Multi-threaded hole automatic detection machine

A testing machine and threaded hole technology, which is applied in the field of automatic multi-threaded hole testing machines, can solve problems such as affecting the overall quality and yield of products, adverse production control, and low detection accuracy, so as to facilitate production control, save manpower and time, and improve detection. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

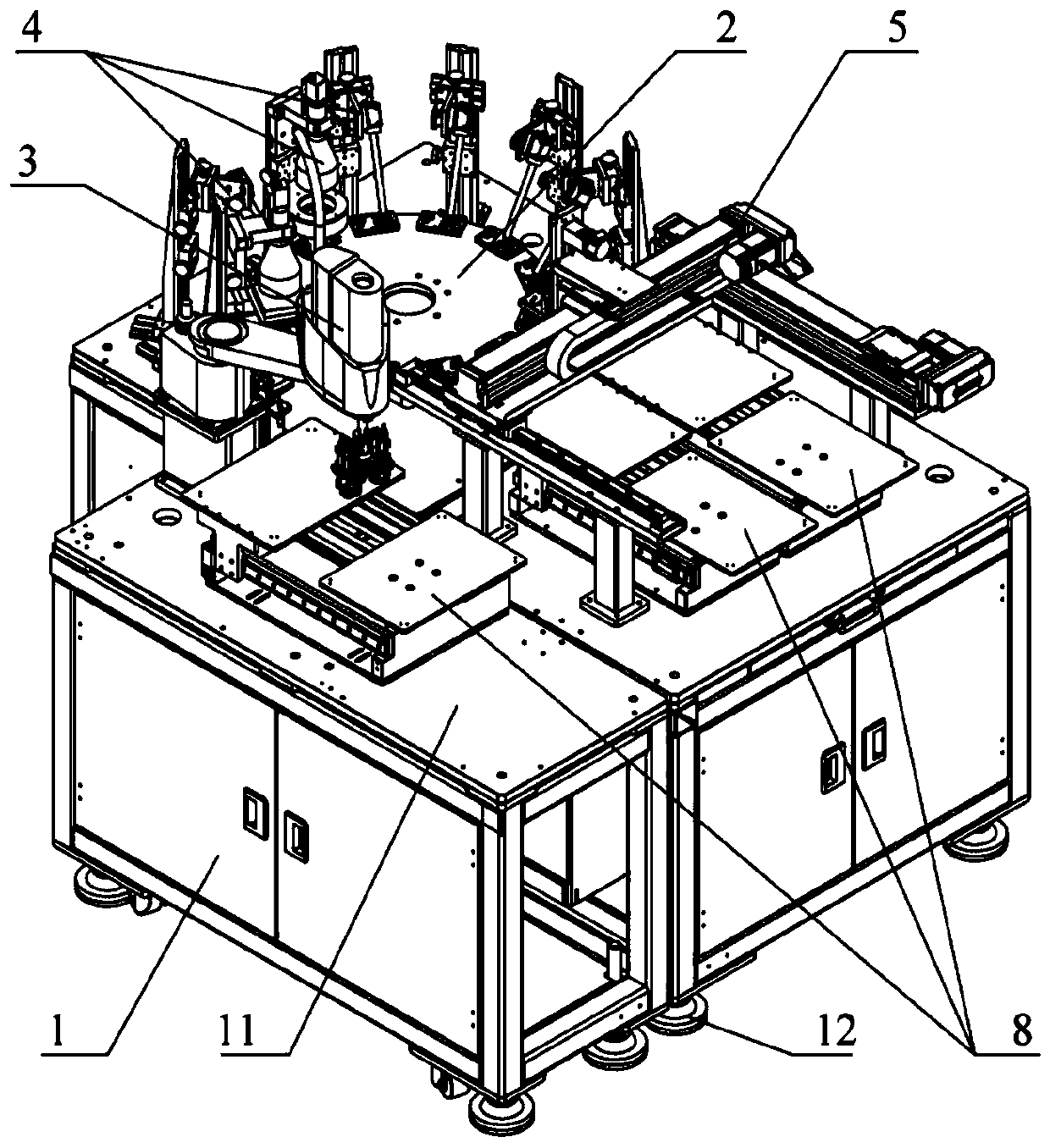

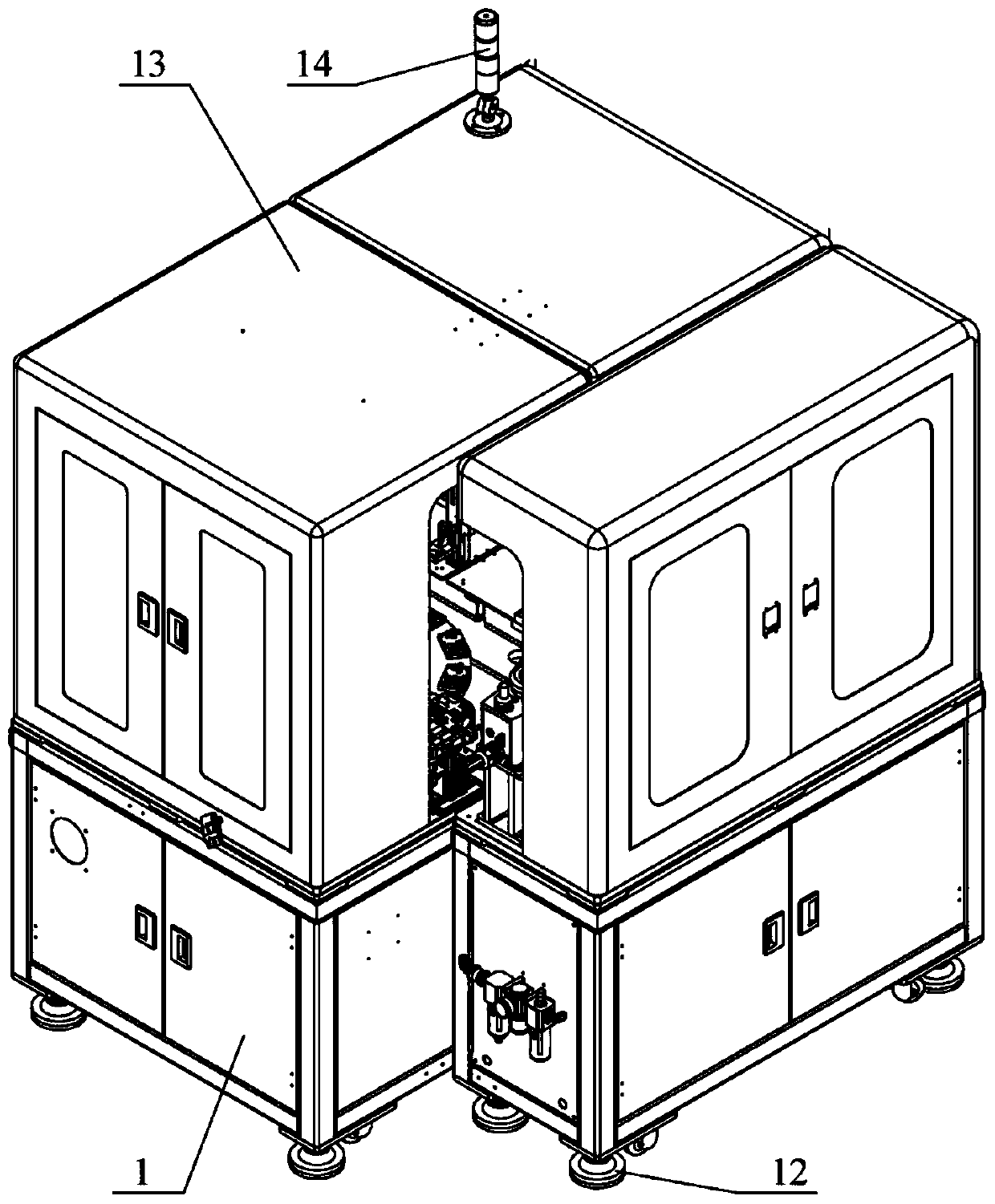

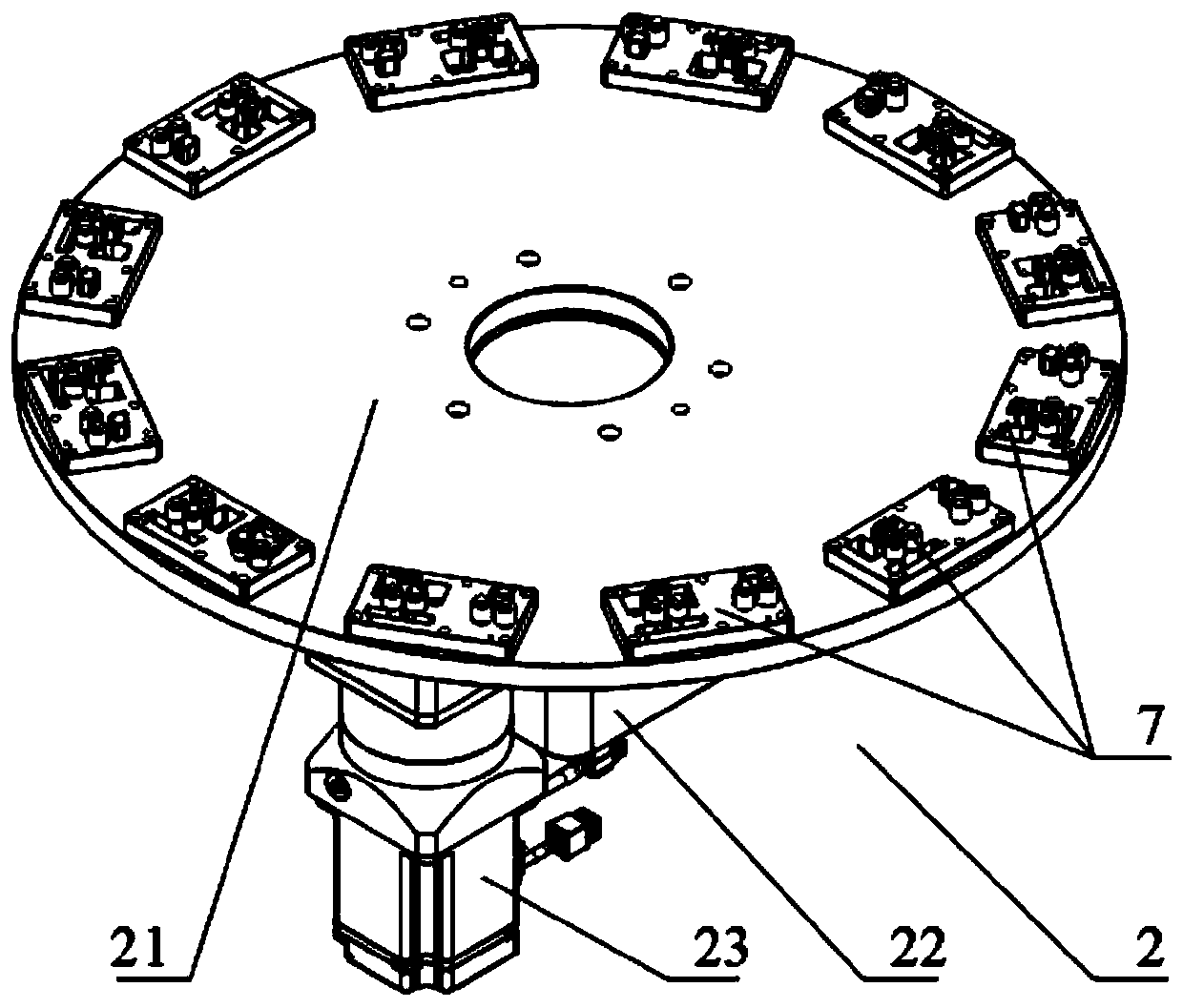

[0033] Such as Figure 1-9As shown, a multi-threaded hole automatic detection machine is mainly used for automatic detection of multiple threaded holes on CNC machining parts, stamping parts, injection molded parts and other products, especially suitable for small and many threaded holes. This detection machine comprises frame 1, and frame 1 is provided with rotary table 2, and the feeding manipulator 3 arranged successively on frame 1 along the circumferential direction of rotary table 2, a plurality of first detection devices 4 and transplanting Feeding device 5, the quantity of the first detection device 4 is determined according to the actual conditions such as concrete products, and on the frame 1, the feeding station of the rotary table 2 and the unloading station are respectively provided with an overturning device 6, and the rotary table 2 is provided with a number of positioning jigs 7 for placing products along its circumferential direction, usually a plurality of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com