Stamping part appearance detection machine

A technology for testing machines and stamping parts, which is applied in the direction of measuring devices, instruments, etc., can solve problems affecting the overall quality of products, fatigue of testing personnel, unfavorable production control, etc., so as to expand market competitiveness, facilitate production control, save manpower and The effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

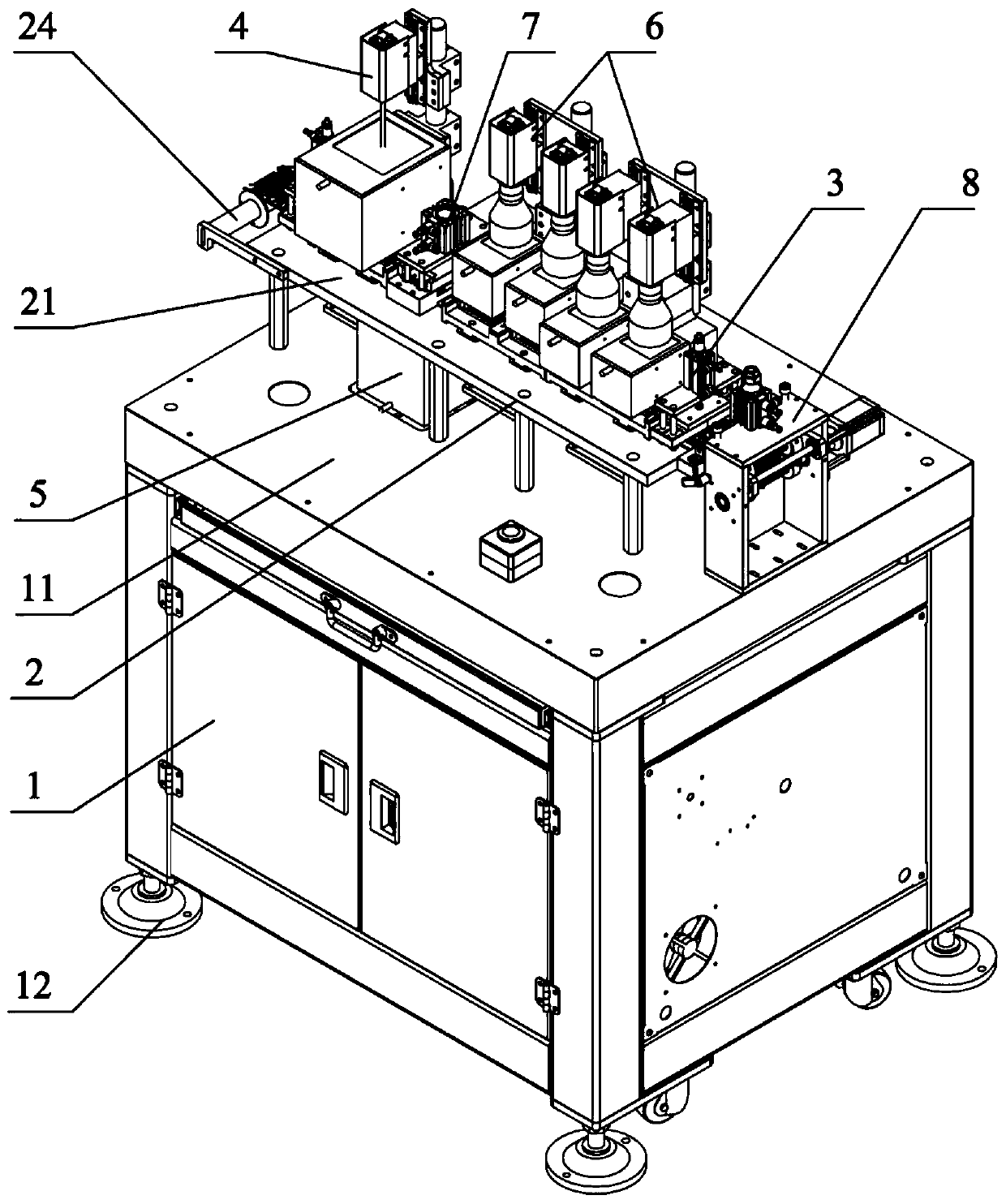

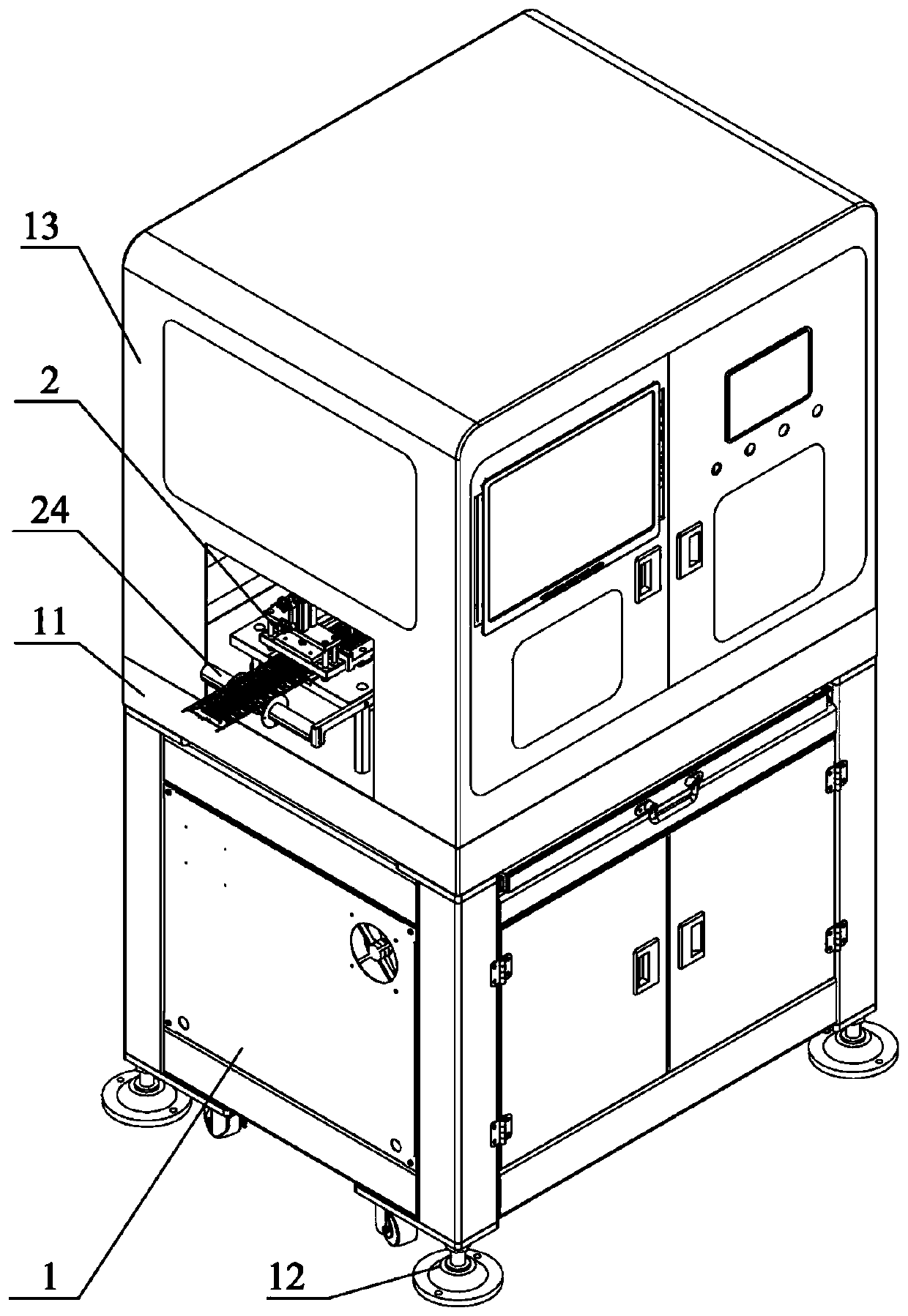

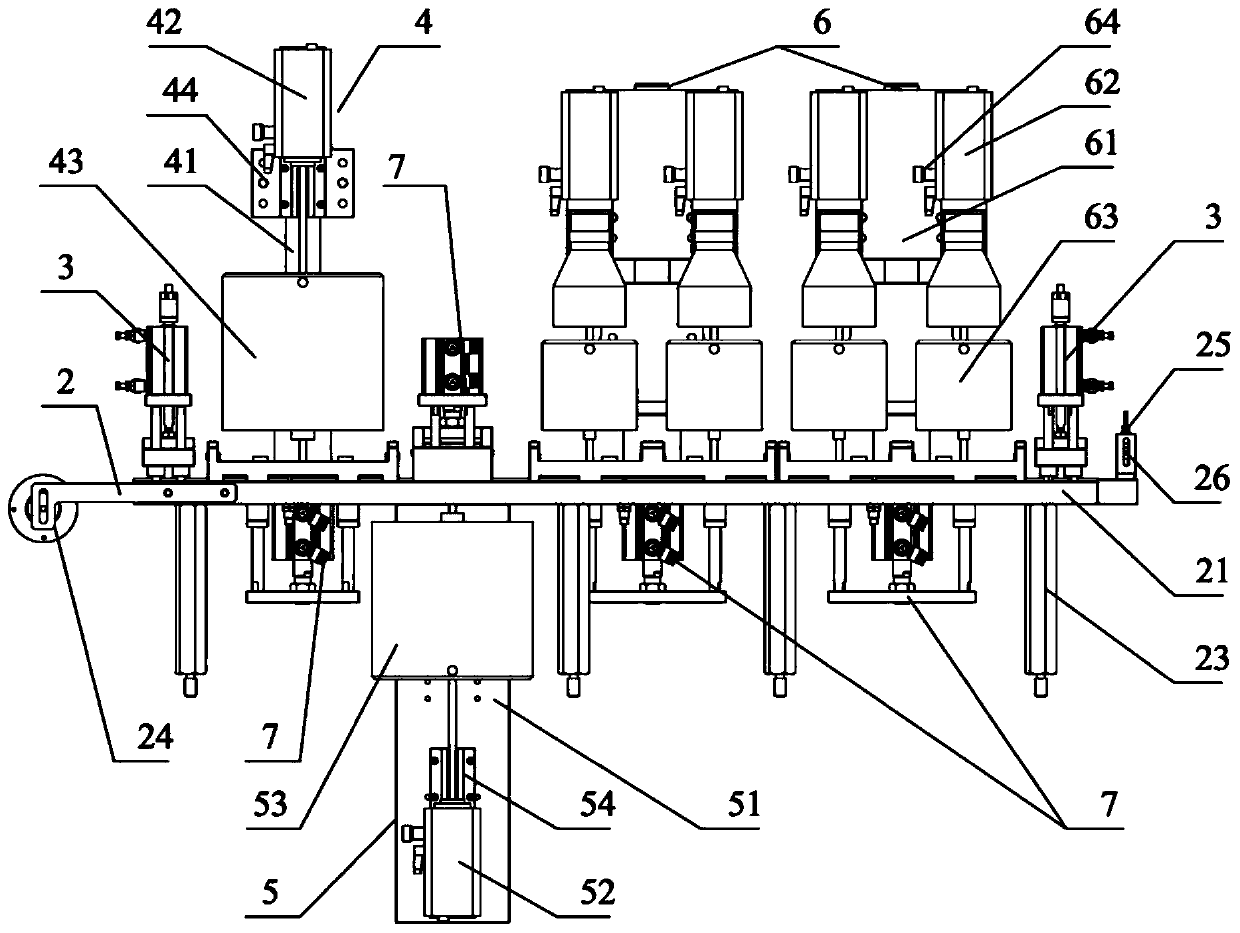

[0035] Such as Figure 1-10 As shown, a stamping part appearance inspection machine includes a frame 1, a feeding table 2 and a material pulling device 8 are arranged in sequence on the frame 1, and a first detection assembly 4 and a second detection assembly 5 are sequentially provided on the feeding table 2 And at least one third detection component 6, the quantity of the third detection component 6 is determined according to specific conditions such as the size and complexity of the product, the first detection component 4 and the third detection component 6 are located above the feeding table 2, the second detection The assembly 5 is located below the feeding table 2, and the feeding table 2 is provided with a positioning assembly 3 for positioning the material belt and a pressing assembly corresponding to the first detection assembly 4, the second detection assembly 5 and the third detection assembly 6 7. The processed products are sequentially arranged on the material b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com