Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Ease of production control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

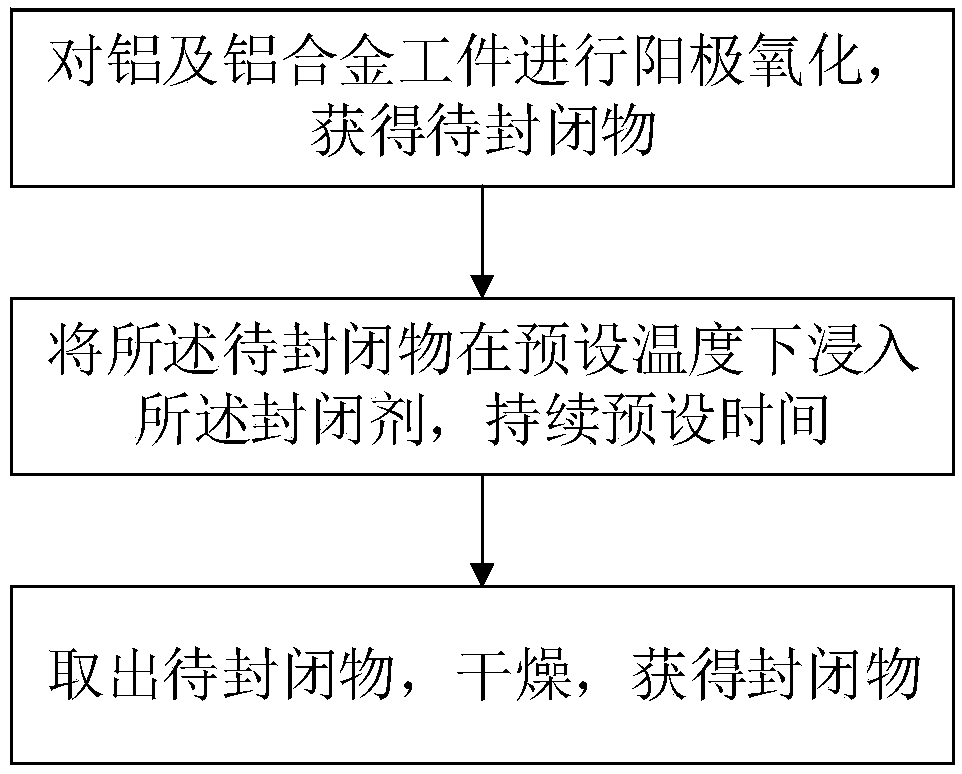

Aluminum and aluminum alloy anode oxidation film high alkali resistant sealant and sealing method

InactiveCN109234782AEasy production controlShorten the timeSurface reaction electrolytic coatingCondensed waterAnode oxidation

The invention provides an aluminum and aluminum alloy anode oxidation film high alkali resistant sealant and a sealing method. The sealant is prepared from nickel acetate, a dispersing agent, a surfactant, a fluoride and the balance of deionized water. The method is that: after aluminum and aluminum alloy workpieces are conventionally anodized, the sealant is immersed for one-step sealing. According to the sealant and the sealing method, one-step sealing treatment is adopted to obtain the aluminum and aluminum alloy workpieces satisfying the industry requirements of resistance to alkali pH 12.5, salt spray resistance and condensed water resistance, sealing steps are fewer, the production control is easy, and the sealing cost is lower.

Owner:保定诺博汽车装饰件有限公司

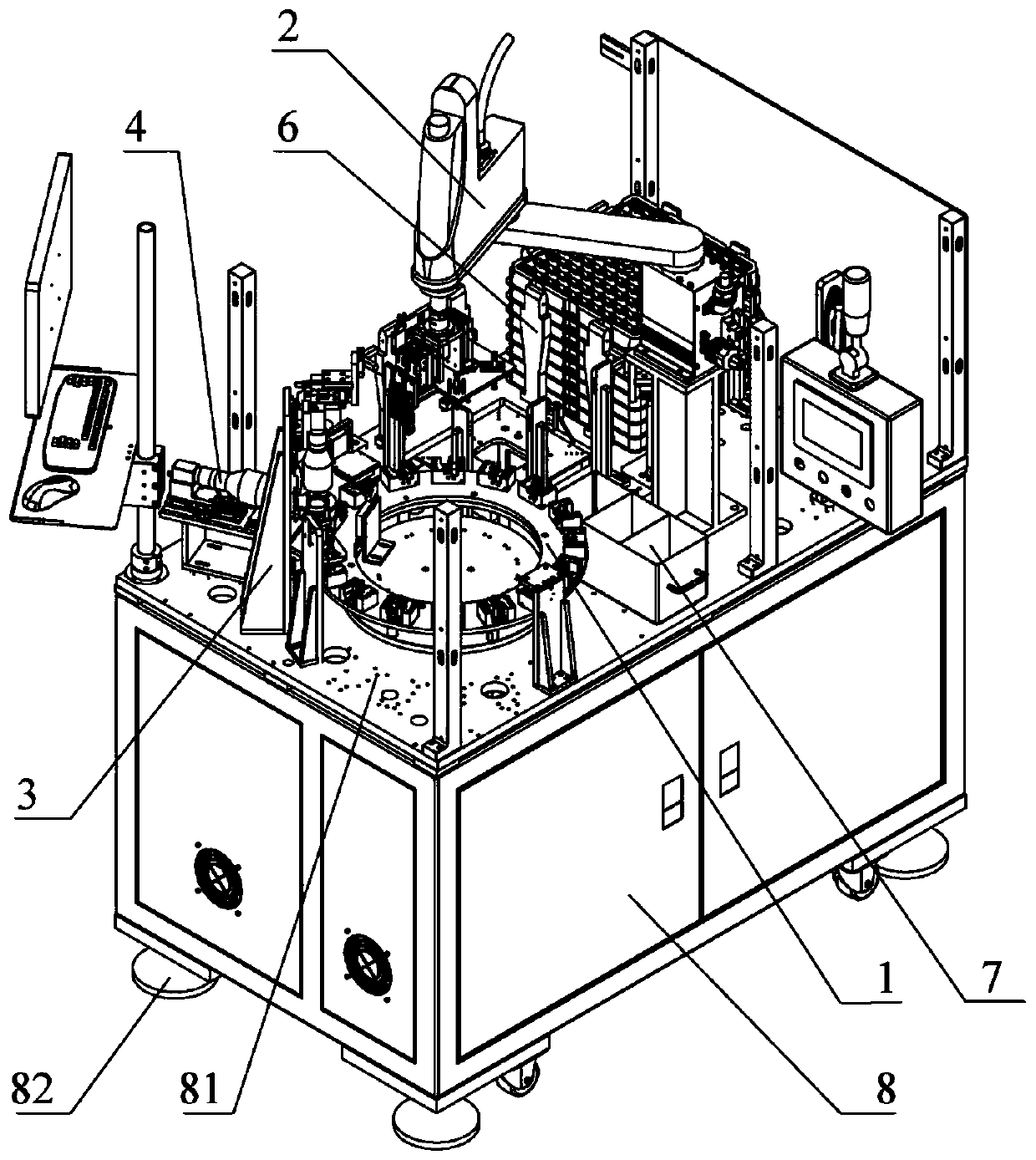

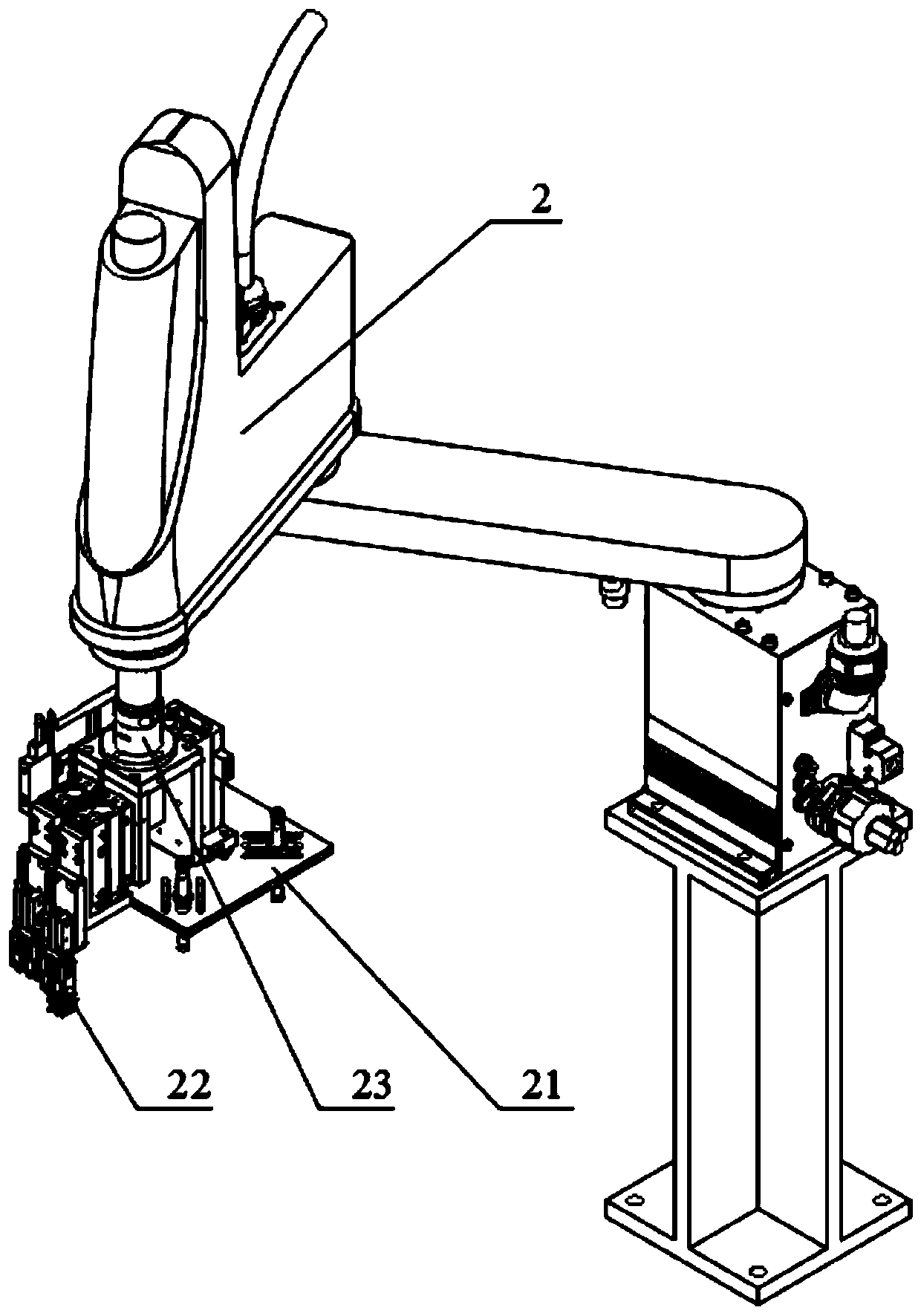

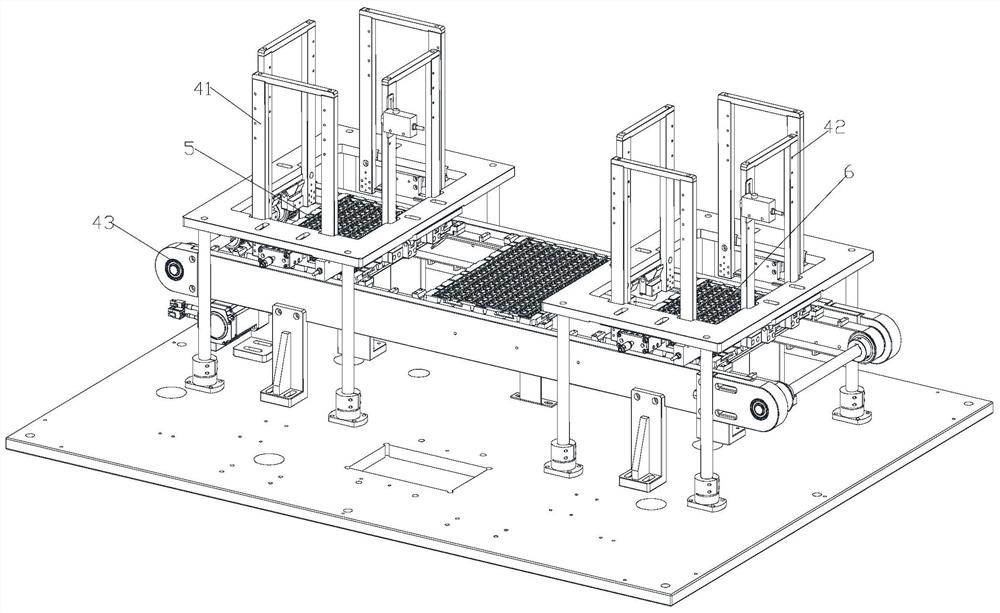

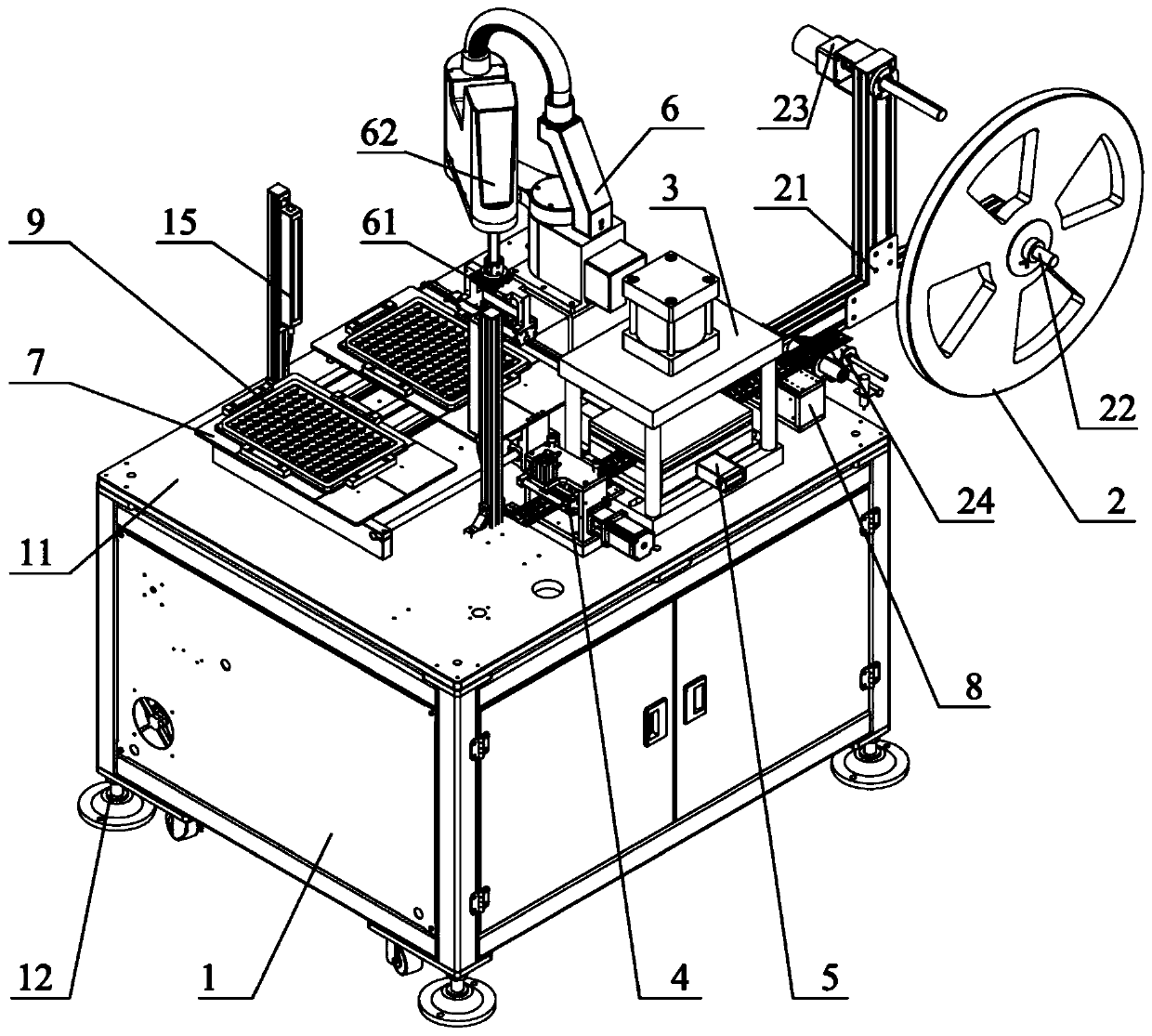

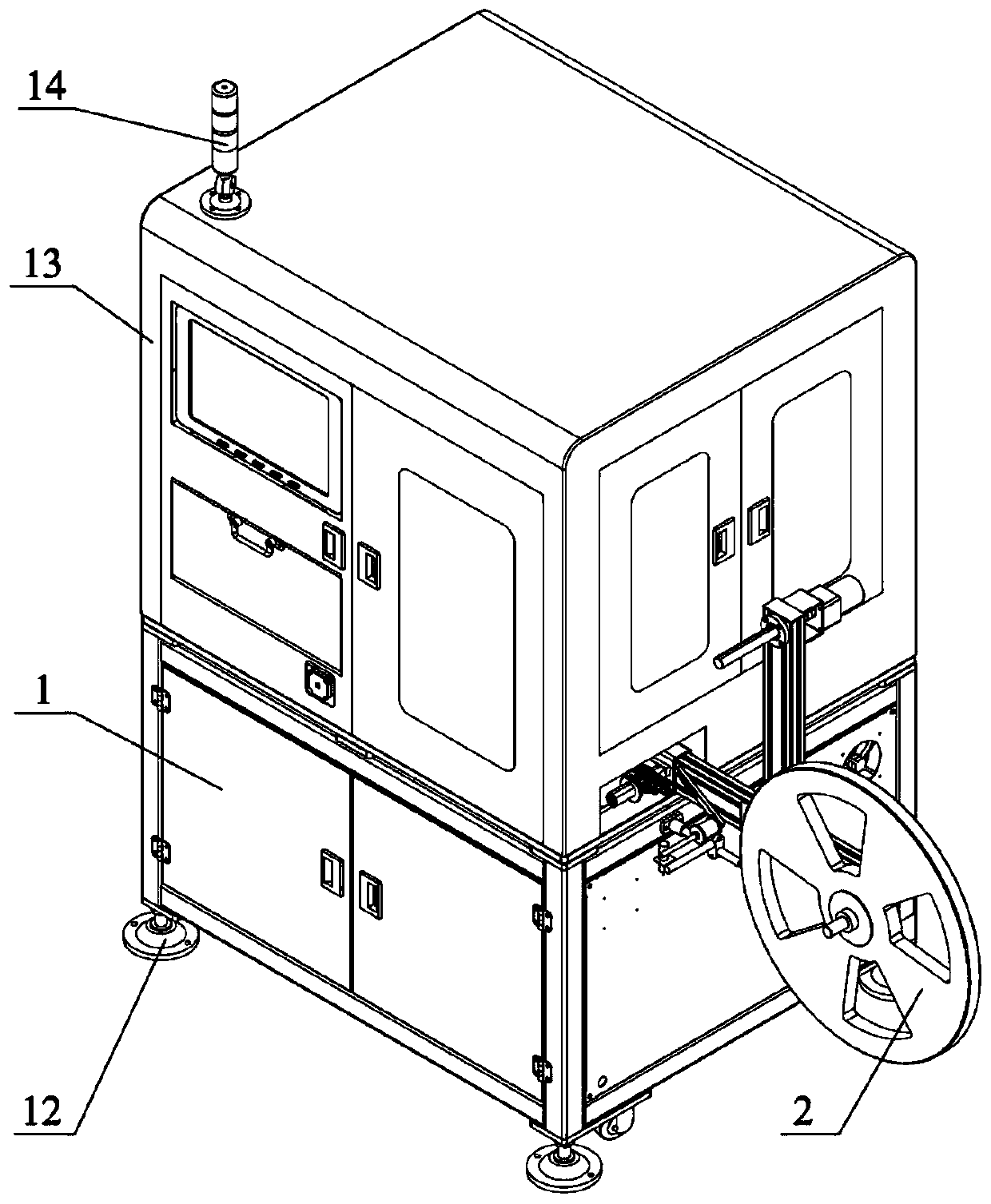

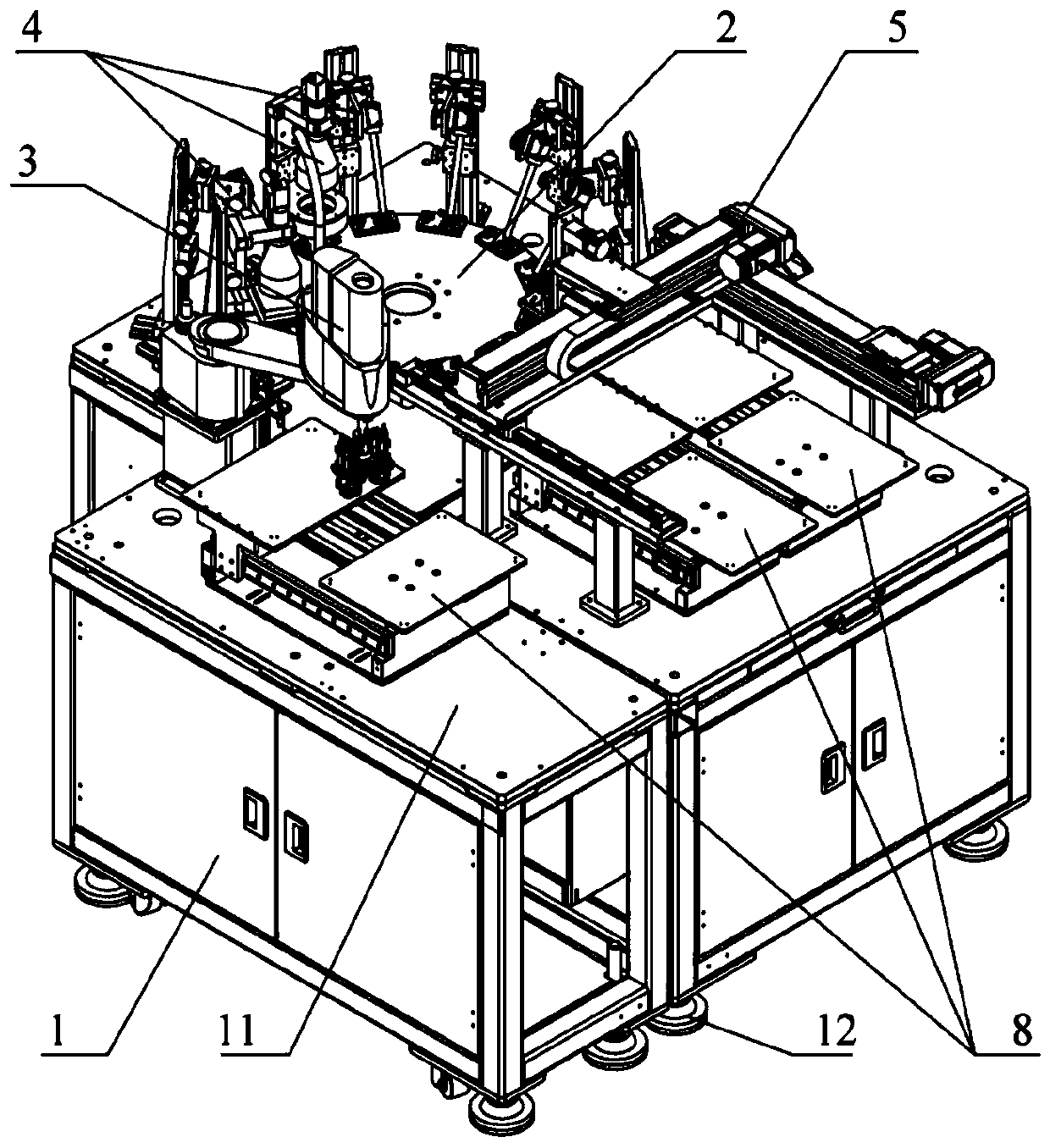

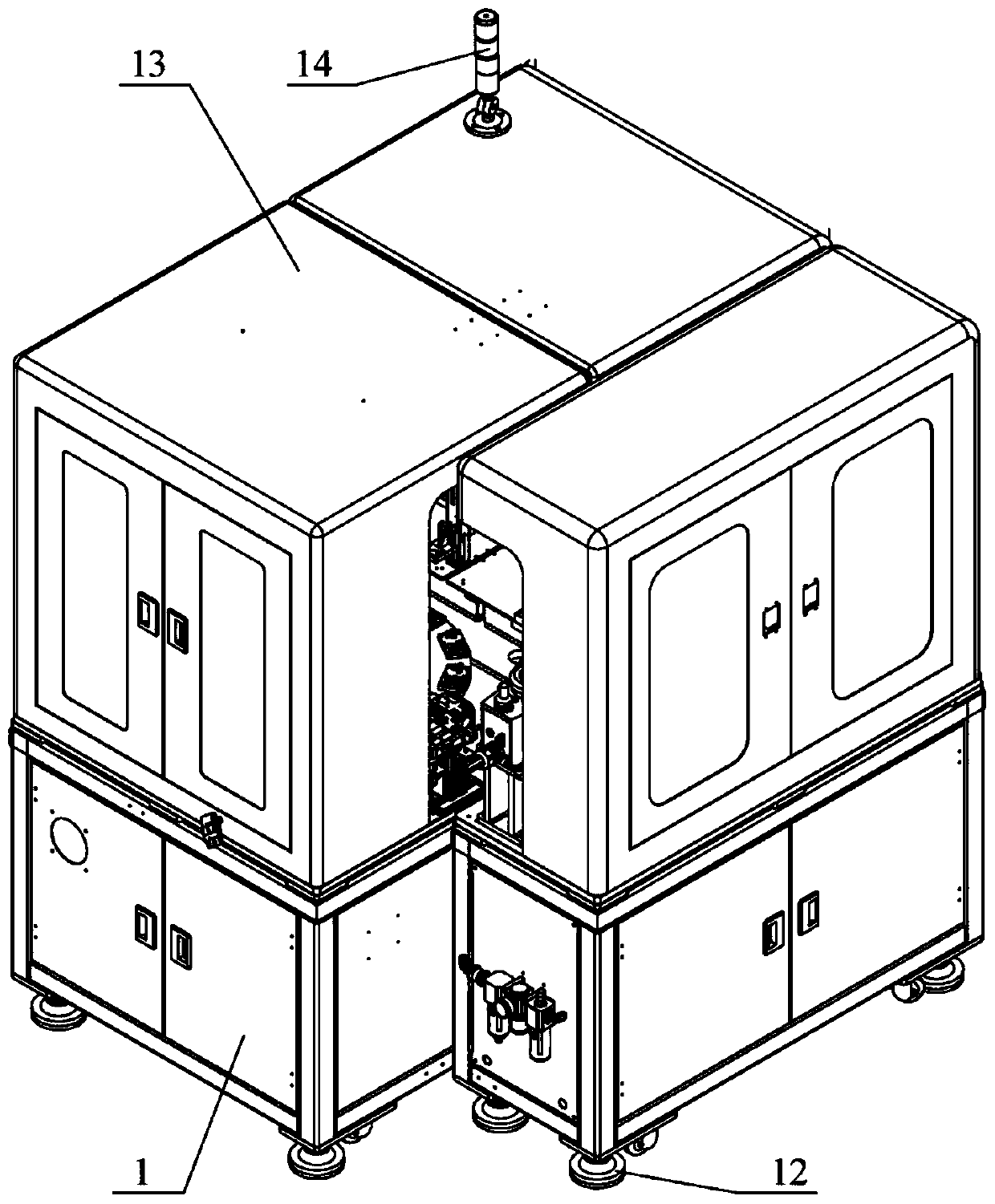

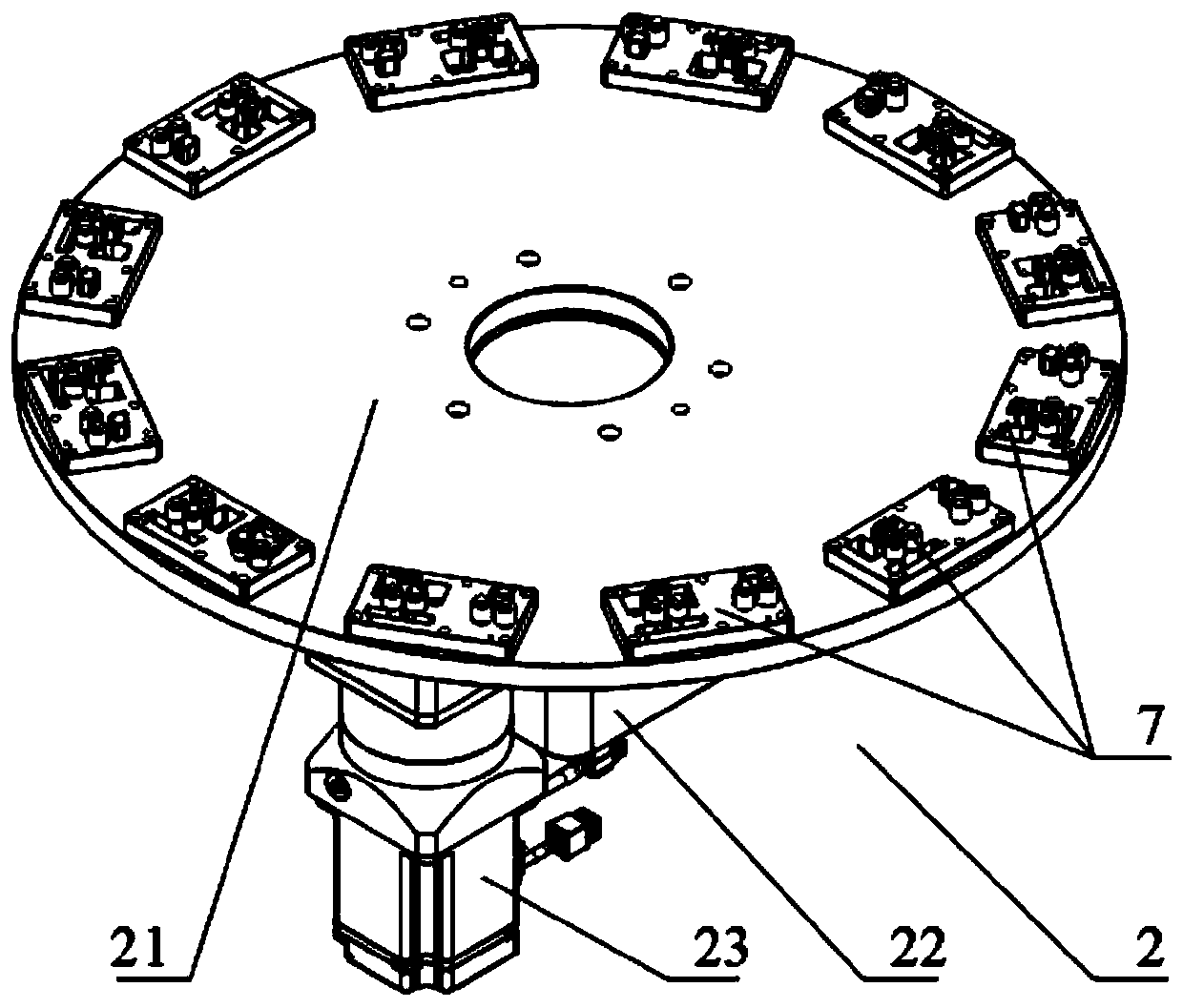

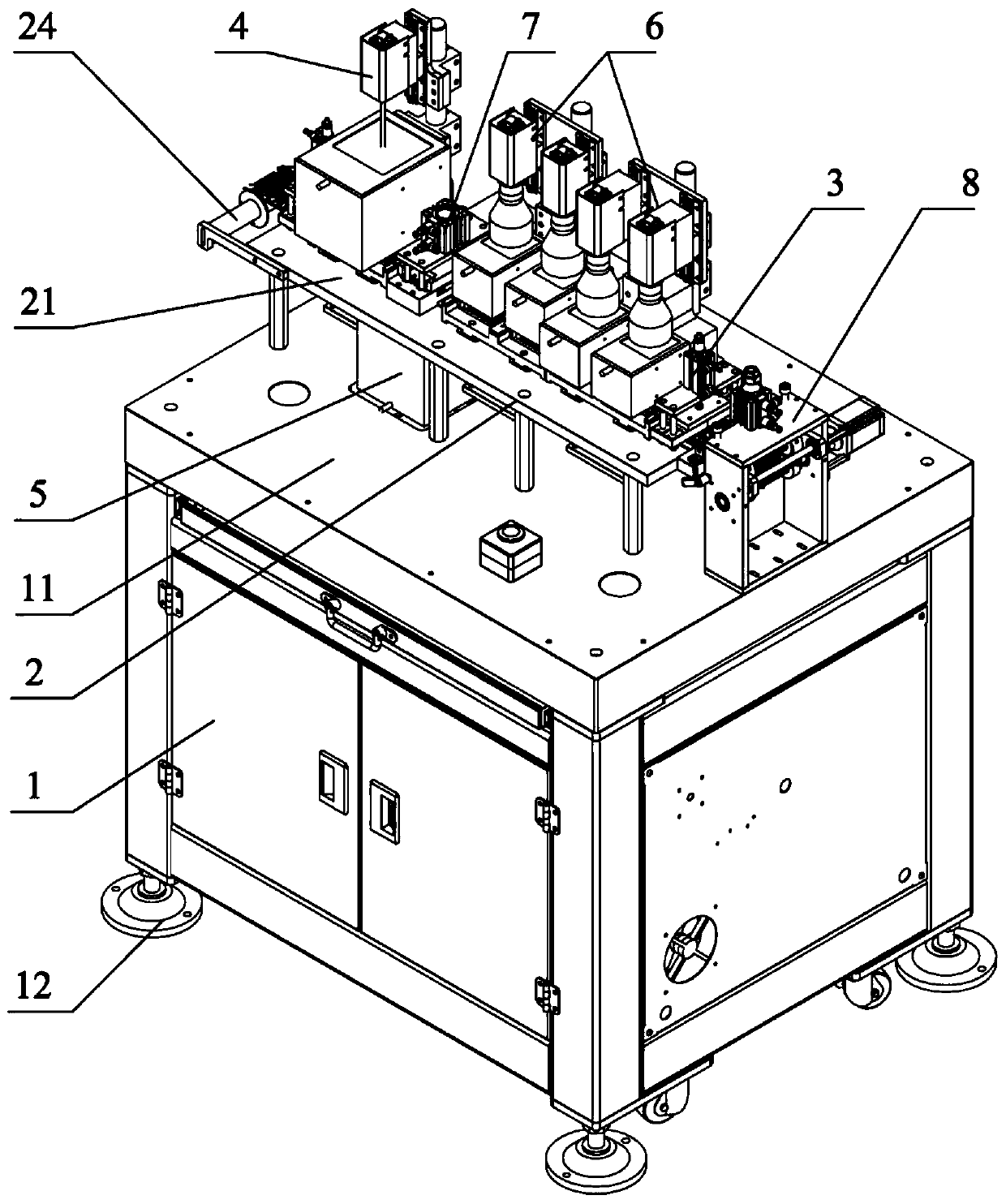

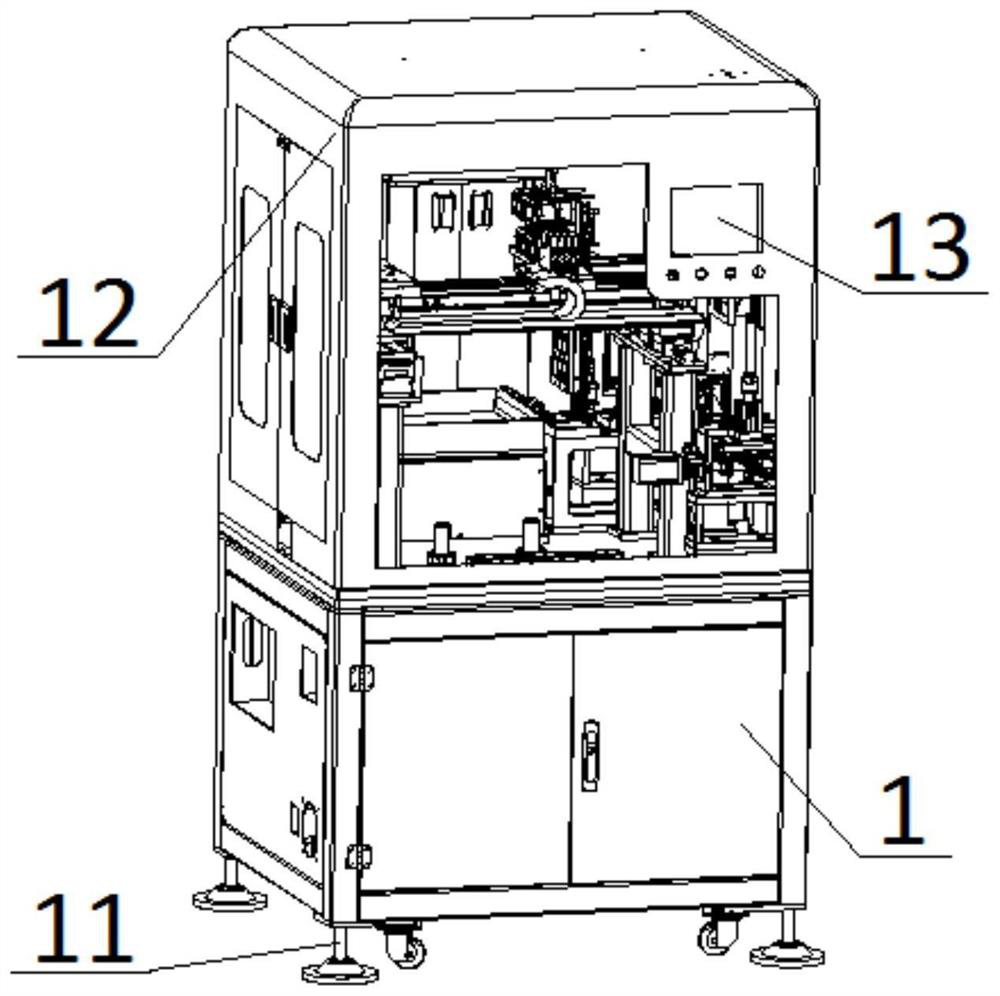

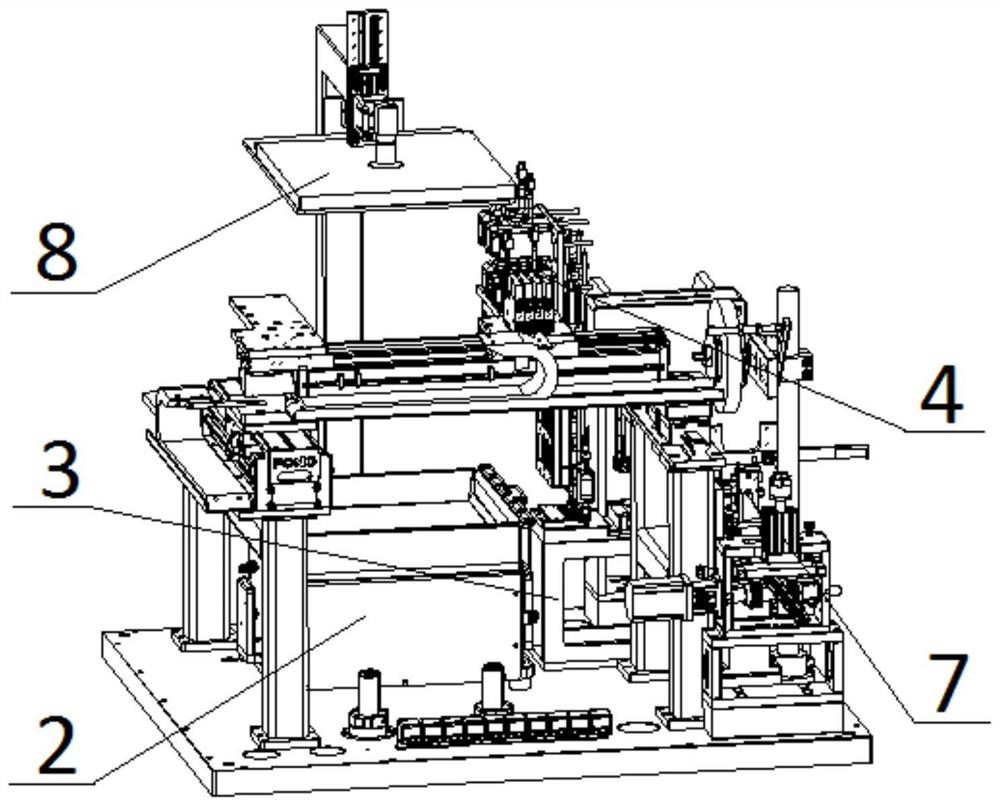

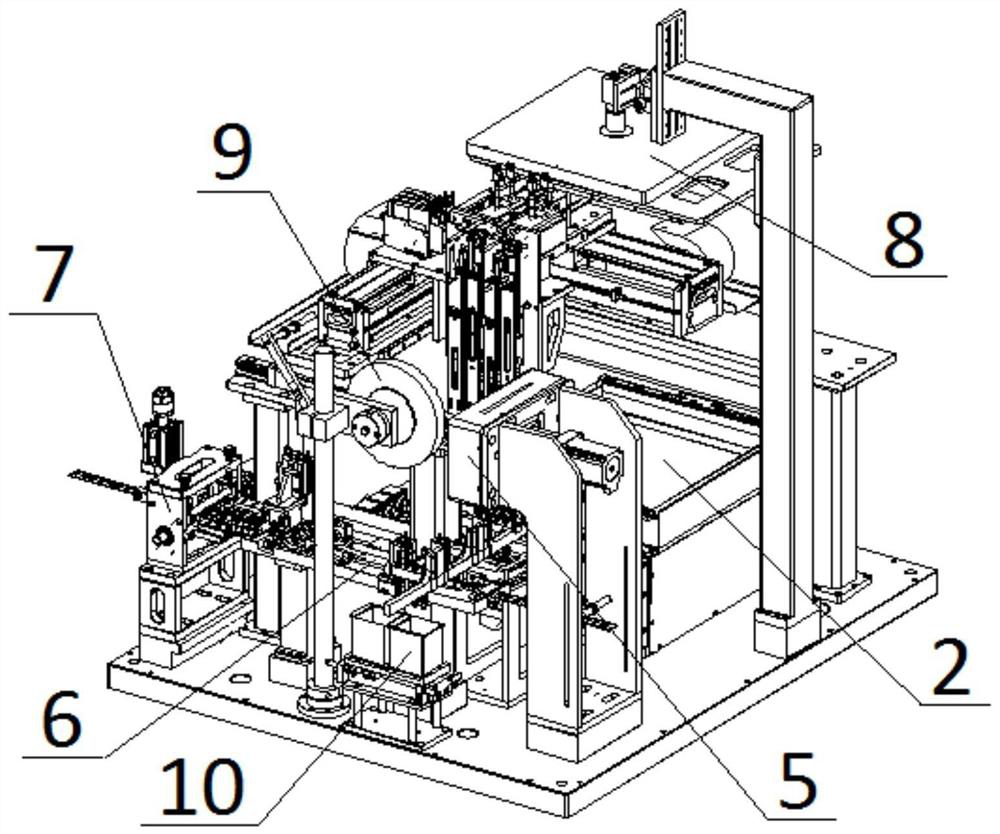

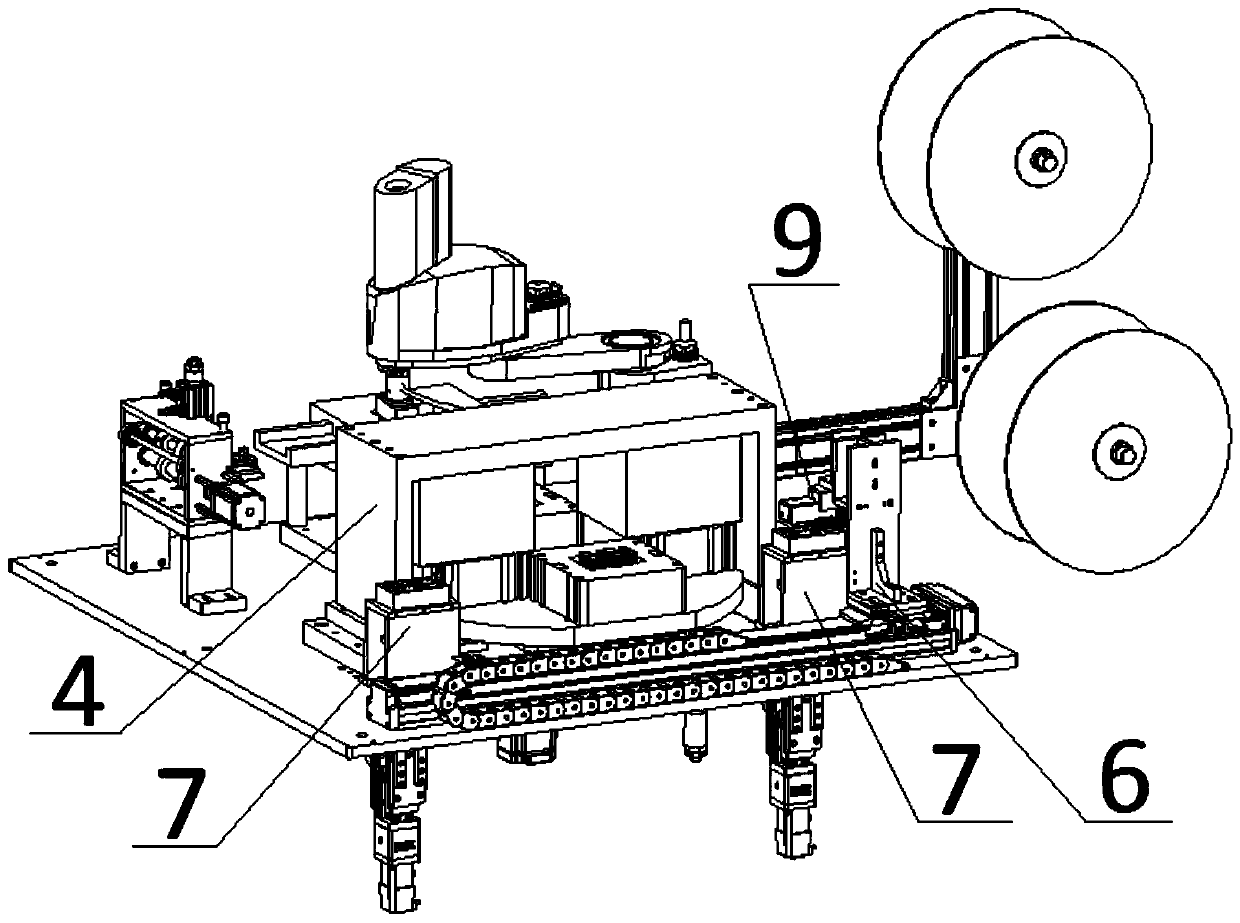

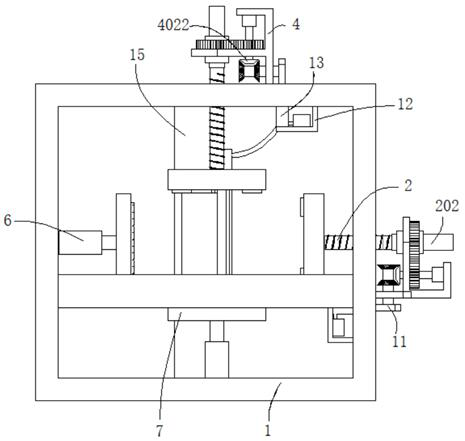

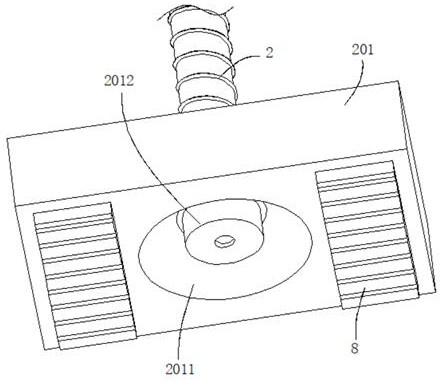

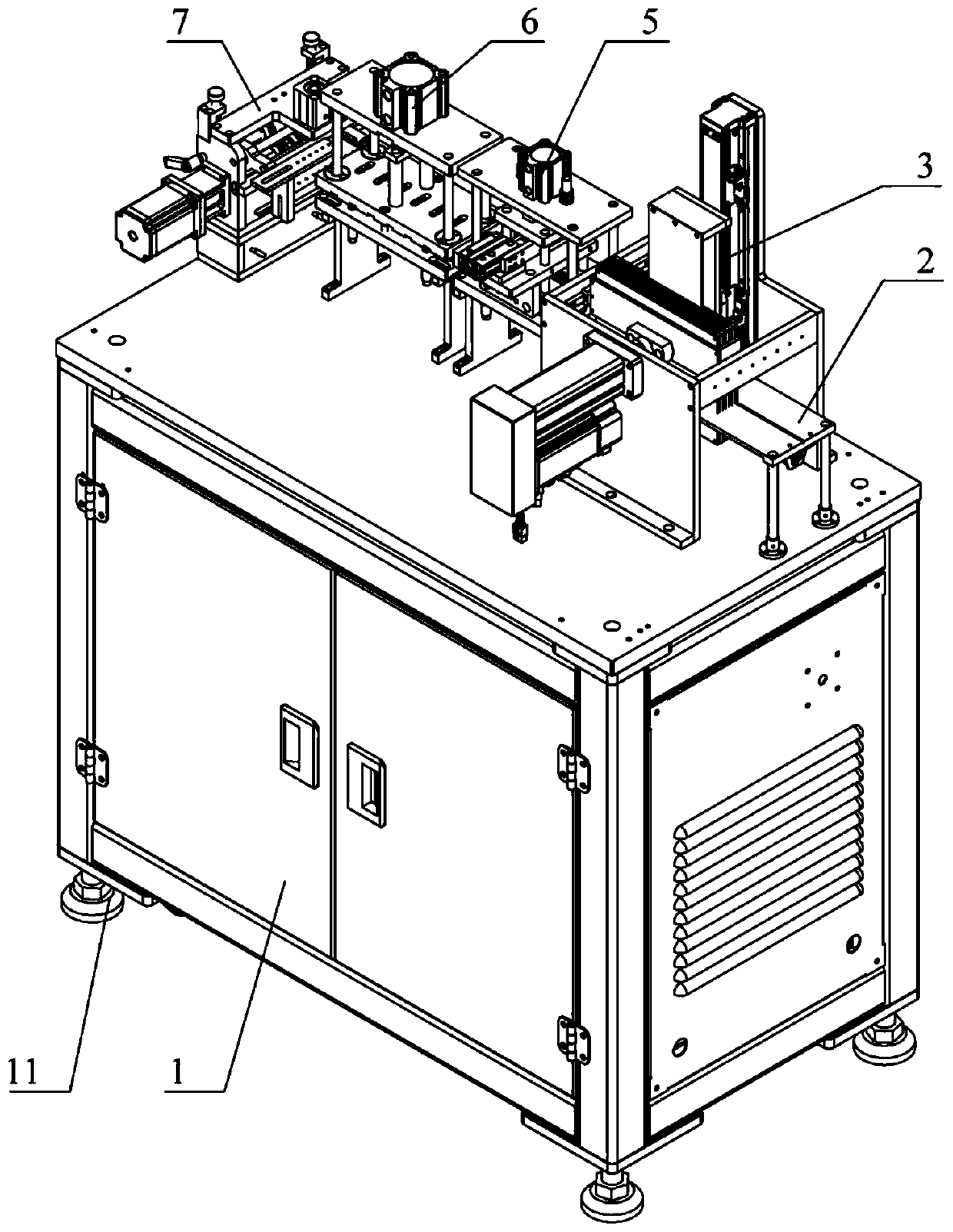

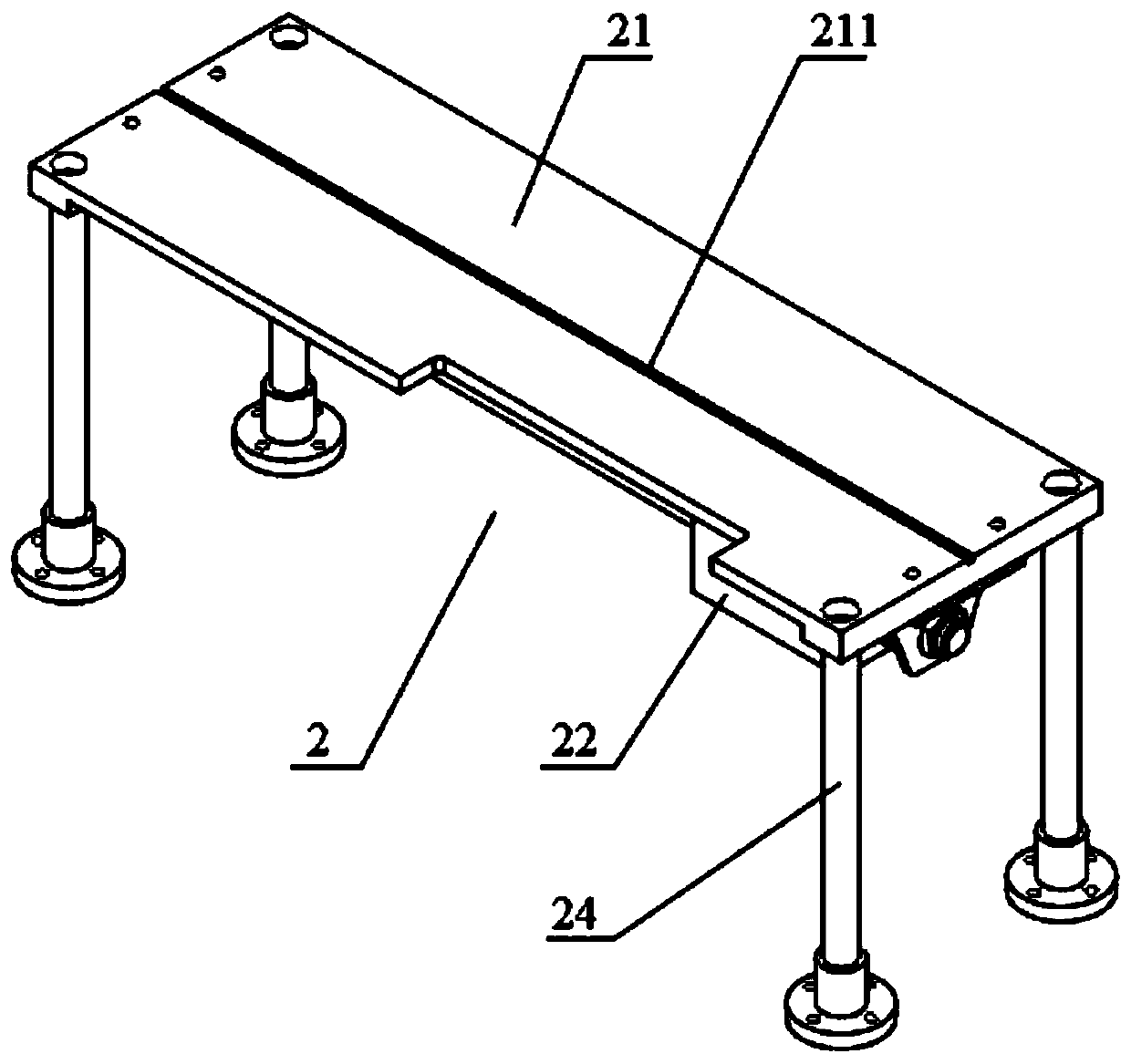

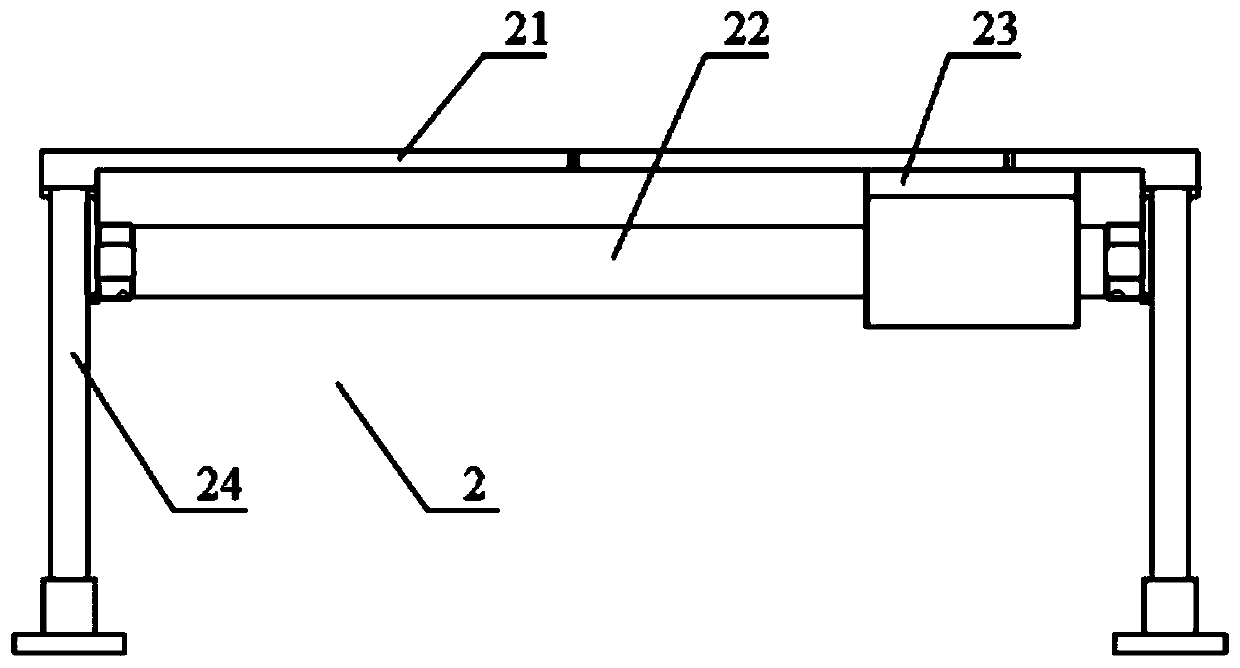

Multi-station detecting and packaging device

PendingCN111532487AFully automatic detectionFully automatic inspection of packagingPackaging automatic controlSortingRobot handProcess engineering

The invention discloses a multi-station detecting and packaging device at least comprising a multi-station rotary plate device, a material taking and placing mechanical hand, an upper detection device, a horizontal detection device, a lower detection device, a material bin device and a waste material collection box. The material taking and placing mechanical hand, the upper detection device, the horizontal detection device and the lower detection device correspondingly cooperate with the multi-station rotary plate device. The material bin device and the waste material collection box correspondingly cooperate with the material taking and placing mechanical hand. Multiple positioning jigs used for containing products are arranged on the multi-station rotary plate device. The material takingand placing mechanical hand can place to-be-detected products on the positioning jigs and place the detected products in material plates or the waste material collection box. By means of the multi-station detecting and packaging device, the products are automatically detected and packaged in a precise and comprehensive manner, the material plates do not need to be manually replaced or stacked, operation is easy and convenient, precision is high, the speed is high, time and labor are effectively saved, and therefore the production efficiency and the overall quality and yield of the products areimproved, the production cost is reduced, and competiveness of the products is enhanced.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

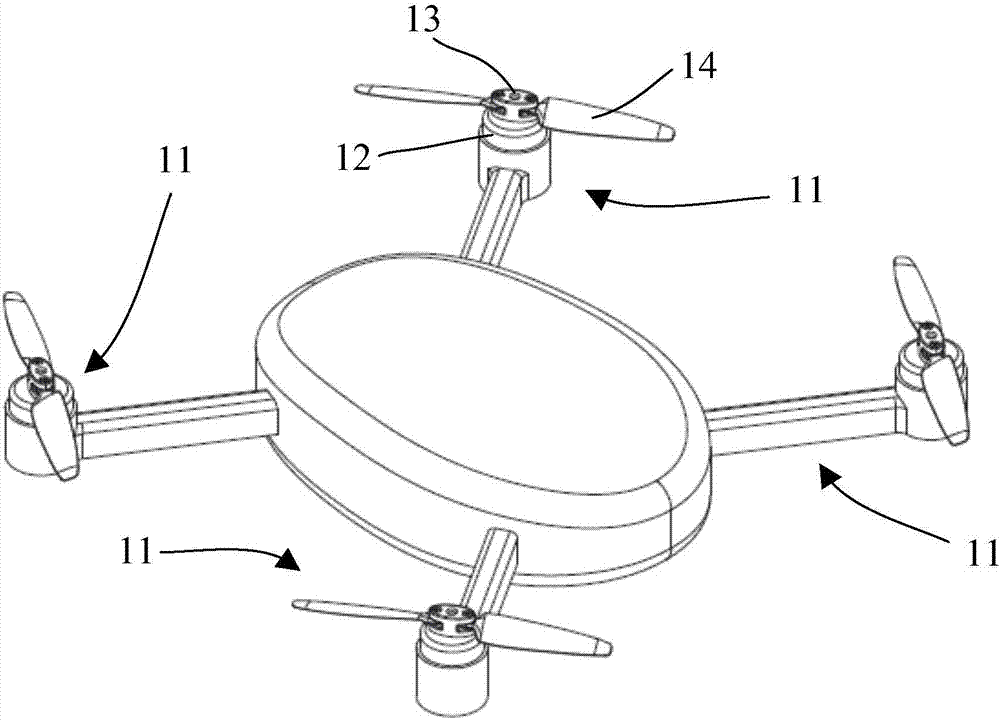

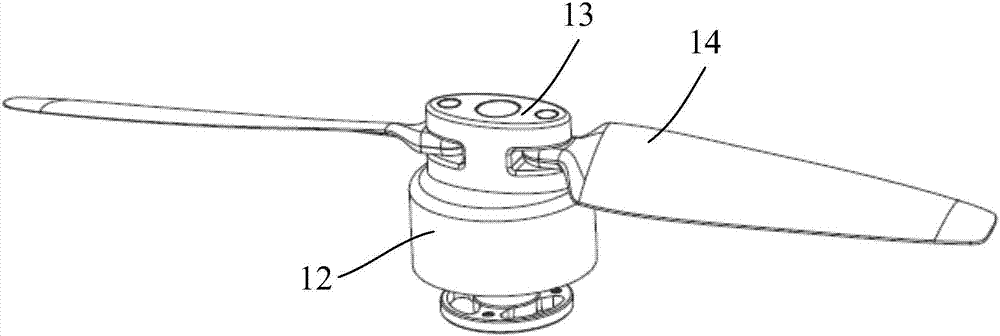

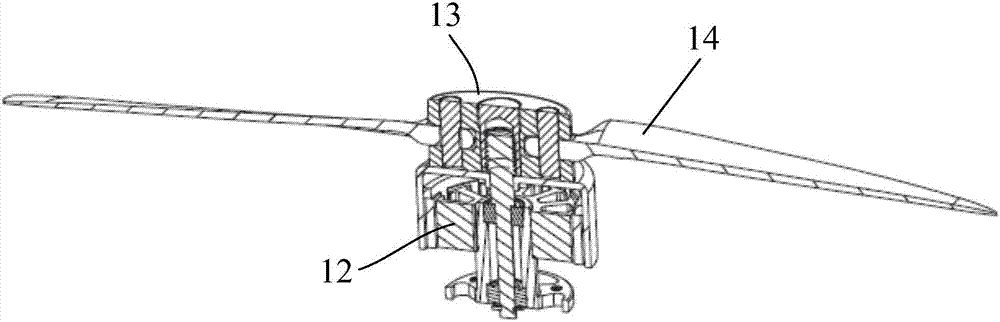

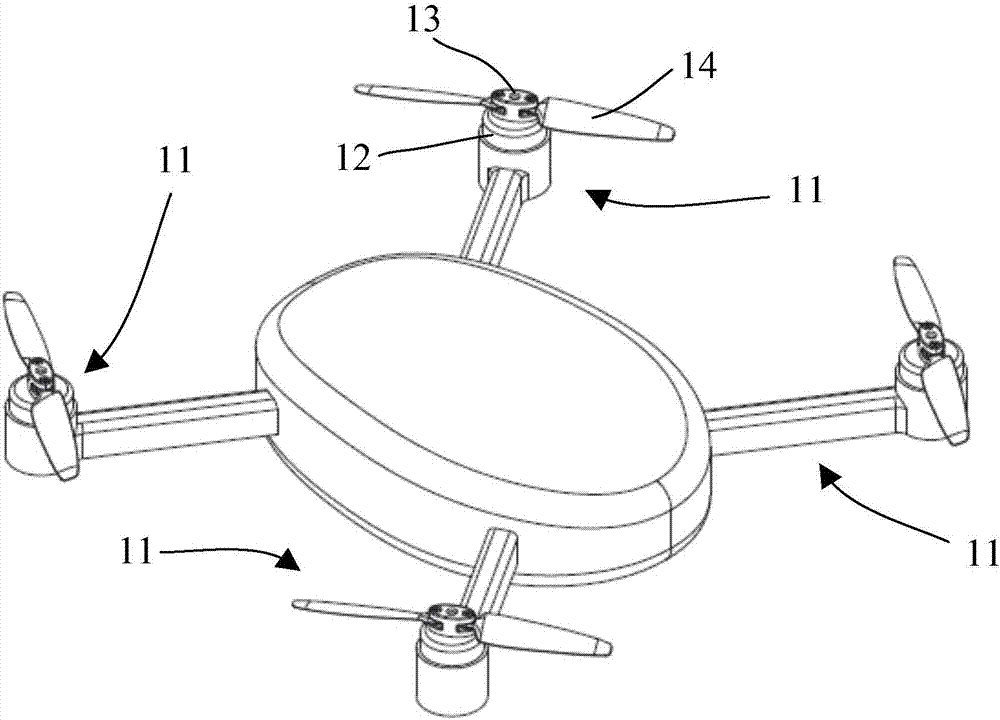

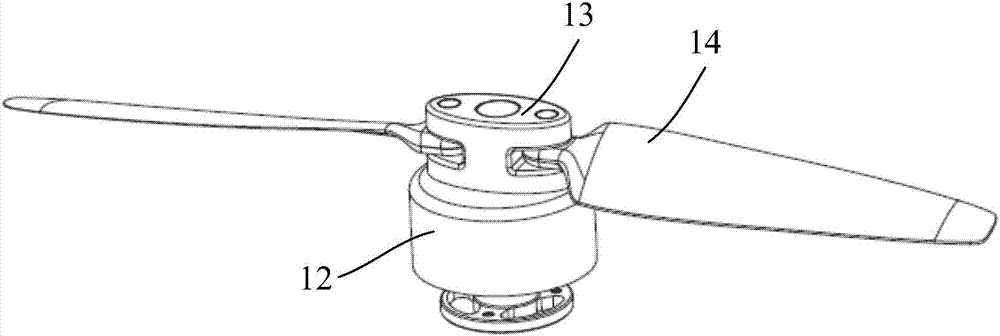

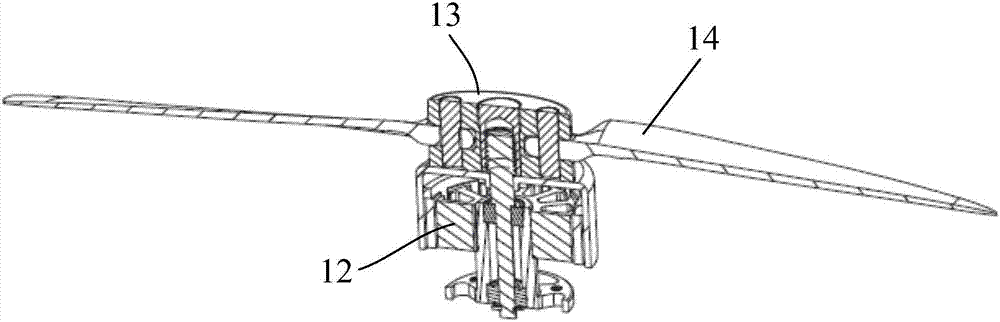

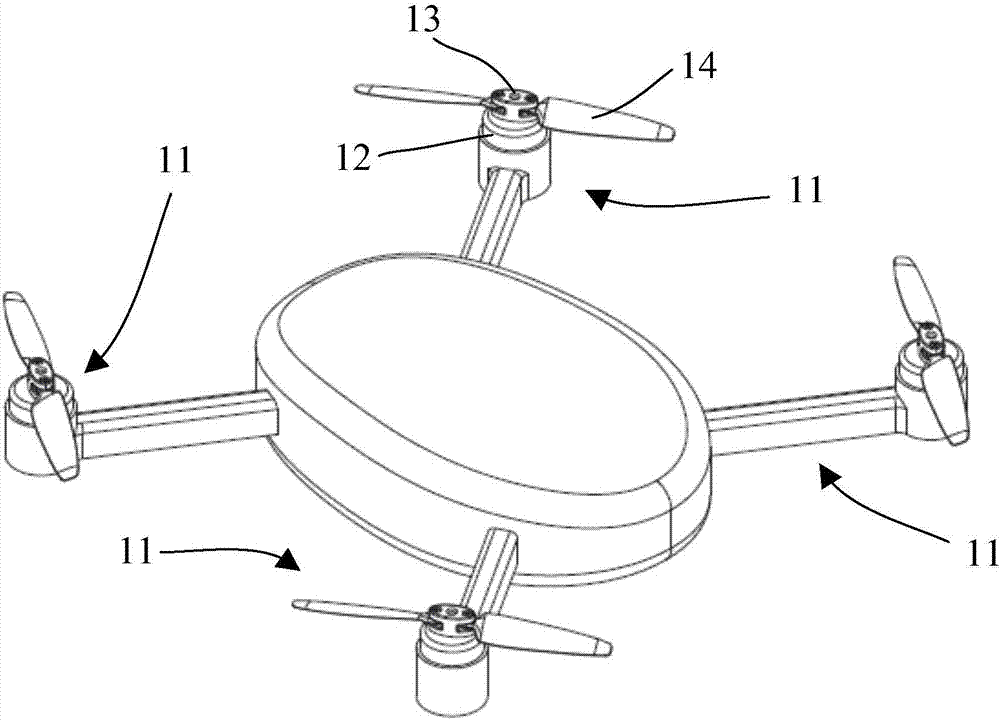

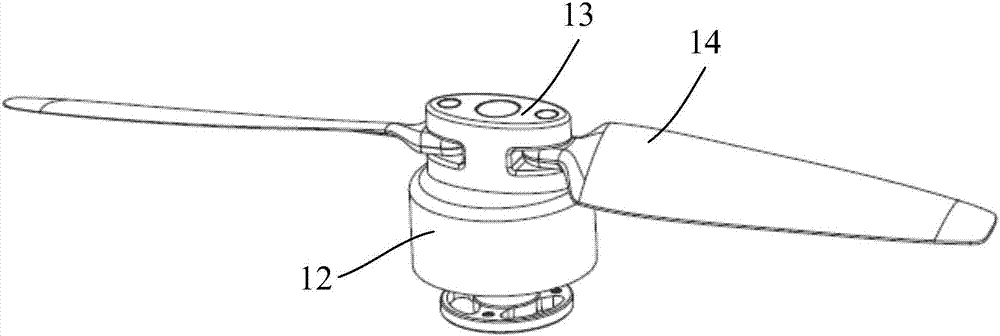

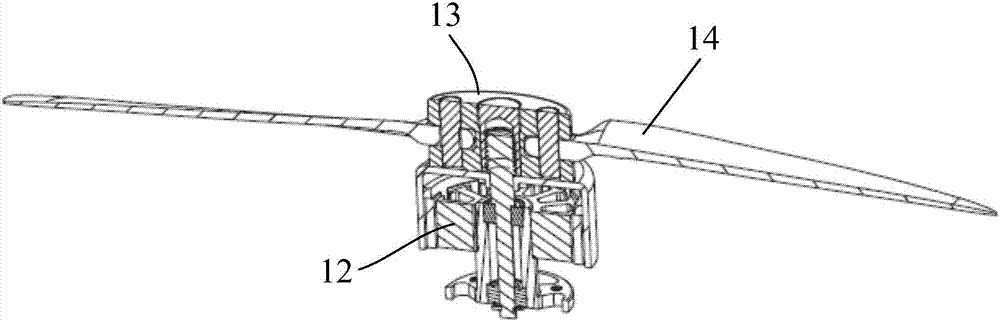

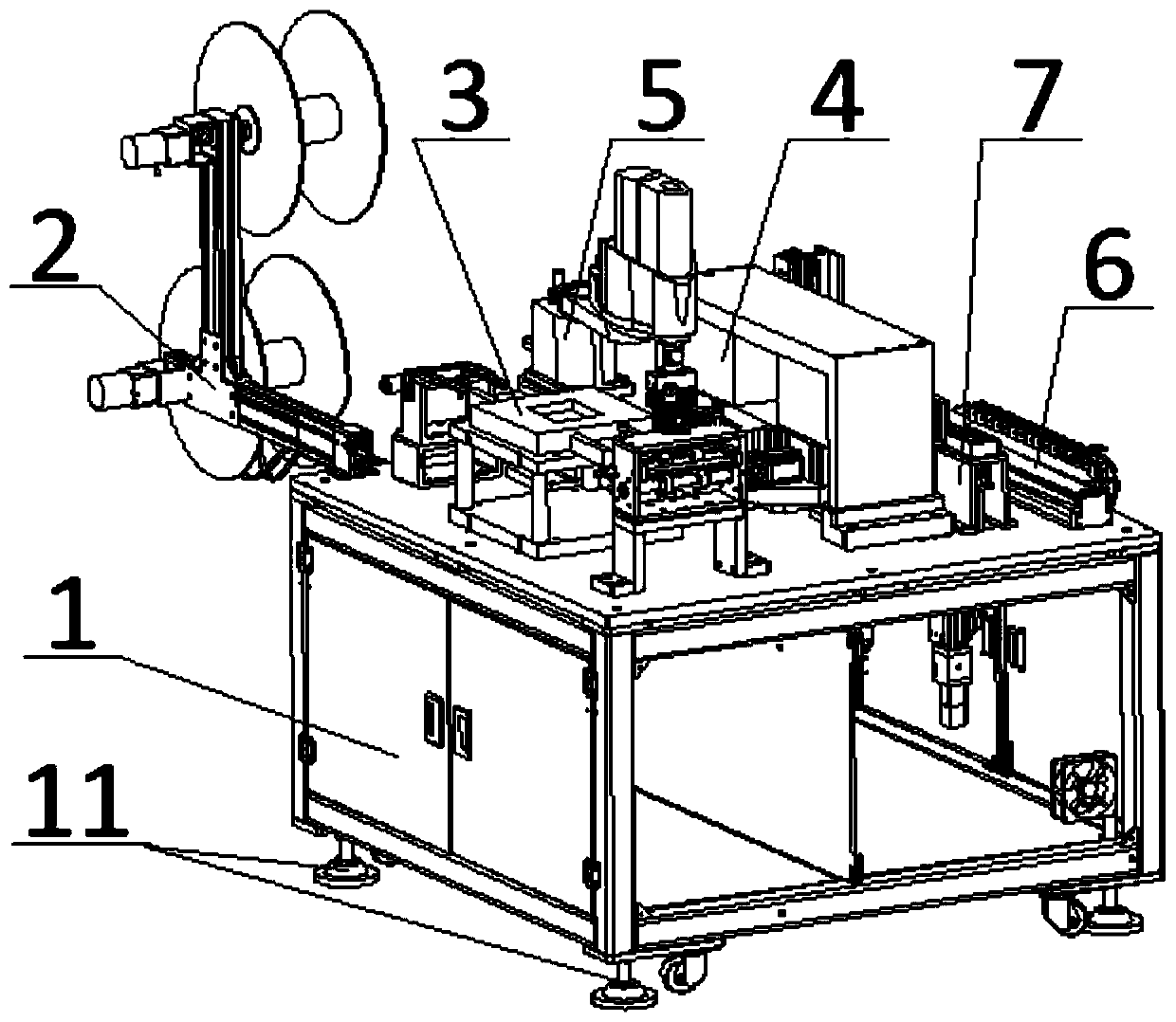

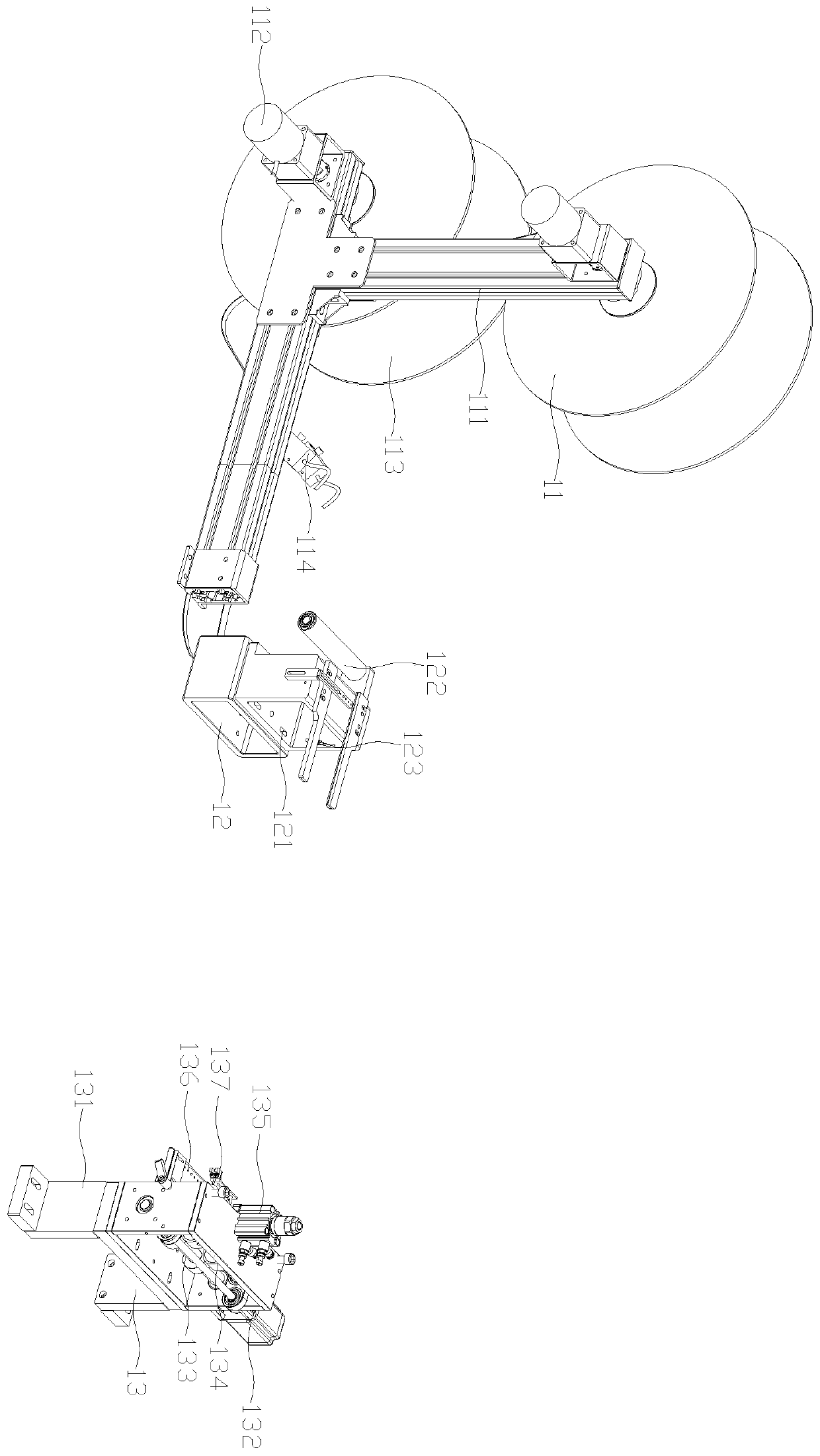

Portable unmanned aerial vehicle, propeller blade rotating assembly, as well as rotating systems and assembling method thereof

The invention relates to a portable unmanned aerial vehicle, propeller blade rotating assemblies, rotating systems as well as an assembling method of the rotating systems. Each propeller blade rotating assembly comprises a propeller seat, propeller blades and connecting shafts, wherein first connecting holes which are cut-through are formed in the propeller seat; a second connecting hole which is cut-through is formed in each of the propeller blades; and each of the connecting shafts is arranged in the corresponding first connecting hole and the corresponding second connecting hole in a penetrating manner, and is in interference fit with the corresponding first connecting hole and in clearance fit with the corresponding second connecting hole. Each of the rotating systems comprises a propeller blade rotating assembly and a motor connected with a fastener, and each of the fasteners is arranged in the corresponding connecting shaft in a penetrating manner and is at least combined with the propeller seat. The portable unmanned aerial vehicle comprises a folding fuselage and a plurality of rotating systems connected with the fuselage. According to the portable unmanned aerial vehicle, the propeller blade rotating assemblies, the rotating systems as well as the assembling method disclosed by the invention, the assembly, replacement and maintenance operation processes of the portable unmanned aerial vehicle are simplified.

Owner:YUNEEC INT (CHINA) CO LTD

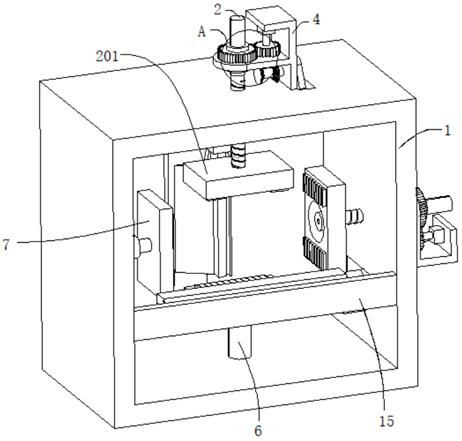

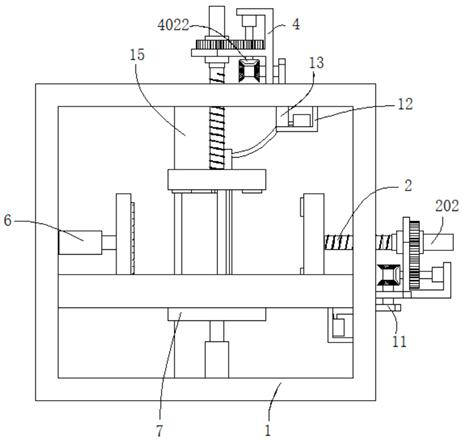

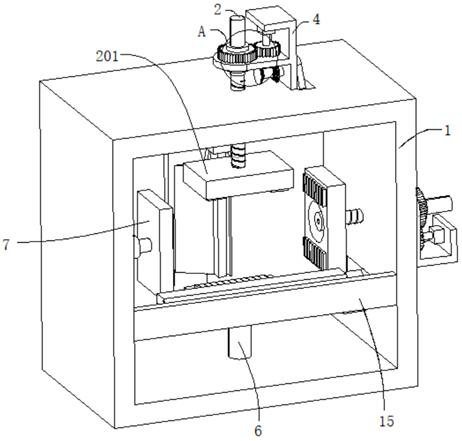

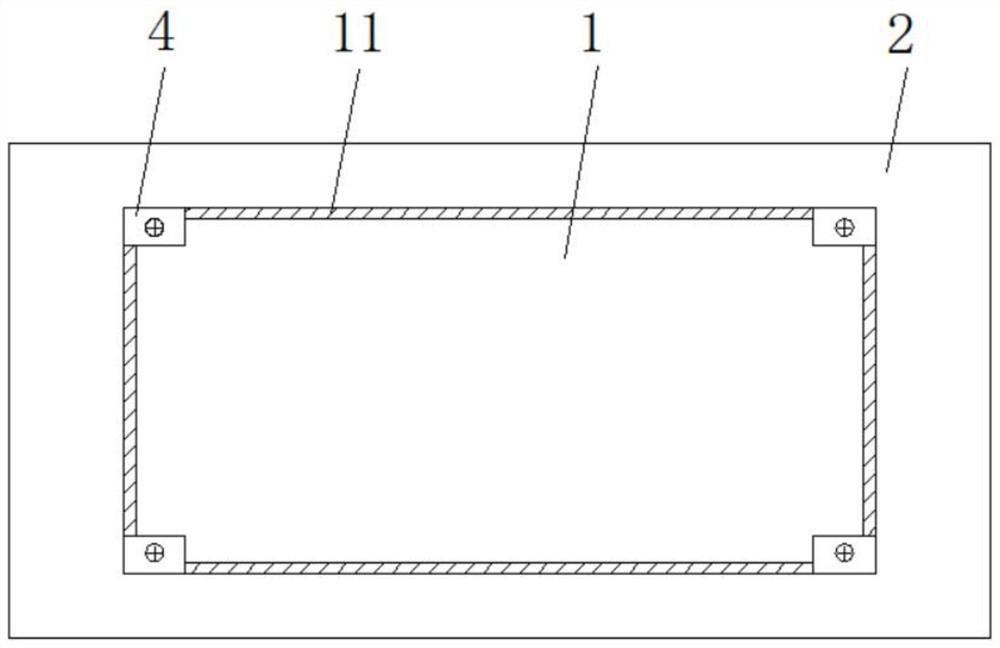

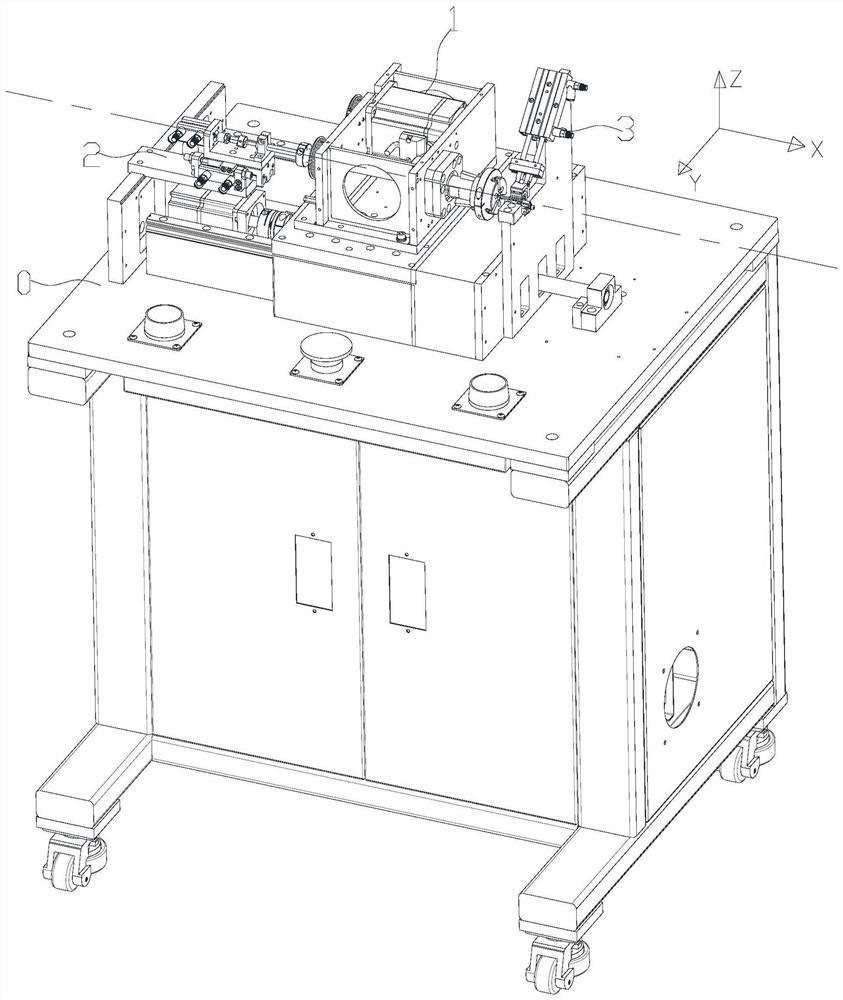

Full-automatic visual inspection device and inspection method for precision electronic stamping part

ActiveCN112122394AFully automatic capture and detectionAccurate and automatic shooting and detectionOptically investigating flaws/contaminationCleaning using toolsVisual inspectionElectric machinery

The invention discloses a full-automatic visual inspection device and inspection method for a precision electronic stamping part, and belongs to the technical field of inspection devices. The full-automatic visual inspection device for the precision electronic stamping part comprises a fixing frame, wherein two positioning mechanisms are connected to the outer wall of the fixing frame, the positioning mechanisms comprise threaded rods correspondingly, the threaded rods are in threaded connection with the interior of the fixing frame, first clamping plates are connected to the outer walls of the threaded rods, grooves are formed in the outer walls of the first clamping plates, cameras are connected to the inner walls of the grooves, moving rods are connected to the ends, away from the firstclamping plates, of the threaded rods, sleeves sleeve the outer walls of the moving rods, the moving rods are slidably connected into the sleeves, supporting seats are connected to the outer wall ofthe fixing frame, the sleeves are rotatably connected into the supporting seats, and motors are connected to the outer walls of the supporting seats. According to the device, a product can be comprehensively, accurately and automatically shot and inspected, inspection is high in precision, high in speed, and high in stability and reliability, the production efficiency and the overall quality of the product are improved, the production cost is reduced, and the production management and control are facilitated.

Owner:昆山捷胜精密电子有限公司

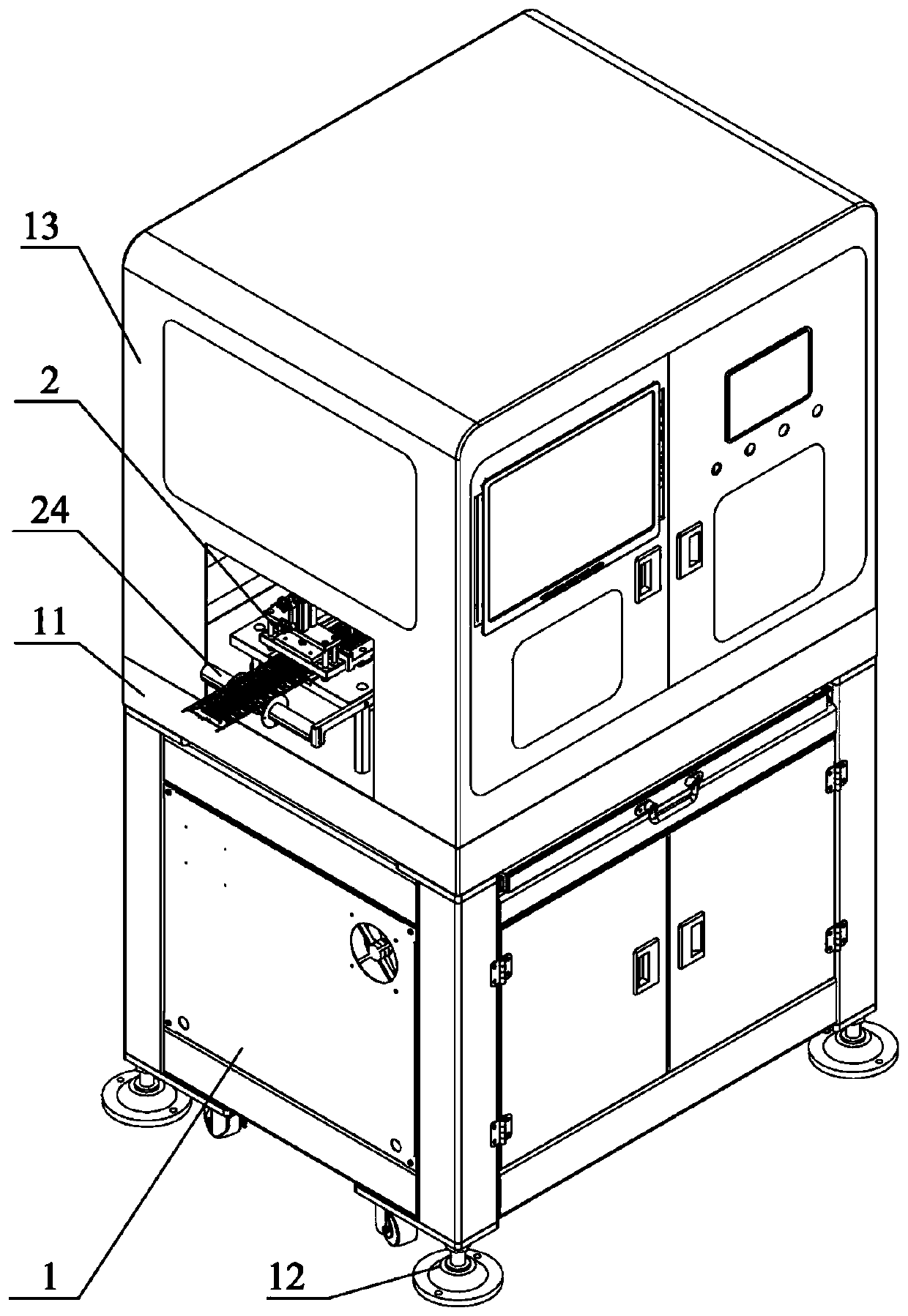

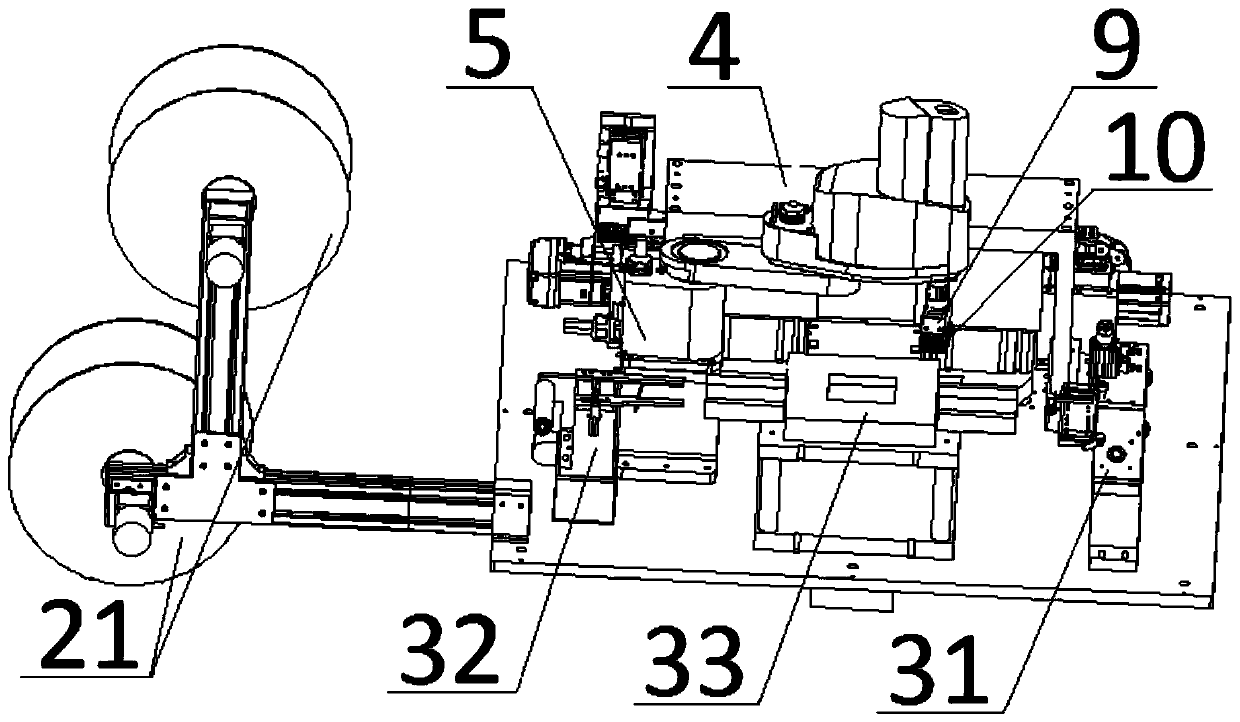

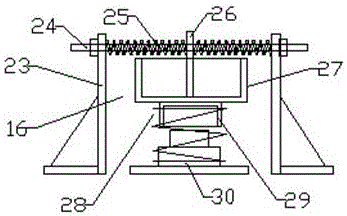

Ejecting and breaking packaging equipment

PendingCN112498823AHigh degree of automationRealize in-line productionPackagingProcess engineeringMechanical engineering

The invention discloses an ejecting and breaking packaging device which comprises a machine table, an ejecting and breaking device and a tray placing device, the ejecting and breaking device and the tray placing device being arranged on the machine table. The ejecting and breaking packaging device further comprises an automatic tray replacing device arranged on the machine table, wherein the ejecting and breaking device is configured to eject and break a material belt, and the tray placing device is configured to transport workpieces obtained after the ejecting and breaking device ejects and breaks the material belt and place the workpieces into trays. The automatic tray replacing device is configured to transport and replace trays; and the automatic tray changing device comprises a firsttray mechanism, a second tray mechanism and a tray conveying mechanism, wherein the first tray mechanism is configured to bear a first tray, the second tray mechanism is configured to bear a second tray, the first tray is an empty tray, the second tray is a full tray, and the tray conveying mechanism is configured to convey the first tray and / or the second tray. The packaging equipment is high inautomation degree, can achieve continuous production, saves the manpower, improves the efficiency and yield, improves the safety coefficient, and facilitates production management and control.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

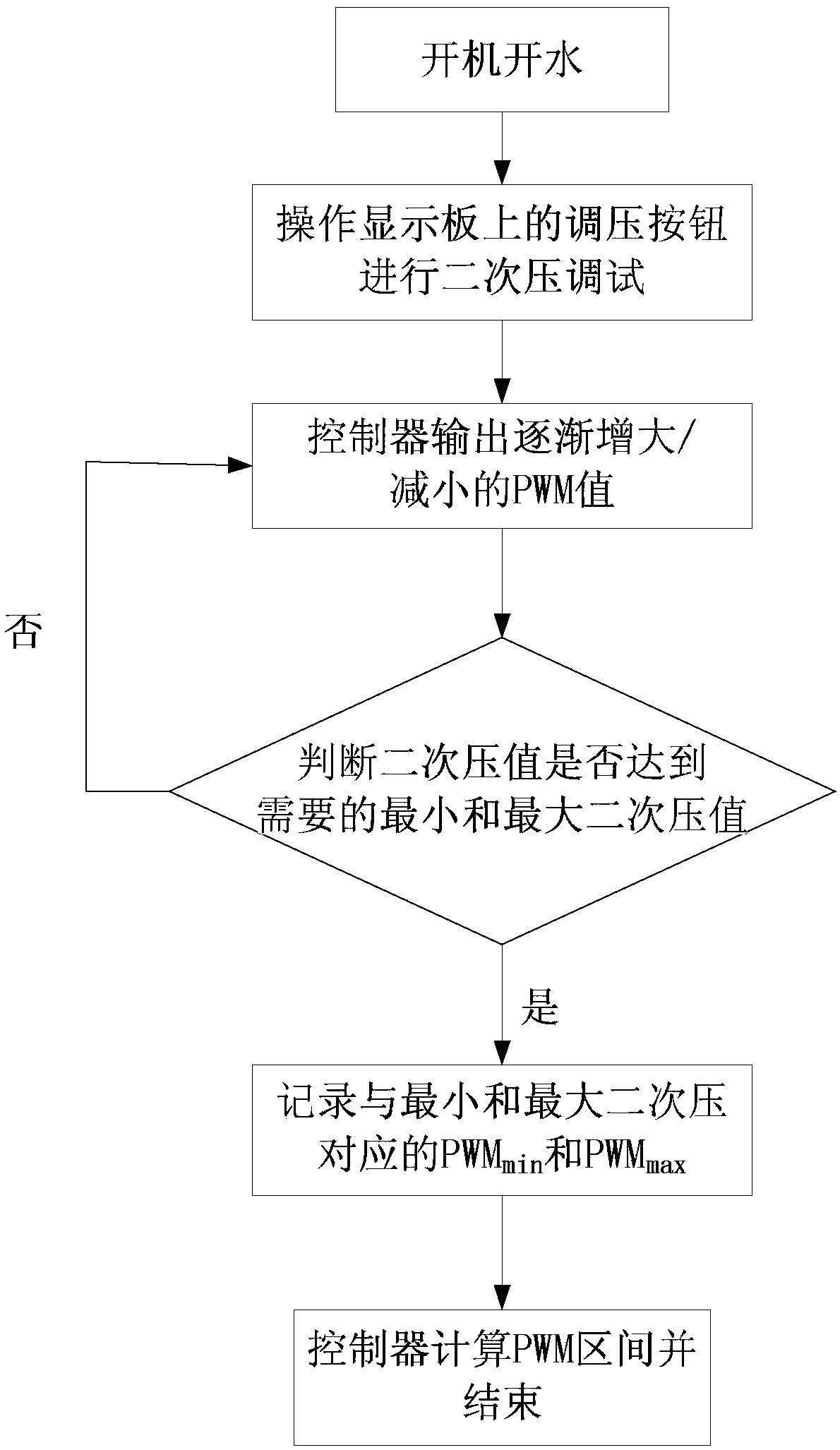

Gas water heater secondary pressure adjusting method and gas water heater

InactiveCN109724258AGuaranteed accuracyEase of production controlFluid heatersEngineeringProportional valve

The invention relates to the technical field of gas water heaters, in particular to a gas water heater secondary pressure adjusting method and a gas water heater. The gas water heater secondary pressure adjusting method specifically comprises the following steps that when the gas water heater works, the pressure of a gas outlet of a proportional valve is detected, the pressure is compared with theset secondary pressure, the PWM value is automatically adjusted according to the comparison result of the pressure and the set secondary pressure until the detection pressure meets the set secondarypressure. In the gas water heater secondary pressure adjusting method, by automatically adjusting the PWM value, the secondary pressure can be adjusted to reach a numerical value the same as the numerical value of the set secondary pressure, the PWM value adjustment is achieved through the automatic adjustment by a controller, and the adjustment can be achieved without manually opening a face shell of the gas water heater; and according to the provided gas water heater, during secondary pressure adjustment, the controller can adjust the secondary pressure by automatically changing the PWM value, due to the fact that the adjustment is automatic adjustment, the accuracy and precision of the adjustment are guaranteed, and management and control are easier to achieve.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Portable unmanned aerial vehicle, propeller blade rotating assemblies, rotating systems as well as assembling method of rotating systems

The invention relates to a portable unmanned aerial vehicle, propeller blade rotating assemblies, rotating systems as well as an assembling method of the rotating systems. Each propeller blade rotating assembly comprises a propeller seat, propeller blades and connecting shafts, wherein first connecting holes separately penetrating through each propeller seat are formed in the corresponding propeller seat; a second connecting hole penetrating through each propeller blade is formed in the corresponding propeller blade; each connecting shaft is arranged in the corresponding first connecting hole and the corresponding second connecting hole in a penetrating manner, in thread fit with the corresponding first connecting hole, and in clearance fit with the corresponding second connecting hole; and each rotating system comprises a propeller blade rotating assembly and a motor connected with the corresponding propeller seat and the corresponding connecting shafts; and the portable unmanned aerial vehicle comprises a foldable unmanned aerial vehicle body and a plurality of rotating systems connected with the unmanned aerial vehicle body. Through the adoption of the portable unmanned aerial vehicle, the propeller blade rotating assemblies, the rotating systems as well as the assembling method of the rotating systems disclosed by the invention, the operating processes of assembling, exchanging and maintaining of the portable unmanned aerial vehicle are simplified.

Owner:YUNEEC INT (CHINA) CO LTD

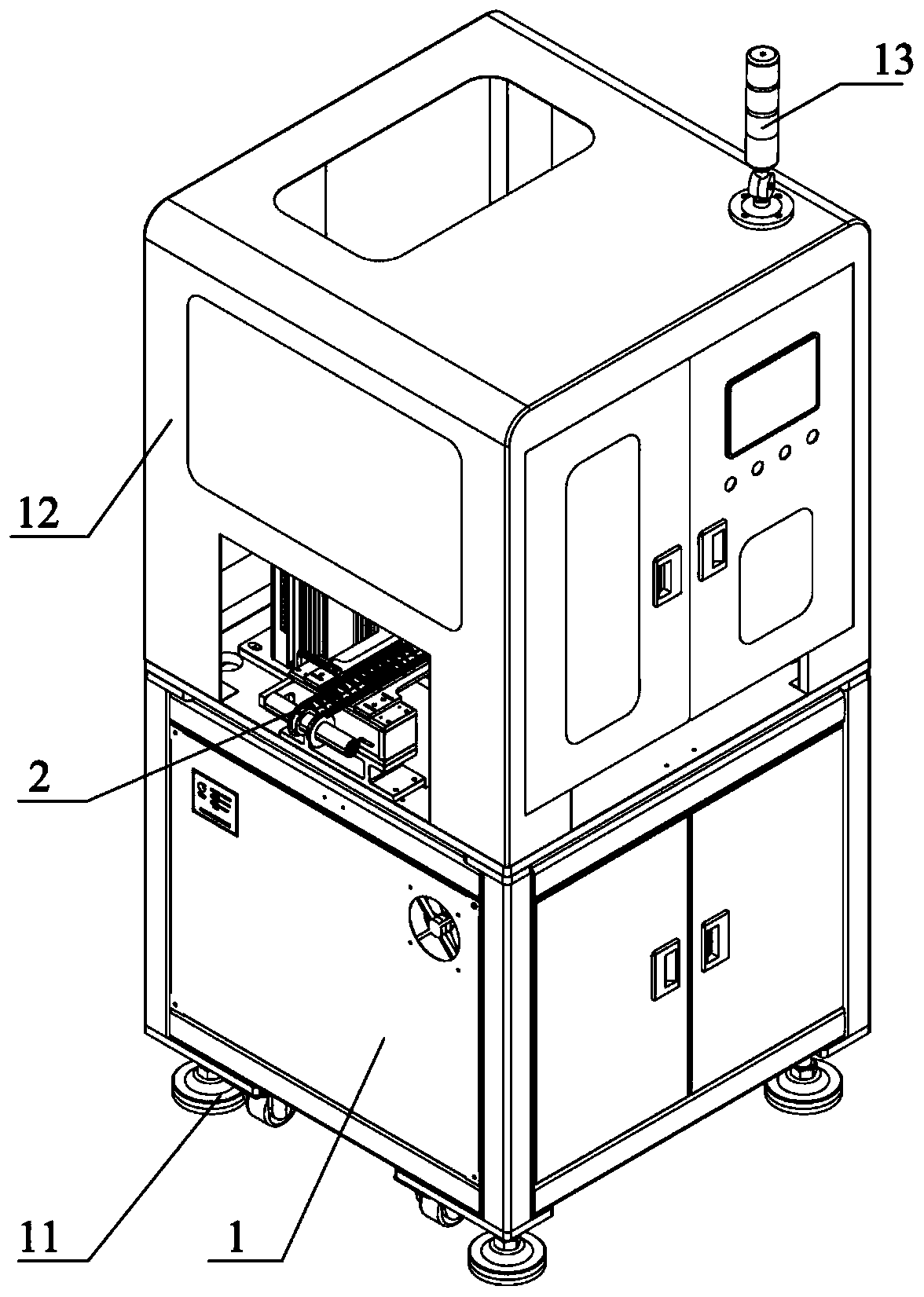

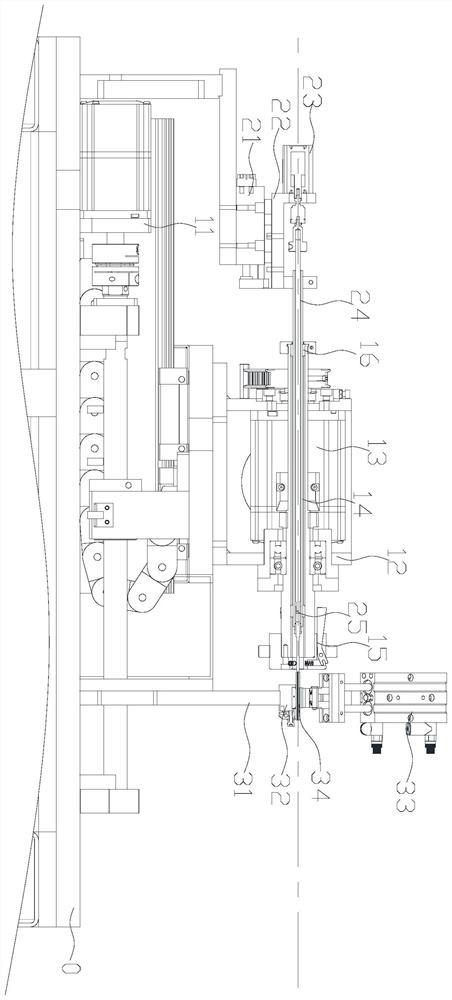

Automatic cut-off, blanking and packaging machine

PendingCN111017345ARealize automatic cut offEasy to operatePackagingIndustrial engineeringBelt conveyor

The invention provides an automatic cut-off, blanking and packaging machine. The machine comprises a rack, wherein the rack is provided with a material discharging device, a stamping blanking device and a material pulling device in sequence, a belt conveyor is arranged below a blanking port of the stamping blanking device, an automatic material taking device for grabbing products and a placing device for placing the grabbed products are arranged at the discharging end of the belt conveyor, the stamping blanking device can punch the products from a material belt, the punched products automatically falls onto the belt conveyor to be conveyed, and the automatic material taking device can automatically grab the products conveyed on the belt conveyor, and automatically place the grabbed products on the placing device. According to the machine, automatic cut-off, blanking and packaging of the products are achieved, manpower and time are effectively saved, the situations that the products areprone to being missed, and the products are polluted are avoided, the application range is wide, and stability and reliability are high, so that the production efficiency and the overall quality of the products are improved, the production cost is reduced, and production management and control are facilitated.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

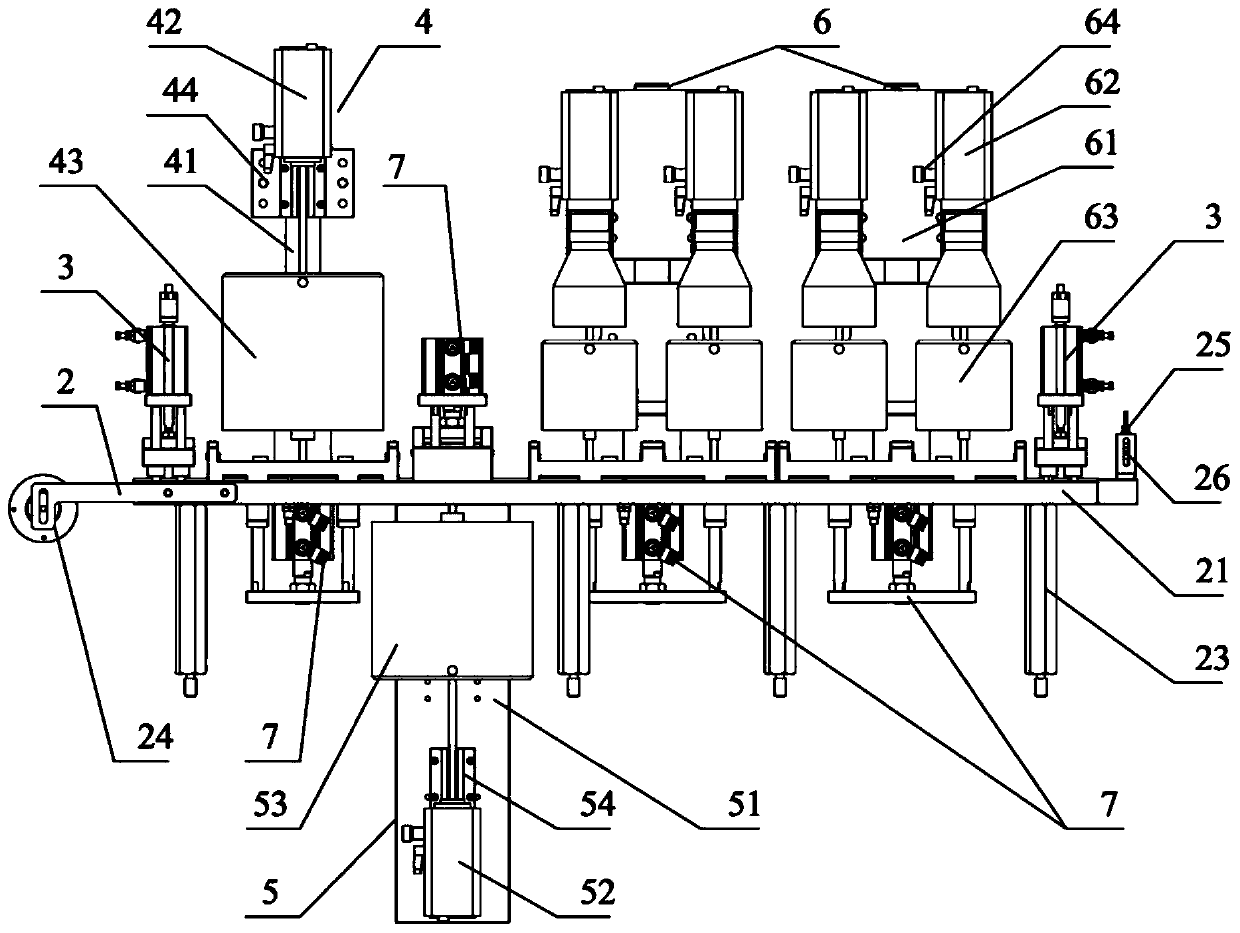

Multi-threaded hole automatic detection machine

The invention provides a multi-threaded hole automatic detection machine, which comprises a rack, wherein a rotary table, loading manipulators, a plurality of first detection devices and transplantingand unloading devices, and turnover devices are arranged on the rack; the loading manipulators are sequentially arranged along the peripheral direction of the rotary table; the turnover devices are arranged on a loading station and an unloading station of the rotary table separately; and a plurality of positioning jigs for placing products are arranged on the rotary table along the peripheral direction thereof. The plurality of first detection devices accurately and comprehensively detect the products on the positioning jigs at a plurality of angles from different directions, so that the multi-threaded hole automatic detection machine is simple and convenient to operate, high in detection accuracy and high in speed, manpower is effectively saved and the time is effectively shortened. Furthermore, the turnover devices on the loading station and the unloading station can turn over the products on the positioning jigs to proper directions, so that accurate and comprehensive detection ofthe products and automatic unloading of the products after detection are facilitated, the production efficiency and the quality and yield of the products are improved, production control is facilitated and the production cost is reduced.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Stamping part appearance detection machine

PendingCN111044102AAccurate detectionEasy to operateMeasurement devicesMachineIndustrial engineering

The invention provides a stamping part appearance detection machine, which comprises a machine frame, wherein a feeding table and a material pulling device are sequentially arranged on the machine frame; a first detection assembly, a second detection assembly and at least one third detection assembly are sequentially arranged on the feeding table; the feeding table is provided with a positioning assembly used for positioning a material belt, and a material pressing assembly correspondingly matched with the first detection assembly, the second detection assembly and the third detection assembly; and the material pulling device can pull the material belt to be conveyed along the feeding table, the positioning assembly and the material pressing assembly can position and press the material belt conveyed along the feeding table, and the first detection assembly, the second detection assembly and the third detection assembly can conduct corresponding detection on products on the material belt. Therefore, the stamping part appearance detection machine can realize comprehensive and precise automatic detection of the products, is high in detection precision and speed, is high in stability and reliability, improves the production efficiency and the overall quality of the products, reduces the production cost, and facilitates production management and control.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

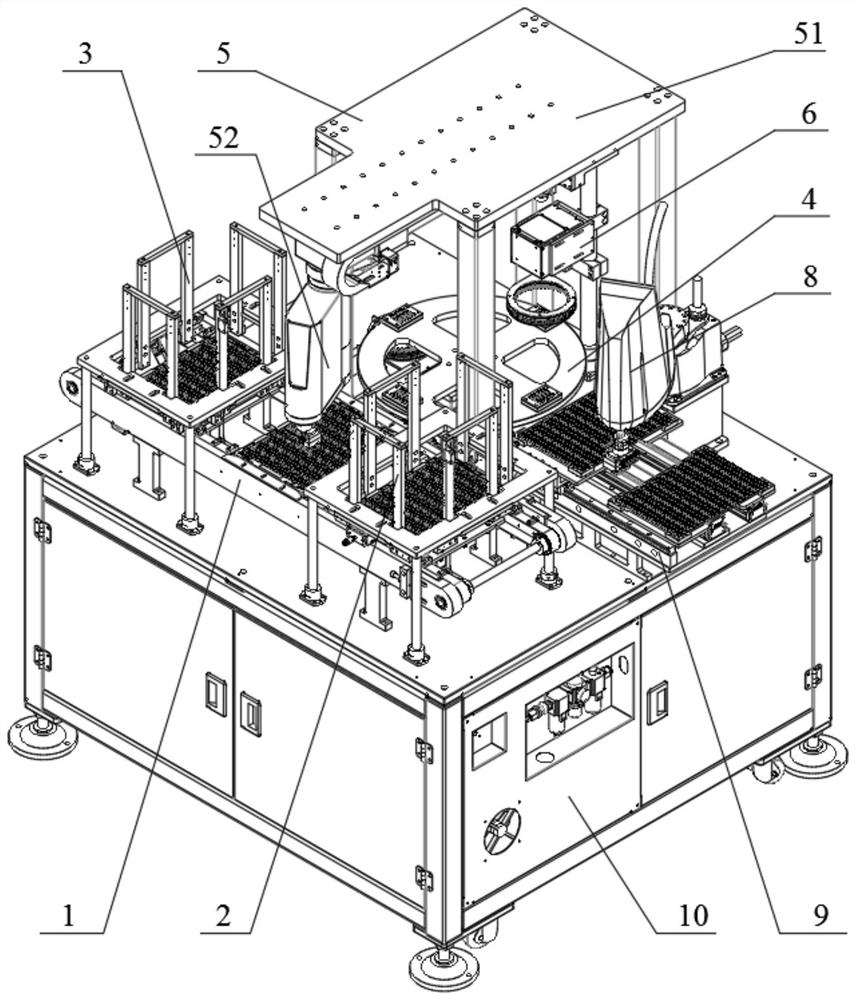

Full-inspection and packaging integrated machine

PendingCN113044549ARealize automatic replacementEasy to operateConveyor partsProcess engineeringMaterial resources

The invention provides a full-inspection and packaging integrated machine. The full-inspection and packaging integrated machine comprises a tray placing device, a tray collecting device, a first conveyor matched with the tray placing device and the tray collecting device, a rotary workbench, a feeding device, an upper detection device, a lower detection device, a discharging device and a material collecting device; the feeding device can take and place products in a feeding disc of the first conveyor into a detection jig on the rotary workbench; the rotary workbench can drive the detection jig to be sequentially and correspondingly matched with the lower detection device, the upper detection device and the discharging device; and the discharging device can take the detected products from the detection jig and place the products on the receiving device. According to the full-inspection and packaging integrated machine, the automatic replacement of the charging tray and the automatic detection and packaging of the product are realized, the operation is convenient, the manpower, material resources and time are effectively saved, the detection precision is high, and false detection, missing detection, product pollution, missing placement and the like are not prone to generation, so that the production efficiency and the product yield are improved, and the production cost is reduced.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

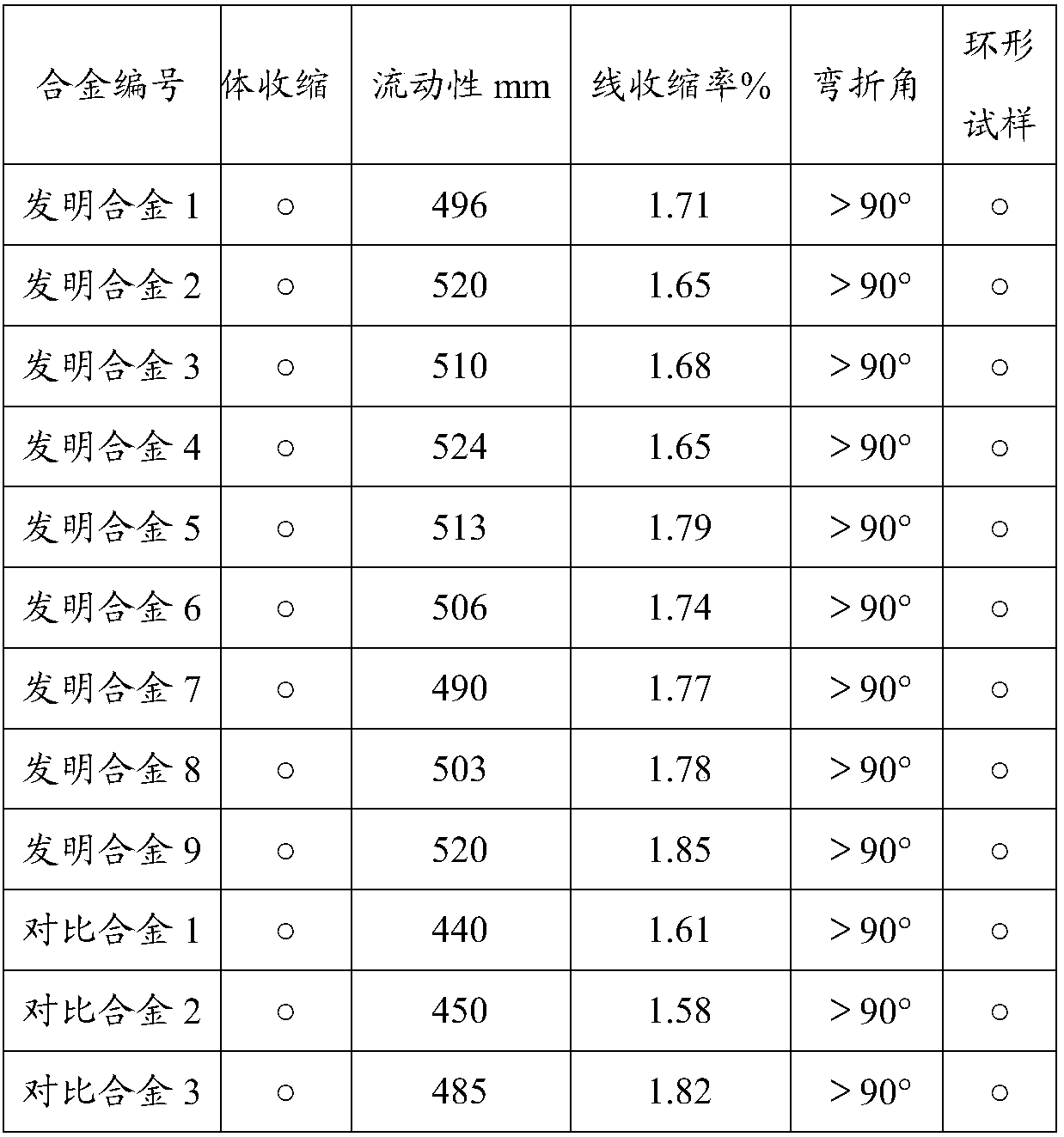

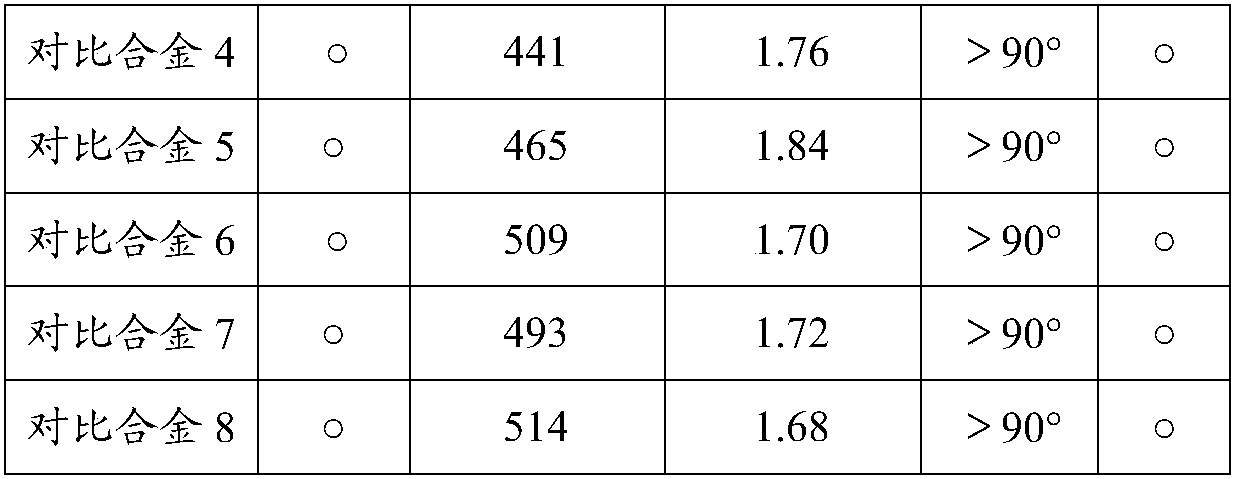

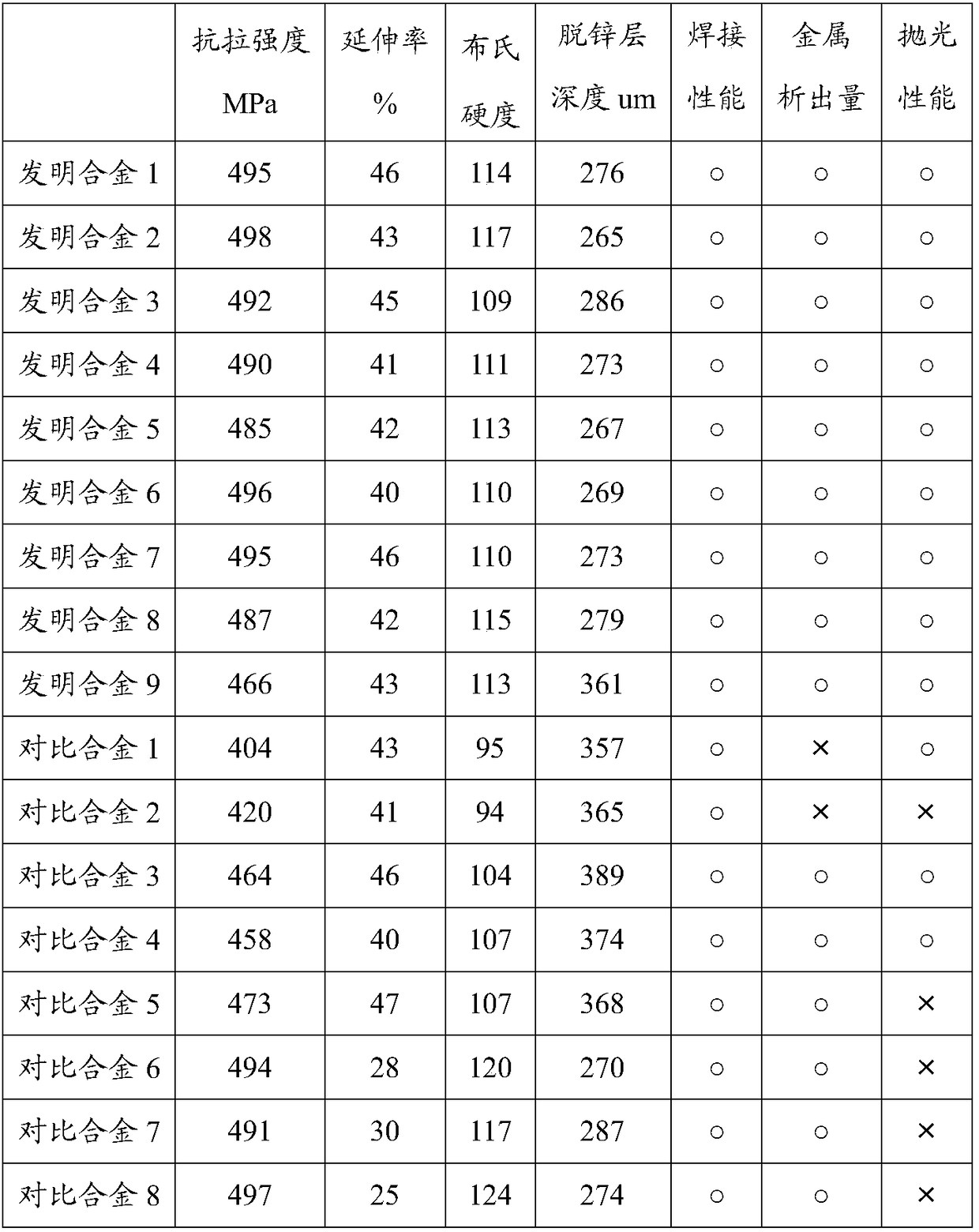

Lead-free and silicon-free brass alloy and manufacturing method thereof

The invention provides a lead-free and silicon-free brass alloy and a manufacturing method thereof. The brass alloy comprises 60-63 wt.% of Cu, 0.6-0.8 wt.% of Si, 0.05-0.15 wt.% of Pb, 0.2-0.5 wt.% of Al, 0-0.3 wt.% of Sn, 0-0.1 wt.% of Ni, 0.02-0.1 wt.% of Fe, 0.0002-0.0010 wt.% B, and the balance of Zn and inevitable impurities, wherein the total content of Cu and Zn is higher than 97.0 wt.%. The lead-free and silicon-free brass alloy is excellent in comprehensive property, in particular, excellent in polishing property, and in particular, suitable for water heating and bathroom parts molded by sand casting and low-pressure casting methods.

Owner:XIAMEN LOTA INT CO LTD

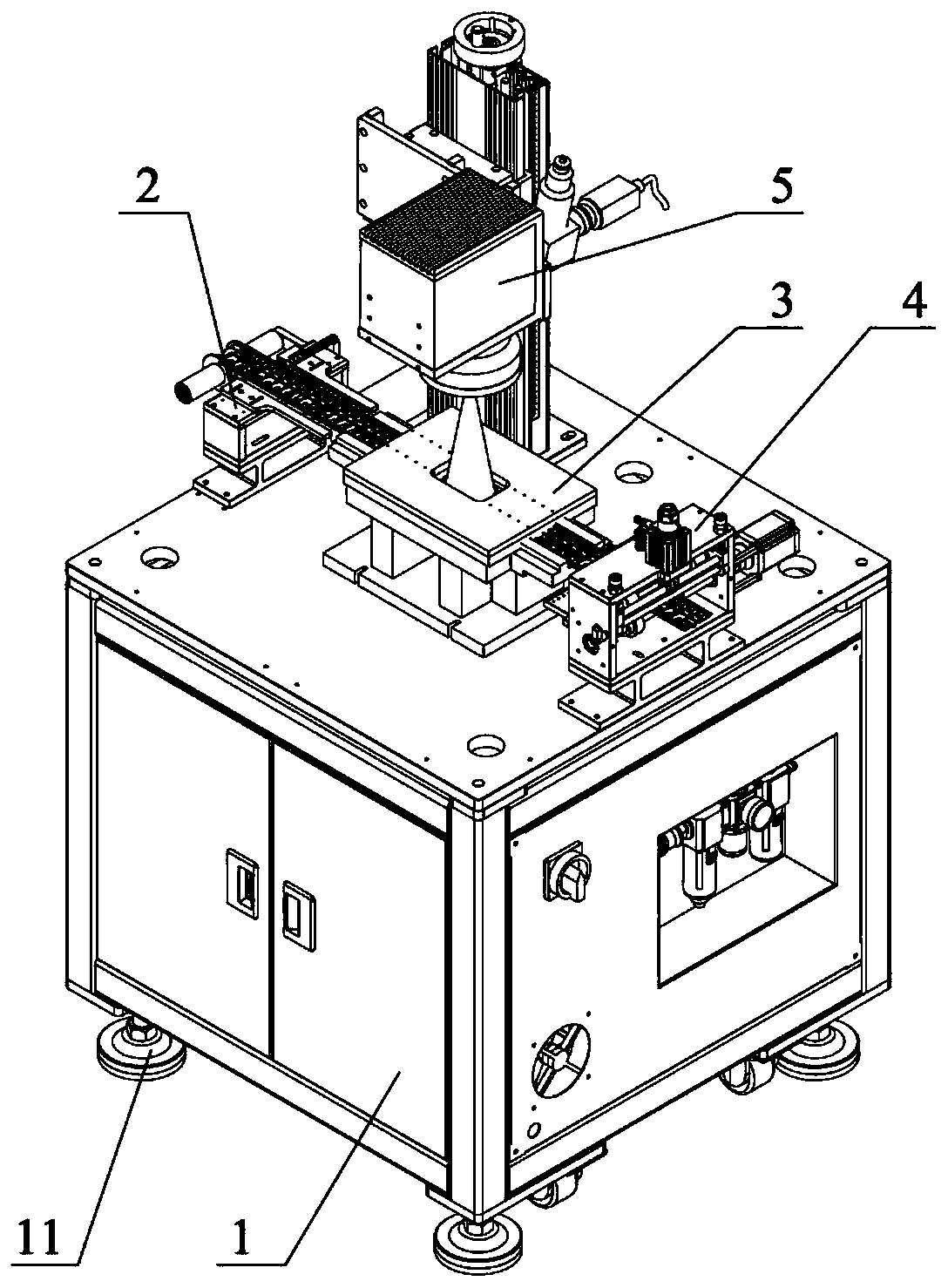

Automatic welding machine

PendingCN111055128ARealize automatic welding processEasy to operateOther manufacturing equipments/toolsLaser beam welding apparatusMachiningIndustrial engineering

The invention provides an automatic welding machine. The automatic welding machine comprises a rack, wherein a guiding device, a stamping device and a material pulling device are sequentially arrangedon the rack, a laser welding device is arranged above the stamping device, a first receding hole corresponding to the laser welding device is formed in the stamping device, the material pulling device can pull a material belt to sequentially penetrate through the guiding device, the stamping device and the material pulling device, the laser welding device can weld a product located in the first receding hole and on the material belt, the stamping device can position and press the material belt penetrating through the stamping device, and can cut off redundant material connecting points of thewelded product. According to the automatic welding machine, automatic welding machining of the product is achieved, operation is easy and convenient, the product machining precision is high, the quality is good, manpower and time are effectively saved, the production efficiency is improved, stability and reliability are high, production management and control are convenient, and the production cost is reduced.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

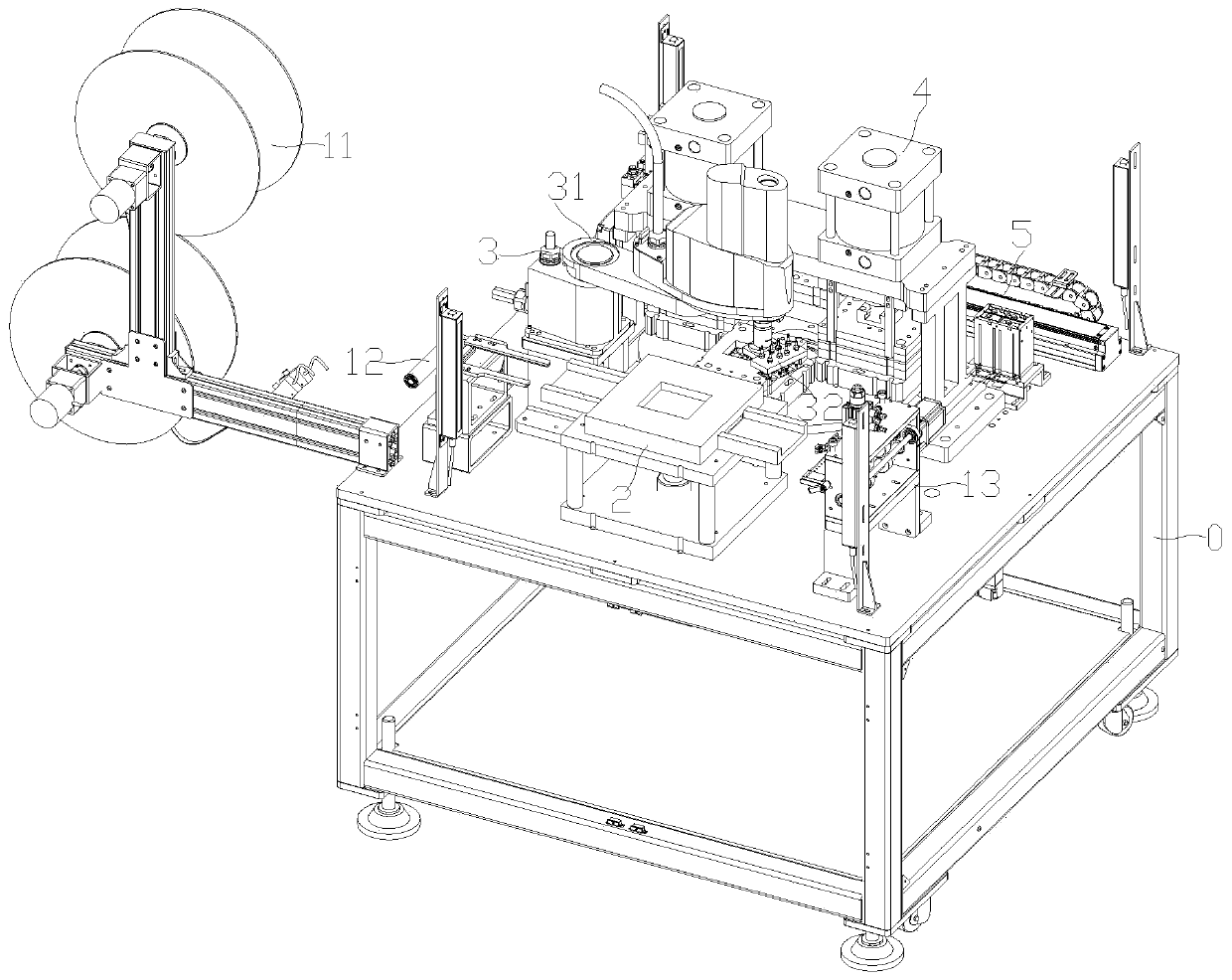

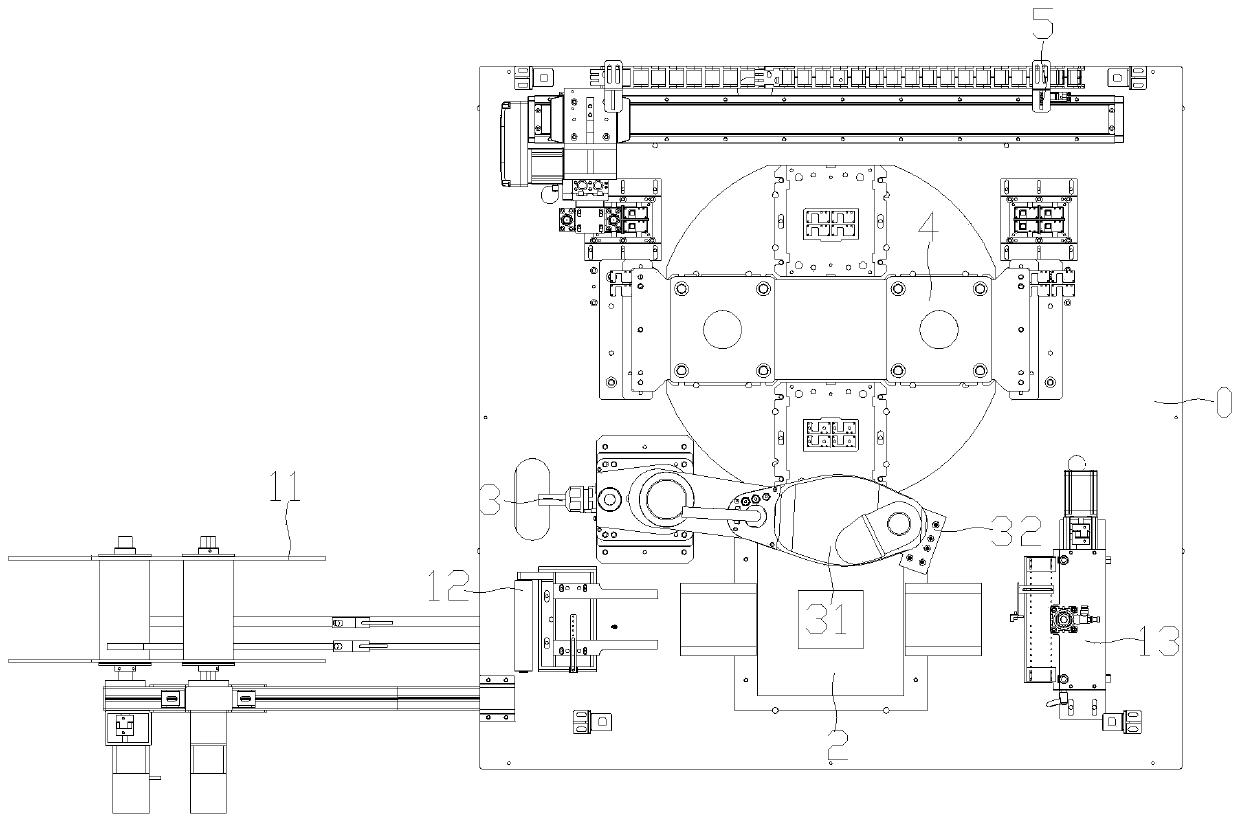

Flexible feeding carrier tape packaging machine

PendingCN112623319AAchieve sharingIncrease productivityPackaging automatic controlReclaimerElectrical and Electronics engineering

The invention discloses a flexible feeding carrier tape packaging machine. The packaging machine comprises a machine frame, and a flexible feeder, an optical detection mechanism, a material taking mechanism, a material placing mechanism, a carrier tape packaging mechanism and a material pulling mechanism are installed on the machine frame. The material taking mechanism is installed on an X-Y motion module, the flexible feeder and the optical detection mechanism are both located below the motion range of the material taking mechanism, and the optical detection mechanism and the carrier tape packaging mechanism are both located within the operation range of the material placing mechanism. The material placing mechanism, the carrier tape packaging mechanism and the material pulling mechanism are sequentially arranged side by side. According to the flexible feeding carrier tape packaging machine, automatic product packaging equipment capable of achieving flexible feeding is provided, the influence of vibration of the flexible feeder on other equipment can be reduced, the production efficiency, the yield and the safety are improved, sharing of products of multiple machine types is achieved, and meanwhile production management and control are facilitated.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

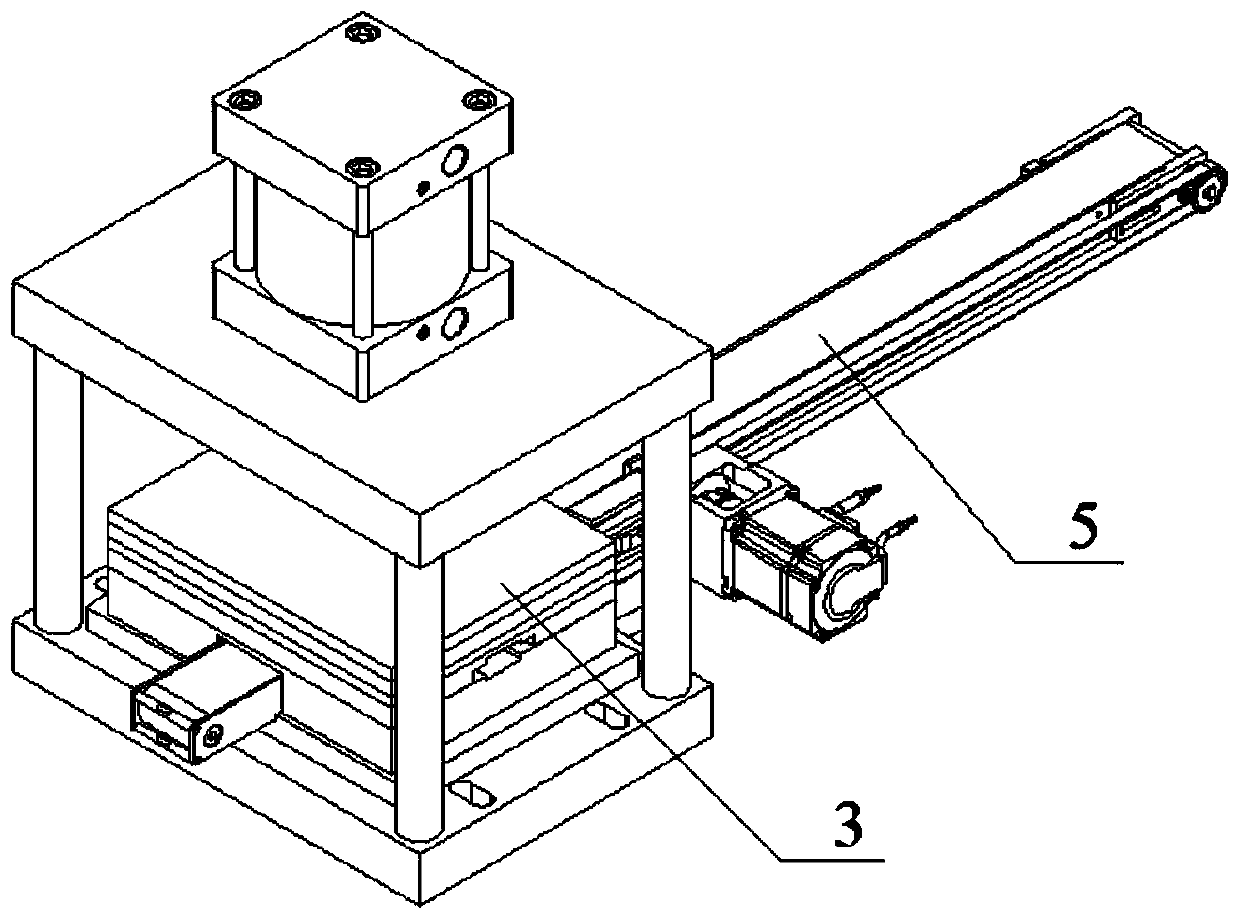

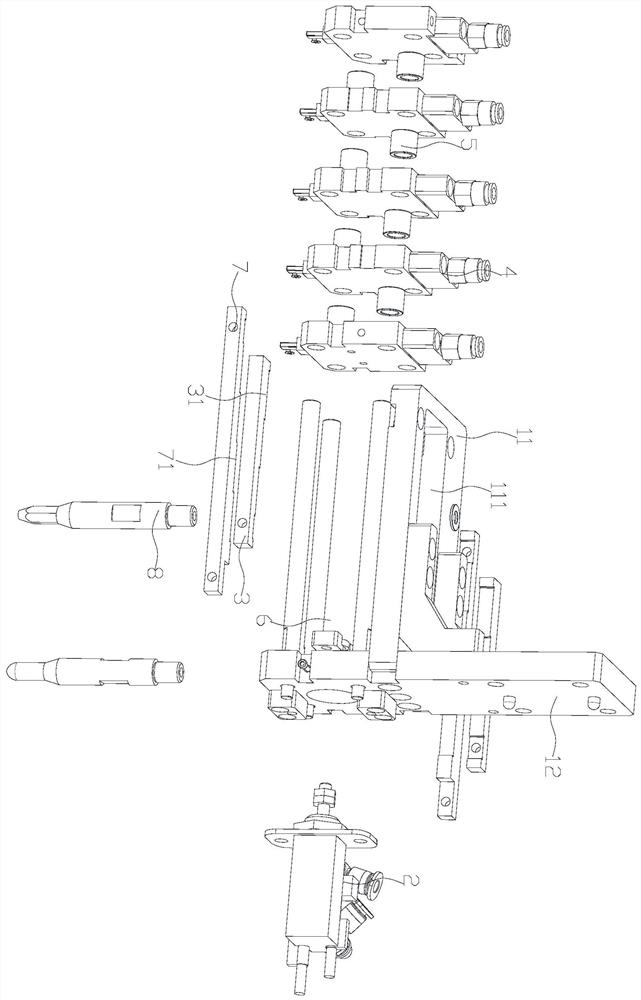

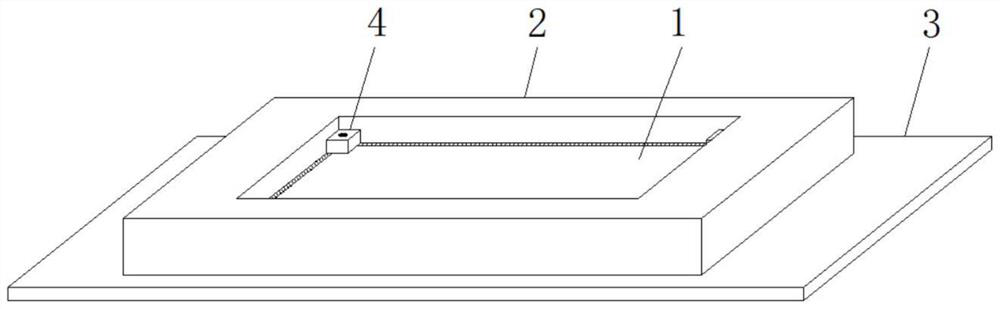

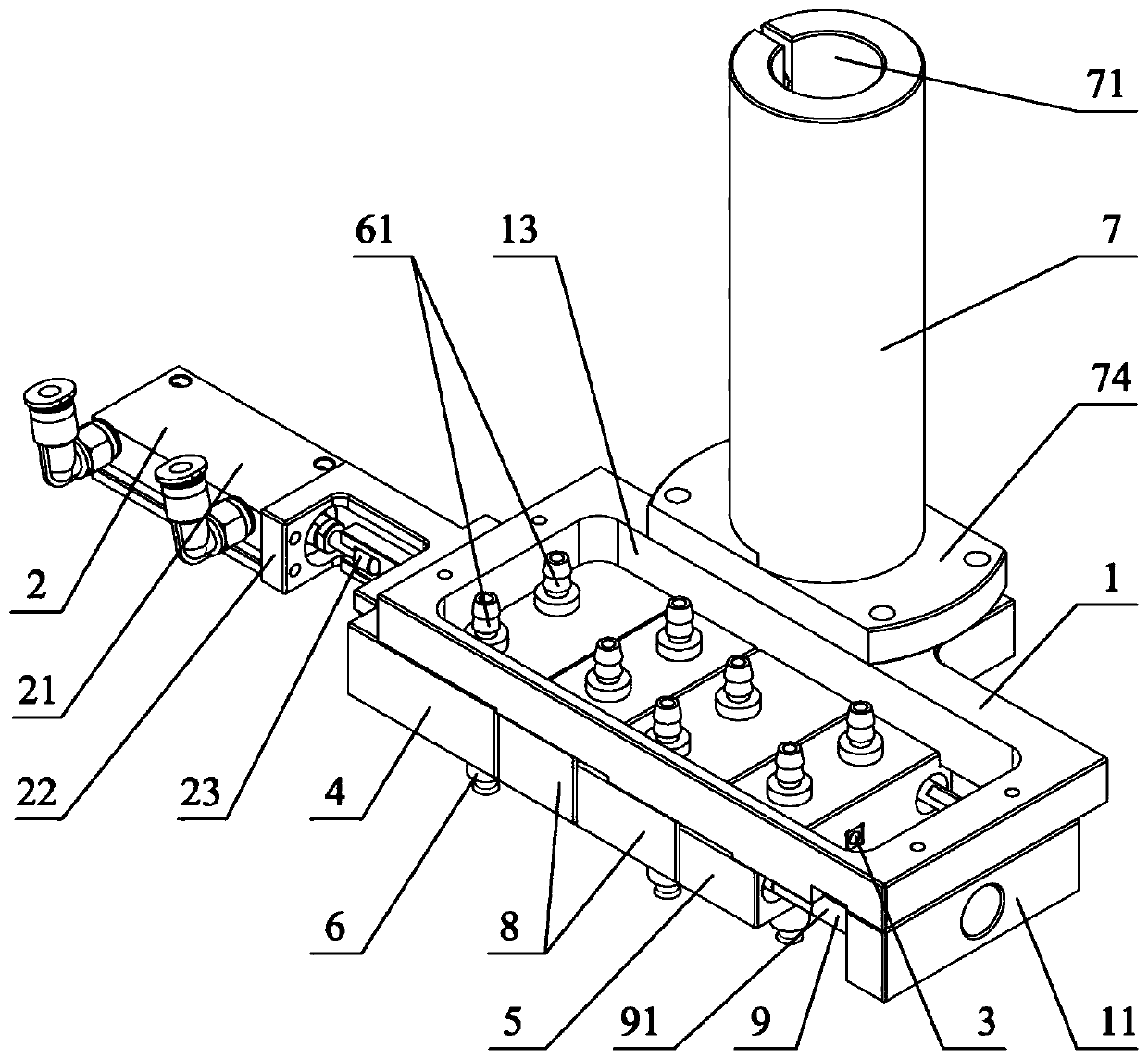

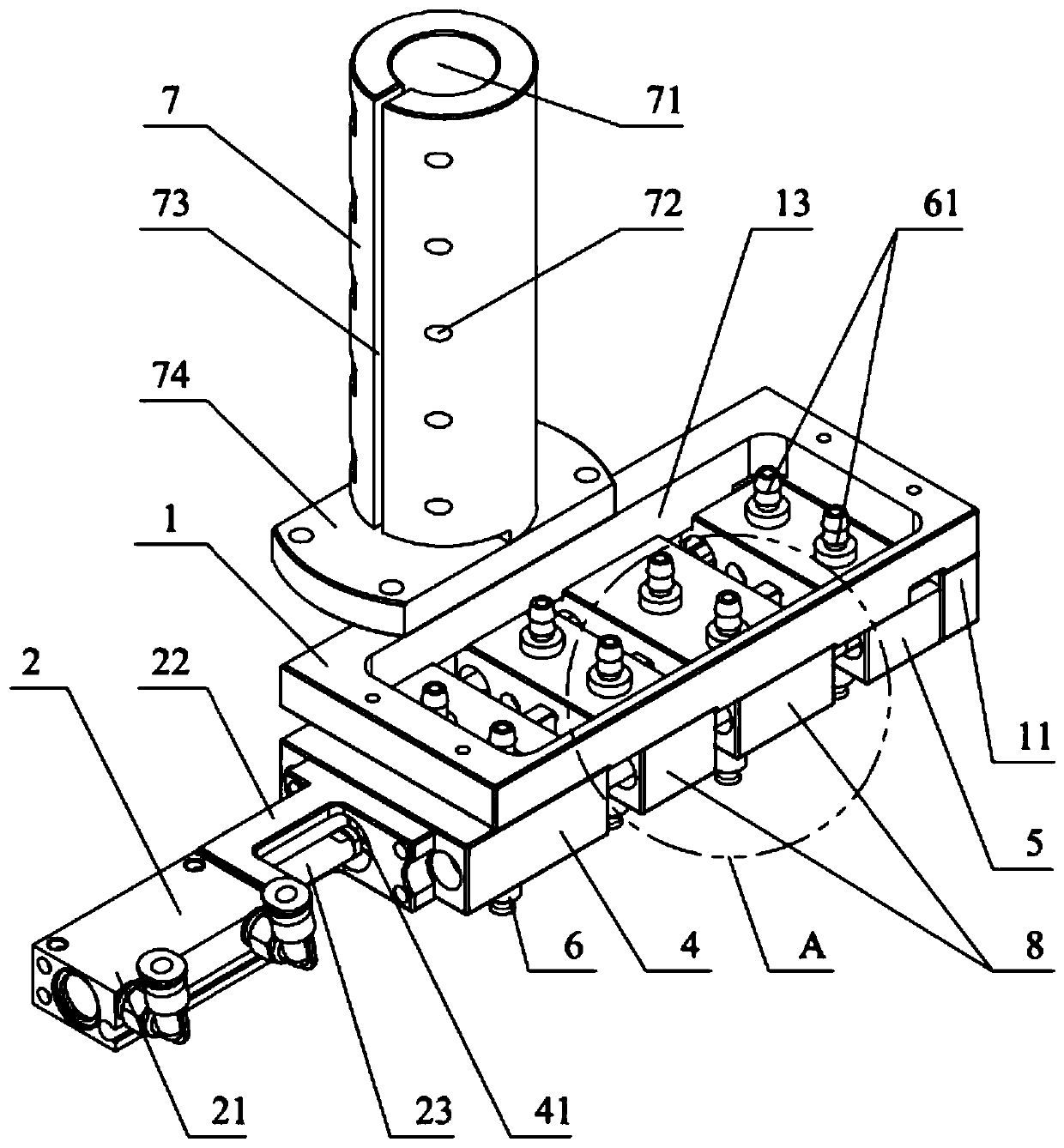

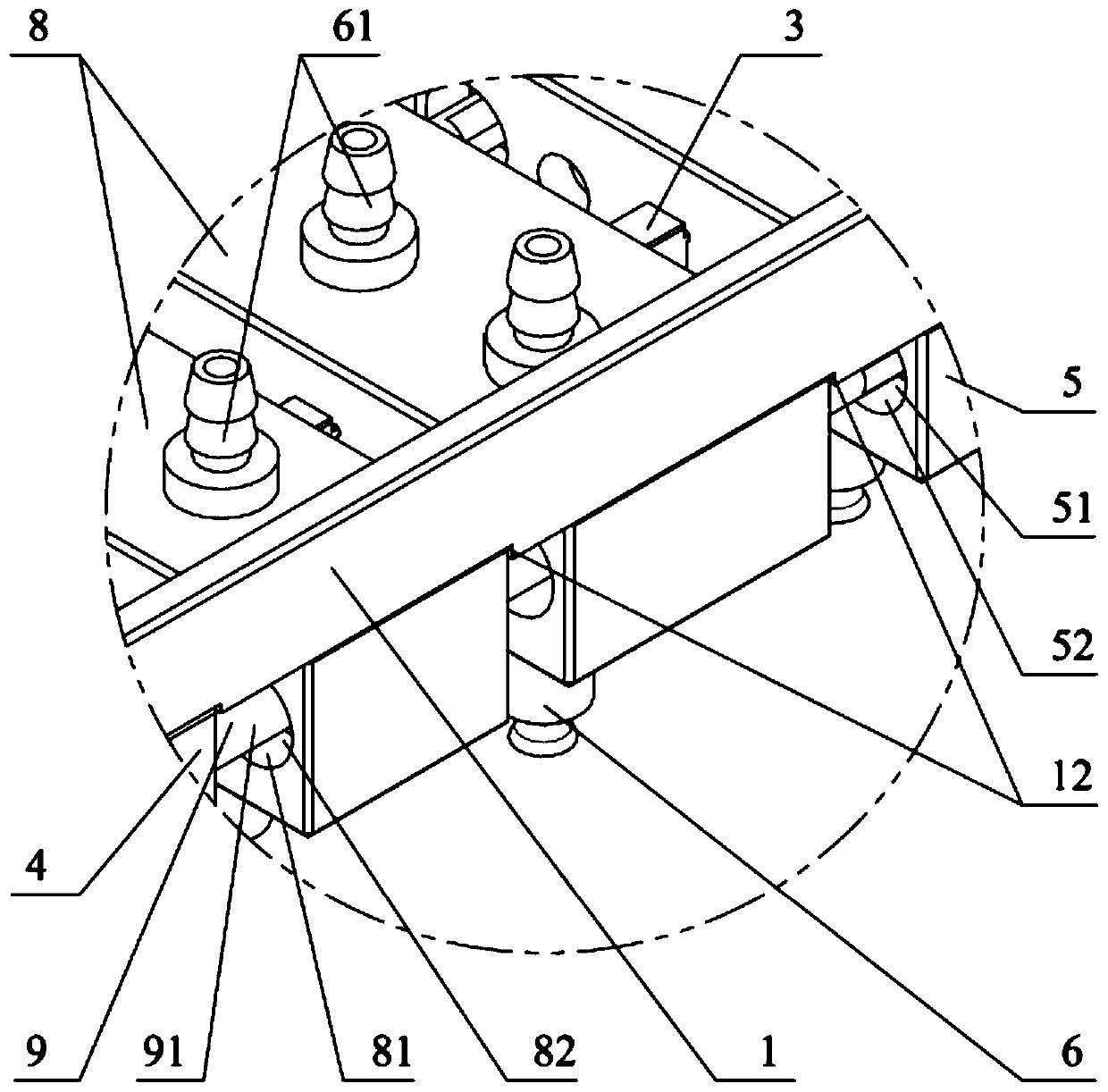

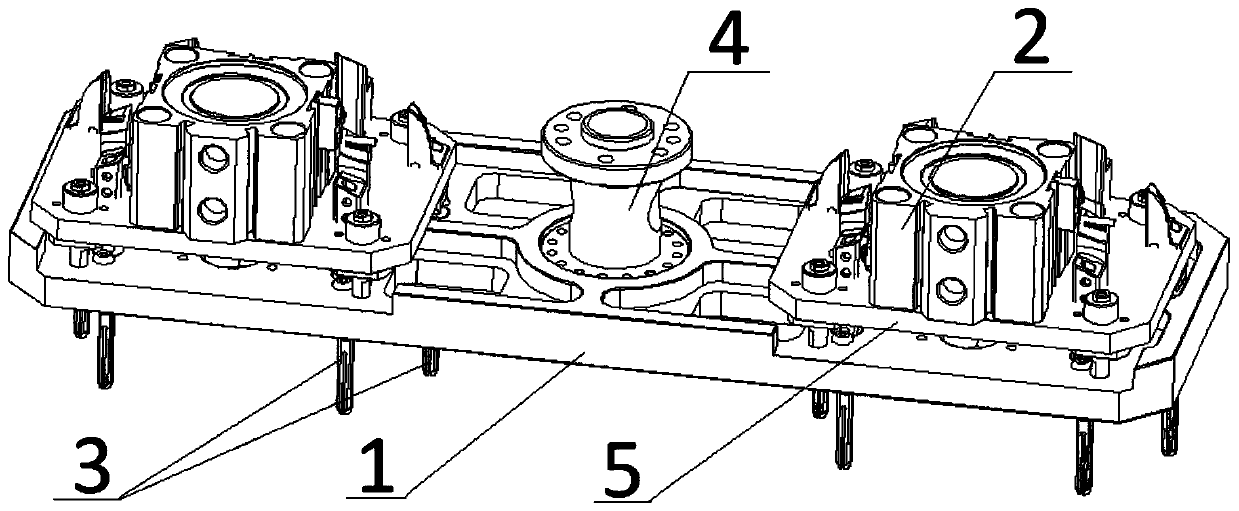

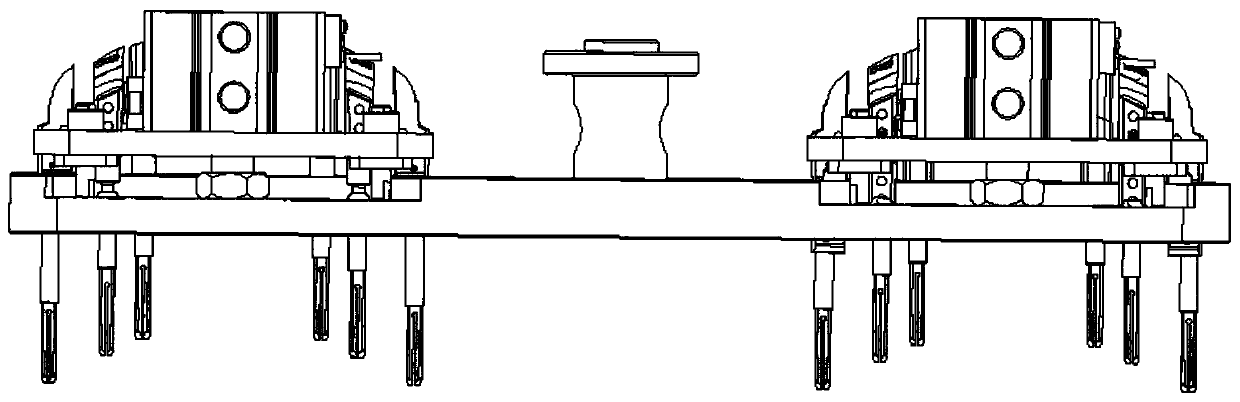

In-mold variable-pitch material moving module

The invention discloses an in-mold variable-pitch material moving module, comprising a mounting base, a driving member, a linkage rod, a plurality of material taking assemblies, a plurality of guide rods and a plurality of push rings. The plurality of material taking assemblies are arranged on the guide rods in a linear array manner; the material taking assembly located at the tail end is fixedlyarranged, and the other material taking assemblies are slidably arranged; the driving member is arranged at one end of the mounting base and in driving connection with the material taking assembly atthe head end; the plurality of push rings are slidably sleeved on the guide rods; the plurality of push rings are all located between every two adjacent material taking assemblies; and the plurality of driving assemblies are in one-way linkage through the linkage rod. The distance between workpieces can be controlled through the module; linkage pitch changing is performed by the push rings and thelinkage rod; when the driving member drives, the material taking assemblies are in linkage through the push rings to implement pitch changing; and when the driving member is reset, the material taking assemblies are linked and reset through the linkage rod. The material moving module can achieve the purposes of implementing on-line production, saving manpower, improving the efficiency and yield and improving the safety coefficient, and facilitates production management and control.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Portable unmanned plane, paddle rotating assembly, rotating system and assembling method thereof

InactiveCN107200124AEasy to assembleRealize the assemblyRotocraftEngineeringElectrical and Electronics engineering

The invention relates to a portable unmanned plane, a paddle rotating assembly, a rotating system and an assembling method thereof. The paddle rotating assembly comprises a paddle seat, paddles and first and second connection pieces, wherein a running-through first connection hole is formed in the paddle seat; running-through second connection holes are formed in the paddles; the first connection piece is provided with a clamping space, and the second connection piece has a limiting feature; the second connection piece is arranged in first and second connection holes in a penetrating manner and is in clearance fit with the two connection holes; and furthermore, the first connection piece is clamped with the second connection piece through the clamping space and the second connection piece is matched with the paddle seat through the limiting feature, so that the limiting feature and the first connection piece can commonly define the displacement of the second connection piece in the axial direction. The rotating system comprises paddle rotating assemblies and motors connected with the paddle seats and the second connection pieces. The portable unmanned plane comprises a folding plane body and a plurality of rotating systems connected with the plane body.

Owner:YUNEEC INT (CHINA) CO LTD

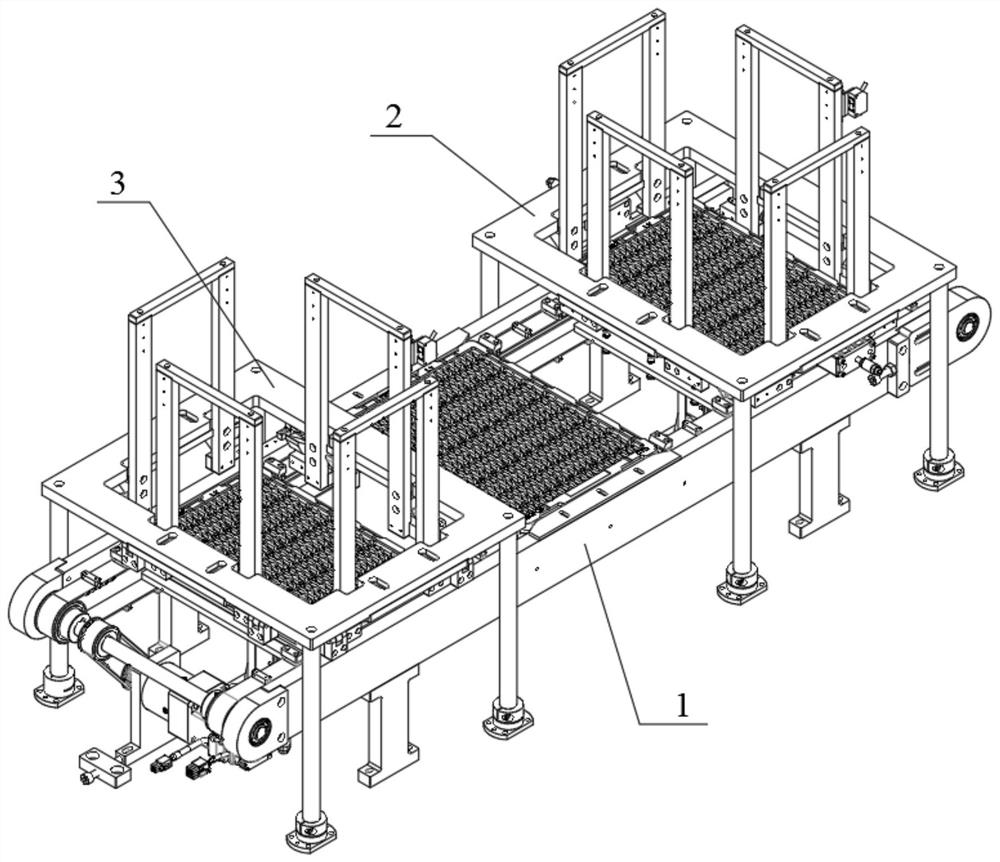

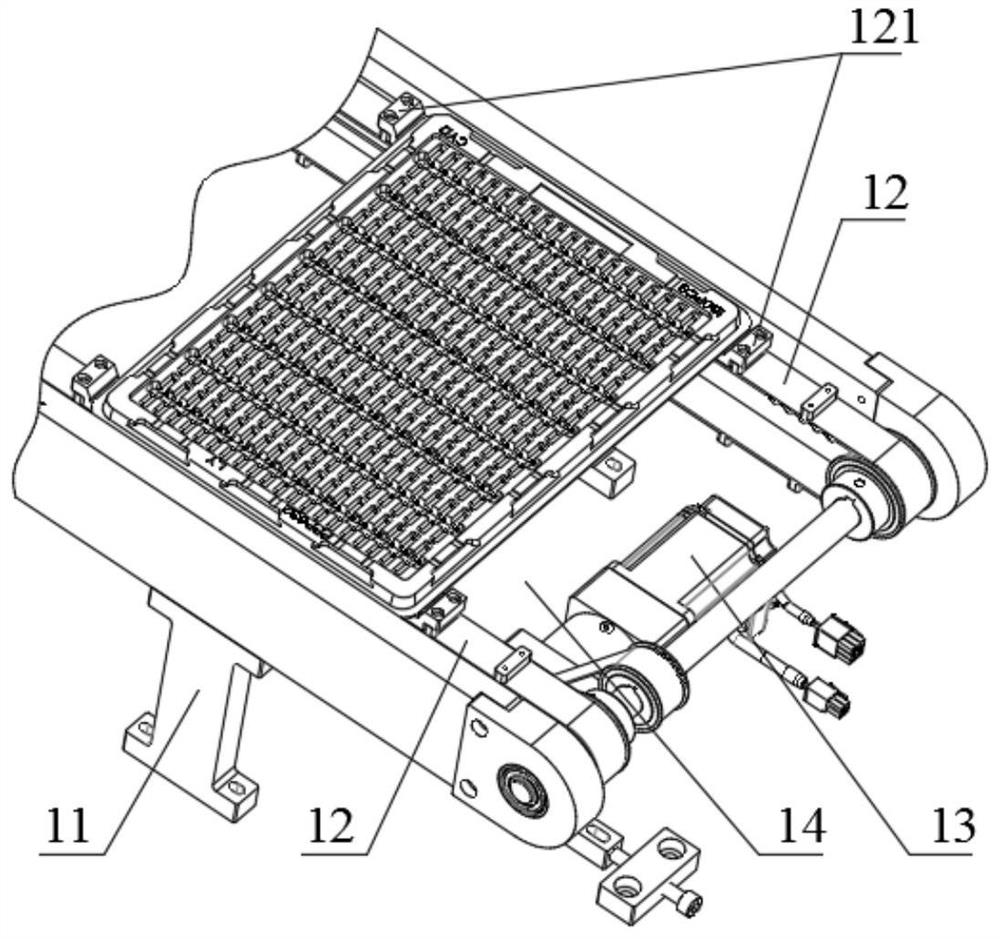

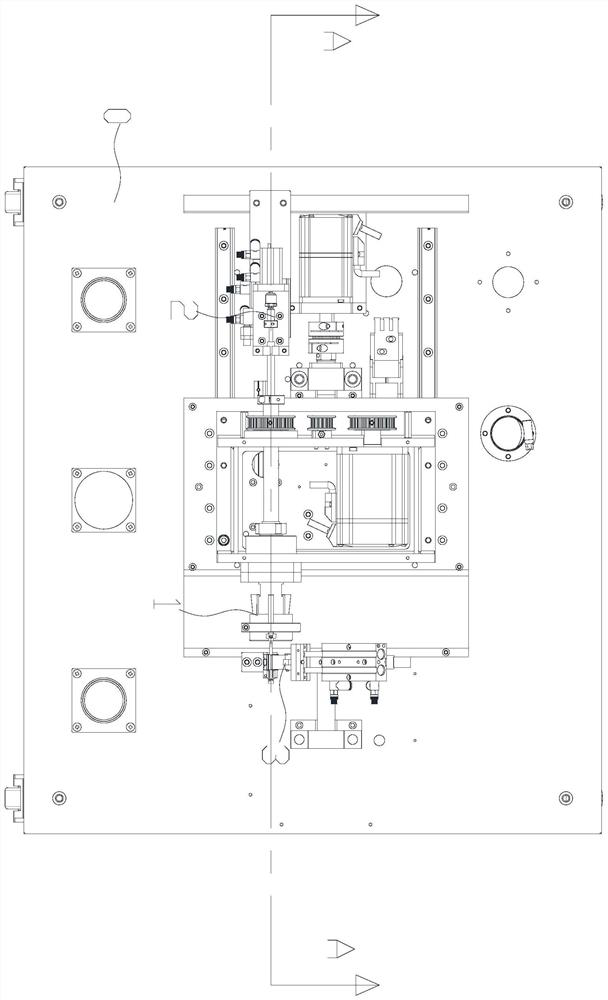

Automated carrier module production line

PendingCN107958588AImprove assembly accuracyImprove efficiencyElectric signal transmission systemsProduction lineProcess engineering

The invention provides an automated carrier module production line. The automated carrier module production line is characterized in that a base feeding mechanism comprises a first tray, a first robotand a streamline carrier, a plurality of bases are put on the first tray, and the first robot is used for transferring the bases onto the streamline carrier; a PCB (printed circuit board) feeding mechanism is connected with the base feeding mechanism and comprises a second tray and a second robot, a plurality of PCBs are put on the second tray, and the second robot is used for transferring the PCBs onto the bases; an upper cover assembling mechanism is connected with the PCB feeding mechanism and comprises a third tray, a third robot and a cover plate press-fit module, a plurality of upper covers are put on the third tray, the third robot is used for clamping the upper covers and then putting the same on the bases of the streamline carrier, and the cover plate press-fit module is used forassembling the upper covers on the bases. The automated carrier module production line can automatically assemble carrier modules and is high in assembling accuracy and efficiency, and production efficiency is improved greatly.

Owner:宁波德晶元科技有限公司

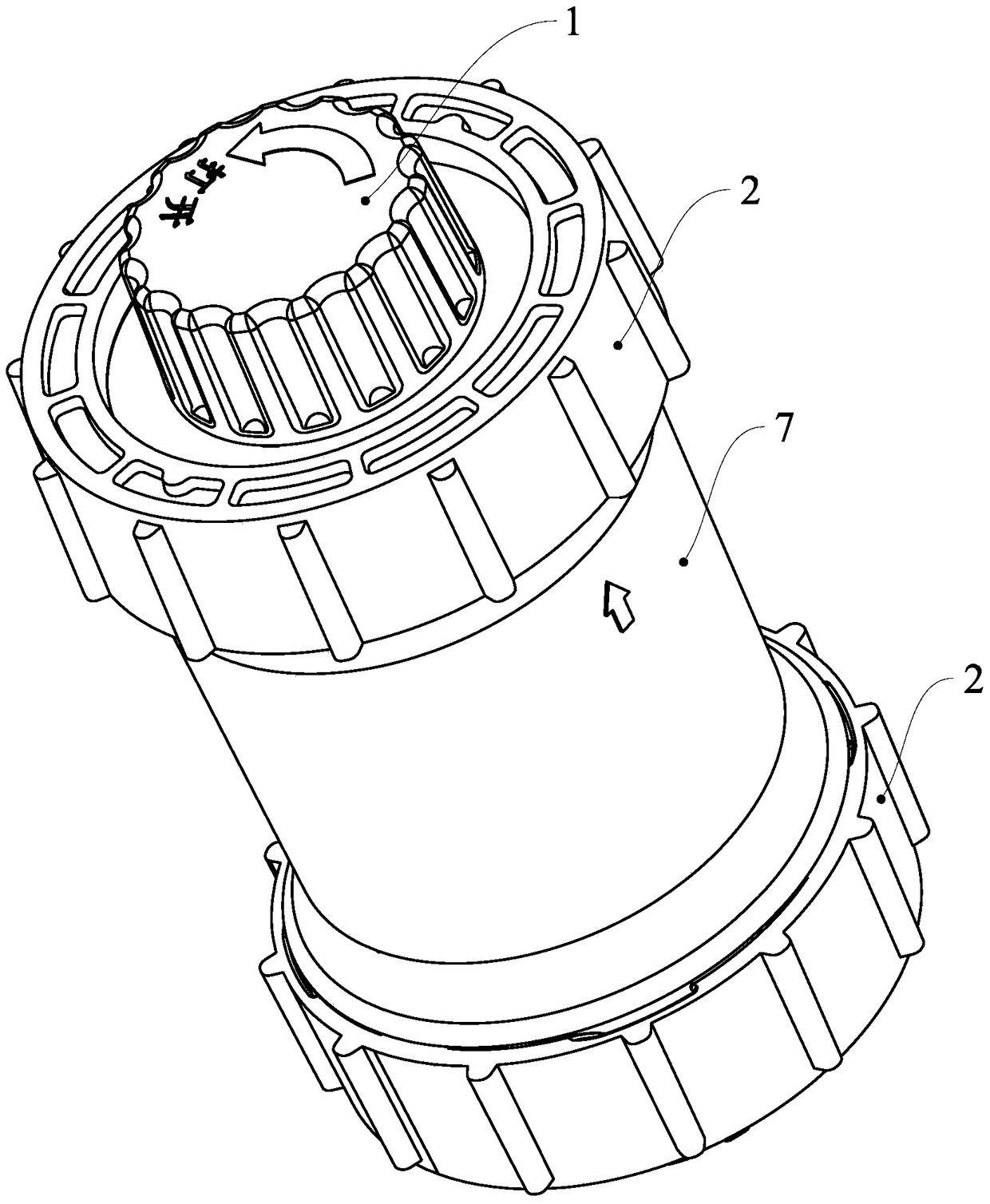

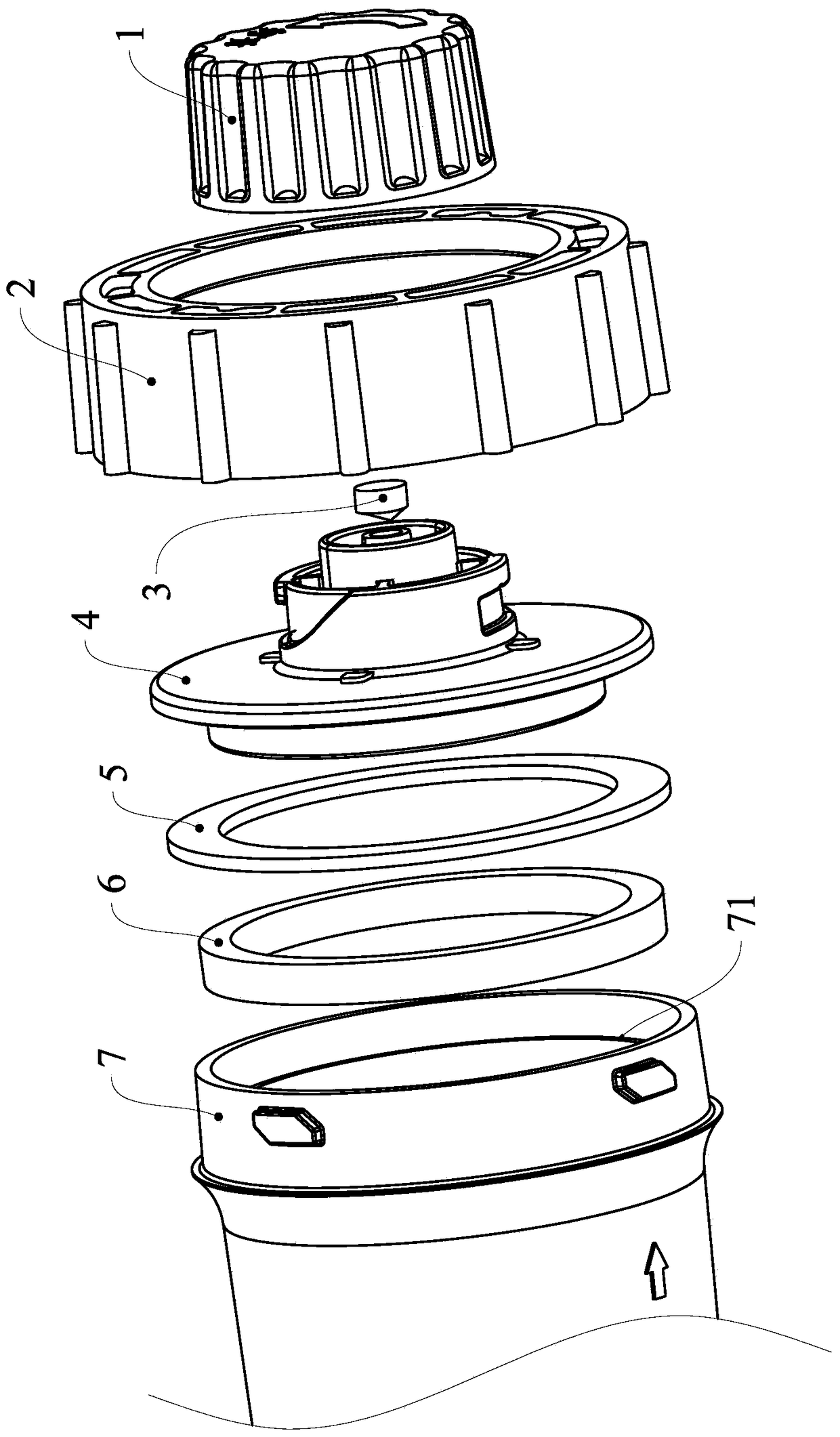

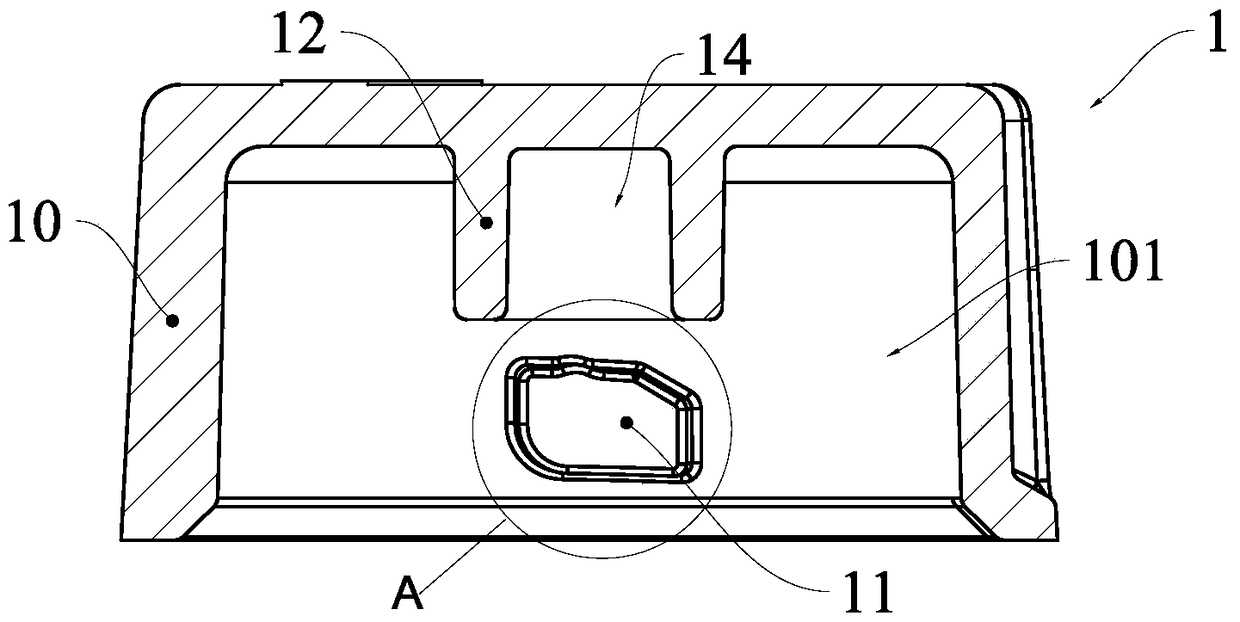

blood purifier

ActiveCN105251074BGuaranteed stabilityEasy to tighten in placeOther blood circulation devicesEngineeringBlood purification

The invention provides a blood purifier, belonging to the field of medical apparatus and instruments. The blood purifier comprises an adsorption column and an end sealing device used for sealing the end of the adsorption column, wherein the end sealing device comprises a cap and an opening sealing part, the opening sealing part comprises an end cap, the end cap comprises a cap body, and a blood nozzle and a cyclic annular coupling wall which are arranged on the cap body, and the cyclic annular coupling wall and the blood nozzle are coaxially arranged outside the peripheral surface of the blood nozzle. The coupled connection between the opening sealing part and the adsorption column and / or the coupled connection between the cap and the end cap are detachable coupled connection of a buckle and a slot. By adopting the connection mode of the coupled connection of the buckle and the slot, a mould of a part can be simplified, the injection molding production cycle can be shortened, and the blood purifier provided by the invention is conducive to managing and controlling the production and reducing the production cost.

Owner:JAFRON BIOMEDICAL

Novel four-station disc automatic rough side pressing machine

PendingCN111346957AAccurate and efficient automatic deburring workSave human effortMetal-working feeding devicesPositioning devicesCircular discRobot hand

The invention discloses a novel four-station disc automatic rough side pressing machine. The machine comprises a worktable, a discharging mechanism, a conveying mechanism, a rough side pressing module, a mechanical arm, a single-axis robot and at least one box loading module are mounted on the worktable, the discharging mechanism and the conveying mechanism are opposite in position, the rough sidepressing module is located between the conveying mechanism and the box loading module, the tail end of the upper portion of the mechanical arm is located above the conveying mechanism and the rough side pressing module and can move, the tail end of the upper portion of the single-axis robot is located above the rough side pressing module and the box loading module and can move, the novel four-station disc automatic rough side pressing machine can achieve online production, multiple 3C part products can be precisely and efficiently subjected to automatic rough side pressing work, on one hand,manpower and time are saved, production cost of a product can be reduced, on the other hand, machining efficiency and precision are improved, product quality and yield can be ensured, and product managing and control are facilitated.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Automatic edge pressing equipment

PendingCN110937446AForce balanceNot prone to tilt damageArticle deliveryWebs handlingProcess engineeringIndustrial engineering

The invention discloses automatic edge pressing equipment. The equipment comprises a machine table, a feeding device, a jacking device, a conveying device and an edge pressing device, wherein the feeding device, the jacking device, the conveying device and the edge pressing device are arranged on the machine table, and the conveying device is located between the jacking device and the edge pressing device; the feeding device is configured to input work materials into the jacking device; the jacking device is configured to jack the work materials; the conveying device is configured to convey the jacked work material into the edge pressing device; and the edge pressing device is configured to press edges of the work materials. The equipment has the beneficial effects that continuous automatic production can be achieved, the equipment works for multiple work materials simultaneously in production steps, and the production efficiency can be effectively improved; the equipment is automatically operated in the whole process, and manual intervention is not needed; and the equipment can realize continuous production, manpower is saved, the efficiency is improved, and production managementand control are facilitated.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

A kind of automatic visual inspection equipment and inspection method for precision electronic stamping parts

ActiveCN112122394BFully automatic capture and detectionAccurate and automatic shooting and detectionOptically investigating flaws/contaminationCleaning using toolsVisual inspectionElectric machinery

The invention discloses an automatic visual inspection equipment and a detection method for precision electronic stamping parts, and belongs to the technical field of inspection equipment. A fully automatic visual inspection equipment for precision electronic stamping parts, comprising a fixing frame, the outer wall of the fixing frame is connected with two sets of positioning mechanisms, the positioning mechanism comprises a threaded rod, the threaded rod is threadedly connected in the fixing frame, and the outer wall of the threaded rod is connected with a first clamping mechanism The outer wall of the first clamping plate has a groove, the inner wall of the groove is connected with a camera, the end of the threaded rod away from the first clamping plate is connected with a moving rod, the outer wall of the moving rod is sleeved with a sleeve, and the moving rod is slidably connected to the sleeve. Inside the tube, the outer wall of the fixing frame is connected with a support seat, the sleeve is rotatably connected in the support seat, and the outer wall of the support seat is connected with a motor; the invention can realize comprehensive and accurate automatic shooting and detection of products, with high detection accuracy, high speed and stability. And high reliability, improve production efficiency and overall product quality, reduce production costs, and facilitate production control.

Owner:昆山捷胜精密电子有限公司

Welding method for realizing high-temperature-resistant metal shell

InactiveCN113814512AReduce usageAffect normal useMetal working apparatusSemiconductor devicesTemperature controlZinc selenide

The invention discloses a welding method for realizing a high-temperature-resistant metal shell. The method comprises the following steps that the first step, after electroplating of bottom nickel on a metal cap body made of a 4J29 material is conducted, electroplating of gold on the surface is conducted, the size of a cap opening is 15mm*20mm, zinc selenide is selected as the material of a light window, the size of the light window is 14.9mm*19.9mm, the edge of the light window is subjected to metallization treatment, a surface welding layer of the light window is a gold layer, and the size of an InSn48 preformed welding piece is determined according to the length and the width of the cap opening, the width of a metallization layer of a light window piece and the welding volume needing to be filled; and the second step, an experimental instrument is prepared, the experimental instrument adopts a vacuum brazing furnace to replace a chain type mesh belt furnace used by traditional brazing, and the vacuum furnace has the advantages of being accurate in temperature control, controllable in furnace atmosphere and vacuum degree and easy and convenient to operate. According to the method, due to an arranged metal limiting block, the position of the zinc selenide light window in the metal cap body can be conveniently fixed through the metal limiting block.

Owner:凯瑞电子诸城有限公司

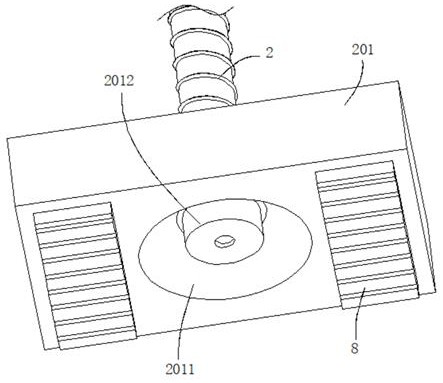

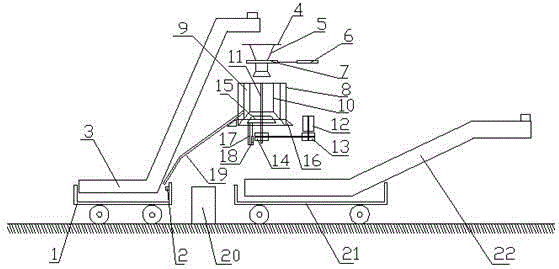

Full-automatic centrifugal deoiling machine

InactiveCN105921291AEase of production controlAvoid polluting the environmentCentrifugesOil separationMultiple dimension

The invention provides a full-automatic centrifugal deoiling machine. The full-automatic centrifugal deoiling machine comprises a feed chain plate type feeding mechanism which is arranged on an oil collection trolley. The tail end of the feed chain plate type feeding mechanism is provided with a weighing and metering mechanism. A centrifugal deoiling mechanism is arranged on the lower portion of the weighing and metering mechanism and mounted on a T-shaped damping anti-inclination safety mechanism. The lower portion of the centrifugal deoiling mechanism is provided with a discharge chain plate type feeding mechanism to form underneath type workpiece discharging. The full-automatic centrifugal deoiling machine further comprises a controller connected with the weighing and metering mechanism and a hydraulic station. The full-automatic centrifugal deoiling machine can conduct full-automatic feeding, weighting and metering, oil separation and discharging, collect oil in the whole process, the weighing weight can be set, noise is ultra-low, deoiling can be centralized independently, continuous production of the previous procedures and the next procedures can be carried out, and multi-angle and multi-dimension continuous production can be carried out, so that the oil in workpieces is completely collected in the whole process, environmental pollution caused by oil is avoided, the safety in the production process is improved, cost is reduced, the deoiling rate is high, the average deoiling rate is greater than 90%, and the deoiling effect is remarkable.

Owner:湛江科田机械设备有限公司

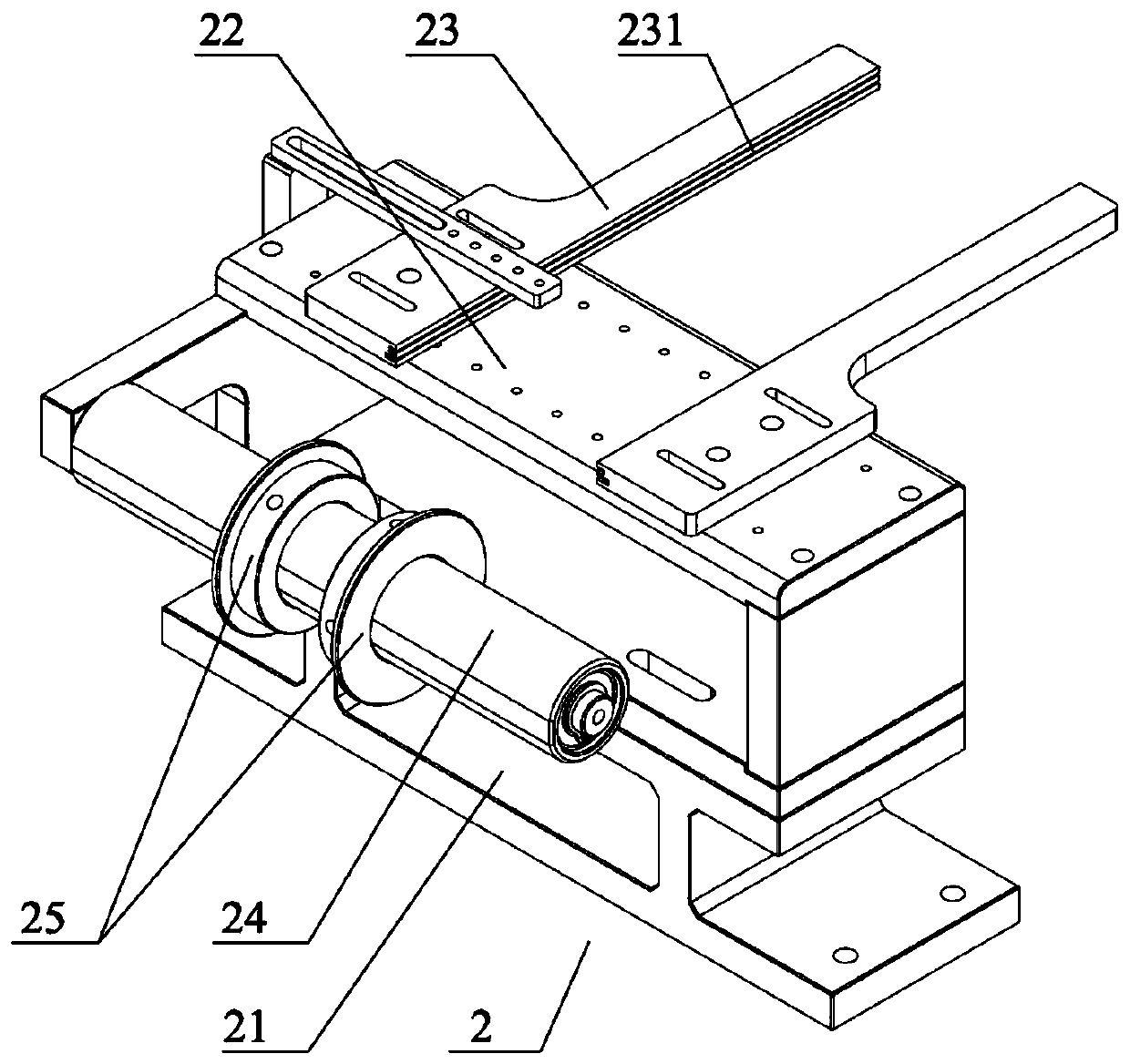

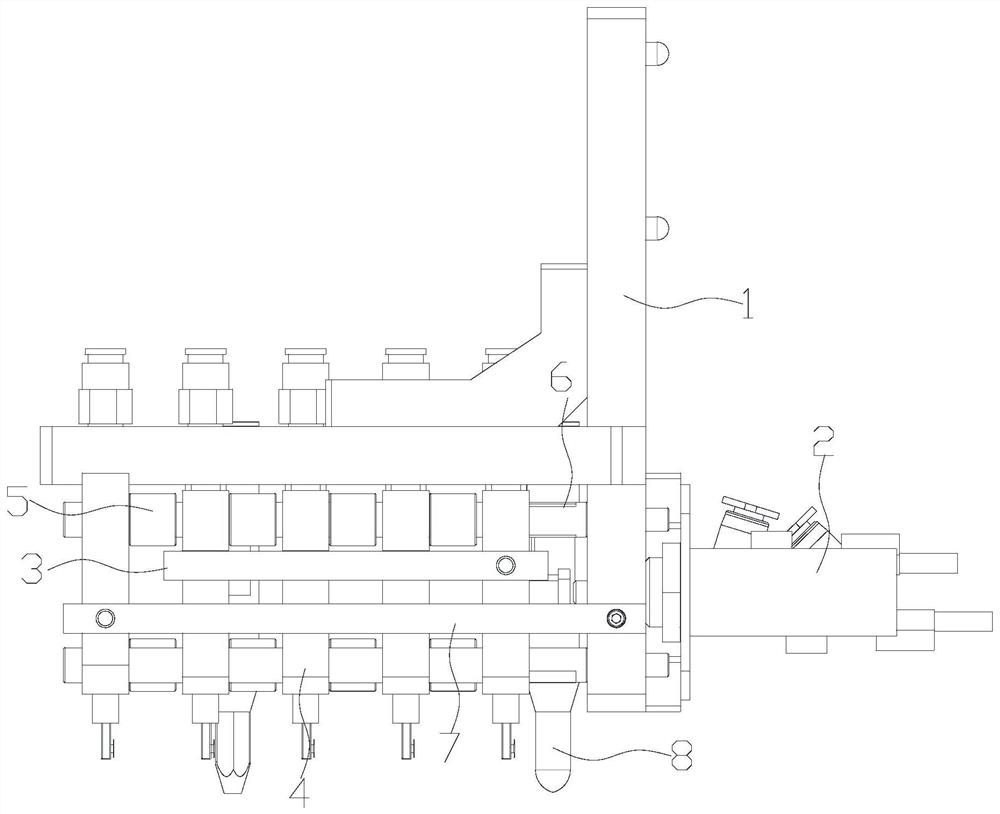

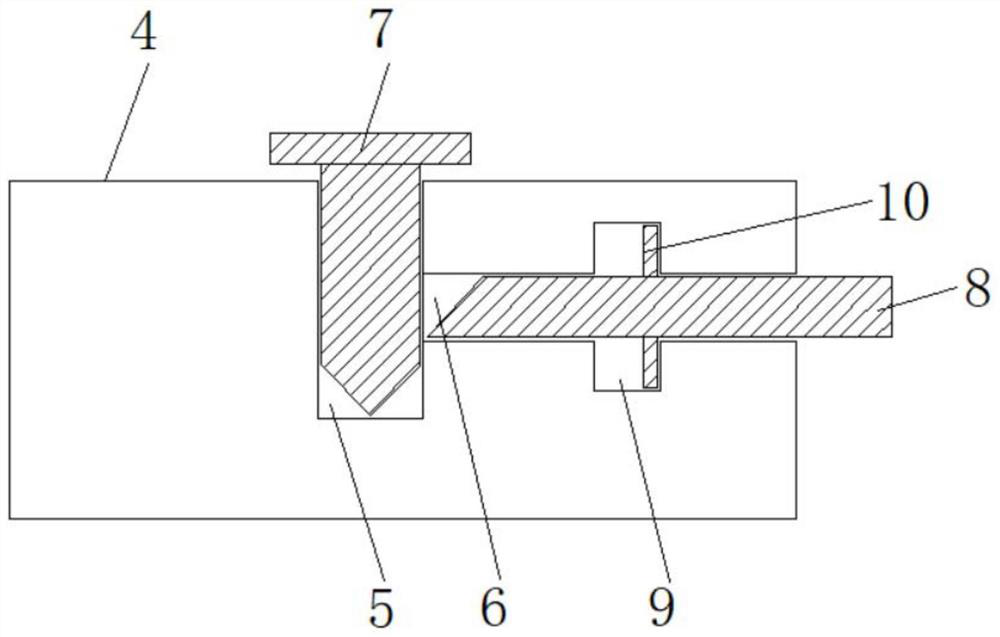

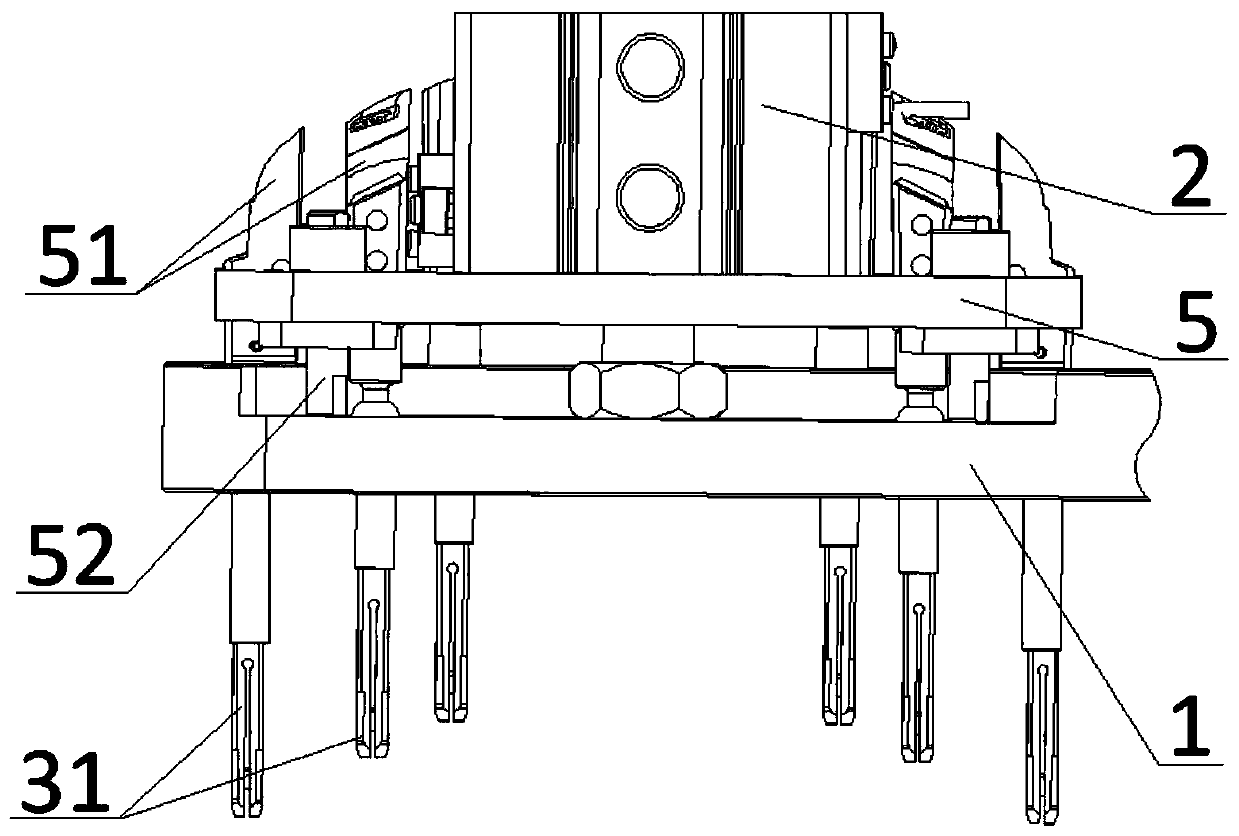

Variable-interval suction head assembly

PendingCN111017301ASimple structureInconvenient to operatePackagingControl theoryMechanical engineering

The invention provides a variable-interval suction head assembly comprising a fixing seat. The fixing seat is provided with a pushing mechanism, a push rod driven by the pushing mechanism, a fixed block and a first sliding block, wherein the fixed block and the first sliding block are sequentially arranged along the push rod, the fixed block is provided with a first through hole allowing the pushrod to penetrate, the fixed block is located between the pushing mechanism and the first sliding block, the first sliding block is fixedly connected with the push rod, the fixed block and the first sliding block are each provided with one group of suction cups, the pushing mechanism can push the first sliding block to slide through the pushing rod so as to enable the intervals between all the groups of suction cups to be changed. The variable-interval suction head assembly is simple in structure and convenient to operate; by means of interval change between all the groups of suction cups, sucked products are convenient to rapidly and accurately place, so that production efficiency and the product yield are improved; and the variable-interval suction head assembly is high in stability and reliability, wide in application range and convenient to produce and control, and lowers the production cost.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

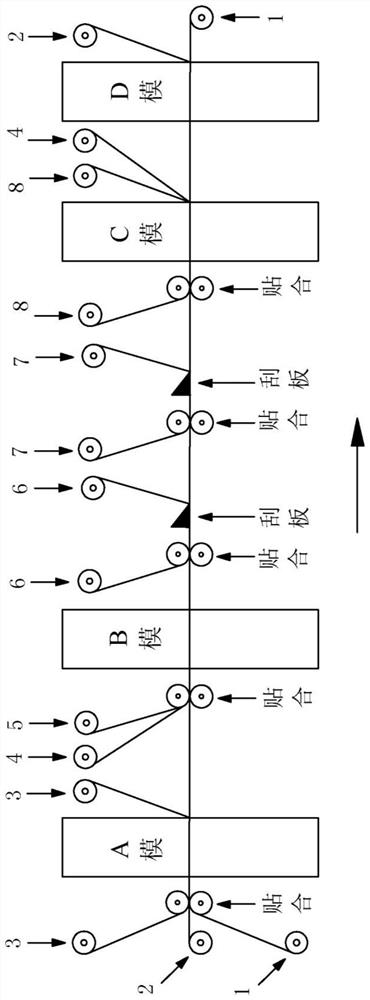

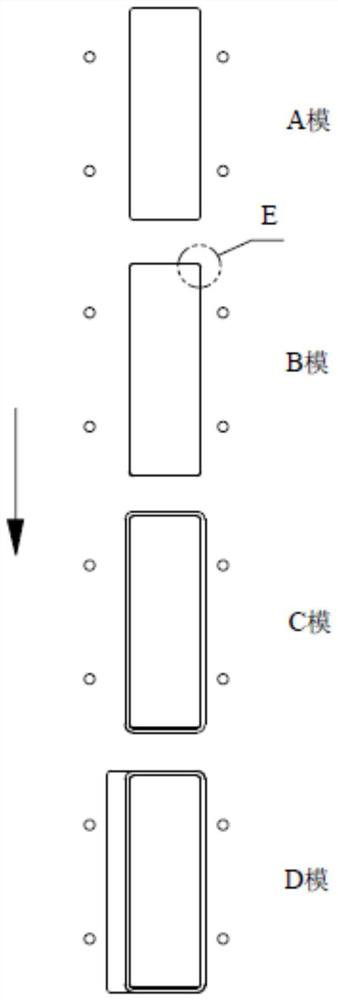

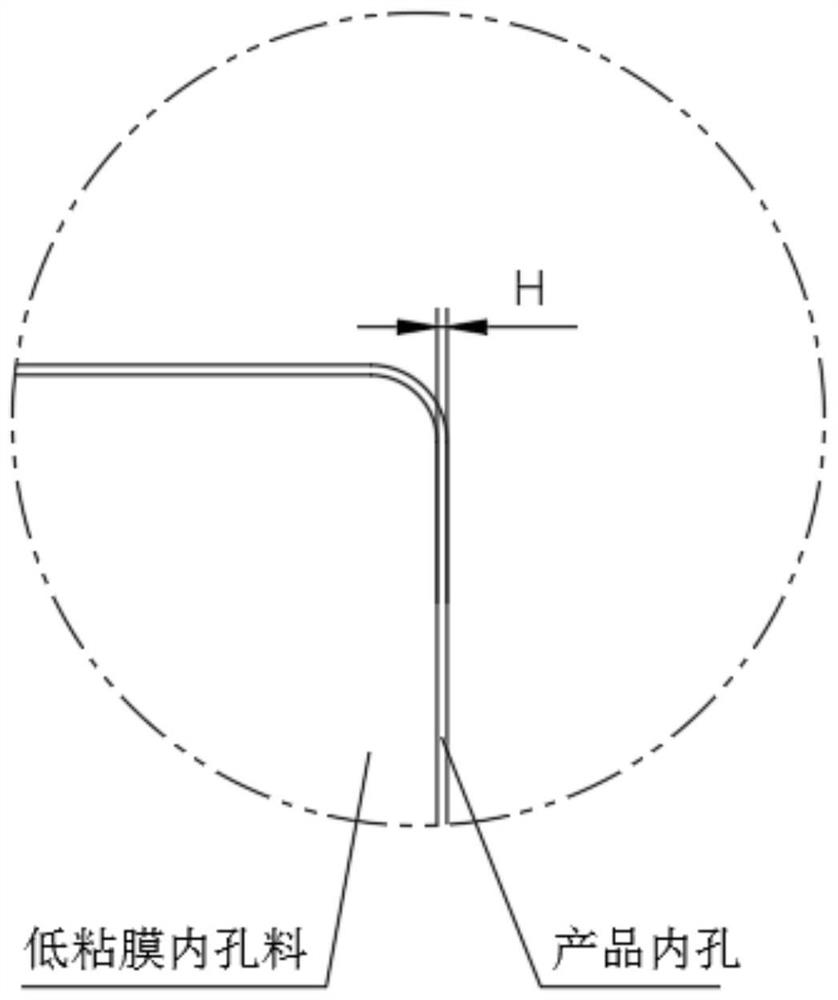

Double-sided adhesive product anti-adhesive waste discharge production process

ActiveCN111675007BPlay the role of anti-stickingEasy to operateArticle deliveryAdhesive beltPaper tape

The disclosure provides a double-sided adhesive product anti-adhesive waste discharge production process, including the following steps: Die-cut the weak mucous membrane inner hole material consistent with the inner hole shape of the product on the weak mucous membrane material belt, and then put the weak mucous membrane material belt Drain, and then attach the main material double-sided adhesive tape and the first paper material tape in sequence, and then die-cut out the inner hole waste of the first face paper, main material double-sided adhesive tape and weak mucous membrane from top to bottom, Then paste the waste tape, then discharge the waste tape, the first paper material tape and the inner hole waste, then paste the second paper material tape, die-cut out the shape of the product, and then put the second paper The material tape and the double-sided adhesive tape of the main material are discharged, and then the shape of the release film corresponding to the product is die-cut, and then the release film material tape is discharged, so that the finished product is obtained on the bottom film material tape. The weak sticky mold of the present disclosure plays the role of anti-sticking, can realize automatic production of product inner hole waste removal, improves production efficiency, product quality and yield rate, and reduces production cost.

Owner:郑州领胜科技有限公司

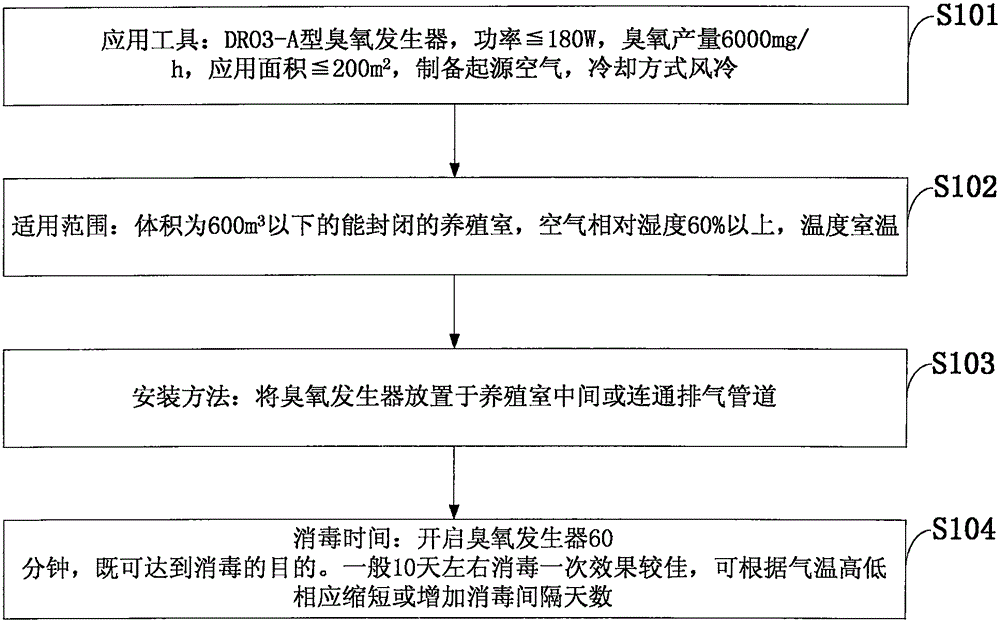

Ozone based giant salamander culture chamber air disinfection method

InactiveCN106512042AEasy to get airEasy to operateGaseous substancesChemicalsGiant salamanderLow temperature plasma

The invention discloses an ozone based giant salamander culture chamber air disinfection method which comprises the following steps: ozone is produced by using an ozone generator and is used for air and surface disinfection of an aquatic product culture chamber; and the ozone generator is placed at the middle part of the aquatic product culture chamber or communicates with an exhaust pipeline, wherein the ozone disinfection time is as follows: the ozone generator is started for 60min, and disinfection is carried out once every ten days. According to the ozone based giant salamander culture chamber air disinfection method, the operation is simple, and automatic treatment is realized; the air disinfection diffusibility is good, the concentration is uniform in distribution without a dead angle, various bacteria and pathogenic microorganisms in the culture chamber are effectively killed without secondary pollution, and thus the method is safe and economic; germs on objects such as culture facilities, relative utensils, articles and work clothes in a space are killed, so as to prevent propagation of the germs, and thus the culture risk is effectively lowered; the deodorization and purification effects are good, and the culture environment is effectively improved; and the ozone with stronger air dispersion ability is produced by adopting a low-temperature plasma technology, the disinfection time is short, the effect is strong, and the larger the humidity in the culture environment is, the better the sterilization effect is.

Owner:SHAANXI INST OF ZOOLOGY NORTHWEST INSTOF ENDANGERED ZOOLOGICAL SPECIES

Equipment for automatically perforating and cutting micro core rods

PendingCN111360896AFacilitate automated in-line productionEase of production controlDomestic articlesMetal working apparatusOpen holeEngineering

The invention provides equipment for automatically perforating and cutting micro core rods. The equipment comprises a rack and a material pushing and perforating device, a material pressing and film absorbing device, a cutting device and a material pulling device which are sequentially arranged on the rack, wherein the rack is provided with a clip feeding device matched with the material pushing and perforating device, and a material belt can be pulled by the material pulling device to sequentially pass through the material pressing and film absorbing device and the cutting device; and the clip feeding device can feed the core rods to the material pushing and perforating device one by one, the material pressing and film absorbing device can press the material belt and suck the upper end ofconductive cloth on the material belt to open hole bodies on the conductive cloth, the material pushing and perforating device can push the core rods to penetrate into the hole bodies on the conductive cloth, and the cutting device can cut the perforated product. According to the equipment, automatic perforating and cutting of the micro core rods are realized, the operation is simple and convenient, the machining precision is high, the speed is high, the manpower and time are effectively saved, the production efficiency and the quality and yield of products are improved, and the production cost is reduced.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

Method for preparing medium-high pressure corrosion foil by using corrosion process with phosphoric acid as corrosion inhibitor

PendingCN114032606AImprove bending performanceImprove product qualityCorrosion inhibitorAluminum Ion

The invention discloses a method for preparing a medium-high pressure corrosion foil by using a corrosion process with phosphoric acid as a corrosion inhibitor. The method comprises the following steps of pre-treatment, hole-forming corrosion, cleaning, reaming corrosion, post-treatment and cleaning, and drying. Specially at the reaming corrosion stage, an aluminum foil subjected to intermediate treatment is put into a solution with the bath solution comprising 5-10 Wt% of nitric acid, 0.2-0.6 Wt% of aluminum ions and 0.5-1.0 Wt% of phosphoric acid, and the phosphoric acid is used as a corrosion inhibitor, so that the content of the corrosive liquid can be accurately measured, and great convenience is brought to production control. Meanwhile, after the phosphoric acid is used as the corrosion inhibitor, the mechanical property, especially the bending property, of the produced corrosion foil after formation is greatly improved, the product quality is improved, and the corrosion foil has very high economic value.

Owner:JIANGSU LIFU ELECTRODE FOIL

Jaw loading and unloading mechanism of novel injection molding six-axle manipulator loading machine

PendingCN110774526AGuarantee personal safetyRealize in-line productionCoatingsRobot handStructural engineering

The invention discloses a jaw loading and unloading mechanism of a novel injection molding six-axle manipulator loading machine. The mechanism comprises a frame plate; cylinders are arranged at the two ends of one side of the frame plate; push rods of the cylinders are connected to the frame plate; each cylinder is connected with multiple jaws; and chucks of the jaws extend to the other side of the frame plate. The jaw loading and unloading mechanism of the novel injection molding six-axle manipulator loading machine realizes automatic loading and unloading of injection molding procedures through installation of the jaws, is more convenient to operate, saves the manpower, material resources and time, improves the production and machining efficiency, can realize online production to achievethe production management and control, and meanwhile, prevents potential safety hazards to guarantee personal safety of operators.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Wire rod girdling automation equipment

PendingCN112448333AEase of production controlSave human effortApparatus for removing/armouring cablesWire rodAutomation

The invention discloses wire rod girdling automation equipment which comprises a machine table, a girdling device, a first fixing device and a second fixing device. The girdling device, the first fixing device and the second fixing device are arranged on the machine table, and the first fixing device and the second fixing device are located at the two ends of the girdling device respectively. Theacting end of the first fixing device extends into the working end of the girdling device, and the acting ends of the girdling device, the first fixing device and the second fixing device are locatedon the same straight line. The equipment is mainly composed of a girdling device, a first fixing device and a second fixing device. In the working process of the equipment, a wire rod is inserted intothe girdling device, one end of the wire rod enters the first fixing device, the other end of the wire rod is matched with the second fixing device, and the first fixing device works and fixes one end of the wire rod; the second fixing device works to fix the other end of the wire rod, and the ring cutting device works to conduct ring cutting on the wire rod, so that the whole ring cutting treatment on the wire rod is completed.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com