800 MPa-grade low-cost tempered dual-phase steel and preparation method thereof

A low-cost, dual-phase steel technology, applied in the field of dual-phase steel for automobile manufacturing and its preparation, can solve the problems of high production cost of 800MPa-grade dual-phase steel, and achieve easy realization of process parameters, simple production control, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

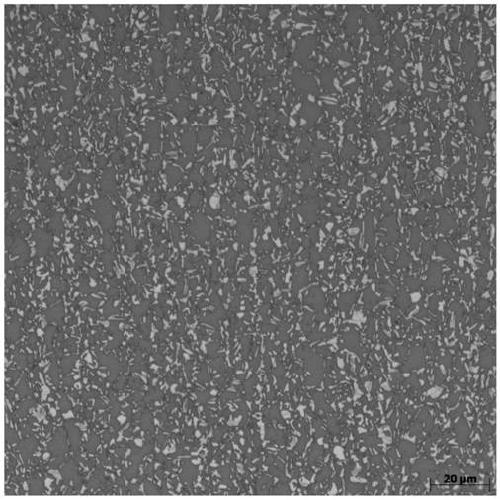

Image

Examples

Embodiment 1

[0017] An 800MPa low-cost tempered dual-phase steel, by weight percentage, its chemical composition is, C: 0.15%; Si: 0.29%; Mn: 1.89%; Cr: 0.25%; Ti: 0.019%; P: 0.032 %; S: 0.008%; Al: 0.065%; the balance is Fe and unavoidable inclusions.

[0018] To prepare the above-mentioned 800MPa low-cost tempered dual-phase steel, the following process flow is adopted: molten iron pretreatment → converter smelting → external refining → continuous casting → heating → controlled rolling and controlled cooling → coiling → pickling → cold rolling → continuous annealing →Smoothness→Functional inspection→Packing and leaving the factory; including the following steps:

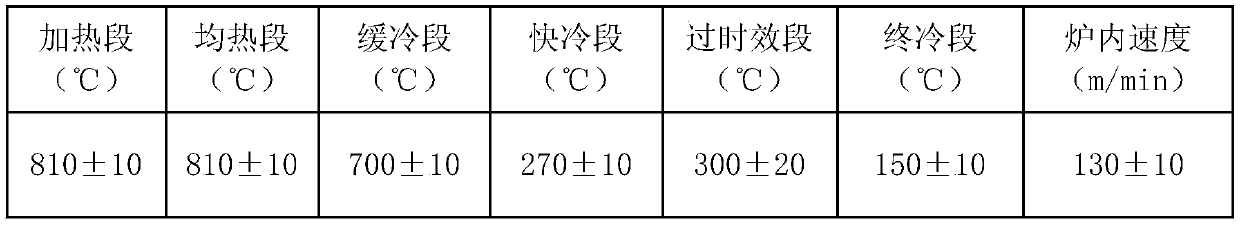

[0019] The heating temperature of the hot-rolled slab is 1230°C, the starting rolling temperature is 1080°C, and the finishing rolling temperature is 860°C; laminar flow cooling is adopted after rolling, the cooling rate is 30°C / s, and the coiling temperature is 550°C; the cold rolling adopts 56 % reduction ratio, continuous a...

Embodiment 2

[0024] A low-cost tempered dual-phase steel of 800MPa grade, by weight percentage, its chemical composition is, C: 0.15%; Si: 0.26%; Mn: 1.92%; Cr: 0.26%; Ti: 0.024%; P: 0.026 %; S: 0.006%; Al: 0.070%; the balance is Fe and unavoidable inclusions.

[0025] To prepare the above-mentioned 800MPa low-cost tempered dual-phase steel, the following process flow is adopted: molten iron pretreatment → converter smelting → external refining → continuous casting → heating → controlled rolling and controlled cooling → coiling → pickling → cold rolling → continuous annealing →Smoothness→Functional inspection→Packing and leaving the factory; including the following steps:

[0026] The heating temperature of the hot-rolled slab is 1210°C, the starting rolling temperature is 1060°C, and the finishing rolling temperature is 850°C; laminar flow cooling is adopted after rolling, the cooling rate is 25°C / s, and the coiling temperature is 530°C; the cold rolling adopts 55°C % reduction ratio, co...

Embodiment 3

[0032] An 800MPa low-cost tempered dual-phase steel, the chemical composition of which is, by weight percentage, C: 0.16%; Si: 0.29%; Mn: 1.84%; Cr: 0.26%; Ti: 0.022%; P: 0.038 %; S: 0.007%; Al: 0.056%; the balance is Fe and unavoidable inclusions.

[0033] To prepare the above-mentioned 800MPa low-cost tempered dual-phase steel, the following process flow is adopted: molten iron pretreatment → converter smelting → external refining → continuous casting → heating → controlled rolling and controlled cooling → coiling → pickling → cold rolling → continuous annealing →Smoothness→Functional inspection→Packing and leaving the factory; including the following steps:

[0034] The heating temperature of the hot-rolled slab is 1260°C, the rolling start temperature is 1100°C, and the final rolling temperature is 890°C; laminar flow cooling is adopted after rolling, the cooling rate is 35°C / s, and the coiling temperature is 580°C; the cold rolling adopts 56 % reduction ratio, continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com