Automatic cut-off, blanking and packaging machine

An automatic cutting and packaging machine technology, applied in packaging and other directions, can solve problems such as excessive manpower, low production efficiency, and affecting the overall quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

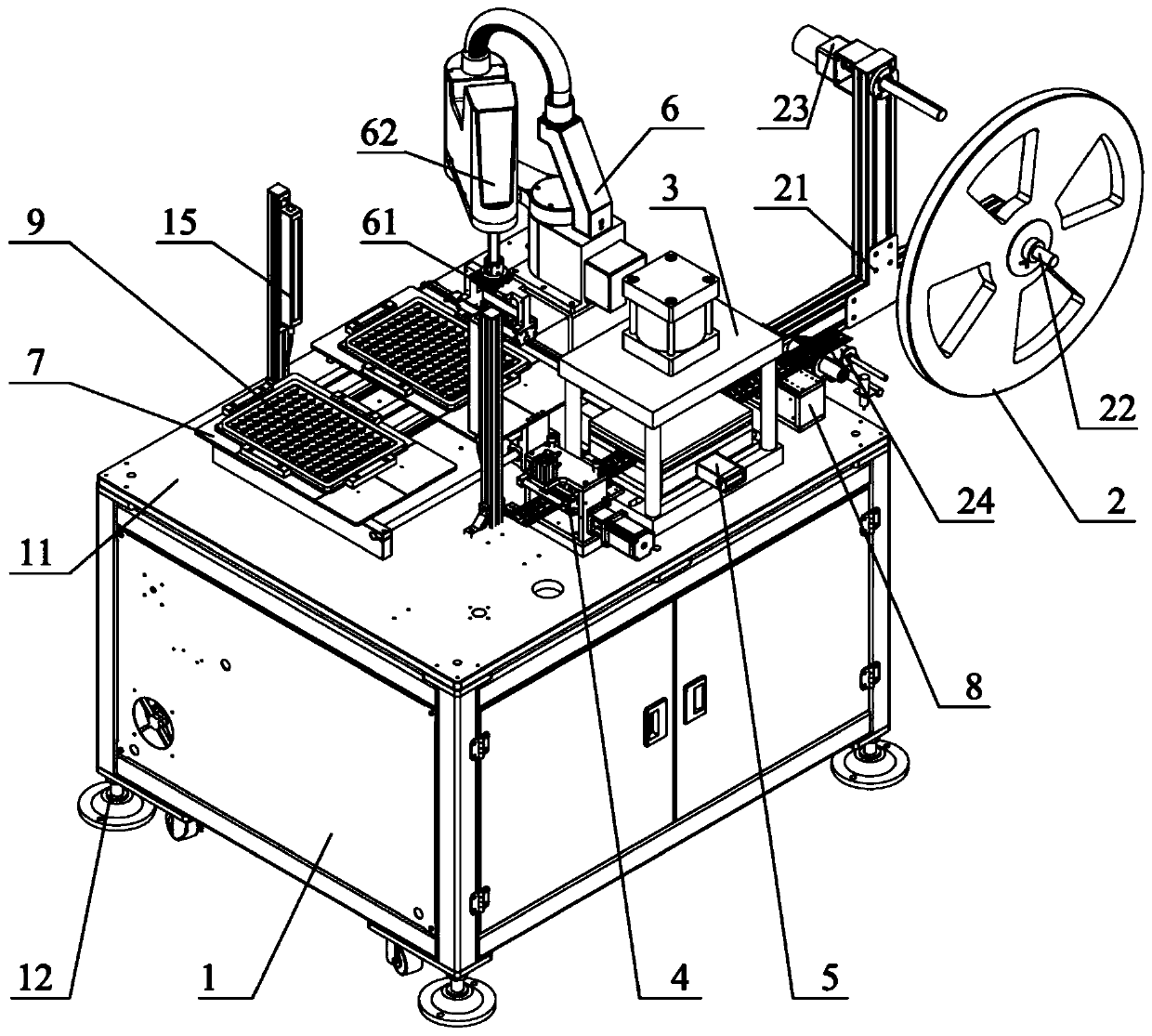

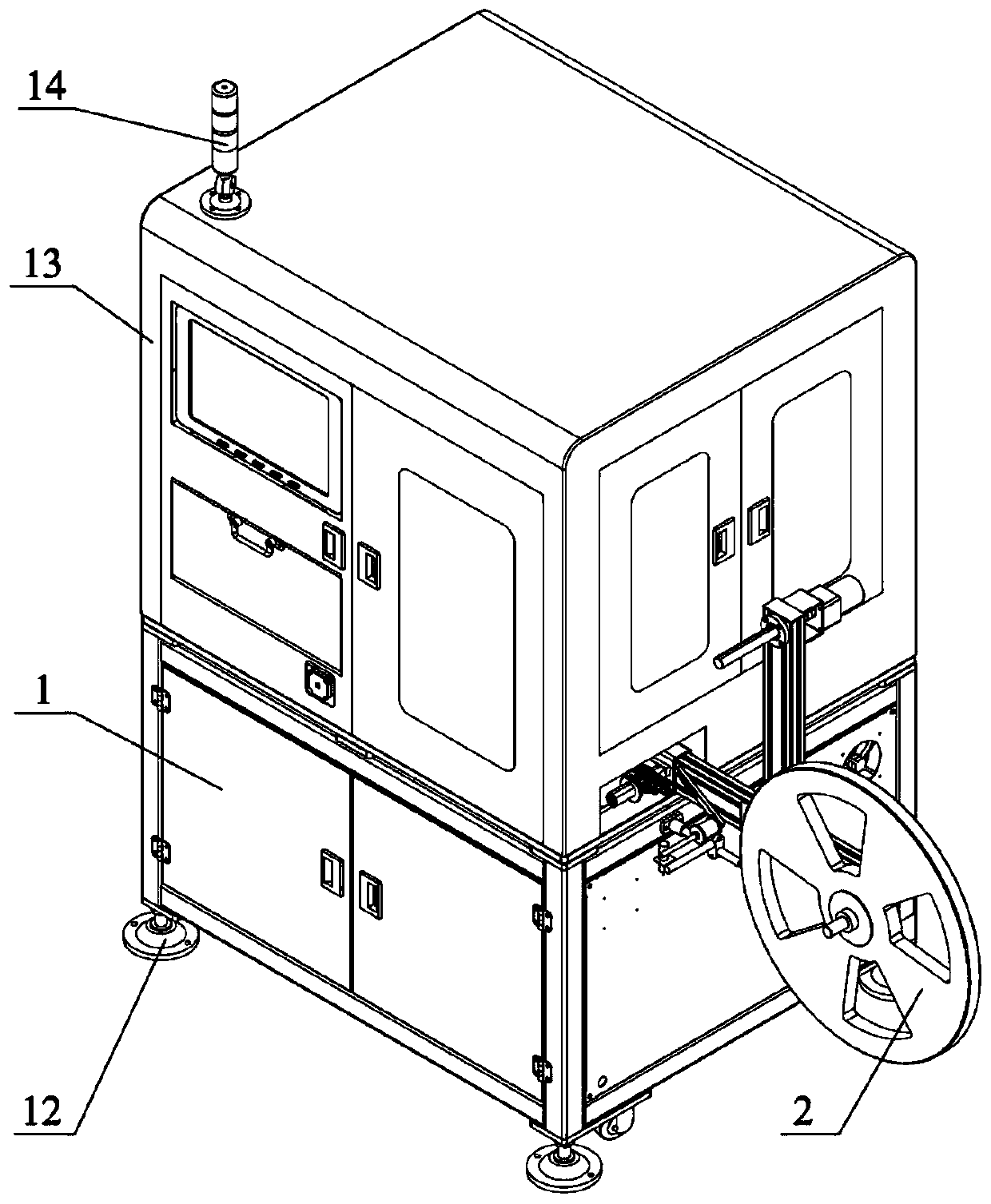

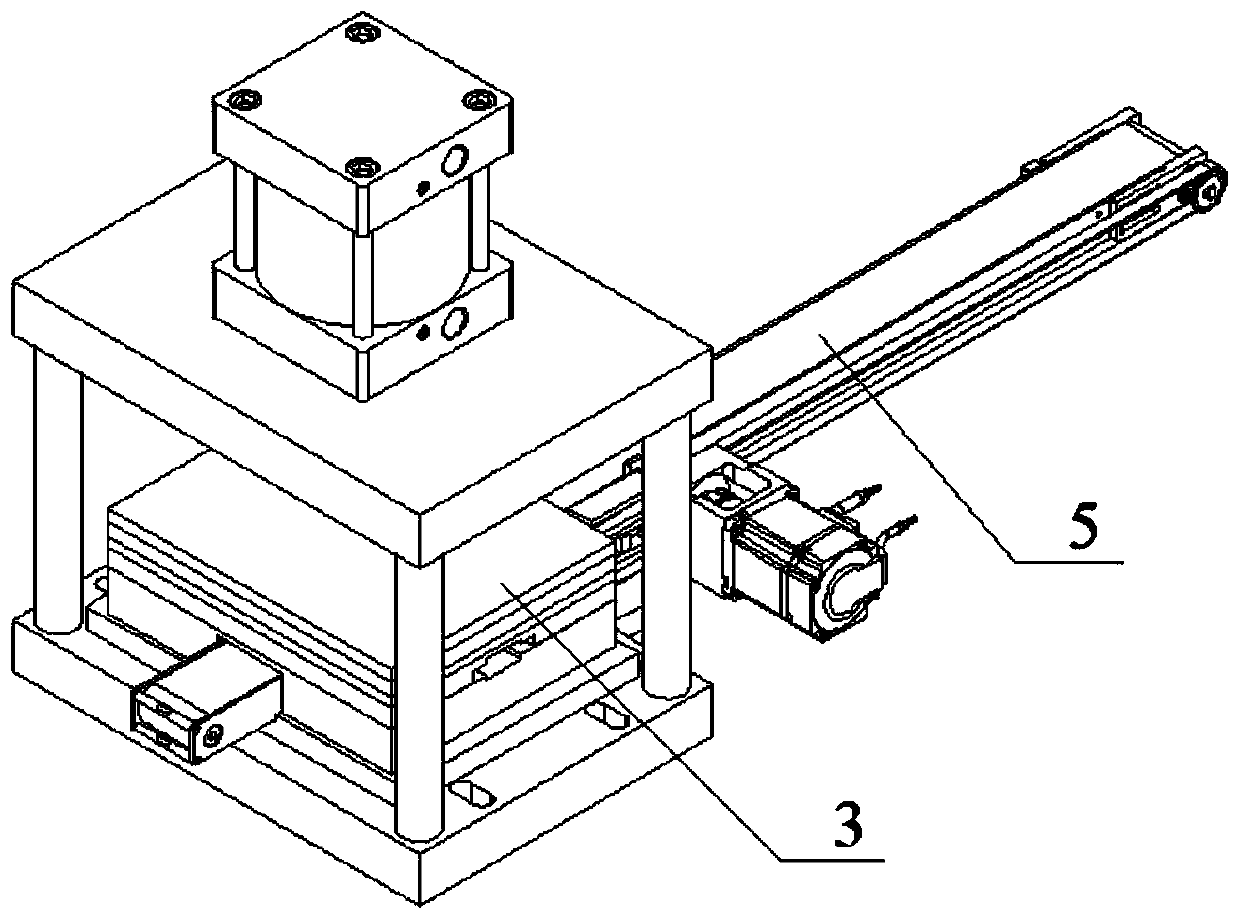

[0038] Such as Figure 1-13 As shown, an automatic cutting and blanking packaging machine includes a frame 1. A working substrate 11 is usually arranged on the frame 1. A discharging device 2, a stamping blanking device 3 and Pulling device 4, punching and blanking device 3 is provided with a belt conveyor 5 below the blanking port, and the discharge end of the belt conveyor 5 is provided with an automatic retrieving device 6 for grabbing products and a place for placing the grabbed products device7. After the product is processed and formed on the material belt, there are still some material connection points between the product and the material belt. The discharge device 2 discharges the material roll, and the material puller 4 pulls the material belt output by the discharge device 2 to pass through in turn. The punching and blanking device 3 and the pulling device 4 carry out feeding. When the product on the material belt corresponds to the punching mechanism of the punchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com