Flow velocity distribution equalizing apparatus

A flow velocity distribution and homogenization technology, applied in the direction of charging system, indirect carbon dioxide emission reduction, combustion method, etc., can solve the problems that the rectifying plate cannot cope, the pressure loss is large, and the catalytic burner has no examples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

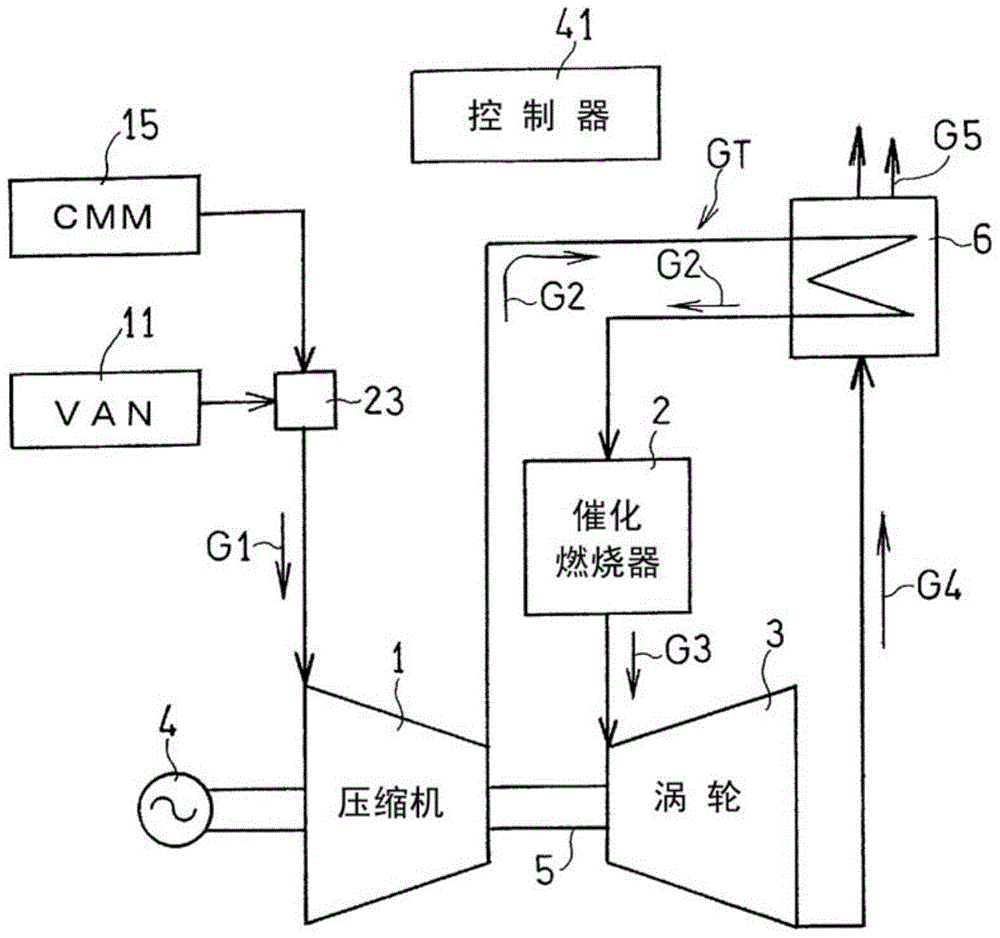

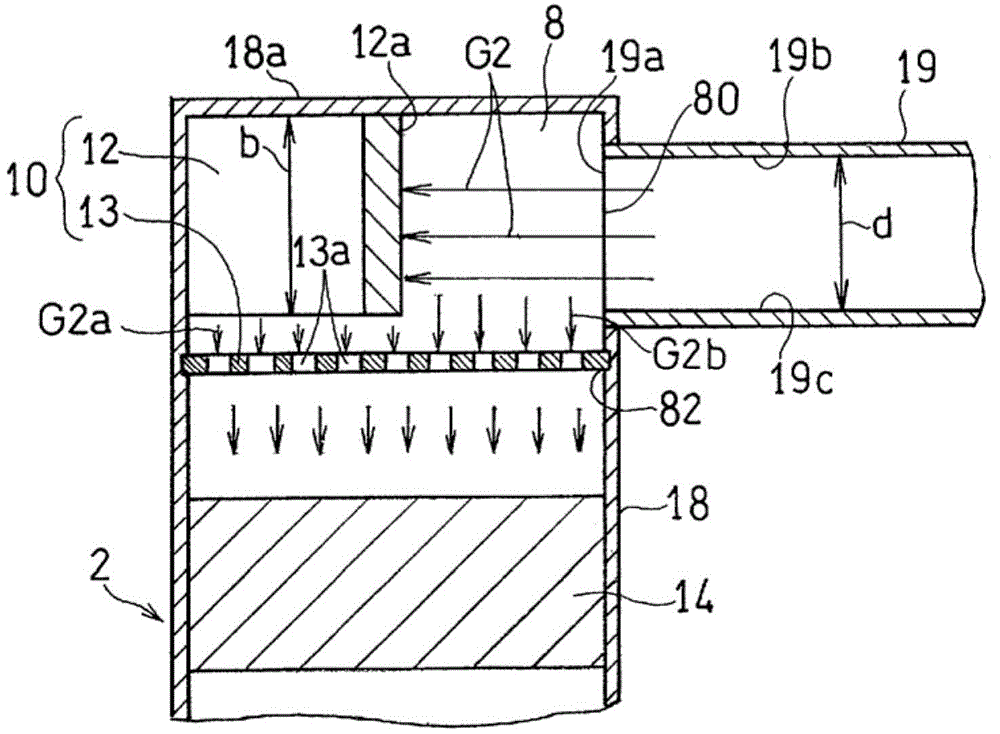

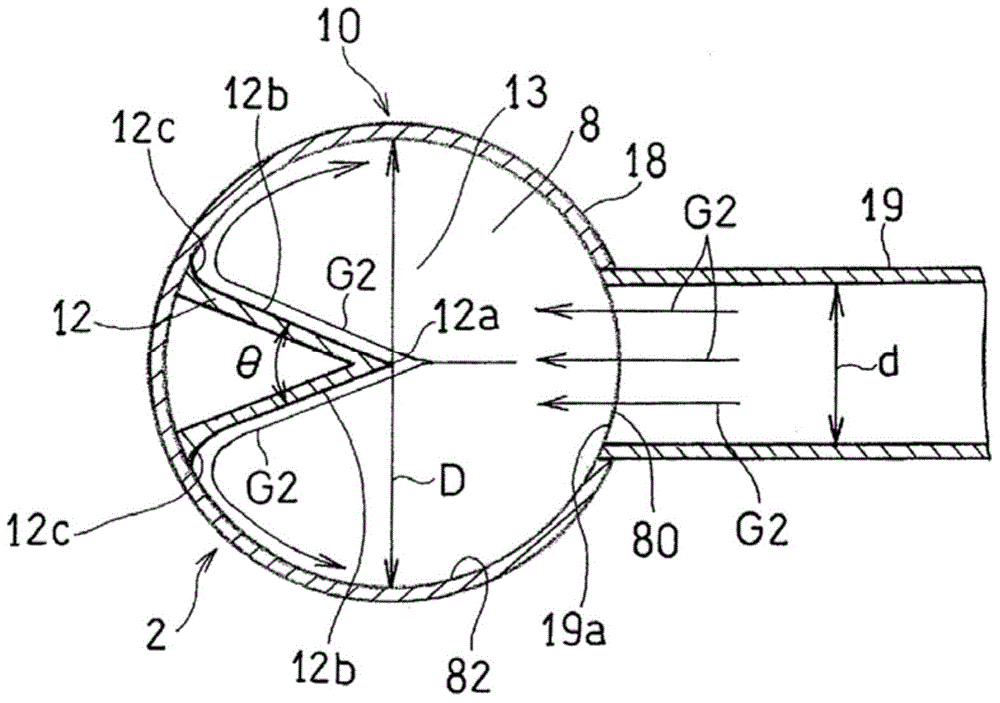

[0027] Preferred embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a block diagram showing a schematic configuration of a gas turbine engine GT provided with a flow velocity distribution equalizing device according to an embodiment of the present invention. In this embodiment, a gas turbine engine GT using a lean fuel as described later is exemplified. This gas turbine engine GT has a compressor 1 , a catalytic combustor 2 containing a catalyst such as platinum or palladium, and a turbine 3 . The generator 4 is driven by the output of the gas turbine engine GT.

[0028] As the low-calorie fuel gas used in the gas turbine engine GT, the following fuel gas can be used. For example, VAM (Ventilation Air Methane; Coal Mine Ventilation Methane) produced in a coal mine is supplied from the VAN supply source 11, and CMM (Coal Mine Methane; Coal Mine Methane) having a combustible component (methane) concentration higher than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com