DC motor

A DC motor and commutator technology, applied in the field of brush DC motors, can solve problems such as poor space efficiency and workability, and achieve the effects of low manufacturing cost, noise removal, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0100] The embodiments of the present invention will be described in detail below with reference to the drawings.

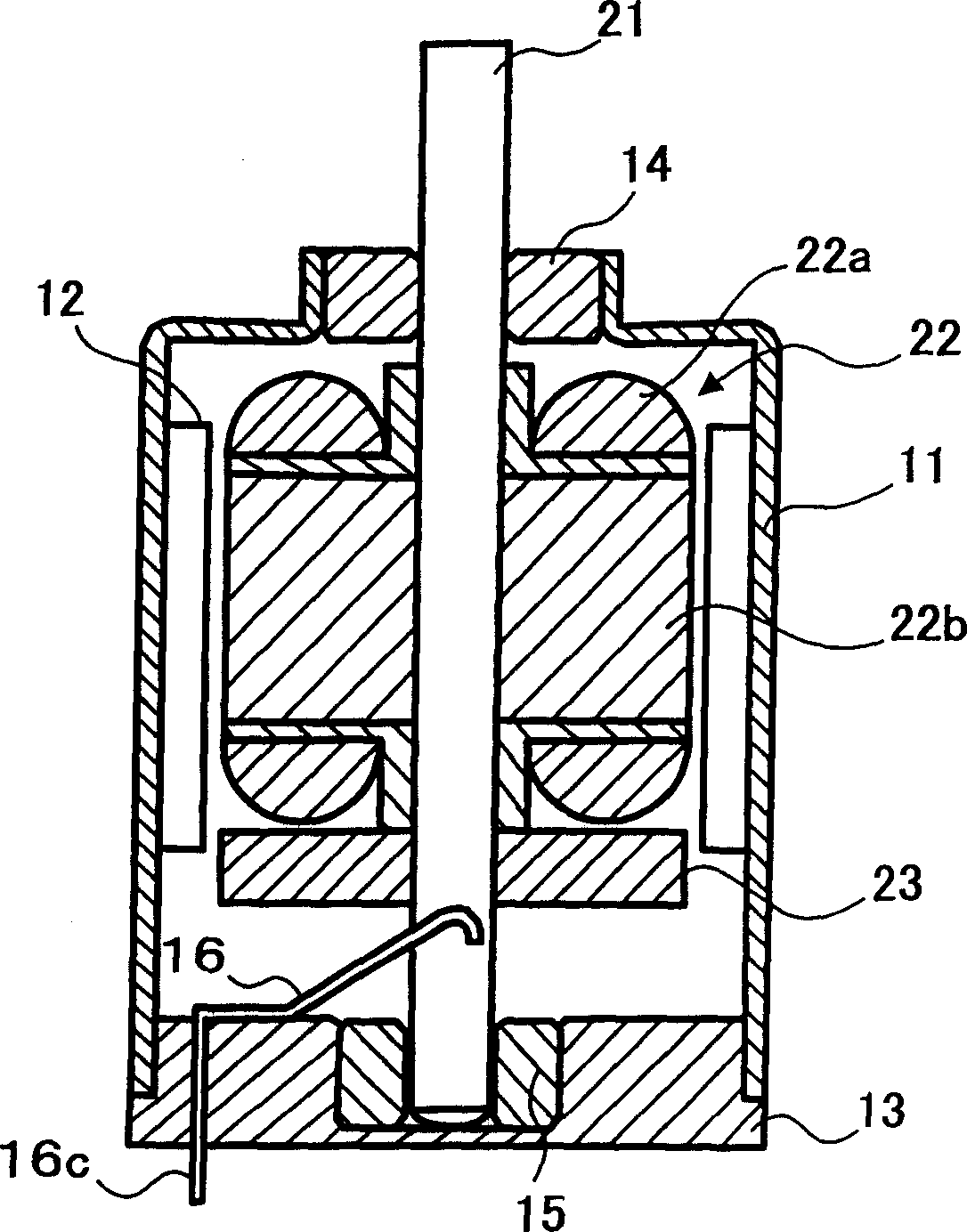

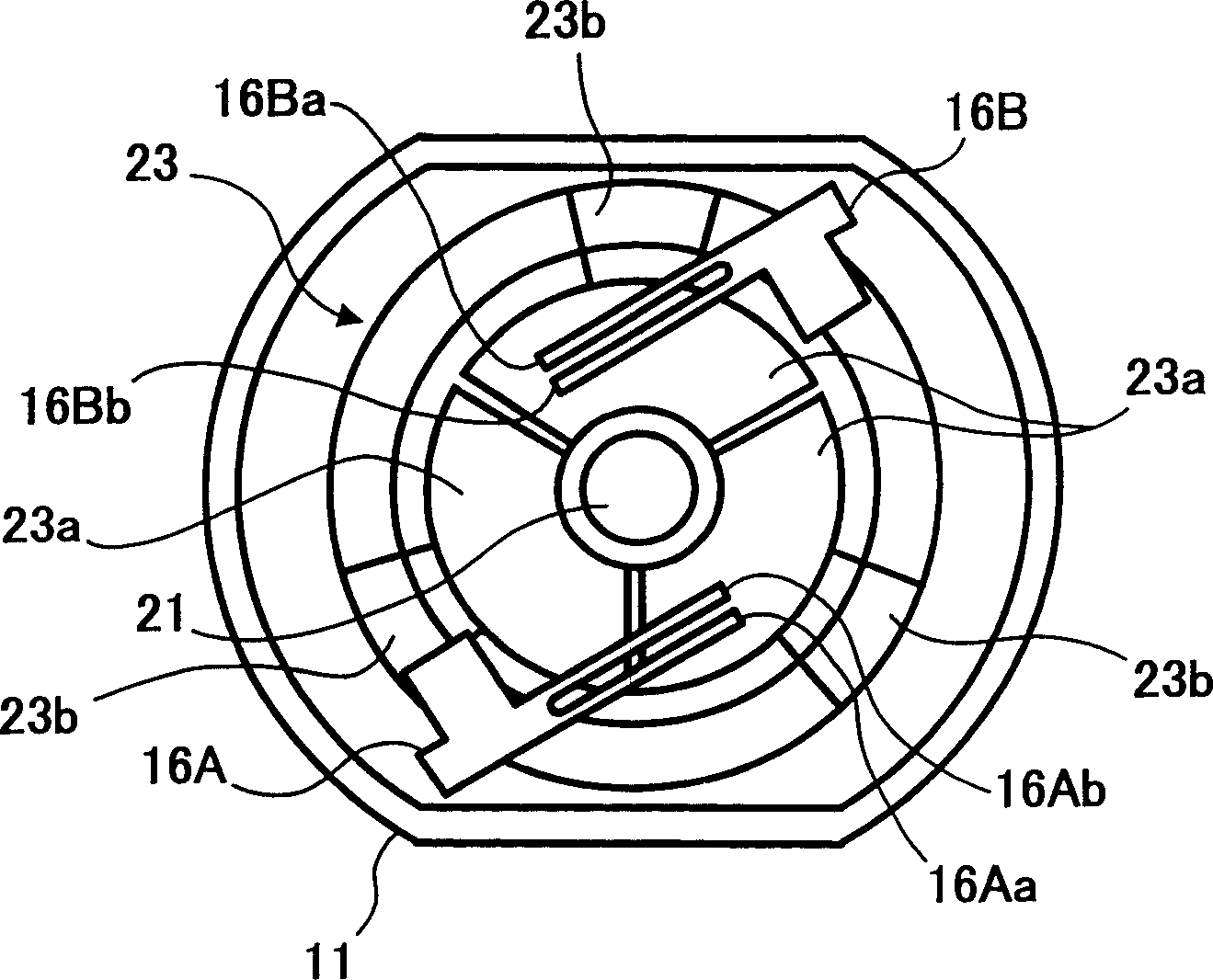

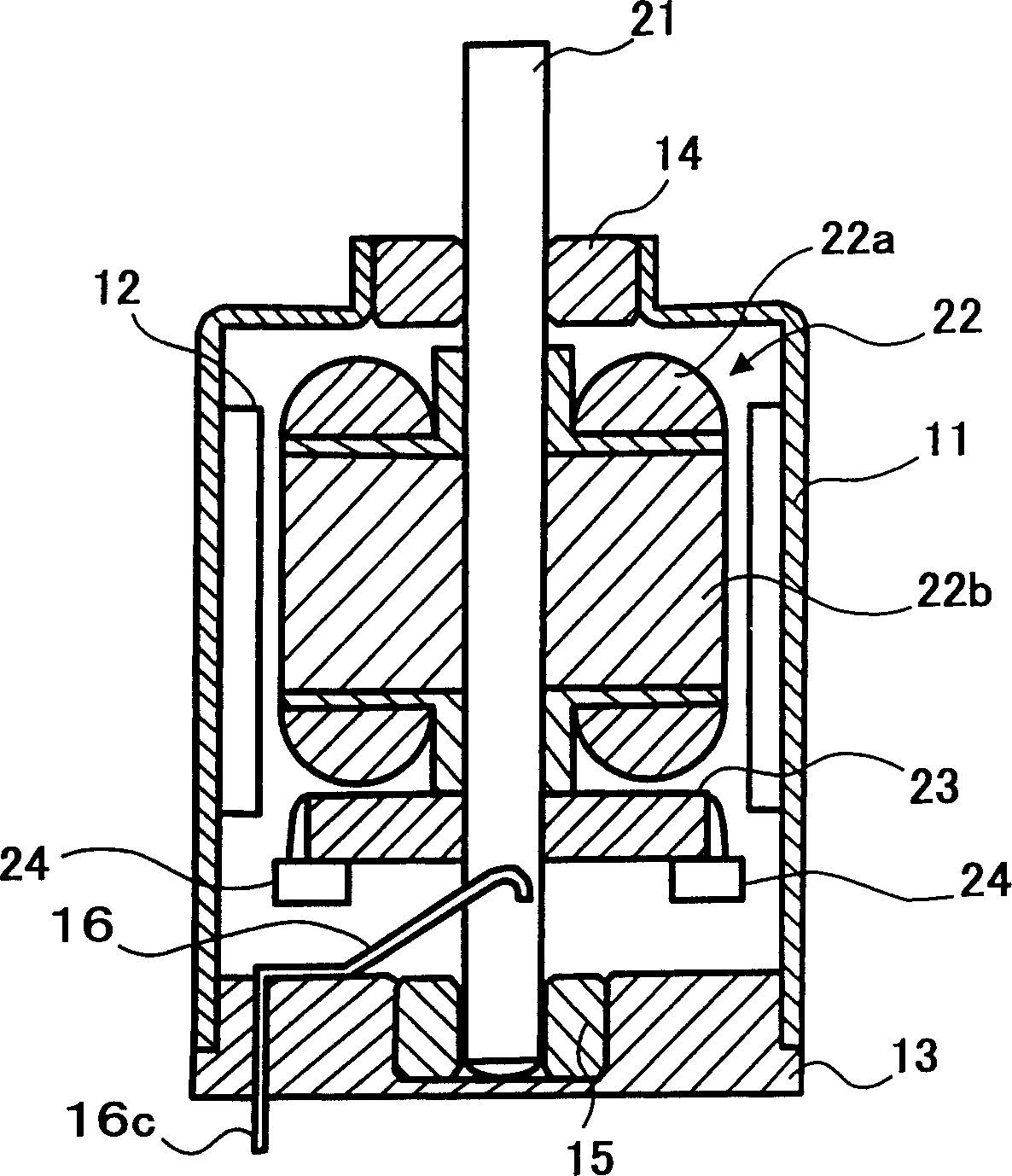

[0101] figure 1 with figure 2 Shows the DC motor related to the first embodiment of the present invention, figure 1 Is the longitudinal section view of the DC motor, figure 2 Is for illustration figure 1 A cross-sectional view of the structure of the sliding part of the DC motor commutator and electrode brushes.

[0102] figure 1 with figure 2 The DC motor shown is provided with a housing 11, a stator 12, a thrust bearing cover 13, an upper bearing 14, a lower bearing 15, an electrode brush 16, a rotating shaft 21, a rotor 22, and a printed circuit board 23. The housing 11, the stator 12, the thrust bearing cover 13, the upper bearing 14, the lower bearing 15, and the electrode brush 16 belong to the stator side structure and do not rotate. The rotating shaft 21, the rotor 22, and the printed circuit board 23 belong to the rotor side structure, are integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com