Welding method for realizing high-temperature-resistant metal shell

A technology of metal casing and welding method, which is applied in metal processing, welding equipment, metal processing equipment, etc., can solve the problems of unusable chips, poor effect, separation, etc., and achieve the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

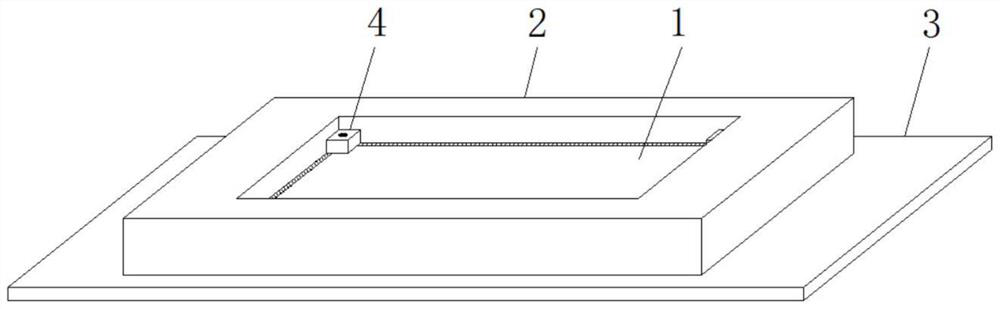

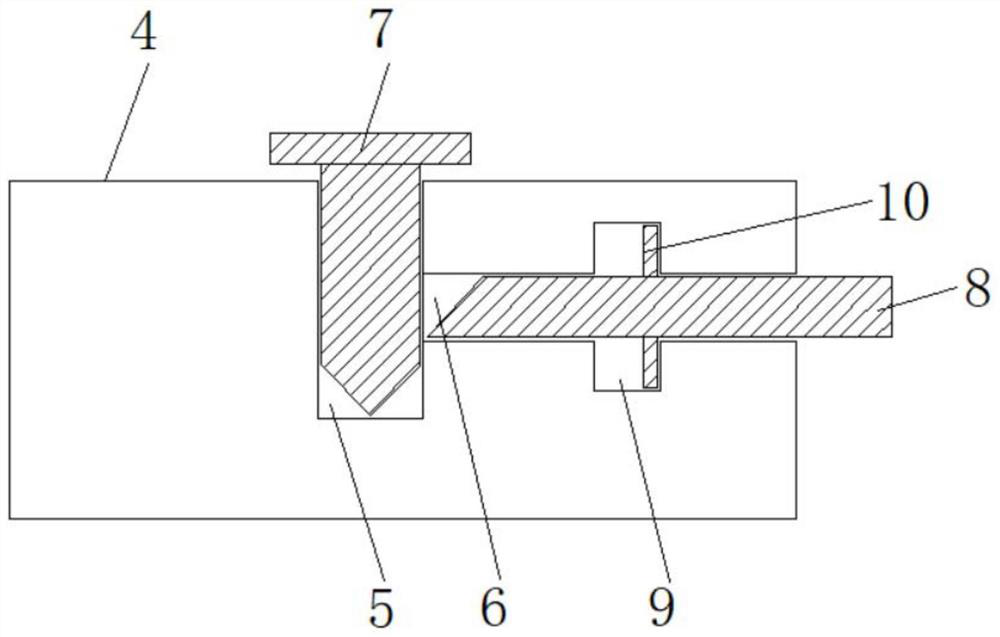

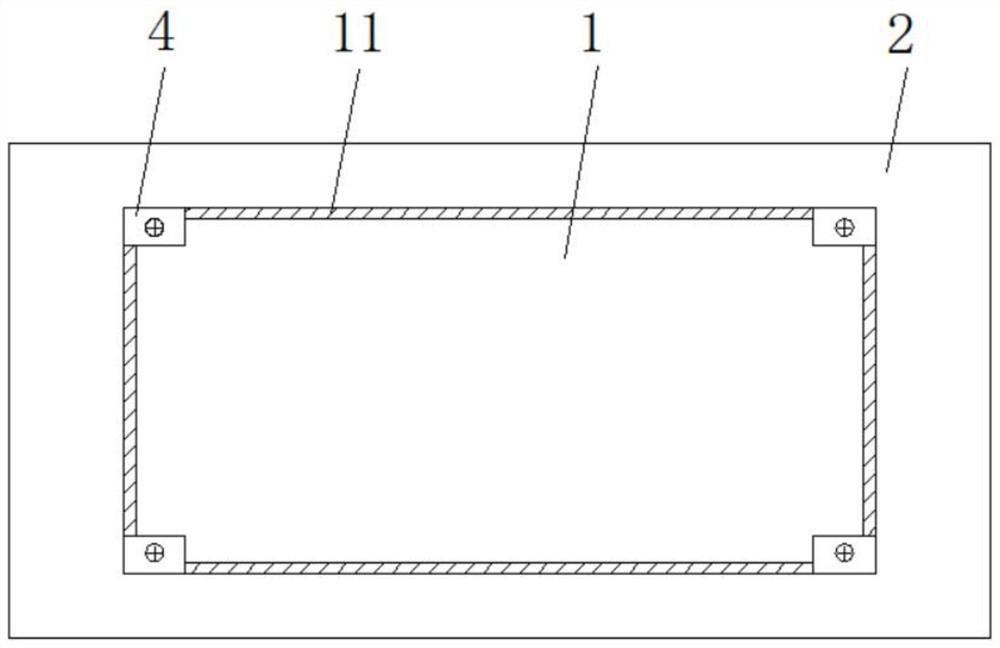

[0035] The invention provides a technical solution: as Figure 1-3 As shown, a welding method for realizing a high-temperature-resistant metal shell includes the following steps:

[0036] Step 1: The metal cap body 2 of 4J29 material is electroplated with nickel on the bottom, and then the surface is electroplated with gold. The size of the cap opening is 15mm×20mm. The surface soldering layer is a gold layer), and the size of the InSn48 solder preform is determined according to the length and width of the cap, the width of the metallization layer of the optical window and the soldering volume to be filled;

[0037] Step 2: Prepare the experimental equipment. The experimental equipment uses a vacuum brazing furnace to replace the chain mesh belt furnace used in traditional brazing. The vacuum furnace has the characteristics of accurate temperature control, controllable atmosphere and vacuum in the furnace, and simple operation methods. The vacuum brazing furnace replaces the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com