Flexible feeding carrier tape packaging machine

A packaging machine and carrier tape technology, used in packaging, packaging protection, transportation and packaging, etc., can solve problems such as equipment vibration, unfavorable production control, and reduce product production efficiency and quality, so as to improve production efficiency and facilitate production management and control. , to achieve the effect of sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

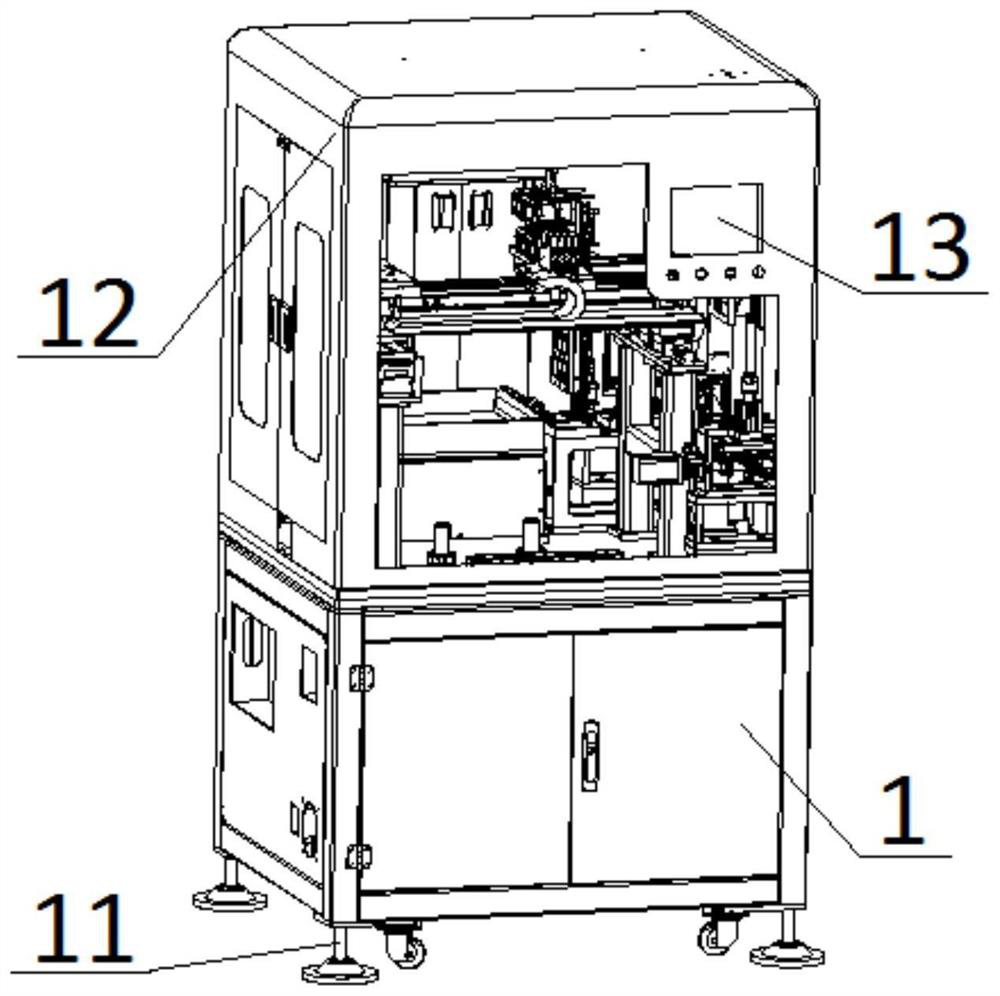

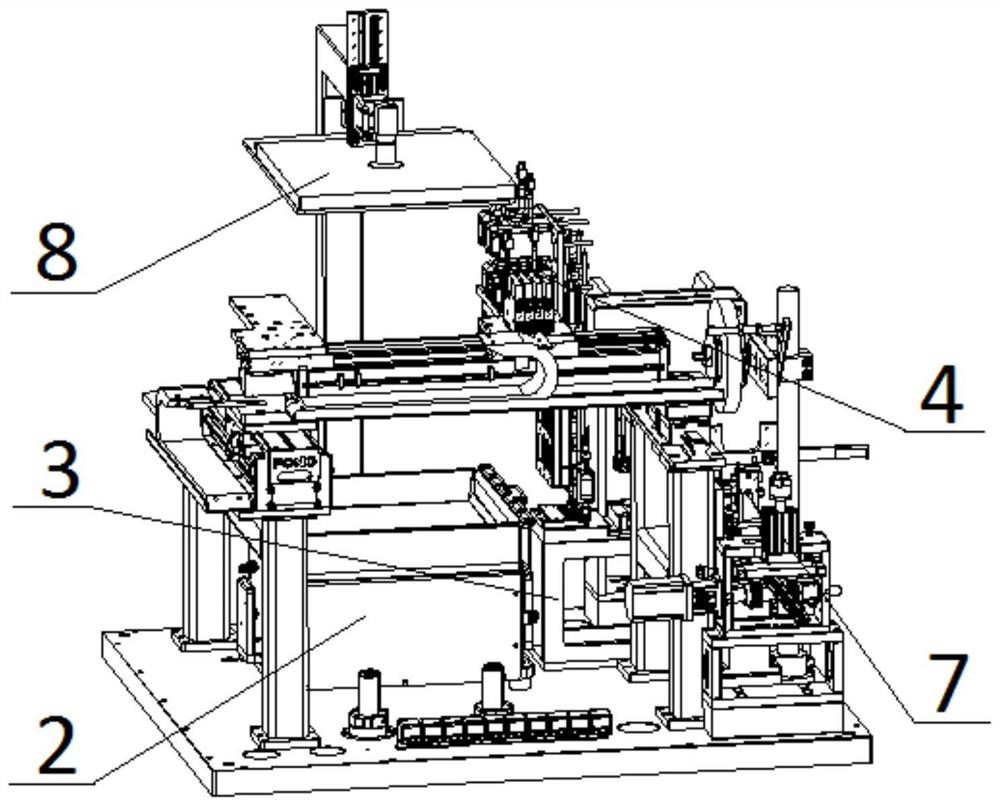

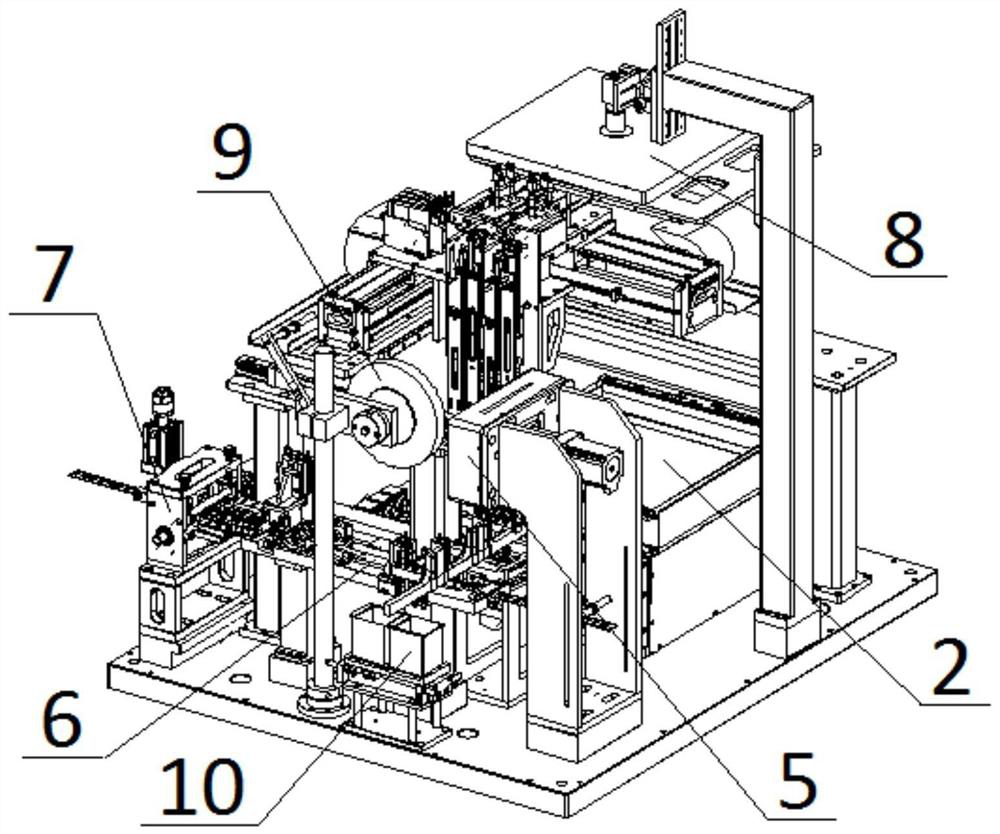

[0023] figure 1 Schematically shows the structure of a flexible feeding carrier tape packaging machine according to an embodiment of the present invention, figure 2 shown figure 1 The inner structure of one of the angles of the flexible feed carrier tape packaging machine after removing the outer cover, image 3 shown figure 2 Another angle structure of the flexible feeding carrier tape packaging machine, Figure 4 shown Figure 5 The structure of the optical detection mechanism in Figure 5 shown image 3 The structure of the reclaiming mechanism in Image 6 shown image 3 The structure of the unwinding mechanism in . like Figure 1-6 As shown, the packaging machine includes a generally square frame 1 on which the main mechanisms are mounted. A support portion 11 is installed at each corner of the bottom of the rack 1, wherein the support portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com