Double-sided adhesive product anti-adhesive waste discharge production process

A production process, double-sided adhesive technology, applied in the direction of thin material processing, sending objects, transportation and packaging, etc., can solve the problems of high labor intensity, high production cost, many manpower, etc., to achieve high safety and reliability, save Time and manpower, the effect of expanding application and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

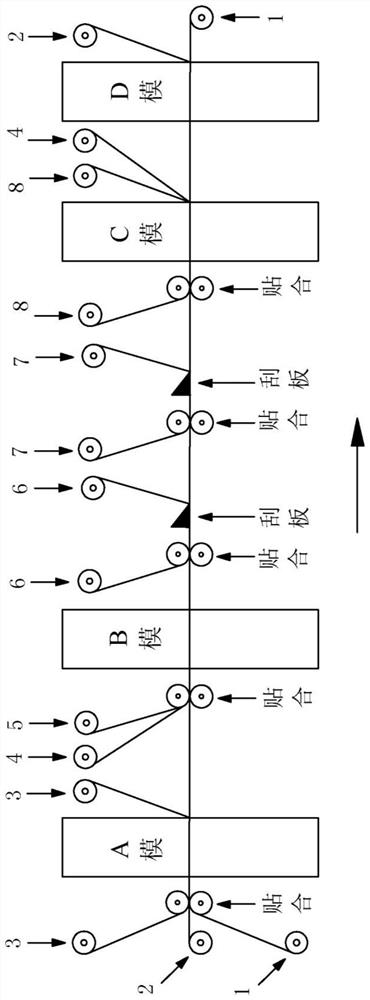

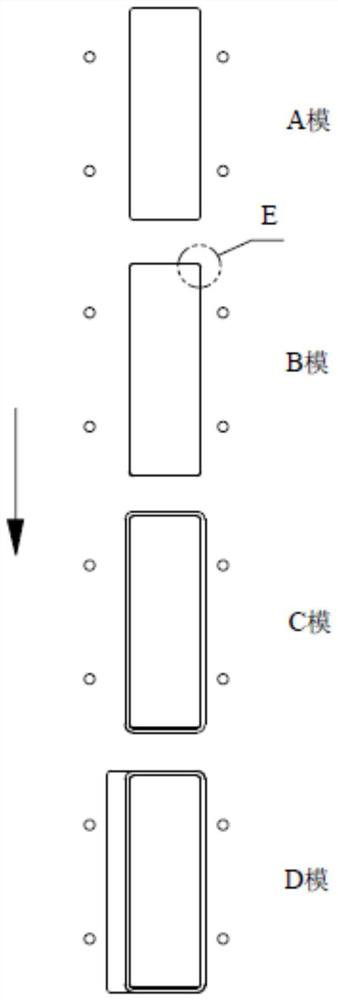

Method used

Image

Examples

Embodiment

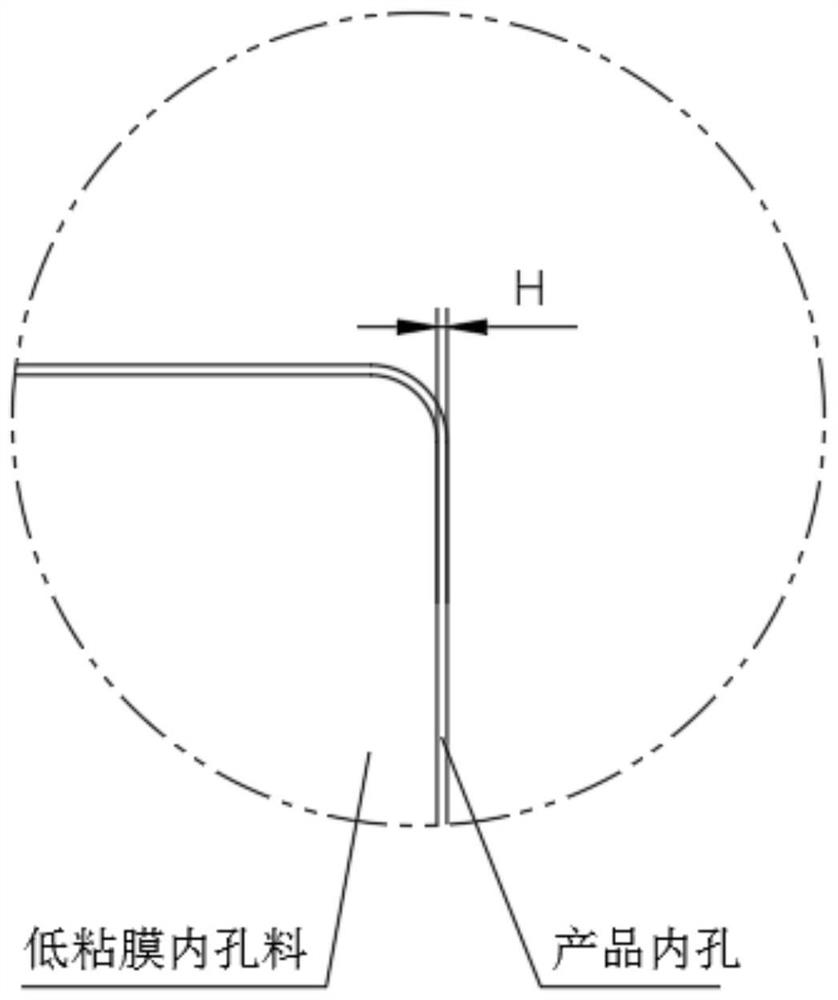

[0032] Such as Figure 5 As shown, the finished product of a double-sided tape product includes face paper, main material double-sided tape and release film that are laminated sequentially from top to bottom. The viscosity is very low. In order to ensure the stability of the finished product and facilitate storage and transportation, the release film usually needs a certain thickness and its viscosity with the double-sided adhesive of the main material is relatively high. The double-sided adhesive of the main material has an inner hole. The shape of the hole depends on the specific situation. The inner hole can be a round hole, an oval hole, a rectangular hole, a polygonal hole or other suitable shapes. The size of the double-sided adhesive of the material, the inner hole of the product in the article refers to the inner hole on the double-sided adhesive part of the main material, and the shape of the product refers to the shape of the double-sided adhesive part of the main ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com