Two-stage centrifugal pump

A technology for centrifugal pumps and rotors, applied to pumps, pump devices, pump components, etc., which can solve the problems of reduced durability and achieve the effects of improved durability, increased discharge flow, and reduced wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention will be described below with reference to the drawings.

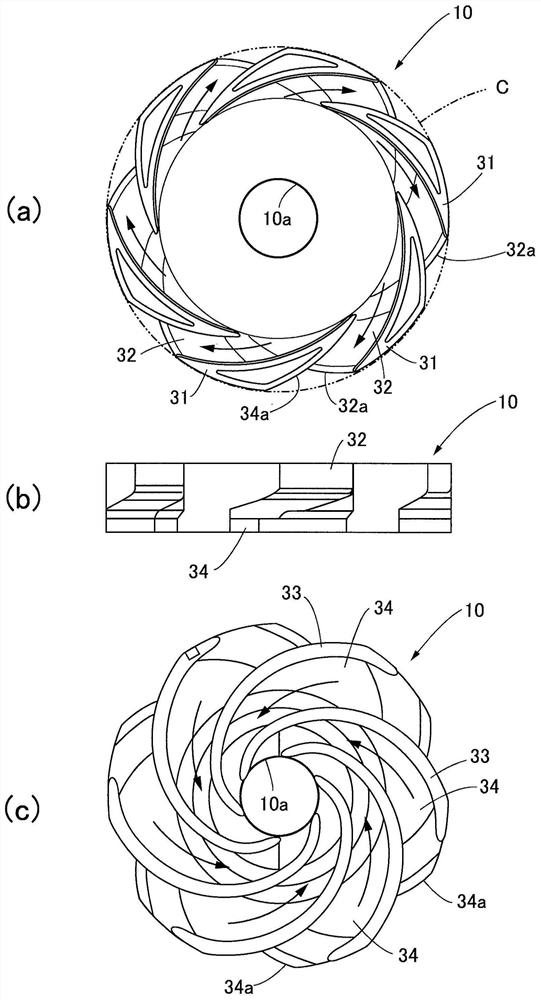

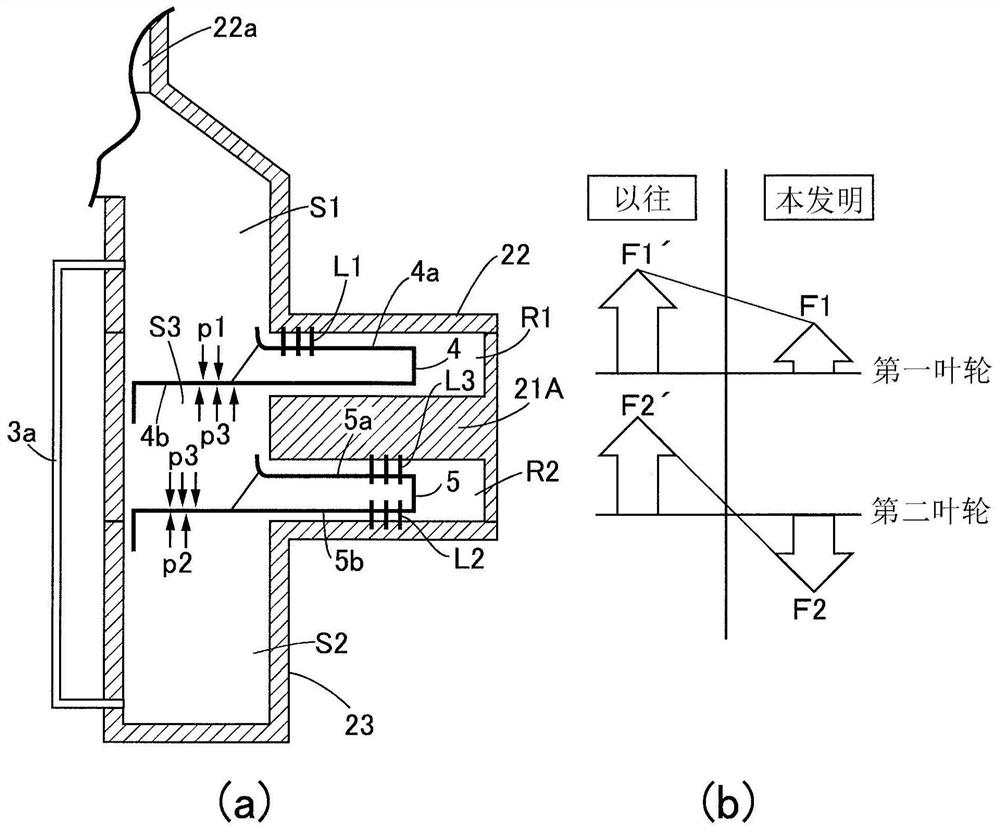

[0062] figure 1 is a longitudinal sectional view of a two-stage centrifugal pump of the present invention, figure 2 It is a figure which shows the guide vane member of this two-stage centrifugal pump, (a) is a top view, (b) is a side view, (c) is a bottom view.

[0063] figure 1 The shown two-stage centrifugal pump 1 is a hermetic motor pump constructed to be figure 1 The pump part P arranged up and down (in the axial direction) and the motor part M as a drive source are connected along the same central axis to form an integral body, and a support shaft 6 is accommodated on the central axis and rotatably held on the support shaft 6 The hollow rotor shaft 3 is used to transmit the rotational power exerted by the motor part M to the pump part P, and sliding bearings 7 and 8 are interposed between the rotor shaft 3 and the support shaft 6 . In addition, the two-stage centrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com