Truss footing cutting device

A cutting device and truss technology, applied in the field of truss processing, can solve the problems of high labor intensity and low production efficiency, and achieve the effects of high automation, improving production efficiency, reducing labor intensity and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

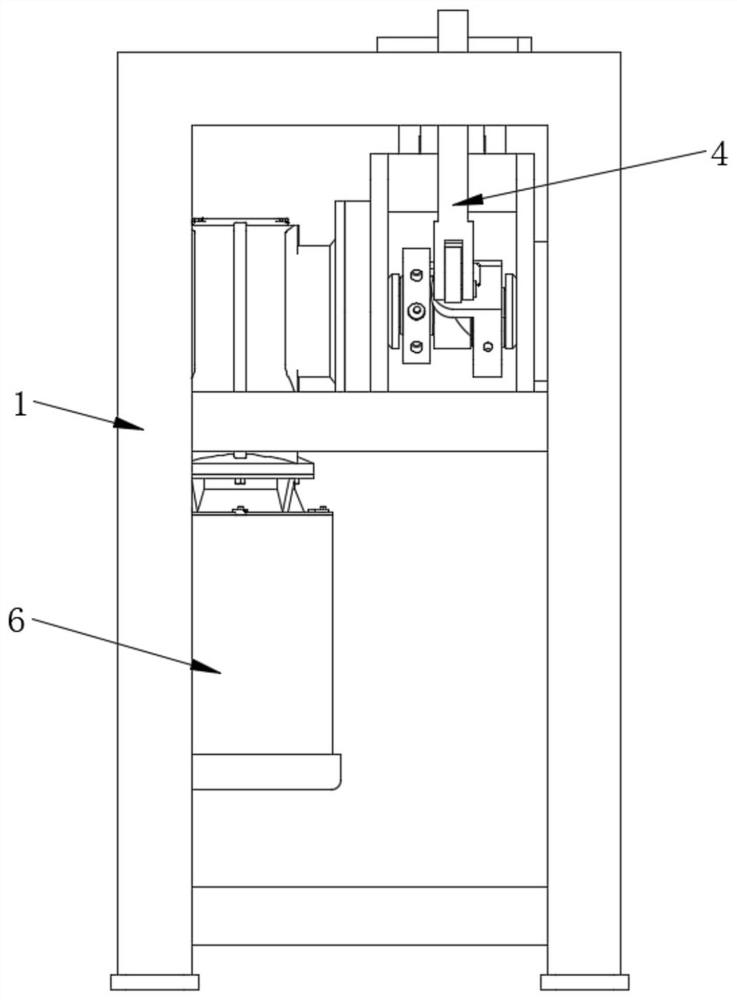

[0044] This embodiment provides a truss foot cutting device, which differs from Embodiment 1 in that the cutting arm of this embodiment is not rotatably disposed on the frame, but is slidably disposed on the frame, and the driving member is used to drive The cutting arm slides, and in this embodiment, no transmission assembly is provided.

[0045] Specifically, a slide rail may be provided on the frame, and a slide block is correspondingly provided on the cutting arm, and the driver drives the cutting arm to slide vertically, and the slide block and the slide rail can serve the purpose of guiding and stabilizing support.

[0046] At the same time, the driving member in this embodiment can be an air cylinder or an oil cylinder, and the output end of the air cylinder or oil cylinder is connected to the cutting arm. The driving part can be set in two, and each driving part is drivingly connected to a cutting arm respectively, and the two driving parts preferably run synchronously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com