Anti-winding and rolling integrated ribbon loom

An anti-winding and integrated technology, which is applied in the direction of winding strips, textiles and papermaking, and textile material cutting, etc. It can solve the problems of ribbon folding, intertwining of ribbons, and increasing the occupied area of the ribbon loom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

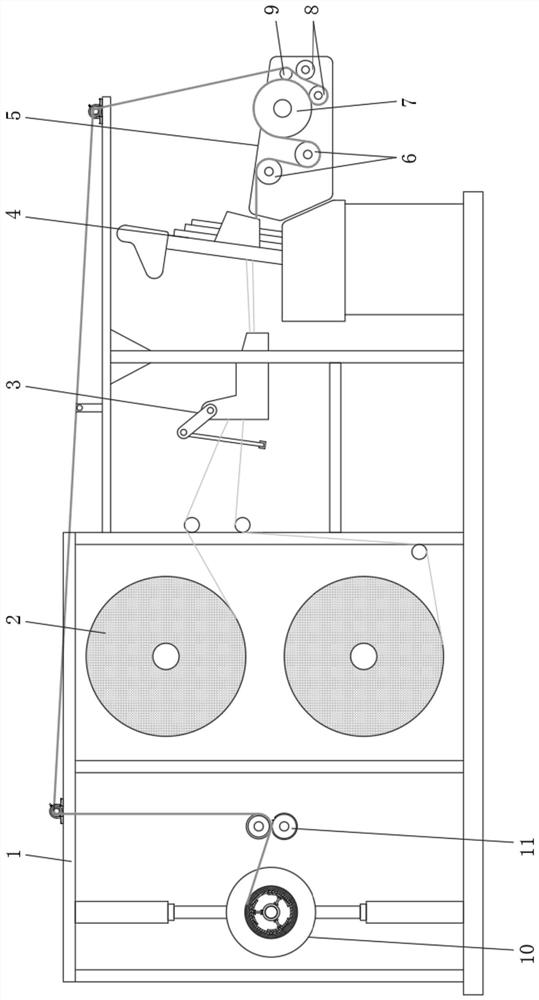

[0033] Embodiment one, with reference to Figure 1-2 , an anti-winding and winding integrated ribbon loom, comprising a frame 1, a warping device 3, a weaving device 4, an anti-winding mechanism 5, a winding mechanism 10 and a cutting mechanism 11, and the inside of the frame 1 is provided with a winding mechanism from right to left. Roll mechanism 10, cutting mechanism 11, wire reel 2, warping device 3, textile device 4, anti-winding mechanism 5, wire reel 2 is provided with two altogether from top to bottom, and the yarn of two wire reels 2 is equal Pass through warping device 3 and weaving device 4 in sequence and weave and form the webbing into anti-winding mechanism 5. Anti-winding mechanism 5 includes first flattening roller 6, driving roller 7, second flattening roller 8, third flattening roller 9. The mounting frame 12, the first paving roller 6, the driving roller 7, the second paving roller 8, and the third paving roller 9 are all erected and fixed by the mounting fr...

Embodiment 2

[0035] Embodiment two, refer to figure 1 and image 3 , the top of the frame 1 is provided with a plurality of transition rollers for erecting the webbing from left to right, and the anti-winding mechanism 5, the cutting mechanism 11 and the winding mechanism 10 are connected by the webbing, and the winding mechanism 10 includes a winding drum 13, a rotating shaft 14. The bearing housing 15, the winding motor 16, the winding motor 16 is installed on one side surface of the frame 1 through the fixing plate, and the output shaft of the winding motor 16 is rotationally connected with one end of the rotating shaft 14 fixed by the bearing housing 15;

[0036]The ribbon weaved by the ribbon loom enters the winding mechanism 10 from the anti-winding mechanism 5 through the top of the frame 1. The rational use of space and the integrated structure design make the ribbon loom compact in structure, which not only reduces the occupied area of the ribbon loom, but also avoids The pheno...

Embodiment 3

[0037] Embodiment three, refer to Figure 3-5 A lower electric telescopic rod 18 and a lower connecting block 20 are arranged below the other end of the rotating shaft 14, and the lower connecting block 20 is fixed on the upper end surface of the lower electric telescopic rod 18, and a buffer pad 22 and an upper connecting block 19 are successively arranged above the lower connecting block 20. 1. The upper electric telescopic rod 17 is fixedly connected, and one side of the lower connecting block 20 and the upper connecting block 19 are equipped with rollers 21 through pin shafts, and three rollers 21 are arranged in a triangular distribution, and the surface of the rotating shaft 14 is covered with a guide sleeve 23, and the guide sleeve 23 is slidably connected with the rotating shaft 14 to open the limit groove 28, the guide sleeve 23 below is hinged with the support plate 25 through the connecting rod 24, and the surface on one side of the guide sleeve 23 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com