Multichannel structure using metal foam to uniformly distribute fluid flow

A technology of metal foam and fluid flow, which is applied in the field of heat and mass transfer applications, can solve problems such as multi-channel flow unevenness, and achieve good application potential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

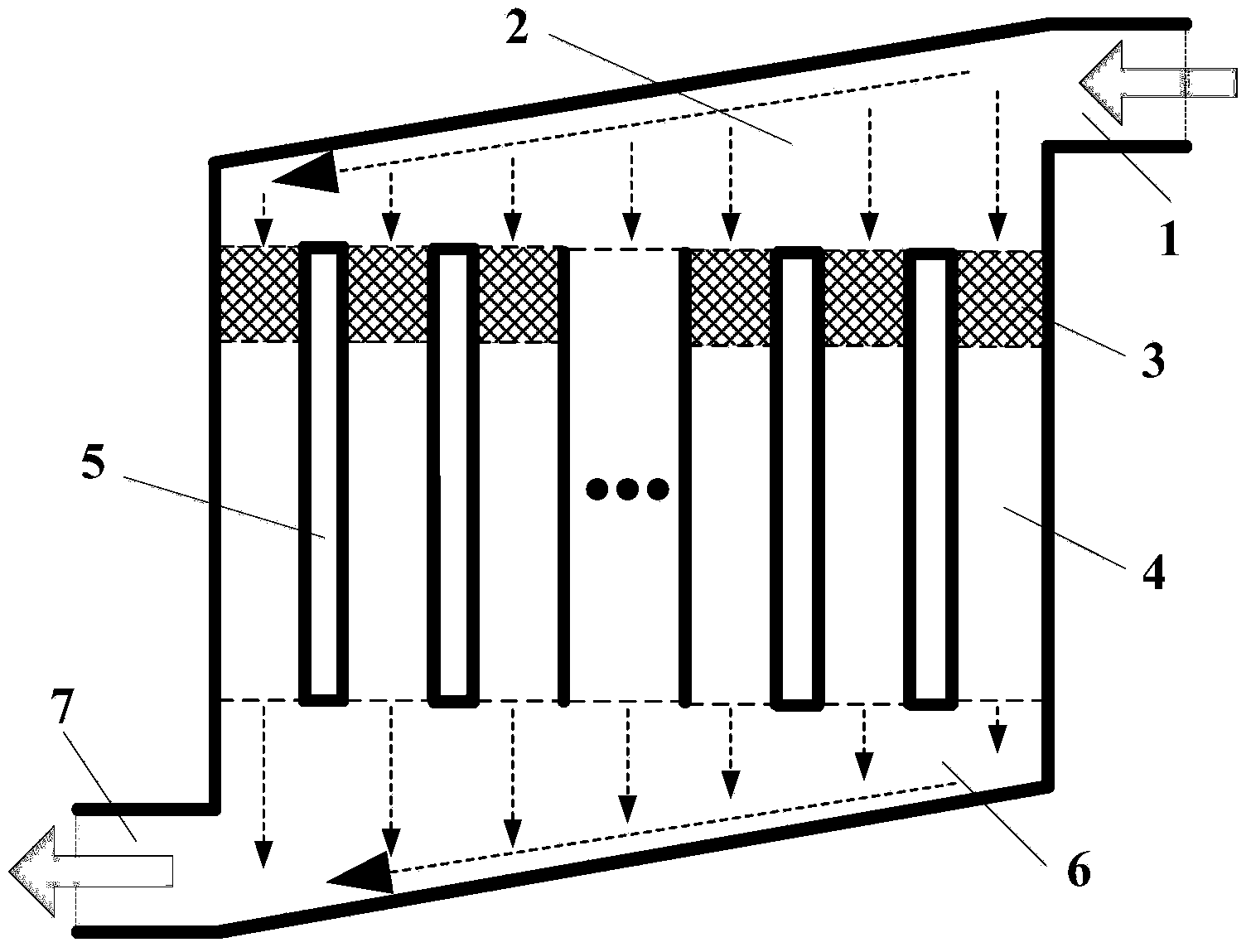

[0024] Specific implementation mode one: combine figure 1 To illustrate, a multi-channel structure that uses metal foam to evenly distribute fluid flow in this embodiment includes a flow channel inlet 1, a distribution end 2, a main channel, a confluence end 6, and a flow channel outlet 7. The flow channel inlet 1, The distribution end 2, the main channel, the confluence end 6 and the flow channel outlet 7 are connected in sequence, and a plurality of channel intervals 5 are set in the main channel to divide the main channel into several sub-channels, and the front end of each sub-channel is filled with metal foam to form a metal foam segment 3 , the part of the sub-channel not filled with metal foam is defined as the foam-free segment 4.

[0025] The present invention maintains flow balance by filling metal foams with equal resistance characteristics at the entrances of each sub-channel.

[0026] The flow direction of the fluid at the channel inlet 1 and the channel outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com