Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Does not lead to large" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

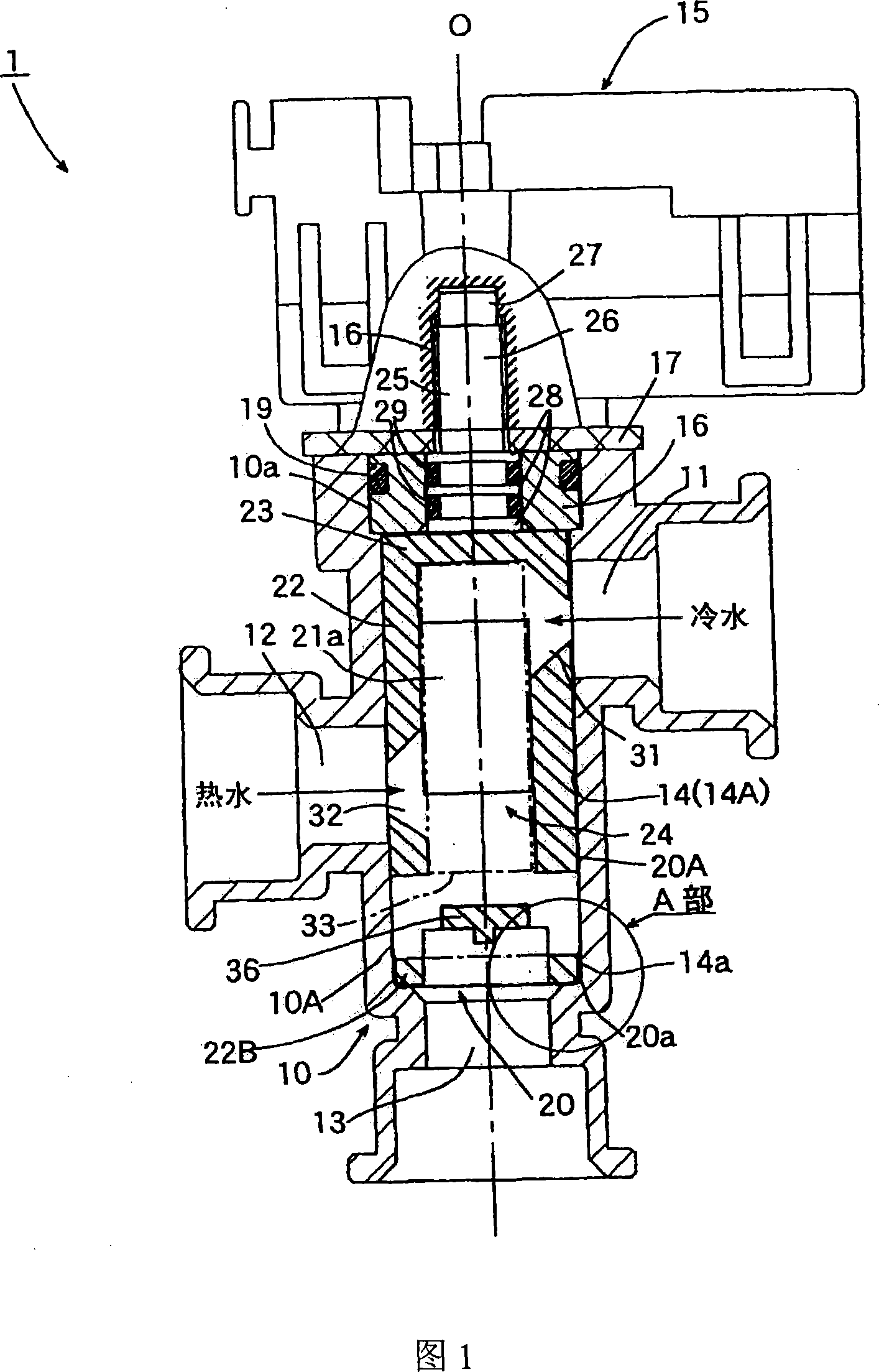

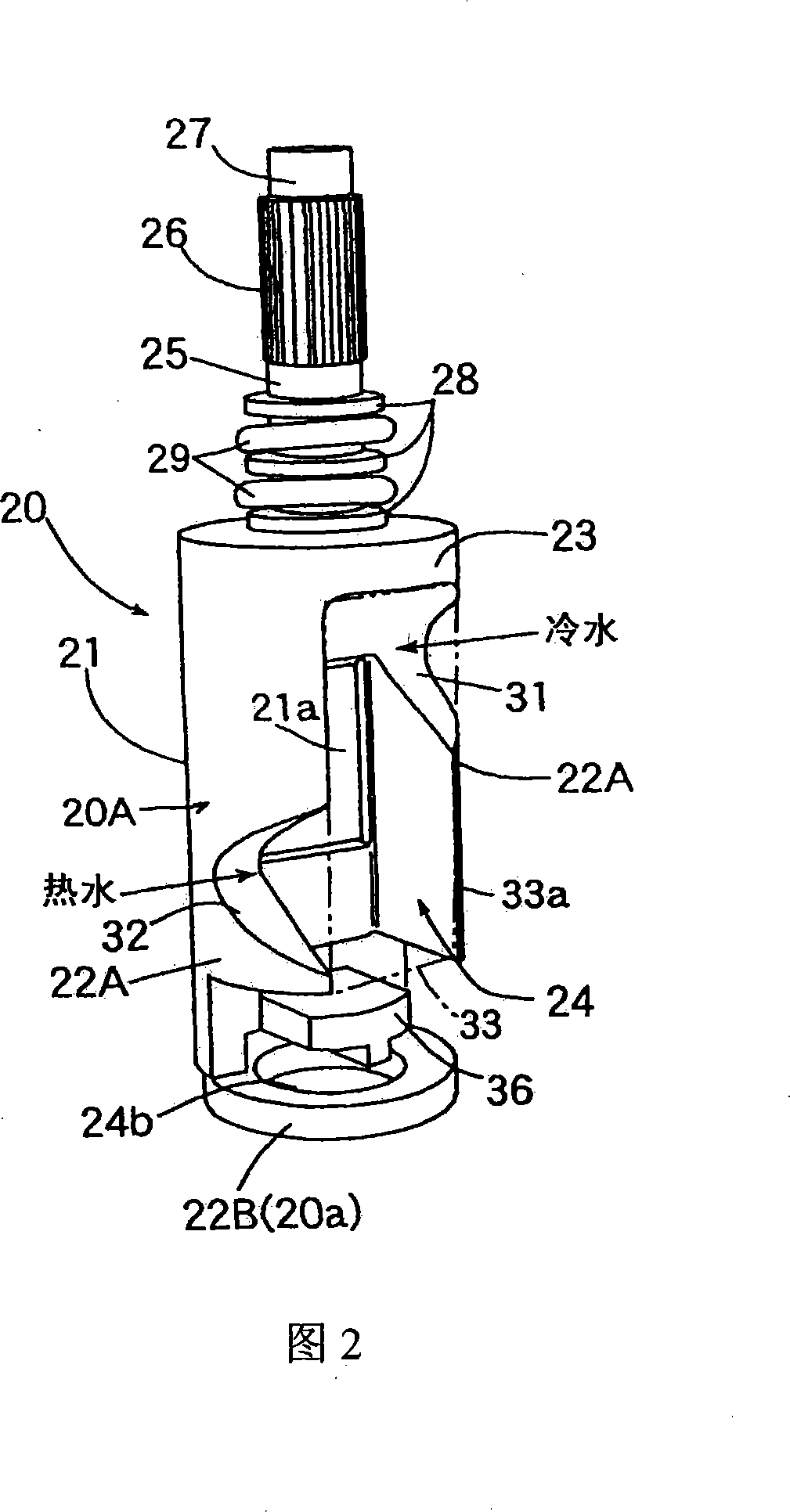

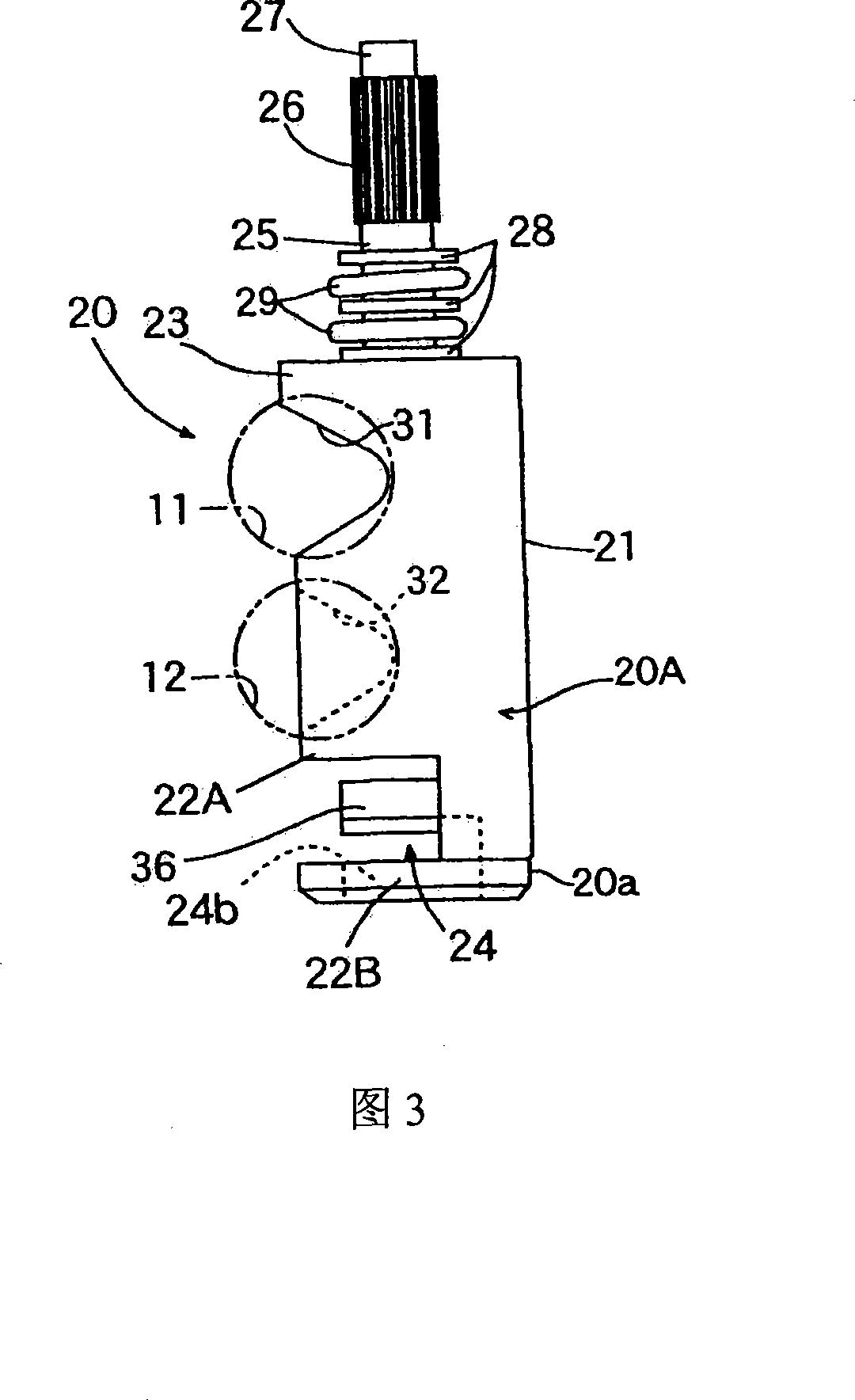

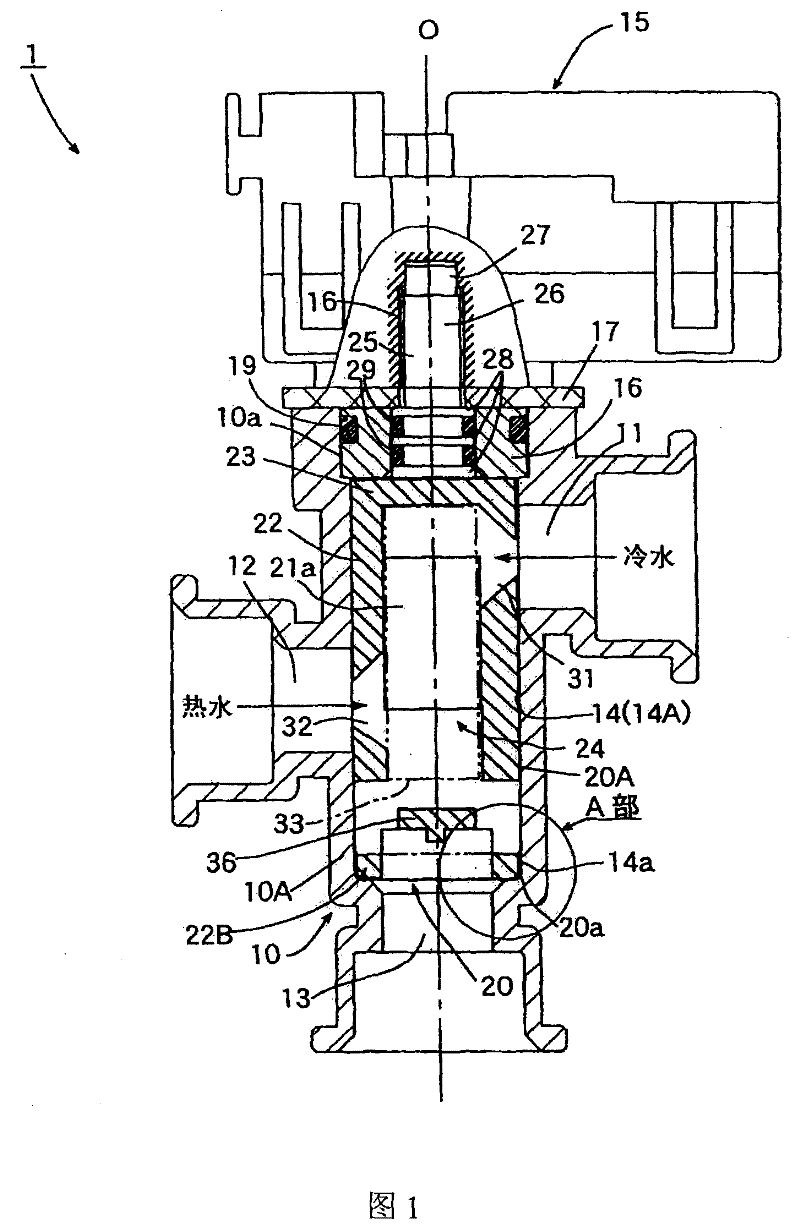

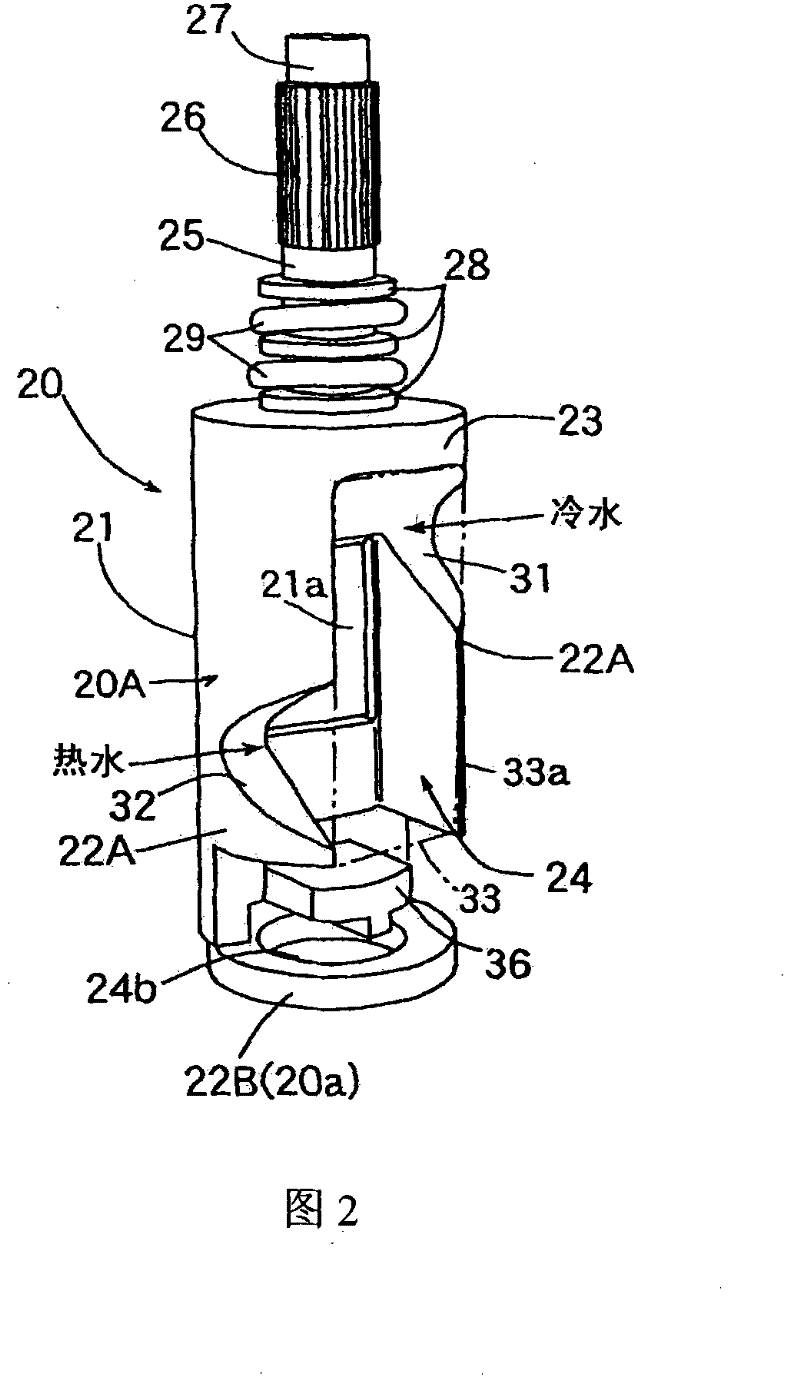

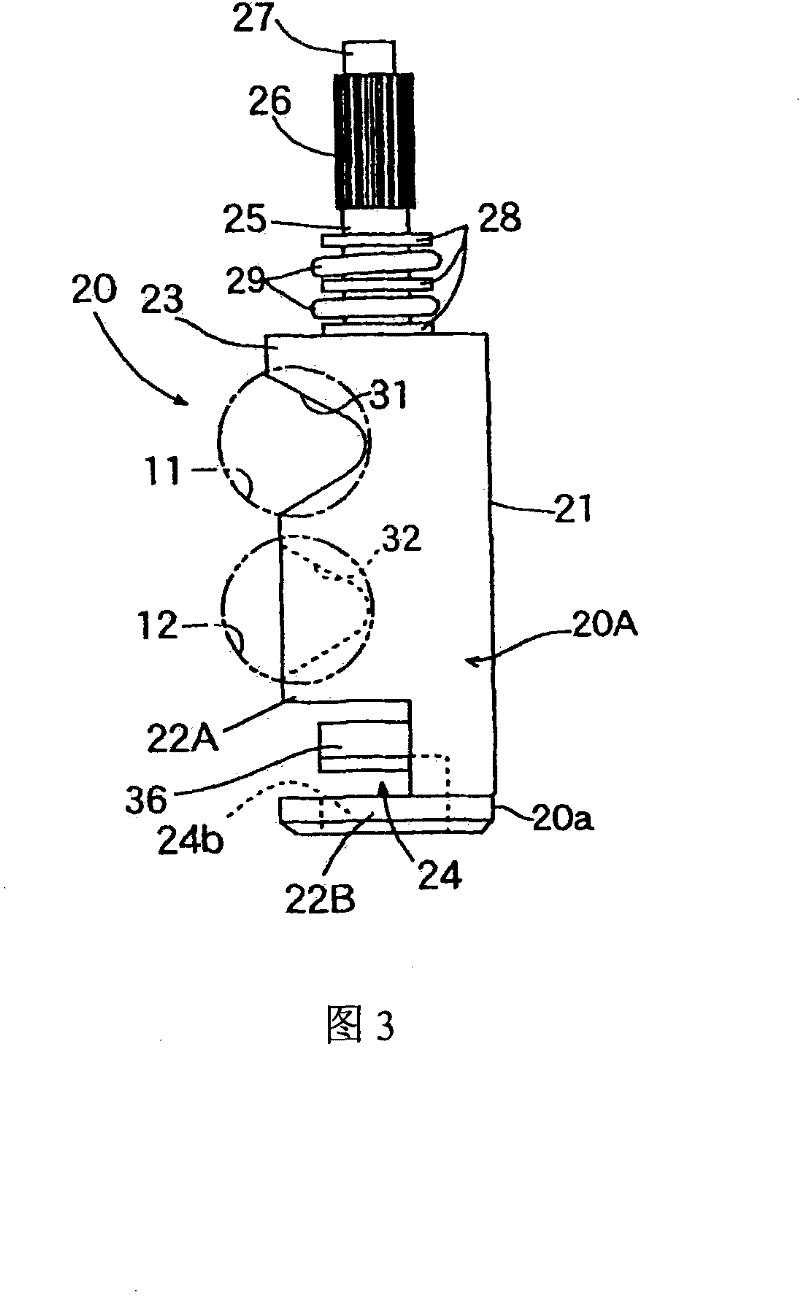

Mixed valve

ActiveCN101135395ADoes not grow verticallyDoes not cause vertical elongationMultiple way valvesWarm waterEngineering

A mixed vale comprises a valve body provided with a first guide-in opening, a second guide-in opening and a guide-out opening; and a cylindraceous valve core rotatably embedded in the valve body. The circumferential wall of the valve core is provided with a first opening part and a second opening part corresponding to the first and second guide-in openings, and is provided with a third opening part over the first and second opening parts. When the valve core rotates, the first guide-in opening is made to all close status from all open status, and the second guide-in opening is made to all open status from all close status, when the valve core further rotates and the first guide-in opening is kept at all close status, the third opening part makes the opening area of the second guide-in opening become minimum from maximum continuously. Adopting the invention, a mixed valve with easy assembly and compact structure can be provided which can quickly and correctly obtain the warm water with required mixing proportion after mixed the cold water and the hot water, and can regulate the flux of water of one side when the guide-in opening of another side is at all close status.

Owner:FUJIKOKI MFG CO LTD

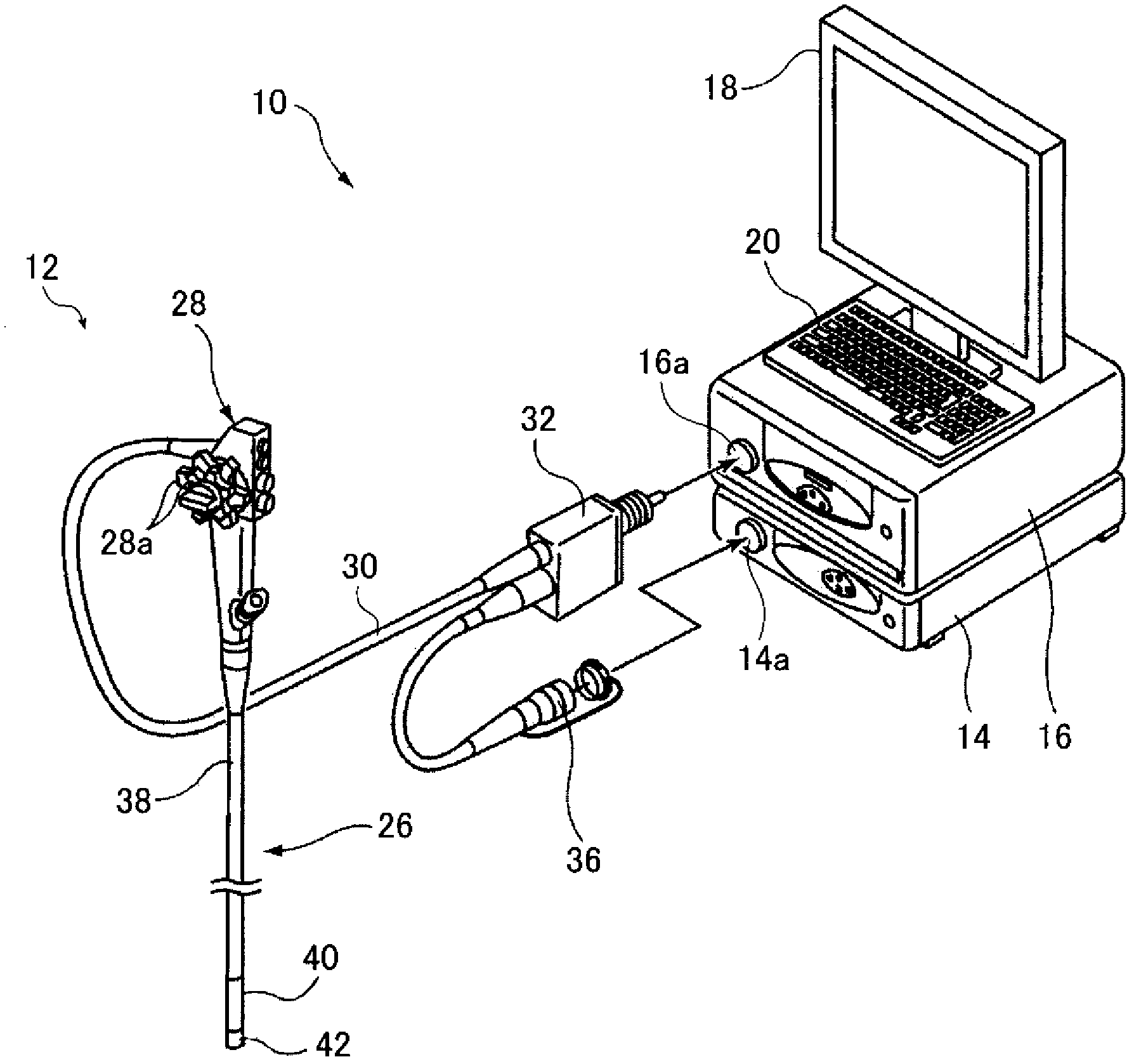

Endoscopic device

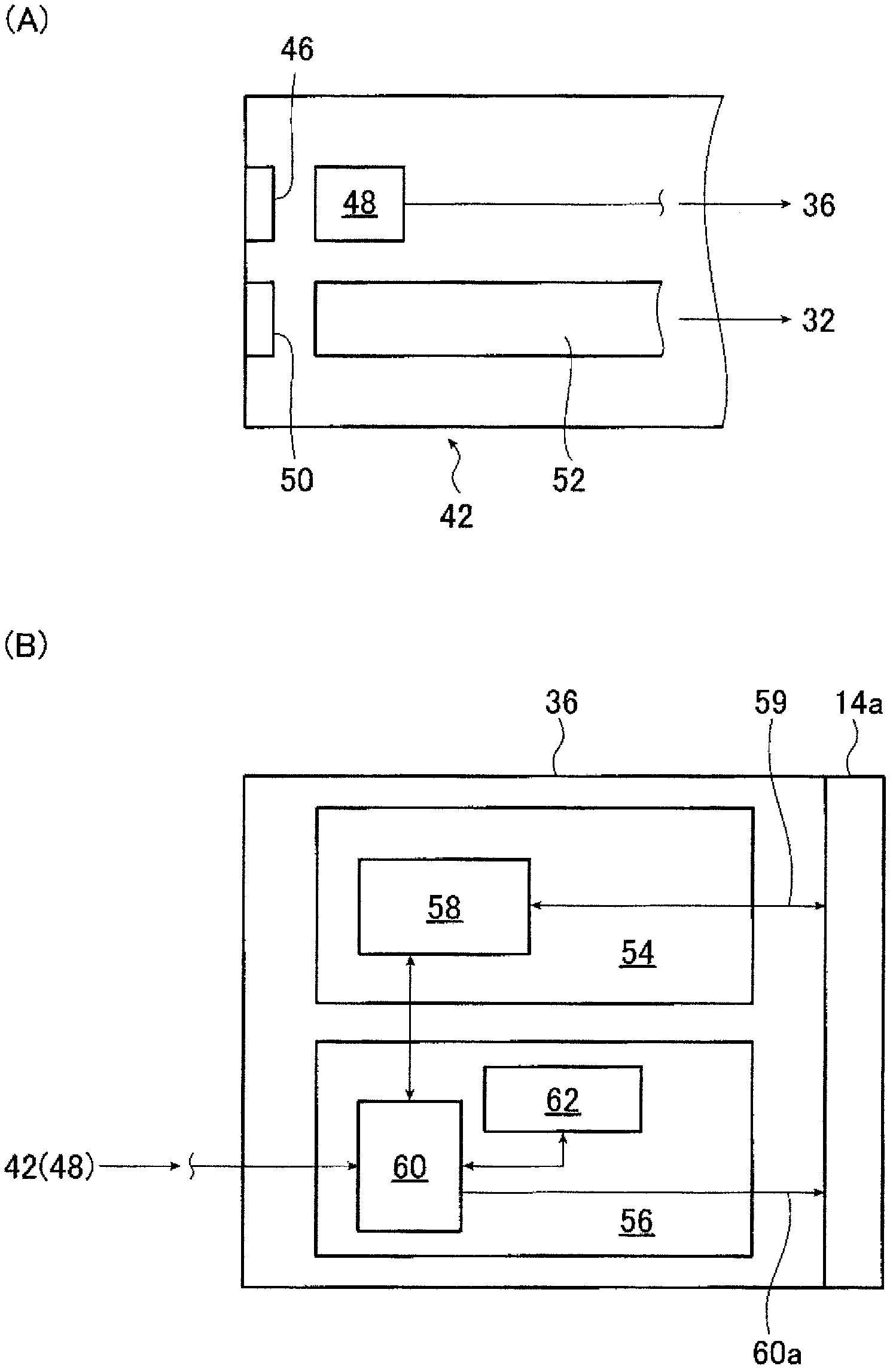

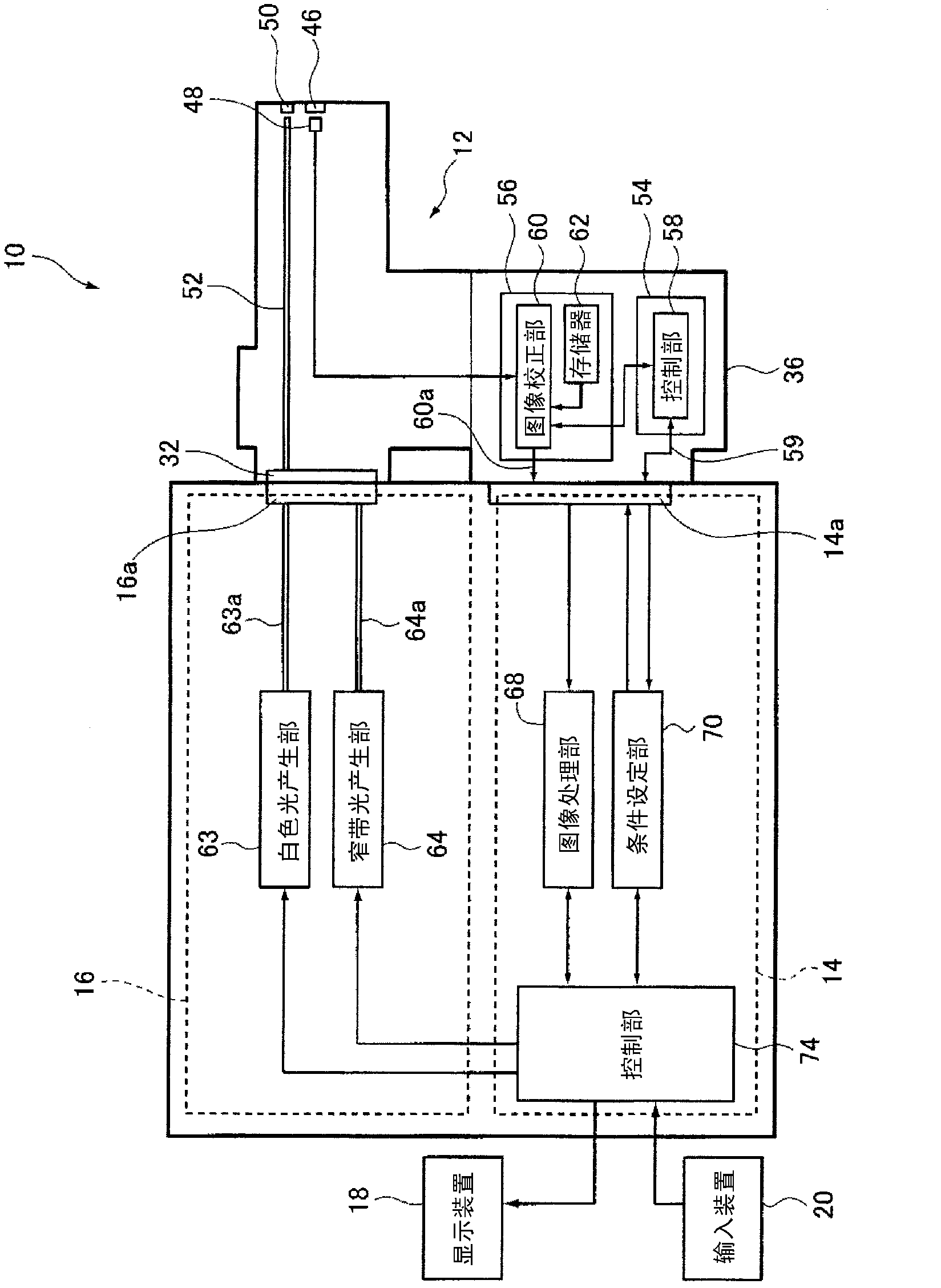

InactiveCN102450998ADoes not lead to largeStable outputTelevision system detailsSurgeryEndoscopeComputer science

To provide an endoscopic device in which an endoscope includes a correction means for an image using a correction parameter such as sensitivity unevenness correction or defective pixel correction, the endoscopic device being capable of storing the correction parameter using an existing I / F without further providing a new device or a signal line. The above-described problem is solved by adopting a configuration in which an endoscopic device includes an endoscope that includes a correction means correcting an image and a storage means storing a correction parameter, a control device, and a generating means generating a correction parameter, wherein the correction parameter generated by the generating means in accordance with the command of the control device is written in the storage means by the correction means.

Owner:FUJIFILM CORP

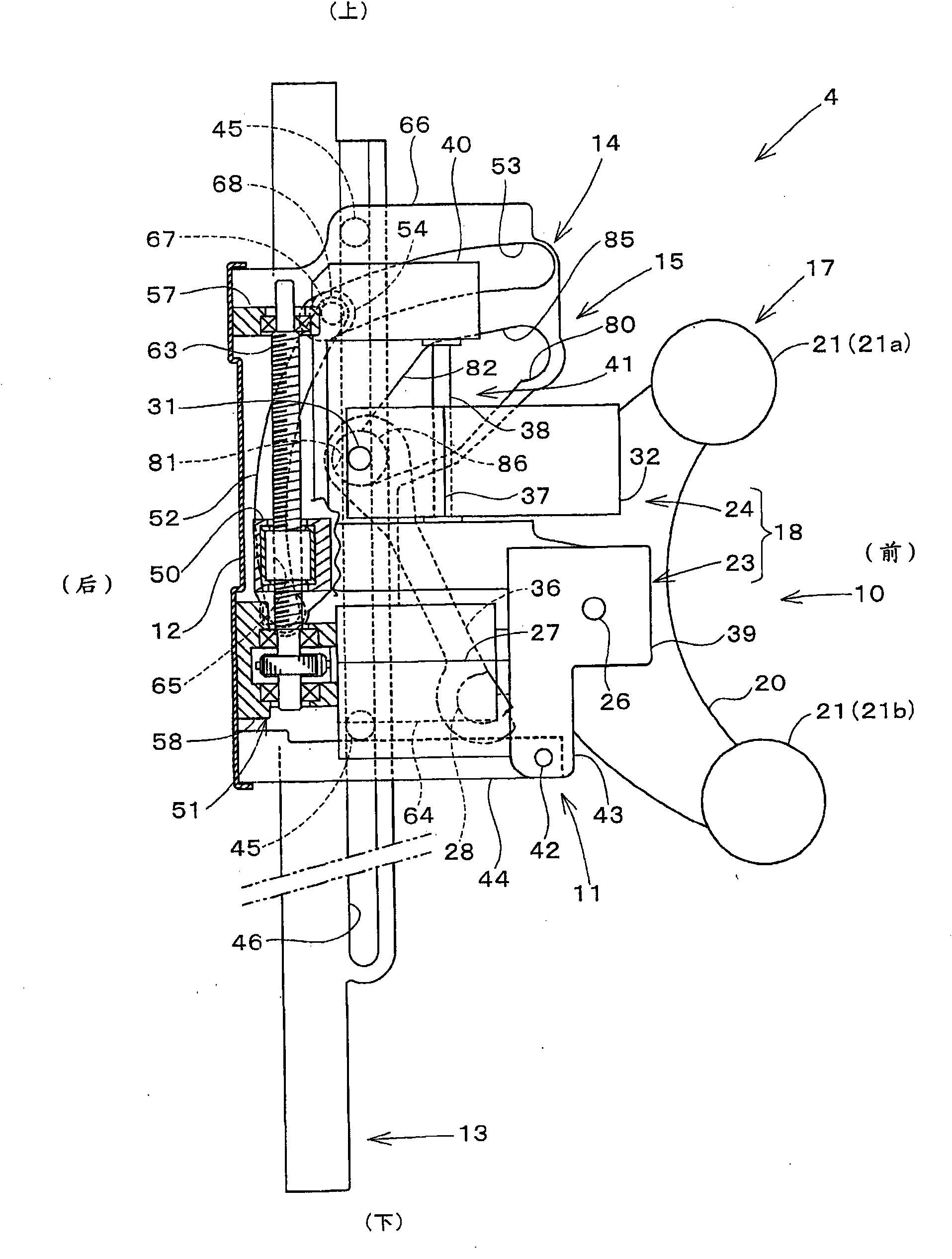

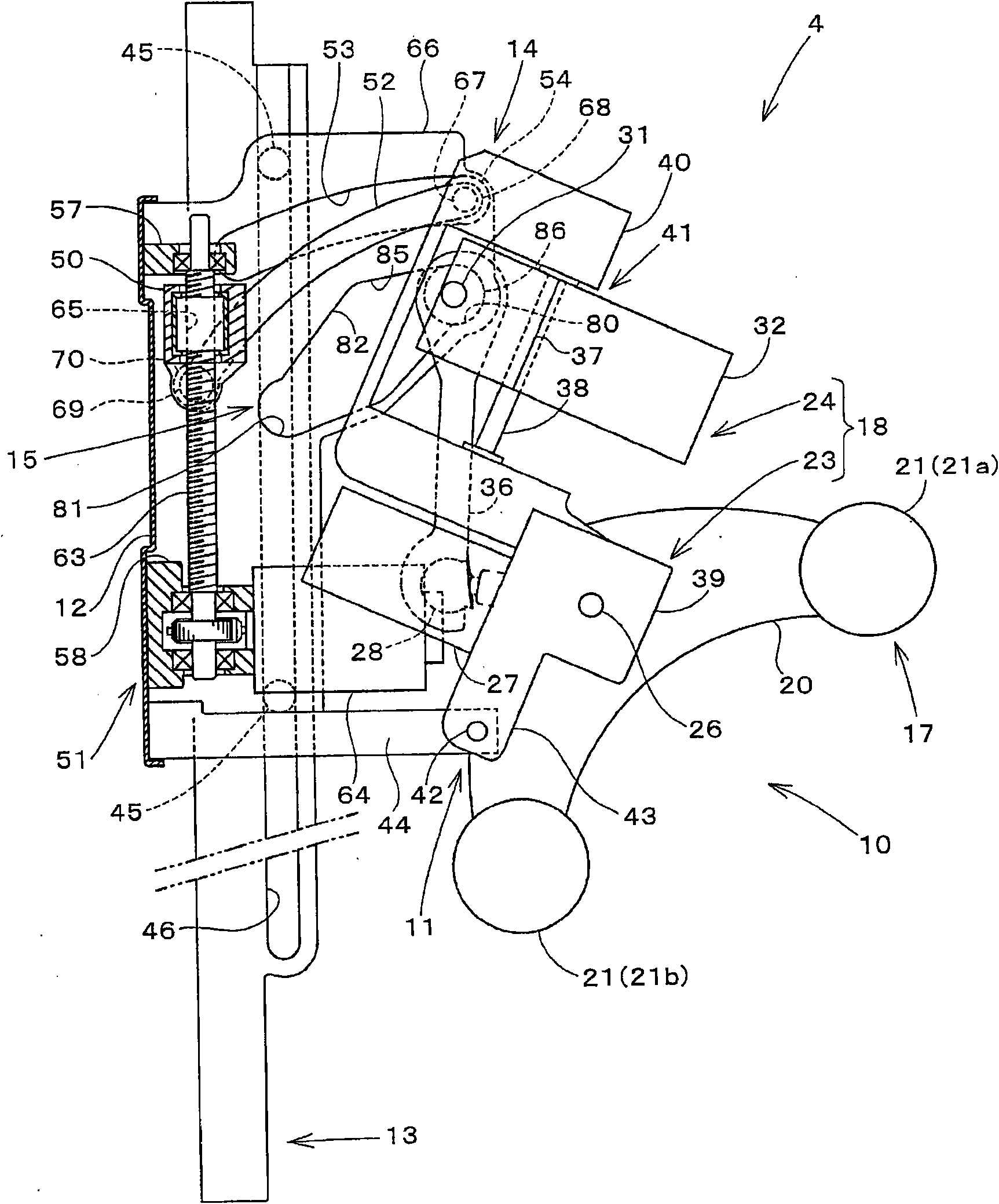

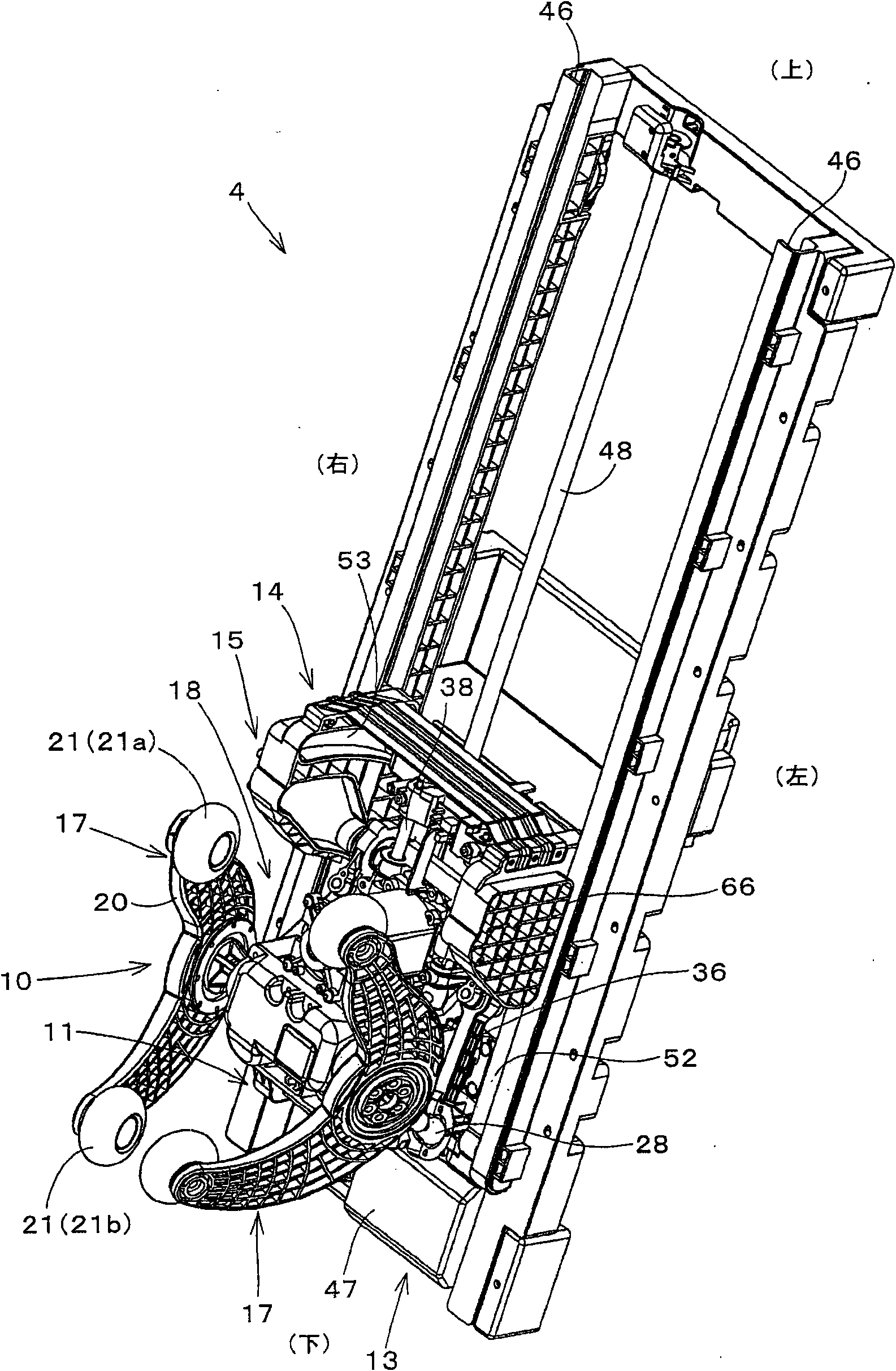

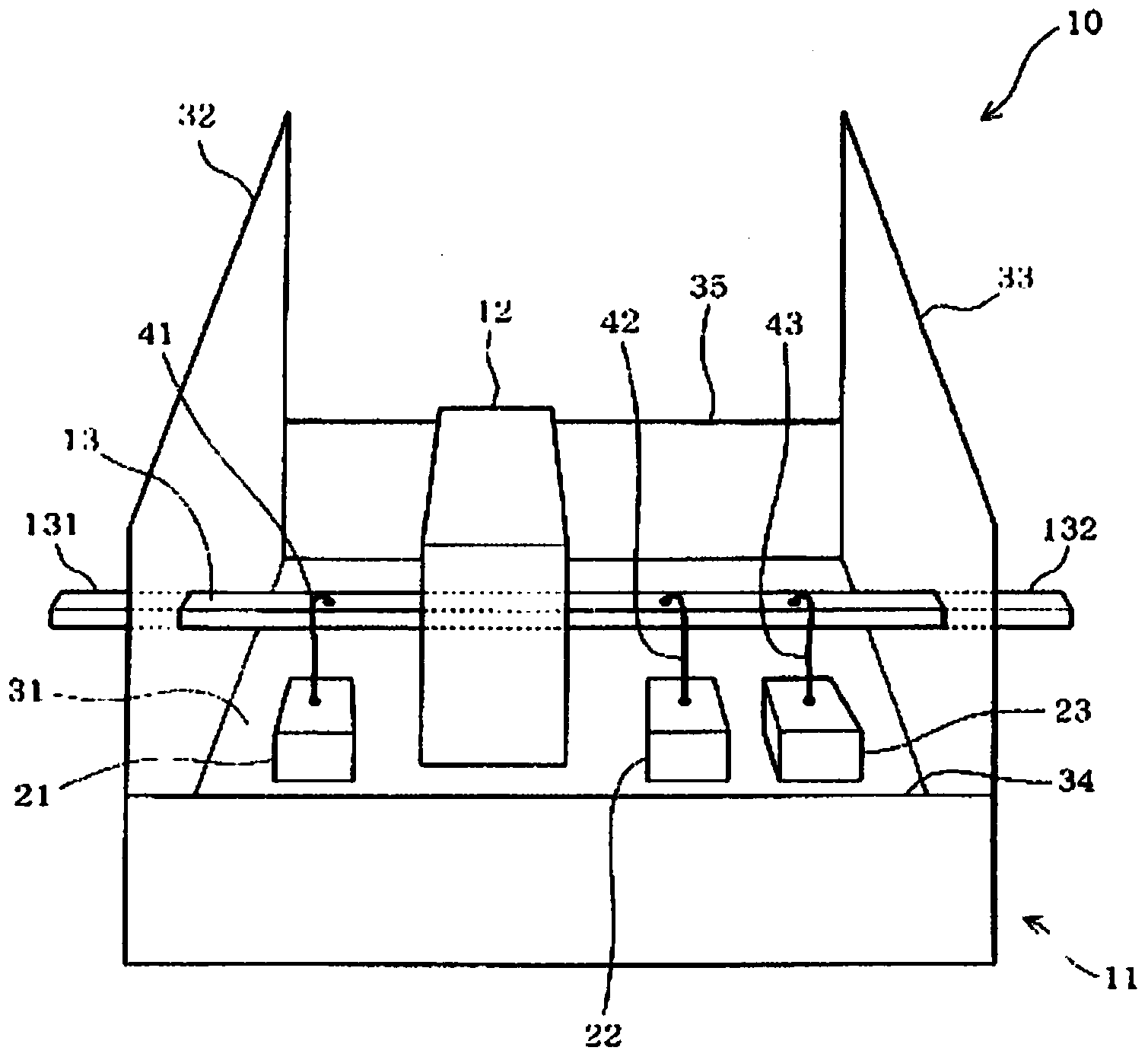

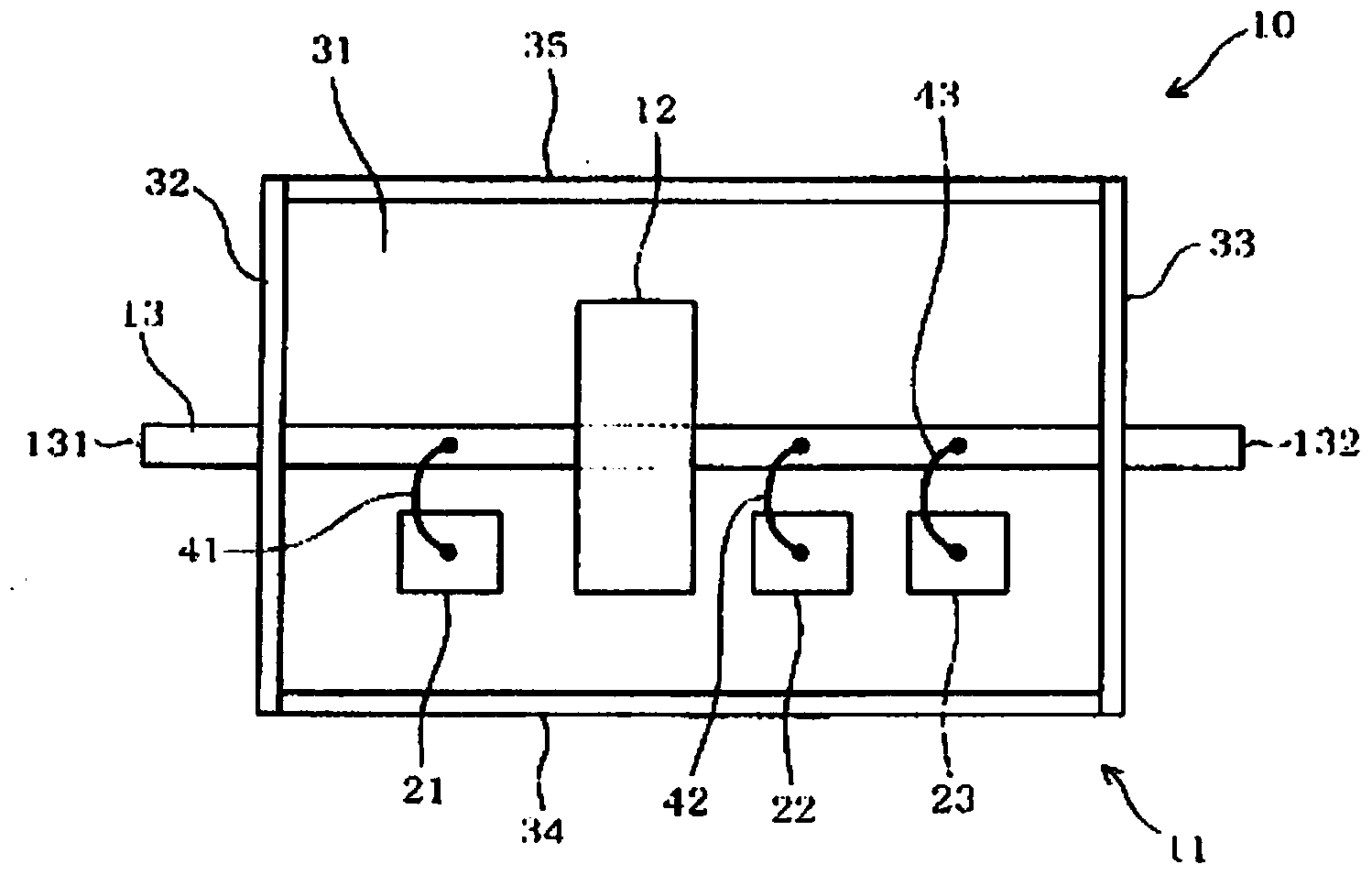

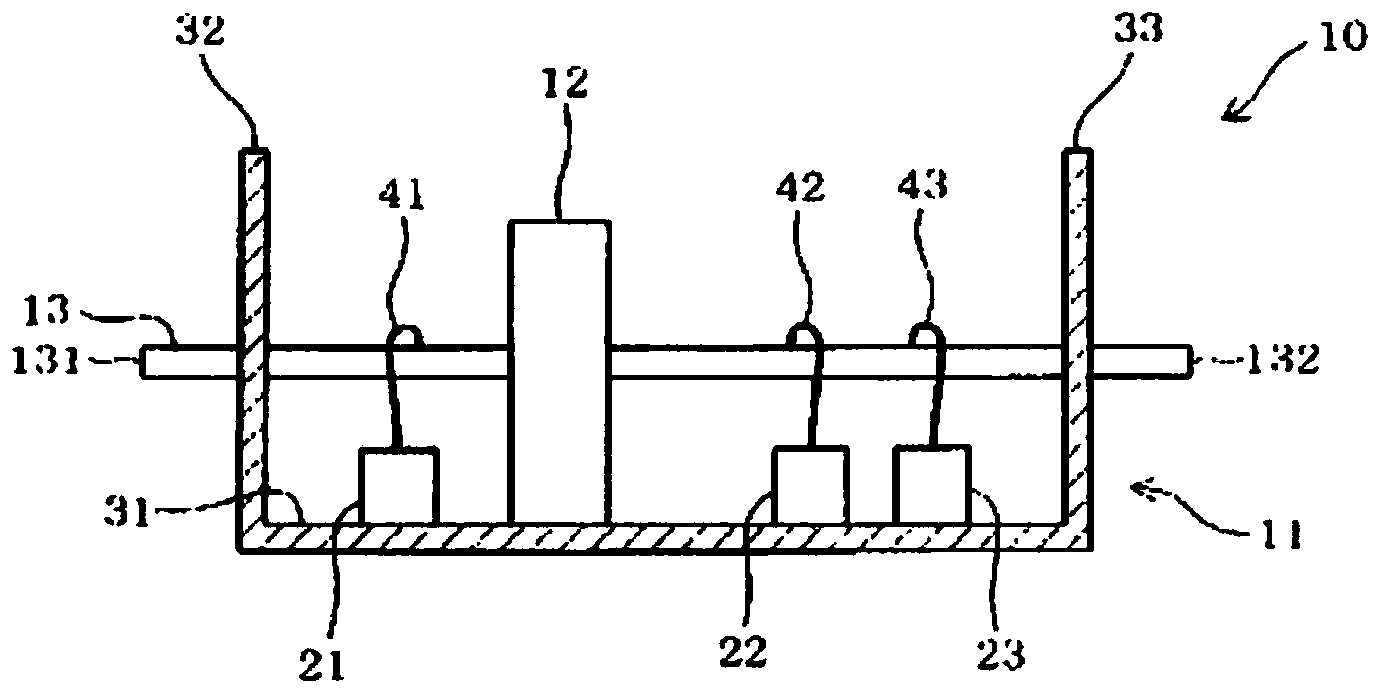

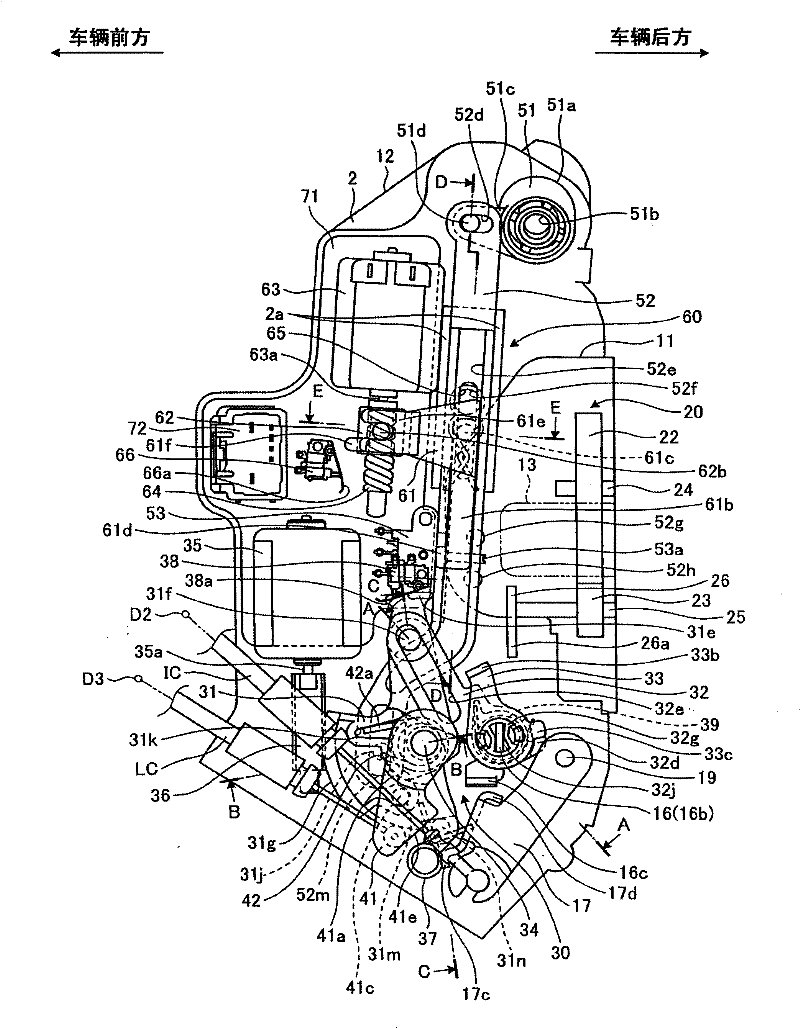

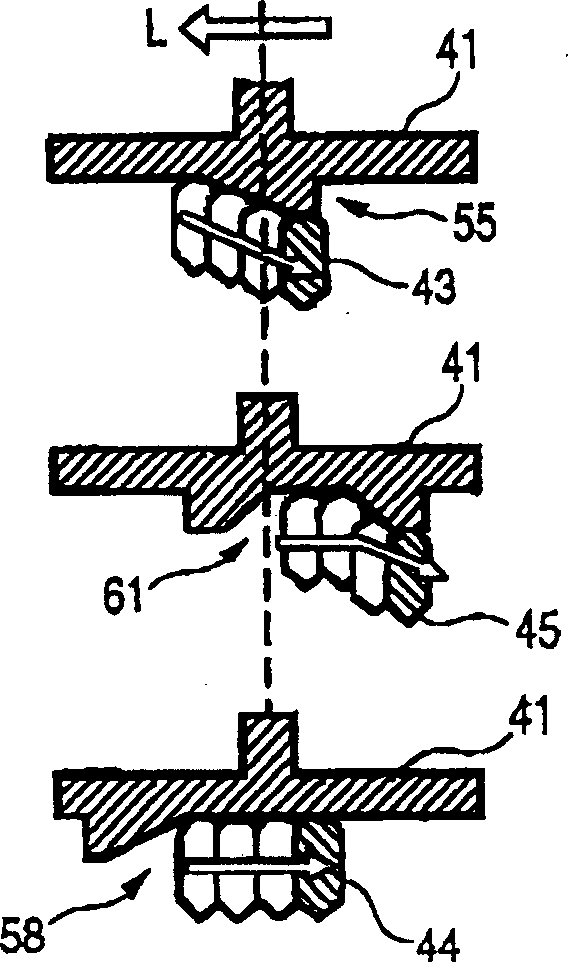

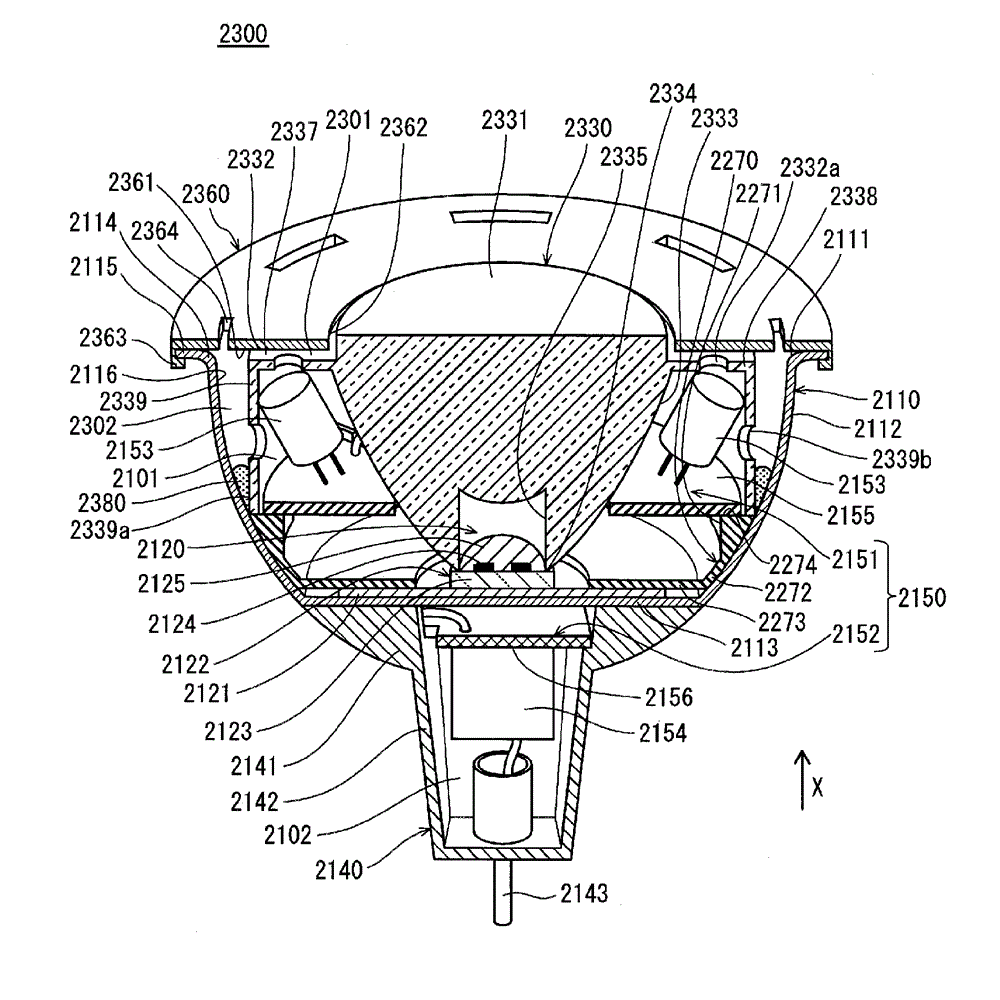

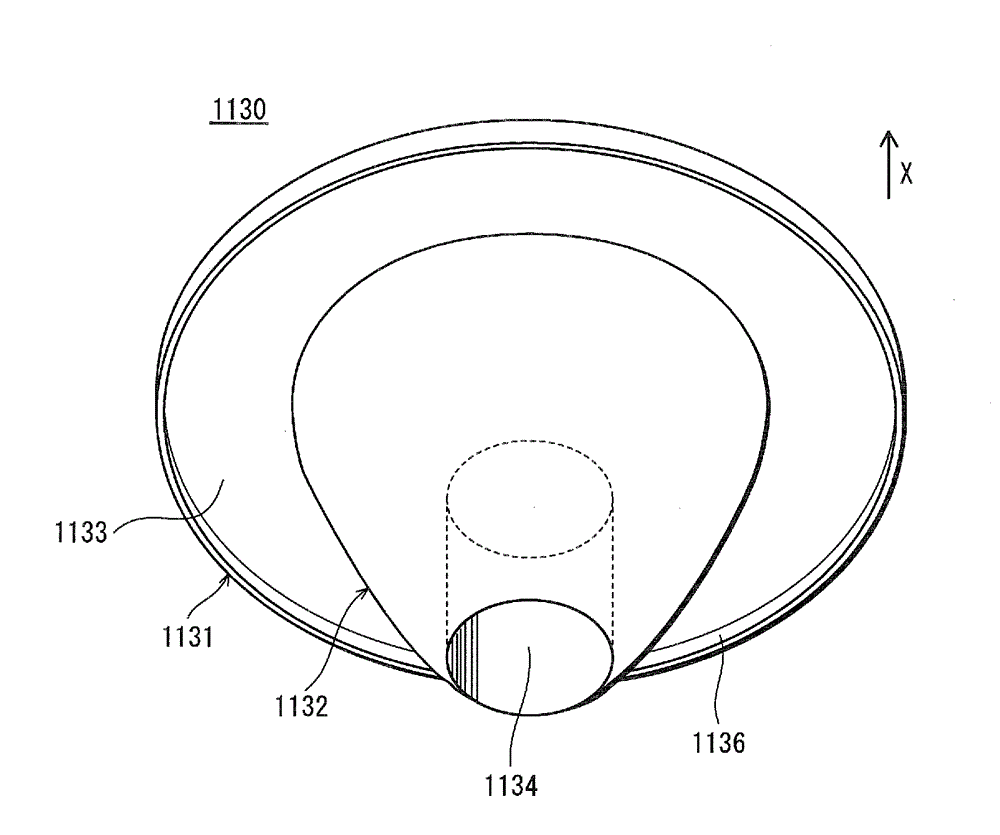

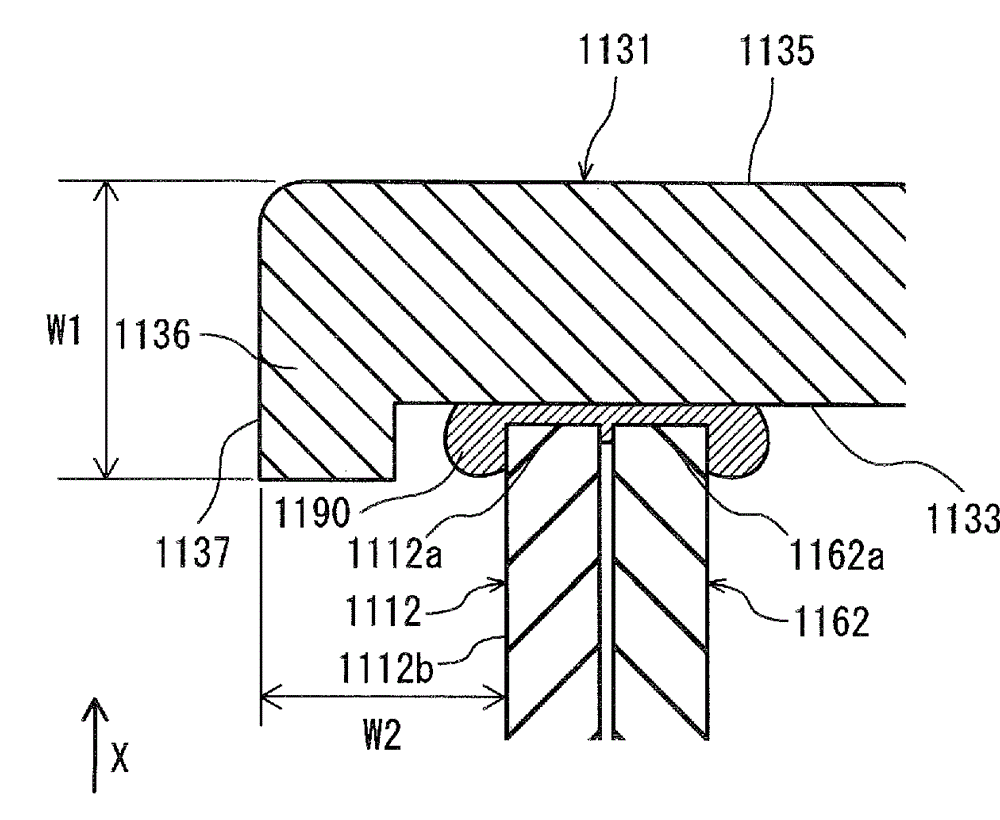

Back massage device provided to chair type massage machine and chair type massage machine with same

ActiveCN102149360ADoes not lead to largeDoes not lead to complexityVibration massageRoller massageMassagePhysical therapy

A back massage device capable of causing a massage mechanism to protrude forward and returning the massage mechanism to the original position, wherein the back massage device is configured so that the massage effect does not deteriorate, the massage mechanism can be moved forward and backward a sufficient amount, and the back massage device is not mechanically large and complex. A back massage device (4) provided to a chair type massage machine (1) is provided with: a massage mechanism (10) having a pair of left and right massage members (17); a base member (12) for pivotably supporting the mechanisms (10) at the lower end side thereof; a vertical movement mechanism (13) for vertically moving the base member (12); an extension / retraction operation mechanism (14) for driving and rocking the massage mechanism (10); and a rocking limiting mechanism (15) for limiting the pivoting angle of the massage mechanism (10) so that, at a raised position, the upper ends of the massage members (17) protrude forward and, at a lowered position, the lower ends of the massage members protrude forward.

Owner:DAITO ELECTRIC MACHINE IND

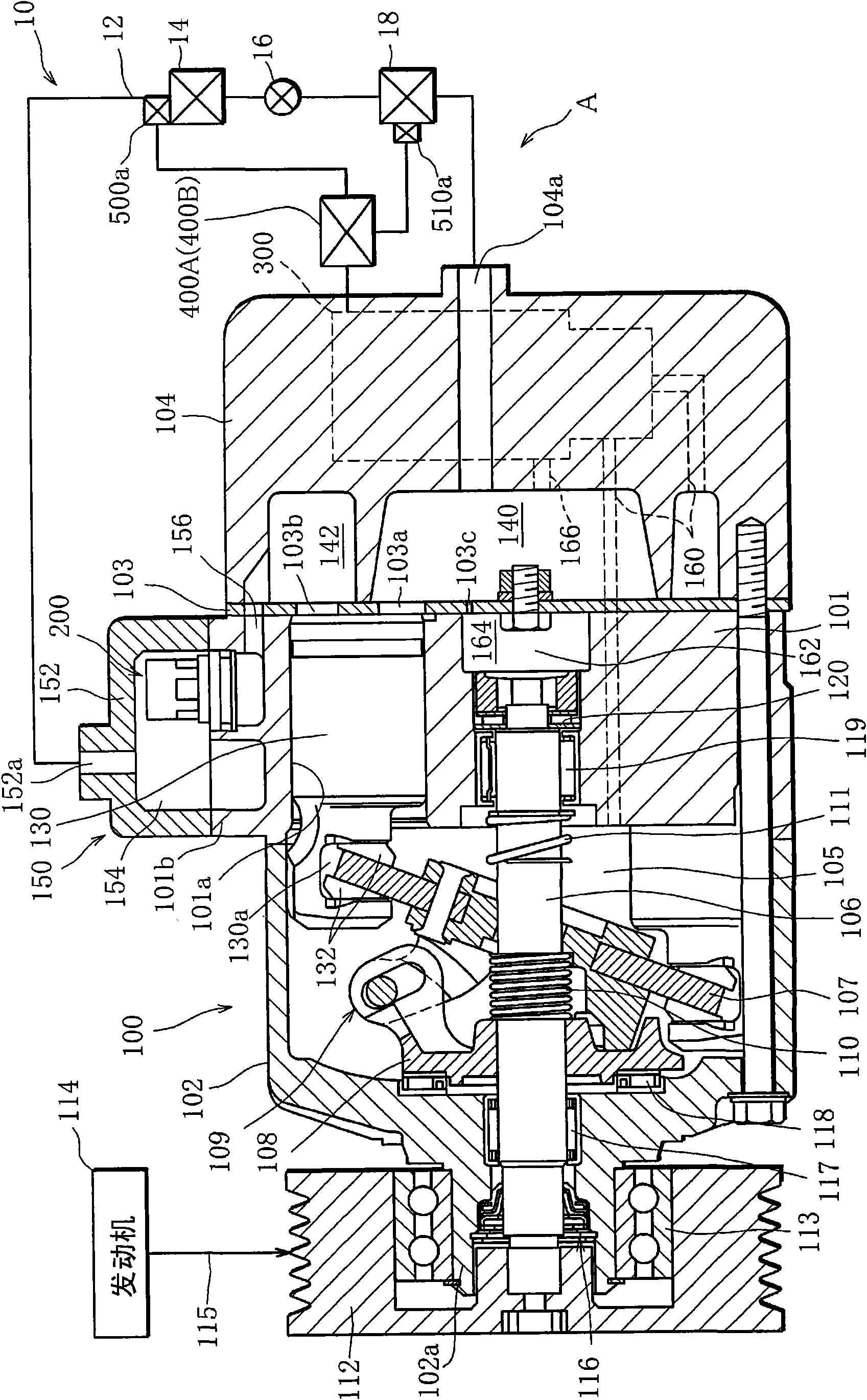

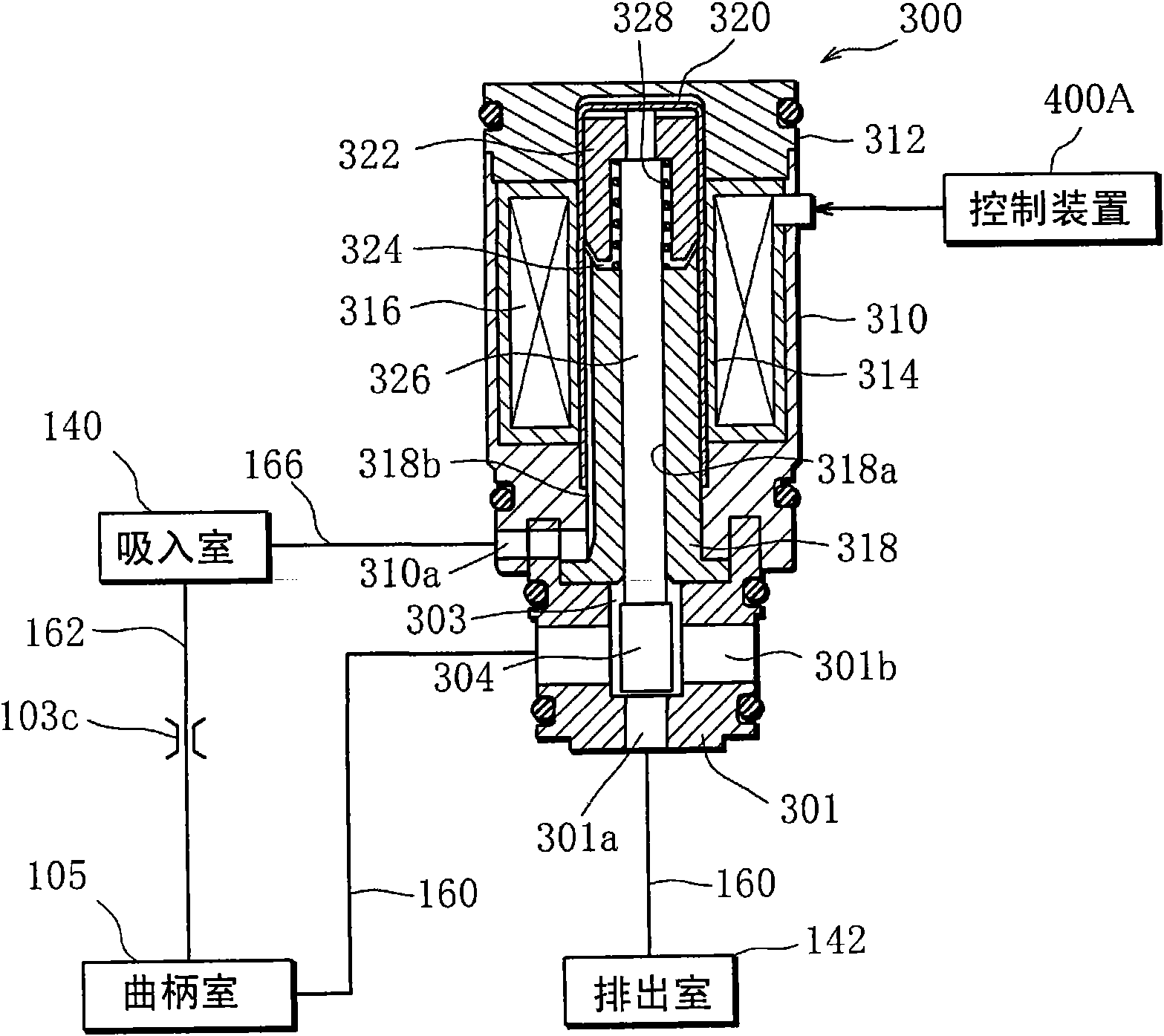

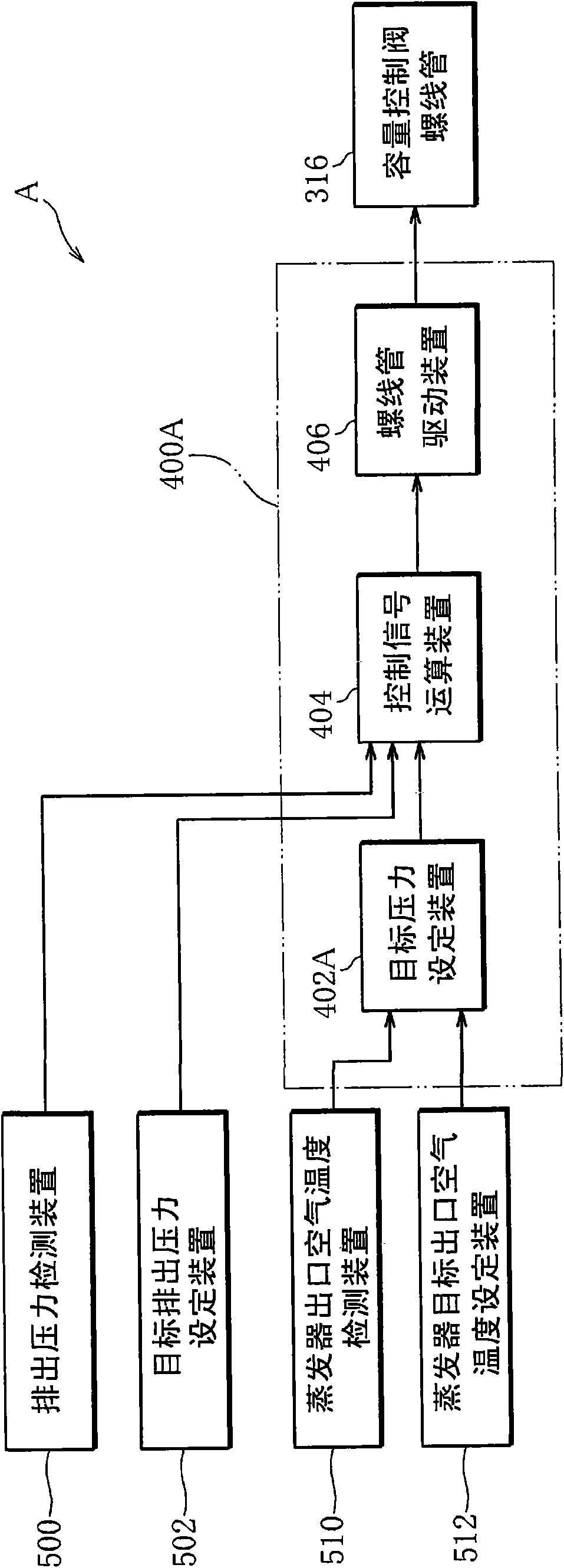

Displacement control system for variable displacement compressor

ActiveCN101605990AComfort adjustment stateOptimum Discharge Capacity ControlAir-treating devicesCompression machines with non-reversible cycleControl systemEngineering

A discharge displacement control system (A) of a variable displacement compressor has target pressure setting means (402A), discharge pressure detection means (500), and electric current regulation means (404, 406). The target pressure setting means (402A) sets a target of either the pressure in a suction chamber or the pressure in a crank chamber based on a target air temperature at the evaporator exit detected by means (510) for detecting the air temperature at the evaporator exit and on a target air temperature at the evaporator exit set by means (512) for setting a target air temperature at the evaporator exit. The discharge pressure detection means (500) detects the pressure of refrigerant in a high-pressure region. The electric current regulation means (404, 406) regulate, based on both the pressure of the refrigerant in the high-pressure region detected by the discharge pressure detection means (500) and the target pressure set by the target pressure setting means (402A), electric current supplied to a solenoid (316) of a displacement control valve.

Owner:SANDEN CO LTD

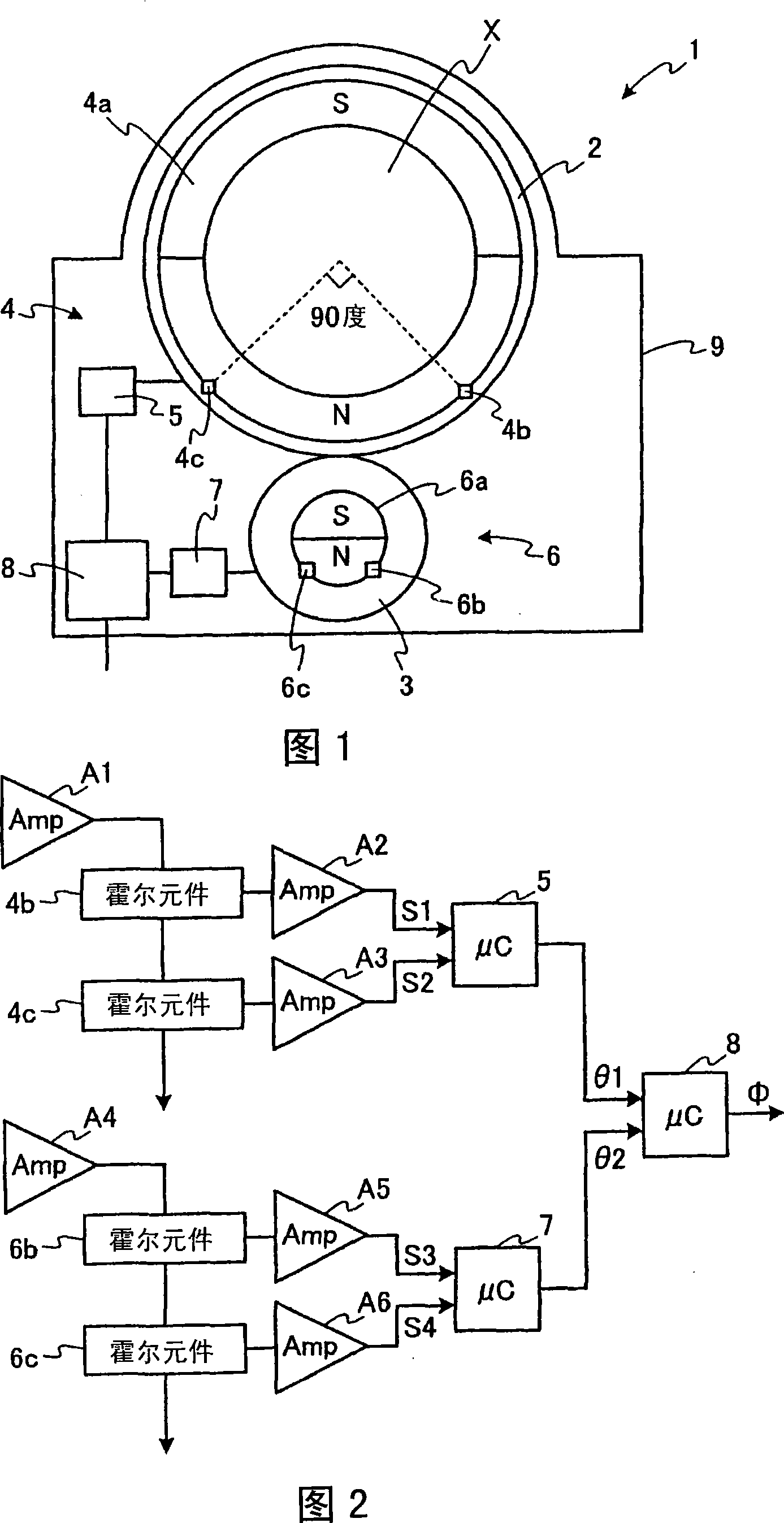

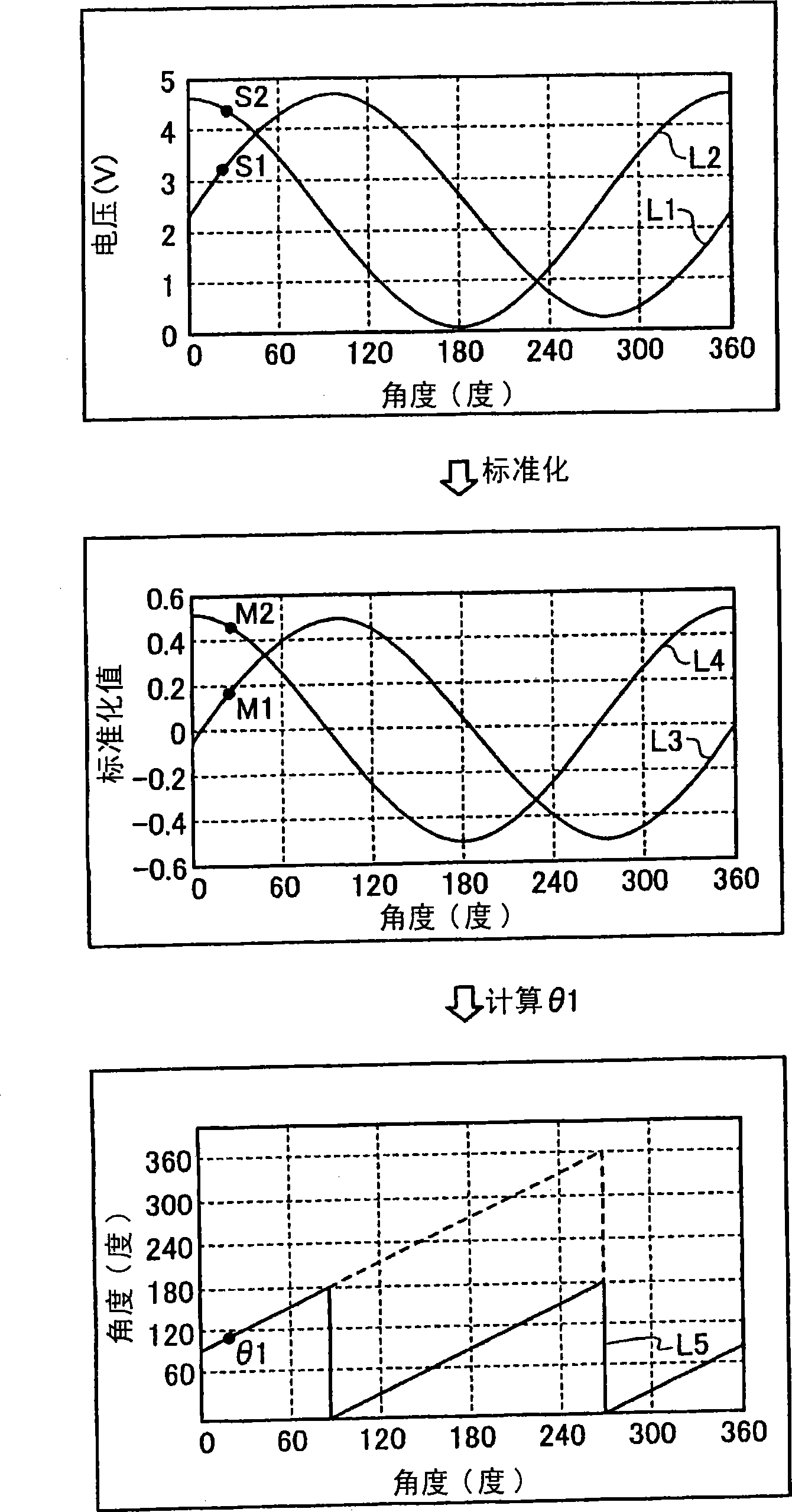

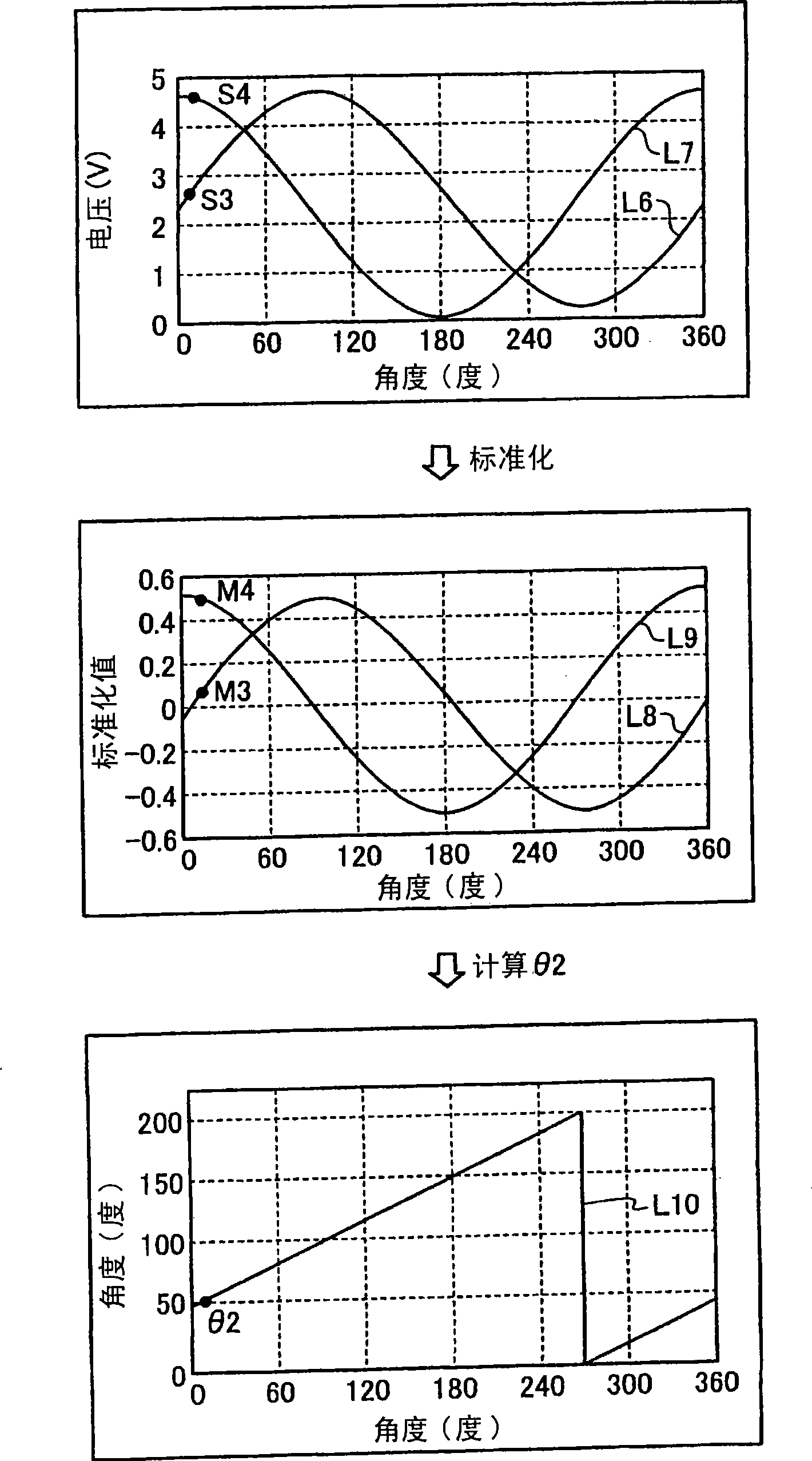

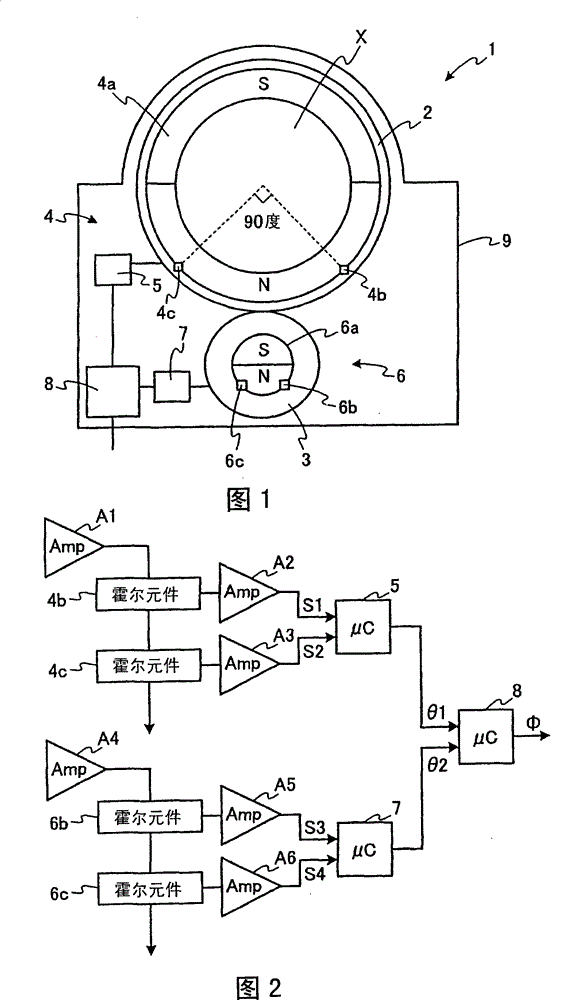

Rotation angle detector

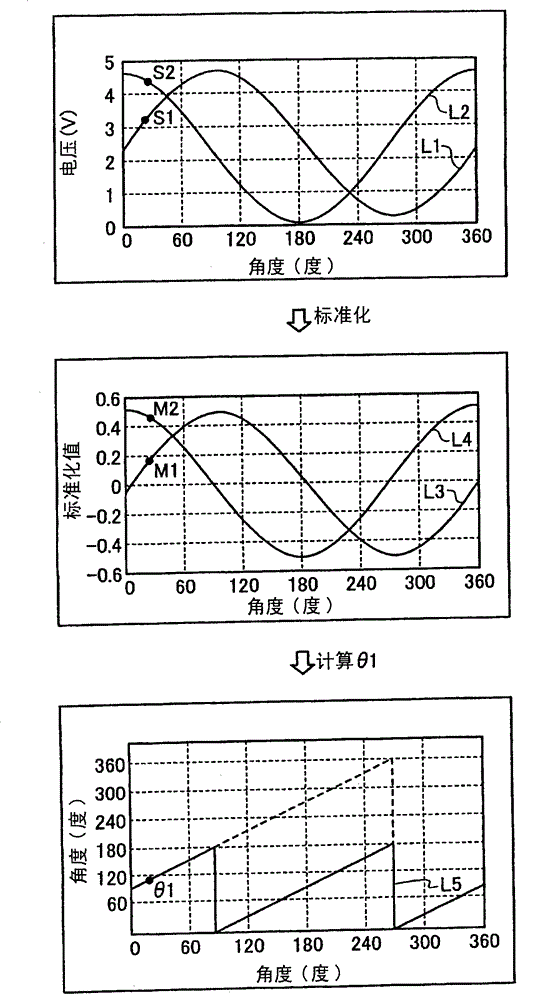

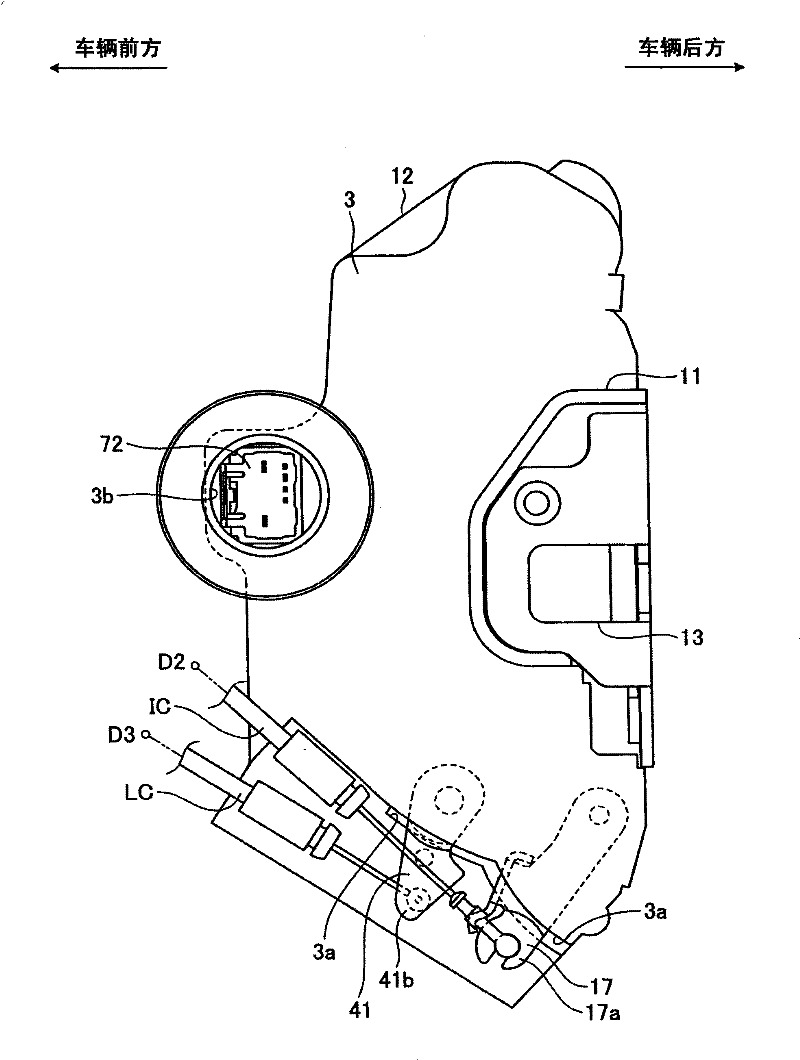

InactiveCN101466996AIncreased Design FreedomWide range of detection anglesUsing electrical meansConverting sensor output electrically/magneticallySolid of revolutionClassical mechanics

A rotation angle detector for detecting a rotation angle of a detectable rotation body, comprises: a primary rotation body to be attached to the detectable rotation body and to rotate as integral with the detectable rotation body; a secondary rotation body to rotate as a predetermined rotation ratio for the primary rotation body; a primary rotation detection mechanism to output a signal to be varied periodically as corresponding to a rotation of the primary rotation body; a secondary rotation detection mechanism to output a signal to be varied periodically as corresponding to a rotation of the secondary rotation body; a signal processing unit to calculate the rotation angles of the primary and the secondary rotation bodies using the signals that the primary and the secondary rotation detection mechanisms output; and an operation processing unit to calculate the rotation angle of the detectable rotation body, based on the calculated rotation angle of the primary or of the secondary rotation body, and on a relative rotation angle between the primary and the secondary rotation body, wherein at least any one of the following signals (A) to (D) is designed to have a cycle as different from one cycle for one rotation of the primary rotation body or of the secondary rotation body; (A) an output signal of the primary rotation detection mechanism; (B) an output signal of the secondary rotation detection mechanism; (C) an input signal from the primary rotation detection mechanism to be processed at the signal processing unit; and (D) an input signal from the secondary rotation detection mechanism to be processed at the signal processing unit.

Owner:FURUKAWA ELECTRIC CO LTD

Electric valve

ActiveCN101220884ANo frictional resistanceIncrease frictional resistanceOperating means/releasing devices for valvesFluid circulation arrangementVALVE PORTValve seat

The invention provides an electro valve of which the valve core comprises: a basal body which is fixed with a taper valve part, a major diameter shaft part, a minor diameter shaft part and a flange part located on a valve seat in turns from the lower; and a collar hanger component whcih is lagged on the minor diameter shaft part of the basal body in a relative move and rotation state in an axial direction, and stopped by a tubby stop part fixed on a valve support to support the lower end of a helical compression spring. When the valve support is located in a lowest position, the undersurface of the collar hanger component is press bonded on a step surface at upper of the major diameter shaft part of the basal body, while a defined gap is formed beteen the undersuface of the collar hanger component and the upper surface of the stop part. When the rotor and the valve support rotates a defined amount from the lowest position, the upper surface of the tubby stop part abuts on the undersurface of the collar hanger component, and the collar hanger component aparts from the upper step surface of the major diameter shaft part; and when the rotor and the valve support further rotates, the collar hanger component pushes the flange part up. The invention can redece the frictional resistance of the structural member, reduce the drive torque needed for opening the valve, obtain a simple structure with a fewer components, and reduce the cost of the device.

Owner:FUJIKOKI MFG CO LTD

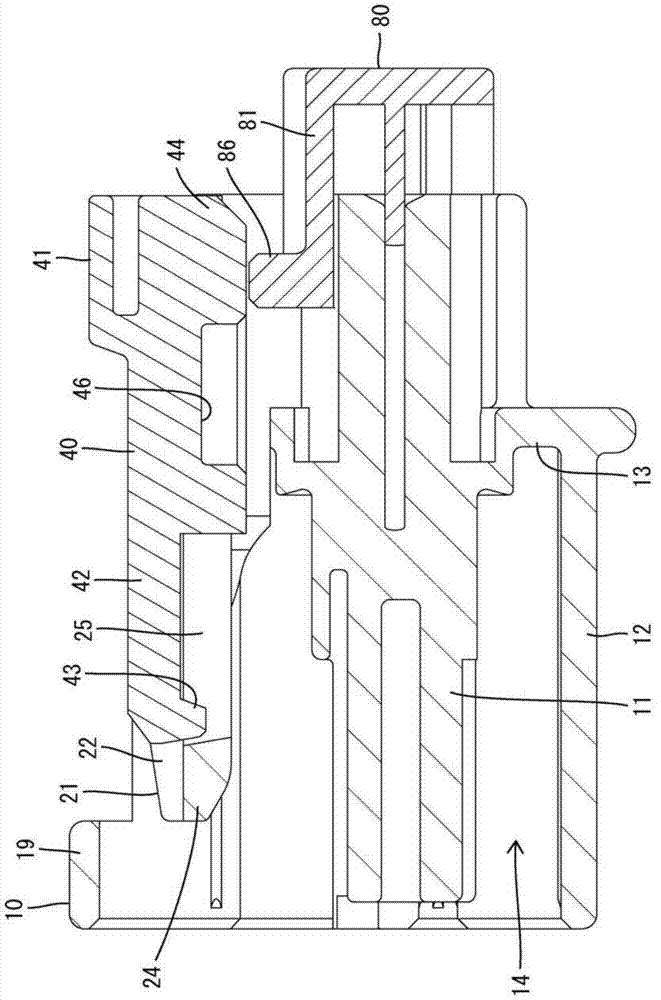

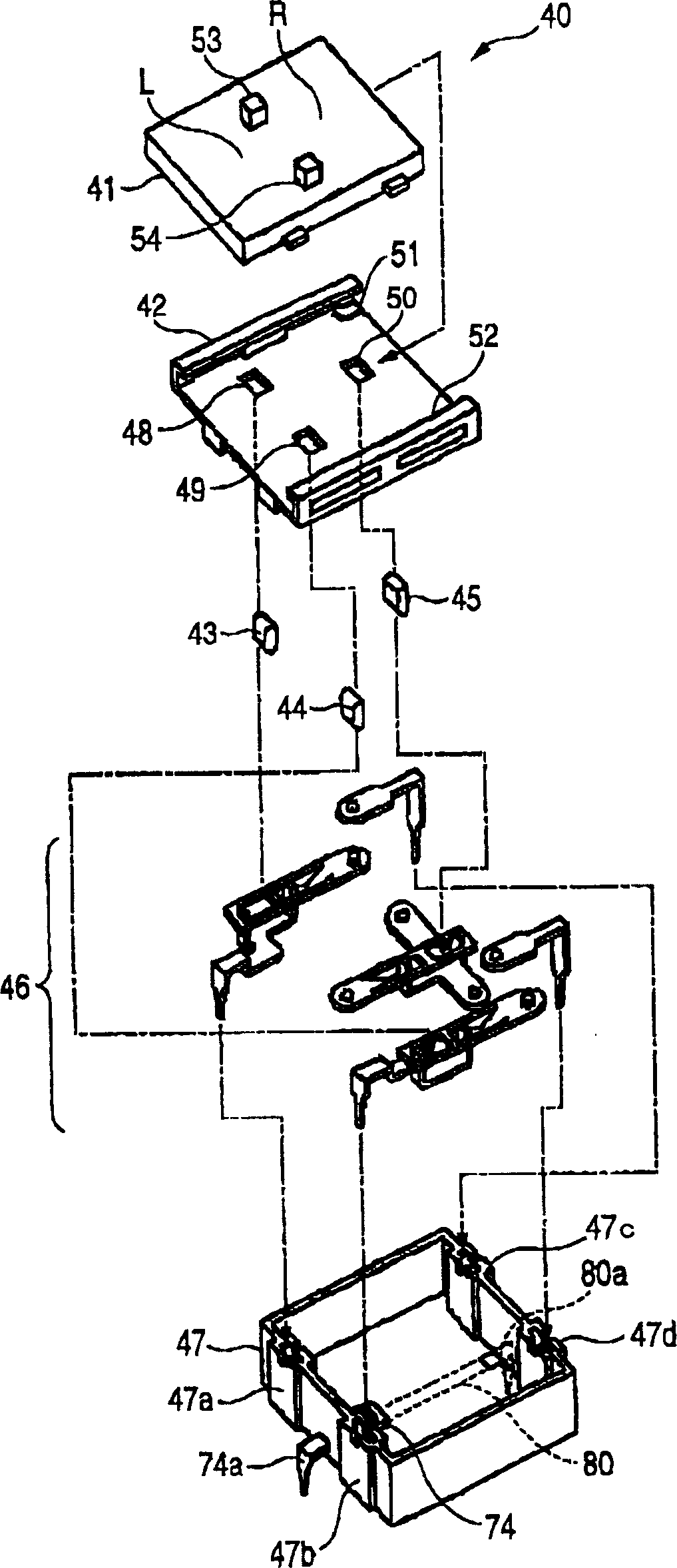

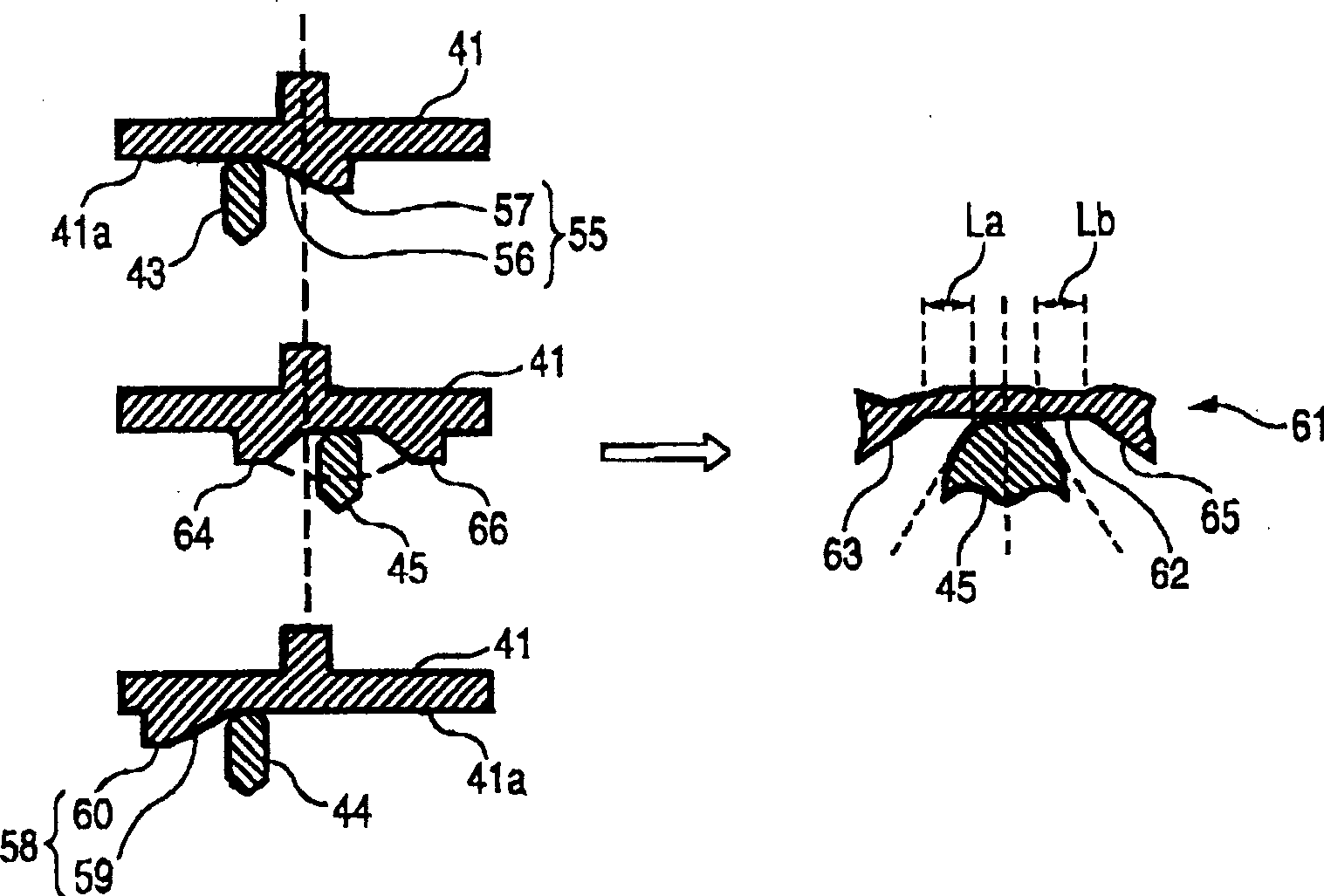

Connector

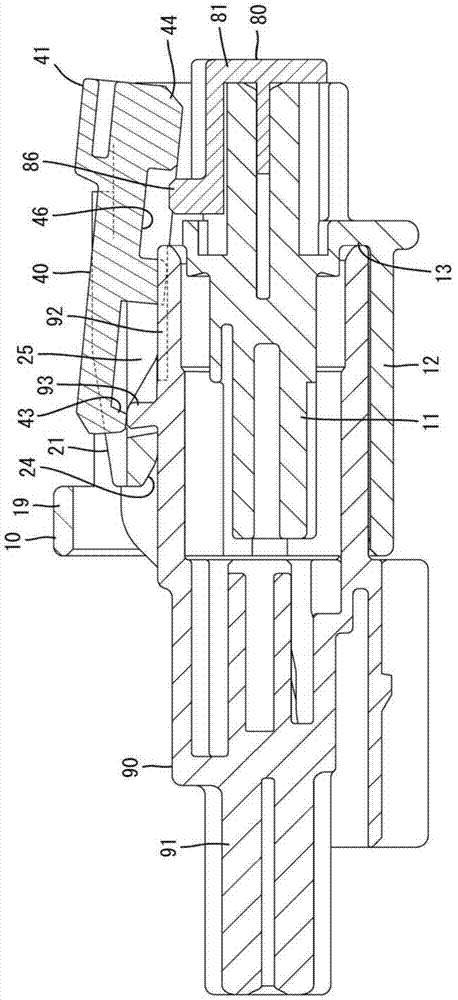

ActiveCN104518362ADoes not lead to largeDoes not lead to complexityIncorrect coupling preventionEngineeringLarge size

The invention discloses a connector which can prevent a detection component from moving freely on the basis of avoiding large size and complexity of a housing. The detection component (40) can be assembled to the housing (10) in the manner of moving between an initial position and a detection position. The detection component is bent and deformed in the process of moving from the initial position to the detection position, and elastically reset in the detection position and maintain the state that the return movement to the initial position with respect to a locking arm (21) is limited. A retainer (80) is installed on the housing. A limiting part (86) is disposed on the retainer. In a state of being correctly installed to the housing, the limiting part (86) is configured in a position corresponding to a retreat part (46) of the detection component in the process when the detection component moves to the detection position from the initial position so as to allow bending of the detection component, and is configured in a position to be withdrawn from the retreat part when the detection component arrives the detection position so as to limit the bending of the detection component.

Owner:SUMITOMO WIRING SYST LTD

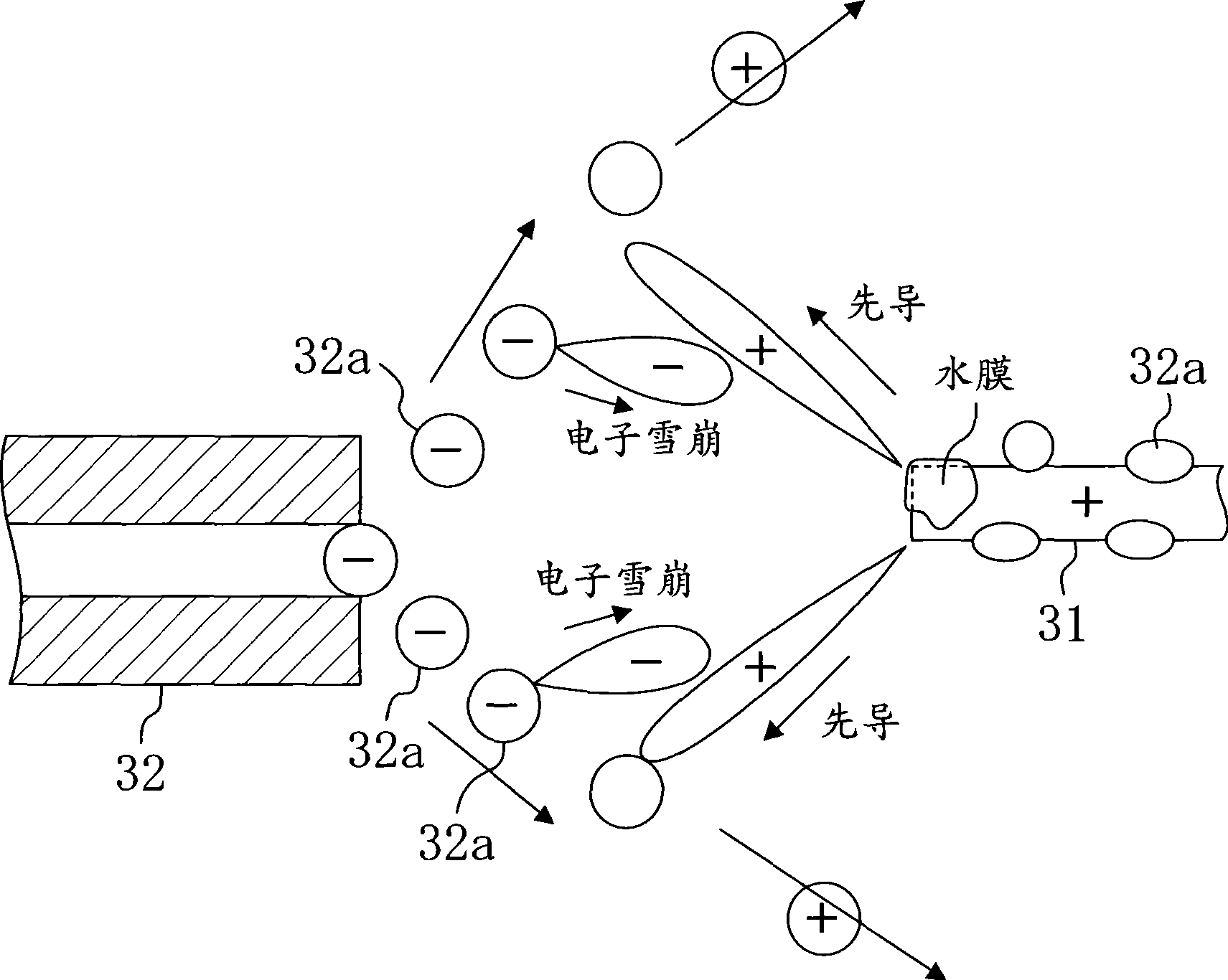

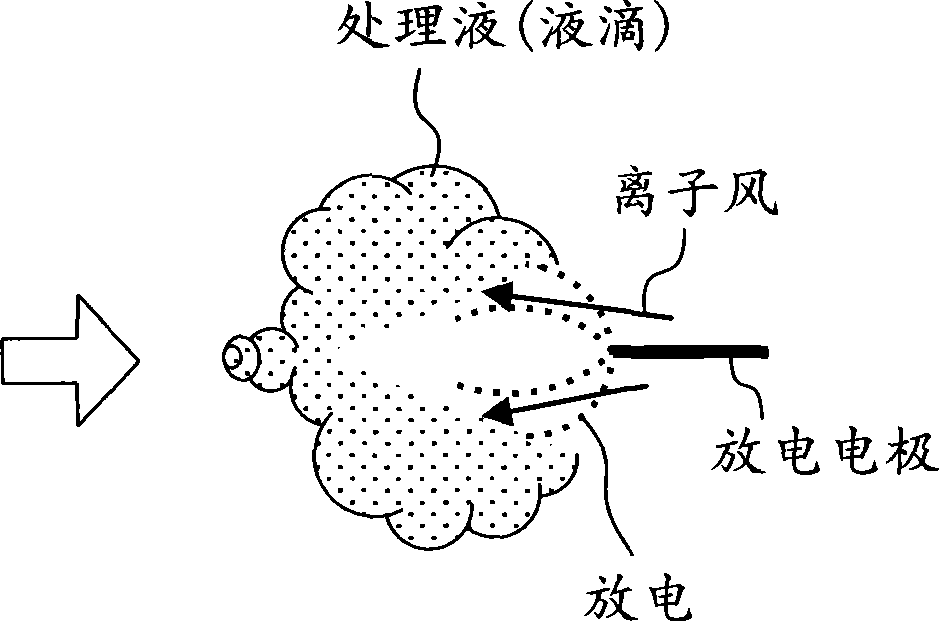

Liquid treating apparatus, air-conditioning apparatus, and humidifier

InactiveCN101466465AImprove purification effectEffectively eliminateAir treatment detailsCondensate preventionPotential differenceEnvironmental engineering

Owner:DAIKIN IND LTD

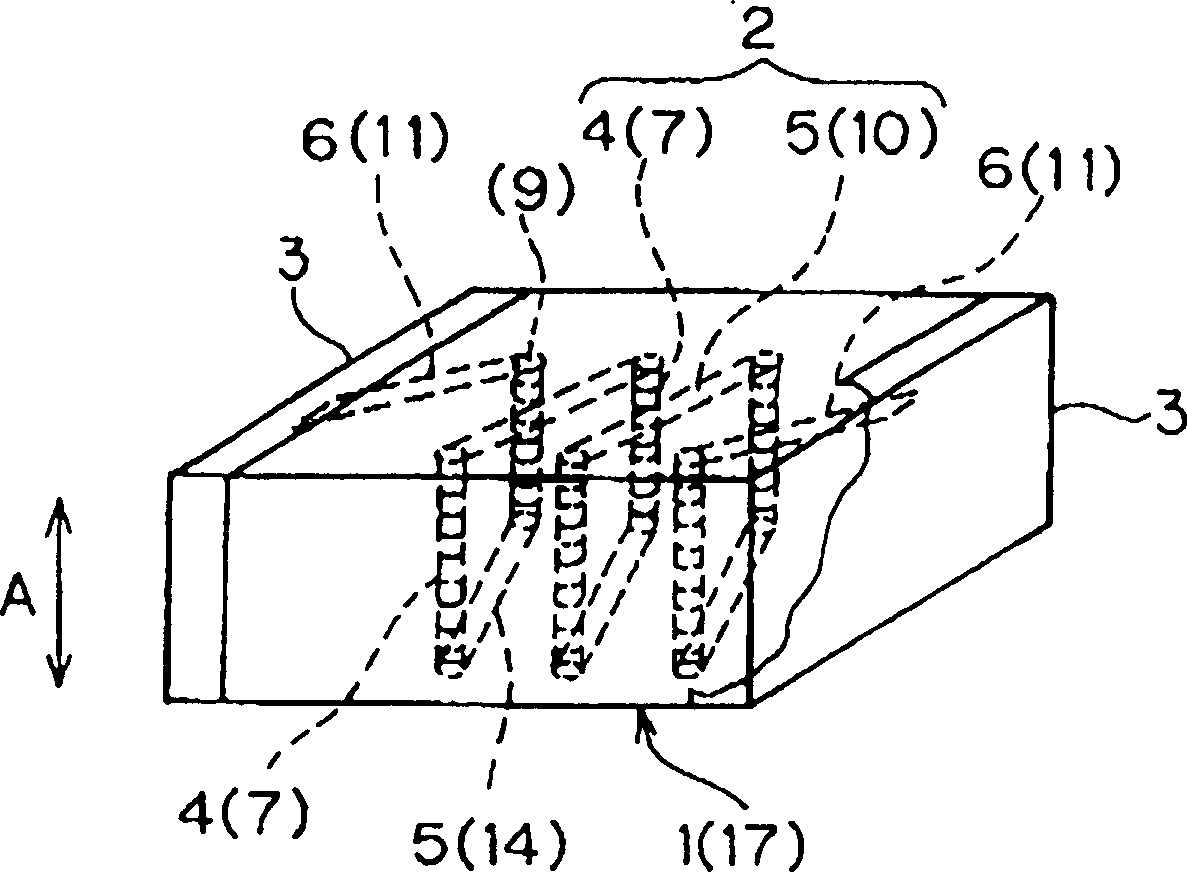

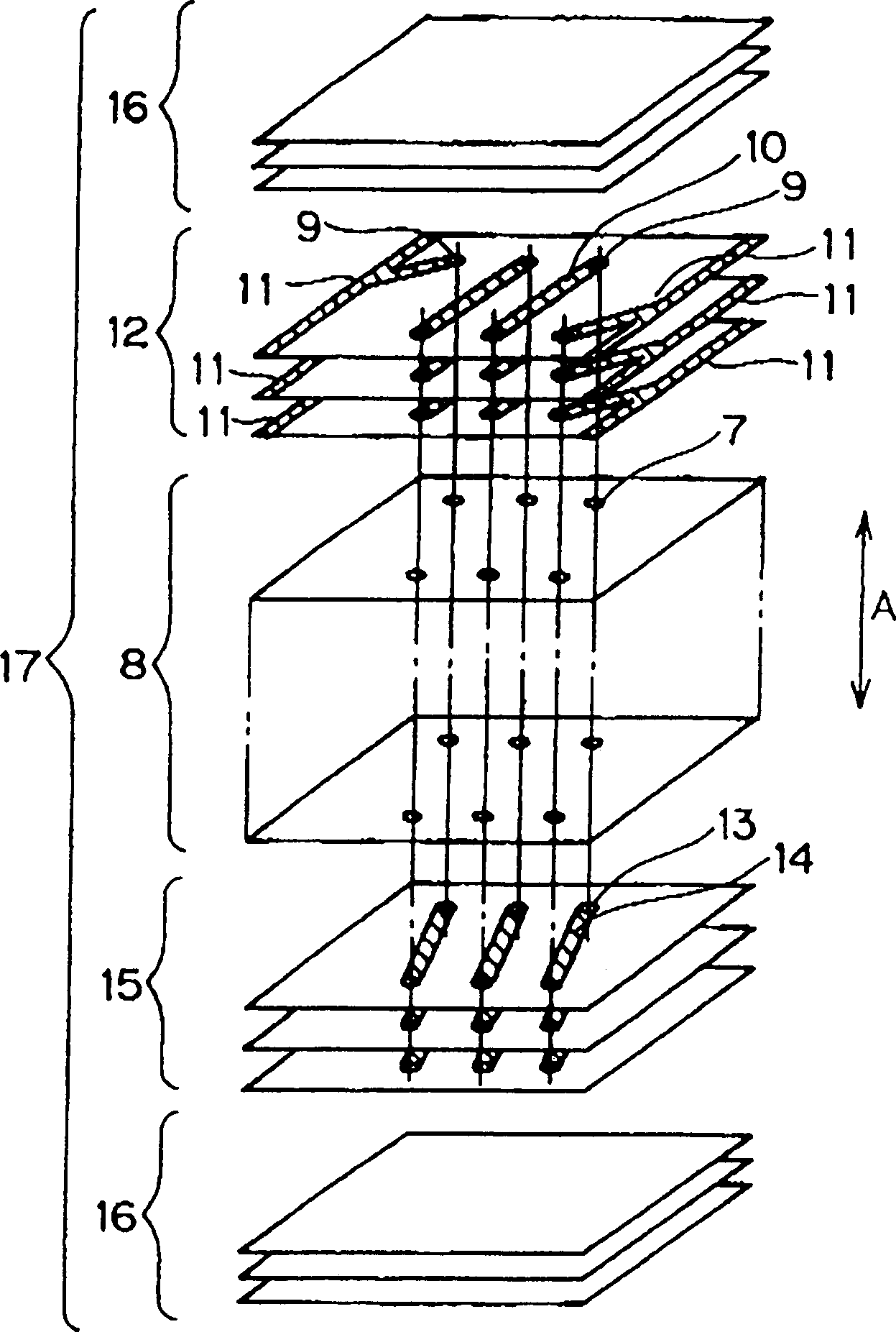

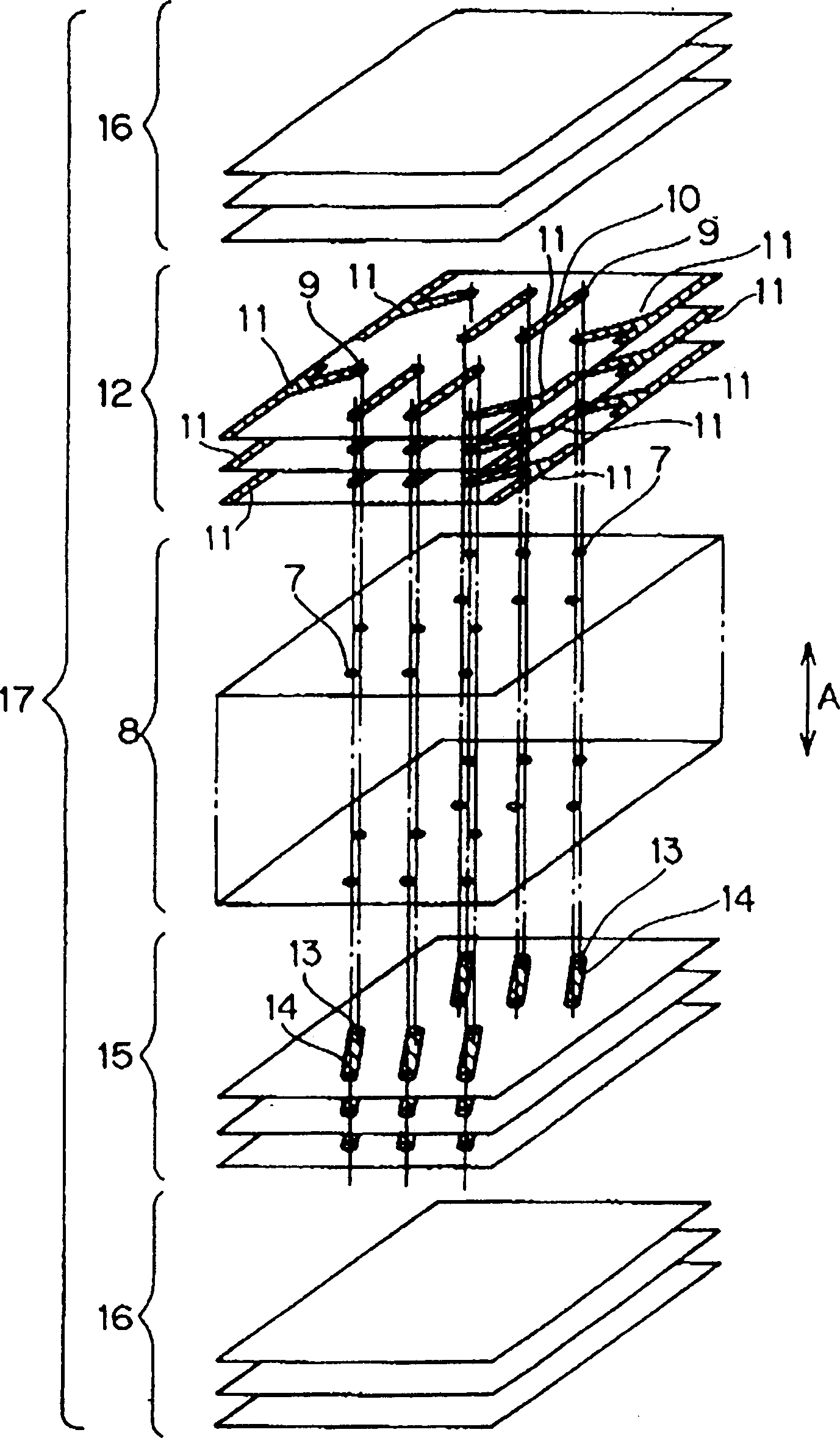

Laminated coil parts and production thereof

InactiveCN1175438CDoes not lead to largeLower resistanceMultiple-port networksTransformers/inductances magnetic coresManufacturing cost reductionElectrical conductor

The present invention provides a laminated coil part. A coil 2, the center axis of which crosses the direction of a lamination A at right angles, is formed by respectively connecting one and the other side end sections of a prescribed via hole of a plurality of via holes 4 provided in the element 1 (laminate), in the direction of lamination A, by belt-like connecting electrodes 5 having plural-layer structures and provided in the element 1, in parallel with the laminating surface (in the direction perpendicular to the direction of lamination A). At the same time, the coil 2 is connected to an external electrode 3 for inputting and outputting through a lead-out electrode 6, which has a plural-layer structure and are provided in parallel with the lamination surface. As a result, the structure is miniaturized, the conductor resistance is reduced and the cost is reduced.

Owner:MURATA MFG CO LTD

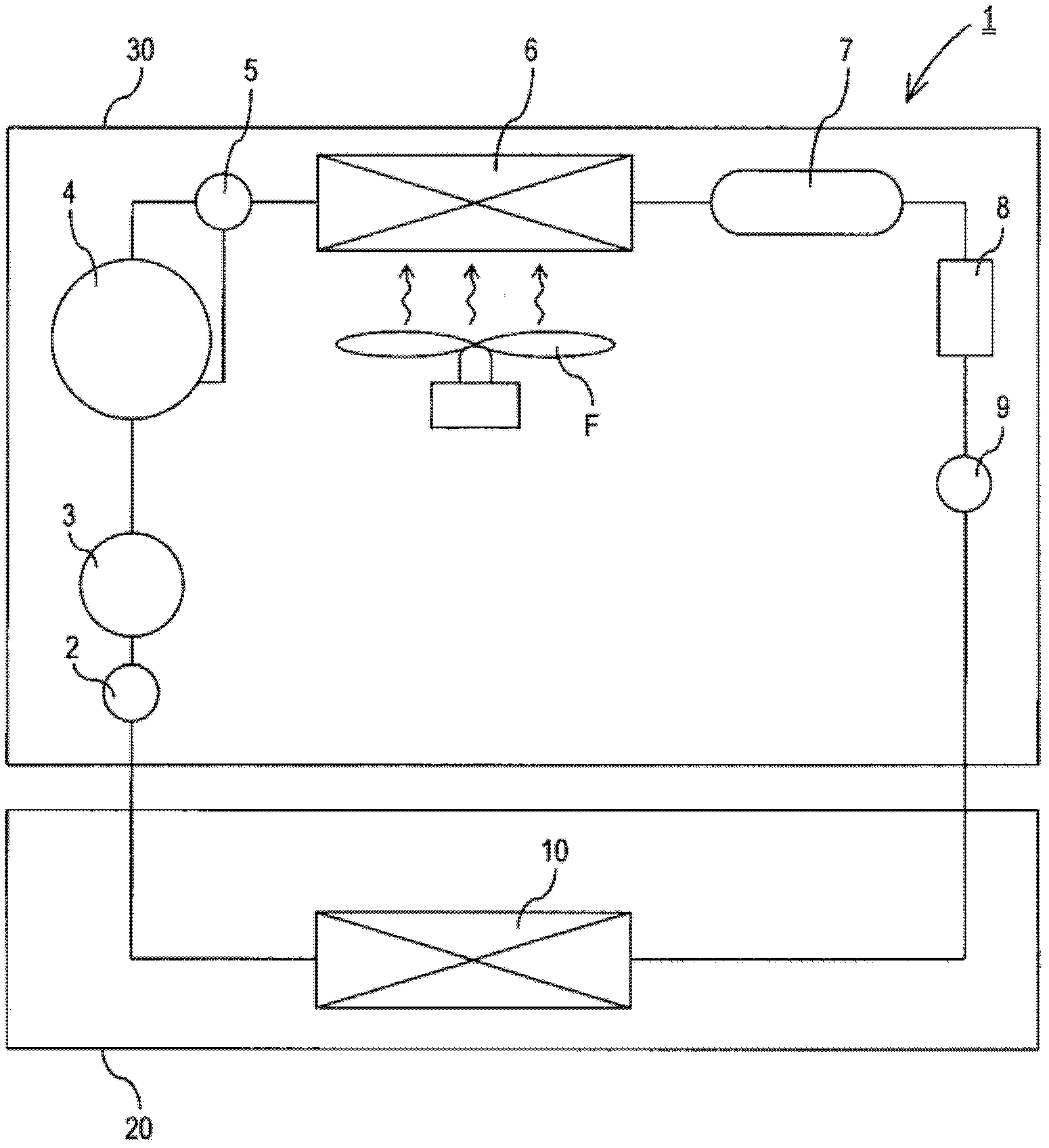

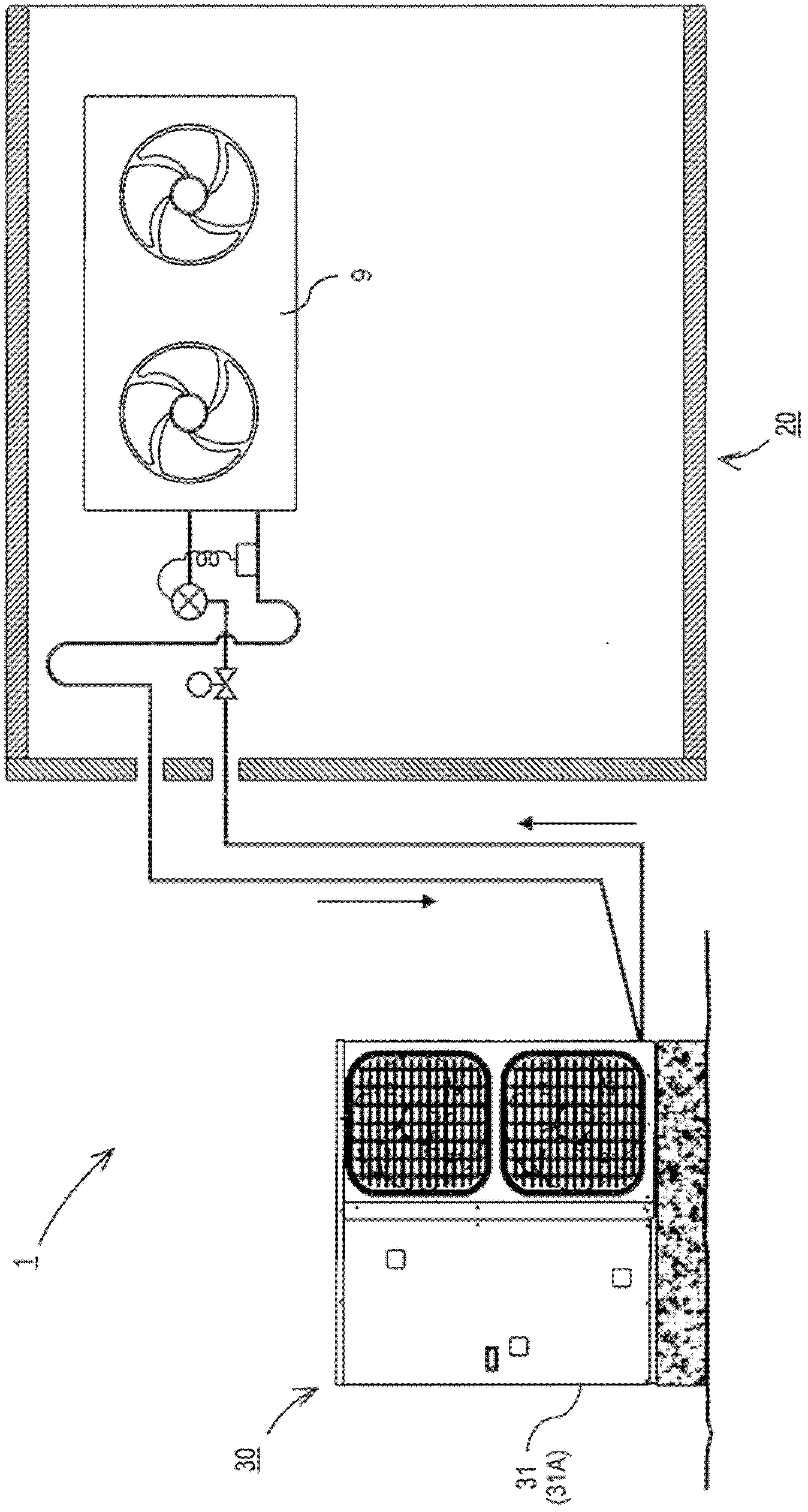

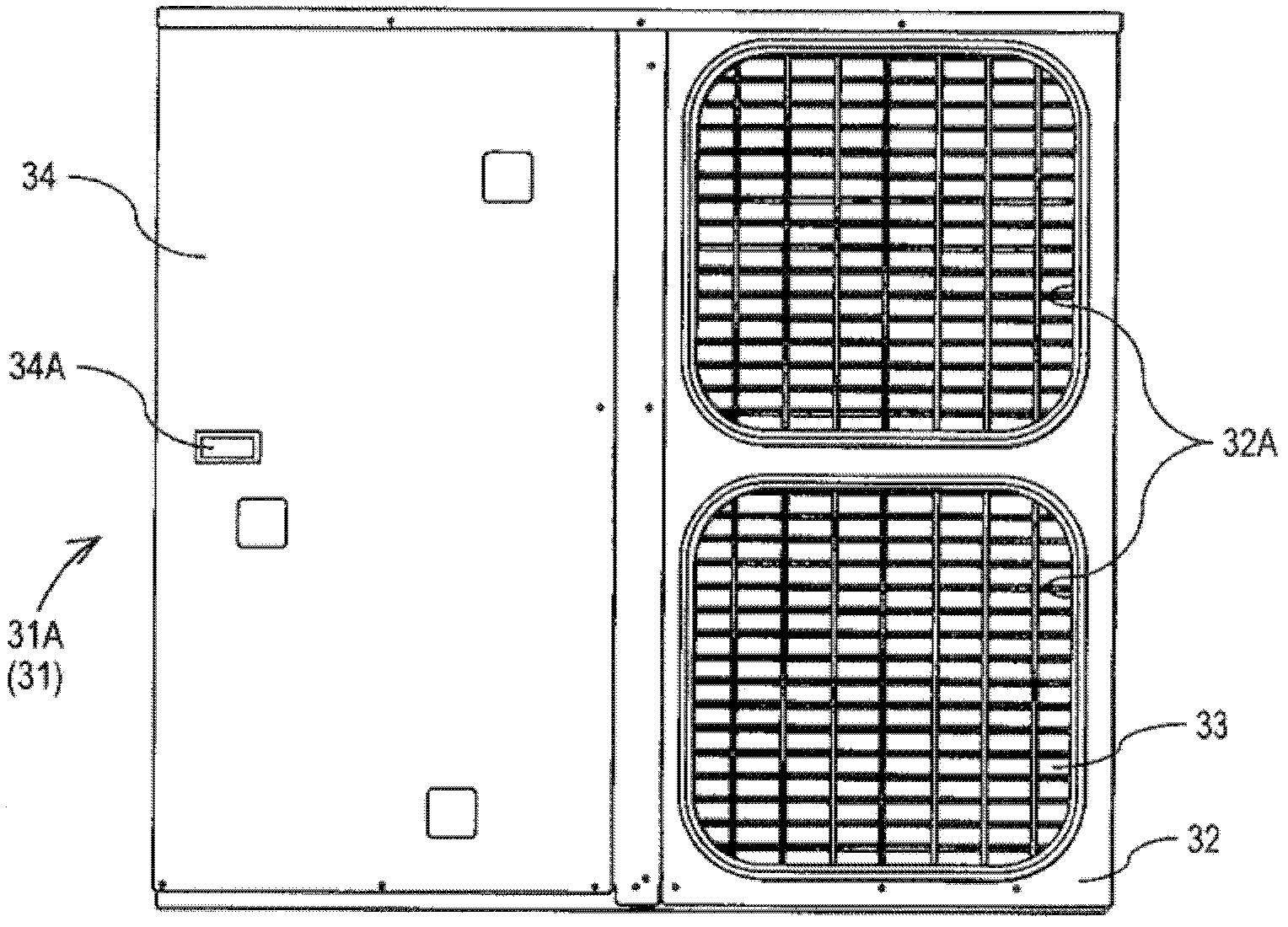

Outdoor unit and refrigerating device

InactiveCN102759212ADoes not lead to largeImprove cooling effectCompression machines with non-reversible cycleElectricityEngineering

The invention provides an outdoor unit and a refrigerating device. The heat dissipation effect can be achieved with low cost and without upsizing of a shell even a special heat dissipation device is not installed additionally. The inside of the shell (31) is provided with a fan chamber (A) which comprises an evaporator (10) and fans (F) for cooling the evaporator, a mechanical chamber (B) which at least comprises a compressor (4) and an accumulator (3), and an electric fitting chamber which is disposed in the upper space of the upper side of the mechanical chamber across a rack and receives various electric fitting components including a converter used for controlling operation of the compressor. The mechanical chamber and the electric fitting chamber are isolated from the fan chamber through a separator horizontally; external air sucked in from an external air suction hole disposed in a back panel of the shell and is an area facing the accumulator is cooled and flows out to the fan chamber through a rainproof exhaust part of the separator after finally flowing through the converter disposed in the innermost part of the electric fitting chamber.

Owner:SANYO ELECTRIC CO LTD

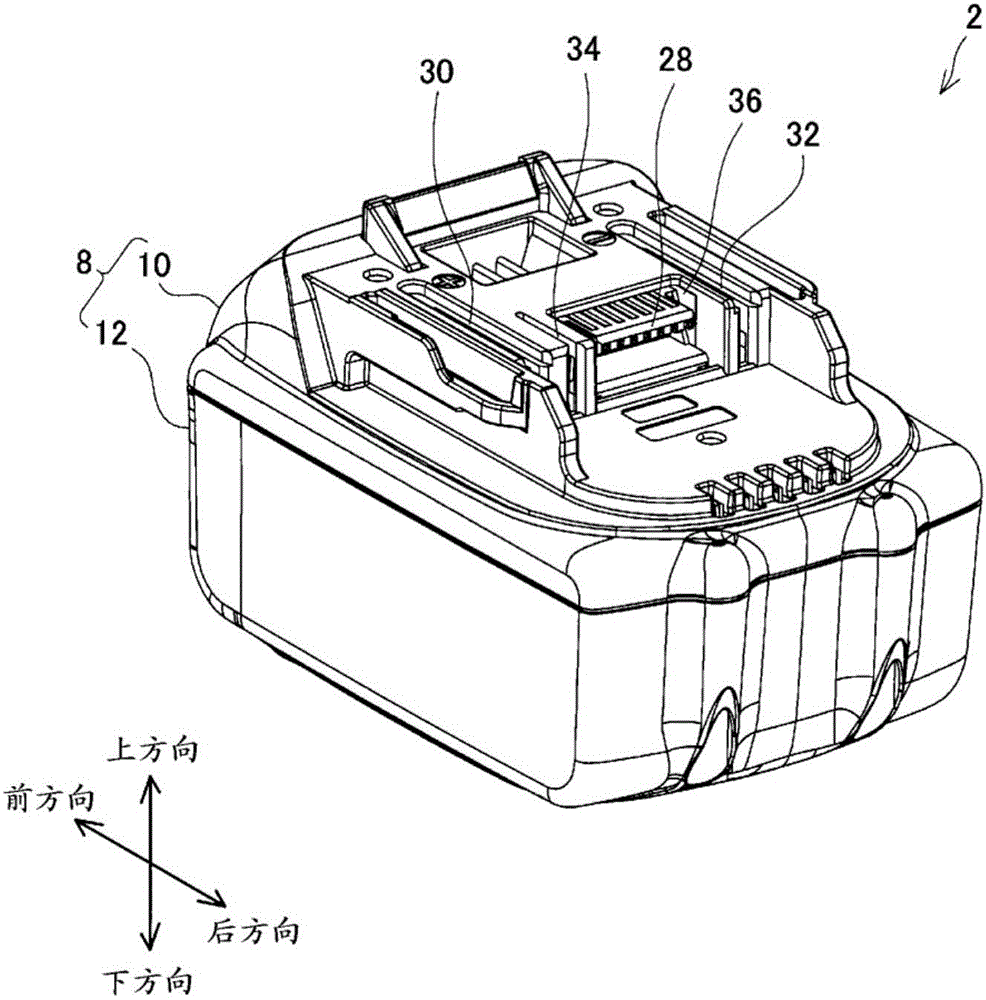

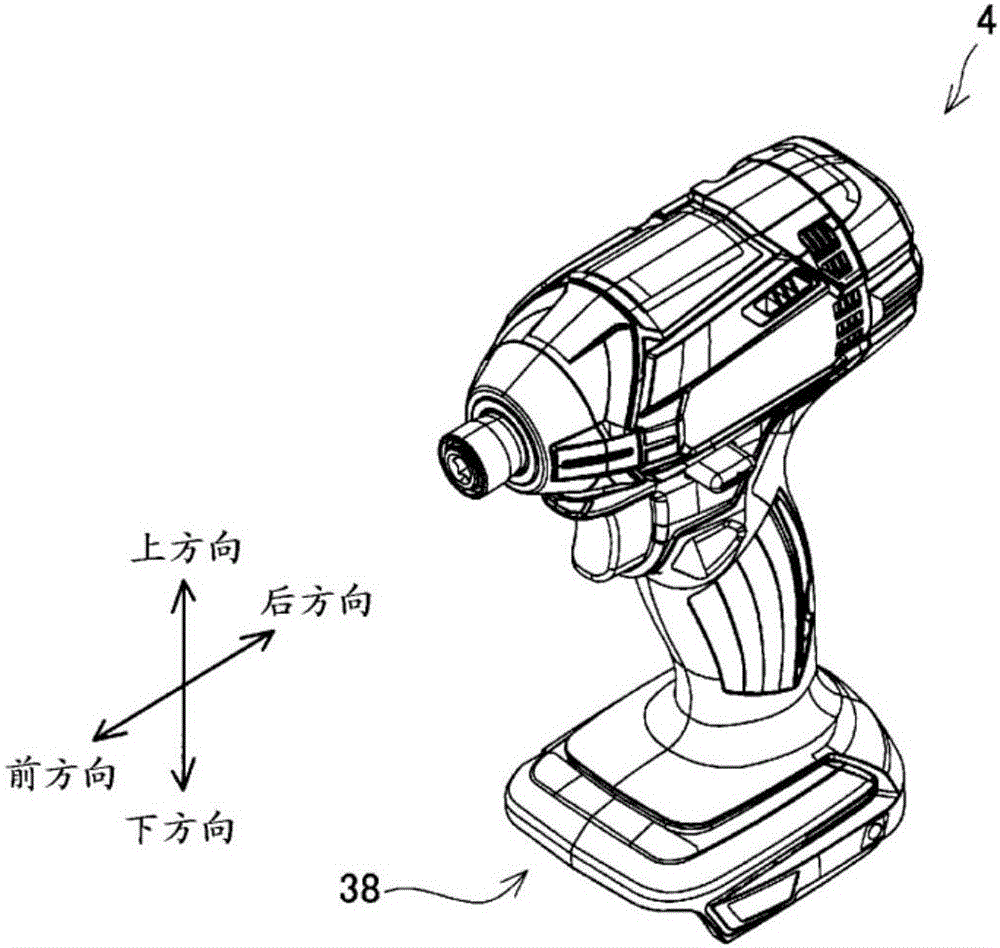

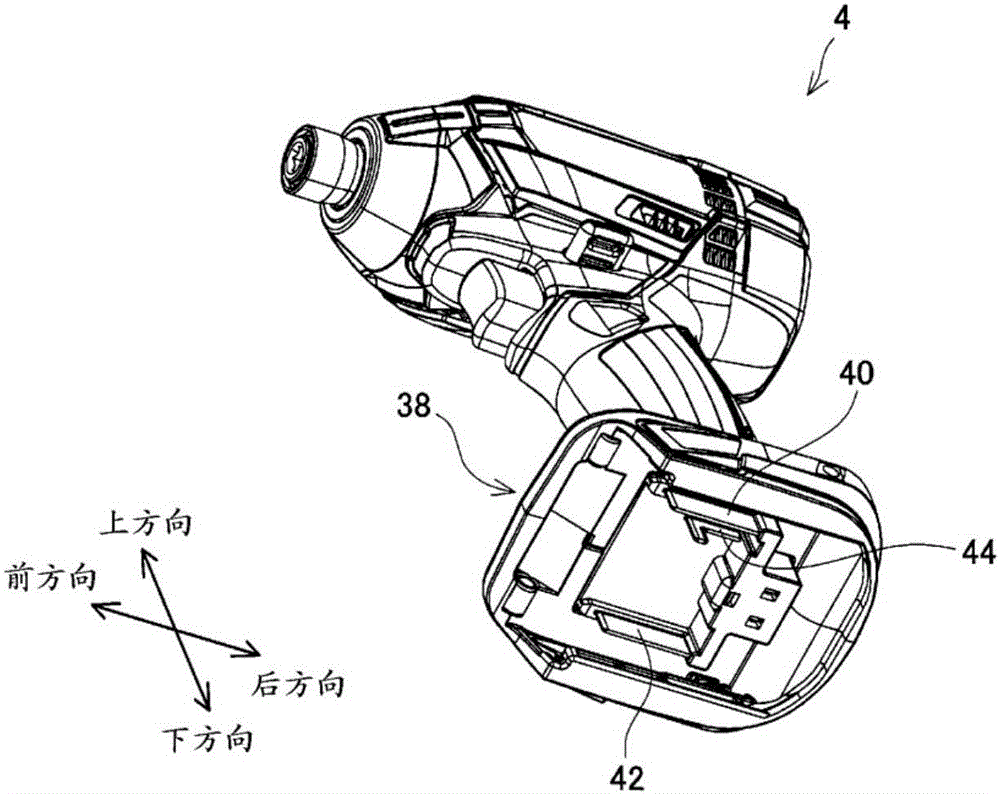

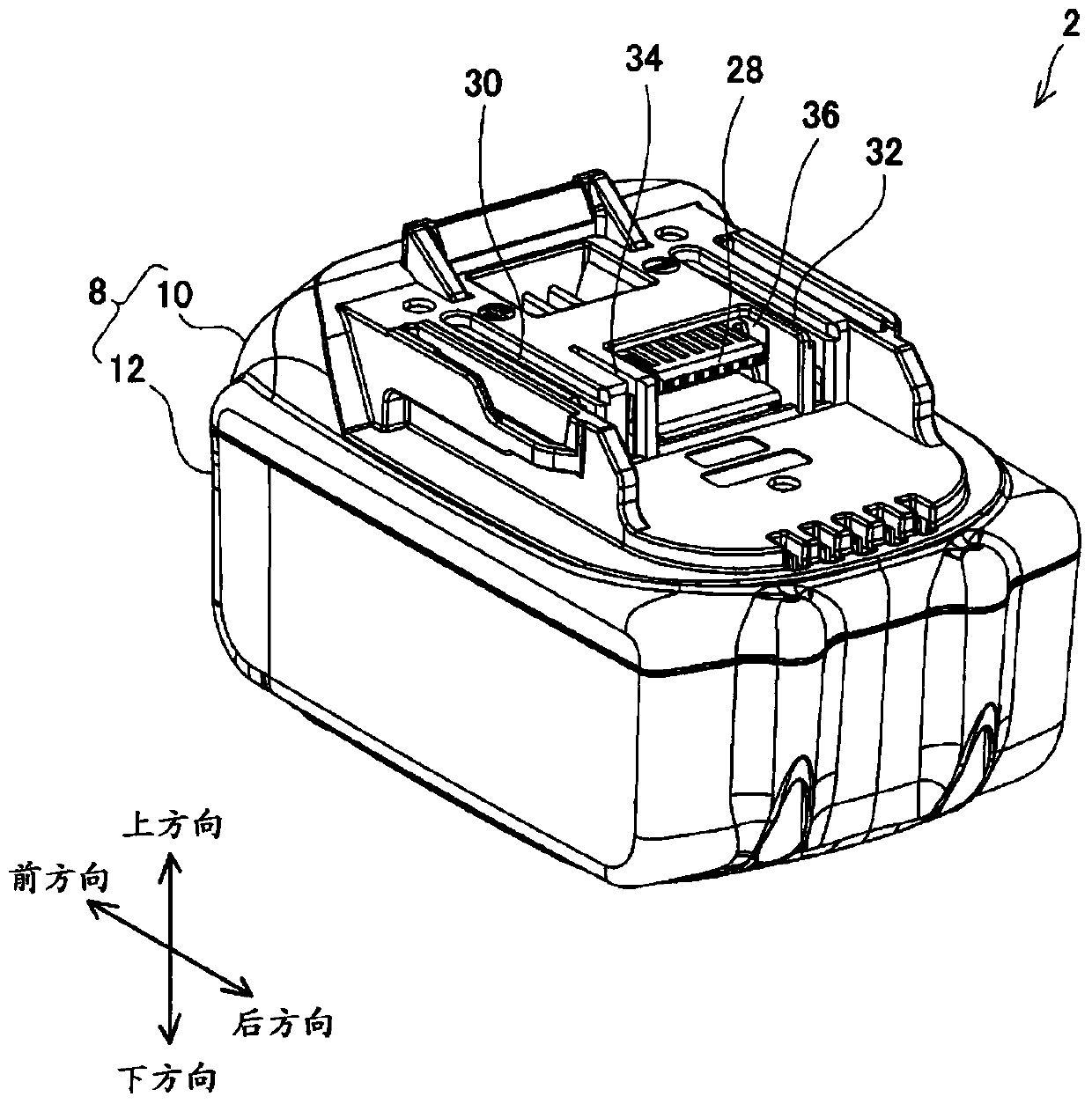

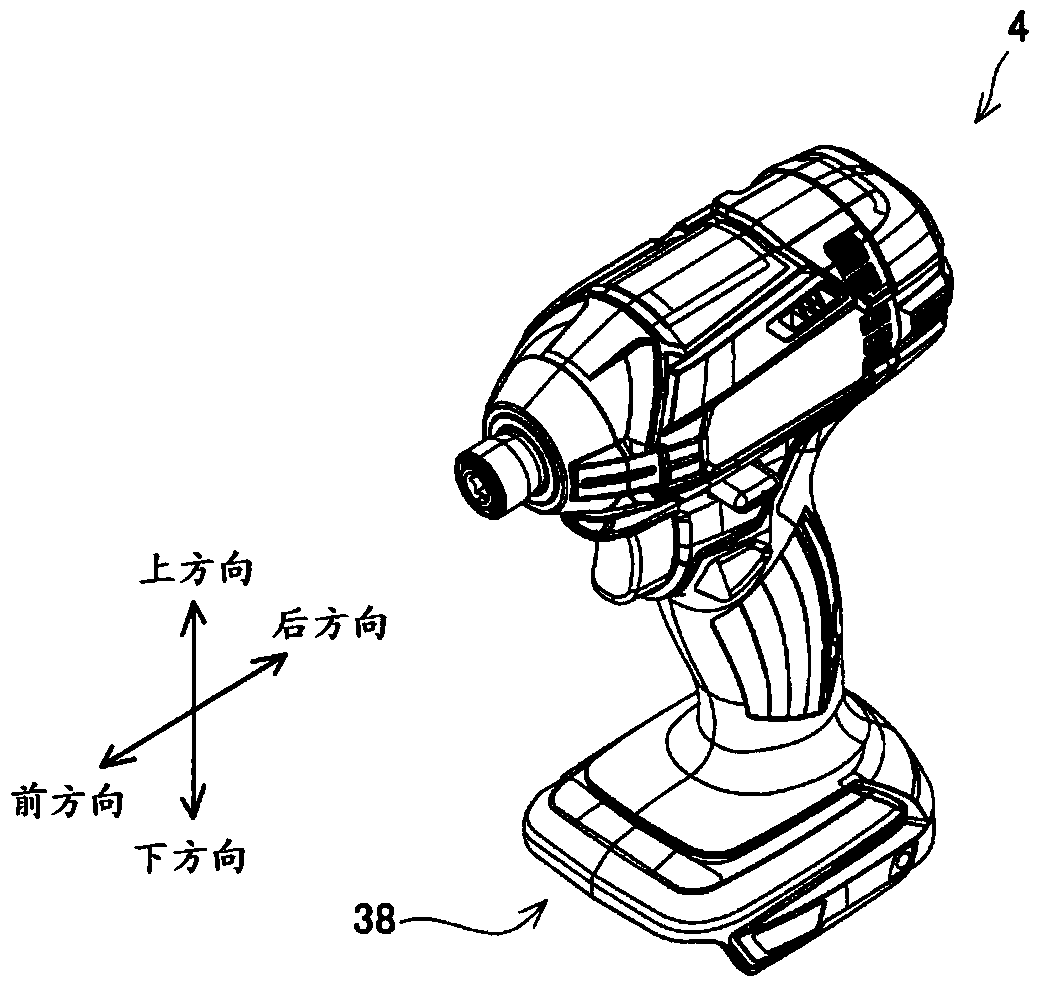

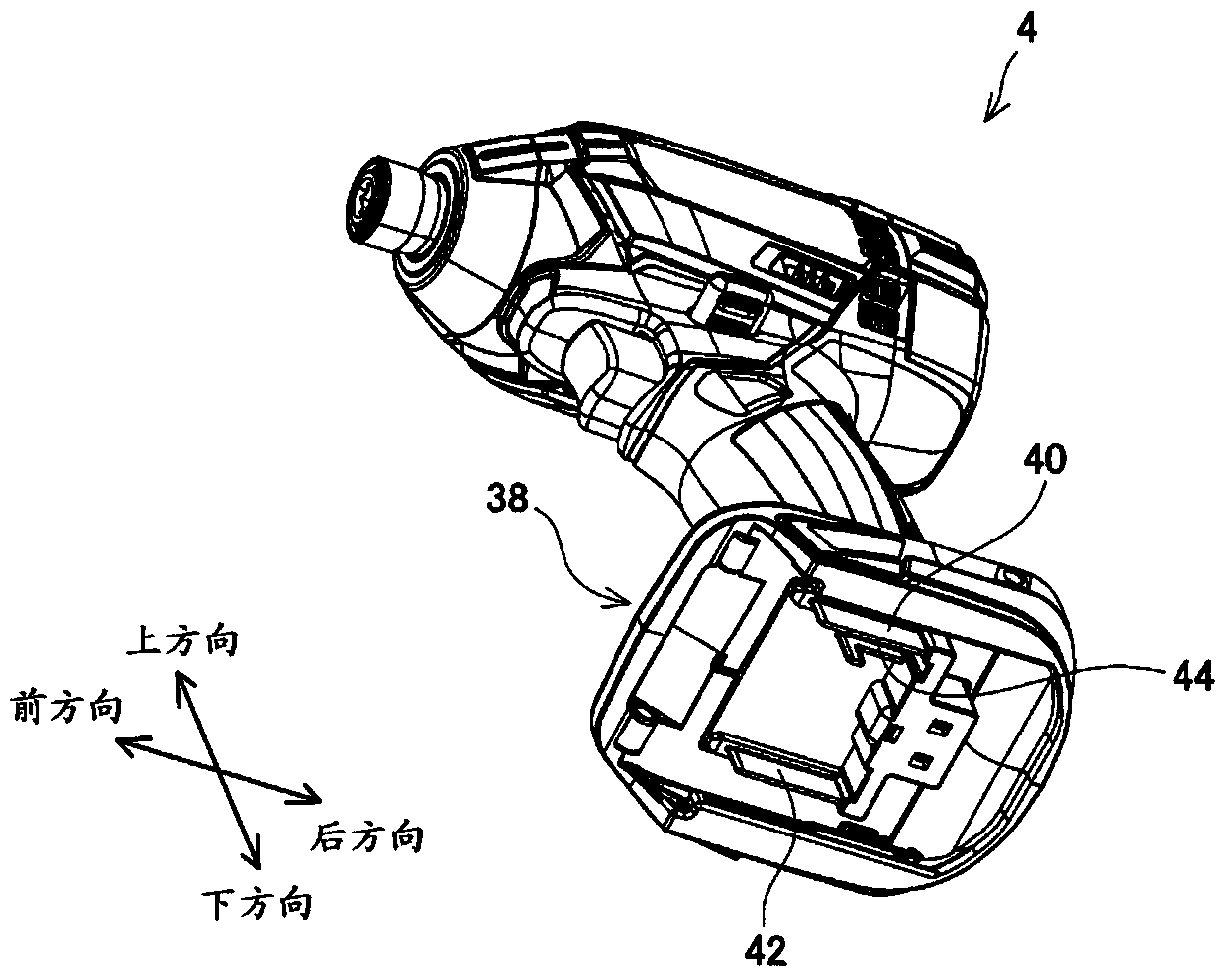

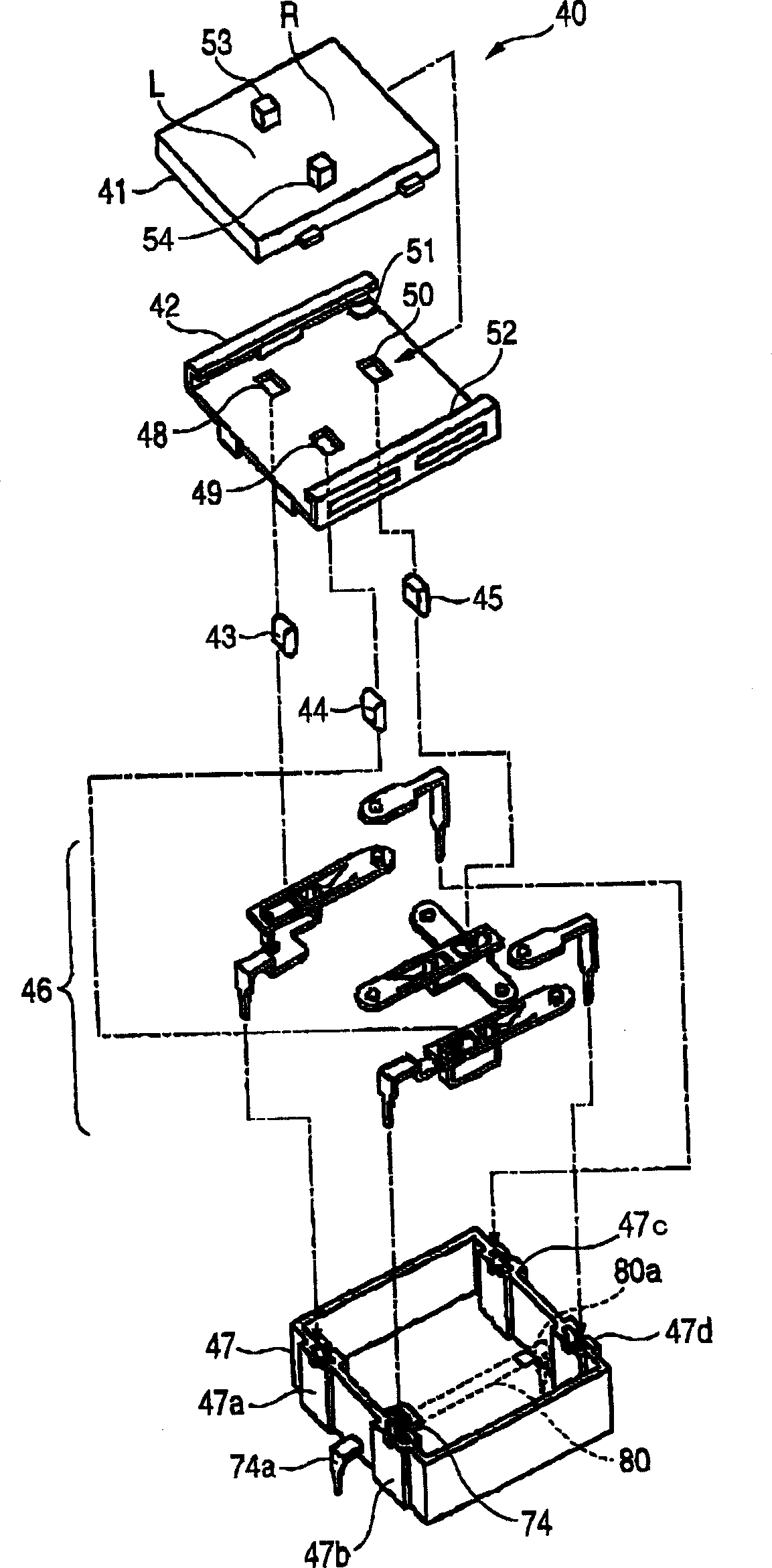

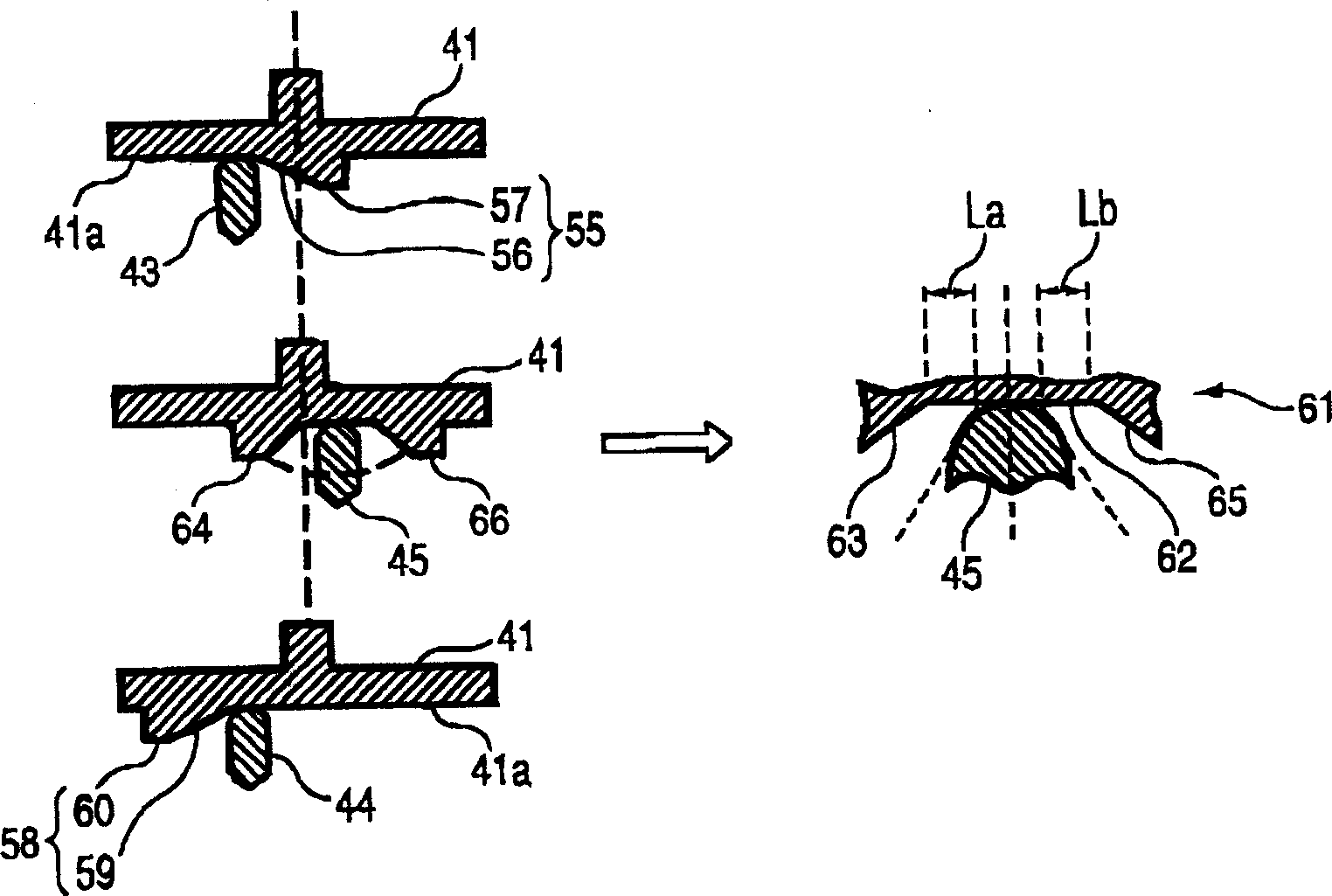

Battery Pack

ActiveCN106340607ADoes not lead to largeIncrease widthElectrically conductive connectionsCoupling device detailsElectrical batteryEngineering

The present description discloses a battery pack capable of being detachably attached to an apparatus including an apparatus terminal having a flat plate-like shape by sliding the battery pack in a sliding direction along the apparatus terminal. The battery pack includes a battery terminal capable of engaging with the apparatus terminal so as to be electrically connected therewith. The battery terminal includes a pair of elastic clamping pieces configured to receive the apparatus terminal when the battery pack is attached to the apparatus and to clamp the apparatus terminal from both sides of the apparatus terminal. In the battery pack, the pair of the elastic clamping pieces extends in a direction perpendicular to the sliding direction.

Owner:MAKITA CORP

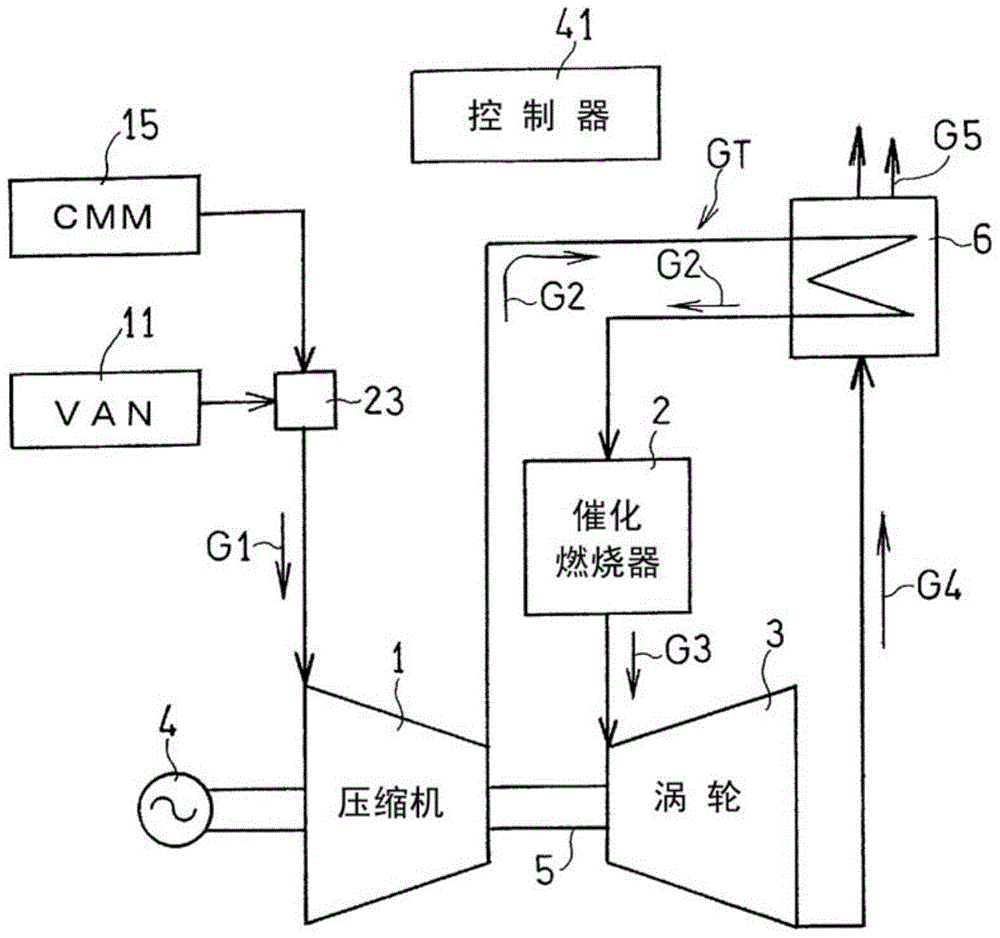

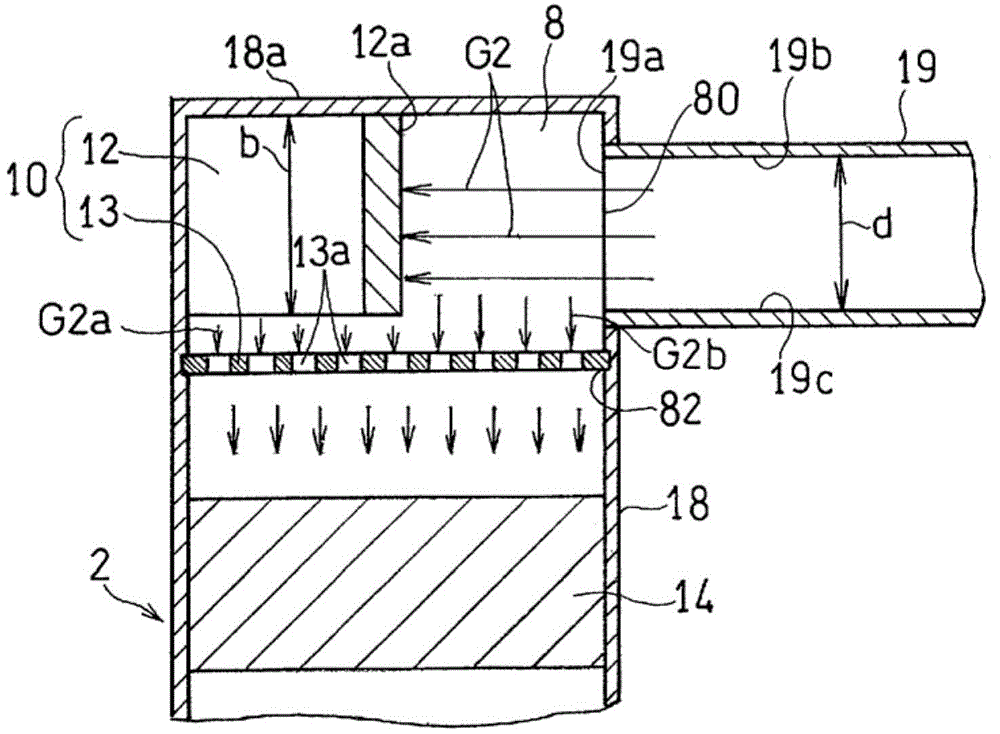

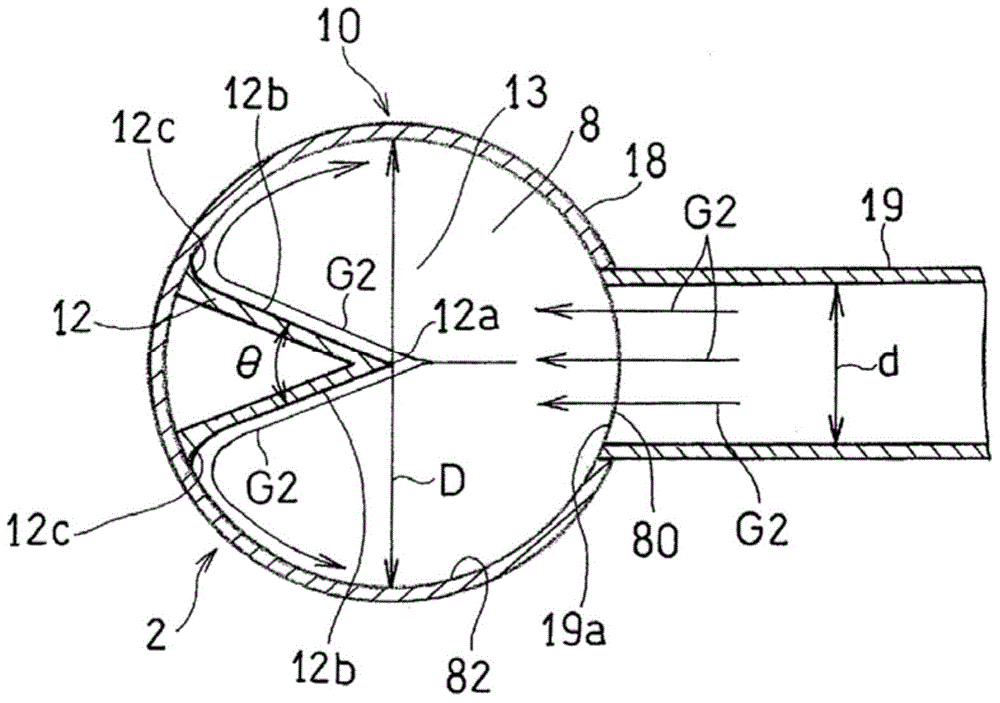

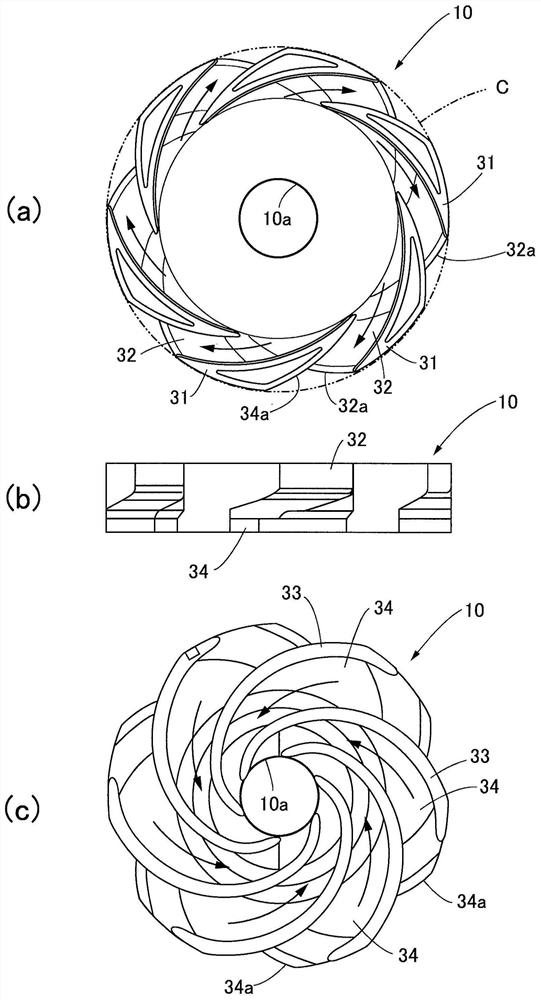

Flow velocity distribution equalizing apparatus

InactiveCN104024738AUniform velocity distributionWill not be enlargedContinuous combustion chamberTurbine/propulsion fuel supply systemsEngineeringFront edge

An apparatus for equalizing flow velocity distribution of a fuel gas supplied into a catalytic combustor includes a rectification vane and a rectification plate in an inlet chamber of the catalyst combustor. The inlet chamber has a round transverse sectional shape and includes an inflow port that allows the fuel gas to inflow radially, and an outflow port for discarding the fuel gas axially. The rectification vane has a front edge oriented towards the inflow port, and a rectifying surface ramified from the front edge so as to extend towards a cylindrical inner wall surface of the inlet chamber such that swirling flow of the fuel gas flown into the inlet chamber, that flows towards the inflow port along the cylindrical inner wall surface, is generated. The rectification plate is located at the outflow port and has openings for allowing the fuel gas to flow therethrough.

Owner:KAWASAKI HEAVY IND LTD

Busbar device with noise filter

InactiveCN104170194AEasy to adjustEasy to remove featuresNon-enclosed substationsMultiple-port networksCapacitanceUltrasound attenuation

A frequency range and an attenuation amount of noise to be eliminated change depending upon to which one of two regions of side frames (34, 35) of a bottom (31) serving as a ground conductor surface first, second and third capacitors (21, 22, 23) are connected. Even if impedance of a ferrite core (12), the shape of a casing (11), capacitances of the capacitors (21, 22, 23), and the like are constant, a noise elimination characteristic changes by changing positions of the first to third capacitors (21, 22, 23). As a result, components including the ferrite core (12) are commonalized and the noise elimination characteristic is easily adjusted in spite of characteristics of electrical equipment.

Owner:KITAGAWA INDS

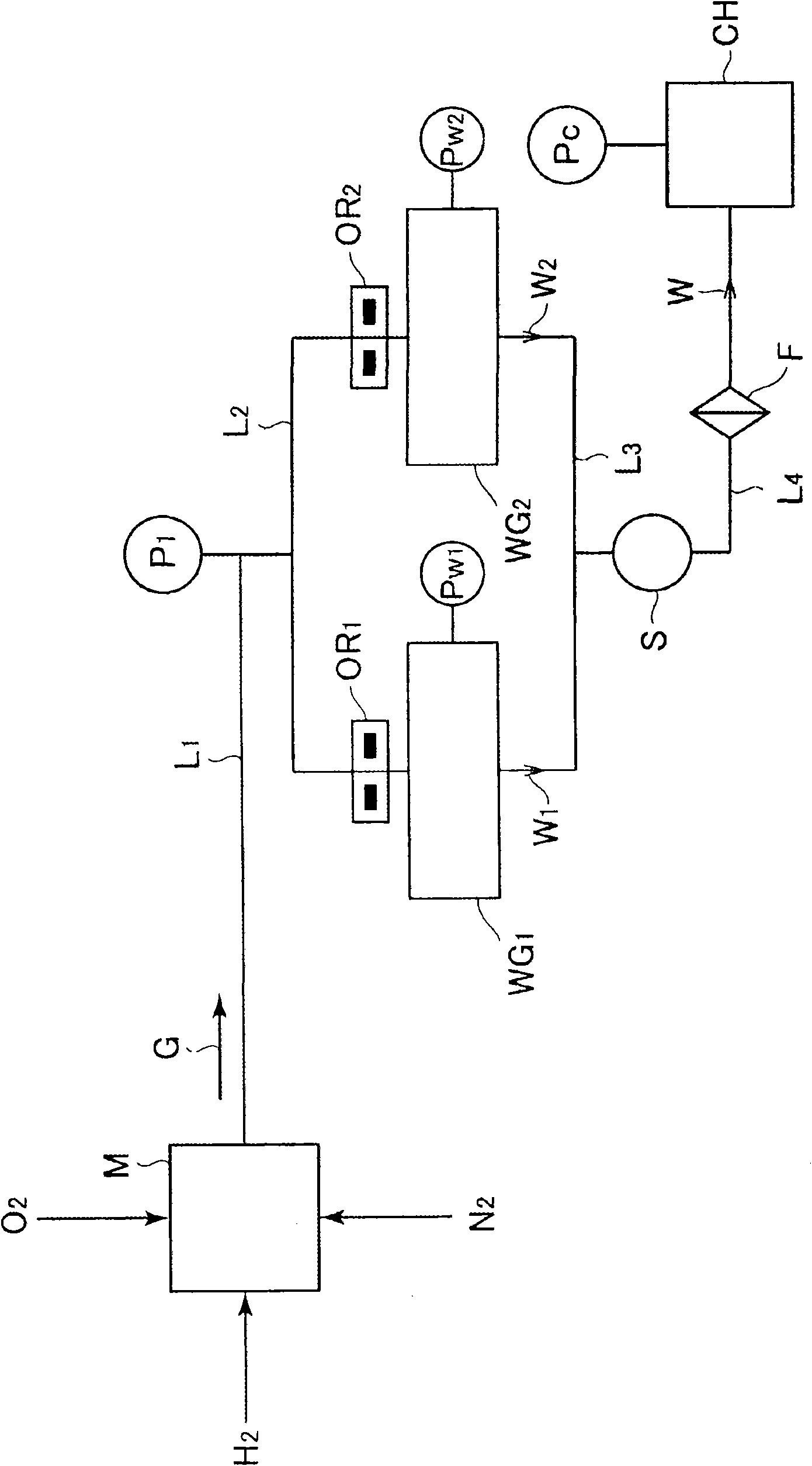

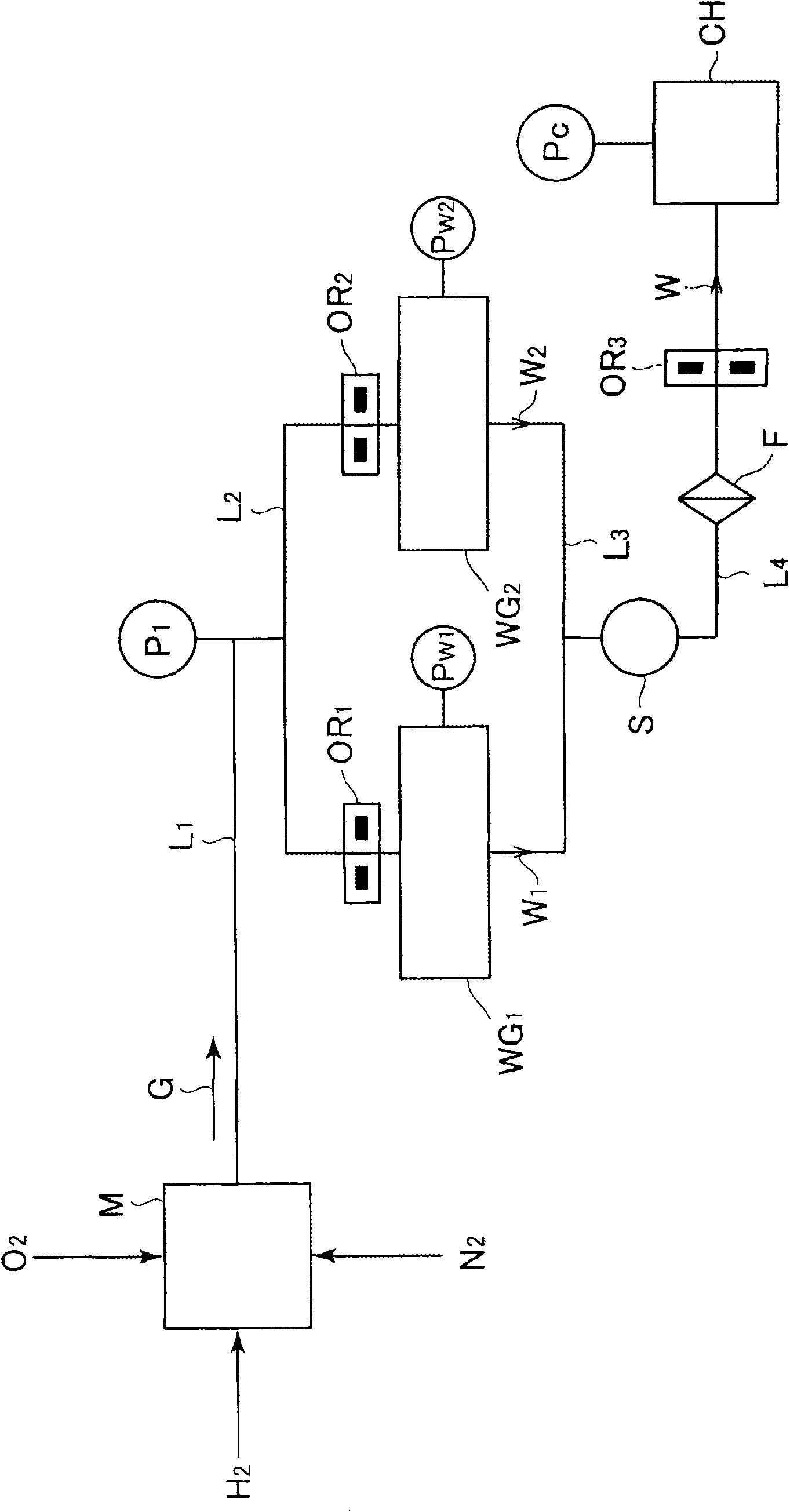

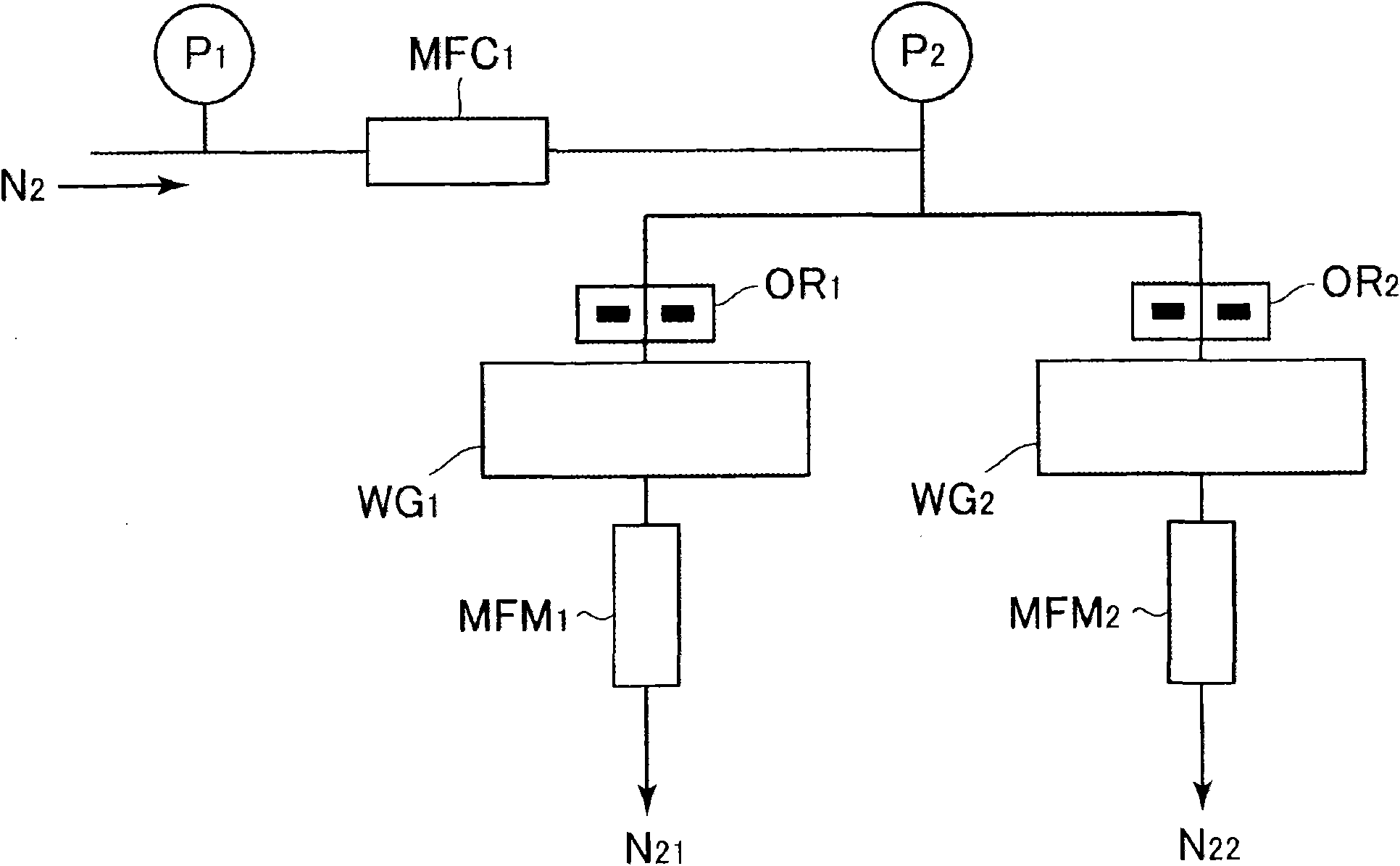

Method of parallel run of reaction furnace for moisture generation

InactiveCN101652318AAccurate shuntDoes not lead to largeGas-gas reaction processesWaterWater useHydrogen

In the event of meeting demands for an increase of the amount of high-purity water fed through parallel run of multiple reaction furnaces for moisture generation, simplification of mixed gas (raw gas)distributor and marked reduction of equipment cost are attained by realizing of the distribution supply of H2 and O2 mixed gas with the use of very simple orifice. Accordingly, there is provided a method of parallel run of reaction furnaces for moisture generation, comprising disposing an orifice with bore of given diameter on the mixed gas entrance side of each of parallelly connected multiple reaction furnaces for moisture generation so that not only is hydrogen / oxygen mixed gas (G) from a mixing unit fed through the orifice to each of the reaction furnaces for moisture generation but alsothe moistures generated by the individual reaction furnaces for moisture generation are joined together and fed to high-purity water using apparatus.

Owner:FUJIKIN INC

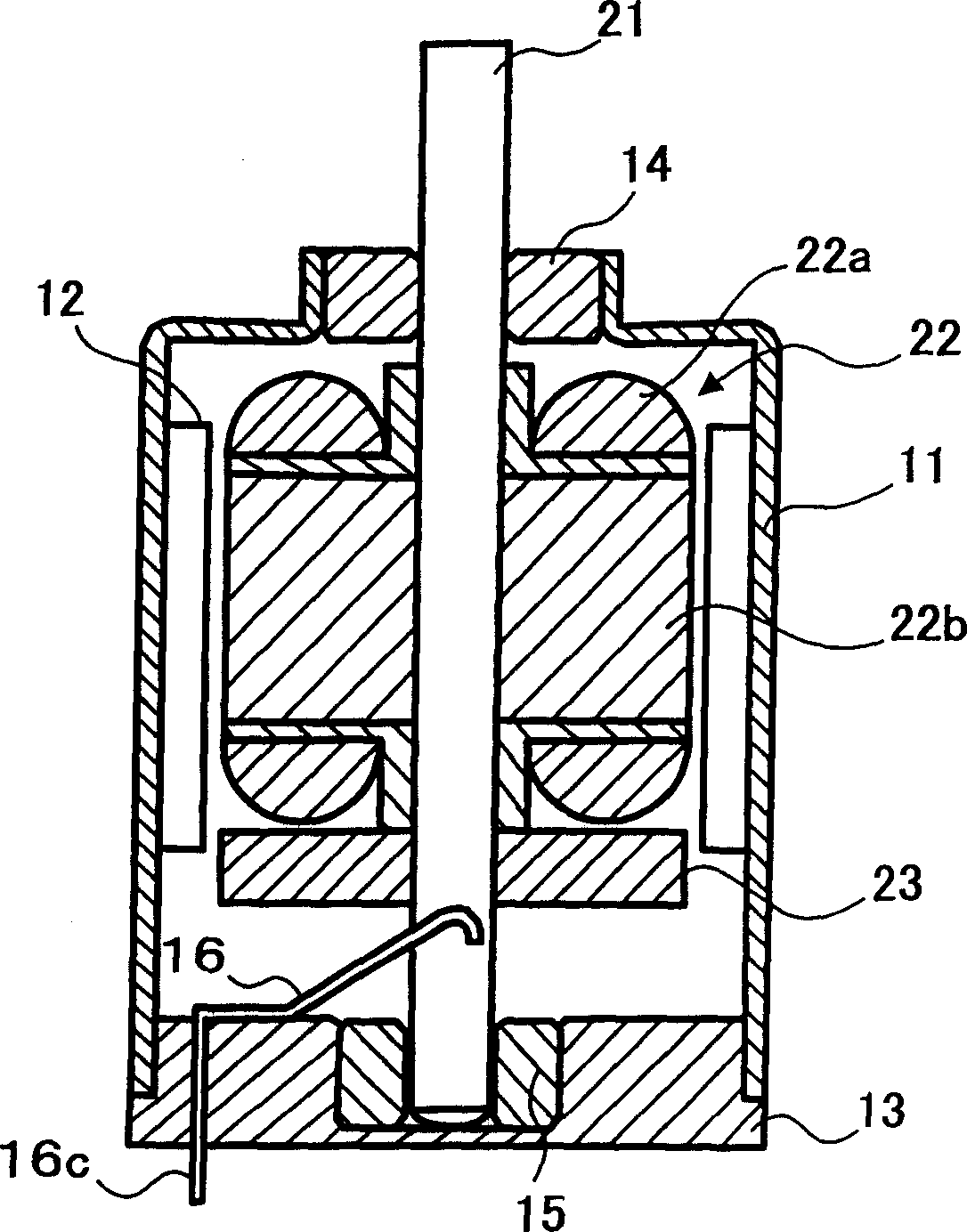

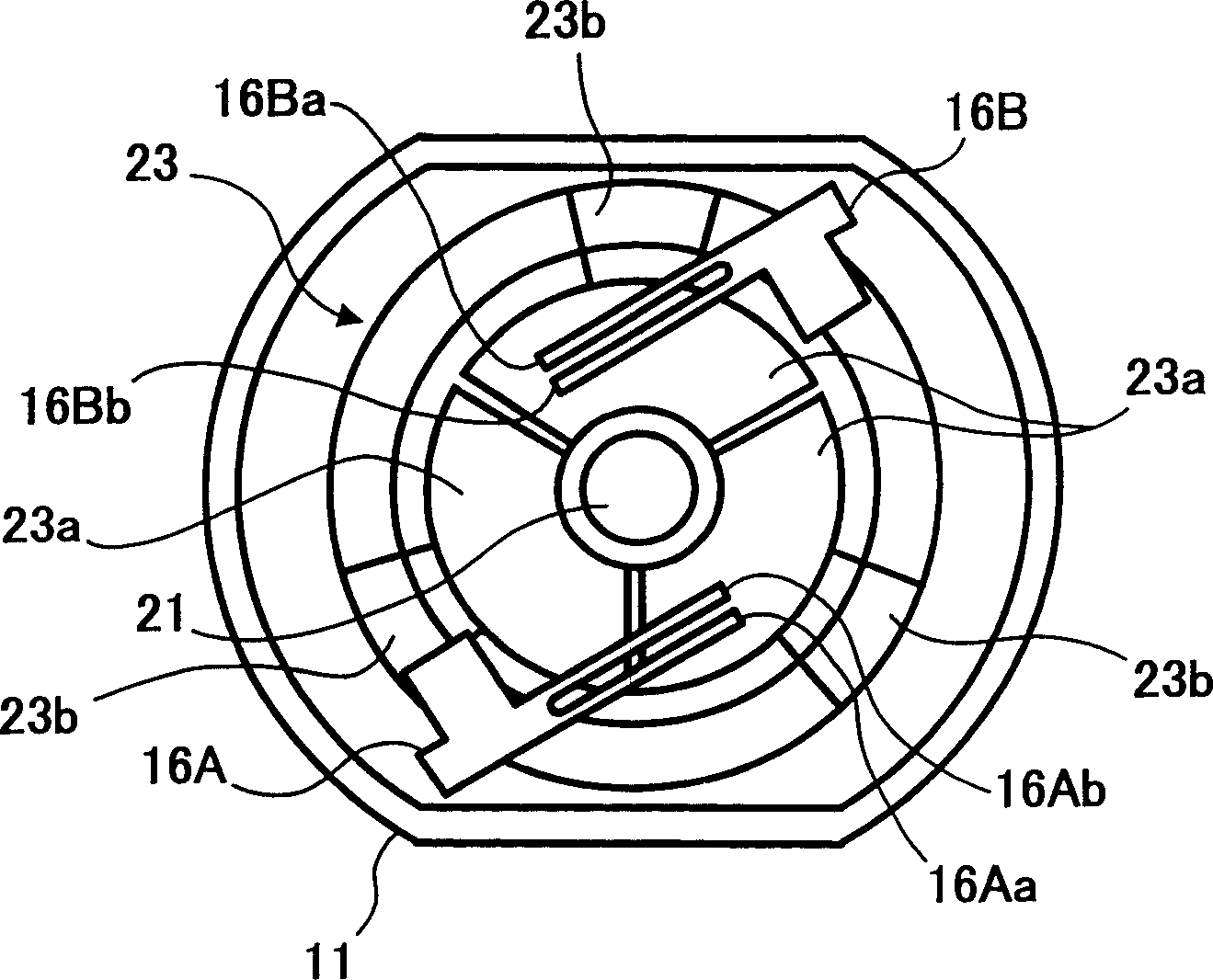

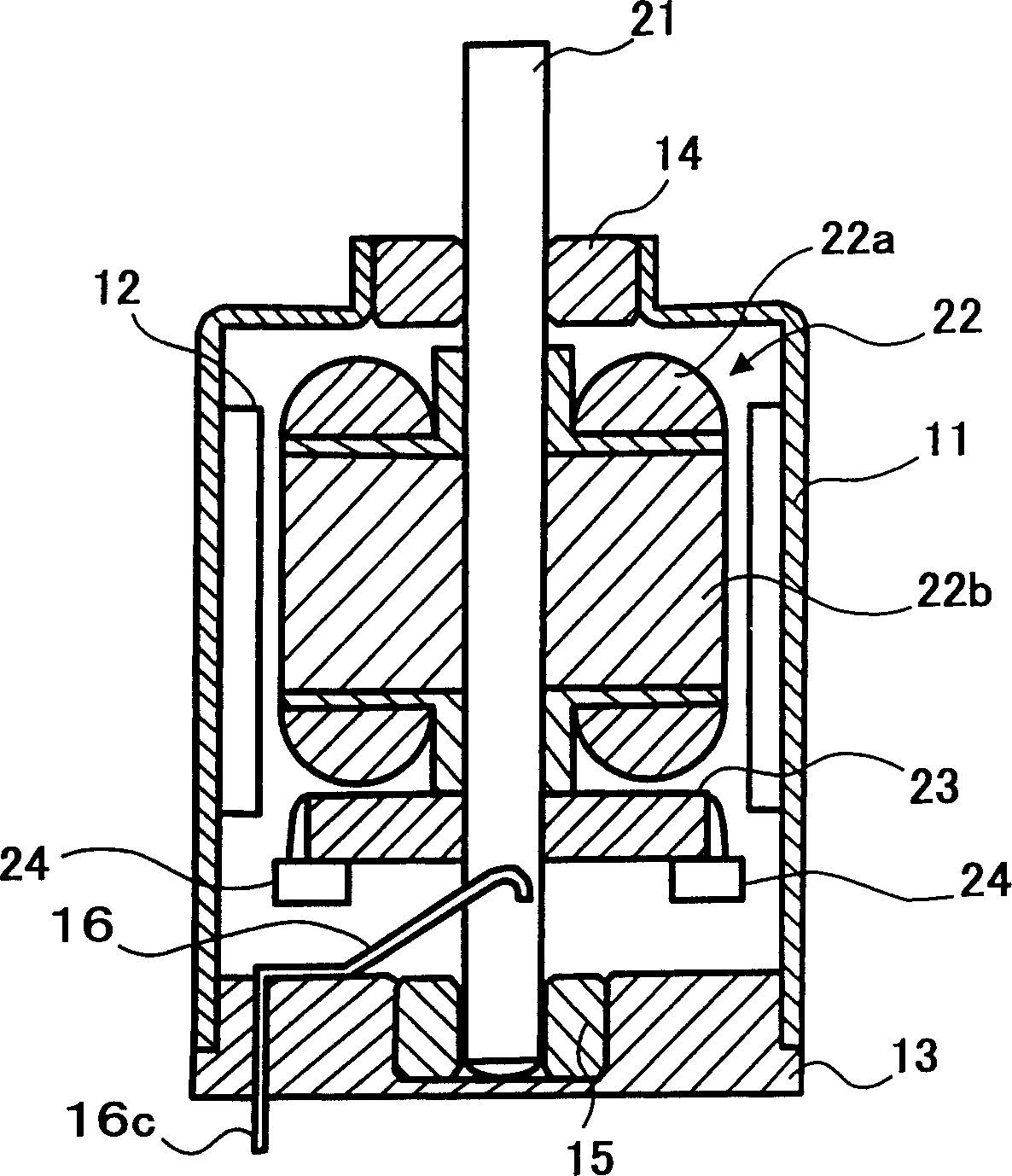

DC motor

InactiveCN1152463CEffective detection of rotationIncreased durabilityRotary current collectorDynamo-electric converter controlMiniaturizationEngineering

Owner:RICOH KK

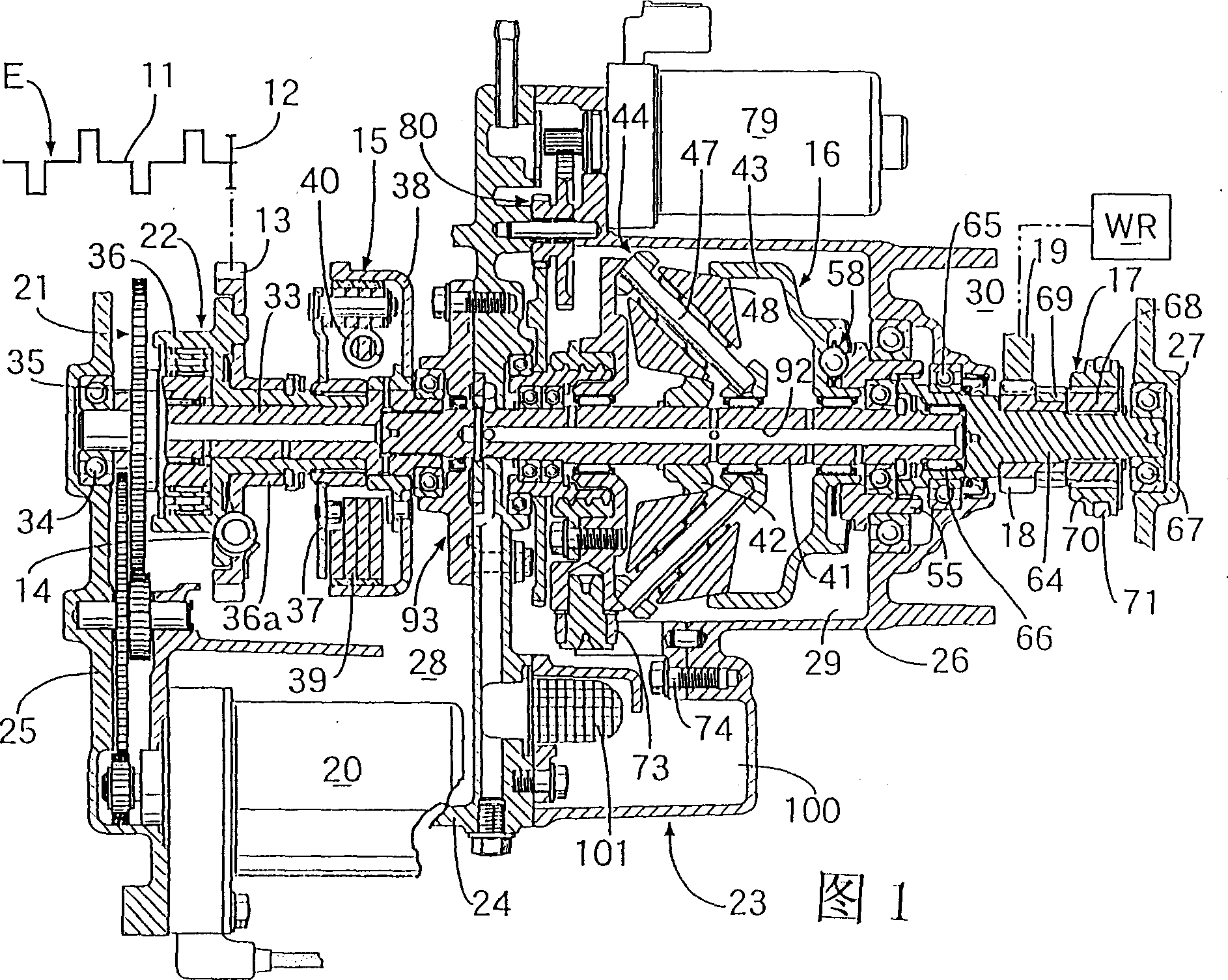

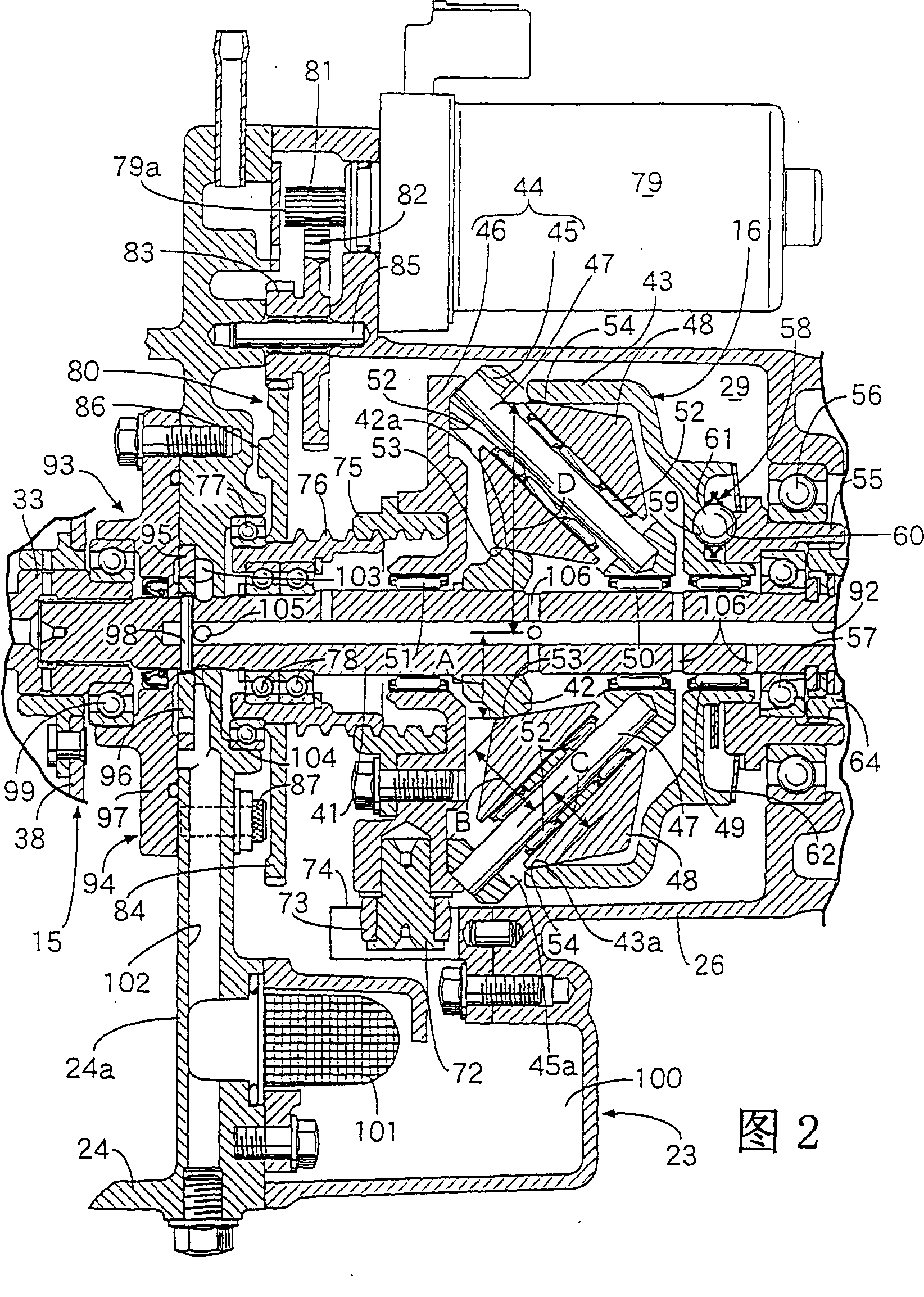

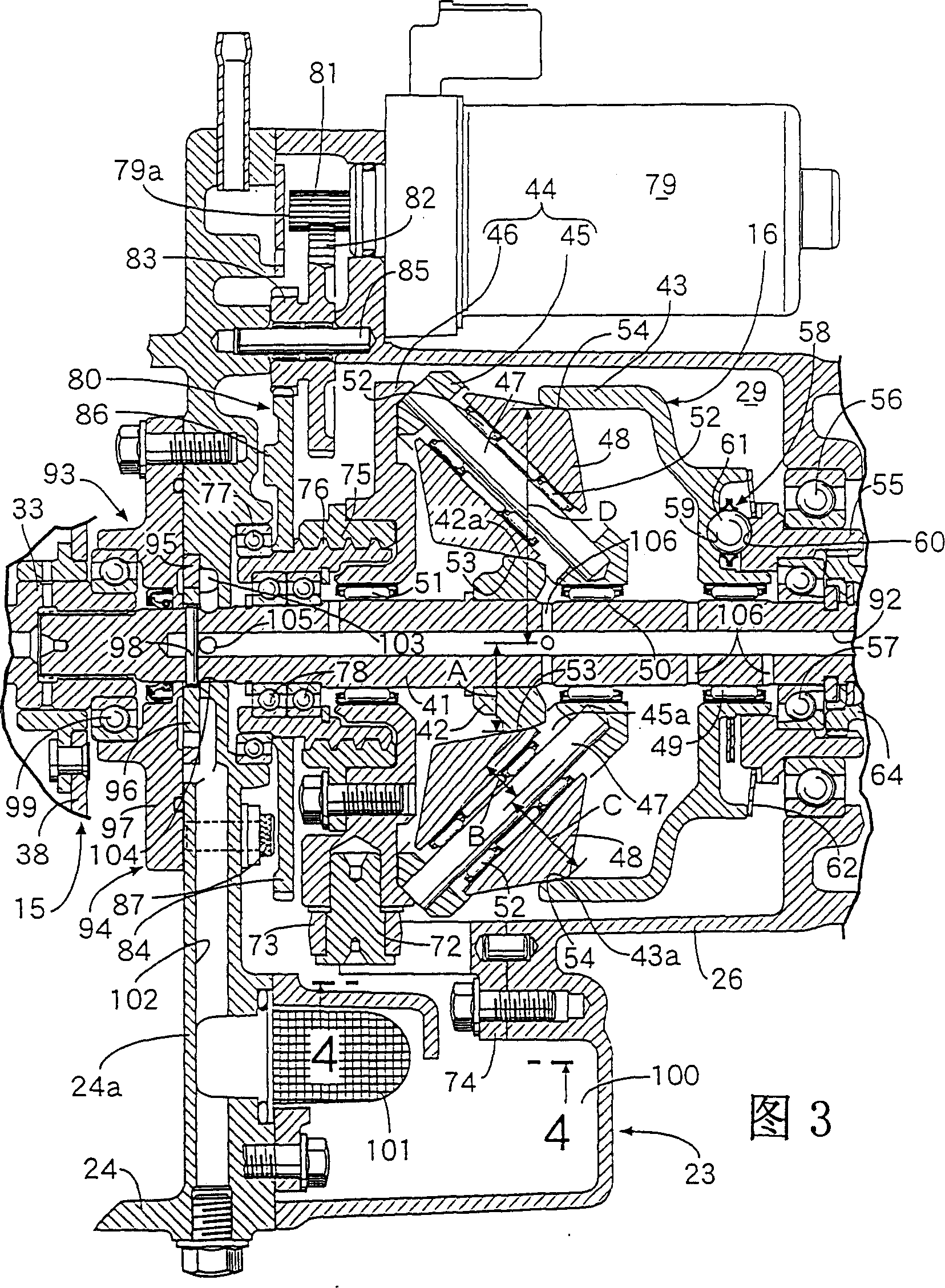

Lubricating oil supply device for stepless speed changer

InactiveCN1144959CDoes not lead to largeCompact structureGear lubrication/coolingGearing controlVariatorOil supply

A lubricating oil supply system for an infinitely variable transmission wherein the infinitely variable transmission has a transmission shaft provided with a lubricating oil path and is rotatably mounted through the wall section of a casing. The infinitely variable transmission is housed in a transmission case partly defined by the wall section. An input rotary member is provided that is relatively unrotatably connected to the transmission shaft on the outside of the transmission case. An oil pump is provided for supplying lubricating oil to the lubricating oil path. The oil pump is located in the casing. In this infinitely variable transmission, the oil passage from the oil pump to the lubricated portion of the infinitely variable transmission is simplified in structure and the oil passage is substantially reduced in length, thereby enabling a decrease in the length of the transmission shaft.

Owner:HONDA MOTOR CO LTD

Rotation angle detector

InactiveCN101466996BIncreased Design FreedomWide range of detection anglesUsing electrical meansConverting sensor output electrically/magneticallyAngular degreesClassical mechanics

A rotation angle detector for detecting a rotation angle of a detectable rotation body, comprises: a primary rotation body to be attached to the detectable rotation body and to rotate as integral with the detectable rotation body; a secondary rotation body to rotate as a predetermined rotation ratio for the primary rotation body; a primary rotation detection mechanism to output a signal to be varied periodically as corresponding to a rotation of the primary rotation body; a secondary rotation detection mechanism to output a signal to be varied periodically as corresponding to a rotation of the secondary rotation body; a signal processing unit to calculate the rotation angles of the primary and the secondary rotation bodies using the signals that the primary and the secondary rotation detection mechanisms output; and an operation processing unit to calculate the rotation angle of the detectable rotation body, based on the calculated rotation angle of the primary or of the secondary rotation body, and on a relative rotation angle between the primary and the secondary rotation body, wherein at least any one of the following signals (A) to (D) is designed to have a cycle as different from one cycle for one rotation of the primary rotation body or of the secondary rotation body; (A) an output signal of the primary rotation detection mechanism; (B) an output signal of the secondary rotation detection mechanism; (C) an input signal from the primary rotation detection mechanism to be processed at the signal processing unit; and (D) an input signal from the secondary rotation detection mechanism to be processed at the signal processing unit.

Owner:FURUKAWA ELECTRIC CO LTD

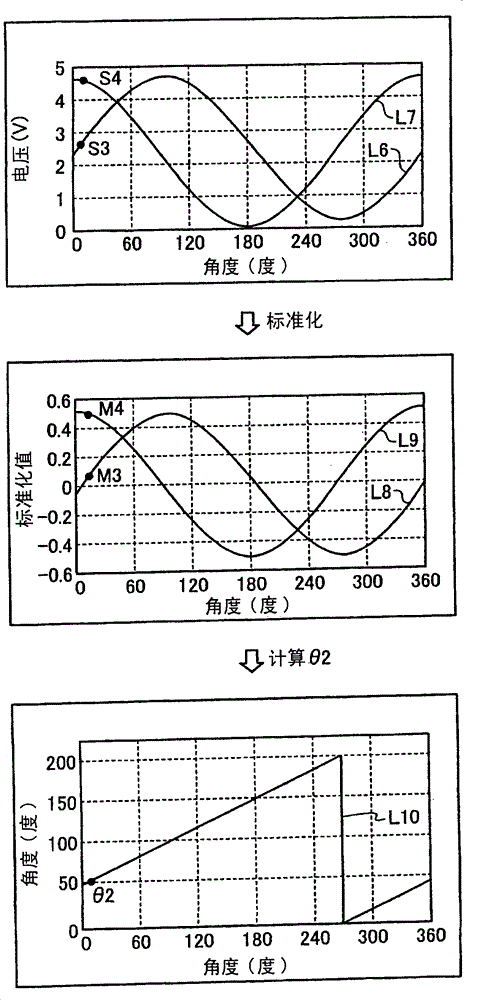

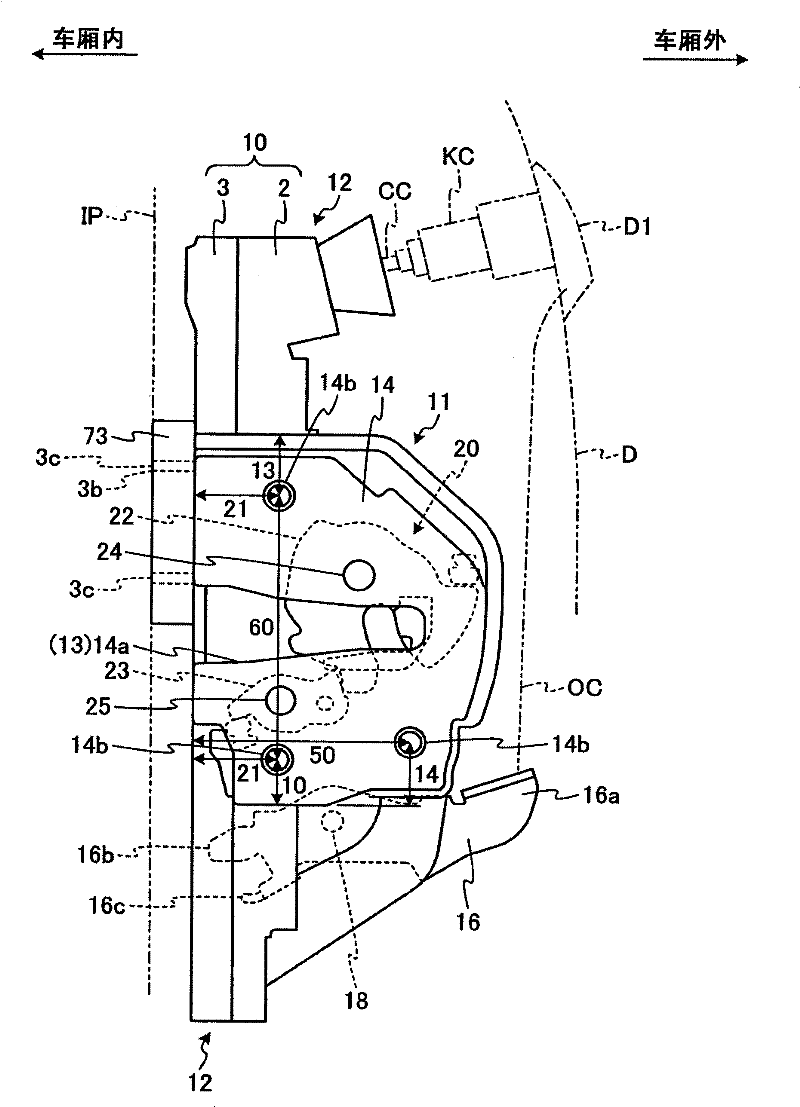

Door lock apparatus

InactiveCN101545342BEasy to operateDoes not lead to largeElectrical locking actuatorsPassenger lock actuationOperabilityEngineering

Owner:MITSUI KINZOKU ACT

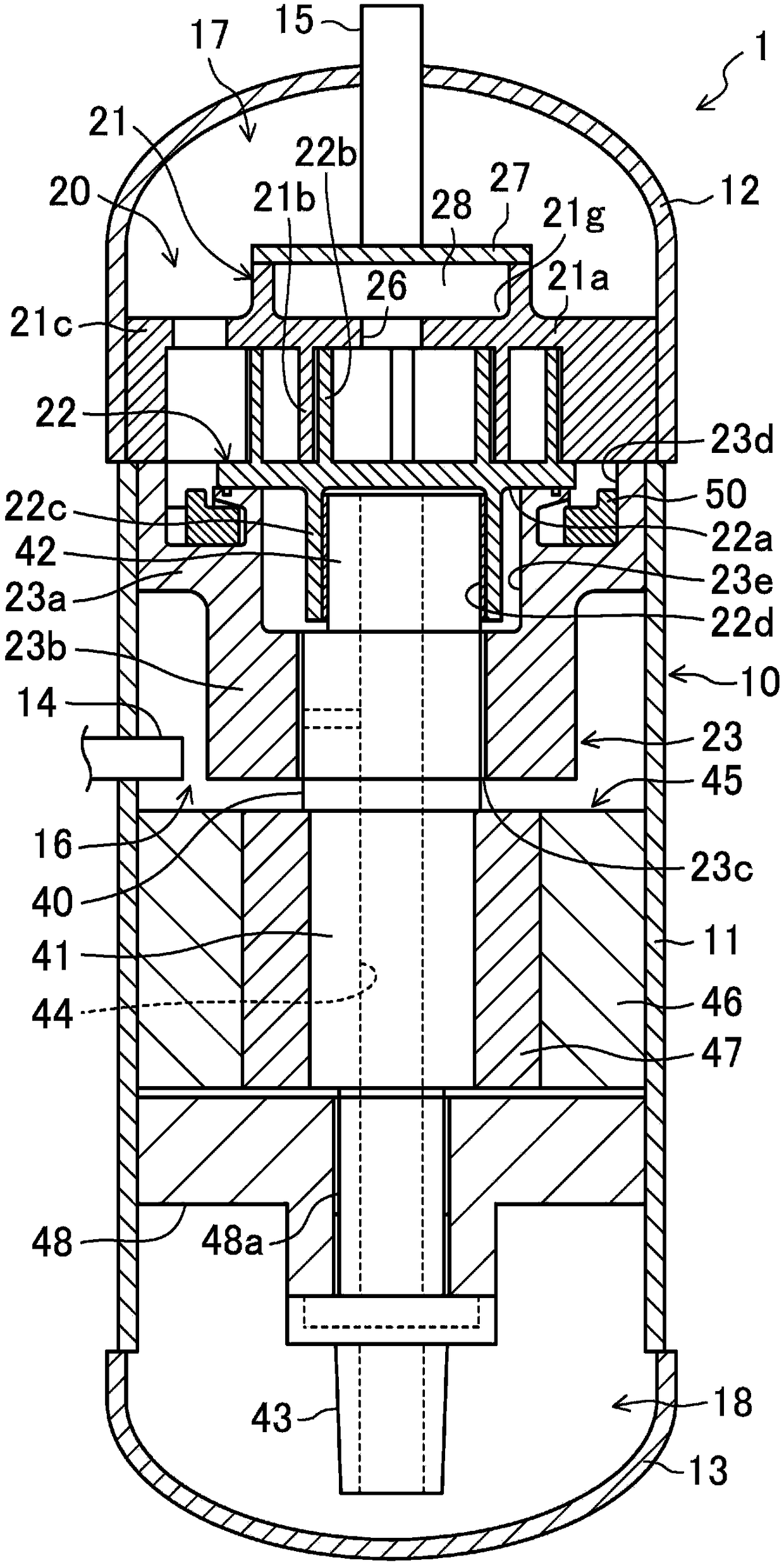

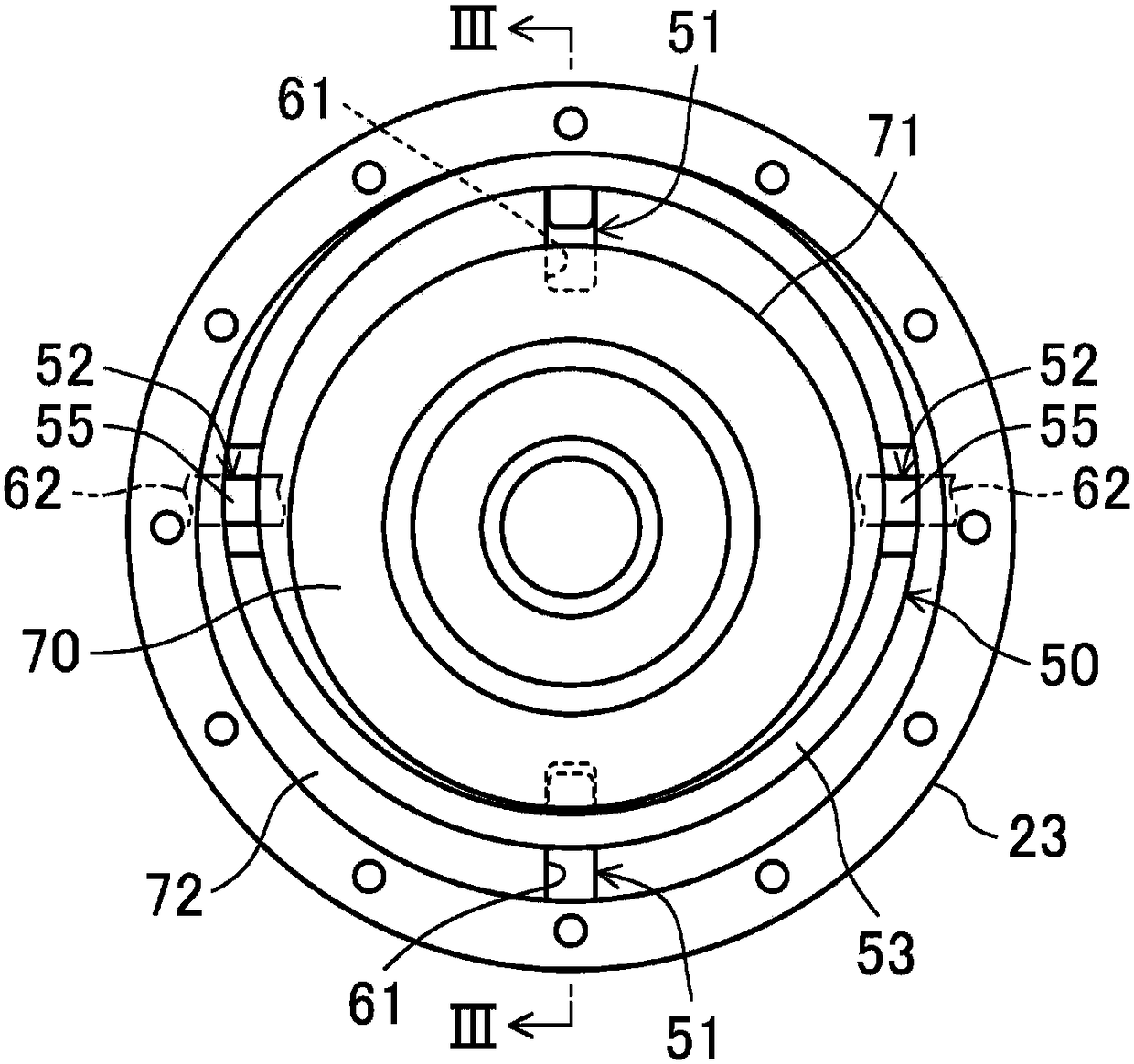

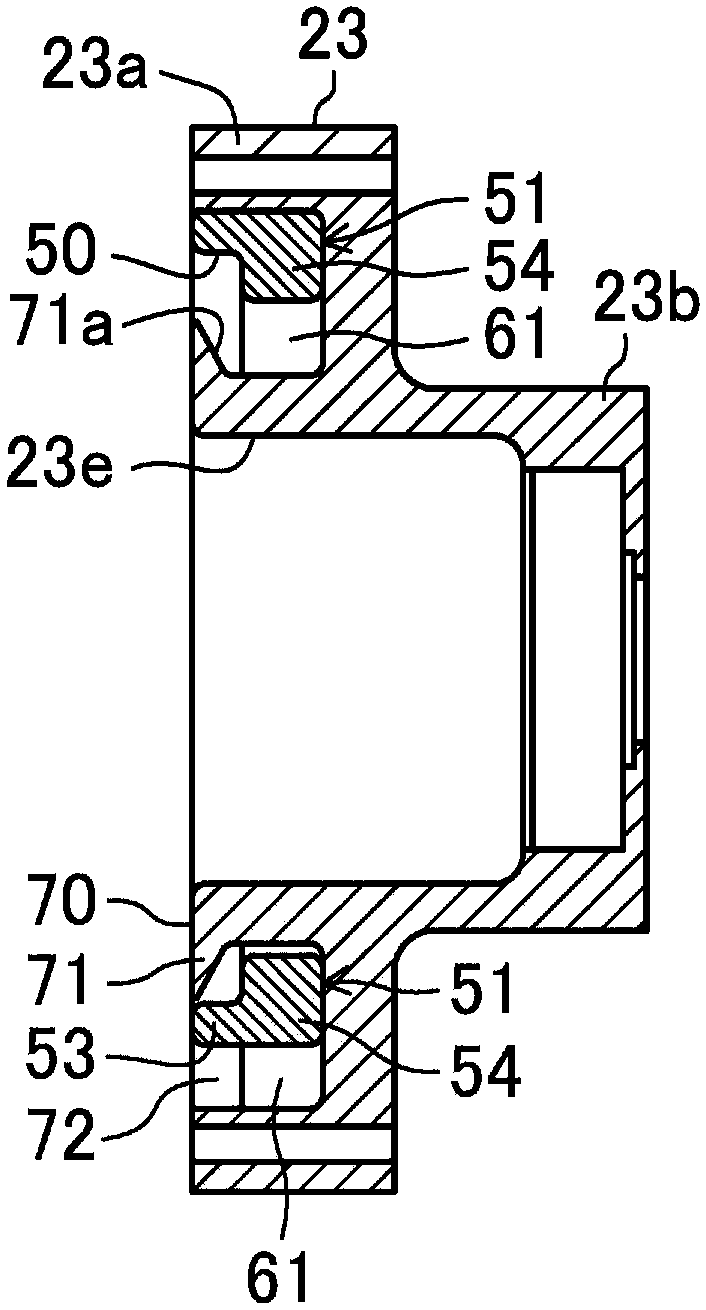

Scroll compressor

InactiveCN108368847ANot strong enoughReduce intensityYielding couplingPump componentsEngineeringFlange

A housing (23)-side first key (54) of an Oldham ring (50) protrudes from a ring section (53) toward the housing (23) and also radially toward the inside of the ring section (53). The flange of the housing (23) has formed thereon: a facing section (71) having a movable scroll facing surface (70); and an annular opening (72) located around the movable scroll facing surface (70) and accommodating thering section (53). A first key groove (61) is formed on the rear surface side of the facing section (71) so as to extend radially inward from the annular opening (72). The configuration ensures the strength of the housing (23) and Oldham ring (50) of the scroll compressor and prevents the movable scroll facing section (70) from becoming small.

Owner:DAIKIN IND LTD

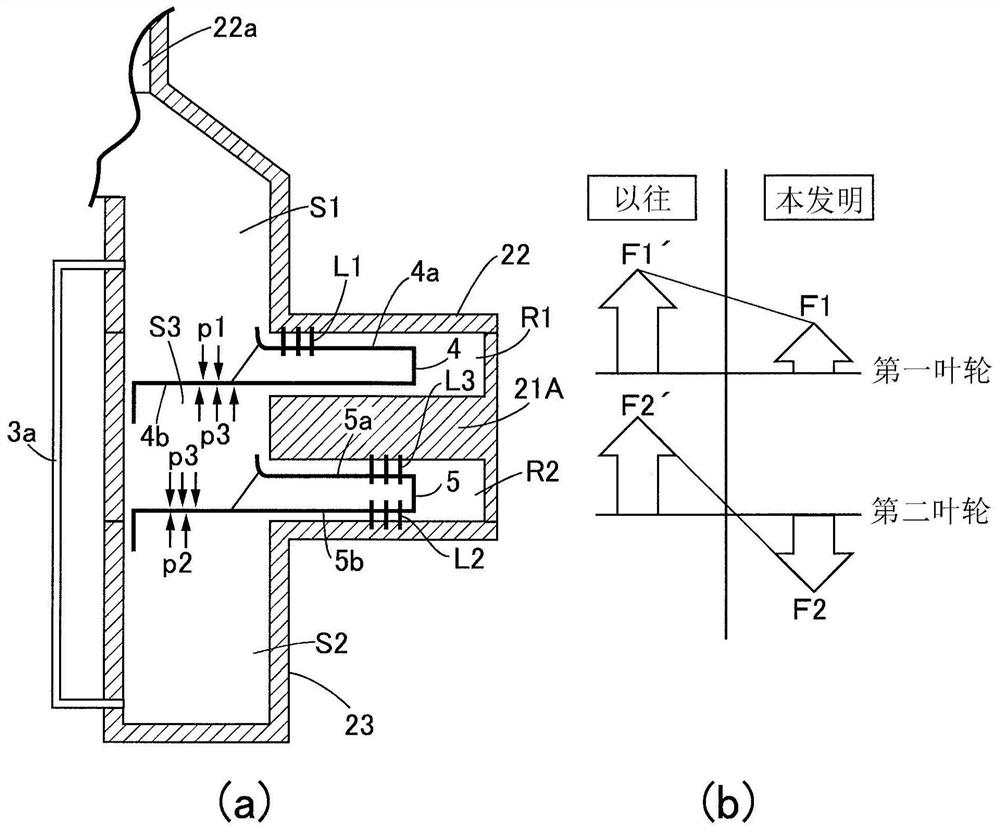

Two-stage centrifugal pump

ActiveCN114060286AInhibit wearIncreased durabilityPump componentsPump installationsSlider bearingPump chamber

The invention provides a two-stage centrifugal pump, which does not cause the structure to be complicated or large, and can inhibit the thrust acting on a rotor shaft to be small, thereby improving the durability of a sliding bearing. The two-stage centrifugal pump (1) is configured such that two first and second impellers are axially mounted on a rotor shaft (3), the first impeller (4) and the second impeller (5) are respectively housed in two pump chambers (R1, R2) partitioned in a pump housing (2), and a first labyrinth seal (L1) is provided between a front surface shroud (4a) of the first impeller and an inner surface of the pump housing facing the front surface shroud (4a) of the first impeller, and a second labyrinth seal section (L2) is provided between a back shield (5b) of the second impeller and the inner surface of the pump housing facing the back shield (5b). The two-stage centrifugal pump is provided with a communication passage (3a). The communication passage is configured so that a first space (S1) closer to the axial center side than the first labyrinth seal part and a second space (S2) closer to the axial center side than the second labyrinth seal part are communicated with each other in the pump housing.

Owner:HITACHI ASTEMO LTD

Switch device

InactiveCN1248264CDoes not lead to largeAvoid damageMan-operated mechanismField or armature current controlElectricityEngineering

A switch unit is provided which is free from causing contact damage even in case applied to a high power voltage, whose switch unit is not greatly increased in size. Switches A and B are to take a motor stop status, a motor forward rotation status and a motor reverse rotation status. A switch C is to electrically connecting and disconnecting between the switches A and B and the power source. This switch C, when the switches A and B transits from the motor forward rotation status or motor reverse rotation status into the motor stop status, is operated from a connection state to a disconnection state at a time of any of completing the transition to the motor stop status and prior to a predetermined marginal period of time.

Owner:ORMON CORP

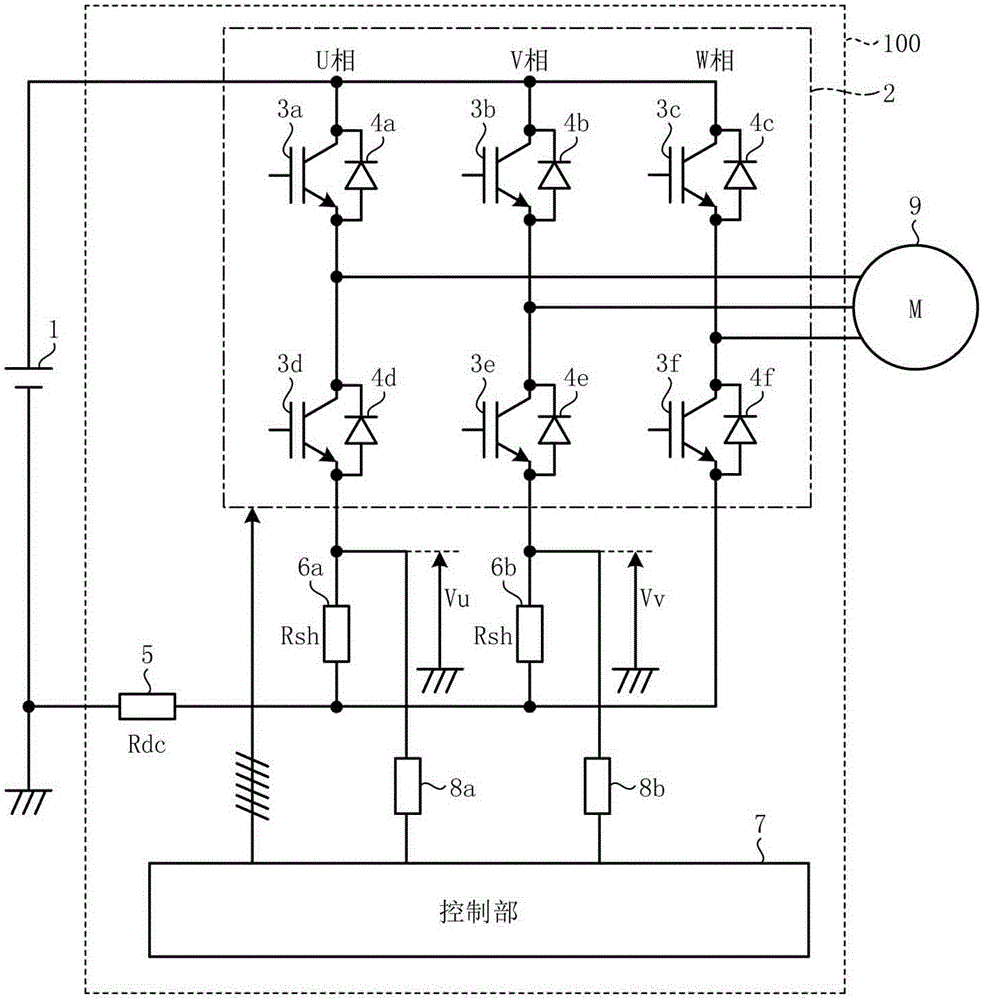

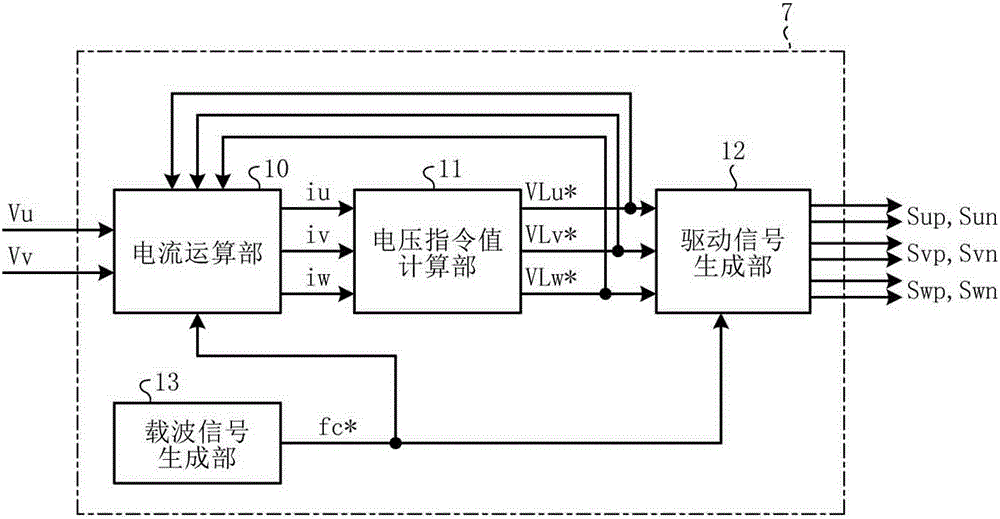

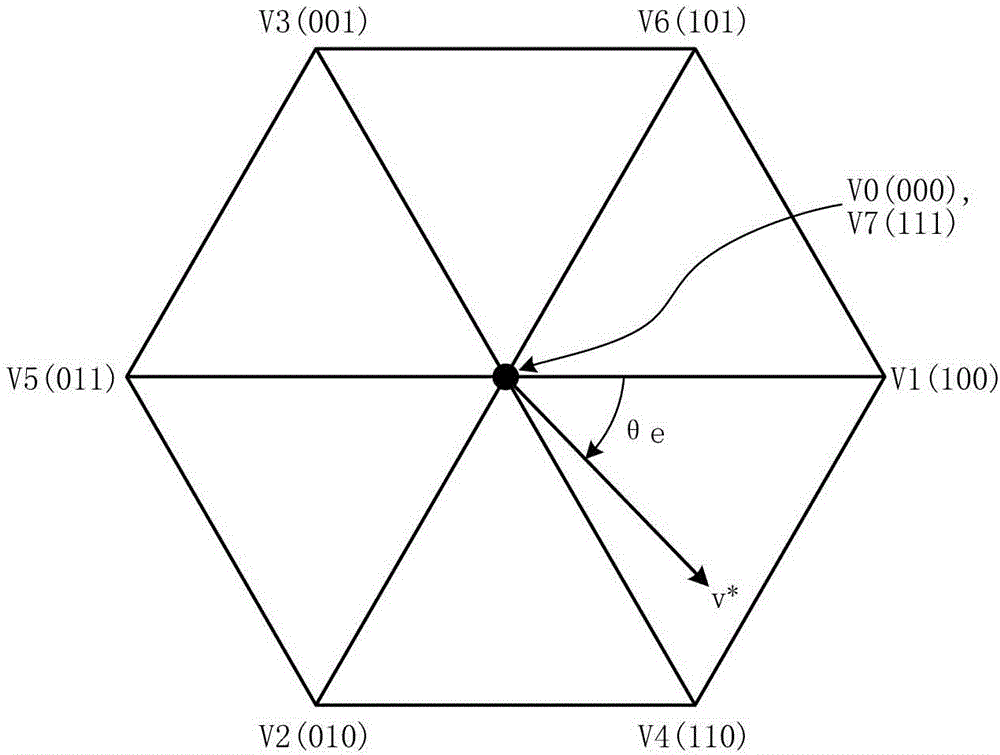

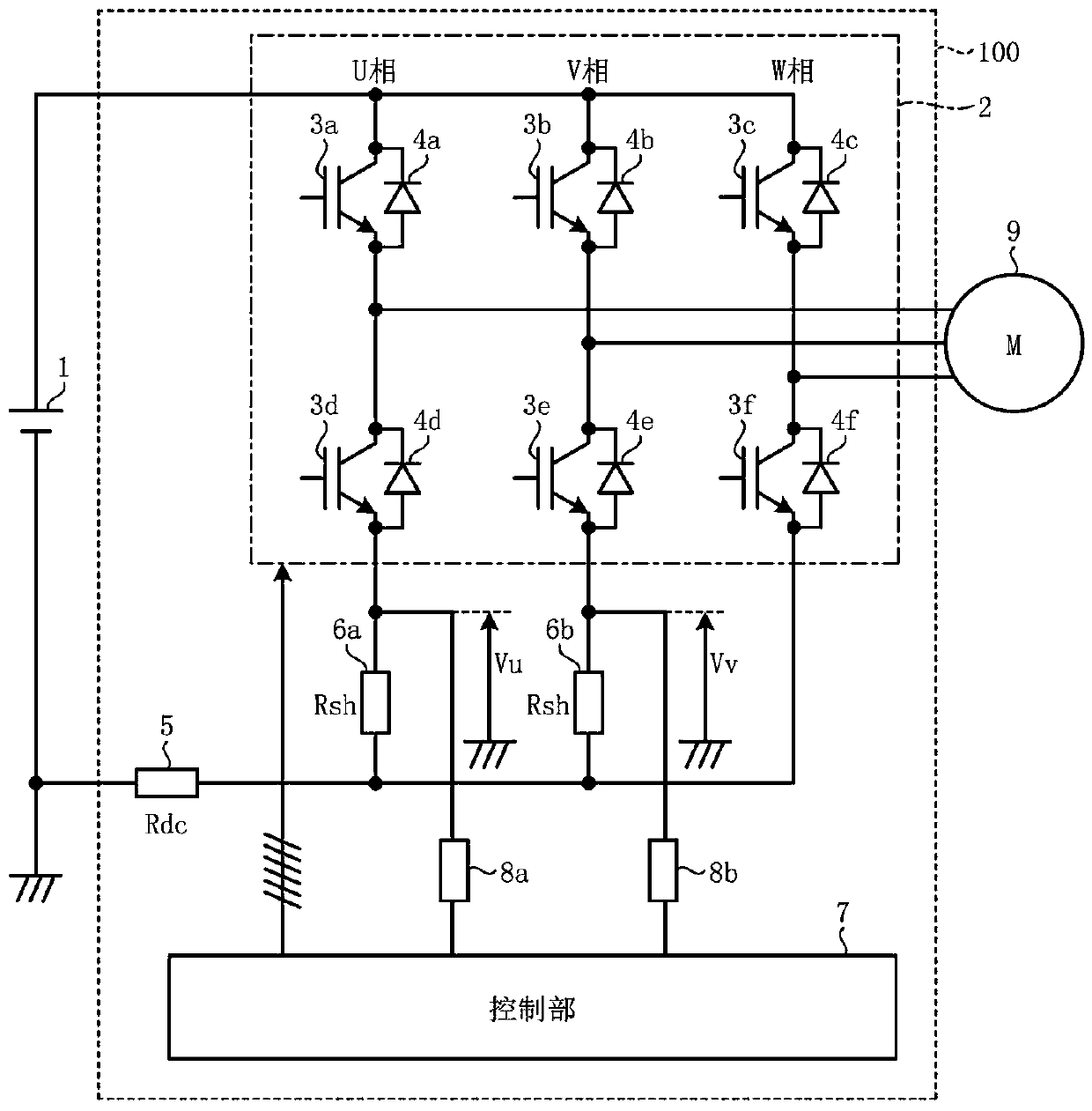

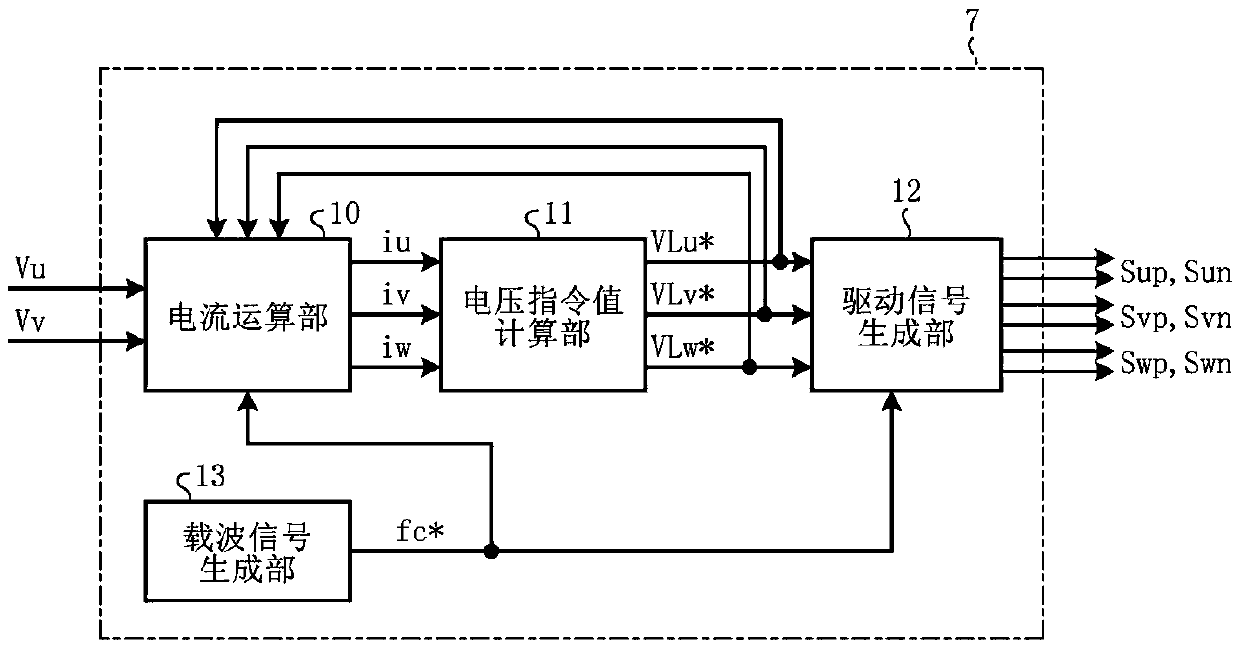

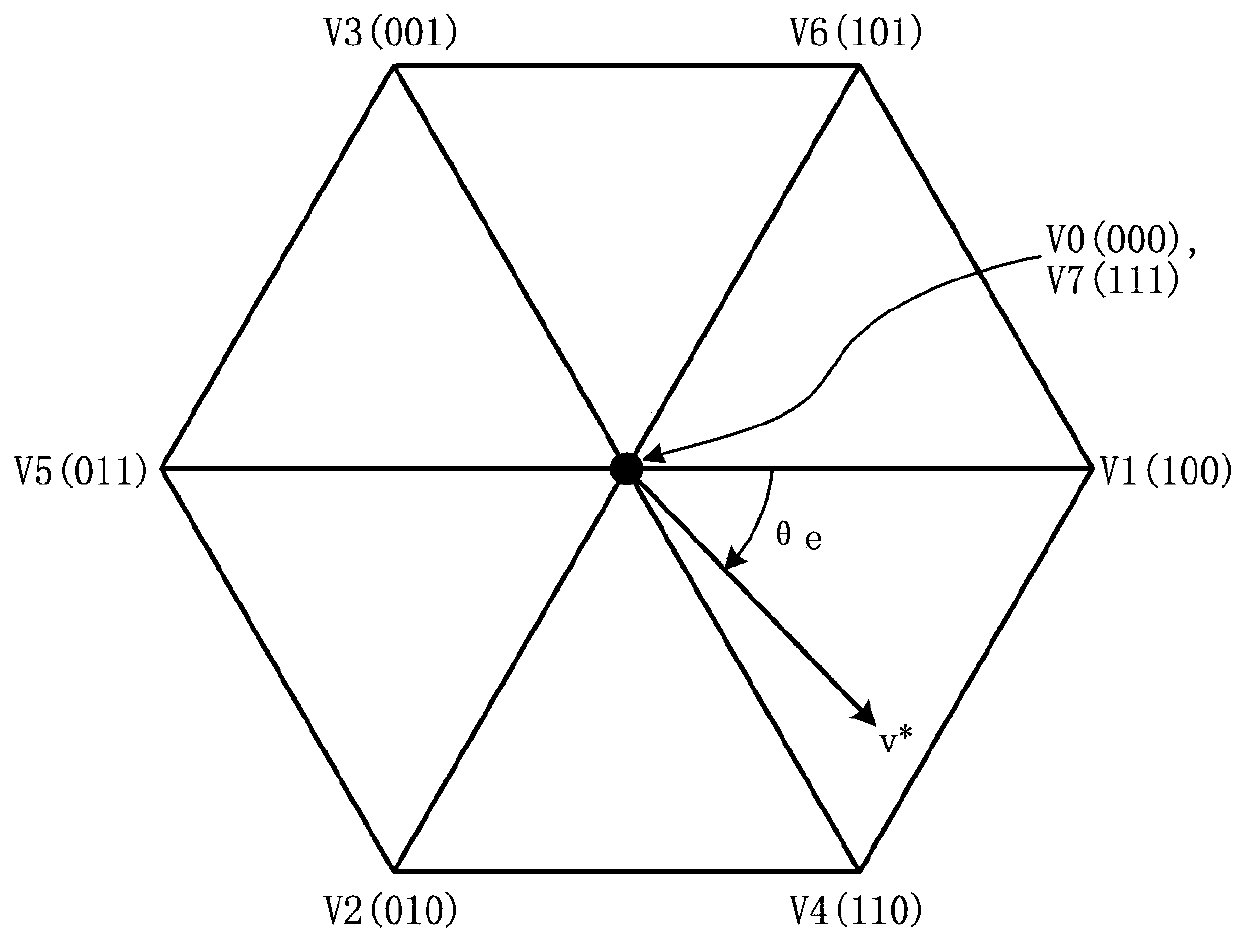

Power convertor, motor driver equipped with power convertor, blower and compressor equipped with motor driver, and air conditioner, refrigerator, and freezer equipped with blower and compressor

ActiveCN105075101AExtended testing periodWill not be enlargedAC motor controlAc-dc conversionElectrical resistance and conductancePhase currents

The purpose of the present invention is to provide a power convertor capable of highly accurate control based on a current in each phase by extending the detection period of the current in each phase without increasing the size of a device and incurring high cost. The power convertor comprises: a power source shunt resister (5) provided in between the negative voltage side of a DC power source (1) and an inverter (2); and per-phase lower-arm shunt resistors (6a, 6b) respectively provided in between two of three per-phase lower-arm switching elements (3d, 3e) and the power source shunt resister (5). The power convertor detects the voltages between the connection points for the per-phase lower-arm switching elements (3d, 3e) and per-phase lower-arm shunt resistors (6a, 6b), and the negative voltage side of the DC power source (1), and calculates the per-phase current flowing in a load device (9) on the basis of each detected value.

Owner:MITSUBISHI ELECTRIC CORP

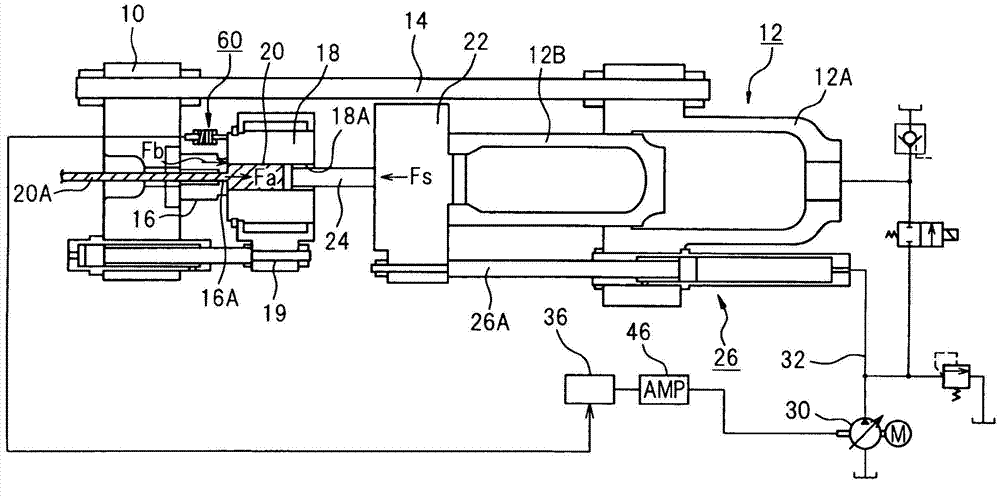

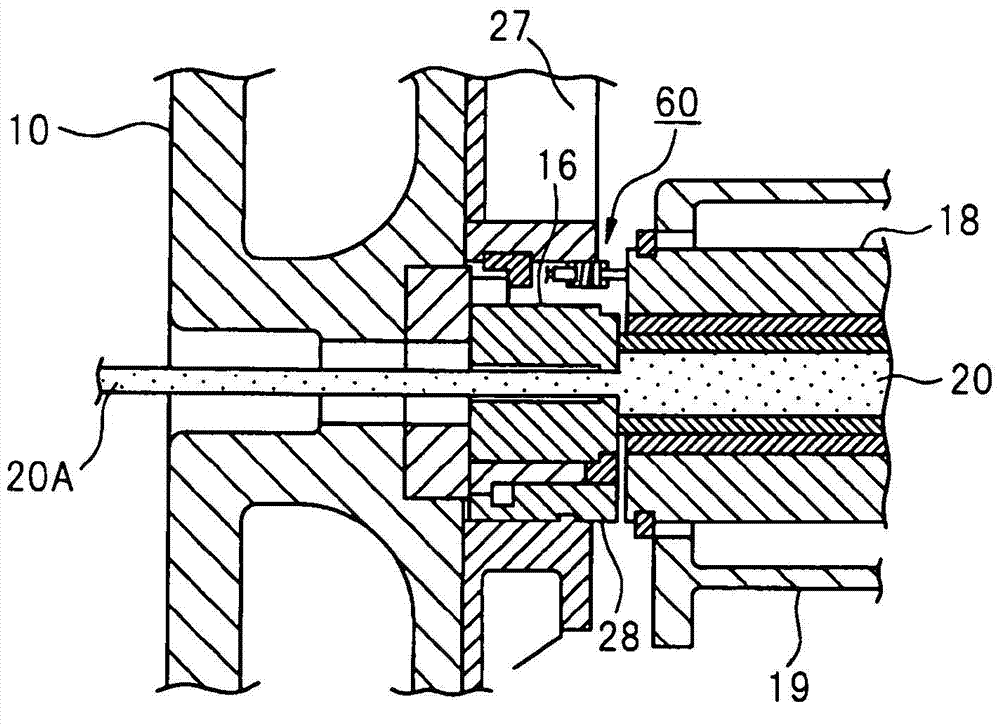

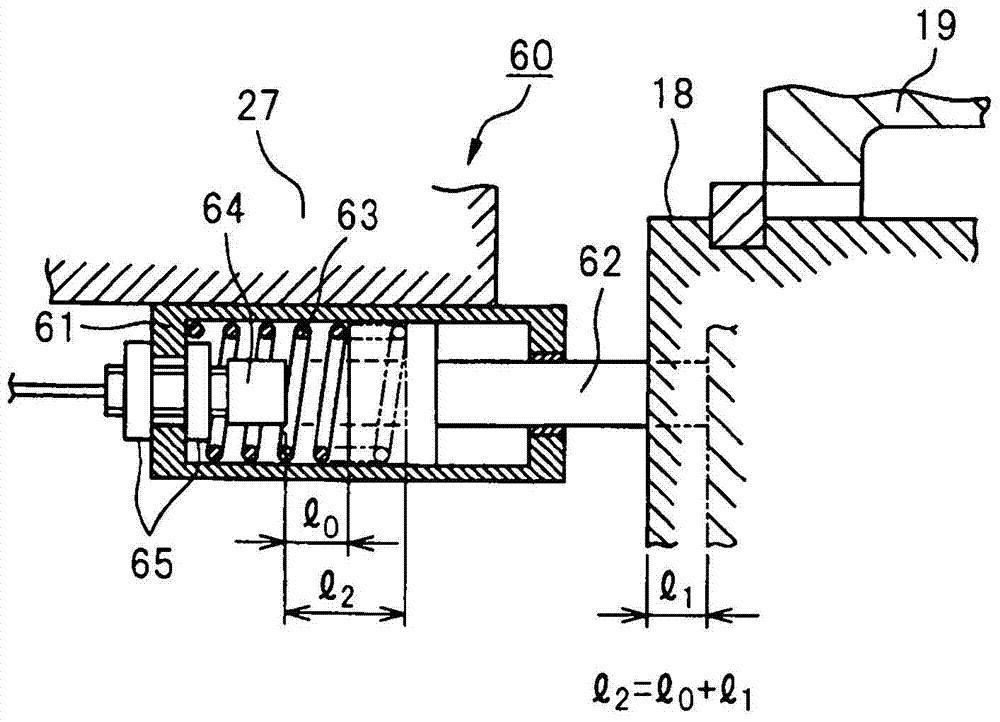

Extrusion press and control method for extrusion press

ActiveCN103781565ADoes not lead to largeNo ejectionExtrusion containersExtrusion control devicesEngineeringBlow out

The invention provides an extrusion press and a control method for the extrusion press. The extrusion press can prevent phenomena in which a billet is blown out during an extrusion process; and the extrusion press is provided with an assembly which can prevent billet blowout with a simple and inexpensive constitution. The extrusion press drives a main cylinder device (12) to extrude, by means of a stem (24), a billet (20) filled into a container (18) from a die (16) and form a product (20A). A gap measurement means (60) that measures a gap, during the extrusion process, arising at the container seal surface formed by pressing the die side end surface of the container (18) against the container side end surface of the die (16) is provided on an end platen (10) on the outer edge part of the container side end surface of the die (16). When the gap arising during the extrusion process is measured and the measured value is within a predetermined range of allowable values, a set value for the extrusion rate is lowered and a warning is issued. When the measured value exceeds the predetermined allowable values, the extrusion process is stopped.

Owner:UBE MASCH CORP LTD

Battery

ActiveCN106340607BDoes not lead to largeIncrease widthElectrically conductive connectionsCoupling device detailsElectrical batteryEngineering

The present invention provides a battery pack capable of increasing the contact area between a device side terminal and a battery side terminal without increasing the size of the battery pack. This specification discloses a battery pack that can be attached to and detached from a device having a flat device-side terminal by sliding in a sliding direction along the device-side terminal. The battery pack includes a battery-side terminal that engages with the device-side terminal to be electrically connected. The battery-side terminal includes a pair of elastic clamping pieces configured to receive the device-side terminal and clamp the device-side terminal from both sides when the battery pack is mounted on the device. In the aforementioned battery pack, the pair of elastic clamping pieces extends in a direction perpendicular to the sliding direction.

Owner:MAKITA CORP

Paralled switch device

InactiveCN1497631ADoes not lead to largeAvoid damageField or armature current controlStarter detailsElectricityVoltage

A switch unit is provided which is free from causing contact damage even in case applied to a high power voltage, whose switch unit is not greatly increased in size. Switches A and B are to take a motor stop status, a motor forward rotation status and a motor reverse rotation status. A switch C is to electrically connecting and disconnecting between the switches A and B and the power source. This switch C, when the switches A and B transits from the motor forward rotation status or motor reverse rotation status into the motor stop status, is operated from a connection state to a disconnection state at a time of any of completing the transition to the motor stop status and prior to a predetermined marginal period of time.

Owner:ORMON CORP

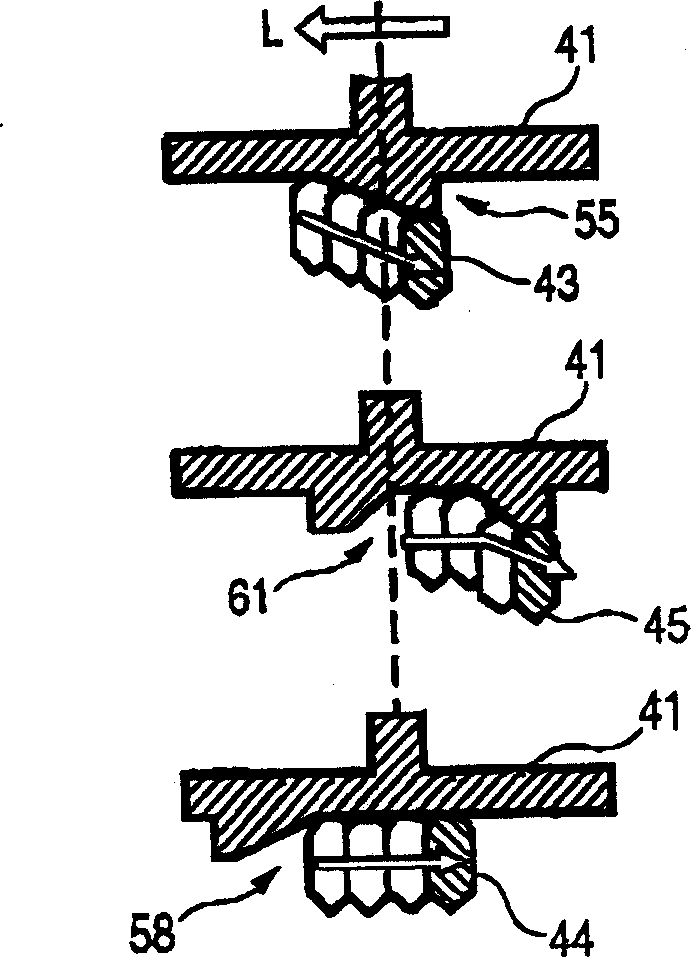

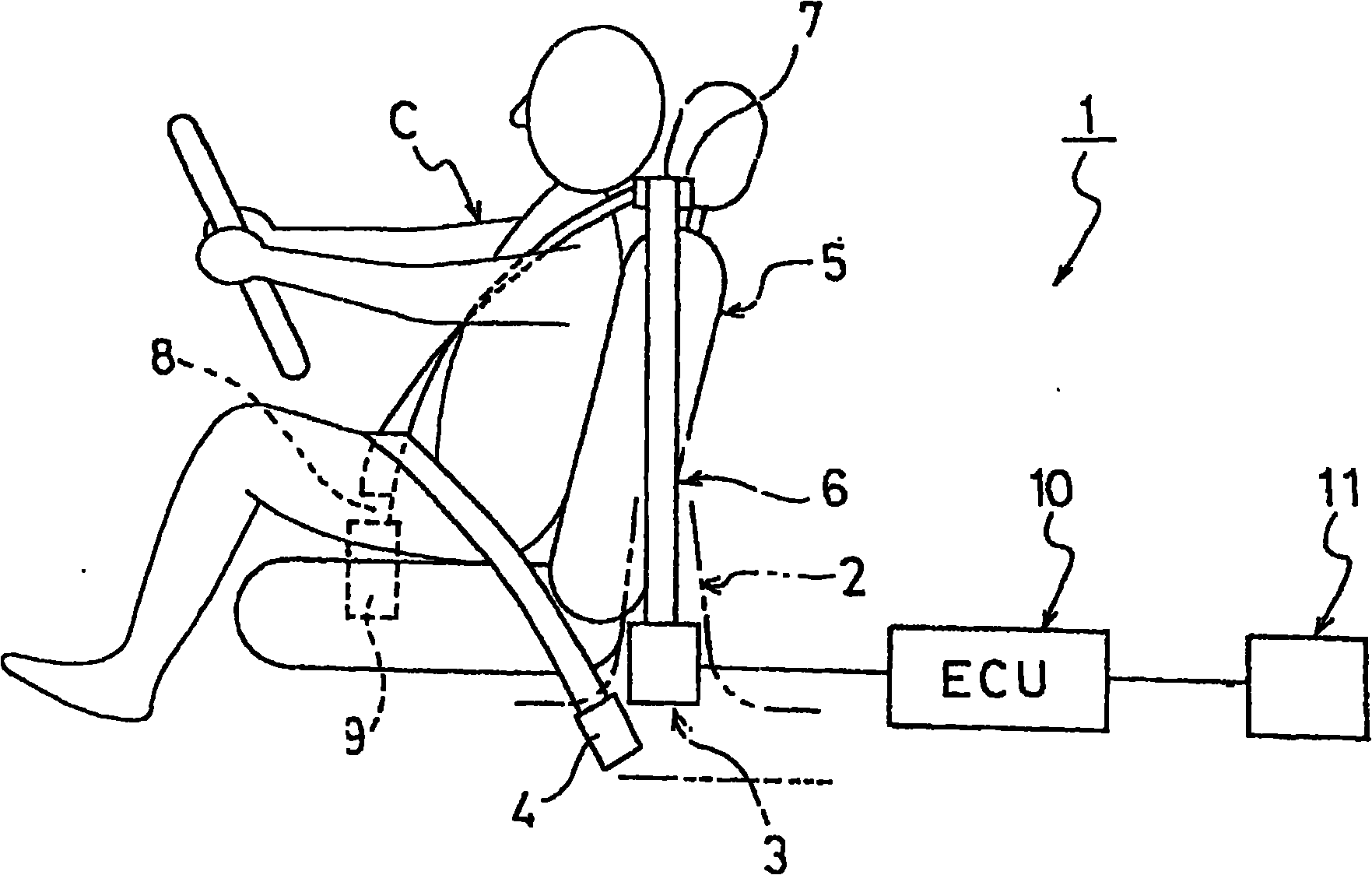

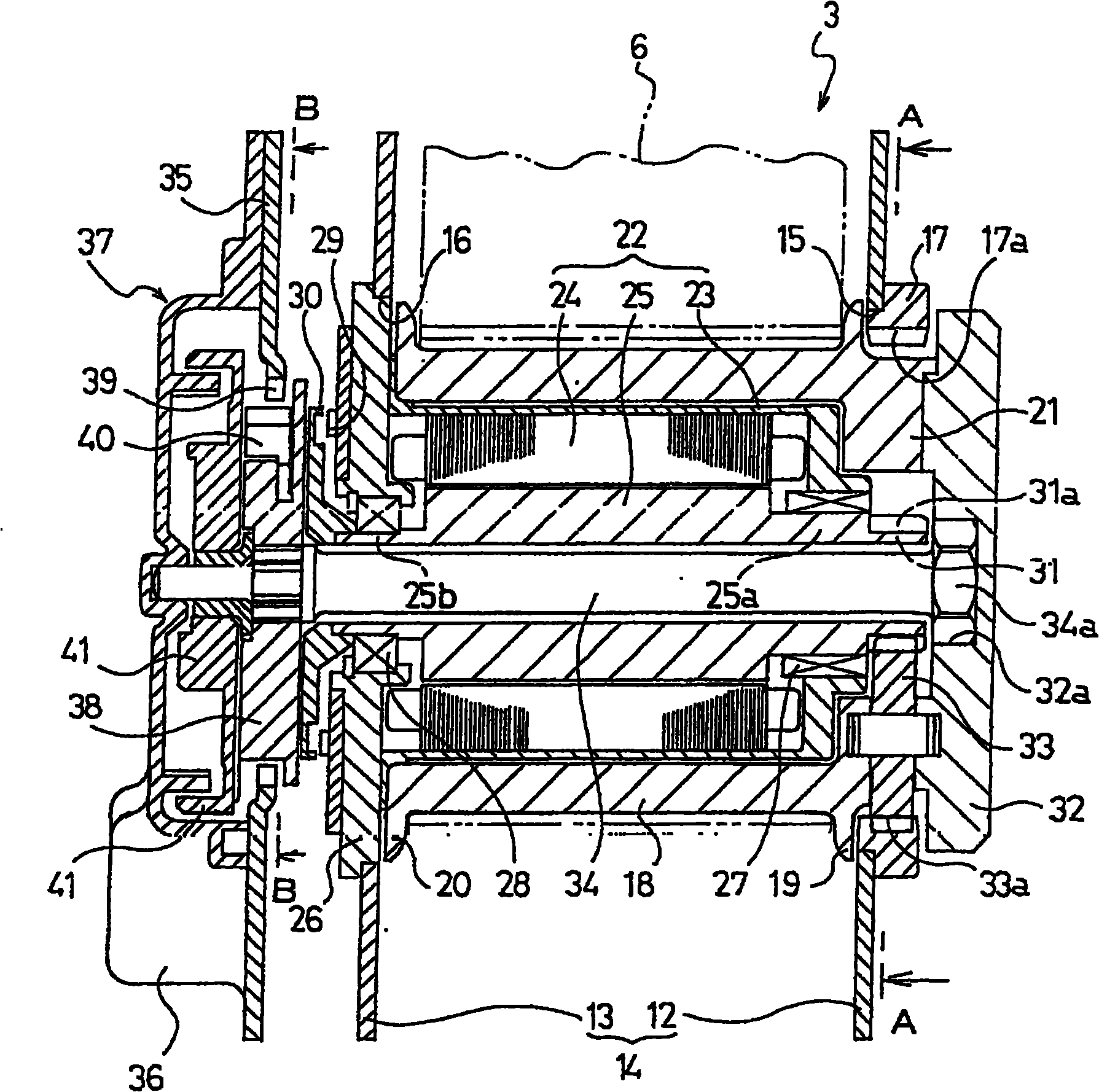

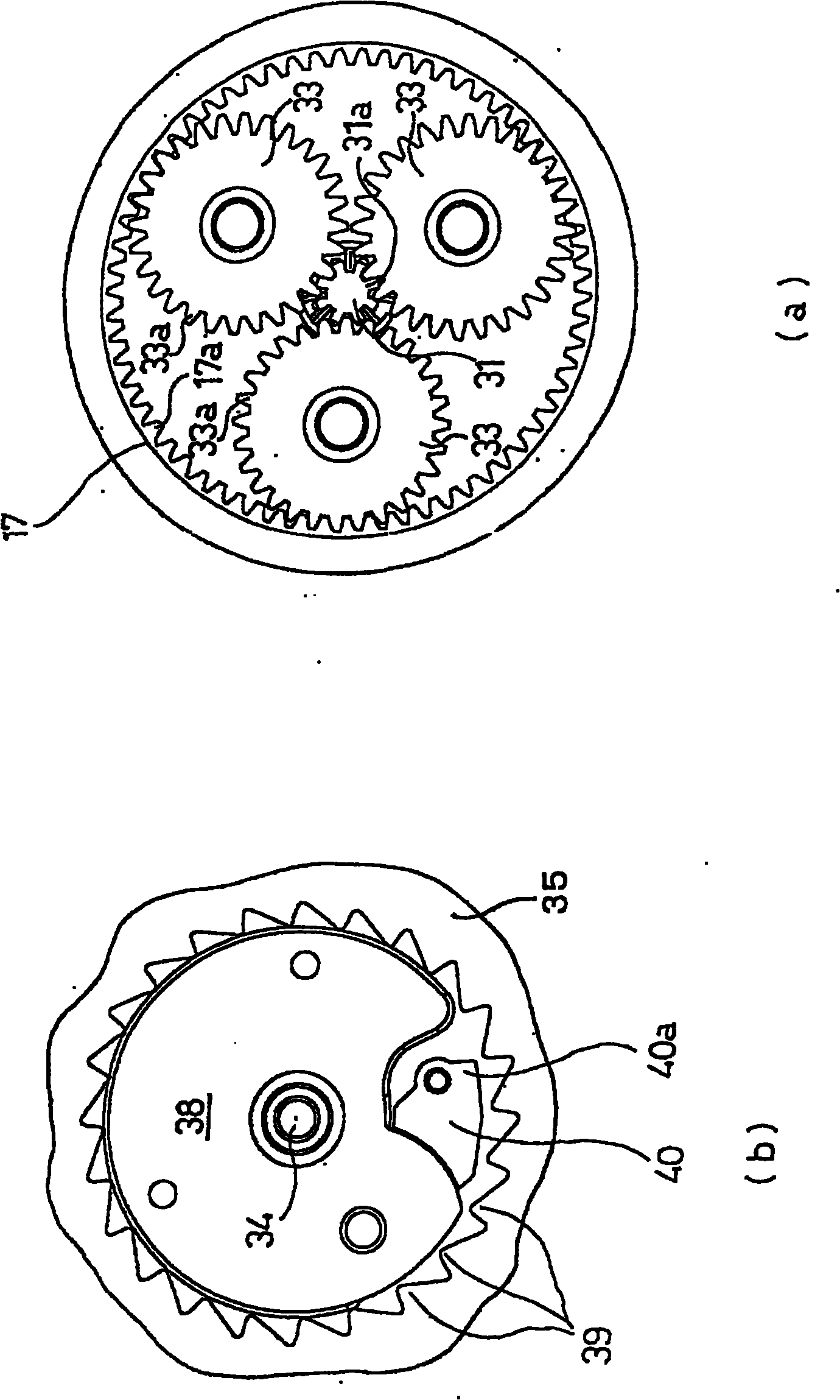

Seat belt retractor and seat belt apparatus

Provided is a motor-driven seat belt retractor which can be formed to have an entire compact size and can absorb impact energy on an occupant in the event of an emergency such as a vehicle collision. An electric motor (22) is disposed inside a cylindrical spool (18). The rotation of the electric motor (22) is transmitted to a spool (18) via a sun gear (31), planetary gears (33) and a carrier (32). In the event of an emergency, a locking mechanism (37) is actuated by the action of a deceleration sensing means (36) to lock the rotation of a locking base (38) in the belt unwinding direction. On the other hand, the spool (18) is about to continue to rotate in the belt unwinding direction by further inertia movement of an occupant so that a head (34a) of a torsion bar (34) of an EA mechanism is biased to rotate in the same direction via a carrier (32). Then, the torsion bar (34) is torsionally deformed, thereby absorbing impact energy on an occupant and limiting load on a seat belt 6 not to be too large.

Owner:TAKATA CORPORATION

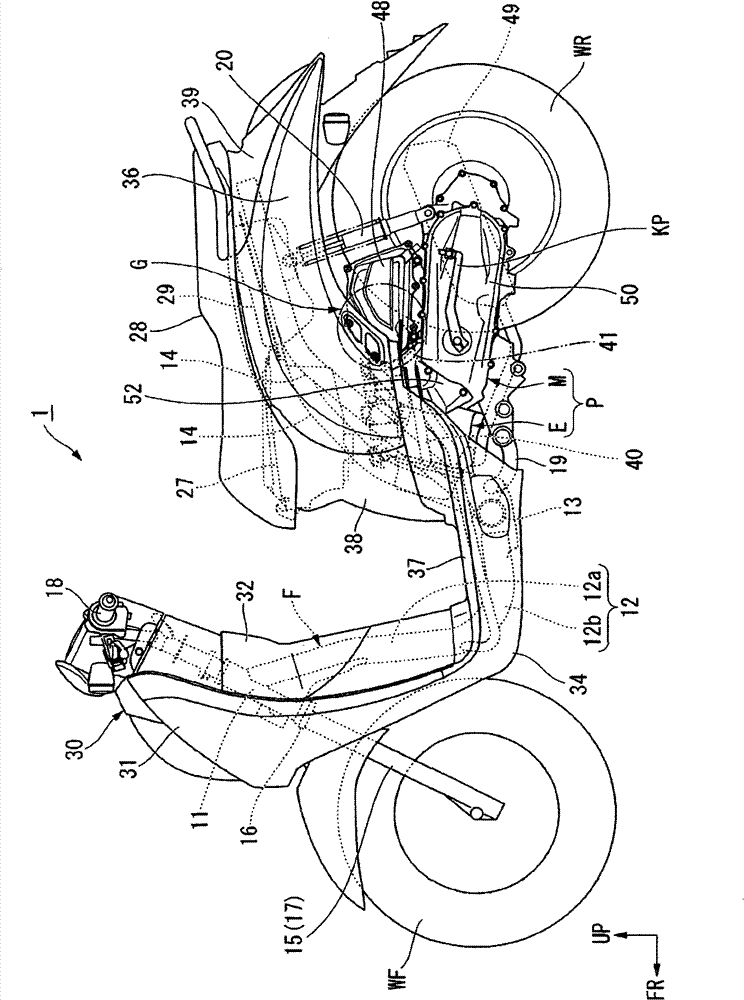

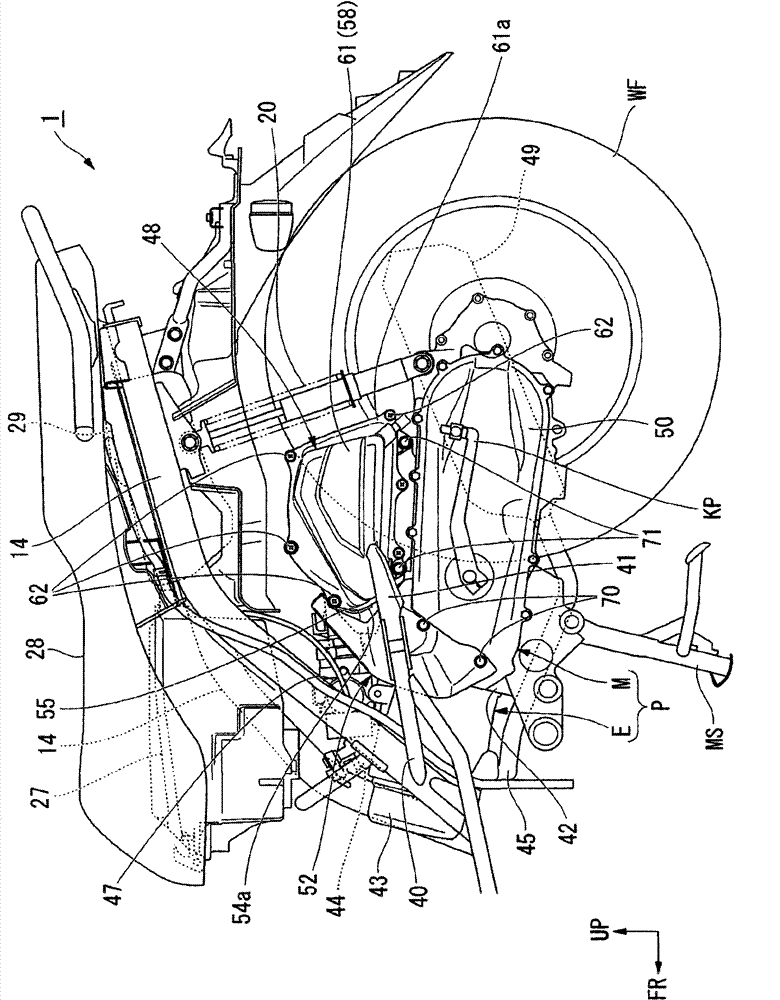

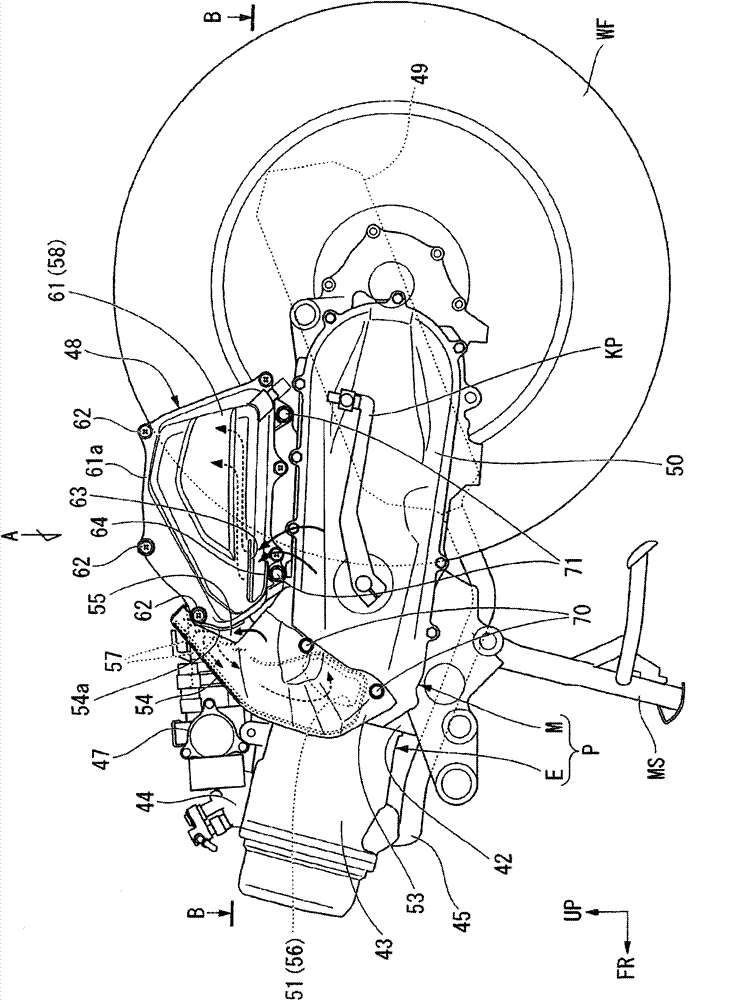

Air inlet structure of a saddle type vehicle

InactiveCN102003310BImprove intake air filling efficiencySuppress inhalationInternal combustion piston enginesAir intakes for fuelAir filterCrankcase

Owner:HONDA MOTOR CO LTD

Mixed valve

ActiveCN101135395BDoes not grow verticallyDoes not cause vertical elongationMultiple way valvesWarm waterEngineering

A mixed vale comprises a valve body provided with a first guide-in opening, a second guide-in opening and a guide-out opening; and a cylindraceous valve core rotatably embedded in the valve body. The circumferential wall of the valve core is provided with a first opening part and a second opening part corresponding to the first and second guide-in openings, and is provided with a third opening part over the first and second opening parts. When the valve core rotates, the first guide-in opening is made to all close status from all open status, and the second guide-in opening is made to all open status from all close status, when the valve core further rotates and the first guide-in opening is kept at all close status, the third opening part makes the opening area of the second guide-in opening become minimum from maximum continuously. Adopting the invention, a mixed valve with easy assembly and compact structure can be provided which can quickly and correctly obtain the warm water withrequired mixing proportion after mixed the cold water and the hot water, and can regulate the flux of water of one side when the guide-in opening of another side is at all close status.

Owner:FUJIKOKI MFG CO LTD

Power conversion devices and their motor drives, blowers, compressors, air conditioners, refrigerators, refrigerators

ActiveCN105075101BExtended testing periodWill not be enlargedAC motor controlAc-dc conversionElectrical resistance and conductancePhase currents

The present invention provides a power conversion device capable of increasing the detection period of each phase current without increasing the size and cost of the device, and realizing high precision control based on each phase current. The power conversion device is provided with: a power supply shunt resistor (5), which is arranged between the negative voltage side of the DC power supply (1) and the inverter (2); and the lower bridge arm shunt resistors (6a, 6b) of each phase, They are respectively arranged between the switching elements (3d, 3e) of the lower bridge arms of each phase of two of the three bridge arms and the power supply shunt resistor (5), wherein the switching elements (3d, 3e) of the lower bridge arms of each phase 3e) and the voltages between the connection points of the lower arm shunt resistors (6a, 6b) of each phase and the negative voltage side of the DC power supply (1), and based on the detected values, calculate the flow into the load device (9 ) of each phase current.

Owner:MITSUBISHI ELECTRIC CORP

Lamp and lighting device

InactiveCN102449382BDoes not lead to largeAchieve high brightnessPoint-like light sourceElectric circuit arrangementsElectricityEffect light

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com