Lubricating oil supply device for stepless speed changer

A technology of continuously variable transmission and transmission, which is applied in the direction of lubricating pumps, transmission devices, friction transmission devices, etc., and can solve problems such as increased protrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

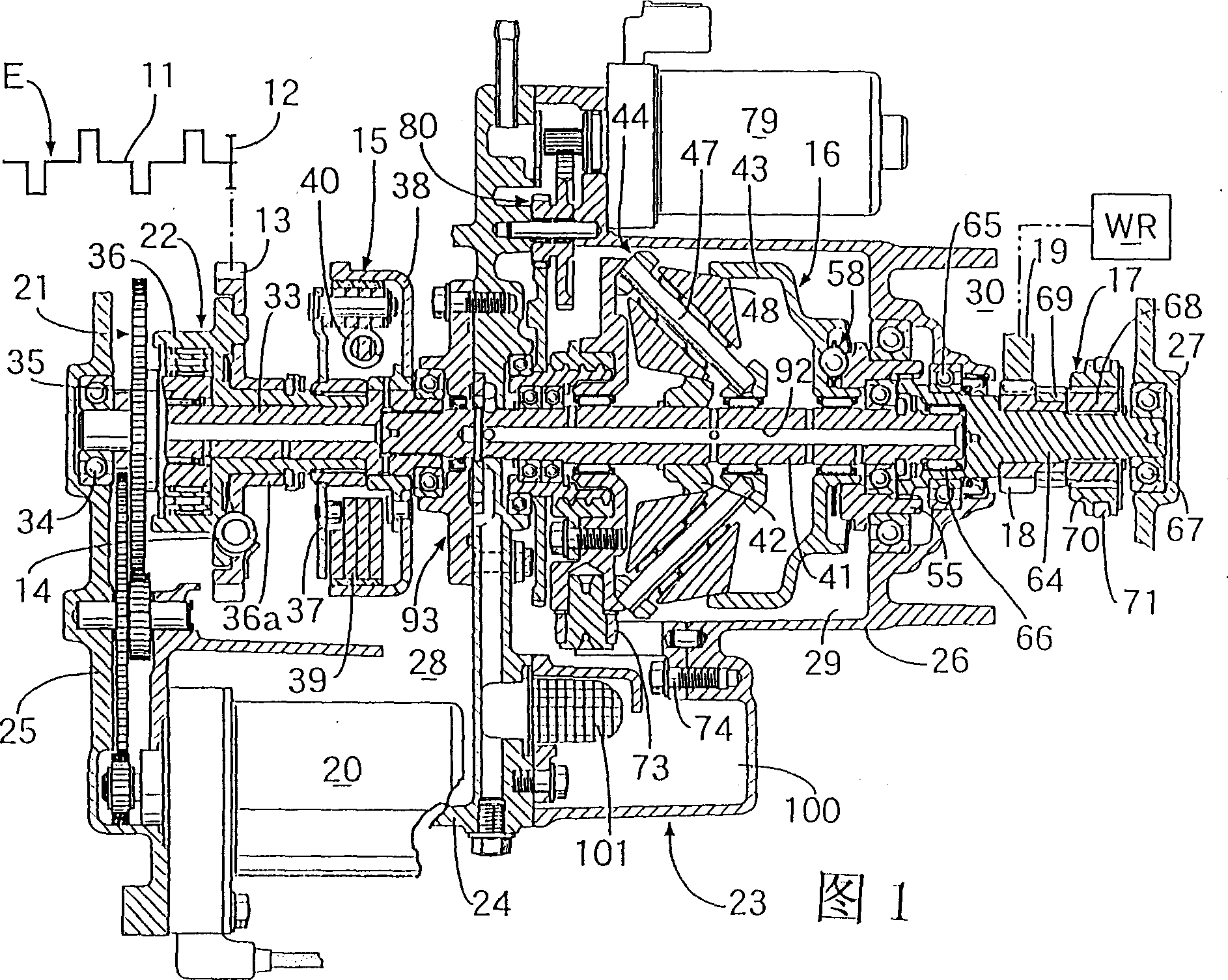

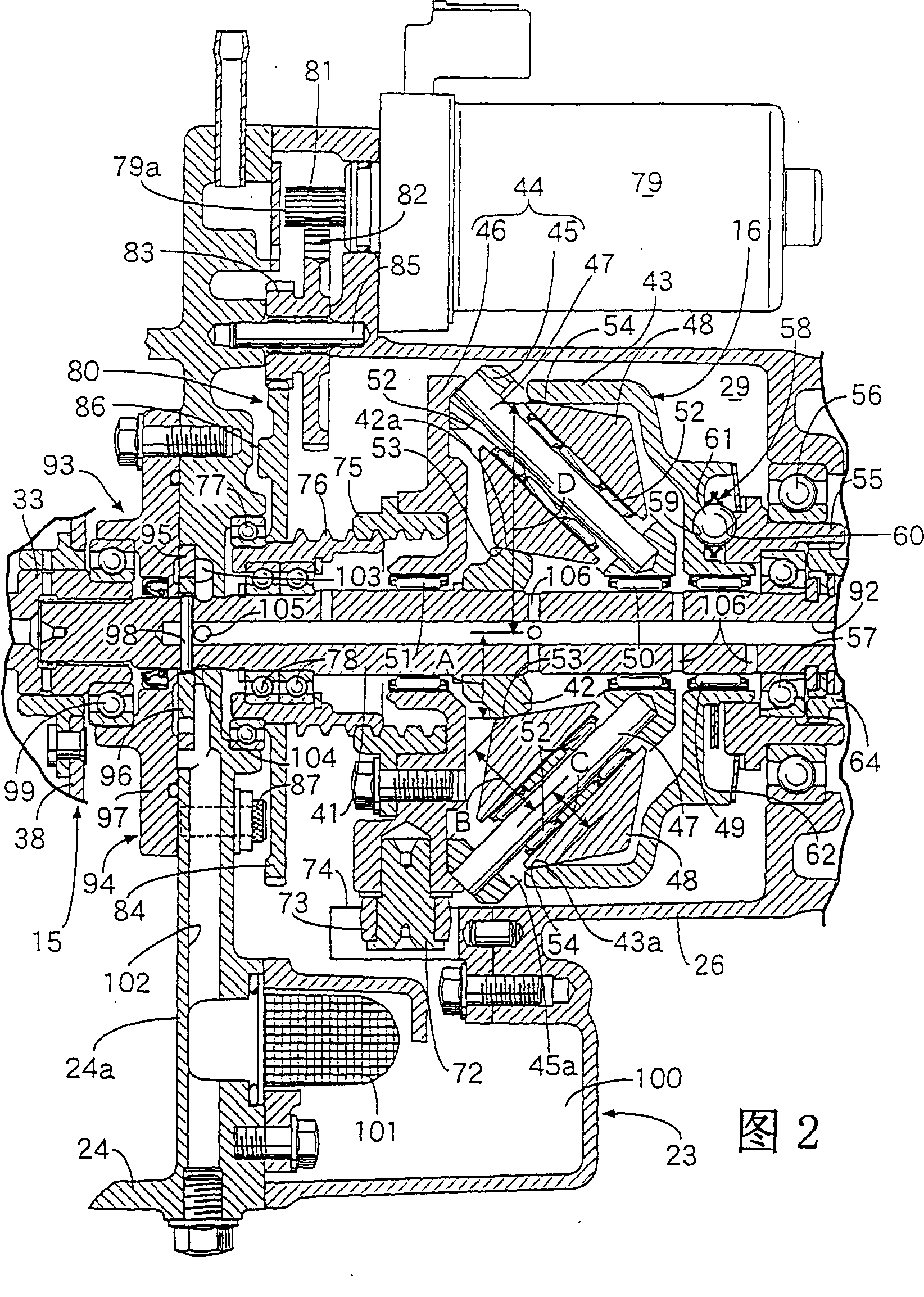

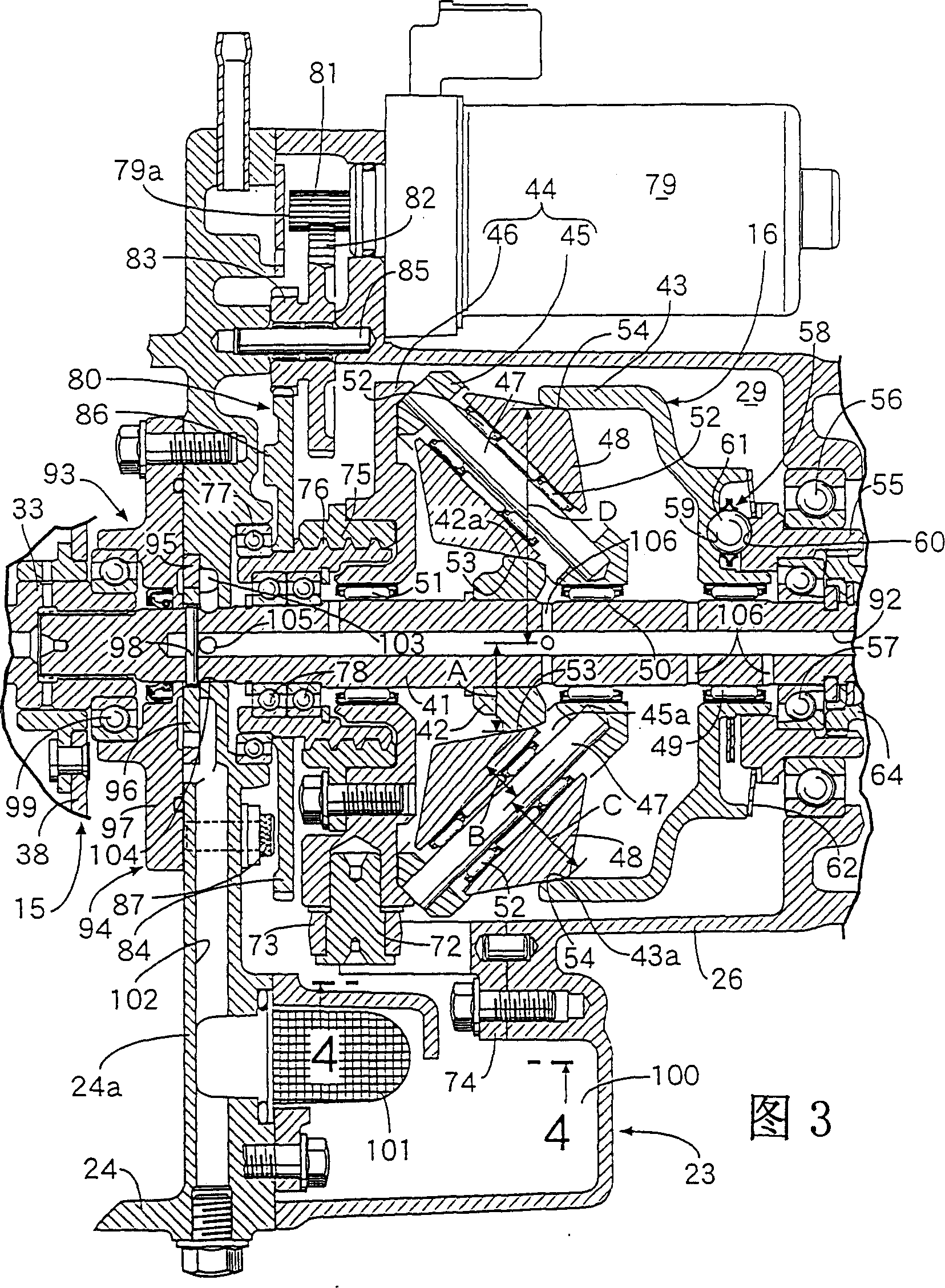

[0017] Hereinafter, an embodiment of the present invention will be described based on an embodiment of the present invention shown in the drawings.

[0018] Figure 1 to Figure 5 One embodiment of the present invention is shown, and FIG. 1 is a longitudinal sectional view showing a power transmission mechanism between an engine and a continuously variable transmission. Fig. 2 is an enlarged longitudinal sectional view of the continuously variable transmission in a low gear ratio state. Fig. 3 is an enlarged longitudinal sectional view of the continuously variable transmission in a high gear ratio state. Figure 4 It is a view from the direction of 4-4 in FIG. 3 . Figure 5 It is a cross-sectional view showing the connection structure between the bracket and the potentiometer.

[0019] First, in FIG. 1, the output of an engine E mounted on a vehicle such as a motorcycle passes through a transmission gear 12, a driven gear 13, a buffer spring 14, an automatic centrifugal clutc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com