Lead-free and silicon-free brass alloy and manufacturing method thereof

A brass alloy and silicon brass technology, applied in the alloy field, can solve the problems of untested silicon brass polishing performance, unsatisfactory polishing performance, and reduced brass processing performance, achieve excellent polishing performance, and facilitate production control , good effect of anti-dezincification corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Preparation and composition analysis of the alloy of the invention and the comparative alloy

[0041] A. Preparation and composition analysis of alloys 1-9 of the present invention

[0042] The alloys 1-9 of the present invention are prepared according to the following method: Weigh Cu, Si, Zn, Al, Sn, Ni, Pb and copper-iron, copper-boron intermediate alloys according to the mass percentage of the environmentally friendly silicon-brass alloy components, in which copper-iron, copper The content of Cu in the boron master alloy is 95wt.%; Si and Ni are placed on the bottom of the power frequency induction furnace, the raw materials of Cu and Zn are placed on top of Si and Ni, and a refining agent is added, and the temperature is raised to 1050~1100℃ until All materials are melted and the surface scum is filtered out;

[0043] Add Al, Sn, and Pb to the obtained material in sequence, stir thoroughly to ensure uniform composition; add copper-iron intermediate alloy to th...

Embodiment 2

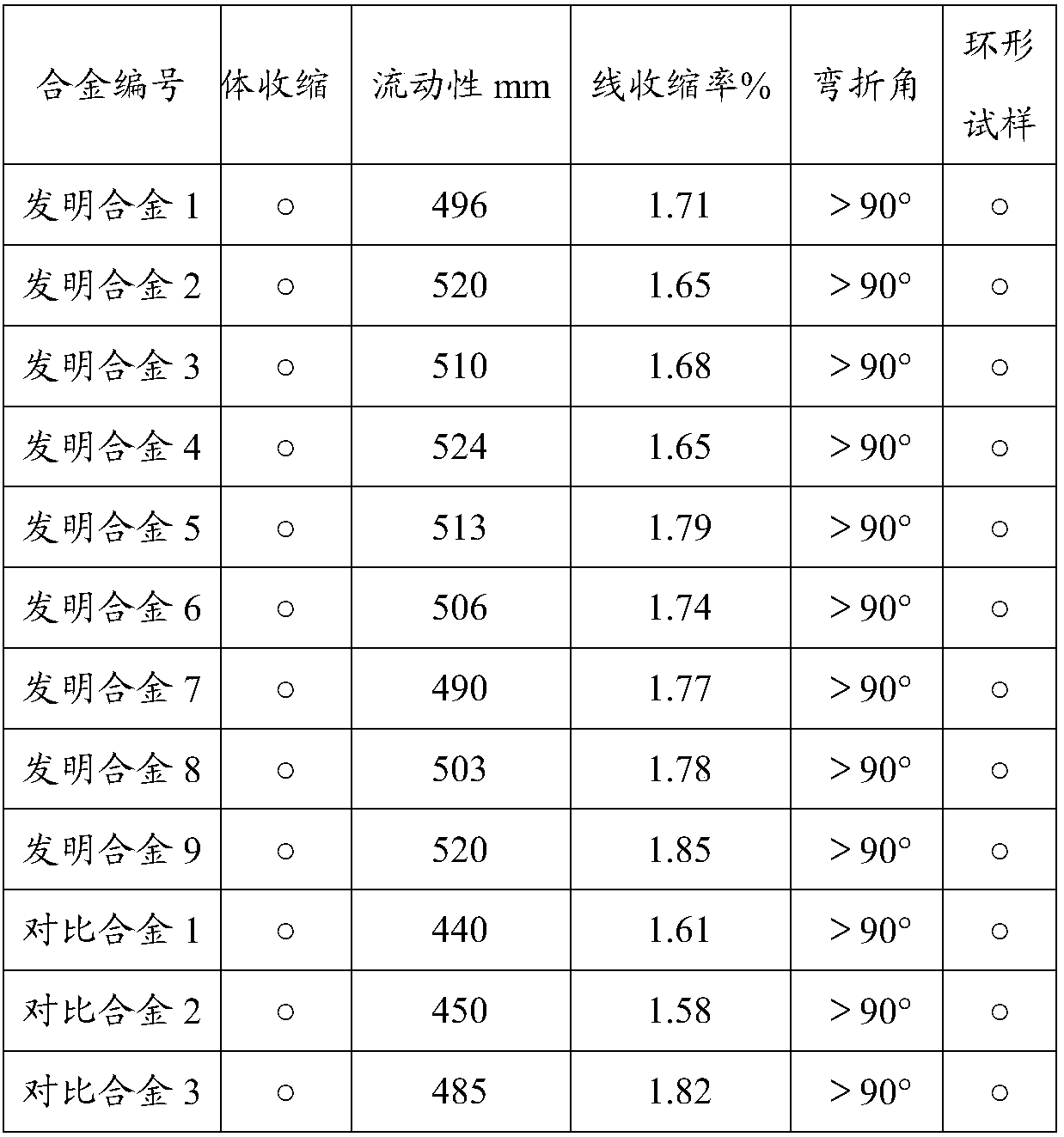

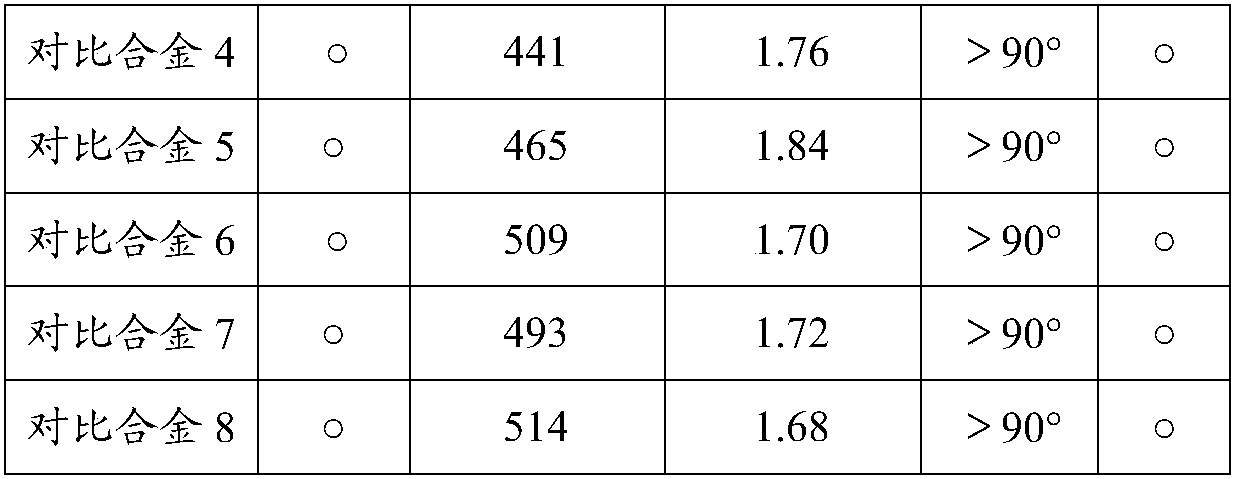

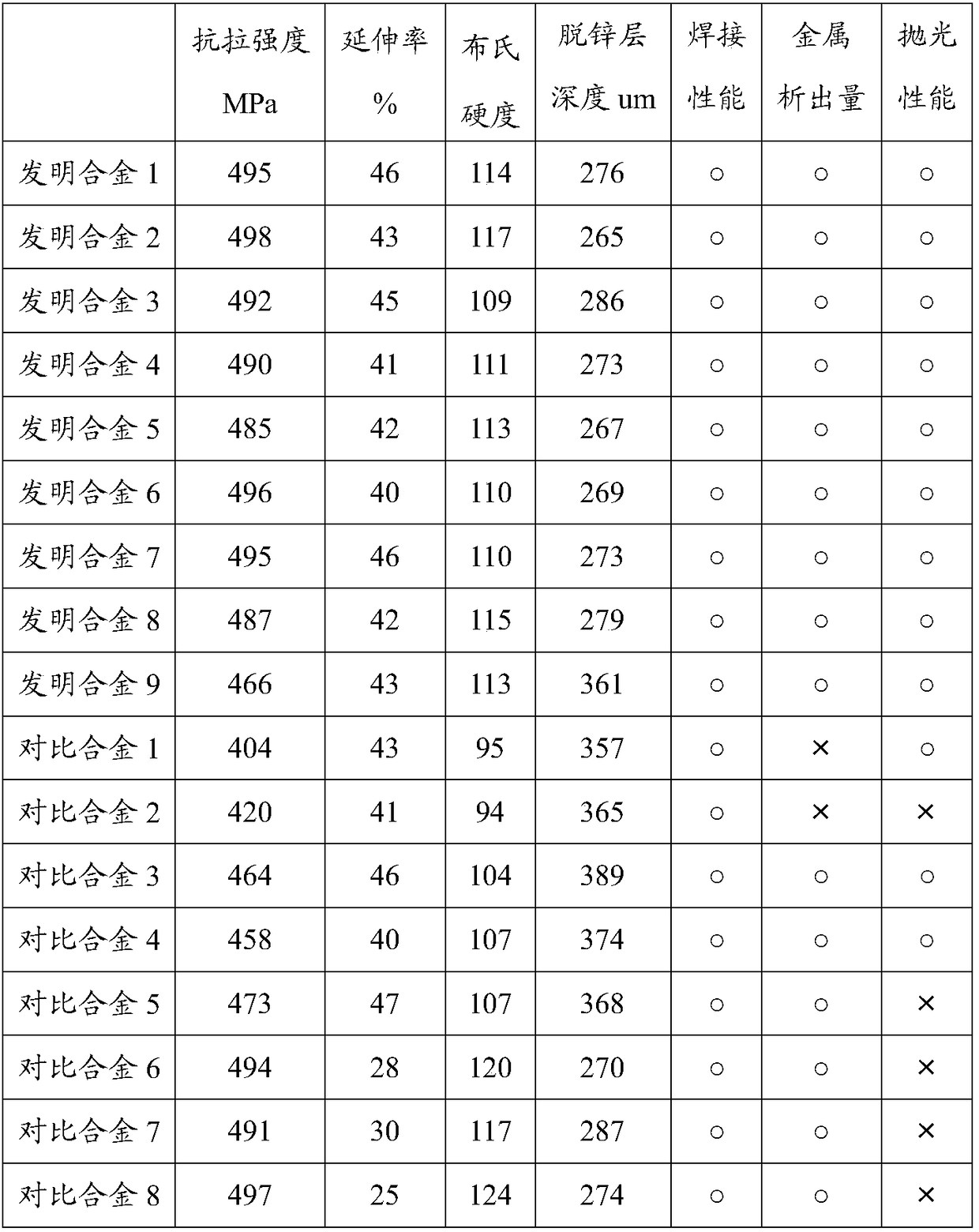

[0051] Example 2 Performance detection of the alloy of the invention and the comparative alloy

[0052] Hereinafter, the various properties of the alloy of the present invention and the comparative alloy obtained from the above preparation examples will be tested. The specific performance test items and methods are as follows, and the test results are shown in Table 2 and Table 3.

[0053] 1. Casting performance

[0054] Volume shrinkage sample: used to evaluate the concentrated shrinkage, dispersed shrinkage and porosity of the alloy. The concentrated shrinkage cavity surface of the volume shrinkage sample is smooth without visible porosity, and the sample section has no visible scattered shrinkage cavities. It is indicated by "○"; the surface of several shrinkage cavities is relatively smooth, and the depth of the bottom visible porosity is less than 5mm. If there is no visible scattered shrinkage cavities in the section of the sample, it is good, which is indicated by "△"; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com