Scroll compressor

A technology of scroll compressors and moving scrolls, which is applied in the field of scroll compressors, can solve the problems of reduced strength and larger torque of the European ring 100, and achieve the effect of improving installation workability and suppressing the reduction of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

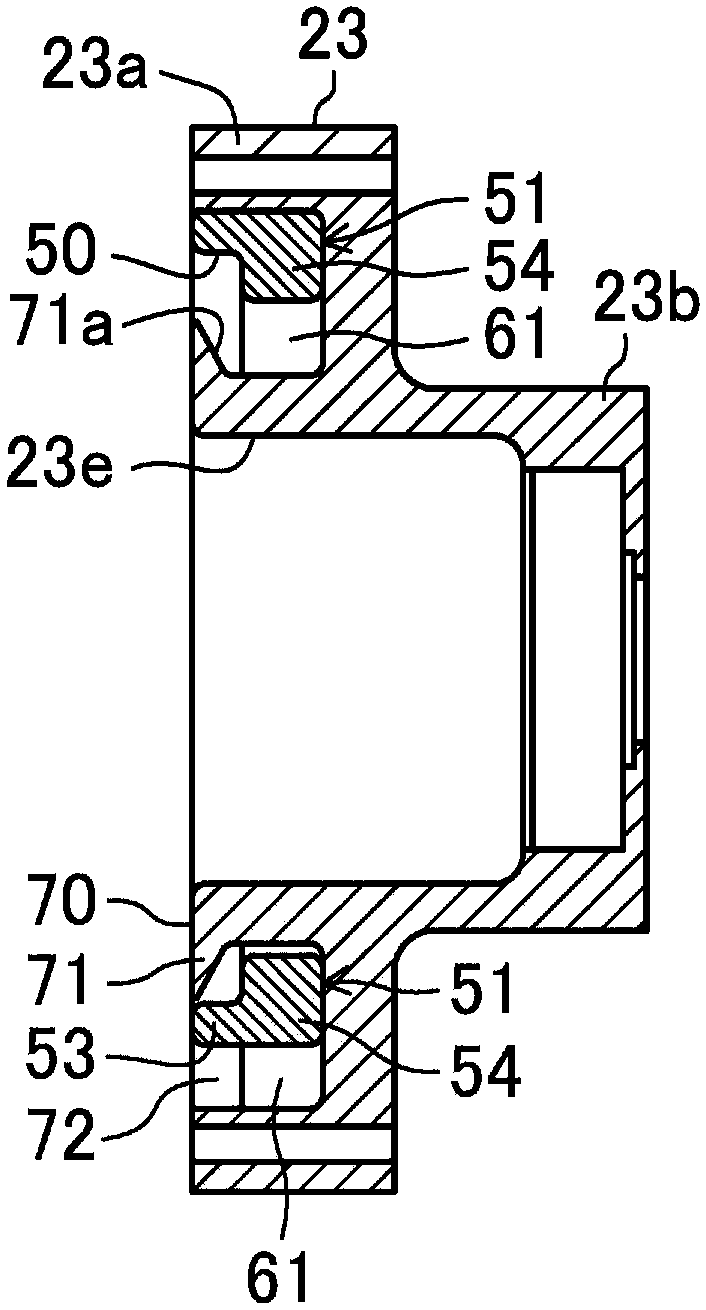

[0104] Such as Figure 12 As shown, the opposing portion 71 may be formed in a plate shape with a constant thickness. Even with the configuration as described above, the first key groove 61 can be easily formed in the main body portion 23 a of the housing 23 , and the first key 54 can be easily mounted in the first key groove 61 .

Deformed example 2

[0106] Such as Figure 13 As shown, the opposing portion 71 may also be constituted by another member fixed to the main body portion 23 a of the housing 23 . Even with the configuration as described above, the first key groove 61 can be easily formed in the main body portion 23 a of the housing 23 , and the first key 54 can be easily mounted in the first key groove 61 .

Deformed example 3

[0108] Such as Figure 14 , Figure 15 As shown, the first key groove 61 may be a groove opened on the outer peripheral surface of the main body portion (flange portion) 23 a of the housing 23 .

[0109] Even with the configuration as described above, the first key groove 61 can be easily formed by a groove opened on the outer peripheral surface of the main body portion (flange portion) 23 a of the housing 23 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com