Ejection structure of mold

A mold and ejector plate technology, applied in the field of ejection structure of the mold, can solve problems such as insufficient strength of the oblique pin, difficulty in taking the product by the manipulator, unbalanced ejection, etc., and achieve the effect of avoiding insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

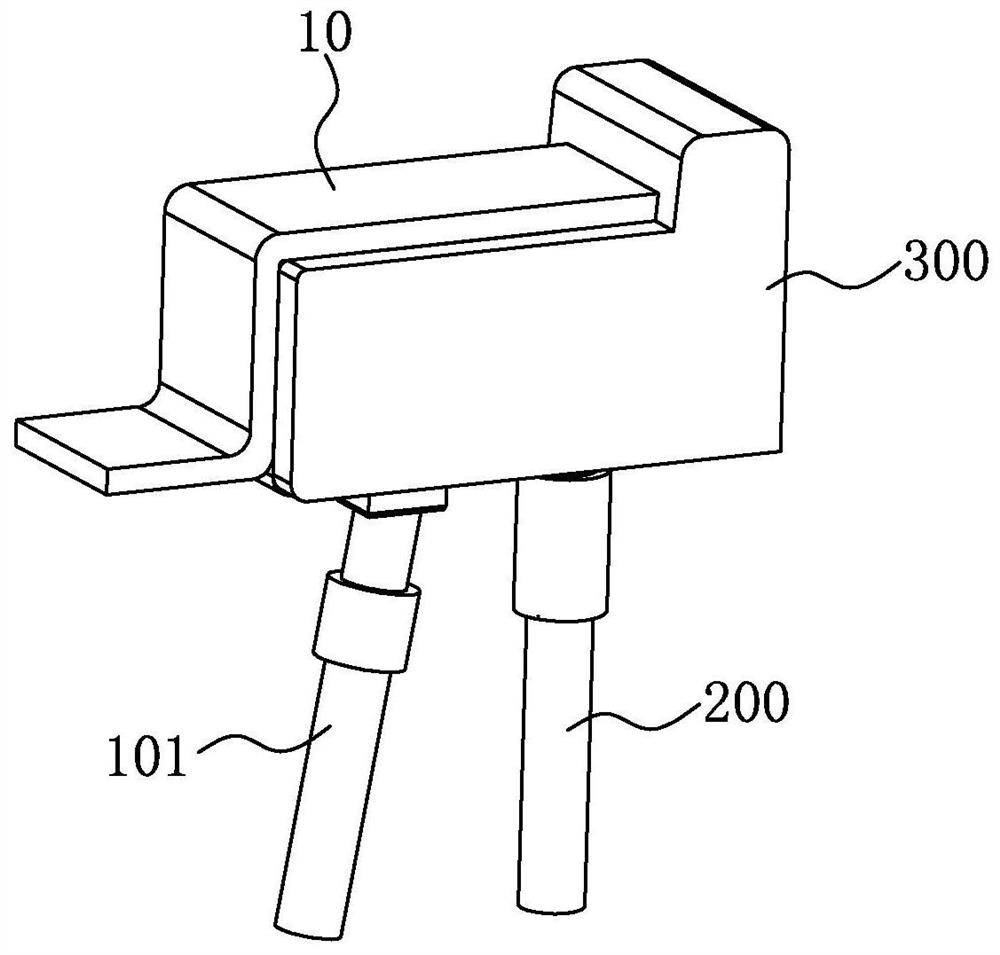

[0021] In order to have a further understanding of the purpose, technical effect and technical means of the present invention, the detailed description is as follows in conjunction with the accompanying drawings.

[0022] see Figure 2-5 shown, where figure 2 Illustrated as a three-dimensional schematic view of the ejection structure of the mold of the present invention, image 3 An exploded perspective view showing the ejection structure of the mold of the present invention, Figure 4 Another perspective exploded view showing the ejection structure of the mold of the present invention, Figure 5 Illustrated is a cross-sectional view of the ejection structure of the mold of the present invention.

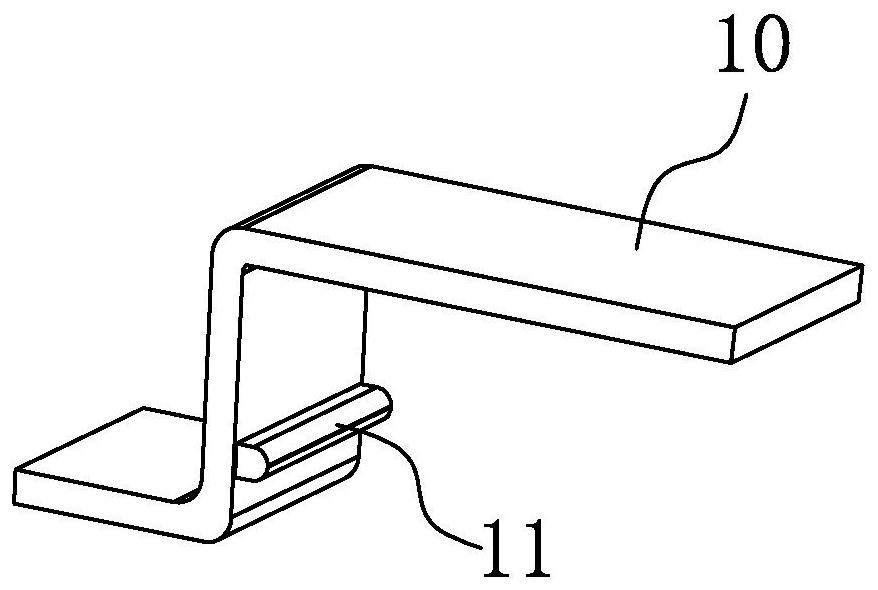

[0023] In this embodiment, the ejection structure of the mold of the present invention is used to eject products 10 with undercuts 11, especially products 10 with larger areas or volumes. The ejection structure of the mold includes:

[0024] Slant pin 100, it has slant pin seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com