blood purifier

A purifier and blood technology, applied in the field of medical devices, can solve the problems of long injection molding production cycle of blood purifier parts, increase the labor time and intensity of medical staff, and difficult production control, so as to facilitate mechanized operation and production control , the effect of simplifying the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

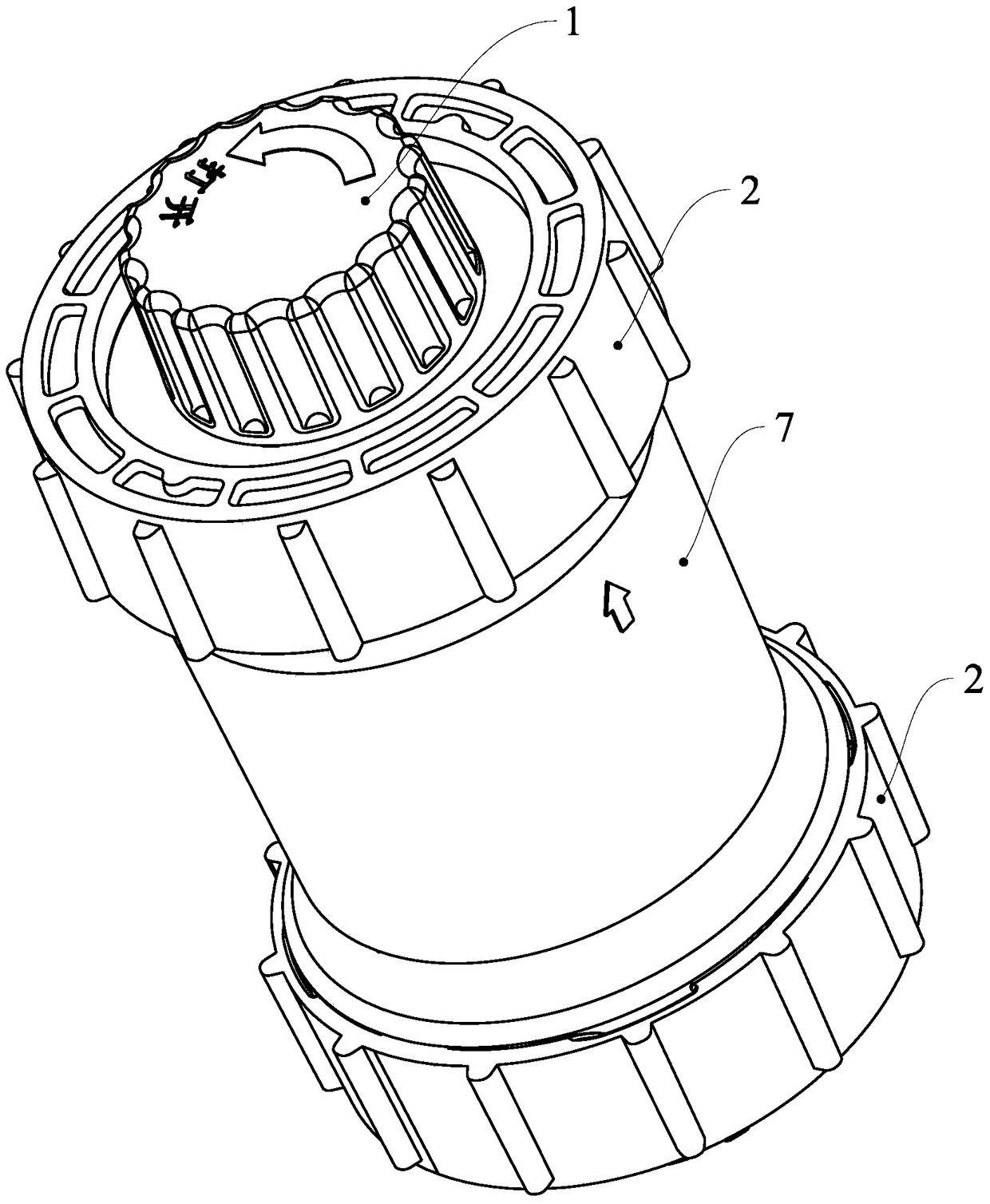

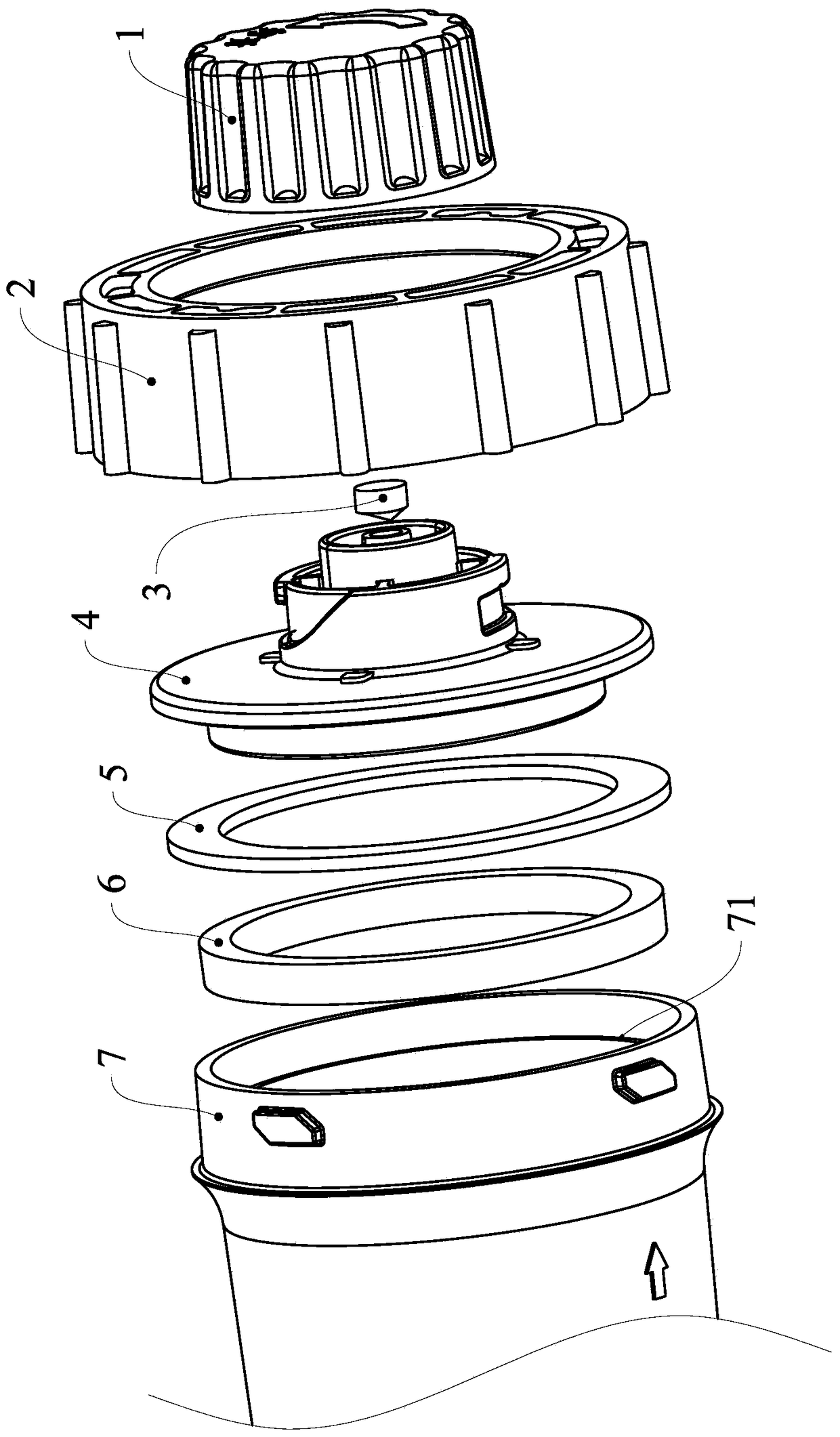

[0044] see figure 1 and figure 2 , The blood purifier consists of an adsorption column 7, an adsorbent placed in the inner cavity of the adsorption column 7, and an end-capping device installed on the end of the adsorption column 7.

[0045] The end sealing device is composed of a cap 1, a lock nut 2, a tapered sealing plug 3, an end cap 4, a flat sealing gasket 5 and a filter screen 6. The end cover 4 and the locking nut 2 constitute the end-blocking part of this embodiment.

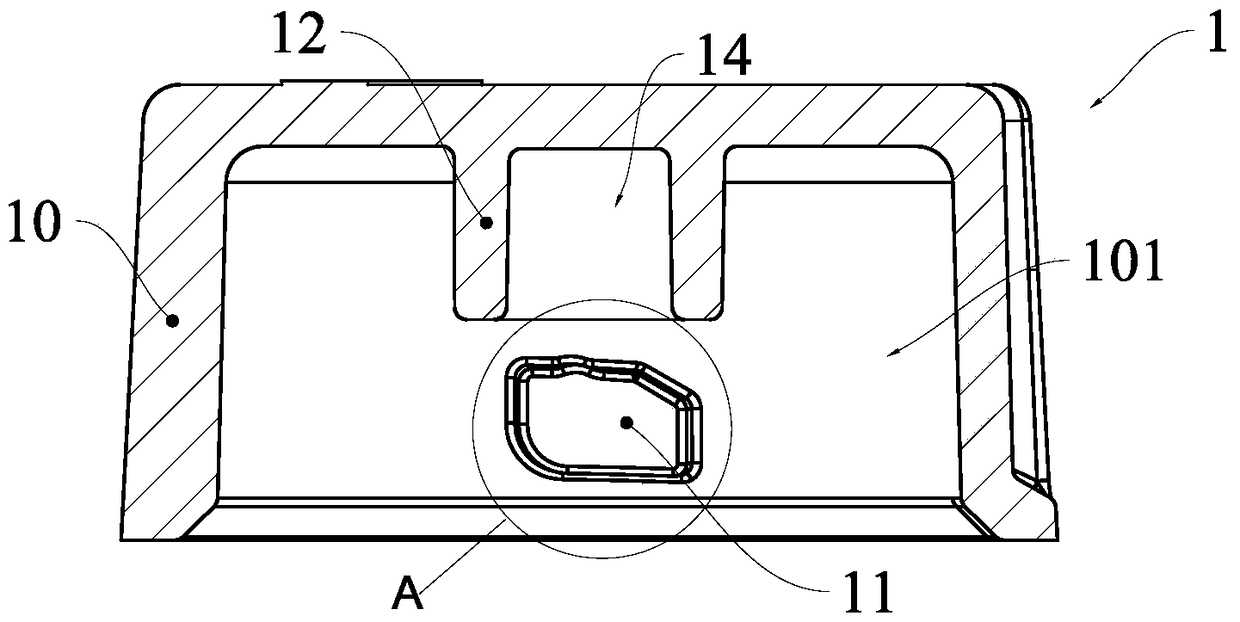

[0046] see Figure 3 to Figure 6 The cap 1 has a cap body 10 with a cylindrical structure. The cap body 10 is formed with an accommodating cavity 101 open at one axial end thereof. The inner surface of the cap body 10 protrudes to form two buckles 11. The buckle 11 is A polygonal structure, two buckles 11 are evenly arranged around the central axis of the cylindrical structure, that is, the line connecting the centers of the two passes through the central axis of the cylindrical structure.

[0047]...

no. 2 example

[0083] As an explanation of the second embodiment of the present invention, only the differences from the first embodiment will be described below.

[0084] The inner surface of the cap is indented to form a locking groove, which is the locking groove formed on the locking nut in the above-mentioned first embodiment.

[0085] The outer surface of the first annular coupling wall of the end cap protrudes outward to form a buckle, which is the buckle formed on the end of the adsorption column in the first embodiment above.

[0086] The outer surface of the end of the adsorption column is indented to form a locking groove, which is the locking groove formed on the outer surface of the first annular coupling wall of the end cap in the first embodiment above.

[0087] The inner surface of the locking nut protrudes to form a buckle, which is the buckle formed on the inner surface of the cap in the above-mentioned first embodiment.

no. 3 example

[0089] As an explanation of the third embodiment of the present invention, only the differences from the first embodiment will be described below.

[0090] see Figure 21 , using a wave-shaped coupled surface to replace the first supported surface, the convex coupling surface and the second supported surface formed on the buckle in the first embodiment above.

[0091] The first supporting surface, the concave coupling surface and the second supporting surface formed on the card slot in the above first embodiment are replaced by a wave-shaped coupling surface matched with the above-mentioned corrugated coupled surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com