Mixed valve

A technology of mixing valve and mixing fluid, applied in valve devices, multi-port valves, mechanical equipment, etc., can solve the problem of inability to add hot water flow throttling, etc., and achieve a low-cost and useful structure, easy processing and assembly, and increased leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

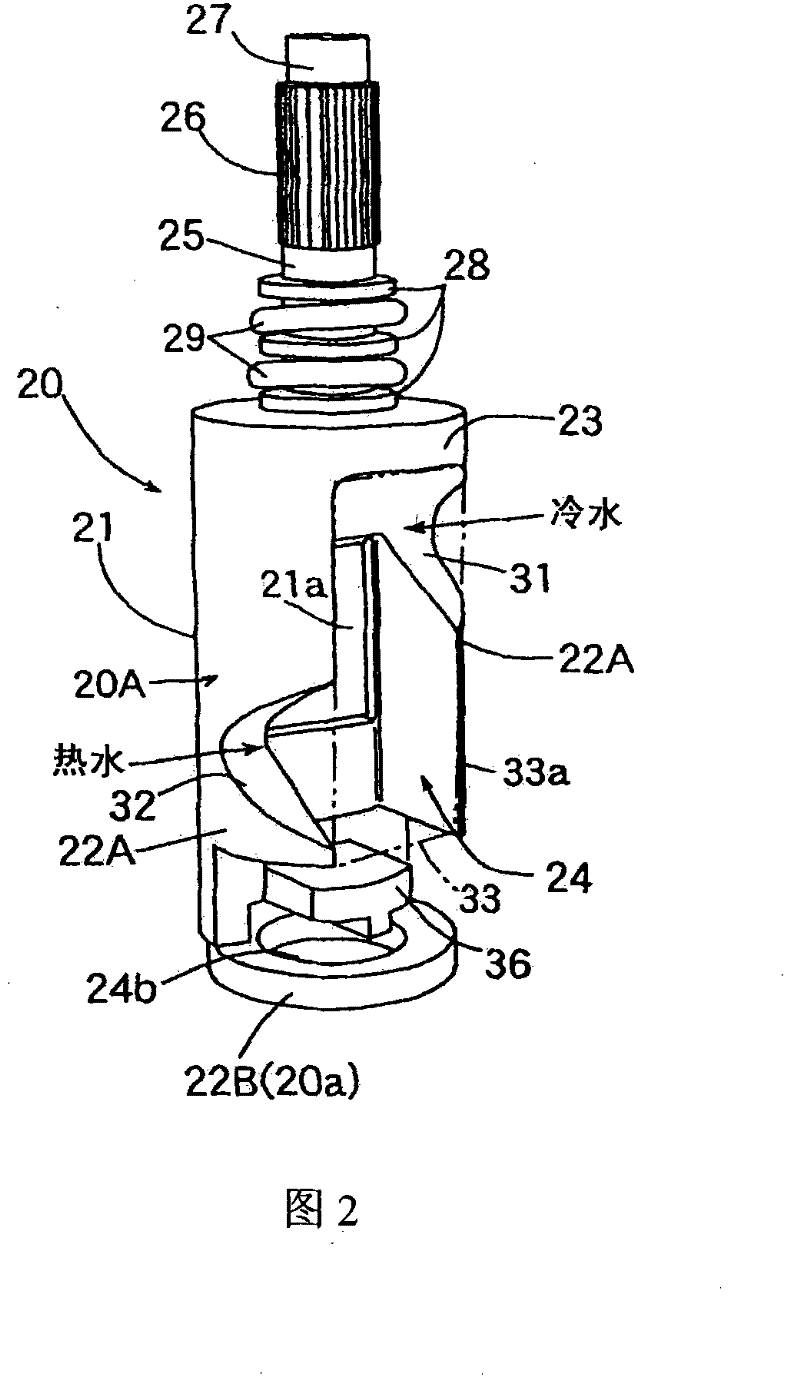

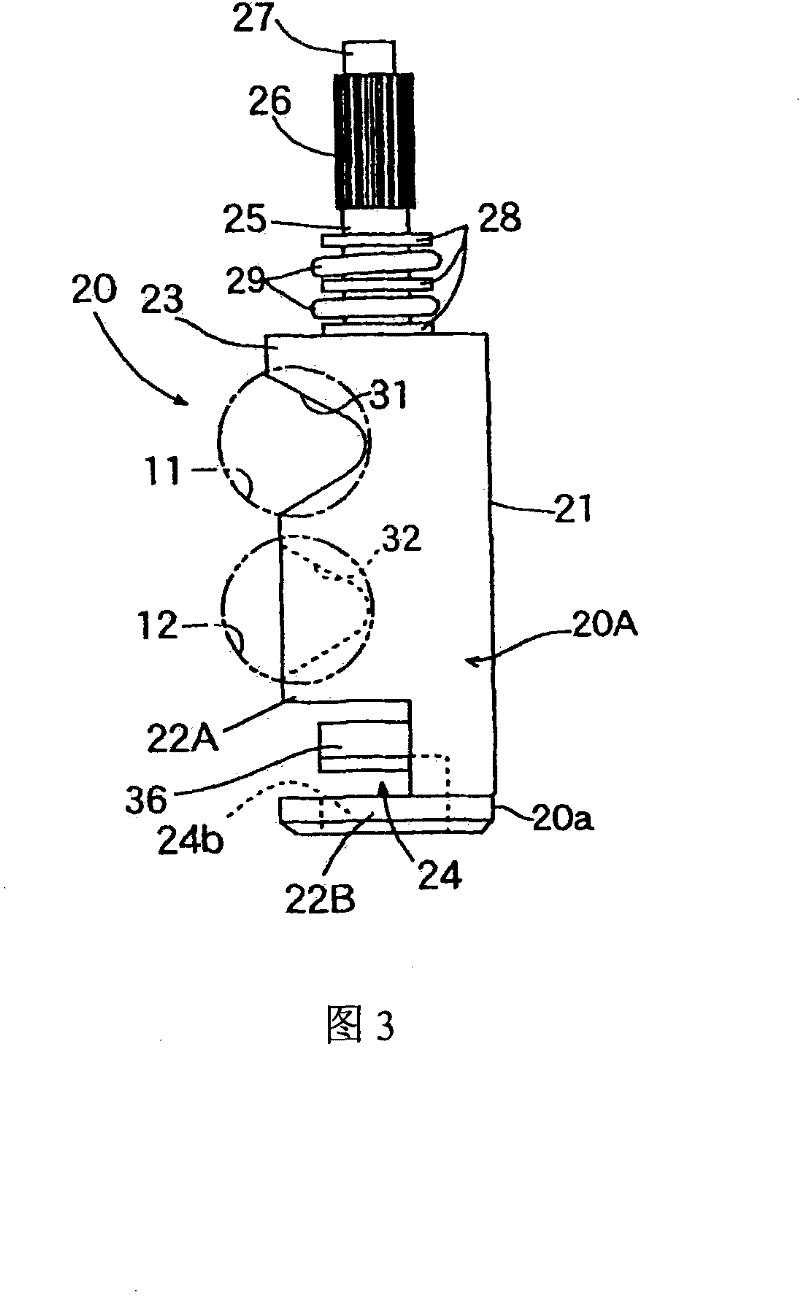

[0049] Hereinafter, an embodiment of the mixing valve according to the first embodiment of the present invention will be described with reference to the drawings.

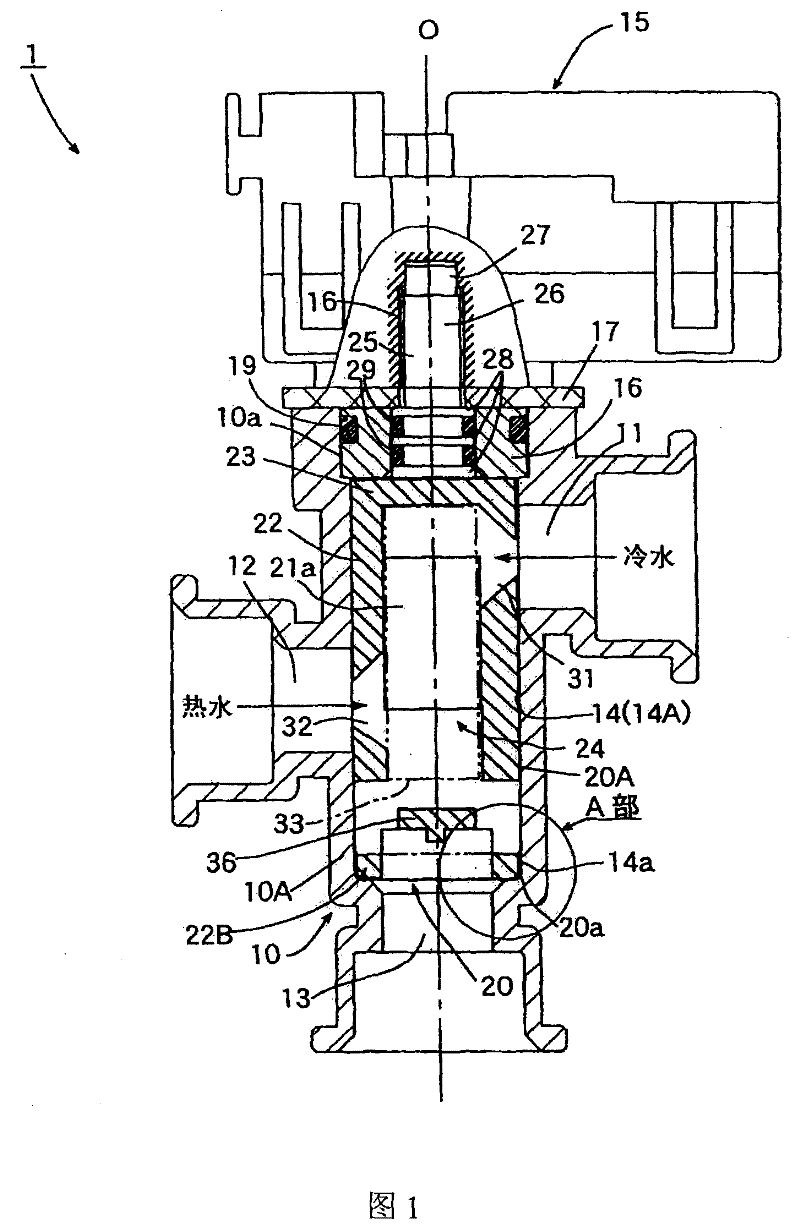

[0050] figure 1 It is a partially cutaway front view showing the first embodiment of the mixing valve of the present invention.

[0051] The mixing valve 1 of the illustrated embodiment is used, for example, in a hot water supply device for mixing cold water and hot water to obtain warm water at a desired temperature. The mixing valve 1 includes: a valve body 10 having a circular cross section. The valve chamber 14 is provided with a cold water inlet 11 connected to the side of the valve chamber 14, a hot water inlet 12, and an outlet 13 connected to the bottom for discharging warm water obtained by mixing cold water and hot water; A rotatable valve core 20 in the valve chamber 14 of the valve body 10; a stepping motor 15 as a driving means for rotating the valve core 20.

[0052] The cold water inlet 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com