Wire rod girdling automation equipment

A technology for automation equipment and wire loops, which is applied to equipment for dismantling/armoring cables, cable installation devices, electrical components, etc., which can solve the problems that the surface of the wire cannot be re-injected, and the injection layer falls off, so as to facilitate production control, Improve efficiency and yield and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

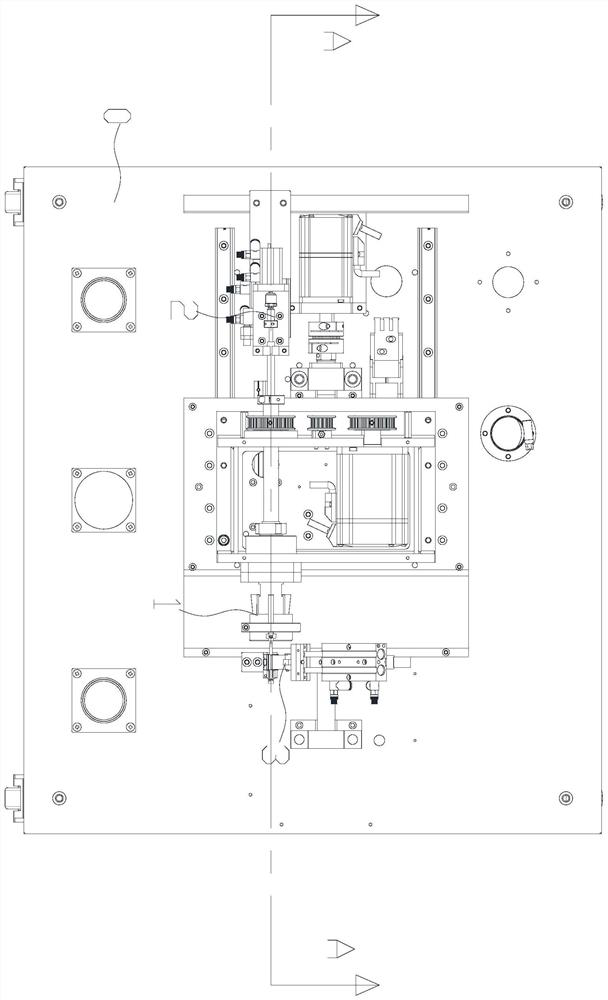

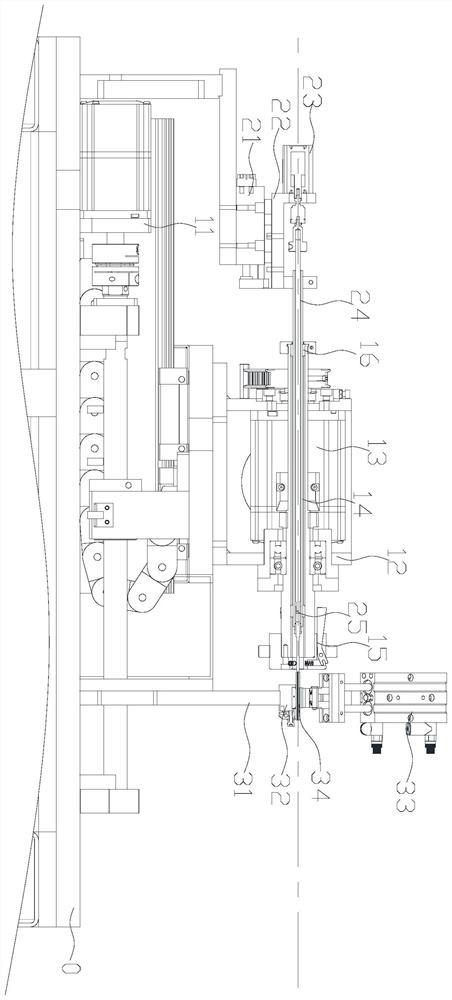

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings. In this description, the positive direction of the X-axis is the right, the negative direction of the X-axis is the left; the positive direction of the Y-axis is the front, and the negative direction of the Y-axis is the back; the positive direction of the Z-axis is The negative direction of the axis is down.

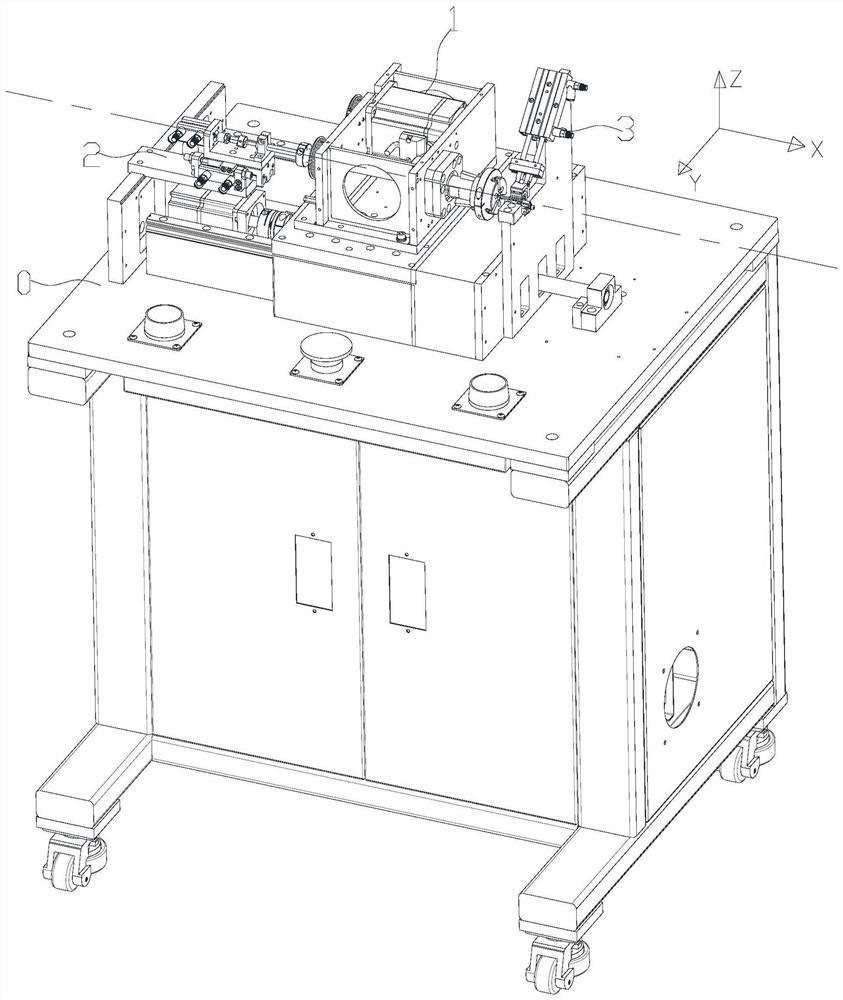

[0036] Figure 1-3 Schematically shows an automatic wire cutting device according to an embodiment of the present invention, including a machine 0, a ring cutting device 1, a first fixing device 2, a second fixing device 3, a ring cutting device 1, a first fixing device The device 2 and the second fixing device 3 are both arranged on the machine table 0, the first fixing device 2 and the second fixing device 3 are respectively located at the left and right ends of the circumcision device 1, and the active end of the first fixing device 2 extends into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com