Aluminum and aluminum alloy anode oxidation film high alkali resistant sealant and sealing method

An anodic oxidation film and anodic oxidation technology, applied in the field of chemical technology, can solve the problems of inconvenient production control, cumbersome steps, high cost, etc., and achieve the effect of easy production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An embodiment of the present invention provides a highly alkali-resistant sealing agent for anodic oxidation films of aluminum and aluminum alloys. The sealing agent includes: nickel acetate, dispersant, surfactant, fluoride, and deionized water as the balance.

[0036] Preferably, the mass fraction of the nickel acetate is 7%-10%, the mass fraction of the dispersant is 0.2%-0.5%, the mass fraction of the surfactant is 0.2%-0.5%, and the fluoride The mass fraction is 1%-3%.

[0037] In the embodiment of the present invention, the content of each component is represented by mass fraction, and the content of each component only needs to be within the above range, for example, 7%, 8%, 9%, 10% or 7%- 0.2%, 0.3%, 0.4%, 0.5% or dispersant of any value within the range of 0.2%-0.5% can be added to nickel acetate with a mass fraction of any value within the range of 10%, and 0.2% can be added %, 0.3%, 0.4%, 0.5% or any mass fraction of surfactant within the range of 0.2%-0.5%,...

Embodiment 2

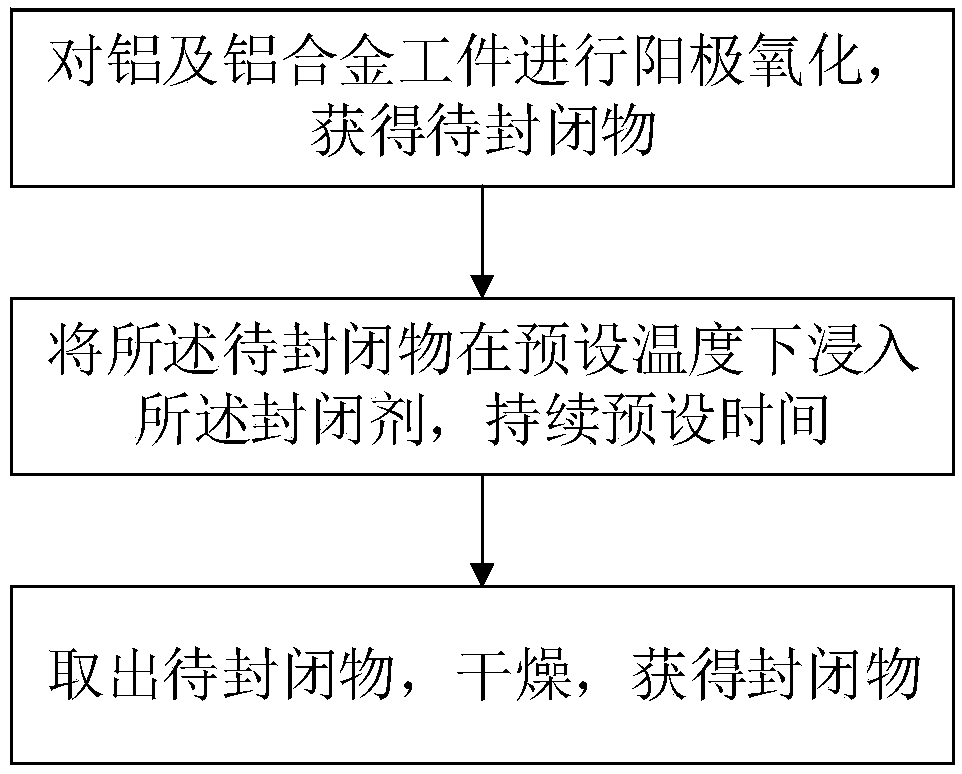

[0047] The embodiment of the present invention proposes a method for sealing aluminum and aluminum alloy anodized films with high alkali resistance,

[0048] Refer to attached figure 1 , the specific steps of the method include:

[0049] Step 1: Carry out anodic oxidation on aluminum and aluminum alloy workpieces to obtain objects to be sealed.

[0050] The anodic oxidation is a conventional oxidation operation of related processes in this field, and technicians can select and adjust the anodic oxidation process according to the actual situation to obtain the best oxidation effect.

[0051] The anodizing protocol used in this protocol is listed below.

[0052] Further, the step of anodizing the aluminum and aluminum alloy to obtain the object to be sealed includes:

[0053] Degreasing: put the aluminum and aluminum alloy workpieces into 30g / L alkaline degreasing agent, and treat them at 50°C for 5-10 minutes;

[0054] Electropolishing: immerse the degreased aluminum and al...

Embodiment 3

[0068] A kind of high alkali-resistant sealing agent, by weight 1kg, take the following raw materials by the following weight: nickel acetate 90g, sodium lauryl sulfate 2g, sodium methylene bis-naphthalene sulfonate 3g, ammonium bifluoride 20g, the above-mentioned The raw materials were added to an appropriate amount of deionized water, fully stirred and dissolved, and configured into a 1kg sealing agent.

[0069] The process is as follows:

[0070] The workpiece material is 6063 aluminum alloy.

[0071] Degreasing: the workpiece is treated with 30g / L alkaline degreasing agent at 50°C for 10 minutes;

[0072] Electropolishing: immerse the degreased workpiece in a mixture of phosphoric acid 800g / L and sulfuric acid 350g / L for electropolishing for 15 minutes;

[0073] Alkali cleaning: immerse the electropolished workpiece in 30g / L sodium hydroxide solution for 1min;

[0074] Illumination: immerse the workpiece after alkali washing in 170g / L sulfuric acid solution for 1min;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com