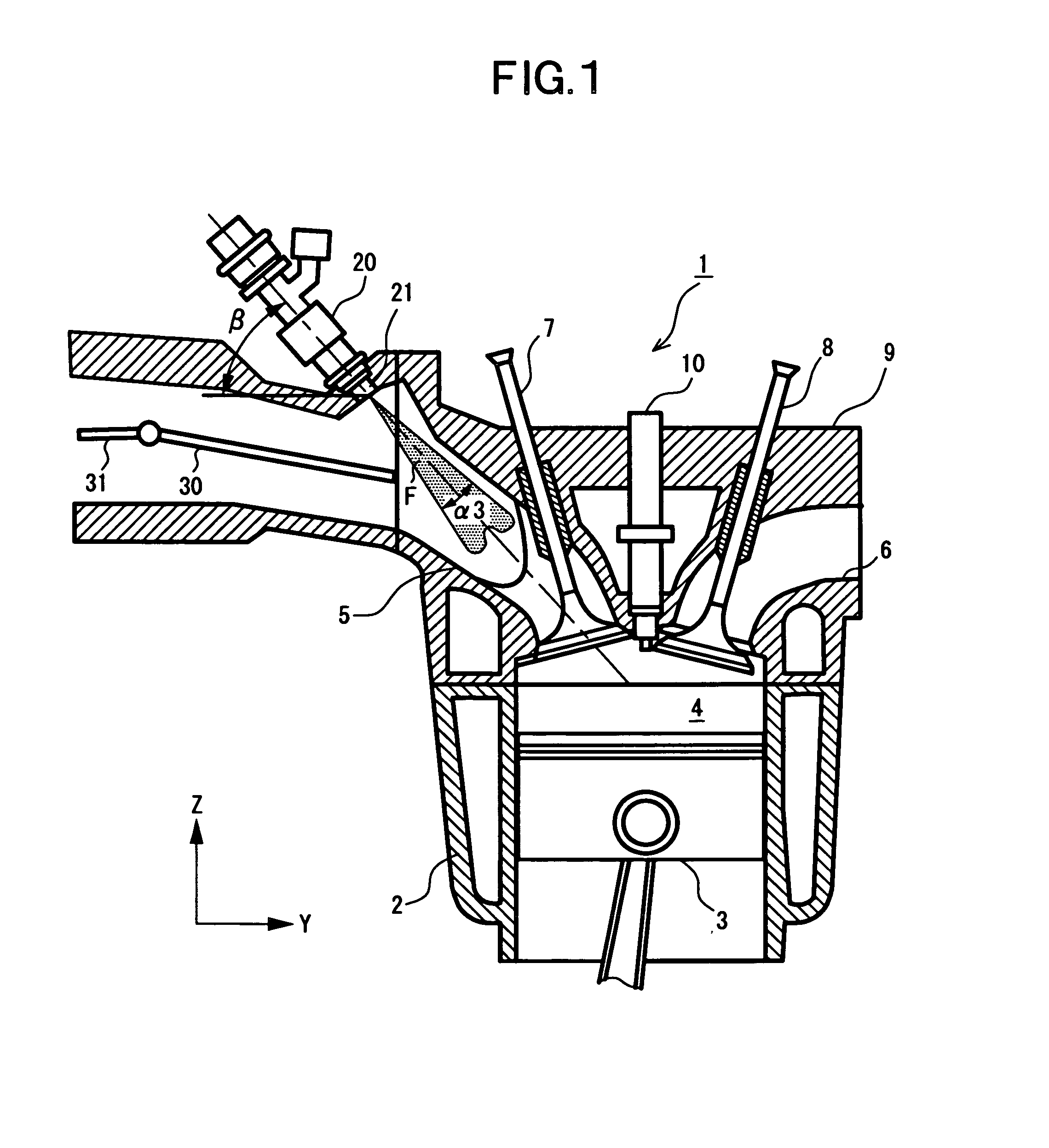

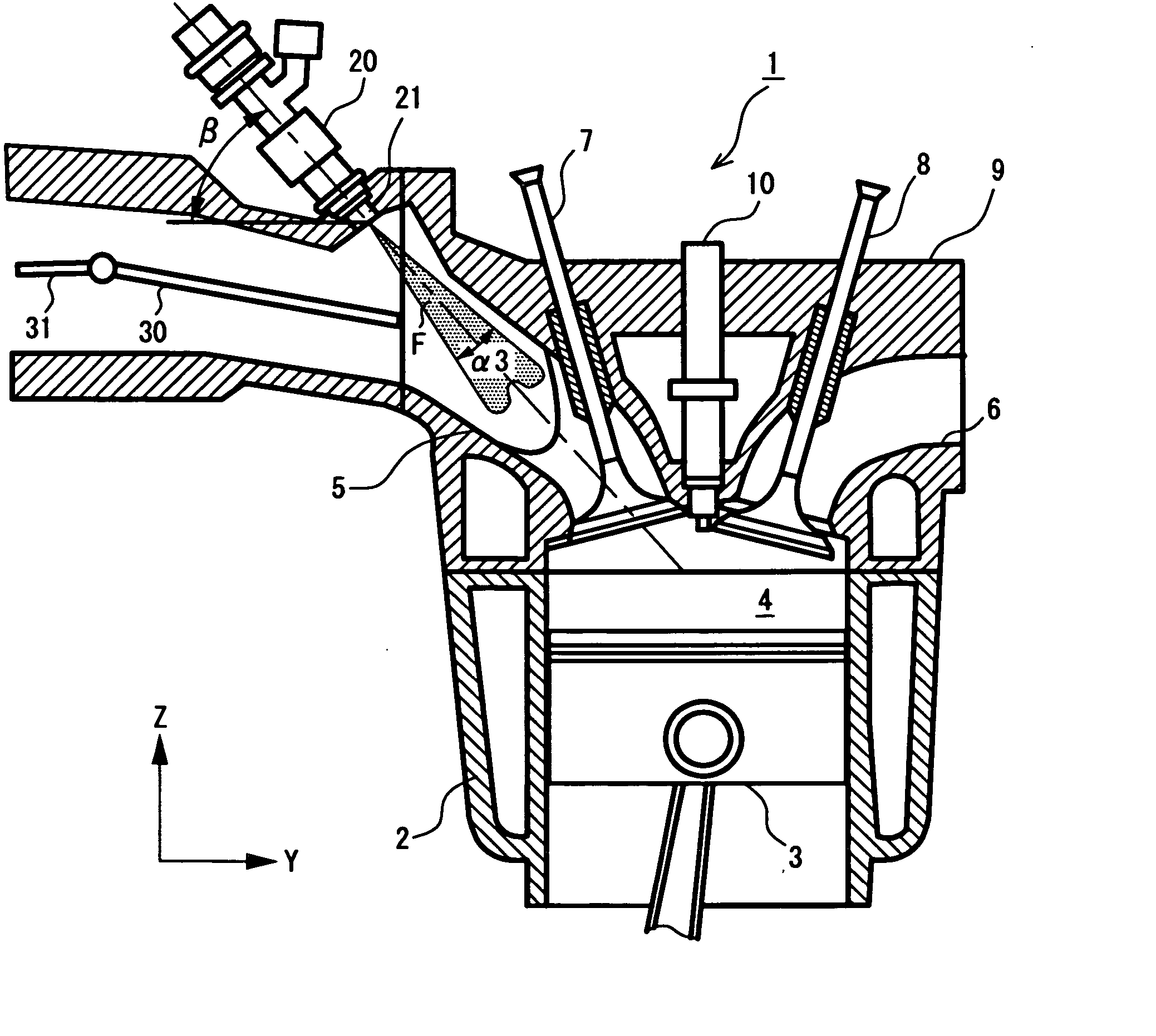

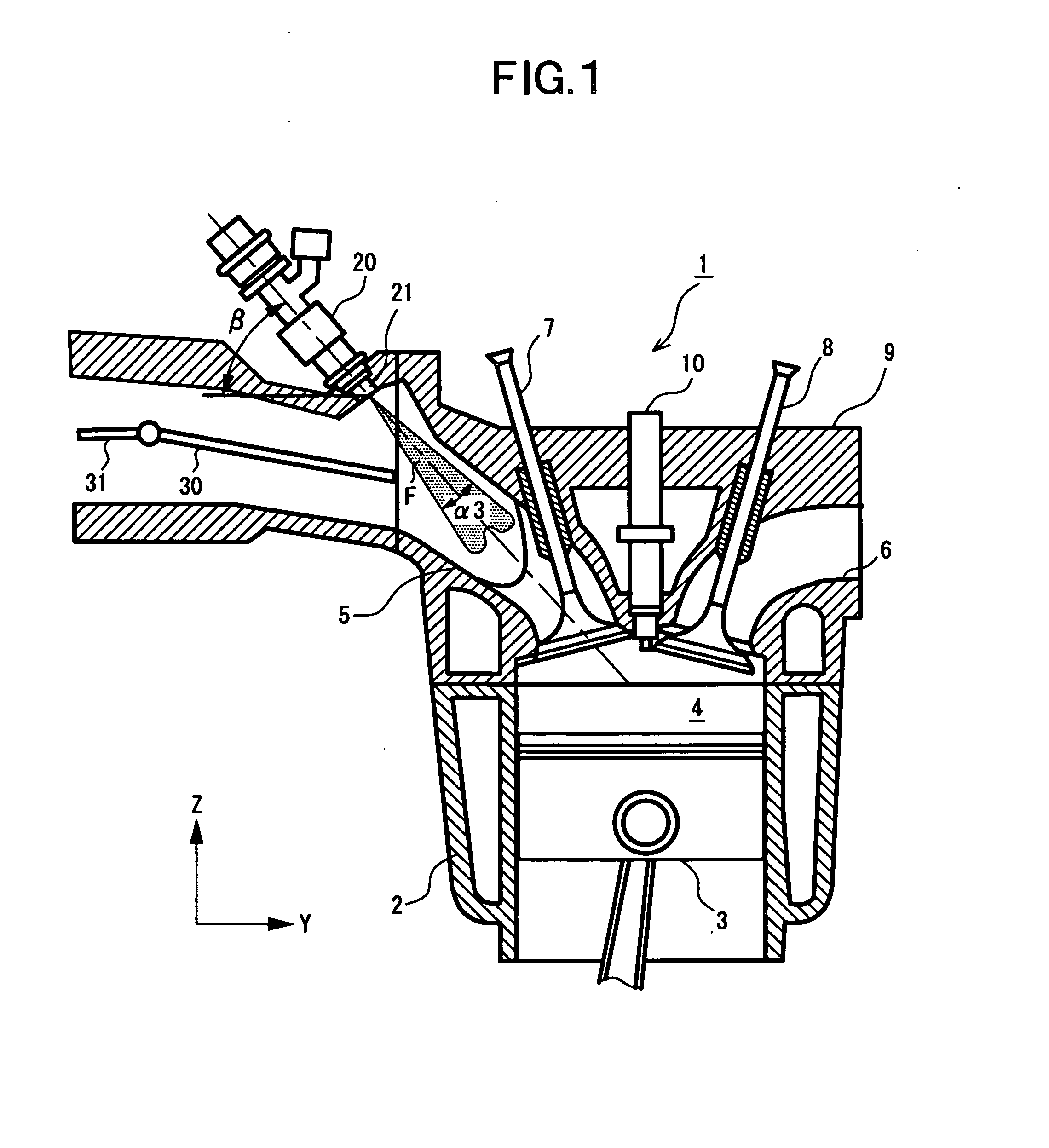

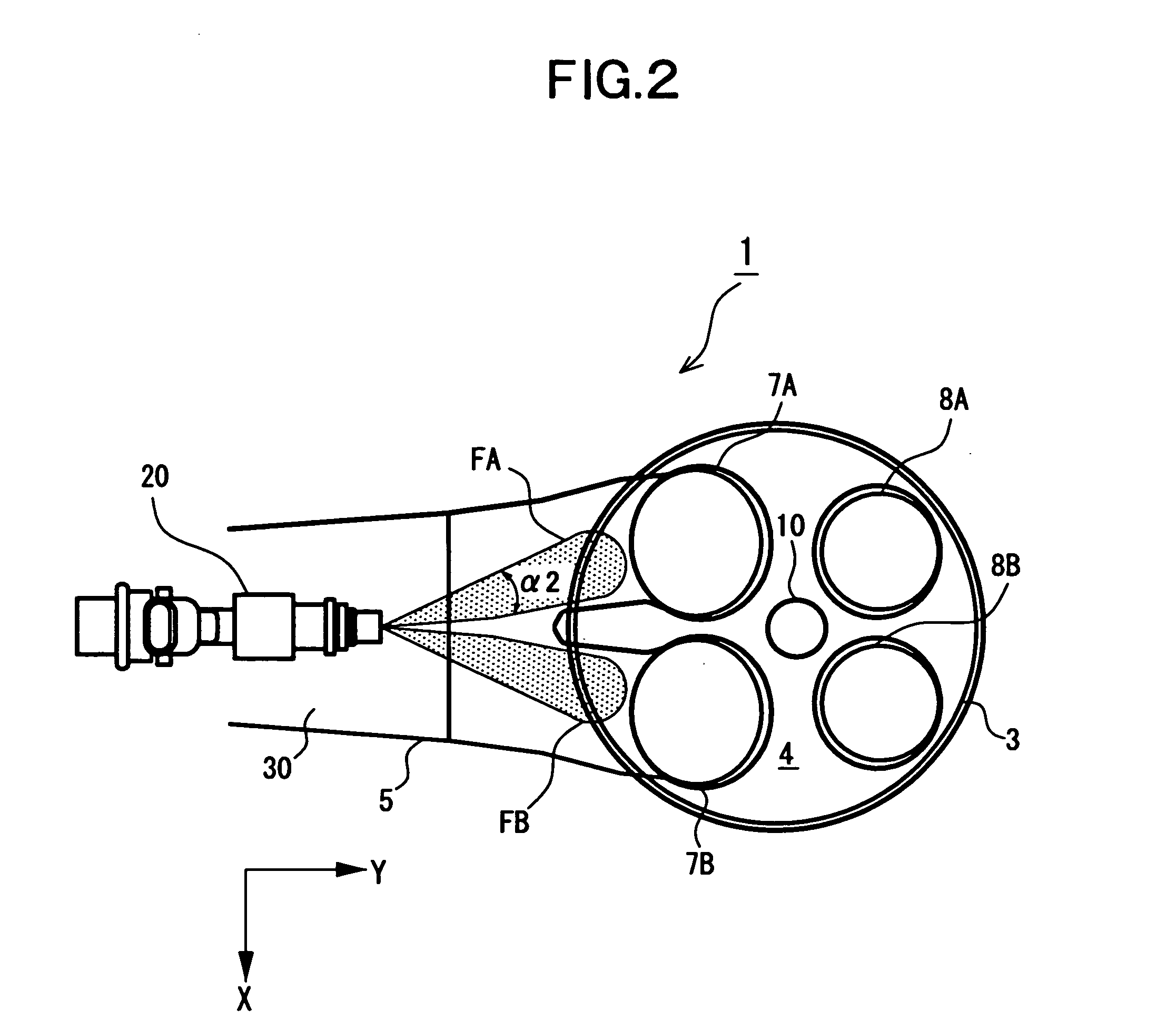

Direct injection spark ignition internal combustion engine and method for controlling same

InactiveUS20090271092A1Suppress productionSuppresses smoke productionElectrical controlInternal combustion piston enginesPistonSpark-ignition engine

A direct injection spark ignition internal combustion engine includes a fuel injection valve and fuel injection control device that controls fuel injection such that a fuel is injected from an upper area of an engine cylinder toward a top face of a piston through the fuel injection valve. The fuel injection control device switches a thrust force of the fuel injected from the fuel injection valve between at least two levels such that the thrust force of the injected fuel becomes weaker when the position of the piston is high than when the position of the piston is low.

Owner:TOYOTA JIDOSHA KK

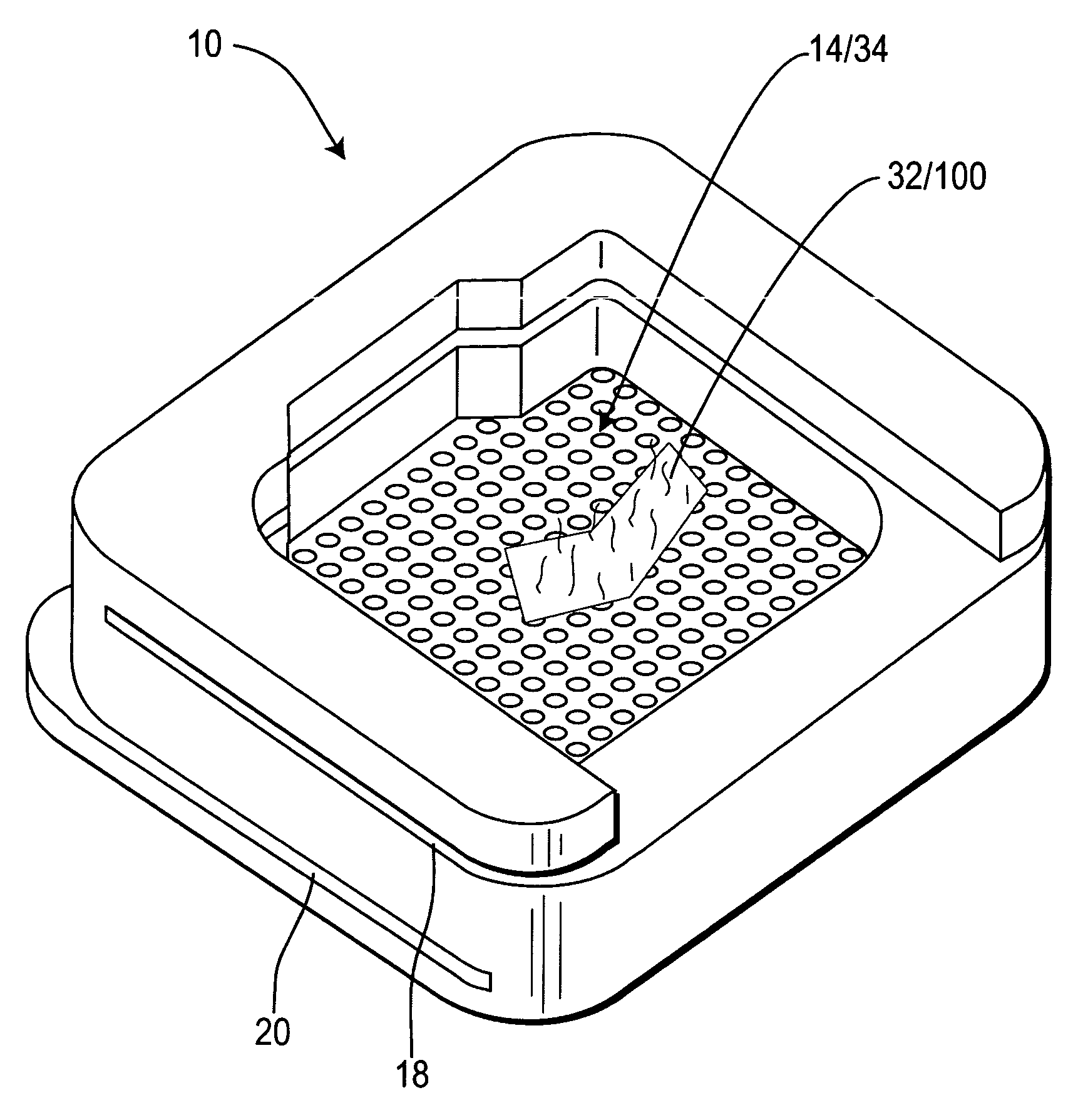

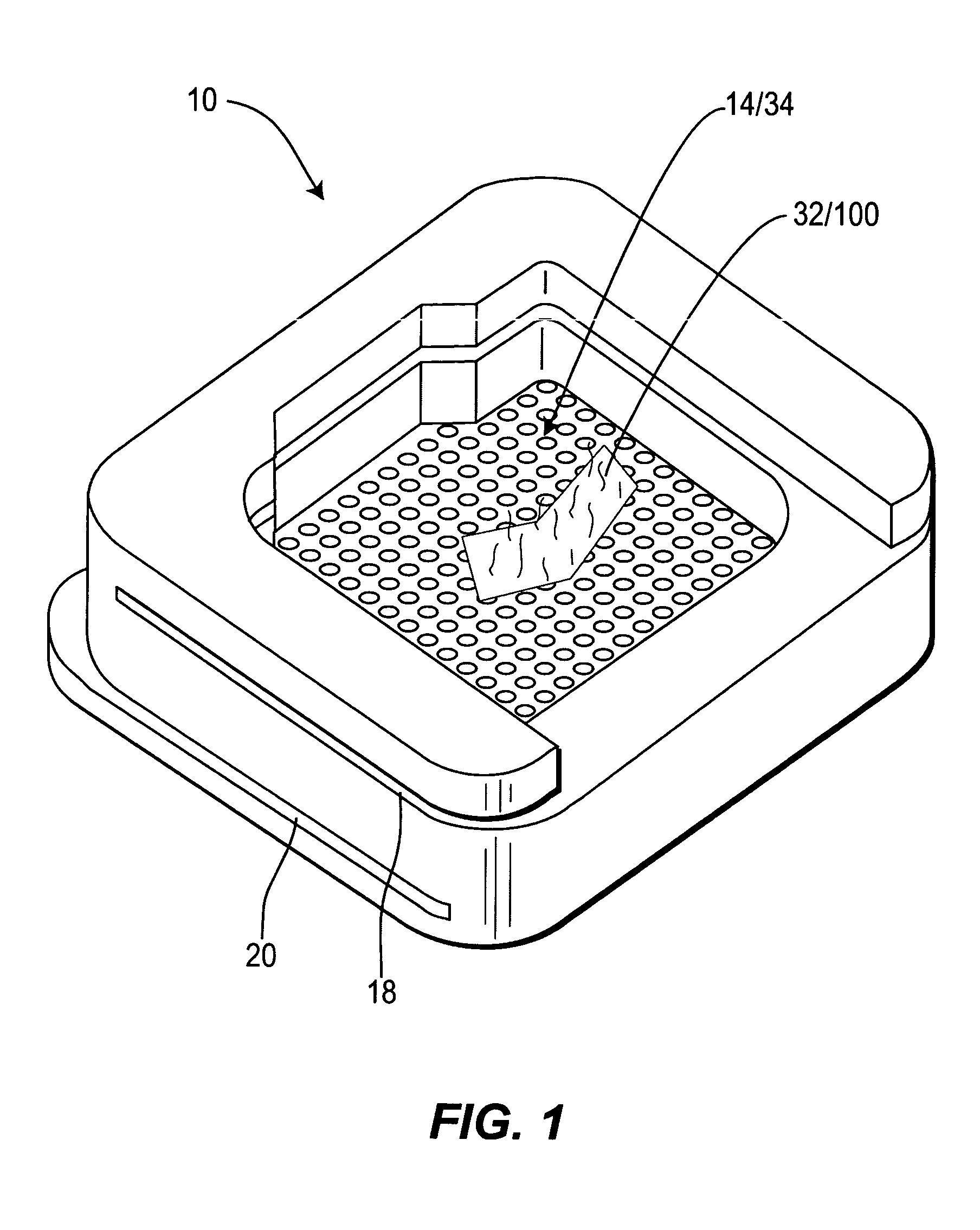

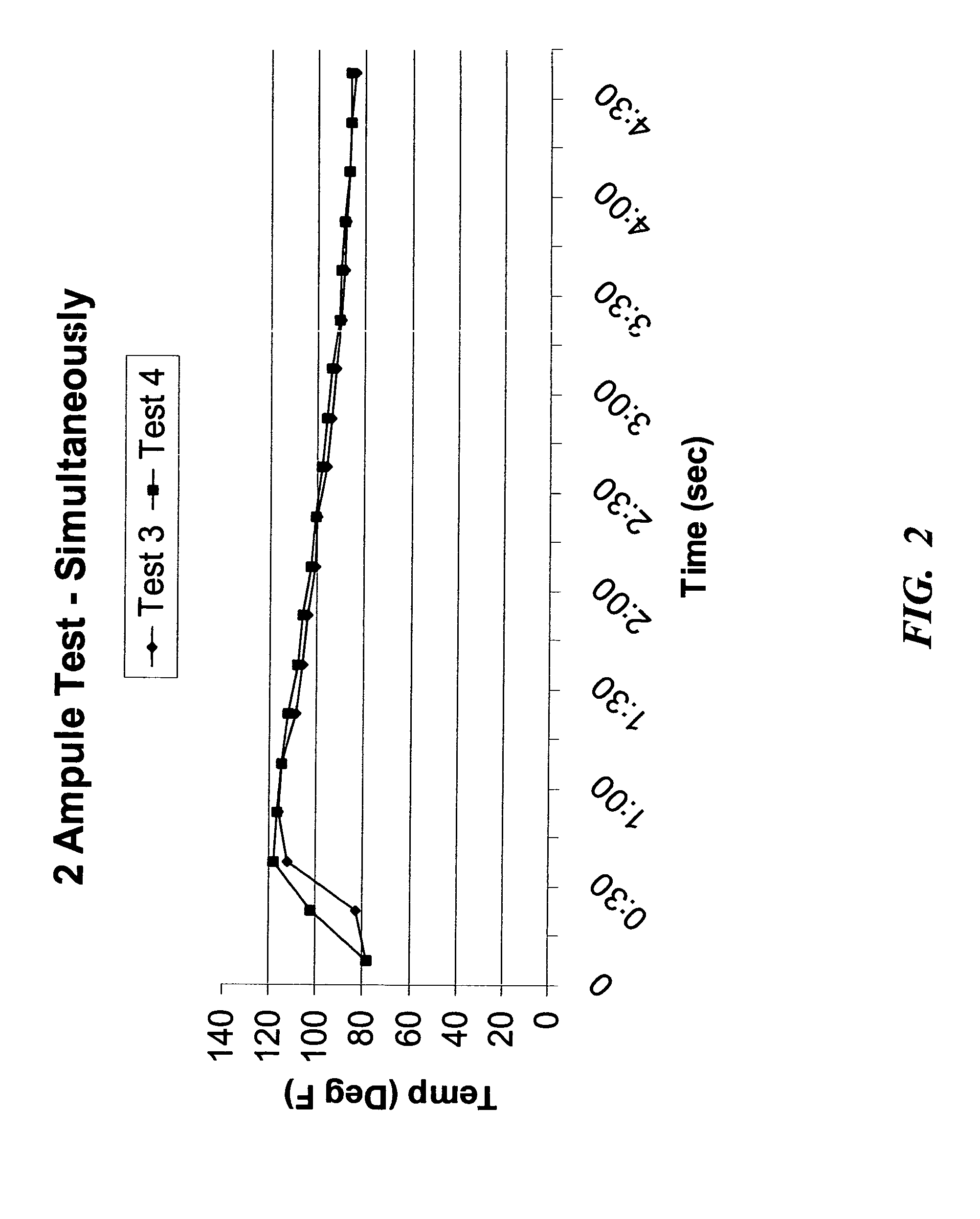

Sample heater assembly and method of use thereof

InactiveUS7036388B1Effectively “vaporized”Heating or cooling apparatusWithdrawing sample devicesVaporizationChemical agent

A sample heater assembly which permits the detection of low volatility agents by existing chemical agent detectors is described. Existing chemical agent detectors often lack the capability to accurately detect low volatility agents, such as the chemical warfare agent VX. The sample heater assembly provides this capability by heating low volatility agents to vaporization and interfacing with the existing chemical agent detector. The sample heater assembly comprises a sample containment reservoir for holding the low volatility agent sample, which can be attached to the chemical agent detector, and a heating element which attaches to the sample containment reservoir for heating the sample.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

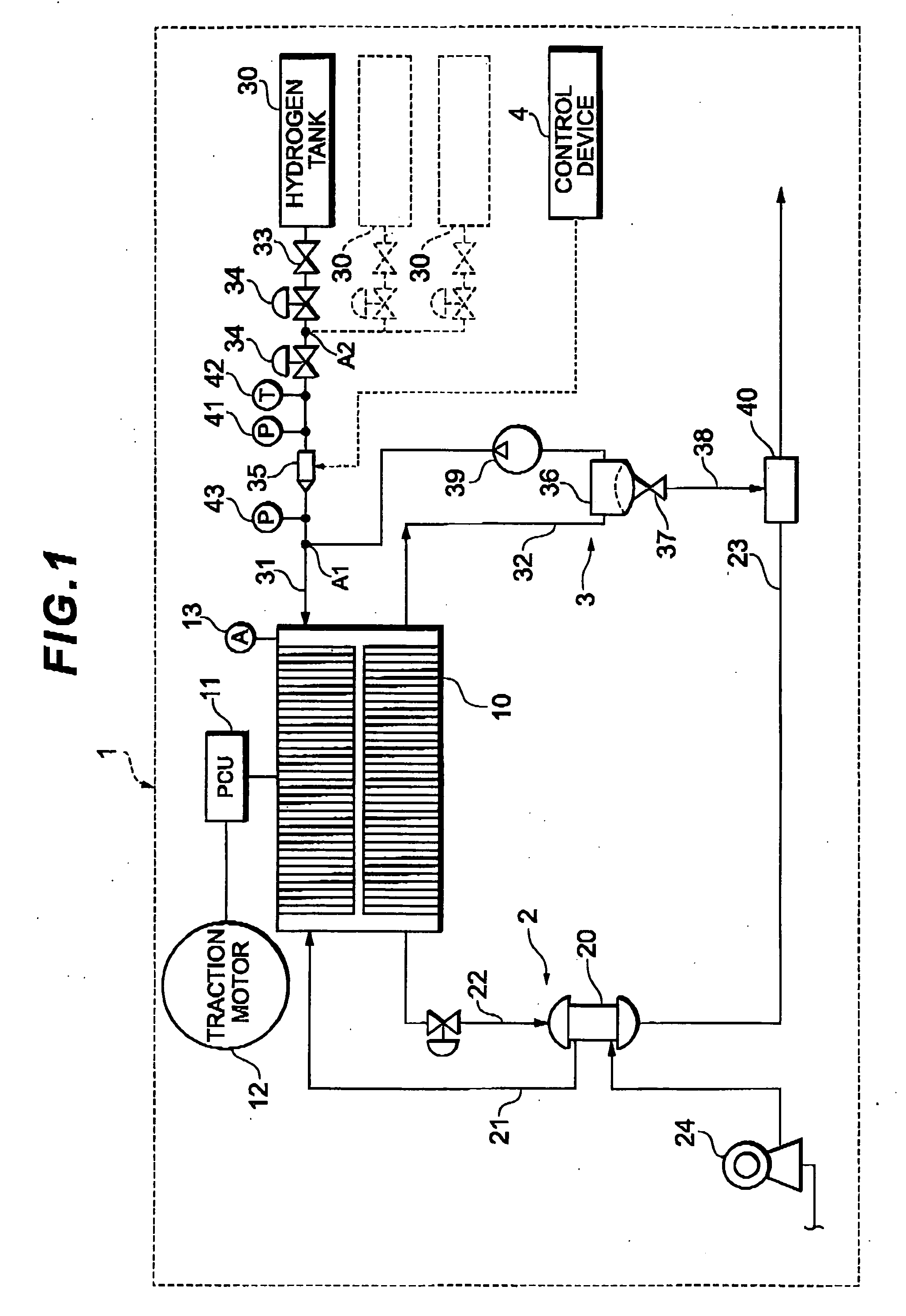

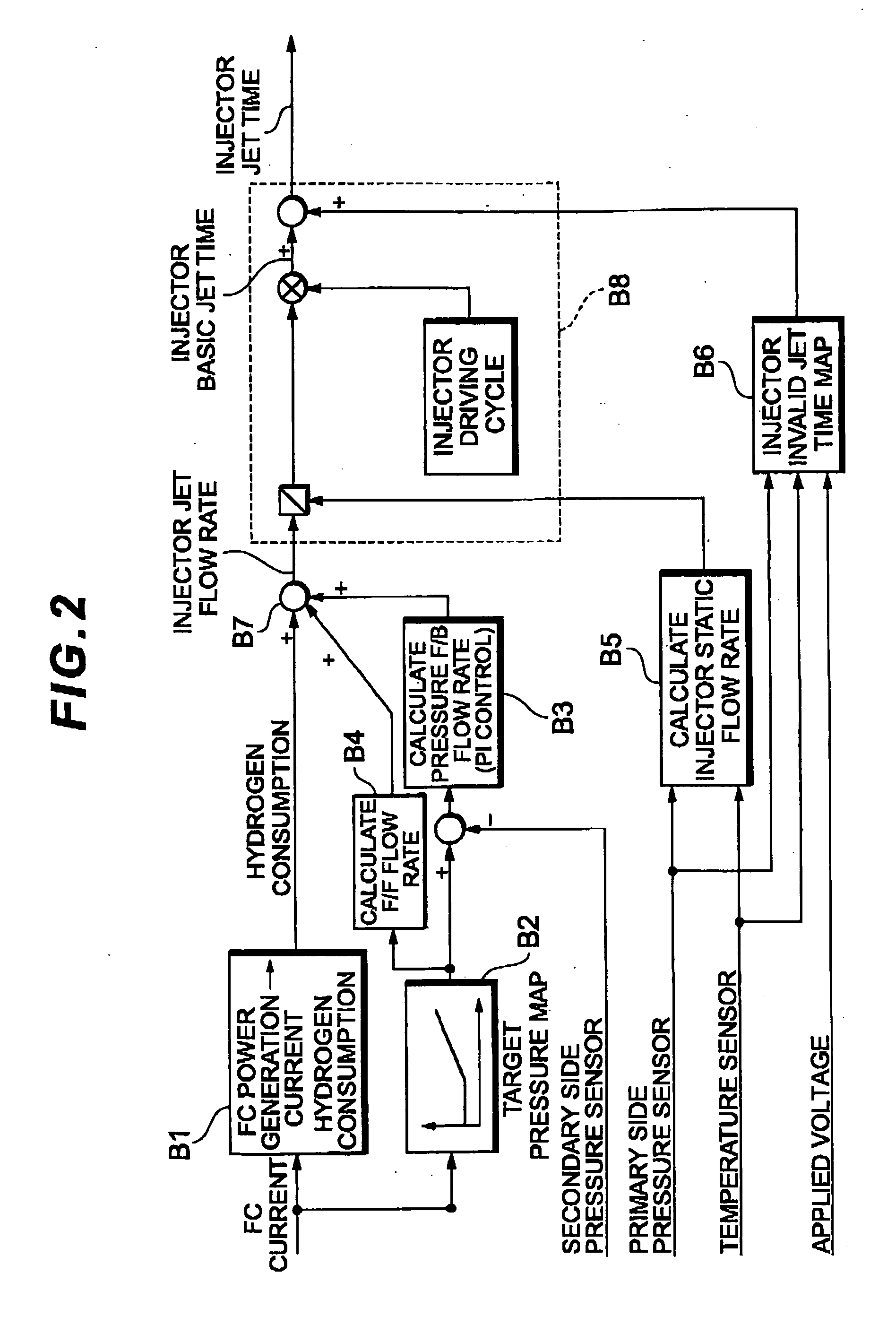

Fuel Cell System and Its Operation Stop Method

ActiveUS20090252997A1Avoid misuseImprove startup reliabilityOperating means/releasing devices for valvesReactant parameters controlFuel cellsHydrogen

The present invention provides a fuel cell system including a fuel cell, a hydrogen gas pipe system for supplying a fuel gas to the fuel cell, and an injector for adjusting a pressure of the upstream side of the hydrogen gas pipe system to supply the hydrogen gas to the downstream side, wherein the injector includes an internal channel for communicating the upstream side of the injector with the downstream side of the injector, and a valve body movably arranged in the internal channel for switching a channel opening area in multiple stages corresponding to a movement position of the valve body, and wherein water at least around the valve body of the injector is reduced when the system stops.

Owner:TOYOTA JIDOSHA KK

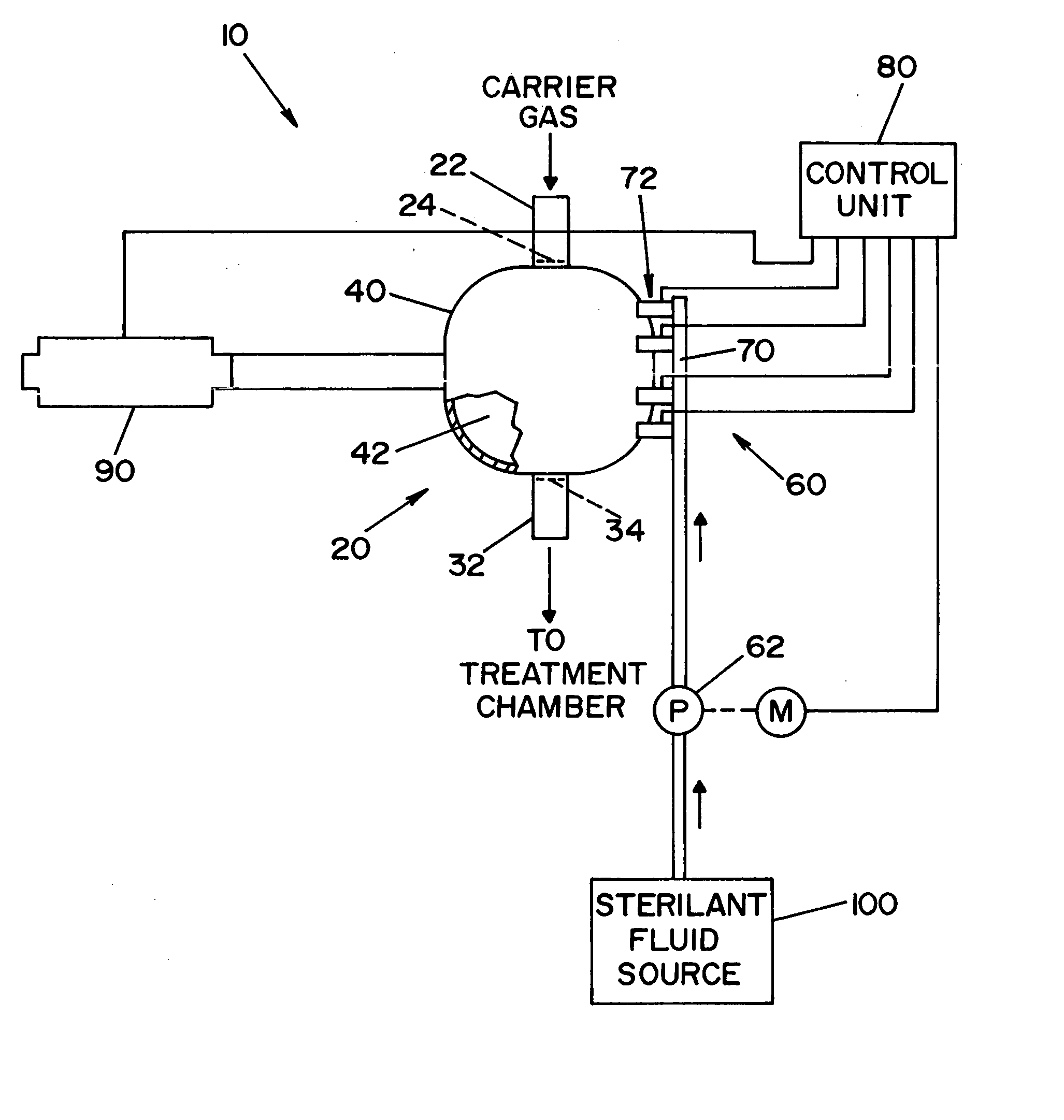

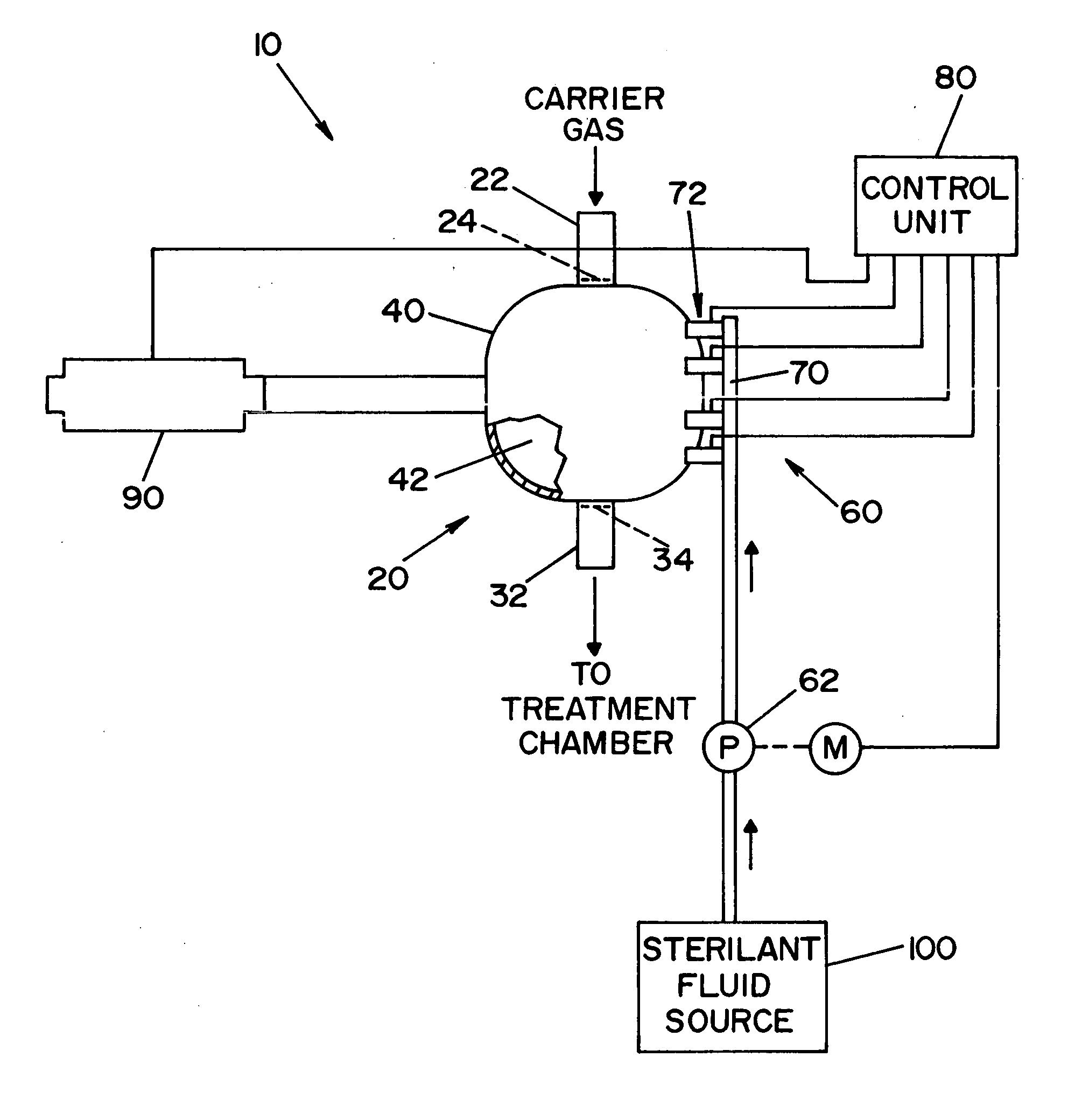

Method and apparatus for vaporizing a sterilant fluid using microwave energy

InactiveUS20050260096A1Efficiently vaporizeEasily scaleLavatory sanitoryChemicalsChemical compositionEngineering

A method and apparatus for vaporizing a sterilant fluid using microwave energy. A sterilant fluid is atomized to produce a spray, mist or fog of sterilant fluid. The atomized sterilant fluid is then exposed to microwave energy produced by a microwave generator. Molecules of at least one chemical component of the sterilant fluid rotate in response to exposure to the microwave energy, thereby vaporizing the sterilant fluid.

Owner:AMERICAN STERILIZER CO

Gas manifold

InactiveUS6123773AAvoid condensationPrevent decomposition and condensationSemiconductor/solid-state device manufacturingChemical vapor deposition coatingStrontiumEngineering

The invention relates to an apparatus and process for the vaporization of liquid precursors and deposition of a film on a suitable substrate. Particularly contemplated is an apparatus and process for the deposition of a metal-oxide film, such as a barium, strontium, titanium oxide (BST) film, on a silicon wafer to make integrated circuit capacitors useful in high capacity dynamic memory modules.

Owner:APPLIED MATERIALS INC

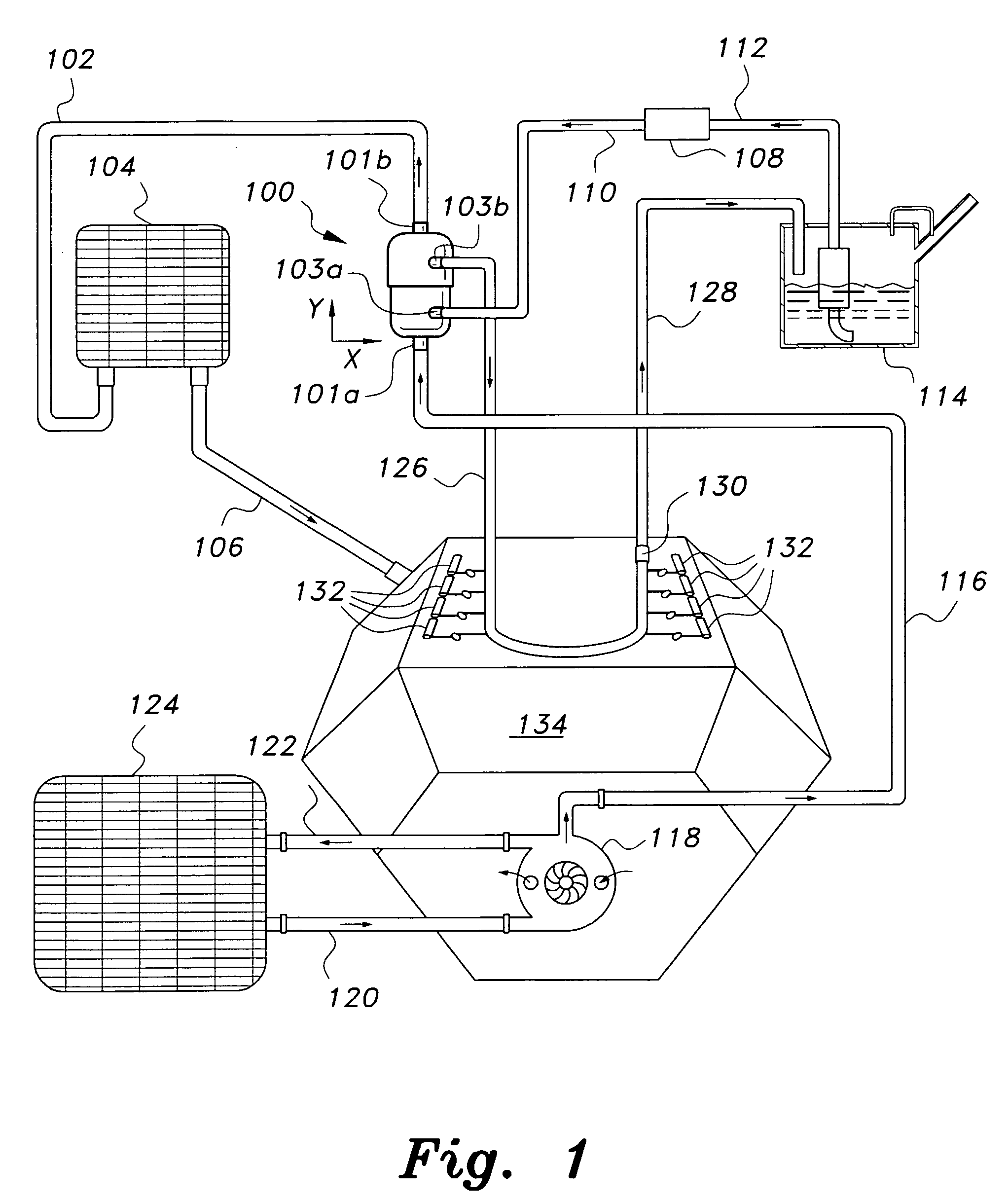

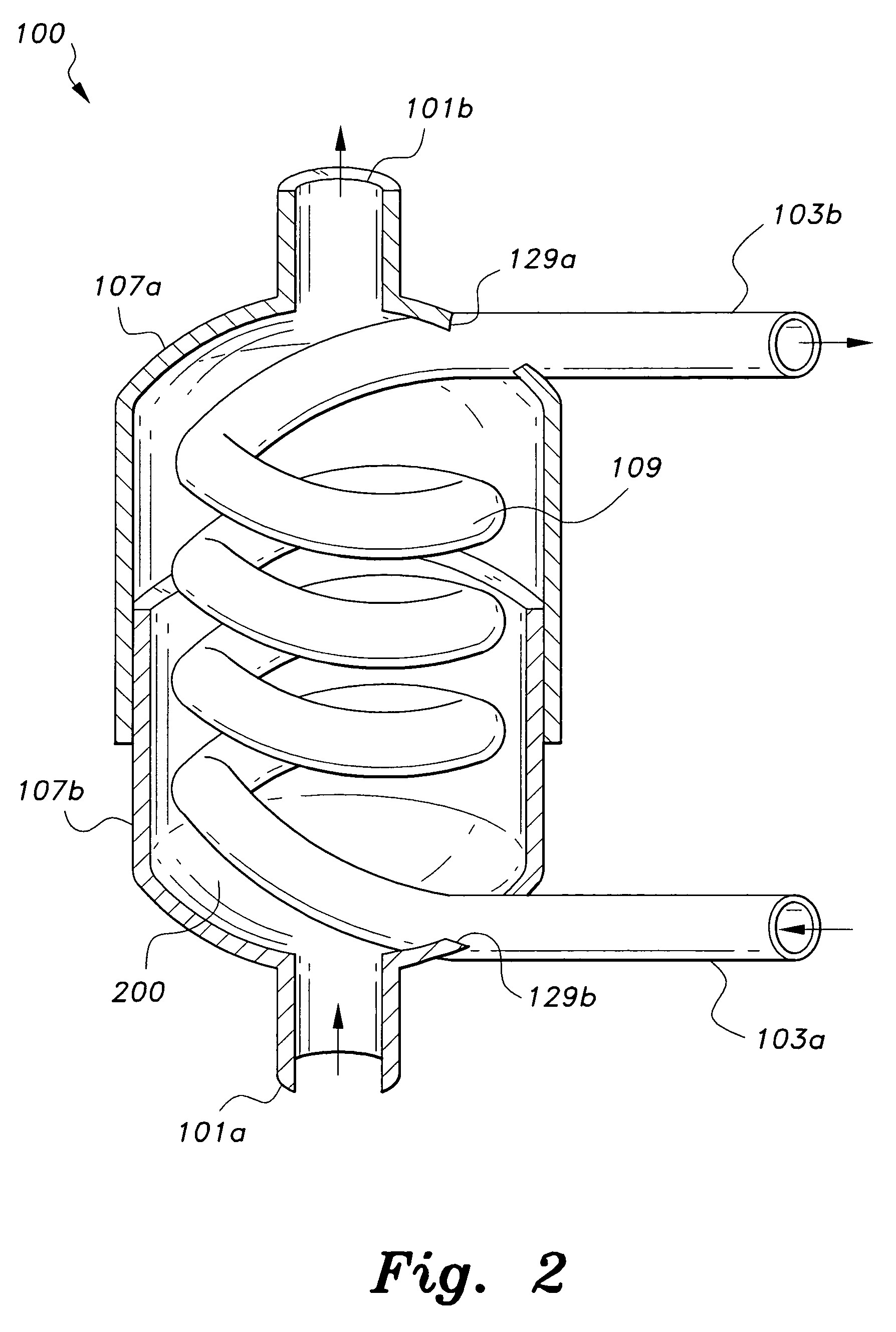

Vehicle fuel preheater

InactiveUS20080314370A1Effectively “vaporized”Efficient combustionCoolant flow controlInternal combustion piston enginesCombustion chamberPlate heat exchanger

The vehicle fuel preheater works on the known fact that by preheating the fuel, the fuel is more effectively vaporized, resulting in more efficient combustion. This preheating is accomplished using heat that normally cycles through the heater core for interior heat. The preheater, i.e., heat exchanger, has a housing, through which heated engine coolant on its way from the cooling pump to the heater core is routed. A coiled copper gas line is routed through the housing, and is connected between a segment of the fuel line and the engine combustion chamber so that the preheater can deliver preheated fuel to the combustion chamber. The heat exchanger is installed in a vertical orientation to prevent air lock in the fuel and cooling systems.

Owner:WEICHE CHRISTOPHER D

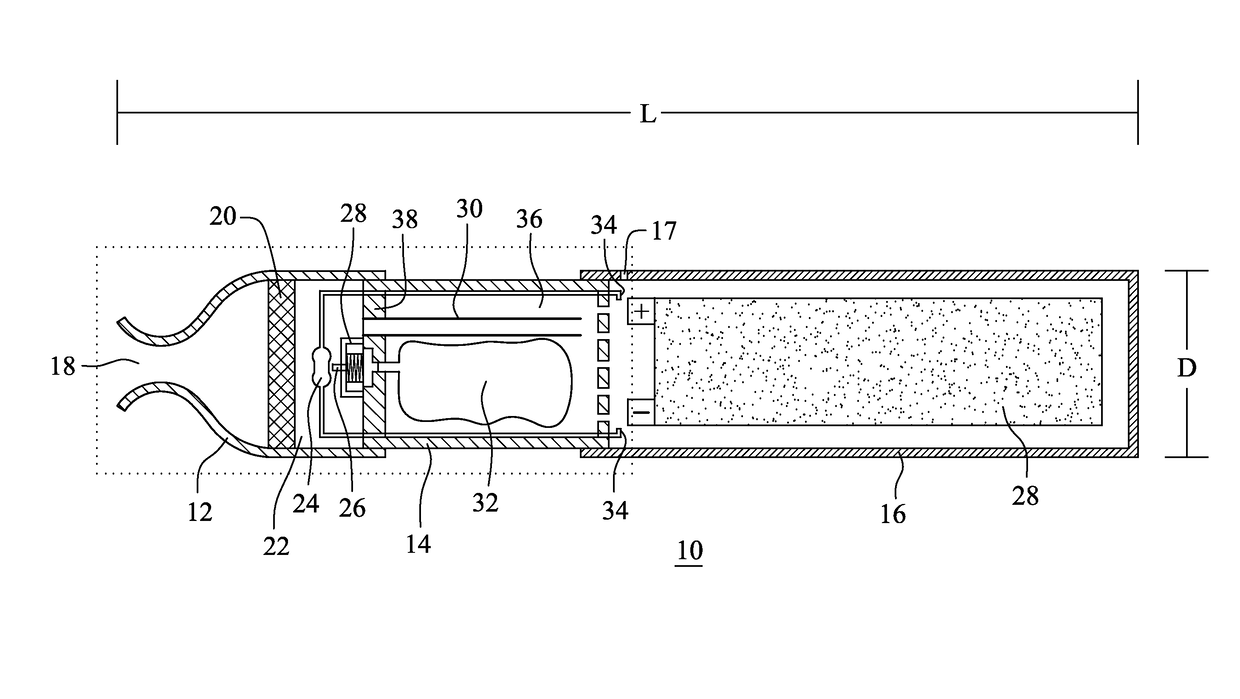

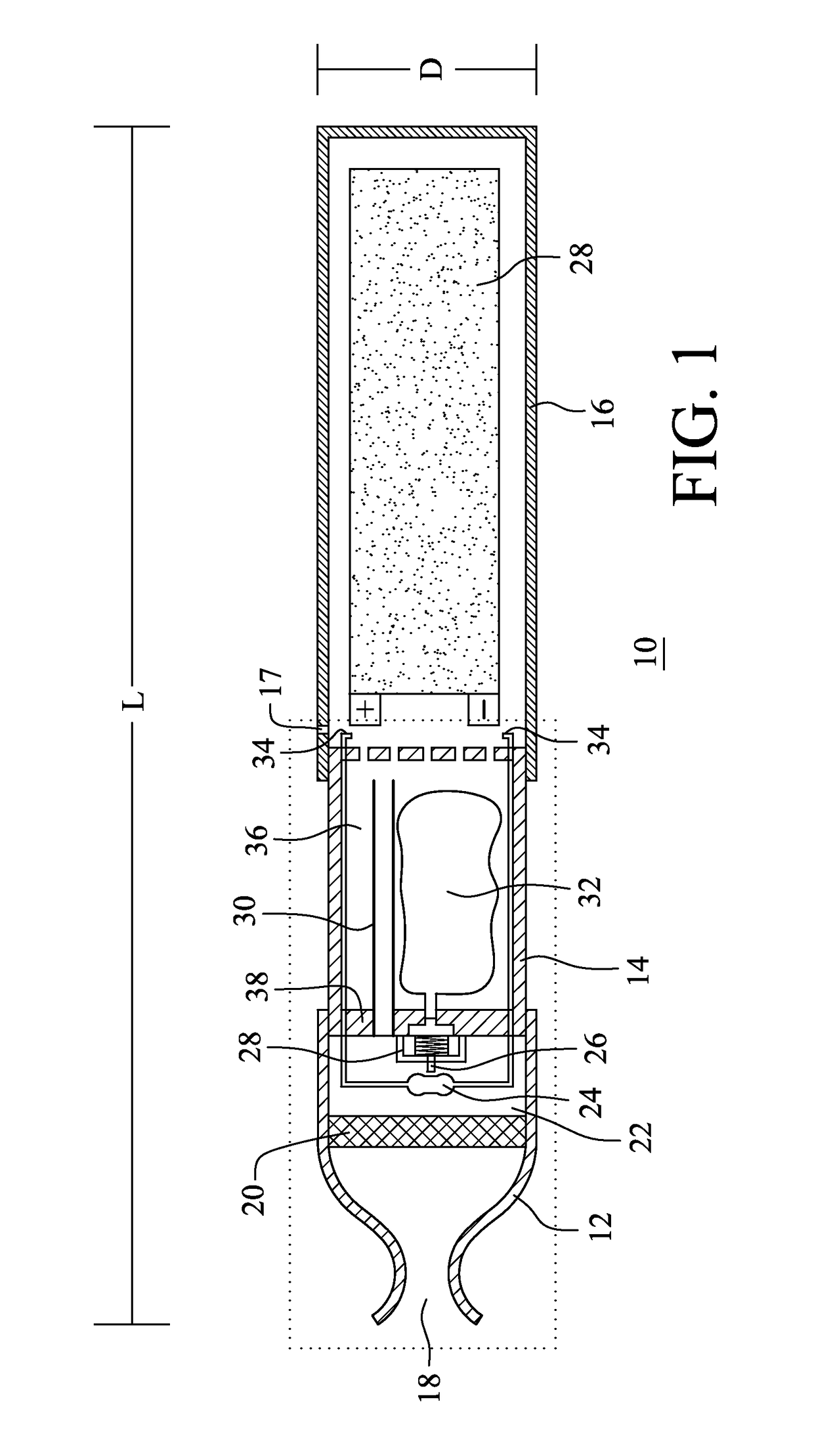

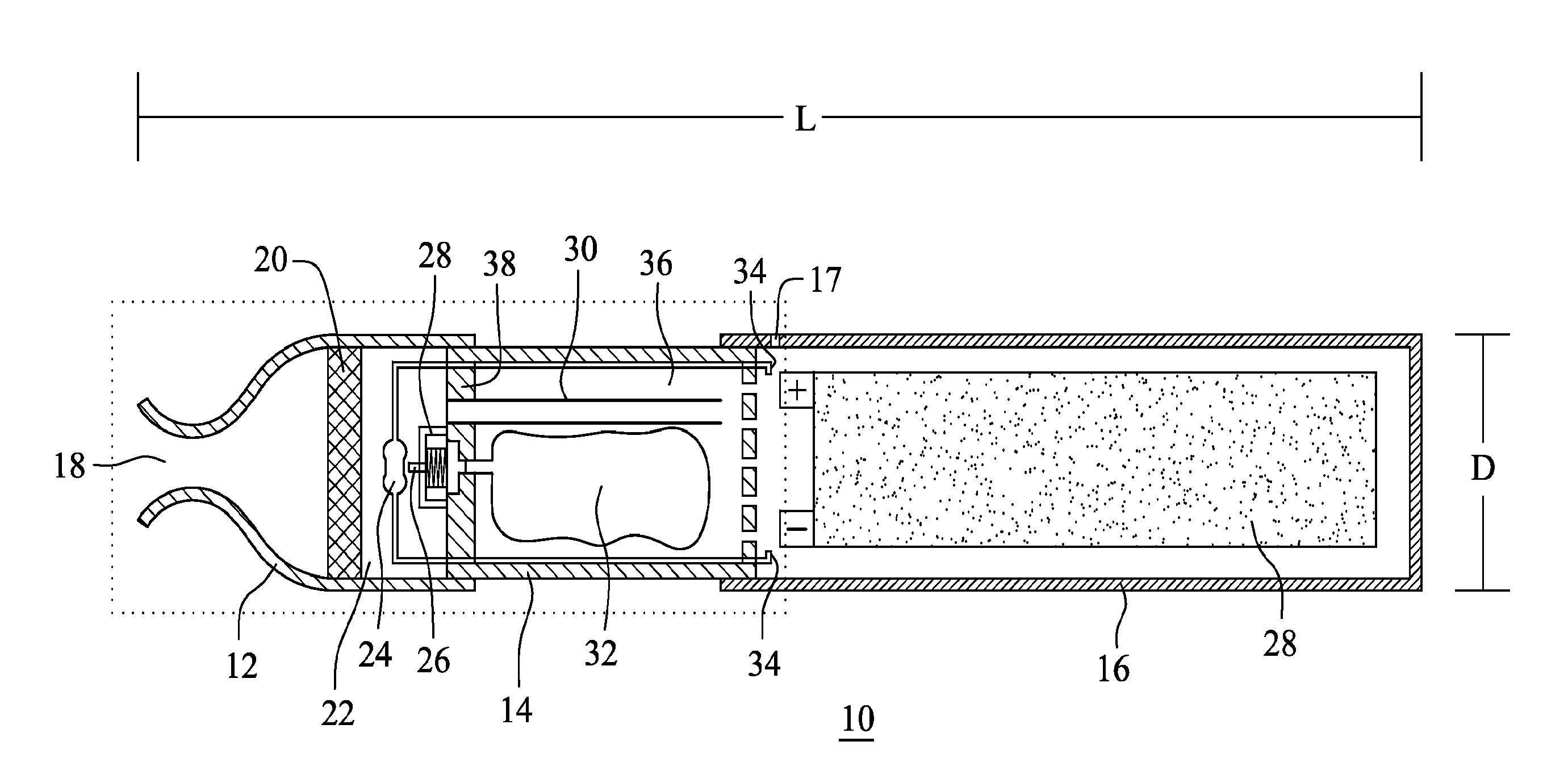

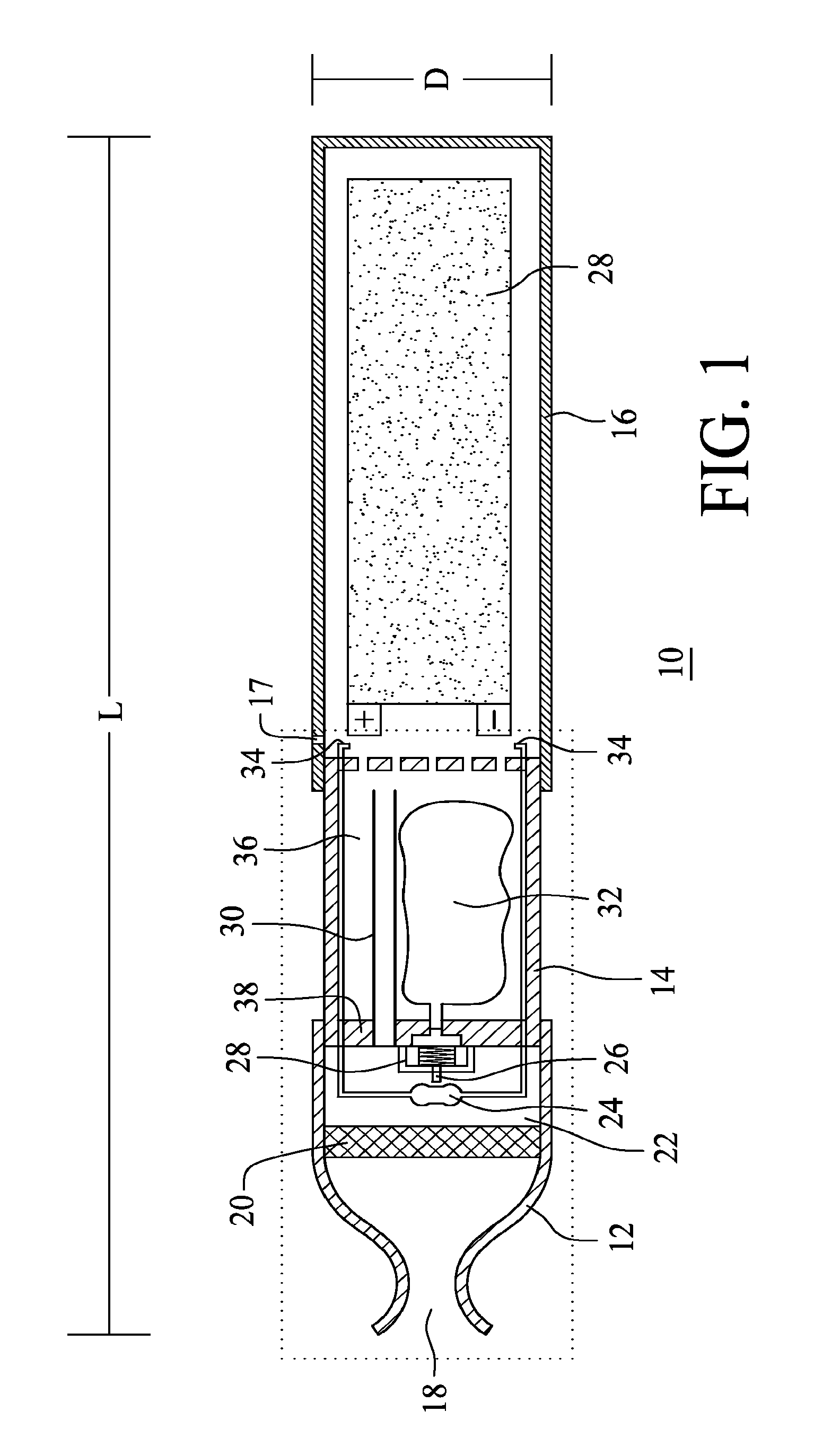

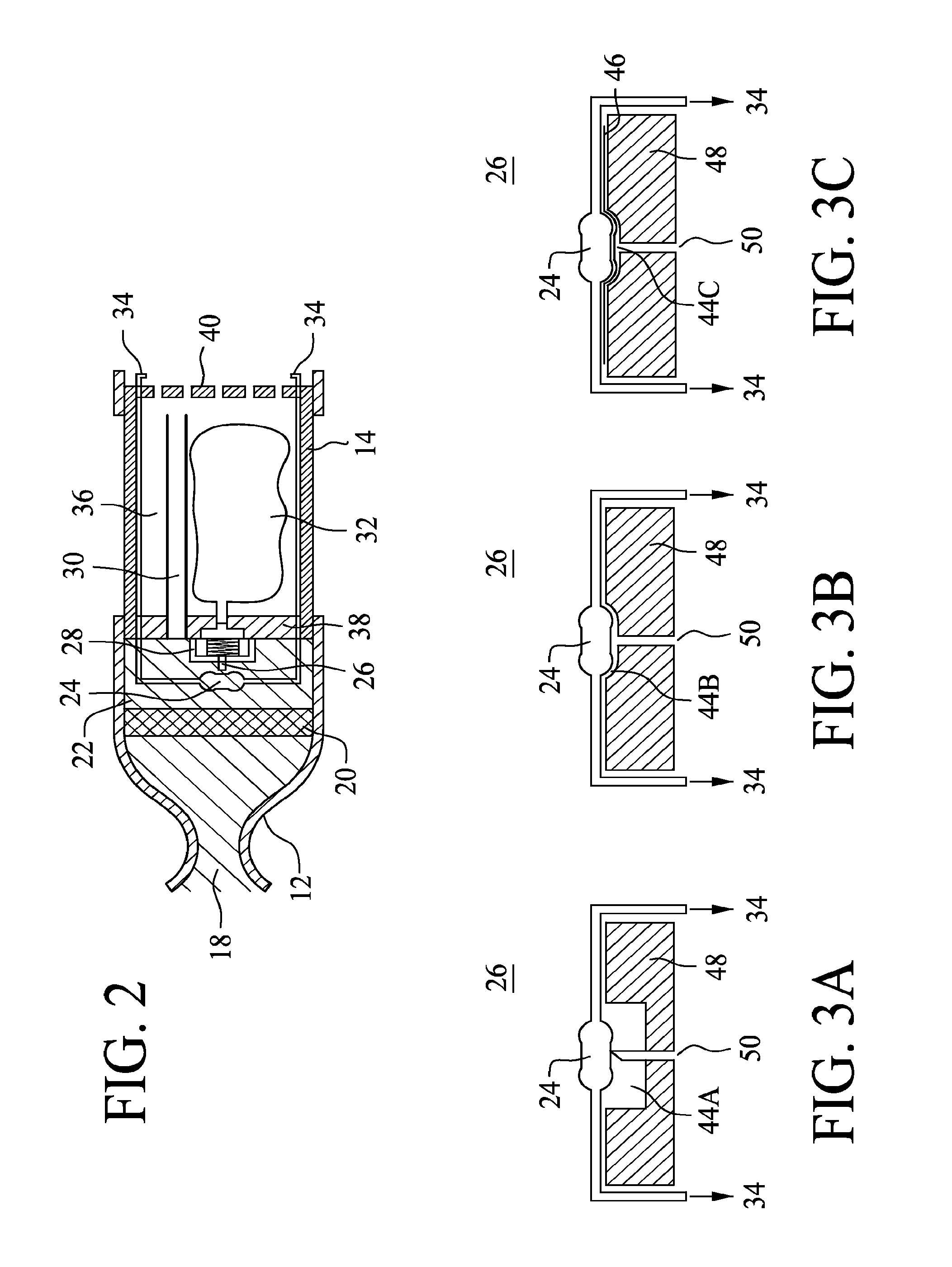

Personal vaporizer with liquid supply by suction

ActiveUS20170013884A1Effectively “vaporized”Increase temperatureSteam generation heating methodsElectric heatingSuction forceEngineering

A personal vaporizer including a pressure-induced liquid transport device that allows a user to draw liquid from a liquid reservoir through applying a suction force on the mouthpiece. The amount of liquid drawn is proportional to the pressure induced, and proportional to the amount of vaporization a user may desired.

Owner:WESTFIELD GROUP

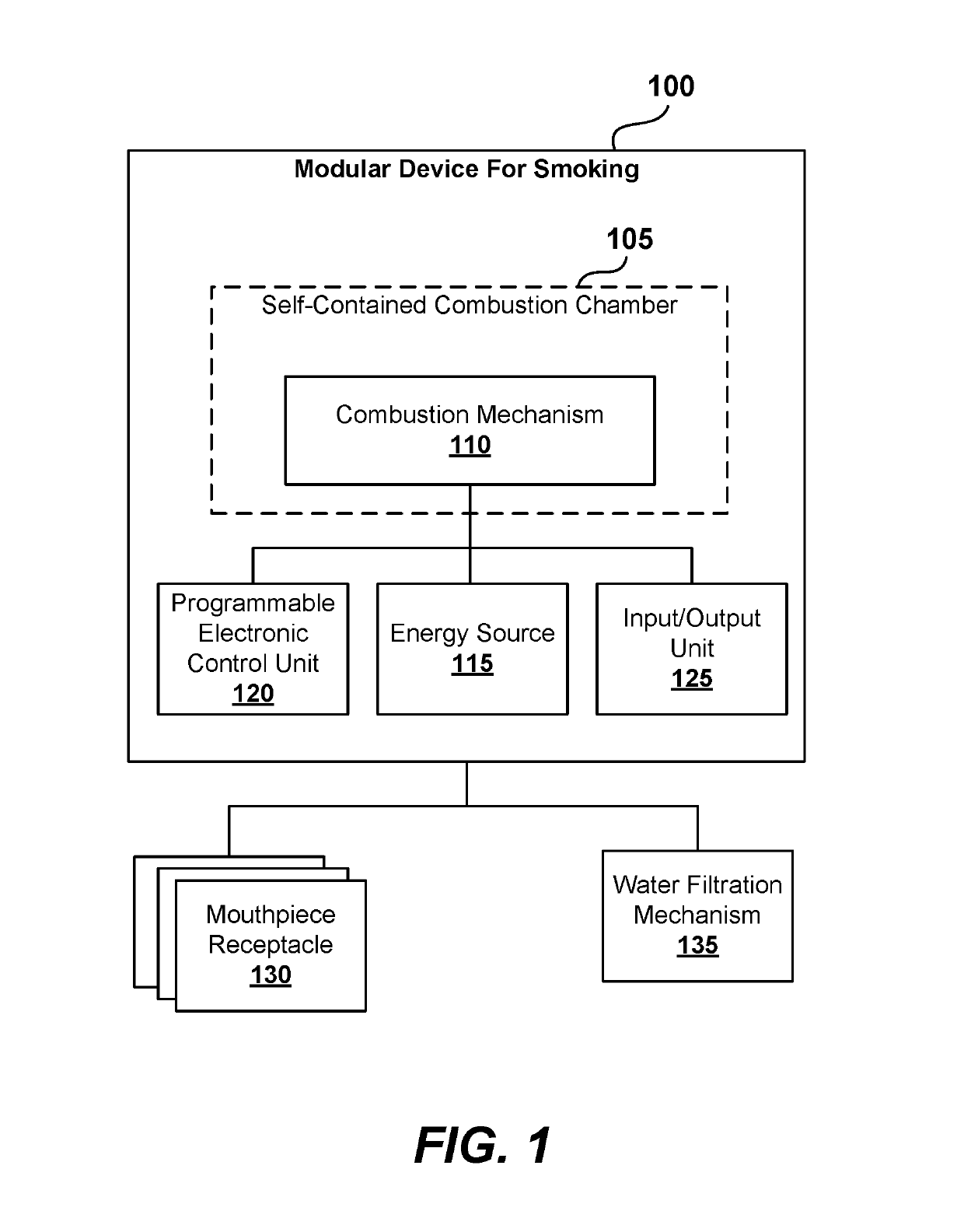

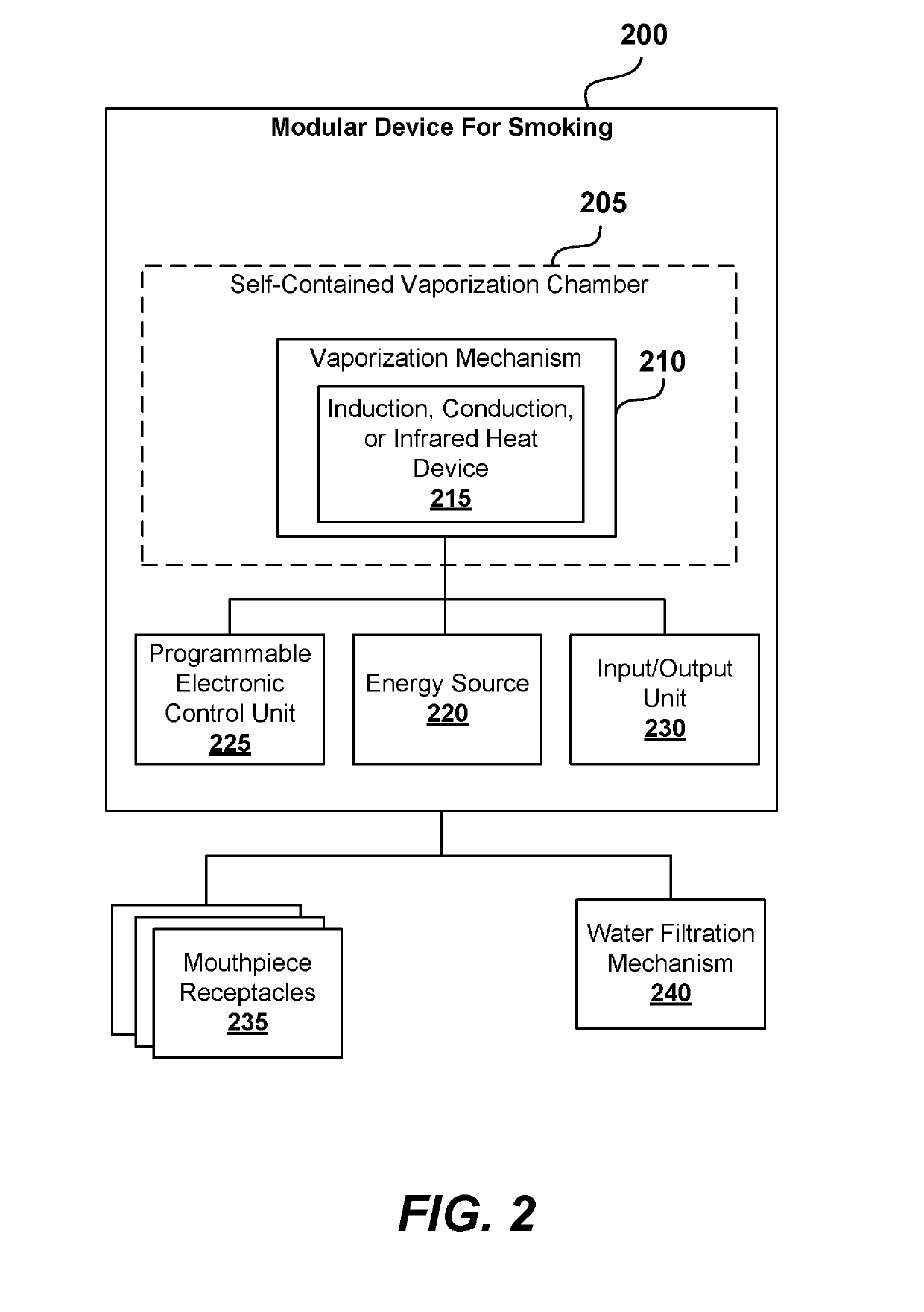

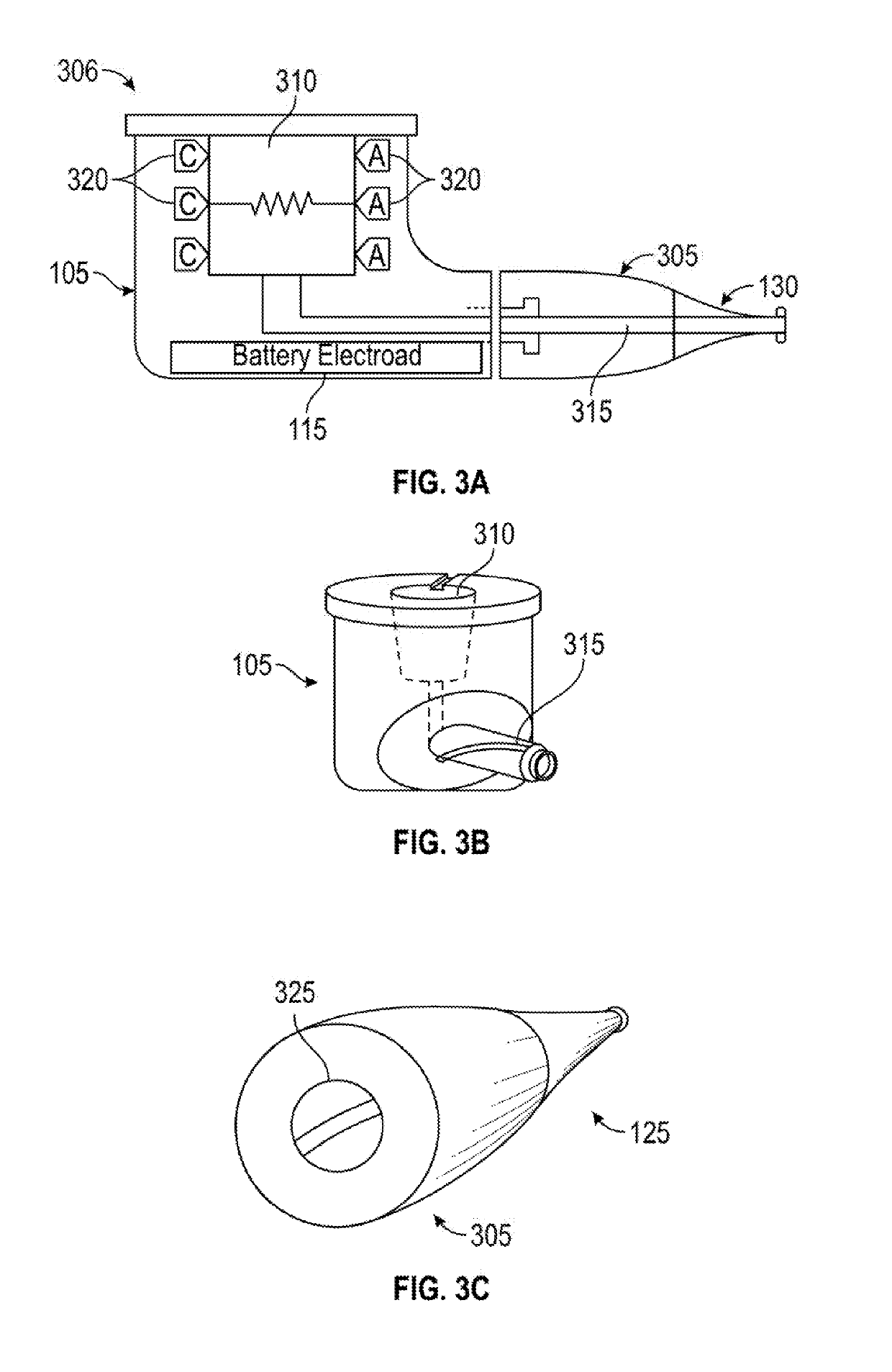

Modular smoking device

ActiveUS20190246691A1Effectively “vaporized”Avoid it happening againElectric discharge heatingTobacco treatmentElectricityElectric discharge

Modular smoking devices that generate vapors of certain materials, such as tobacco or cannabis are disclosed. The technology provides for intelligent ignition, combustion, or vaporization of given material at the appropriate temperatures that prevent generation of harmful and unwanted byproducts. According to one embodiment, the modular smoking device comprises a self-contained combustion chamber to hold the material, a combustion mechanism integrated with the self-contained combustion chamber, and an energy source, such as a rechargeable battery, to power the combustion mechanism. The combustion mechanism is configured to provide targeted combustion of the material, where the active ingredients generated upon the combustion are consumed by inhaling a smoke or vapor resulting from the combustion or vaporization. The self-contained combustion chamber includes a lighterless combustion mechanism such as a piezoelectric lighter or a Tesla coil lighter that is designed to arc an electric discharge through the material in the self-contained combustion chamber.

Owner:MCCOY DAVID

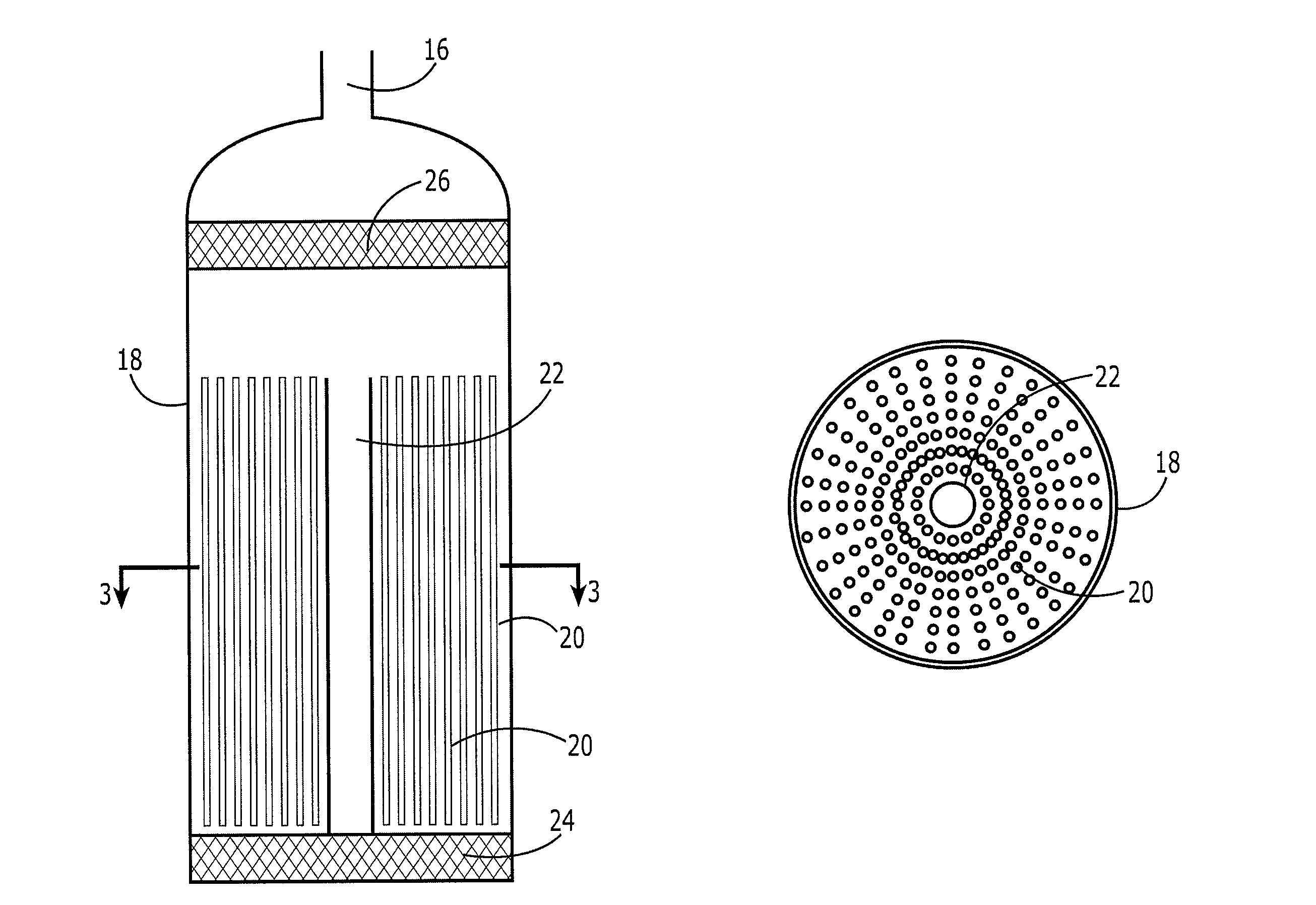

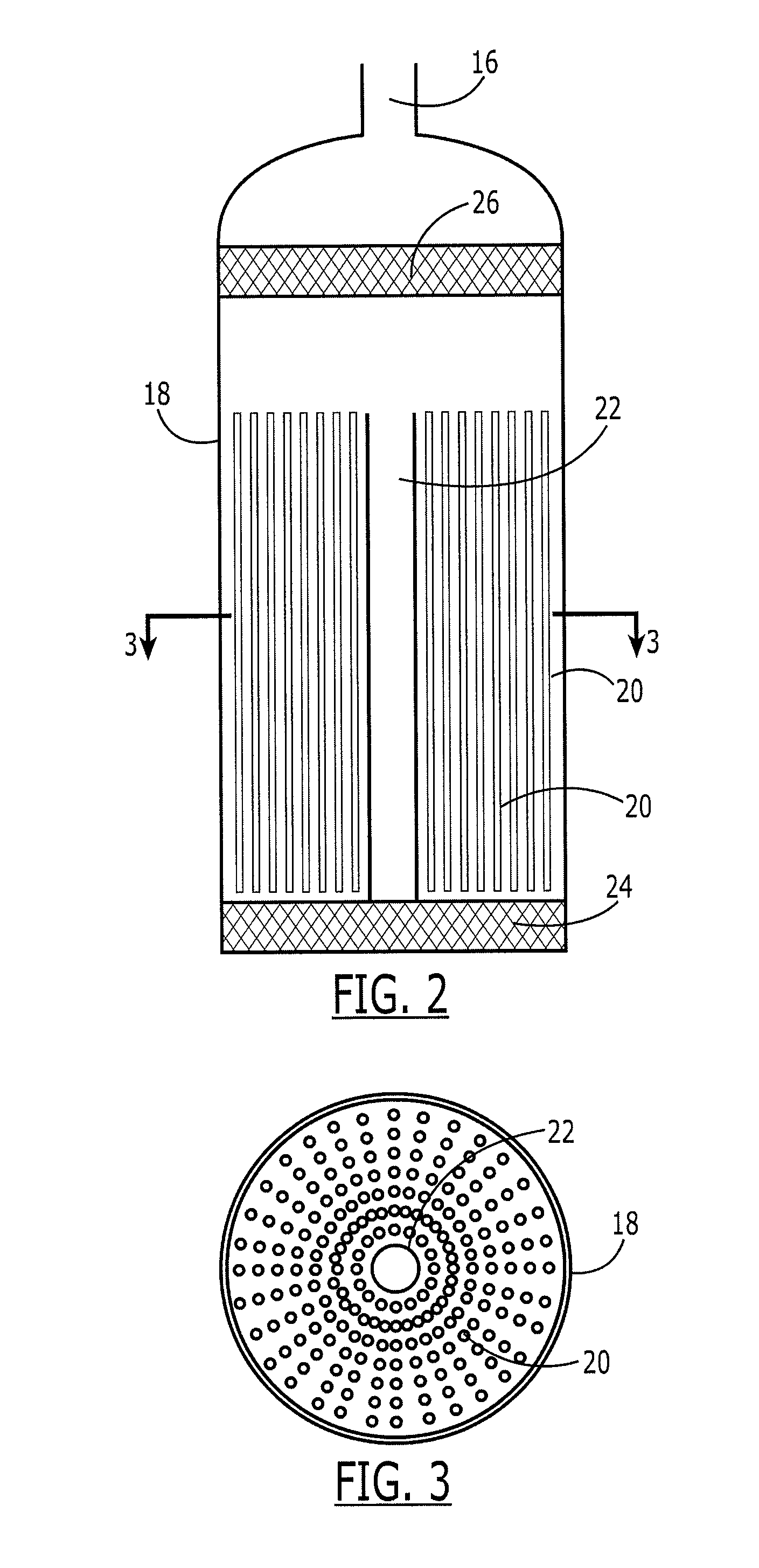

Apparatus and process for vaporizing a heavy hydrocarbon feedstock with steam

InactiveUS20050014986A1Reduce riskIncrease of pressure dropThermal non-catalytic crackingEvaporationVaporizationHydrocarbon

Apparatus for the vaporization of a heavy hydrocarbon feedstock with steam includes a frusto-conically-shaped element which is capable of inducing a gentle swirl pattern to a liquid-containing stream, which device is connected to the feed inlet pipe of the mixing nozzle. This swirl-inducing device effects a 90° bending of the flow direction of the hydrocarbon feedstock while simultaneously effecting a swirl pattern of the liquid part thereof, thereby forcing the liquid against the wall of the feed inlet pipe extending downwardly to the mixing nozzle with such velocity component perpendicular to the tube's longitudinal axis that an annular flow pattern is re-established.

Owner:SHELL OIL CO

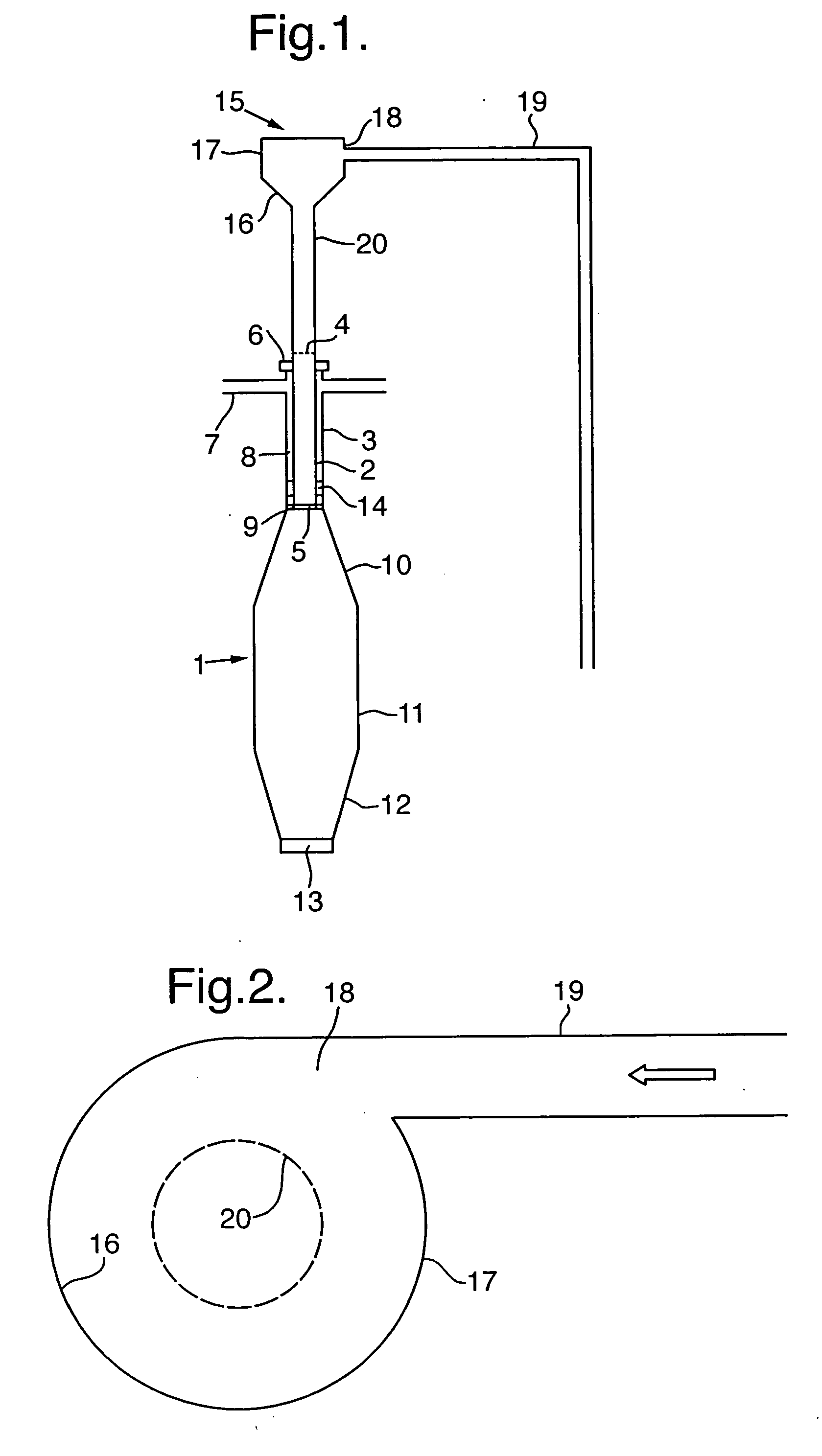

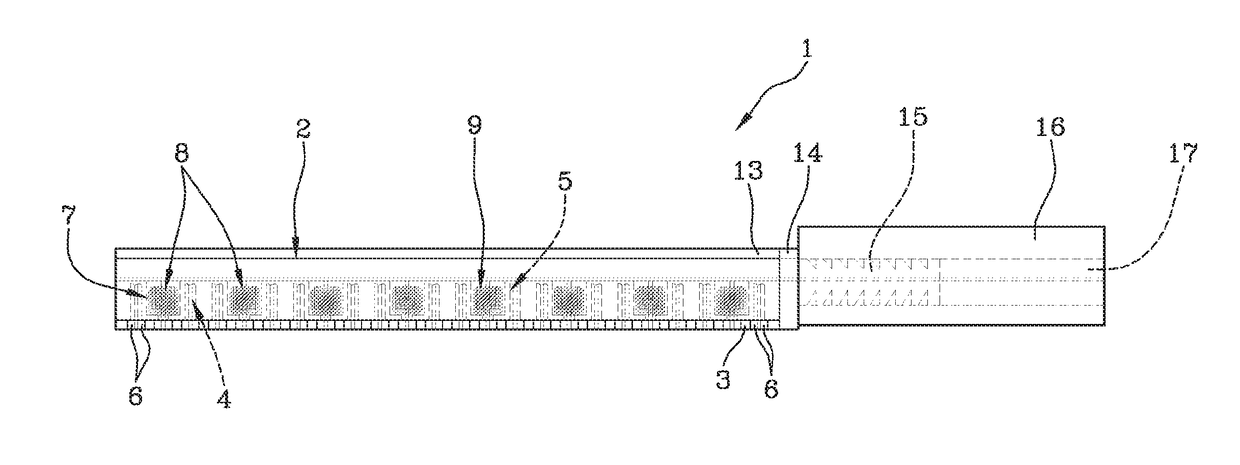

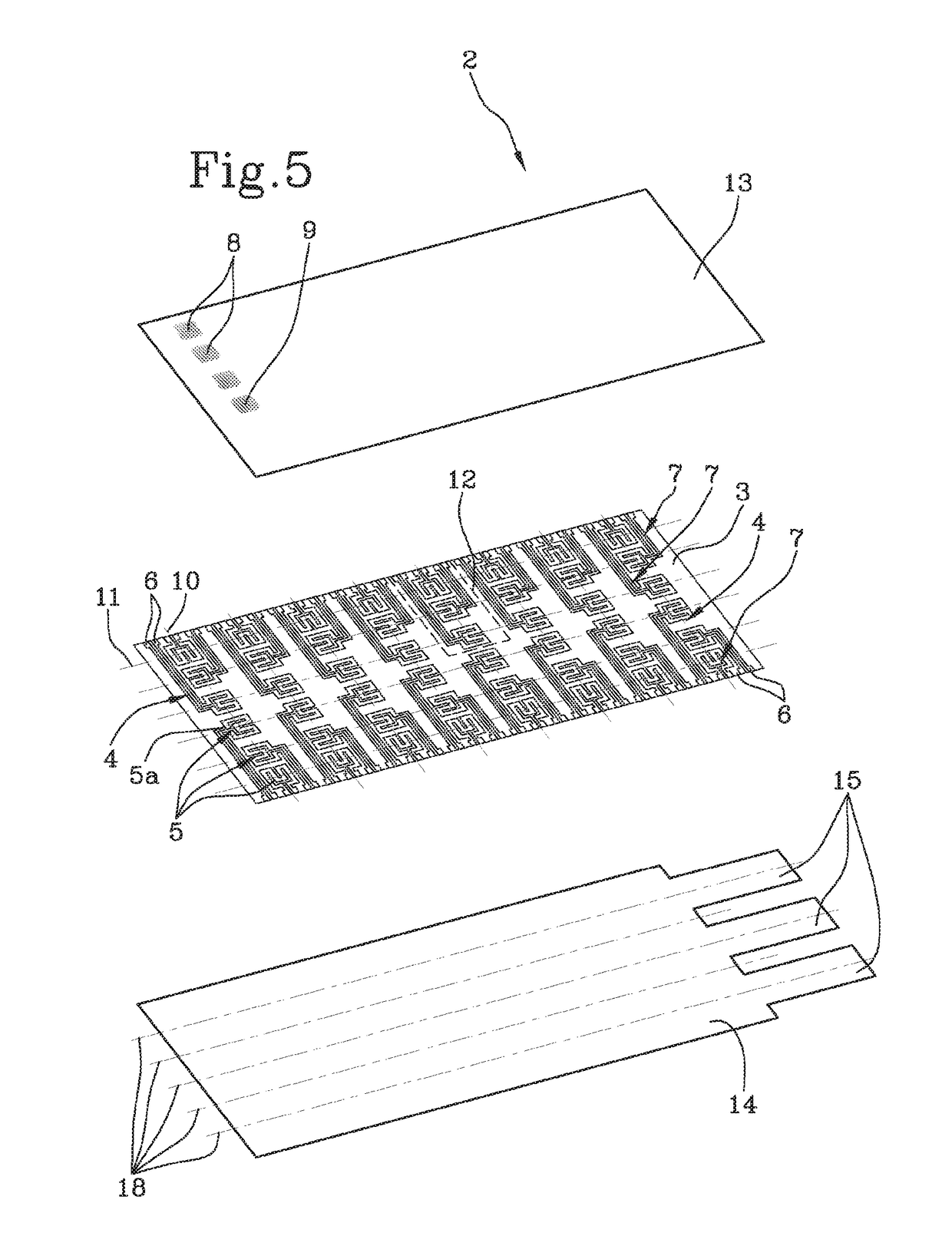

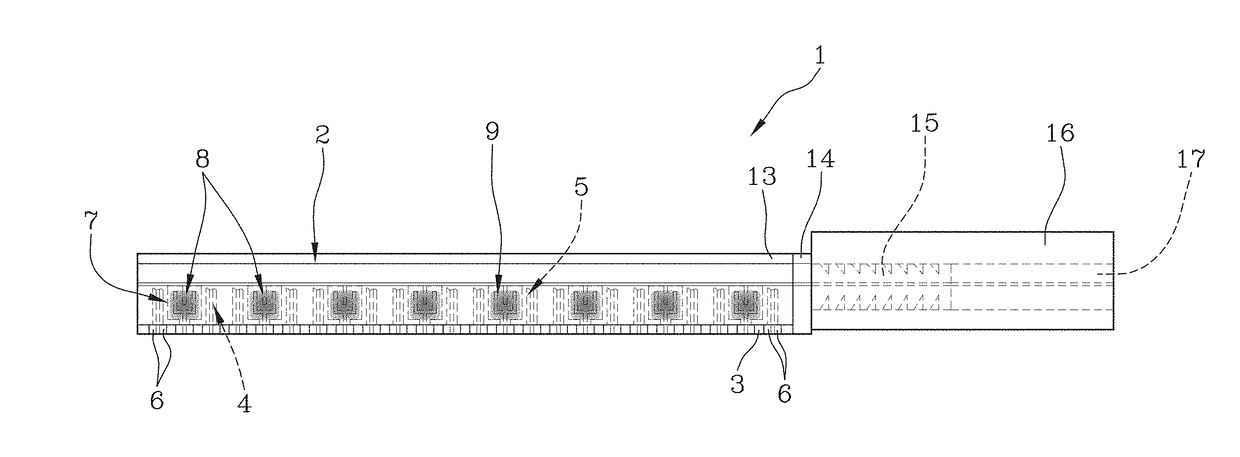

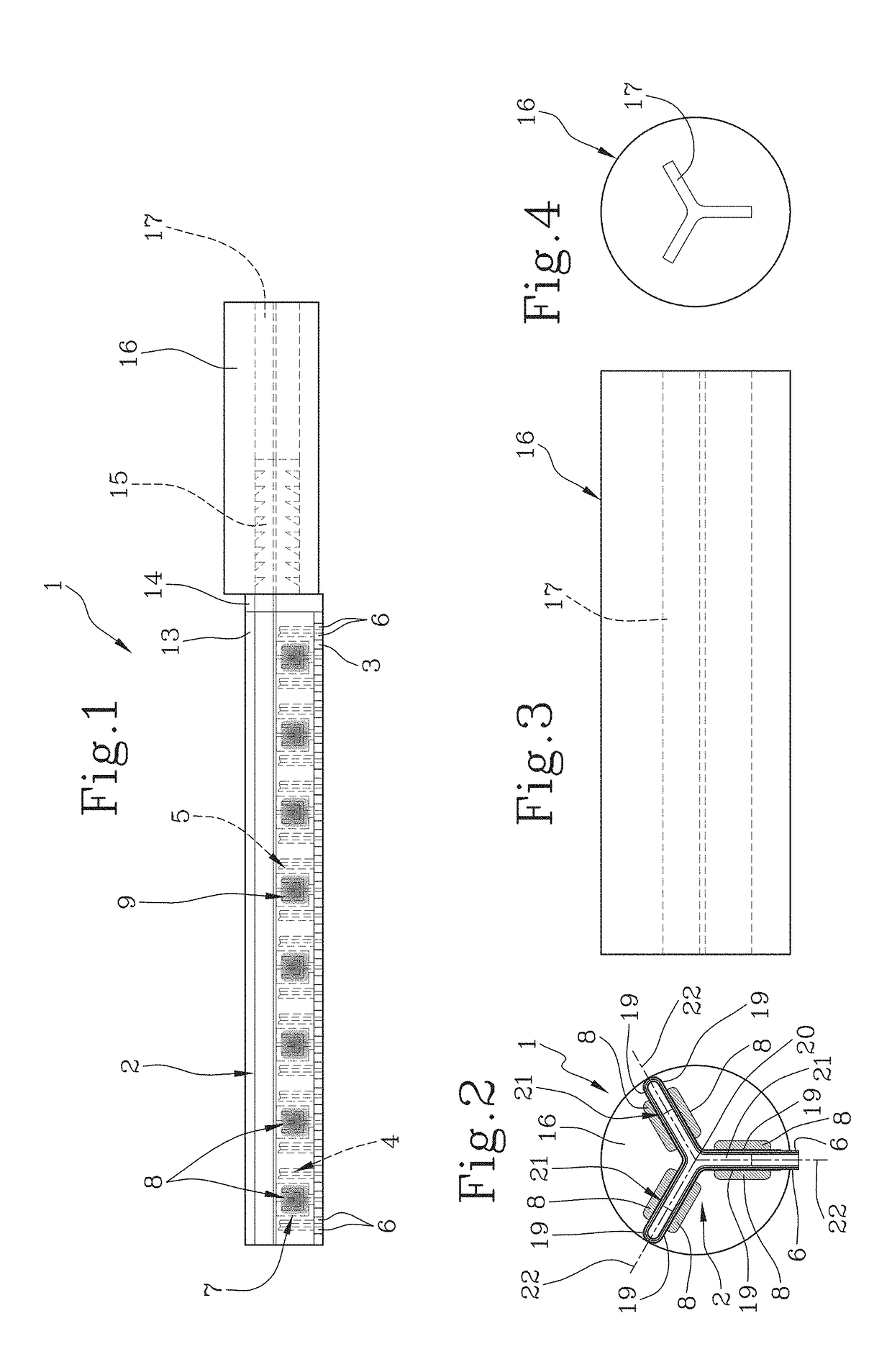

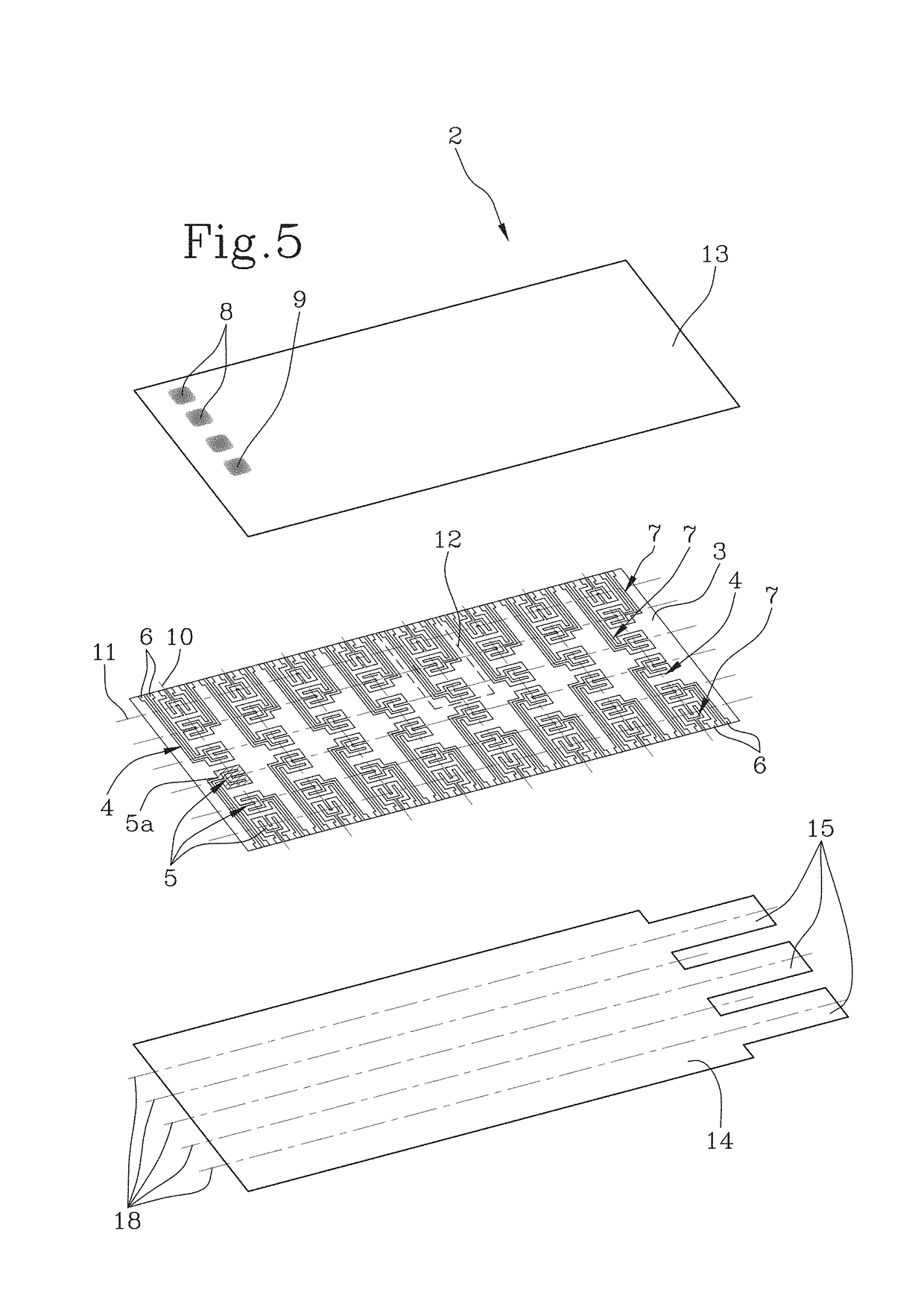

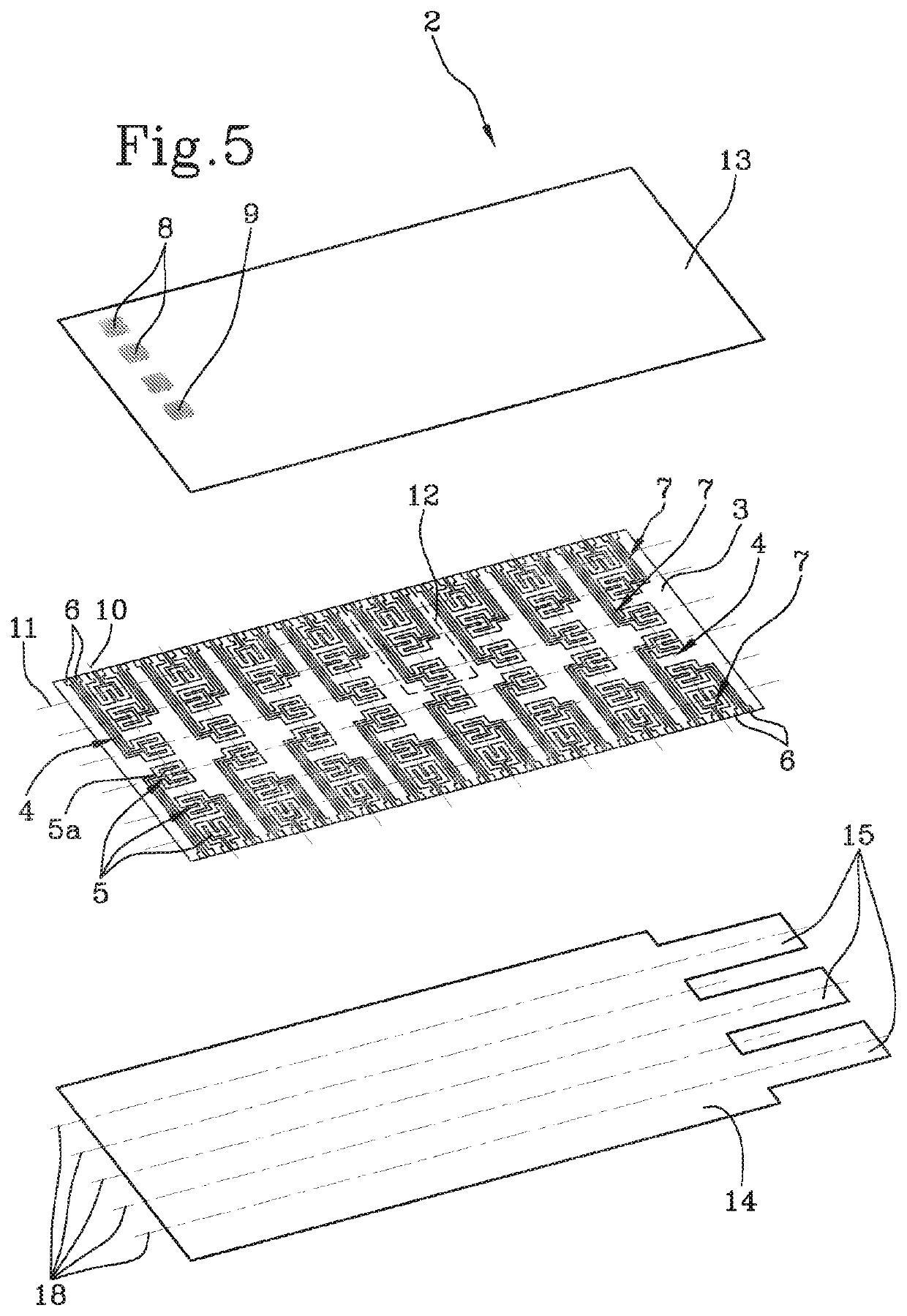

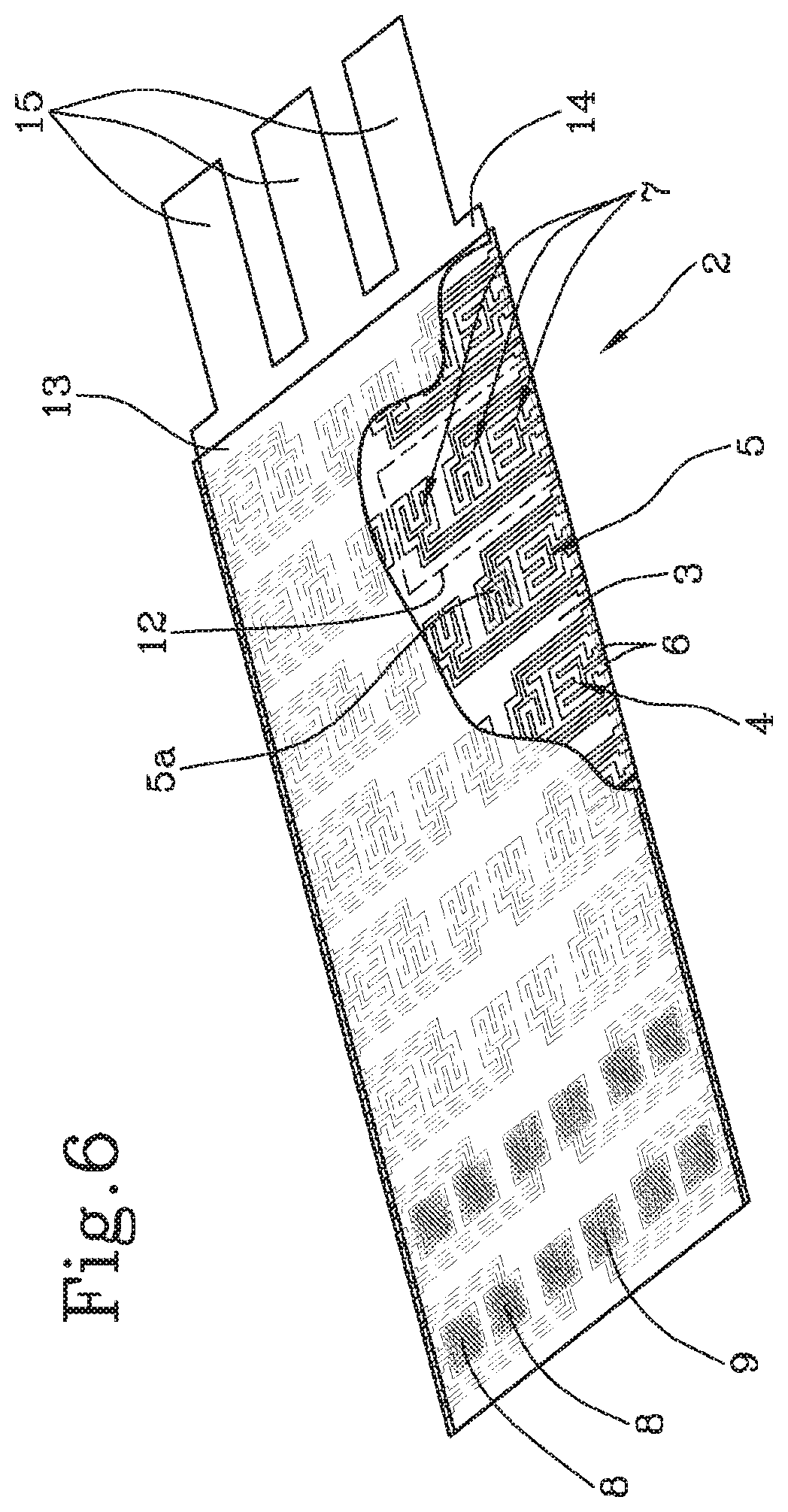

Electric cartridge for electronic cigarette and electronic cigarette

ActiveUS20180116285A1Effectively “ vaporize ”Effectively “vaporized”Tobacco devicesInhalatorsElectrically conductivePower flow

An electric cartridge for an electronic cigarette including a piece of flexible substrate material including at least a flexible film which mounts an electrically conductive network in the form of an array and defining a plurality of resistive zones (pixels) and a plurality of power supply pins for supplying one or more electric currents and connected to the resistive zones. The resistive zones define heating means and are grouped into distinct modules. Each module corresponds to an uninterrupted portion of the electrically conductive network and includes at least one resistive zone and respective power supply pins. The electric cartridge includes a plurality of portions of aromatic substance positioned on at least one face of the piece of flexible material. Each portion is associated with a resistive zone and positioned in proximity to a heating surface of the respective resistive zone.

Owner:GD SPA

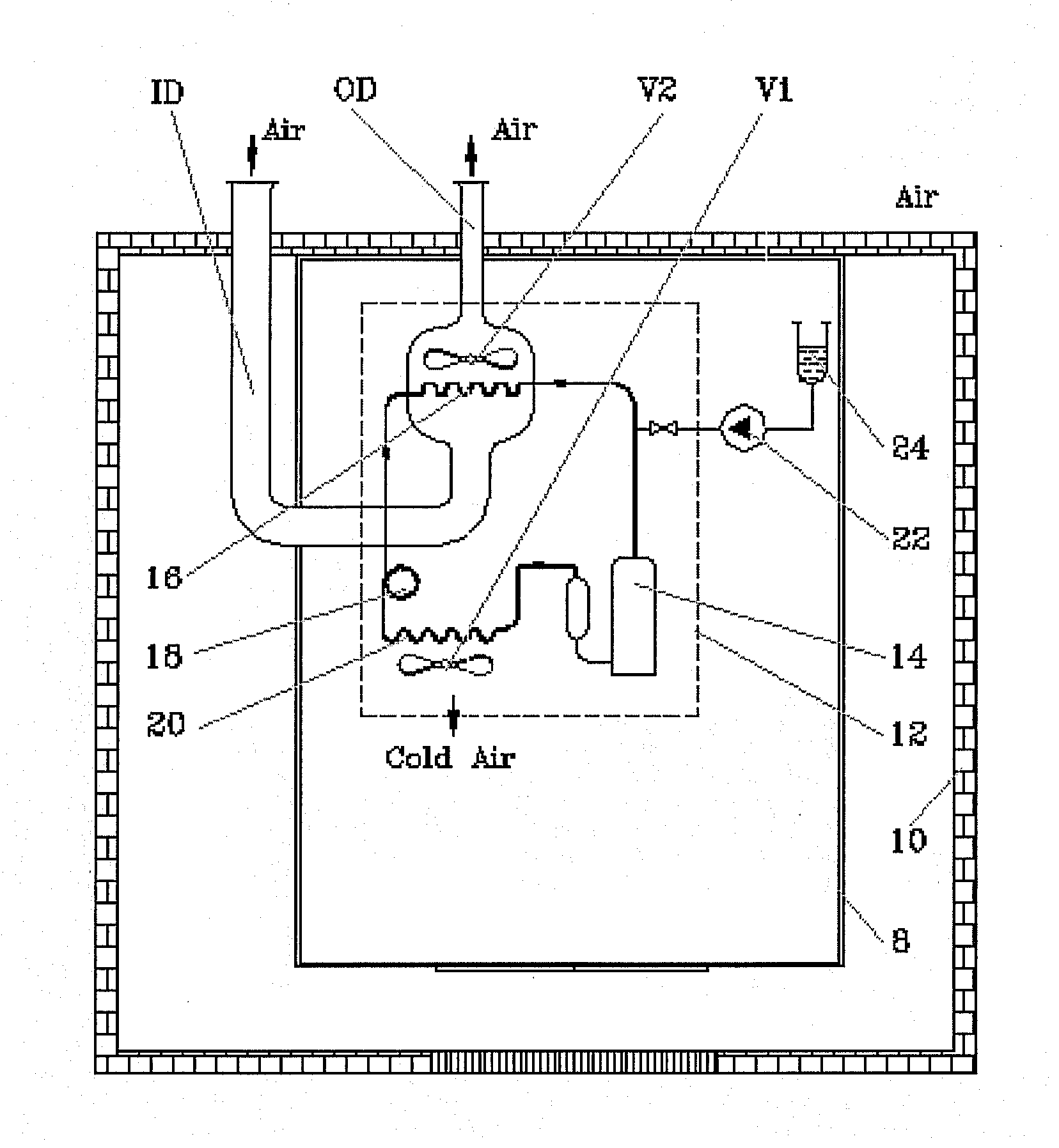

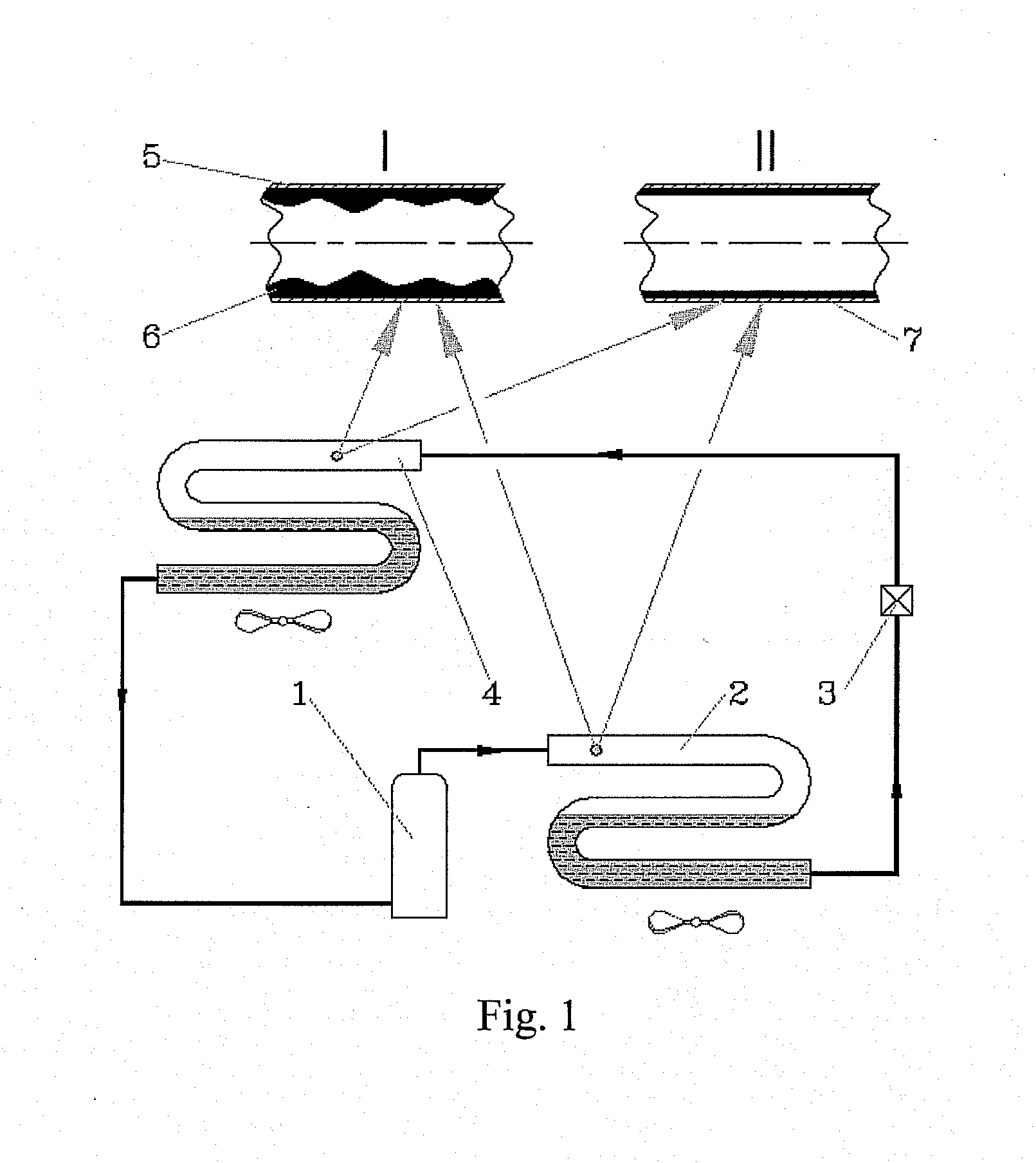

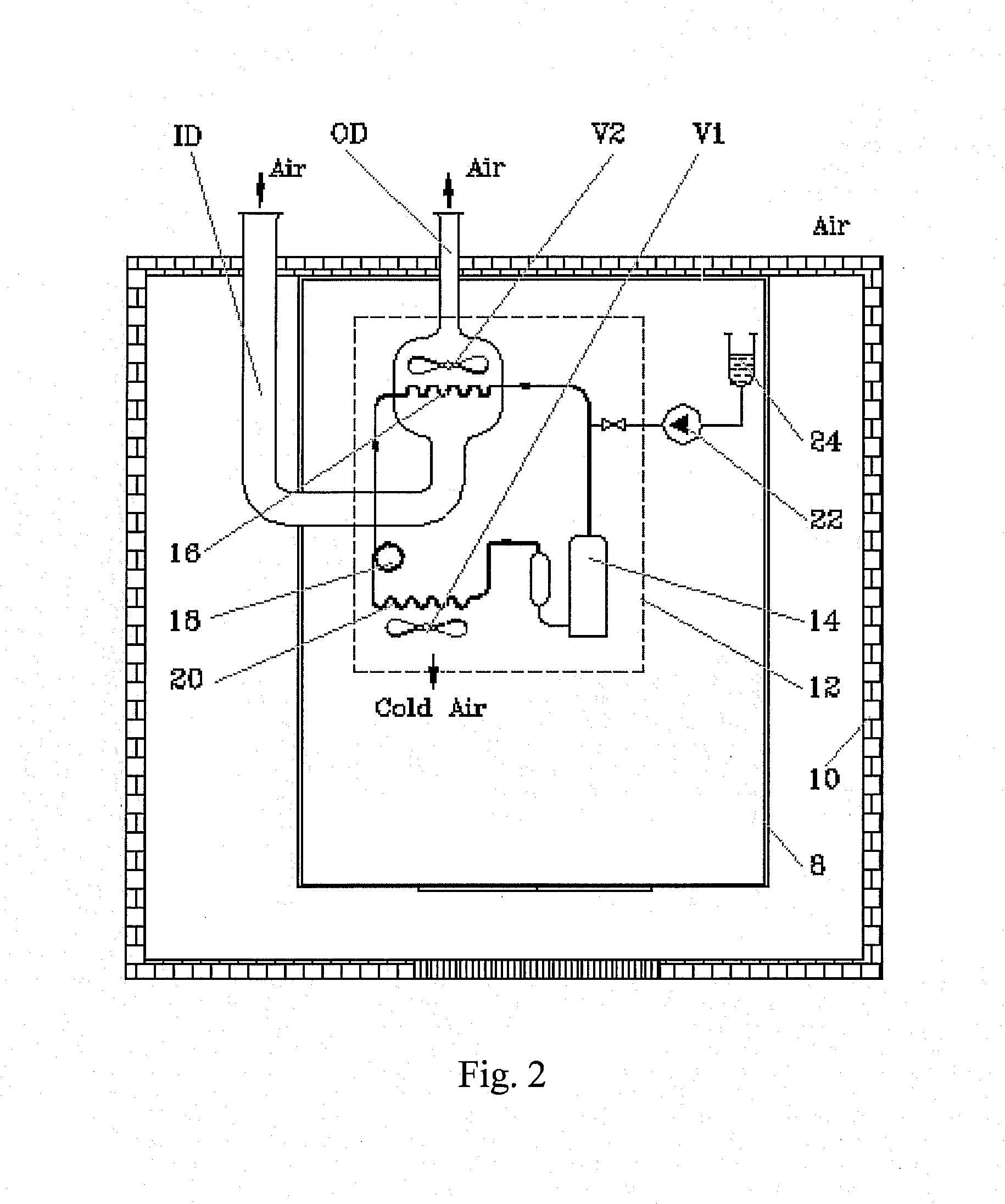

Refrigerants

InactiveUS20140131613A1Efficient and convenient evacuationEffectively “vaporized”Heat-exchange elementsThermodynamic cycleRefrigerant

Refrigerants for use in a thermodynamic cycle taking place in a system producing either hot or cold are disclosed. The refrigerants comprise binary azeotrope mixture of saturated hydrocarbon with either methanol or ethanol. The refrigerants are of preventing undesirable formation of oil film on the inner surface of the circulating system and thus to improve the performance of the system.

Owner:GALKOR ENERGY SYST

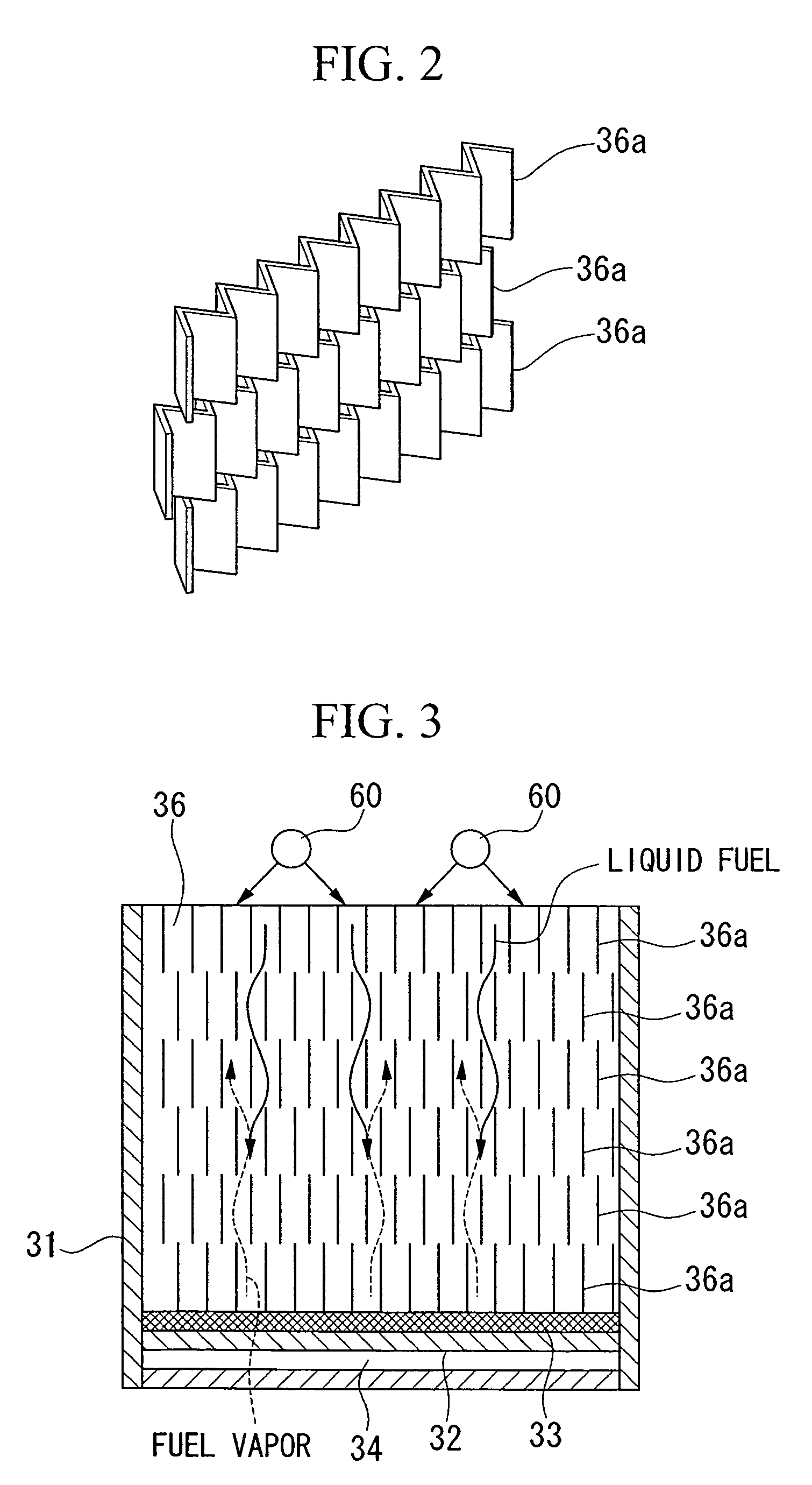

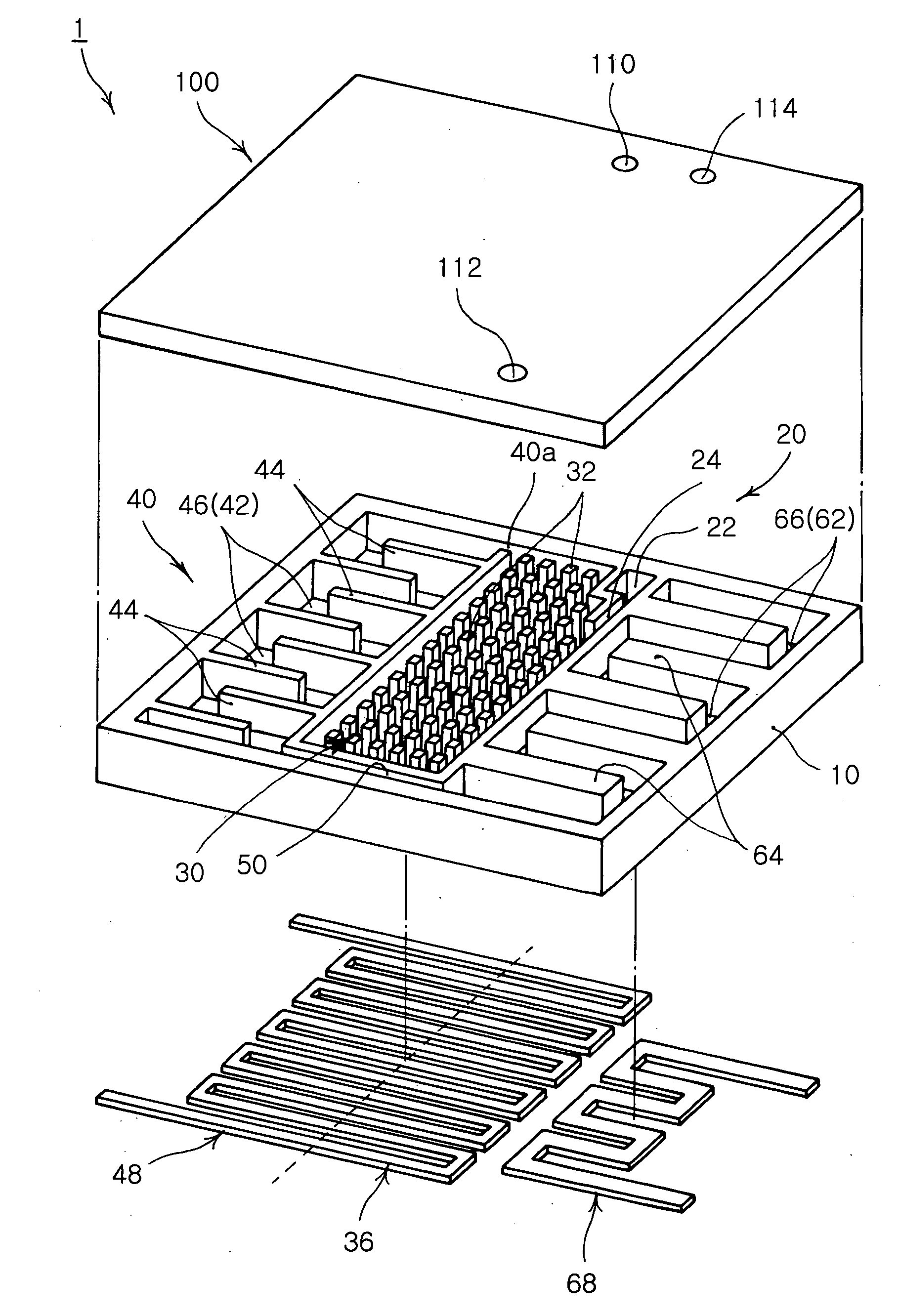

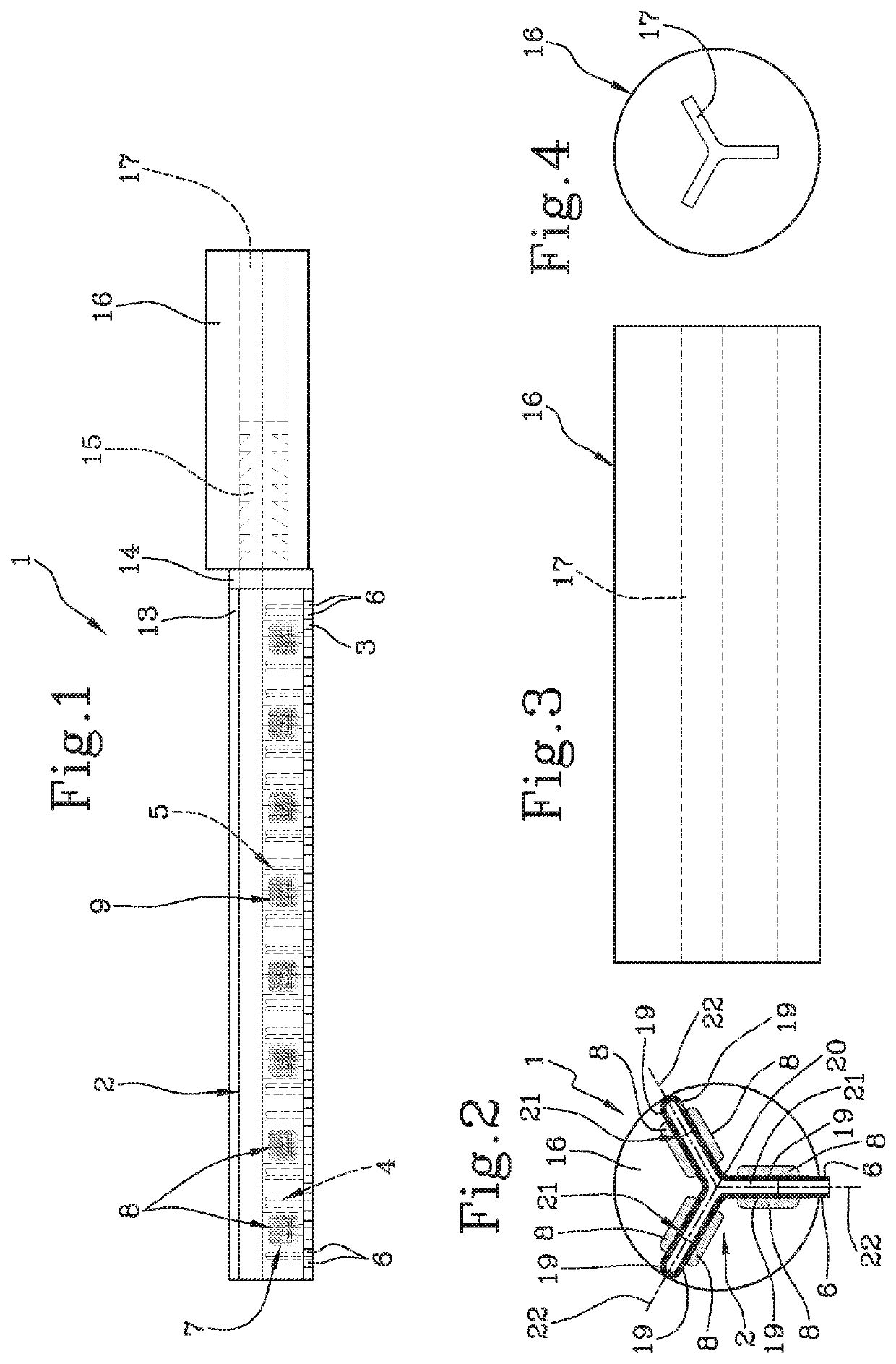

Thin type micro reforming apparatus

InactiveUS20070077186A1Increase surface areaIncrease evaporate efficiencyHydrogenChemical/physical/physico-chemical microreactorsNuclear engineeringThermal radiation

A thin type reforming apparatus used for a fuel cell is provided. In the thin type reforming apparatus, a substrate has a passage formed therein, and a fuel inlet introduces fuel to the passage. An evaporator is disposed within the substrate downstream of the fuel inlet, and includes a bubble remover for imparting a flow resistance to the fuel in a liquid state, removing bubbles and vaporizing the fuel. A reformer has a passage formed downstream of the evaporator, and reforms the fuel to hydrogen gas through a heat absorbing reaction. A CO remover has a passage formed downstream of the reformer and removes CO gas included in the hydrogen gas through a heat radiating reaction. A cover covers an upper portion of the substrate and sealing the passages from an outside.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

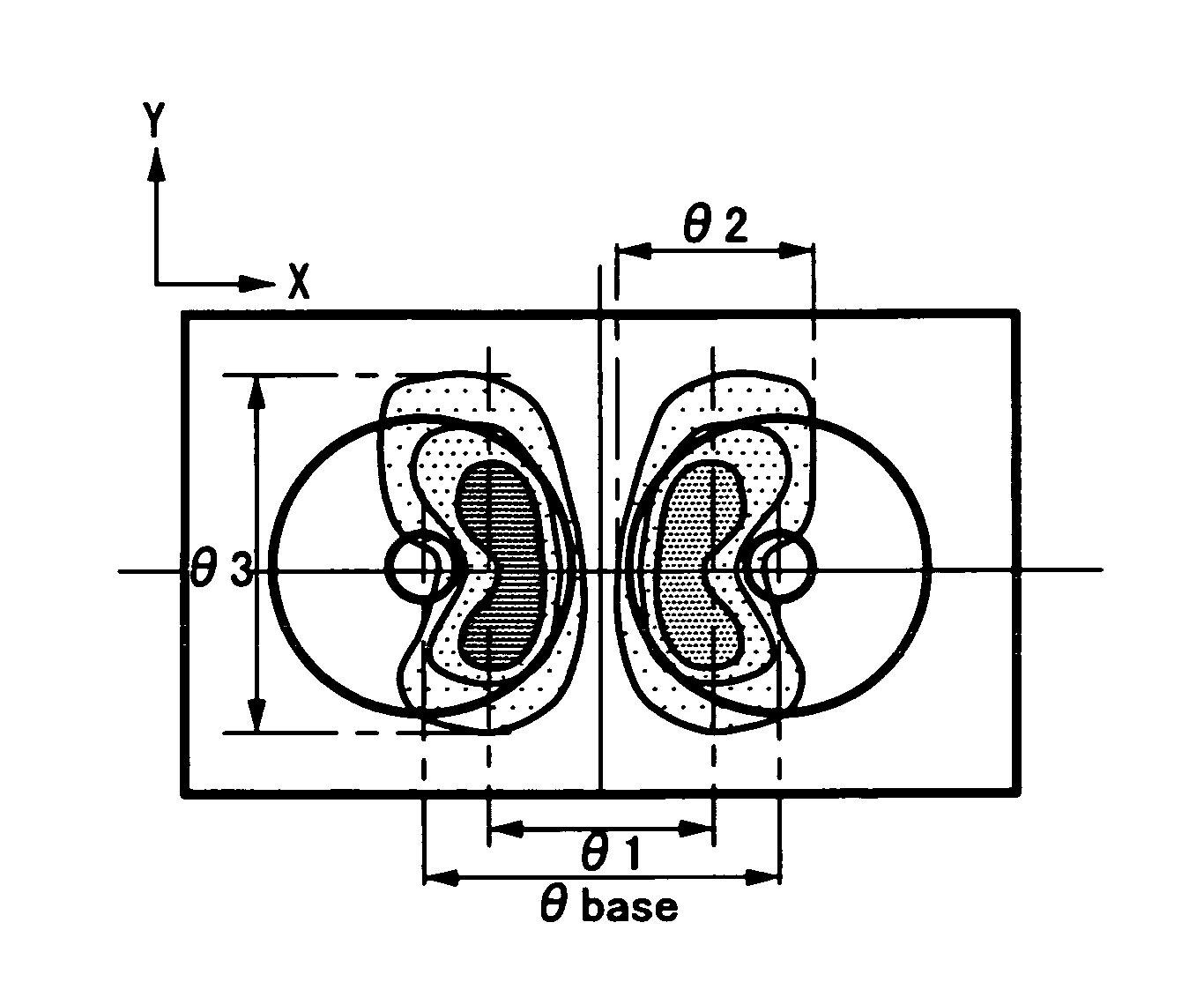

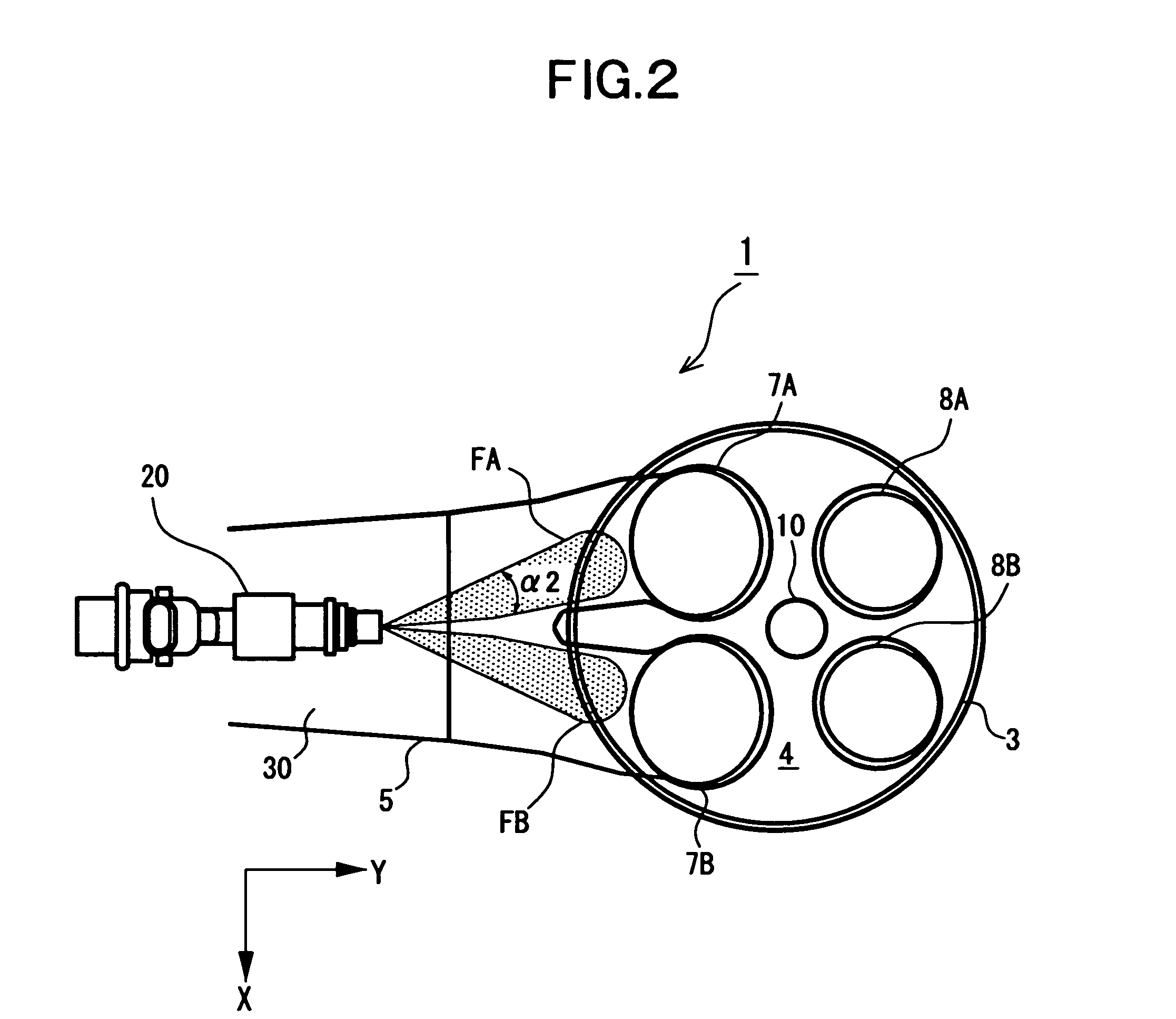

Fuel injection apparatus for and method of internal combustion engine, and fuel injection valve

InactiveUS7565894B2Effectively “vaporized”Improve efficiencyInternal combustion piston enginesFuel injection apparatusExternal combustion engineInlet valve

Fuel injection technology of an internal combustion engine is configured in such a manner that in a case where in inlet pipe interior of the engine is partitioned by a rectifying plate into upper and lower flow paths, a flow velocity at a center of the flow path on an upper side, and at a center of the flow path on a lower side is increased. Consequently, a flow velocity distribution of air in a cylinder diametrical direction of a valve head of an inlet valve becomes a peak value on both sides of the valve head center. Therefore, by impinging most of the injected fuel spray upon both sides of the center of the valve head, vaporization of the fuel spray can be performed with good efficiency.

Owner:HITACHI LTD

Electric cartridge for an electronic cigarette and method for making the electric cigarette

ActiveUS20180116286A1Effectively “ vaporize ”Versatile and reliableTobacco devicesInhalatorsElectrically conductiveEngineering

The electric cartridge for an electronic cigarette of this invention comprises a piece of flexible substrate material comprising at least a flexible film which mounts an electrically conductive network in the form of an array and defining a plurality of resistive zones (pixels) and a plurality of power supply pins for supplying one or more electric currents and connected to the resistive zones. The resistive zones define heating means and are grouped into distinct modules. Each module corresponds to an uninterrupted portion of the electrically conductive network and comprises at least one resistive zone and respective power supply pins. The electric cartridge includes a plurality of portions of aromatic substance positioned on at least one face of the piece of flexible material. Each portion is associated with a resistive zone and positioned in proximity to a heating surface of the respective resistive zone.

Owner:GD SPA

Heater element for a vaporization device

ActiveUS20180153215A1Reduce surface roughnessHeating up fastSteam generation heating methodsContainer filling methodsPorous layerHeating element

A heating element for a vaporizing device, a vaporizing device containing the heating element, and a method for vaporizing fluid ejected by an ejection head. The heating element includes a conductive material deposited onto an insulative substrate, a protective layer deposited onto the conductive layer, and a porous layer having a porosity of at least about 50% deposited onto the protective layer. The heating element has an effective surface area (ESA) for fluid vaporization that is greater than a planar surface area defined by dimensions of the heating element so that a fluid contact surface of the heating element is greater than the planar surface area of the heating element.

Owner:FUNAI ELECTRIC CO LTD

Fuel injection apparatus for and method of internal combustion engine, and fuel injection valve

InactiveUS20070056555A1Effectively “vaporized”Improve efficiencyInternal combustion piston enginesFuel injection apparatusInlet valveEngineering

Fuel injection technology of an internal combustion engine is configured in such a manner that in a case where in inlet pipe interior of the engine is partitioned by a rectifying plate into upper and lower flow paths, a flow velocity at a center of the flow path on an upper side, and at a center of the flow path on a lower side is increased. Consequently, a flow velocity distribution of air in a cylinder diametrical direction of a valve head of an inlet valve becomes a peak value on both sides of the valve head center. Therefore, by impinging most of the injected fuel spray upon both sides of the center of the valve head, vaporization of the fuel spray can be performed with good efficiency.

Owner:HITACHI LTD

Electric cartridge for electronic cigarette and electronic cigarette

ActiveUS10517328B2Effectively “vaporized”Versatile and reliableTobacco pipesTobacco devicesElectrical resistance and conductancePower flow

Owner:GD SPA

Heater element for a vaporization device

ActiveUS9993027B1Effectively “vaporized”Improve vaporization efficiencySteam generation heating methodsContainer filling methodsPorous layerConductive materials

Owner:FUNAI ELECTRIC CO LTD

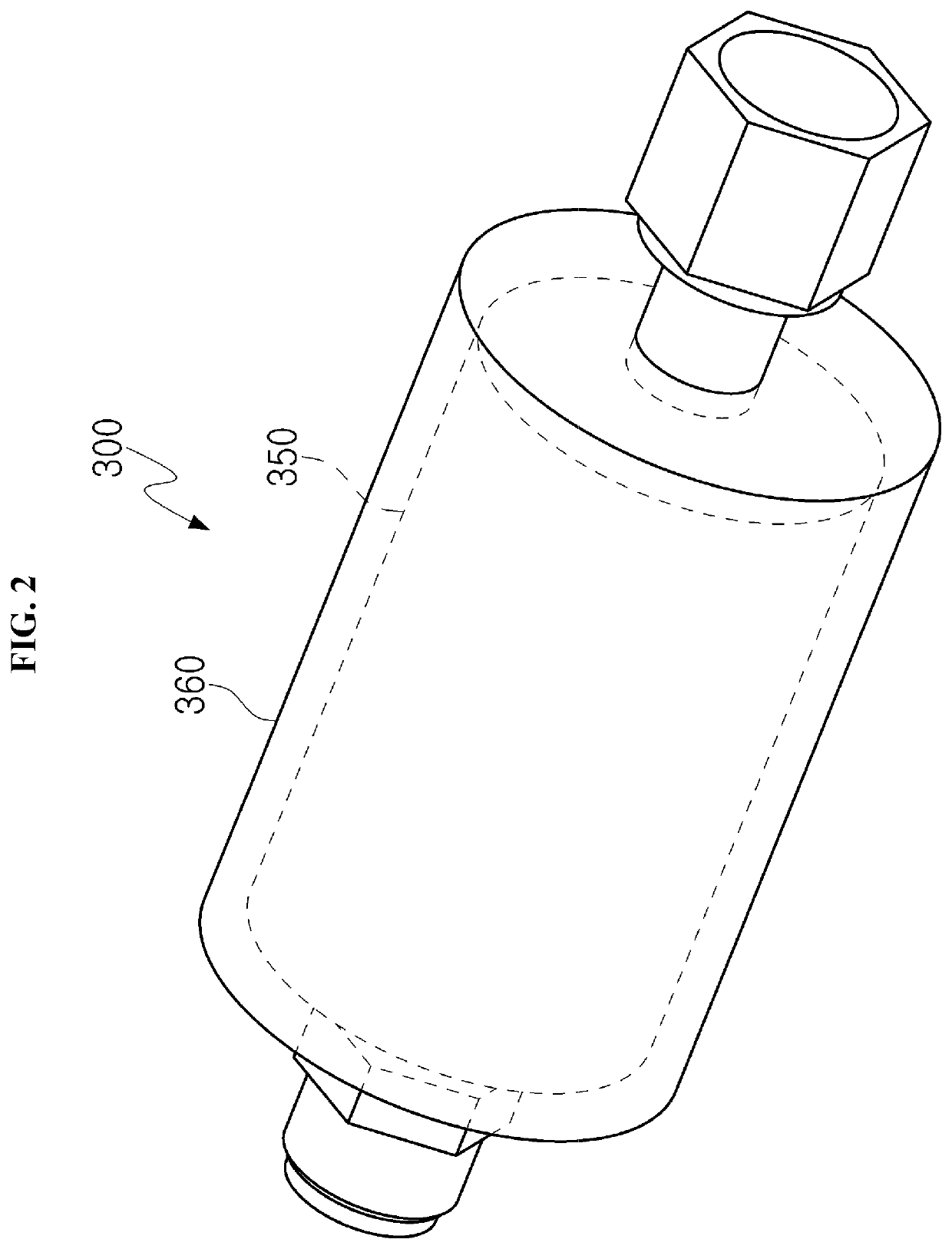

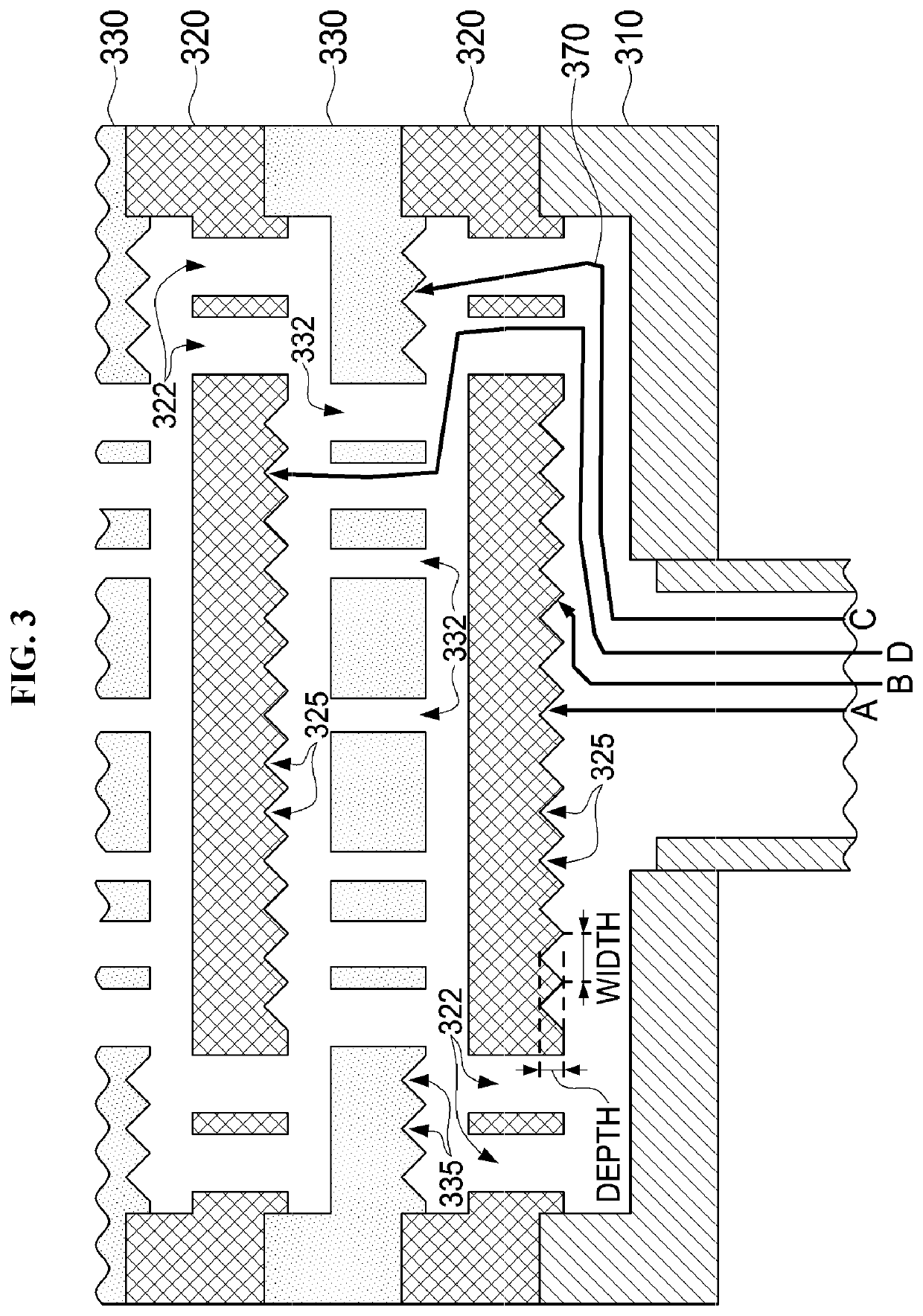

Substrate processing apparatus, vaporization system and mist filter

ActiveUS10767260B2Effectively “vaporized”Combination devicesSemiconductor/solid-state device manufacturingGas supplyElectrical and Electronics engineering

A substrate processing apparatus includes a process chamber accommodating a substrate; a gas supply system; and an exhaust system. The supply system includes a vaporizer and a mist filter, the mist filter including a plurality of first plates and a plurality of second plates. Each of the first plates includes a first plate portion having a plurality of first grooves on a surface thereof and a first flow path. Each of the second plates includes a second plate portion having a plurality of second grooves on a surface thereof and a second flow path. When the plurality of first and second plates are arranged alternatively, the plurality of first grooves are configured to face the second flow path and the plurality of second grooves are configured to face the first flow path, such that the first flow path and the second flow path are not in-line.

Owner:KOKUSA ELECTRIC CO LTD

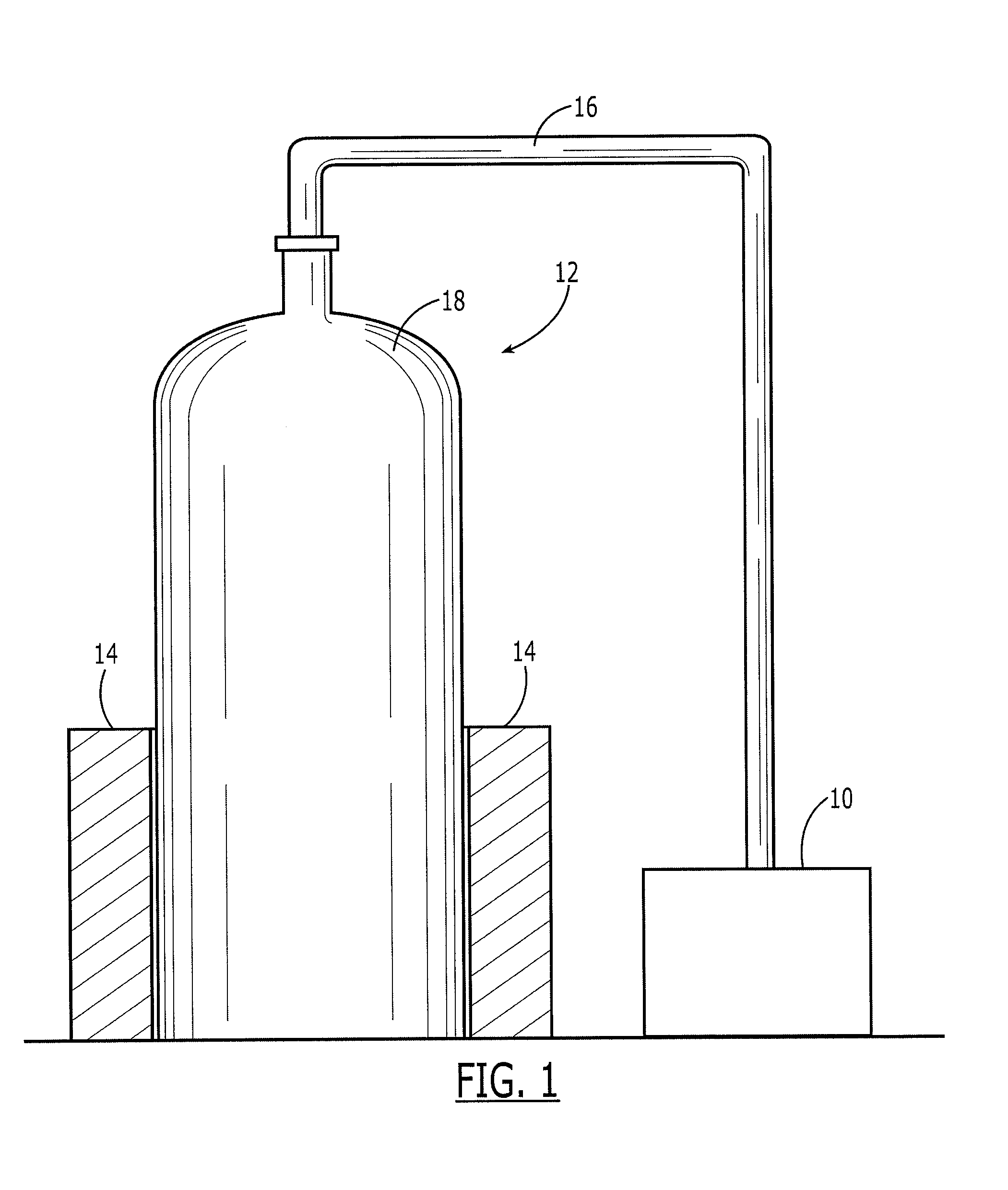

Method and apparatus for vaporizing liquid

InactiveUS7954459B2Facilitate heat transfer and vaporizationEffectively “vaporized”Boiler water tubesSteam generation using pressureEngineeringVaporization

An apparatus and method for vaporizing liquid are provided which employ a plurality of rods disposed within a storage vessel that serve as the heat transfer element. While the plurality of rods are generally submerged by the liquid fuel to facilitate heat transfer and vaporization of the liquid fuel, the rods may be packed closely together such that the liquid inventory required to maintain the rods in a submerged state is substantially less than required by conventional fuel supply systems, thereby permitting the weight of a fuel supply system that incorporates the apparatus and method to be reduced while still permitting effective vaporization of the fuel.

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com