A kind of automatic visual inspection equipment and inspection method for precision electronic stamping parts

A visual inspection, precision electronic technology, applied in measuring devices, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of missed detection, misjudgment, poor detection accuracy, unfavorable production control, etc., to achieve stability and reliability. High performance, reduce production costs, and facilitate production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

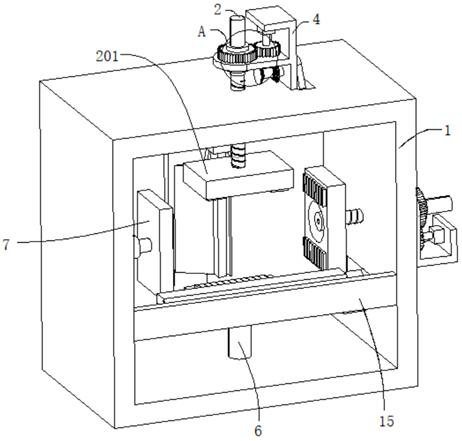

Embodiment 1

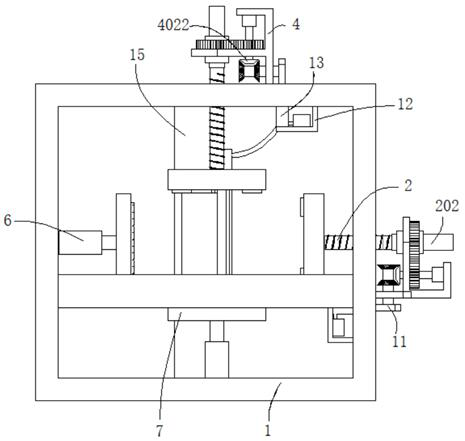

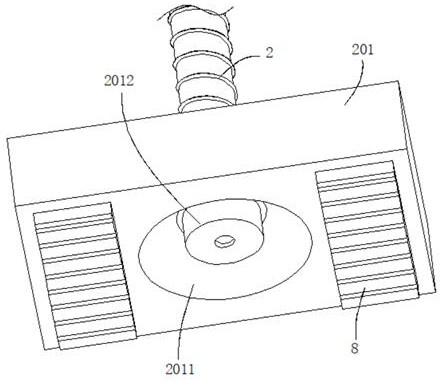

[0038] refer to Figure 1-5 , an automatic visual inspection equipment for precision electronic stamping parts, including a fixing frame 1, the outer wall of the fixing frame 1 is connected with two sets of positioning mechanisms, the positioning mechanism includes a threaded rod 2, the threaded rod 2 is threadedly connected in the fixing frame 1, and the threaded rod 2 A first clamping plate 201 is connected to the outer wall, a groove 2011 is drilled on the outer wall of the first clamping plate 201, a camera 2012 is connected to the inner wall of the groove 2011, and a moving rod 202 is connected to the end of the threaded rod 2 away from the first clamping plate 201, The outer wall of the moving rod 202 is sleeved with a sleeve 3, the moving rod 202 is slidably connected in the sleeve 3, the outer wall of the fixed frame 1 is connected with a support seat 4, the sleeve 3 is rotatably connected in the support seat 4, and the outer wall of the support seat 4 is connected with...

Embodiment 2

[0041] refer to figure 1 , figure 2 , Image 6 , Figure 7 and Figure 8 , an automatic visual inspection equipment for precision electronic stamping parts, which is basically the same as Embodiment 1. Further, the end of the rotating shaft 402 away from the motor 401 passes through the support base 4 and is connected with a first bevel gear 4022. The outer walls on both sides of the gear 4022 are meshed with a second bevel gear 9, the outer walls of the two second bevel gears 9 are connected with a rotating rod 10, the rotating rod 10 is rotatably connected in the support seat 4, and the outer wall of the rotating rod 10 is connected with a cam 11, fixed The inner wall of the frame 1 is connected with a support plate 12, the outer wall of the support plate 12 is connected with a working pipe 13 and a water tank 14, a water inlet pipe 141 is connected between the working pipe 13 and the water tank 14, a piston 131 is slidably connected to the inner wall of the working pipe...

Embodiment 3

[0044] refer to Figure 1-8 , an automatic visual inspection equipment for precision electronic stamping parts, which is basically the same as Embodiment 1. Further, the outer wall of the sleeve 3 is connected with a guide strip 301, and the outer wall of the moving rod 202 is drilled with a guide groove that matches the guide strip 301. 2021; improve the stability of the movement of the moving rod 202 in the casing 3.

[0045] The invention also discloses a detection method of automatic visual detection equipment for precision electronic stamping parts, comprising the following steps:

[0046] S1: Place the stamping part on the second clamping plate 7 of the first group of positioning mechanisms, control the first group of positioning mechanisms to work, make the motor 401 run, the motor 401 drives the first gear 4021 to rotate through the rotating shaft 402, the first gear 4021 meshes with the second gear 5, so that the second gear 5 drives the casing 3 to rotate, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com