Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Continuous printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

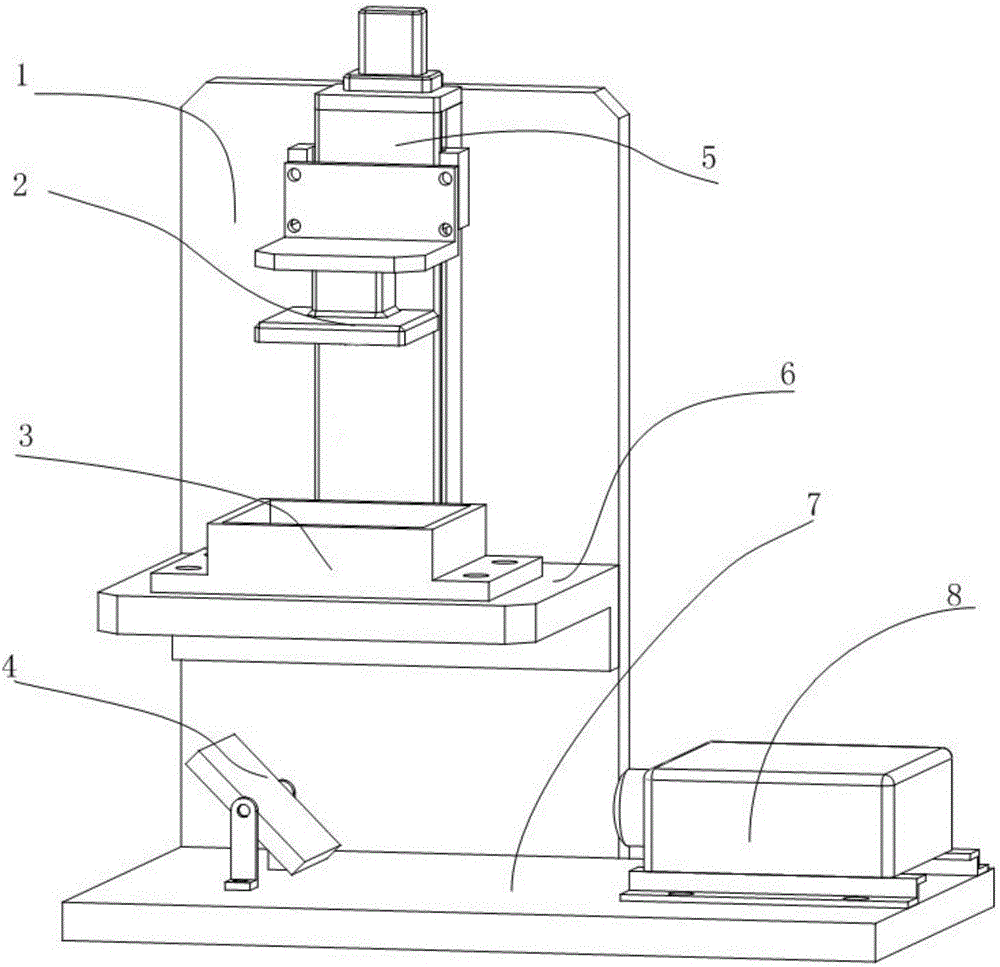

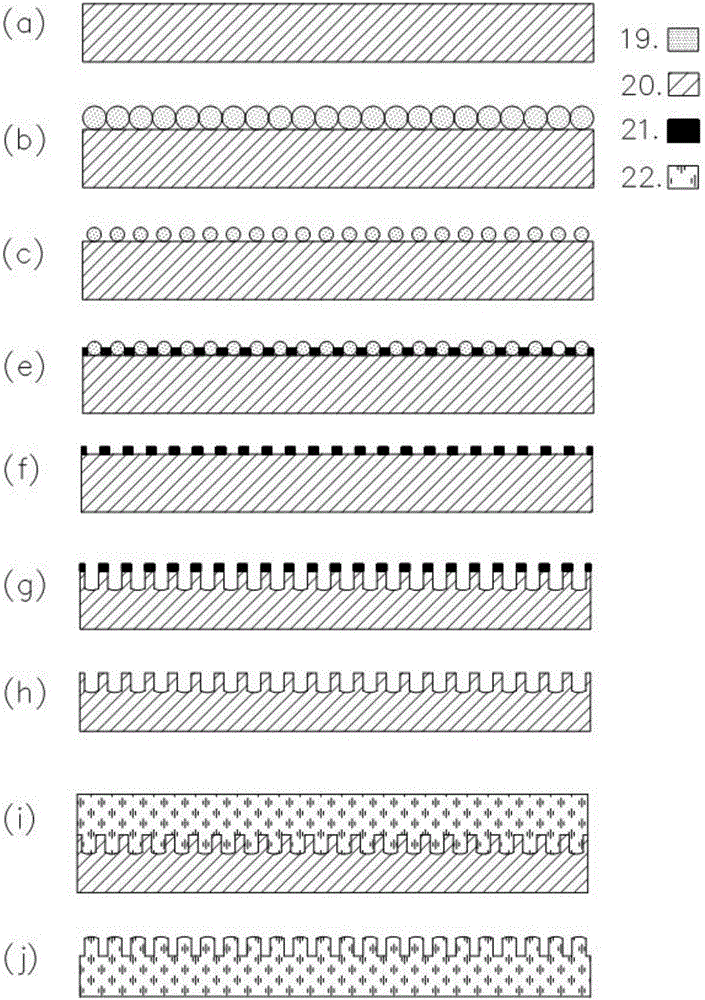

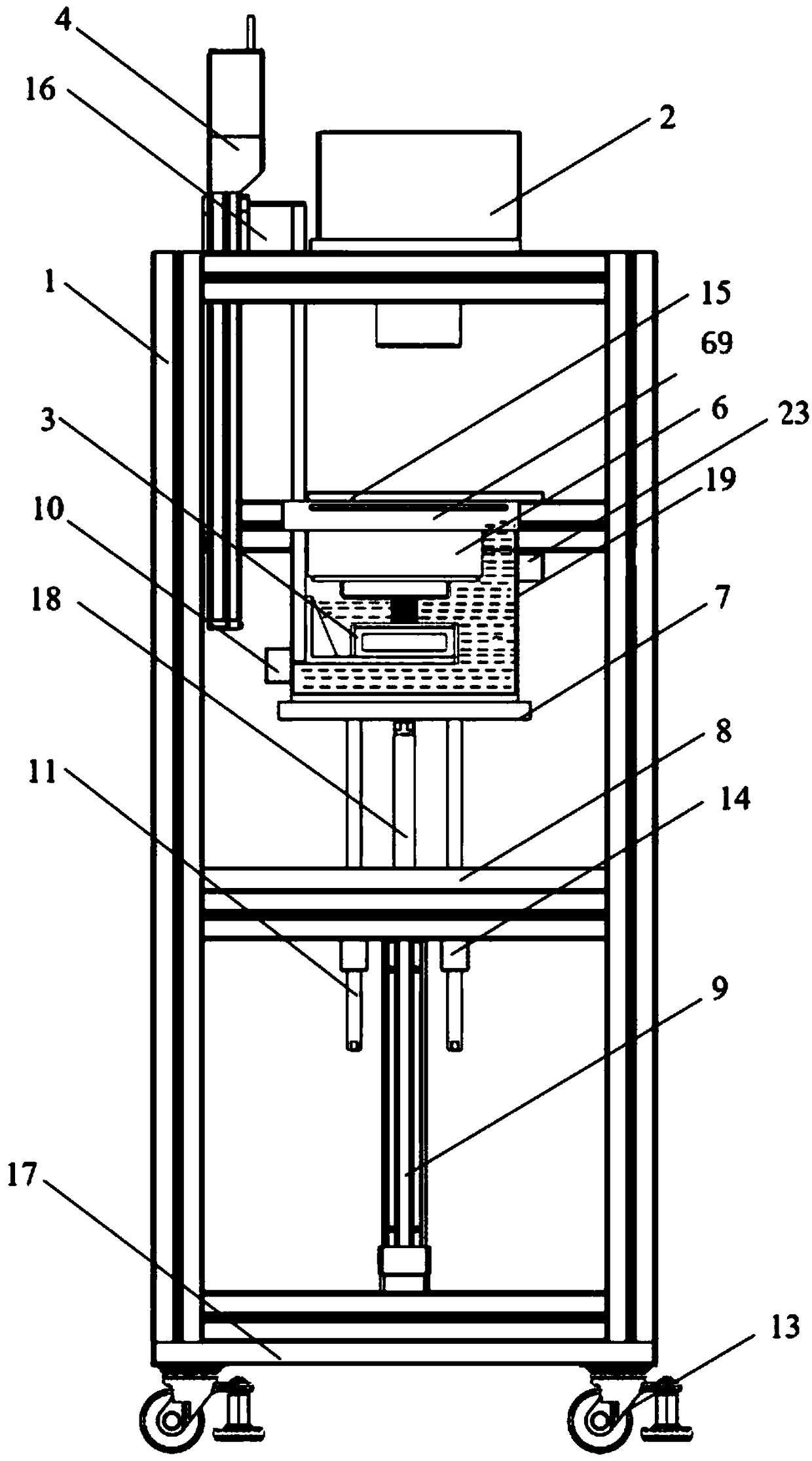

Continuous instantaneous exposure photocuring printer provided with anti-sticking resistance-reducing nano-structured tank bottom

ActiveCN105799168ALow flow resistanceReduce contact areaAdditive manufacturing apparatus3D object support structuresOptical transmittanceEngineering

The invention discloses a continuous instantaneous exposure photocuring printer provided with an anti-sticking resistance-reducing nano-structured tank bottom. The printer comprises a curing light source, a micromirror array, a resin tank, a bearing plate for bearing printing parts, a side supporting plate, a feeding device and a base. The base is used for fixing the curing light source, the micromirror array and the side supporting plate. The resin tank and the feeding device are fixed to the side supporting plate. The bearing plate for bearing the printing parts is connected with the feeding device. The surface of the resin tank is made of a breathable lyophobic material, and the surface of the resin tank is of a quasi-periodical nano structure; the drag force in the lifting process for part printing is reduced through the nano lyophobic structure, and the contact area between resin and the boundary of the tank bottom is reduced; and the light transmittance can be increased through a sub-wavelength nano-structured array on the surface of the tank bottom. By the adoption of the continuous instantaneous exposure photocuring printer provided with the anti-sticking resistance-reducing nano-structured tank bottom, the adhesive force between the bottom of a part and the surface of the tank bottom can be obviously reduced in the printing process, and thus continuous and rapid printing of high-precision complex microstructures is achieved.

Owner:XI AN JIAOTONG UNIV

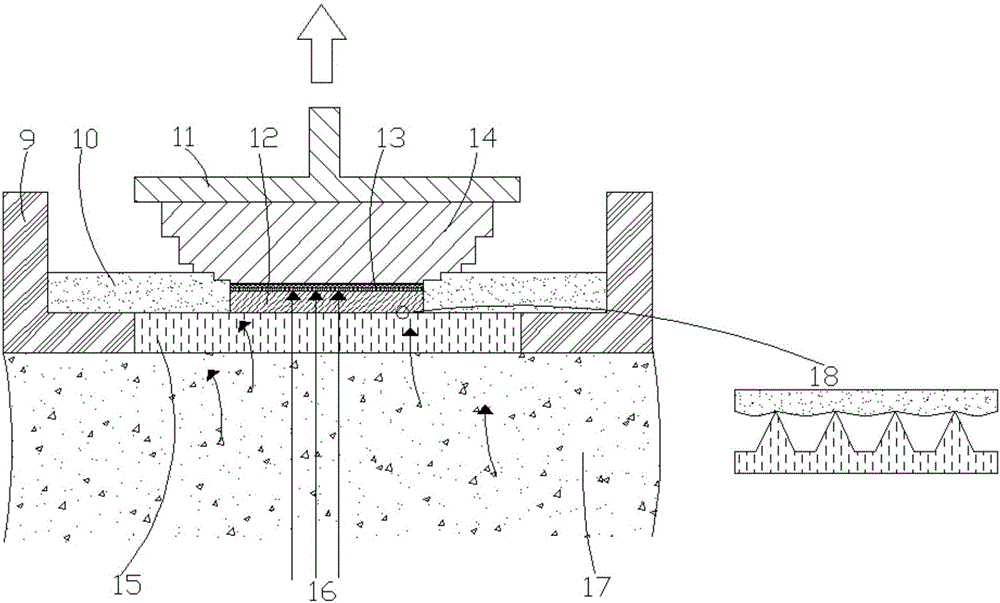

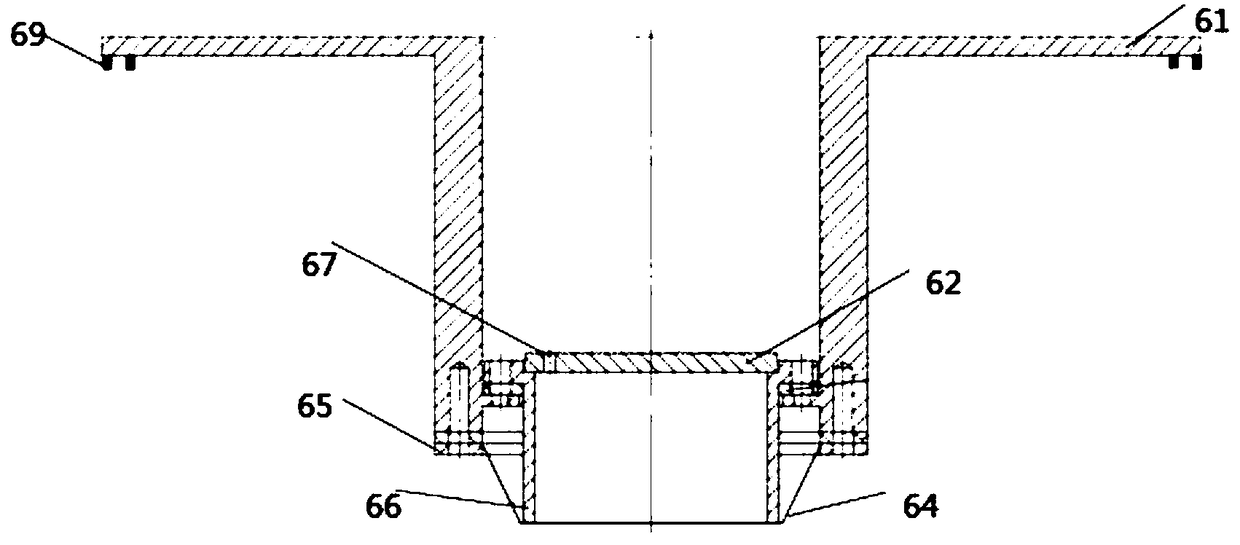

Oxygen supply sizing agent groove system and ceramic surface exposure 3D continuous printing method

ActiveCN105034138AUniform air pressureAvoid bondingAdditive manufacturing apparatusCeramic shaping apparatusBonding problemsSizing

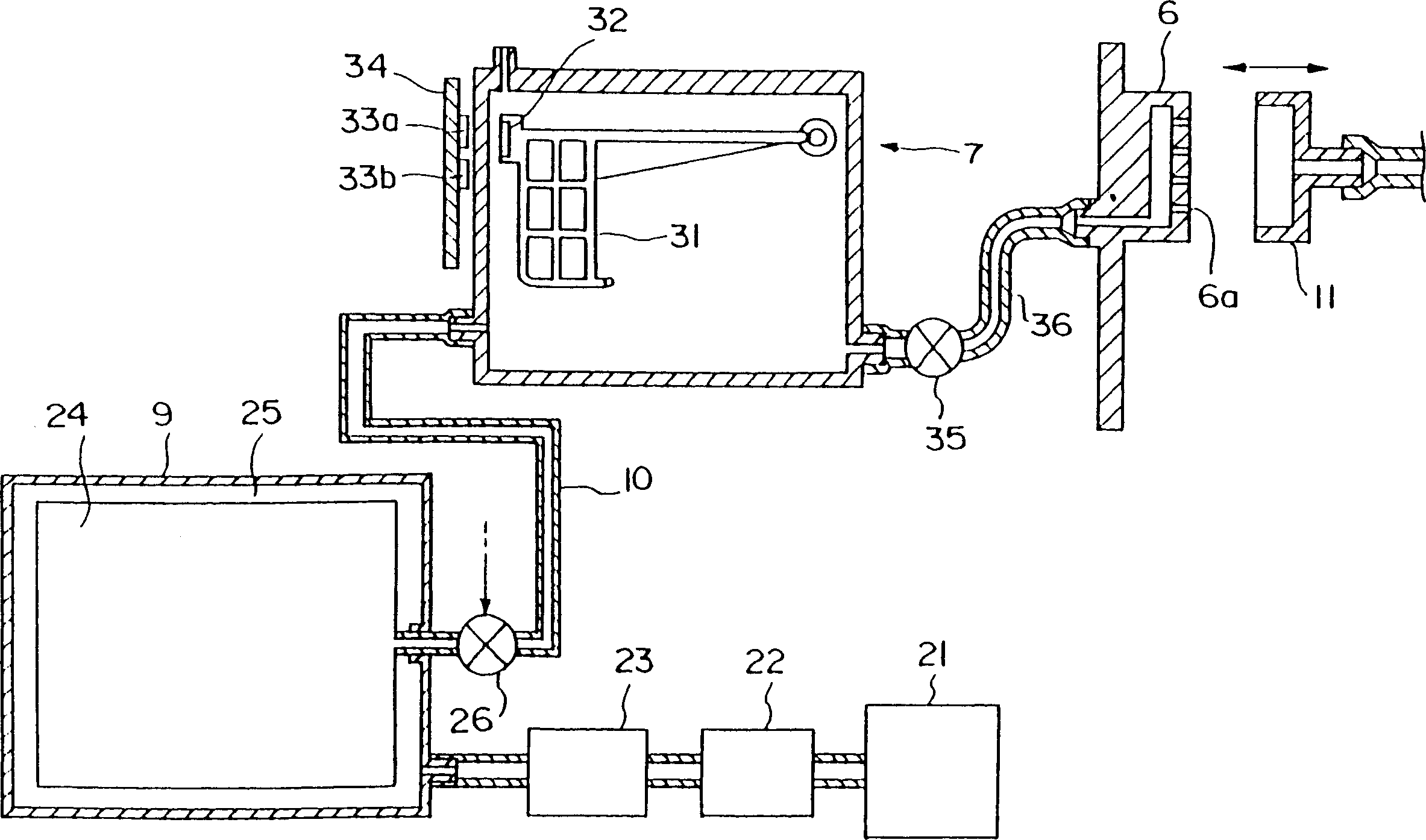

The invention discloses an oxygen supply sizing agent groove system and a ceramic surface exposure 3D continuous printing method. The oxygen supply sizing agent groove system comprises an oxygen supply device, a base plate, a connecting pipe, an air-permeable thin film and a sizing agent groove which is of a cylindrical structure; an annular protrusion is horizontally arranged on the inner wall of the sizing agent groove, the upper surface of an annular groove is covered with the air-permeable thin film, the annular groove is formed in the lower surface of the annular protrusion, the base plate is fixed to the bottom of the sizing agent groove, an annular seal structure is defined by the annular groove and the base plate, and a seal chamber is defined by the base plate, the annular protrusion and the air-permeable thin film; multiple through holes are evenly formed in the side wall of the annular protrusion, the annular seal structure is communicated with the seal chamber through the through holes, one end of the connecting pipe is connected with the oxygen supply device, and the other end of the connecting pipe passes through the wall surface of the sizing agent groove and the side face of the annular groove and is inserted into the annual seal structure. By means of the oxygen supply sizing agent groove system, the bonding problem of ceramic biscuits and base plates can be effectively solved, and thereby the continuous ceramic printing is achieved.

Owner:陕西科陶增材智造科技有限公司

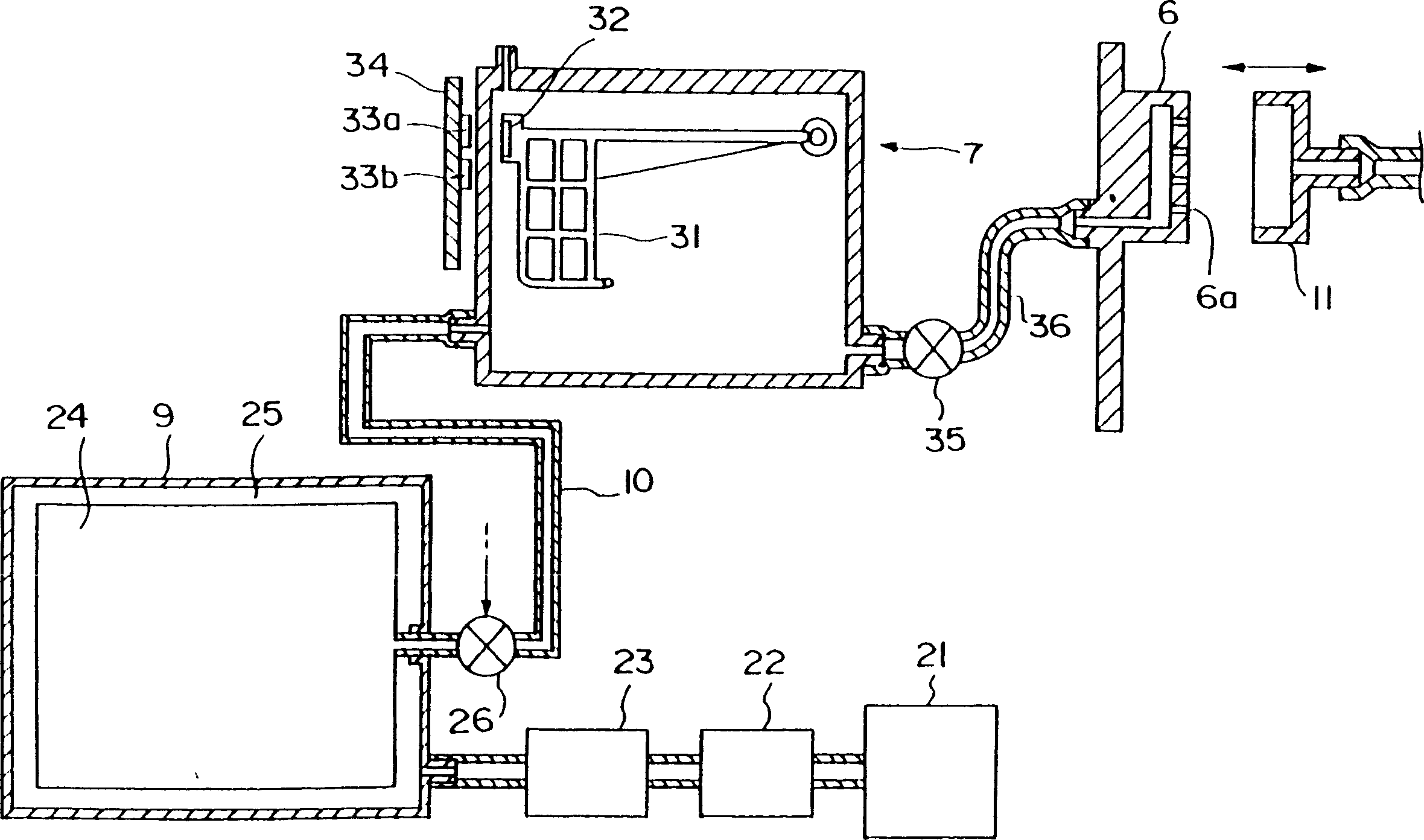

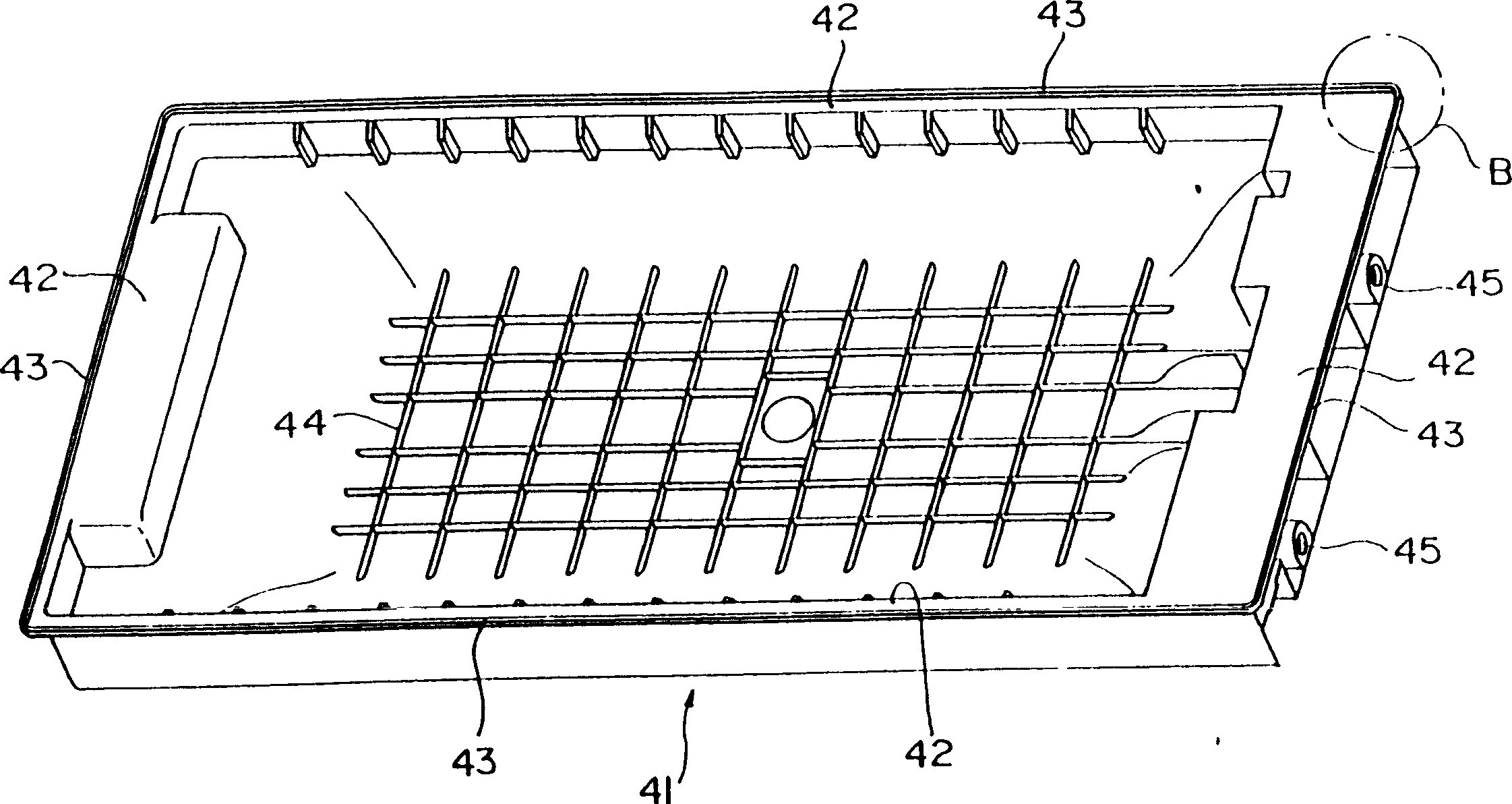

Ink cartridge for ink-jet printer

The invention provides an ink cartridge for an ink jet printer. The ink is supplied to a print head by the action of air pressure after the ink cartridge is applied with air pressure generated by an air pressure pump. An ink pack made of flexible material with ink packed in is provided in the ink cartridge. A pressure chamber applied by the air pressure generated by the air pressure pump is provided between the housing of the ink cartridge and the ink pack. A pressured air inlet for guiding in the pressured air generated by the air pressure pump is provided on the housing of the ink cartridge. An ink outlet for guiding the ink out of the ink pack is provided on the ink pack. When the ink cartridge is detached from the printer, the pressured air inlet is opened to communicate the pressure chamber with atmosphere and the ink outlet is closed. The assembly and disassembly of the ink cartridge is convenient, and the ink cartridge and the components are reused easily, so that it is in favor of resource conservation.

Owner:SEIKO EPSON CORP

Resin printing ink vacuum hole plugging printing device and method

ActiveCN105034553AImprove efficiencyGuaranteed stabilityScreen printersPrinting inkPrinted circuit board

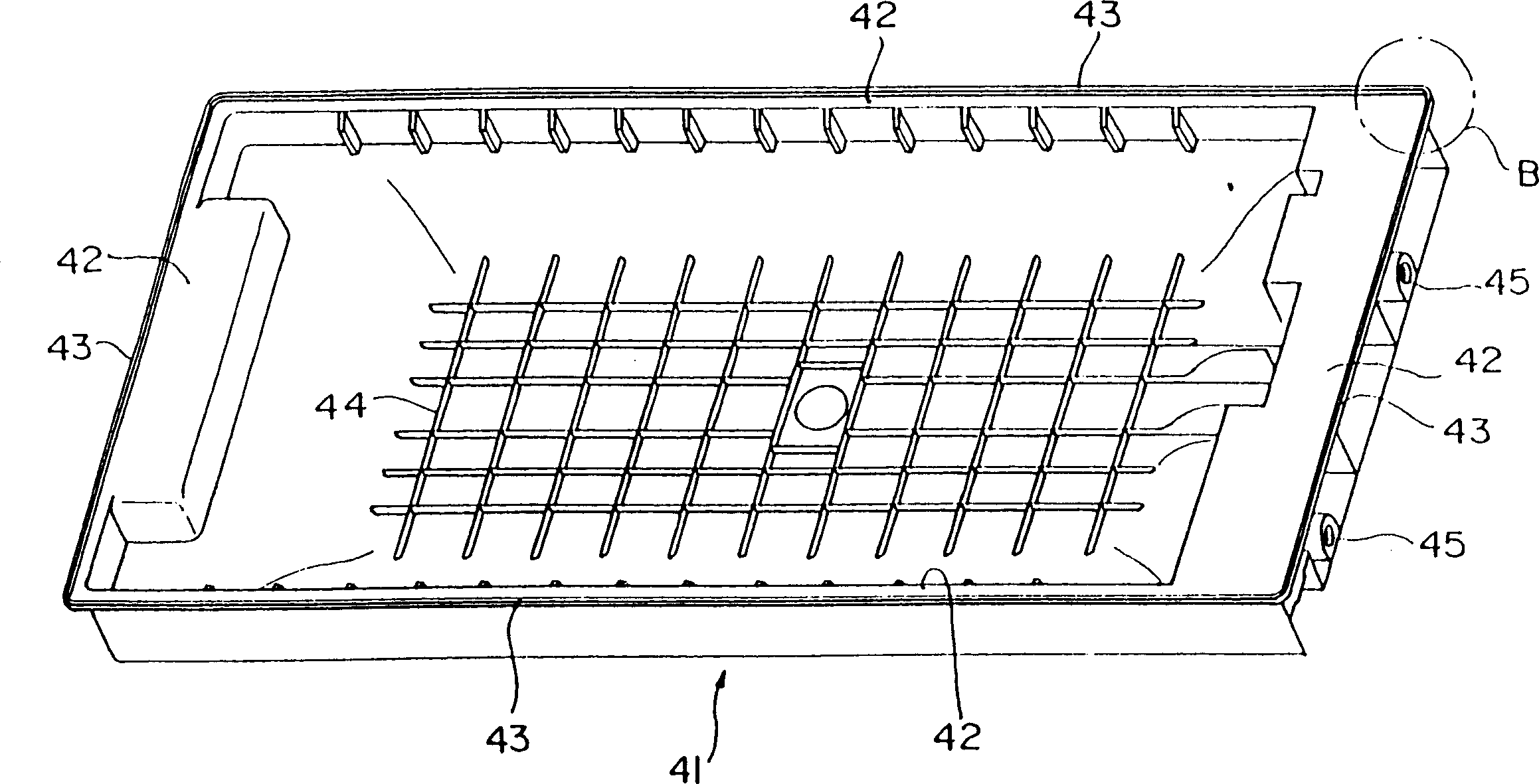

The invention relates to a resin printing ink vacuum hole plugging printing device which comprises a main printing bin. A transit bin is arranged on one side of the main printing bin. The main printing bin and the transit bin are communicated. The transit bin comprises a bin body and a bin cover plate. The bin body is internally provided with a space capable of containing a printing platen. The printing platen is driven by a platen displacement transmission structure so that the position of the printing platen can be adjusted. The upper surface of the printing platen is provided with an isolation frame attached to the printing platen. The isolation frame is driven to ascend and descend vertically through a lifting assembly and is of a homocentric-squares-shaped structure. The isolation frame is attached to the upper surface of the printing platen when descending to the position of the lower end. A printed circuit board arranged on the upper surface of the printing platen is located in the homocentric-squares-shaped space of the isolation frame. After the bin cover plate is closed, the printed circuit board is located in the airtight space in the bin body. According to the resin printing ink vacuum hole plugging printing device, the defect that the working vacuum degree of a whole main printing bin needs to be damaged in each technological process of a traditional printing device is overcome; the printing efficiency is improved; and the stability of the quality of printed products is improved.

Owner:昆山晟丰精密机械有限公司

Printing device with drying function

PendingCN107599624AAchieve the purpose of dryingAvoid damagePrinting press partsCardboardPrinting ink

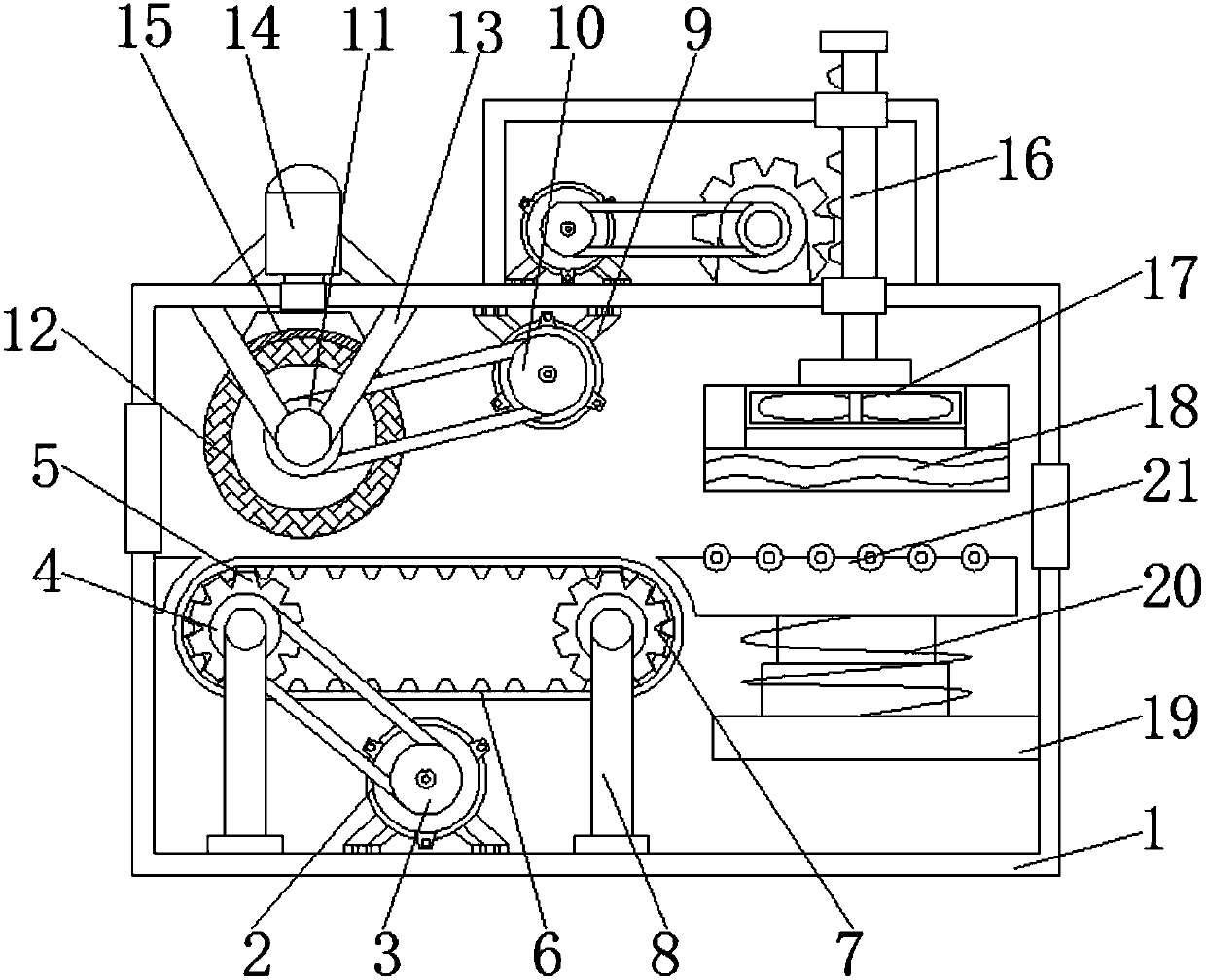

The invention discloses a printing device with a drying function. The printing device comprises an outer frame, wherein a first motor is fixedly connected to the bottom part of the inner wall of the outer frame, one end of an output shaft of the first motor is fixedly connected with a first belt wheel, and the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt. The invention relates to the technical field of printing devices. According to the printing device with the drying function, printing is carried out conveniently, the printing effect isimproved, meanwhile, continuous printing can be achieved, time is saved, working efficiency is improved, and the burden of workers is relieved; later-stage processing can carried out conveniently, the position of drying can be adjusted to prevent a paper board from being damaged, so that practicability of the device is improved; the paper board can be conveniently discharged, and can be stabilized conveniently in the drying process, so that printing effect is prevented from being influenced; and printing ink is conveniently brushed onto the surface of a printing roller, so that printing is achieved, discharging and feeding of the device are convenient, and use by people is convenient.

Owner:安吉腾新印刷厂

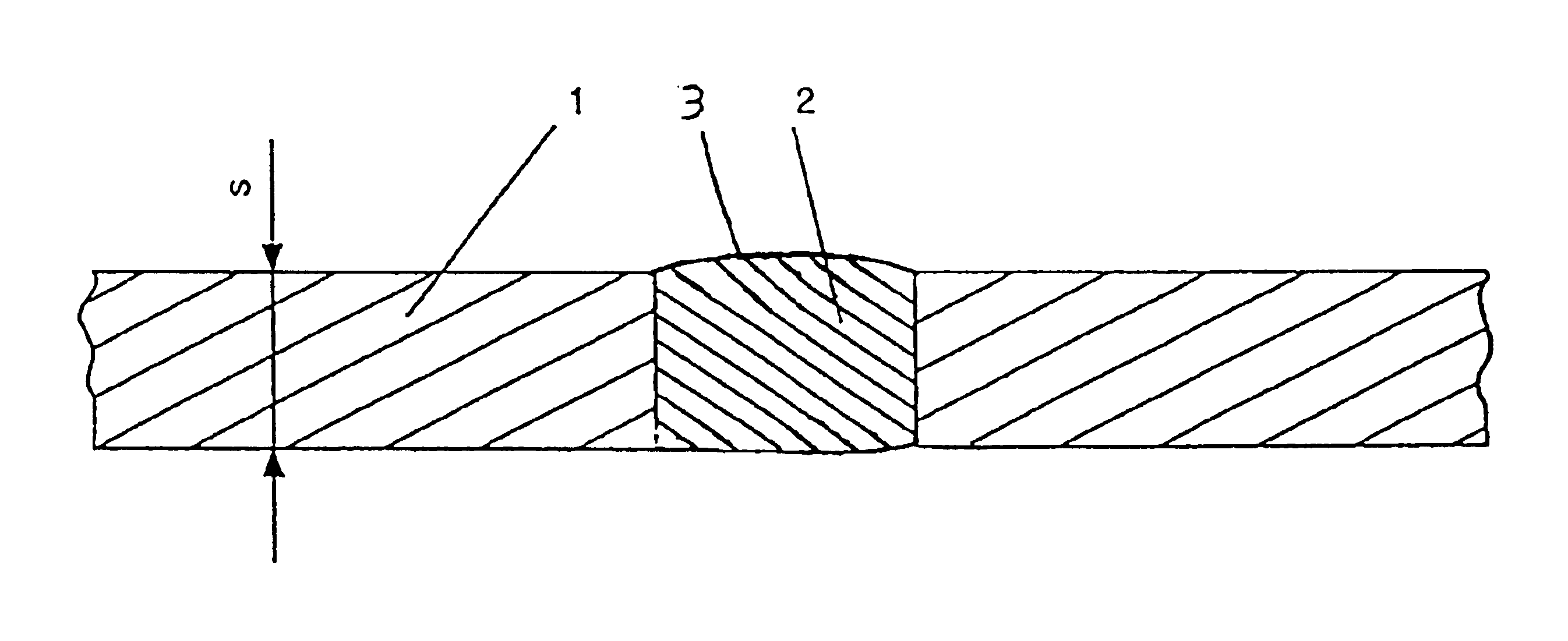

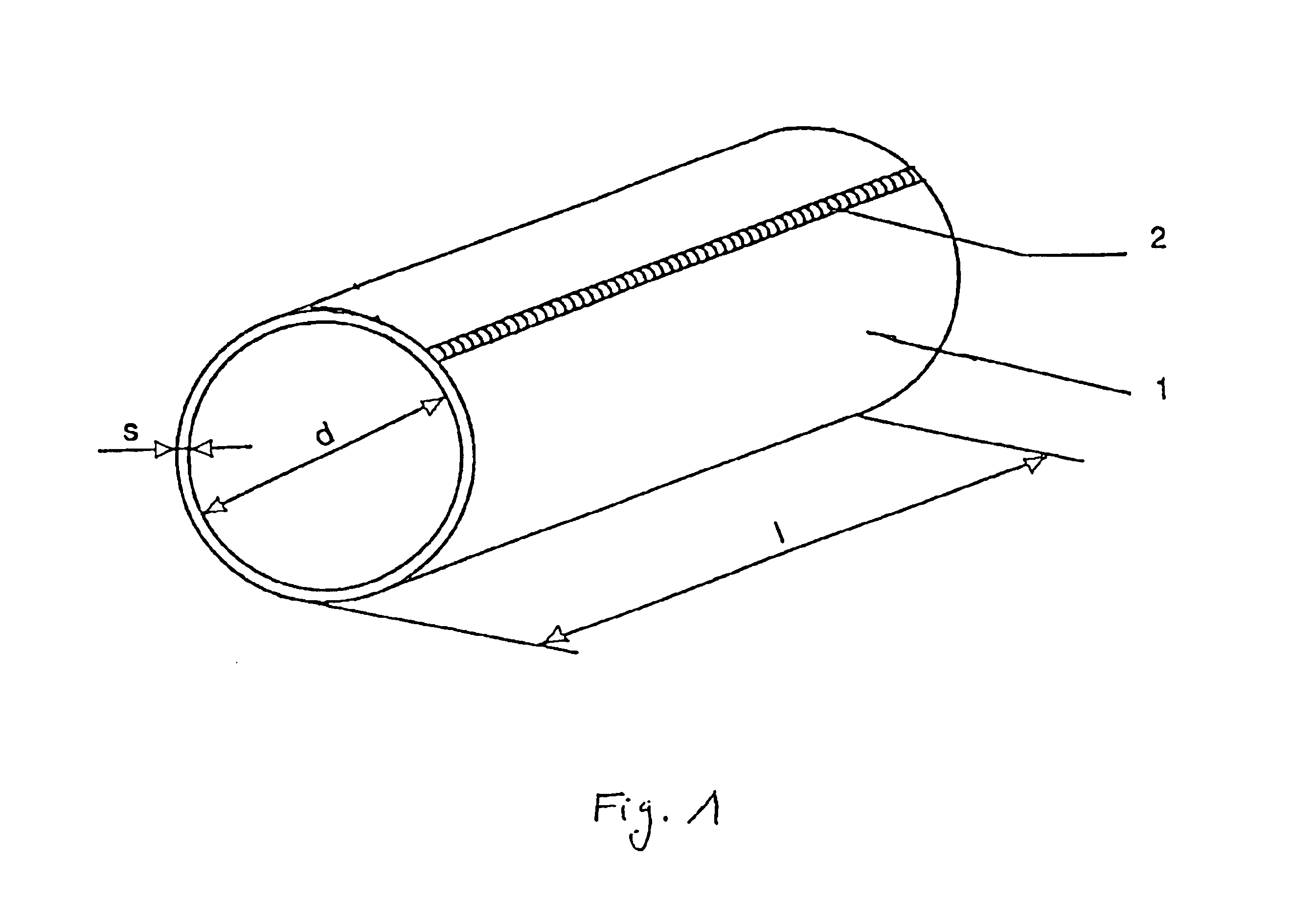

Carrying sleeve for printing and transfer forms and a process for production of such a carrying sleeve

A carrying sleeve, for painting and transfer forms of a metal material, the initial form of which is a rectangular thin-walled flat sheet. The sheet is bent into the desired hollow cylindrical form and the edges of the sheet which point toward one another are permanently connected together. The sleeve surface is processed in order to form a homogeneous continuous outer surface, so that continuous printing can be carried out.

Owner:MANROLANAD AG

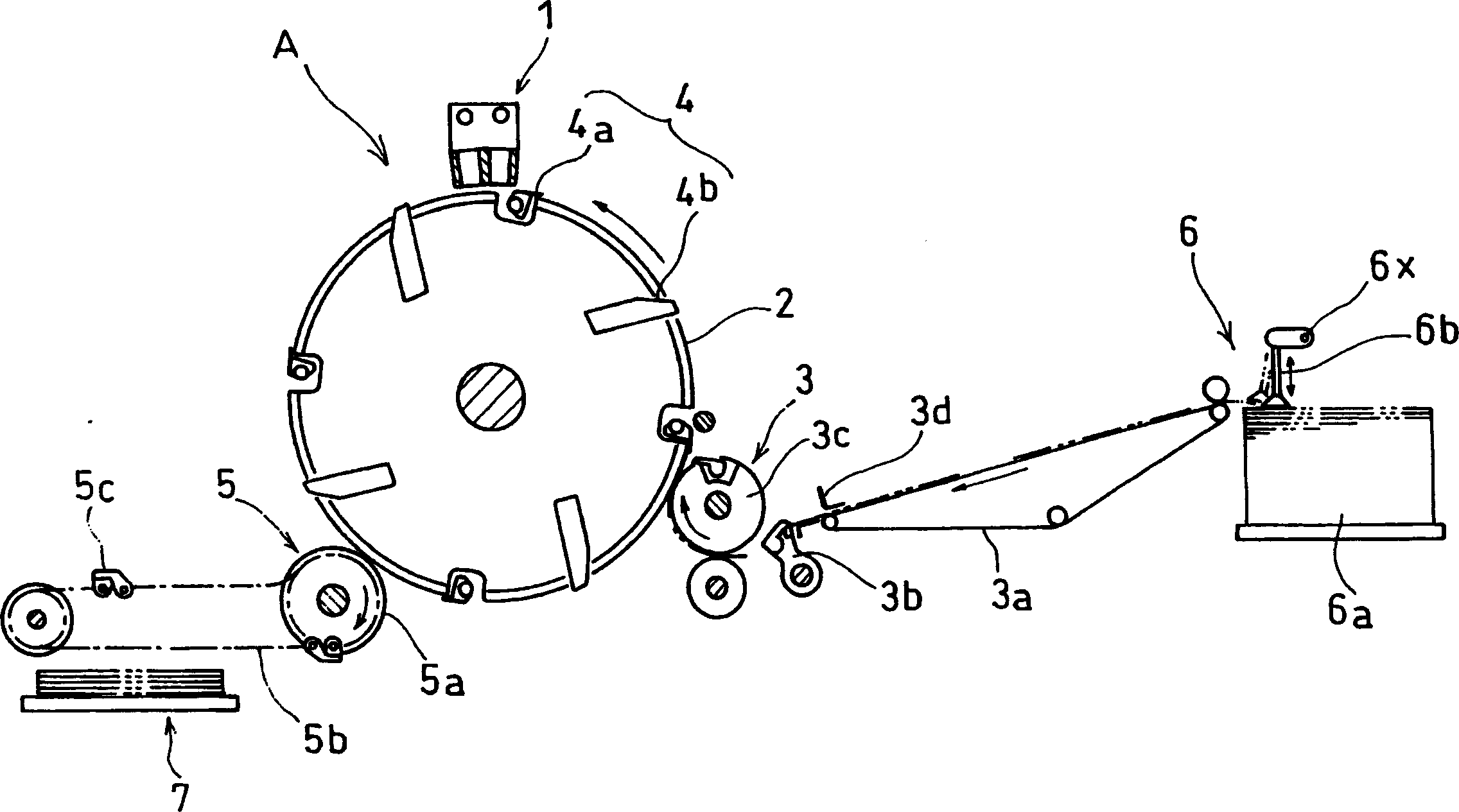

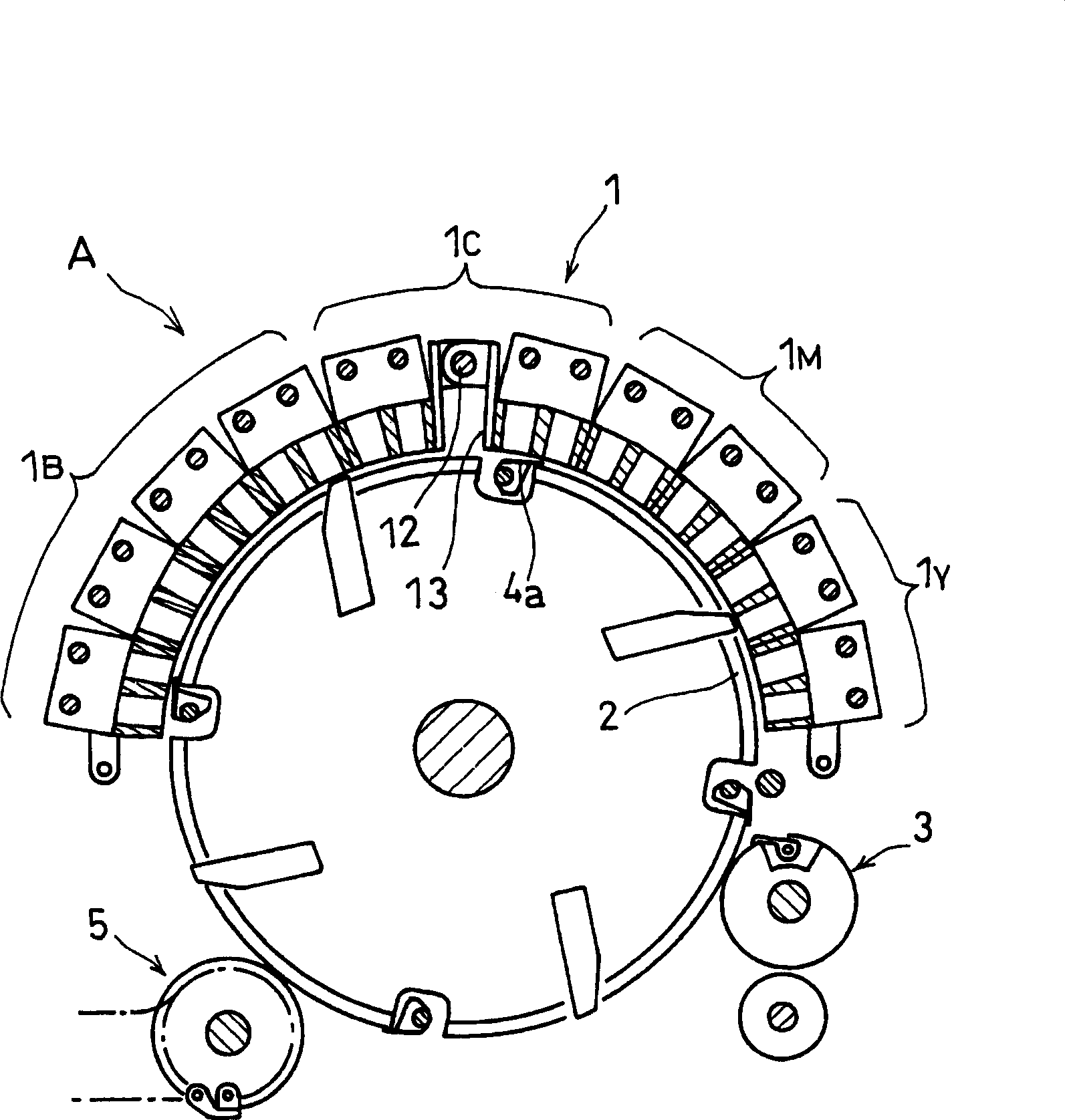

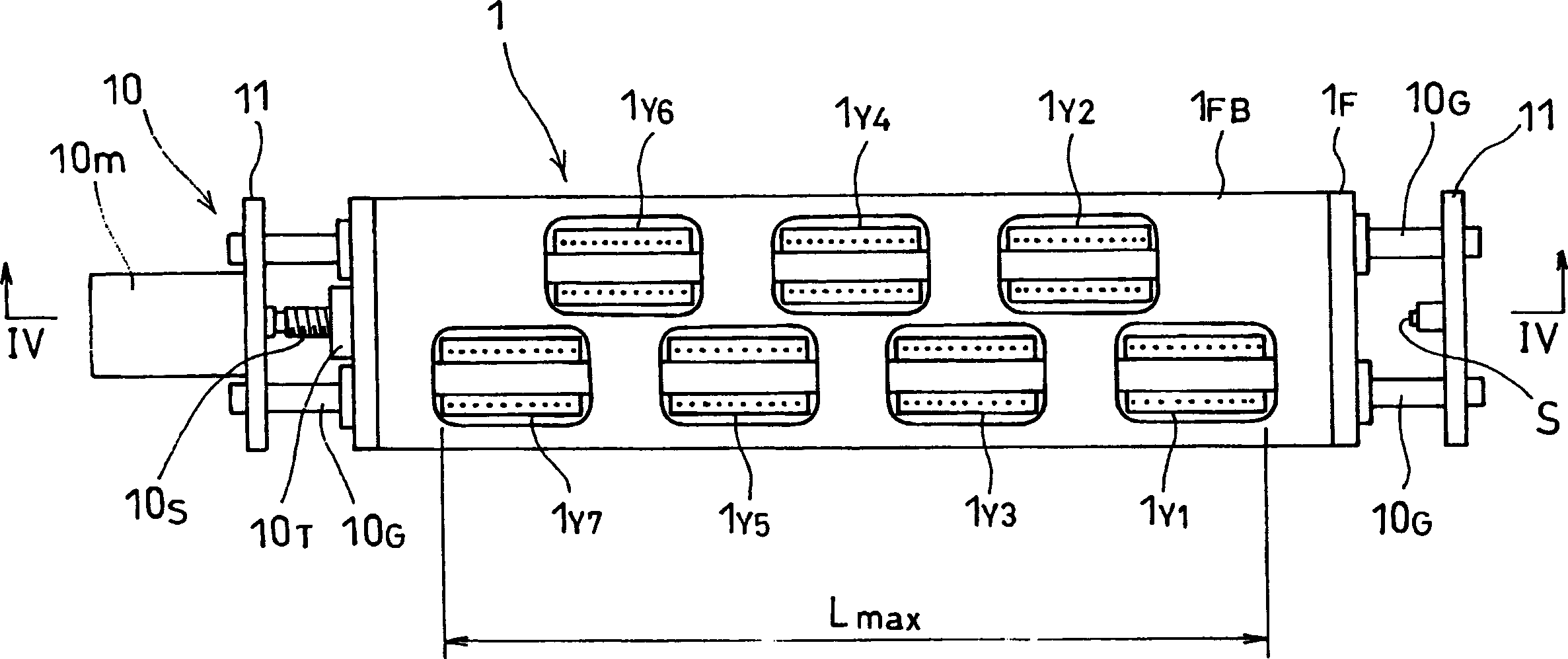

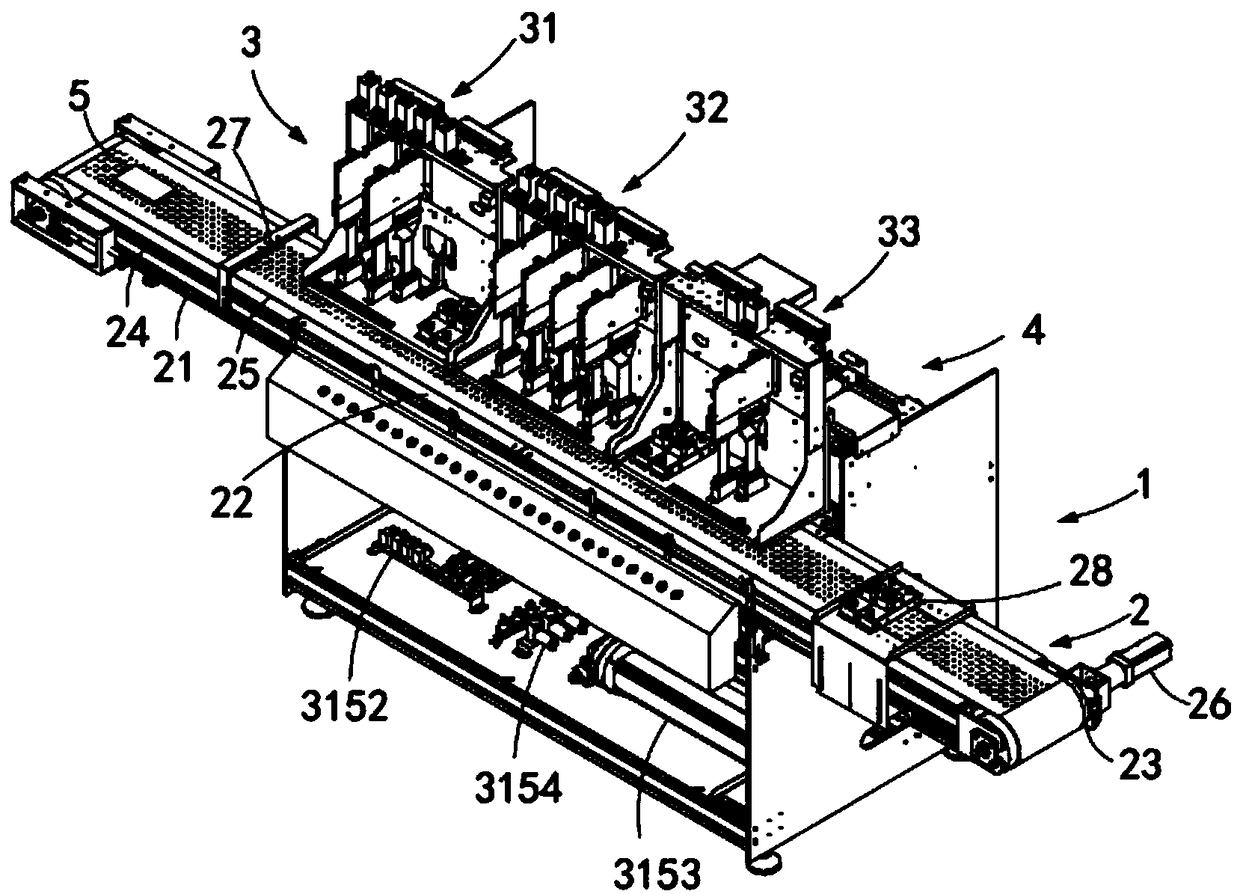

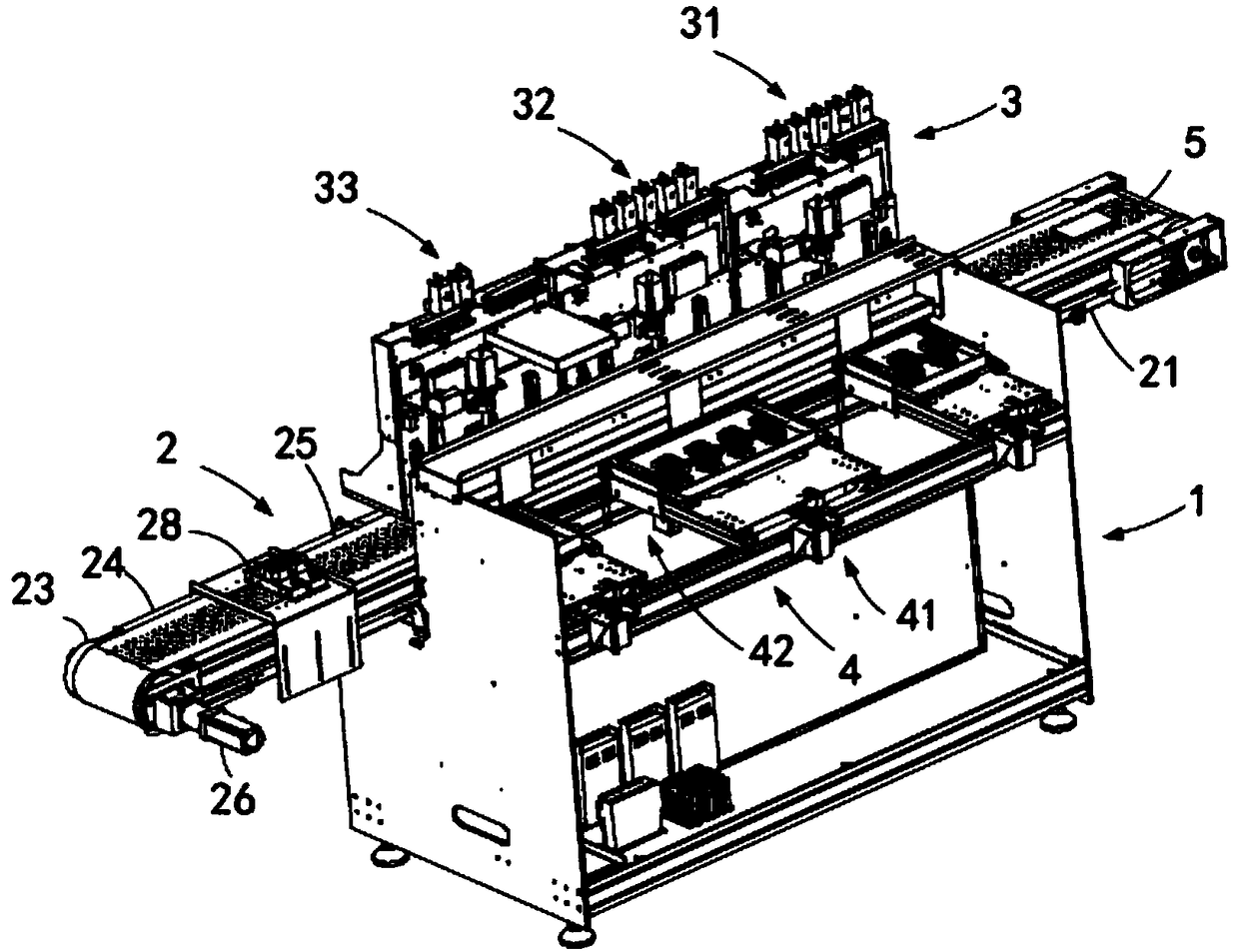

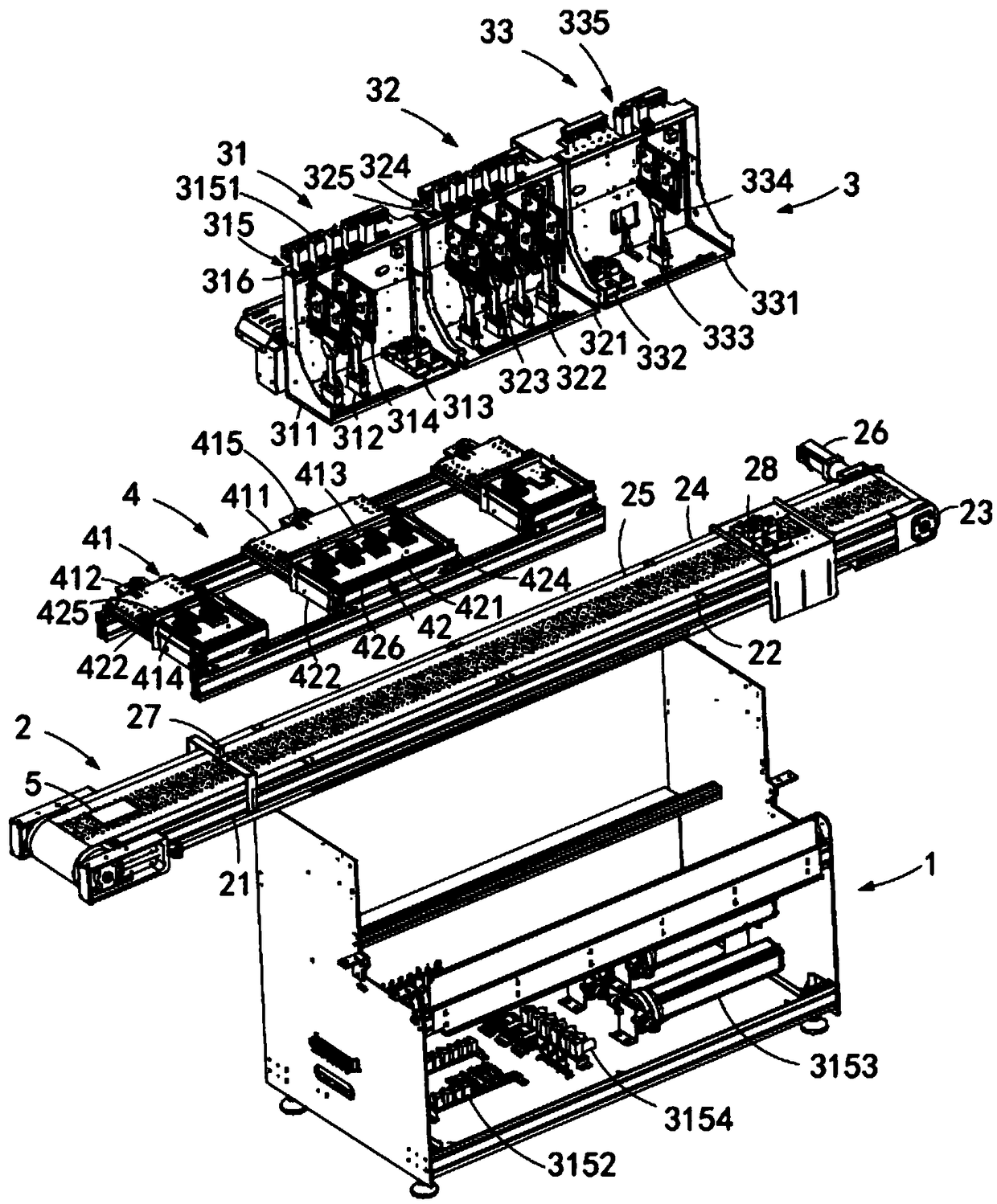

Line-dot recorder

InactiveCN1849214AImprove picture qualitySolve the problem of printing efficiency declinePower drive mechanismsPaper sheetRecording head

A line type dot recording device capable of solving the problem of low printing efficiency (printing time for one sheet) (long time) when a printing medium is moved by a rotating cylinder and an image is formed in a predetermined printing area by multi-way dot recording The problem is that it is possible to efficiently form high-quality images on a plurality of printing media. The line type dot recording device A comprises: as a recording head, a head (1) of a recording element having a plurality of ink ejection outlets (nozzles) in an inkjet system; The paper feeding mechanism (3) for feeding paper from the drum, the mounting and holding mechanism (4) for mounting and holding 4 sheets of paper on the drum, and the paper ejecting mechanism (5) for discharging paper are made by using 4-way multiplex in the sub-scanning direction. Dot recording is carried out in the road method, and the drum is rotated at 4 times the speed to form an image with 4 rotations, which can eliminate the problem of low printing efficiency and obtain high-quality images.

Owner:小藤 治彦

Ink cartridge for ink-jet printer

This invention provides a print cartridge used in ink-jet printer. With the pressure cast by an air pressure pump, the print cartridge provides the printing ink for the printing head; inside the said print cartridge installs a printing ink bag, which packs ink inside and is formed by flexible material; between the outer part of the print cartridge and the said printing ink bag mounts a pressure room in which the pressure is produced by the air pressure pump; on the outer part of the print cartridge sets up a pressure air inlet which introduces pressure air produced by the air pressure pump; on the said printing ink bag installs an ink leading-out terminal which can lead out the ink from the printing ink bag; when the print cartridge is dismantled from the printer, the said pressure air inlet opens, so as to interconnect the said pressure room with the atmosphere, and the ink leading out terminal is closed. This invention is characterized in that the print cartridge can easily be assembled and dismantled, and the print cartridge and the constitute parts thereof can be easily reused, and thus saves resources.

Owner:SEIKO EPSON CORP

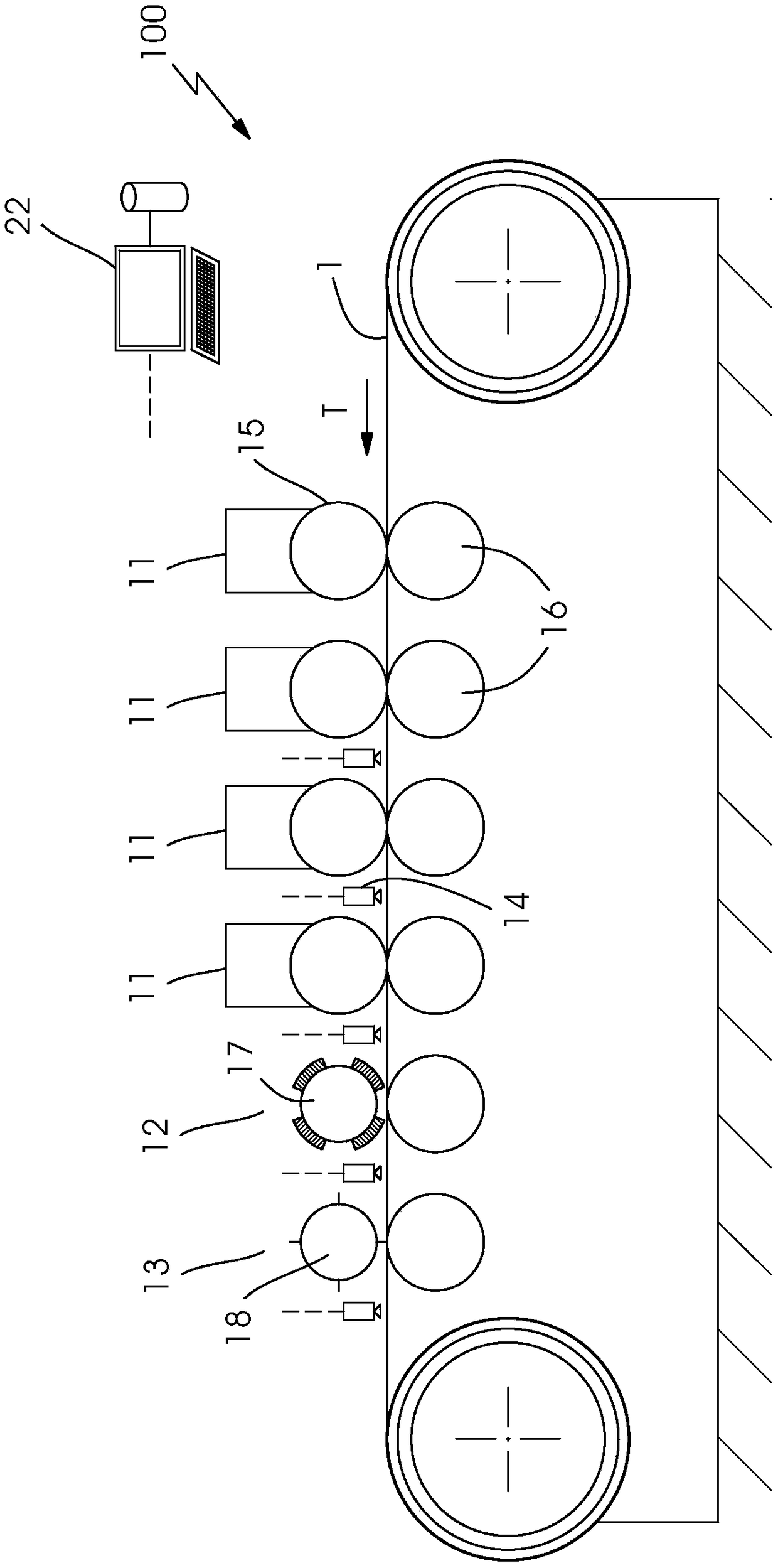

Straight-paper-path flexo printing machine

InactiveCN103963424AContinuous printingMeet needsRotary letterpress machinesPrinting inkPulp and paper industry

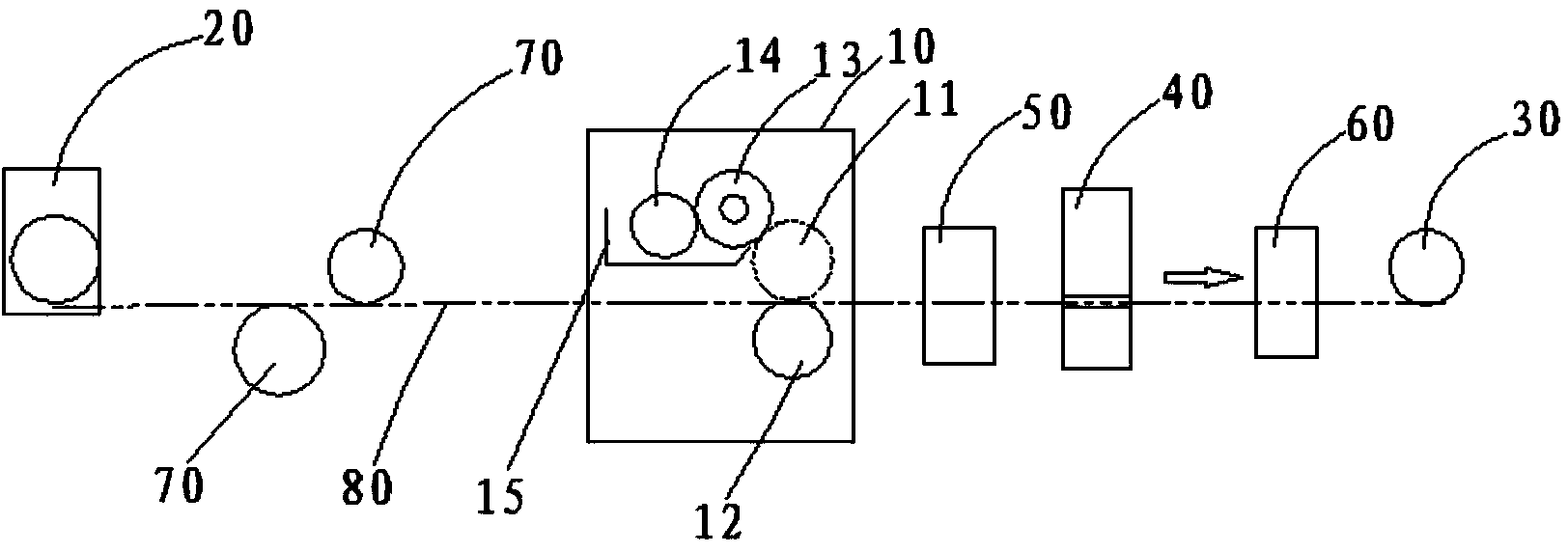

The invention discloses a straight-paper-path flexo printing machine. The straight-paper-path flexo printing machine comprises a feeding unit, a printing unit, a drying unit and a receiving unit, wherein the feeding unit, the printing unit, the drying unit and the receiving unit are sequentially arranged on a straight paper path. The printing unit comprises a printing ink plate arranged on one side of the paper path, an ink feed roller arranged on the printing ink plate, an anilox roller tangential to the ink feed roller, a forme roller tangential to the anilox roller, and a printing roller which is arranged on the other side of the paper path and is tangential to the forme roller. Through the straight-paper-path flexo printing machine, paper exits from the feeding unit and enters the printing unit, the forme roller in the printing unit prints printing ink on the paper, and then the paper enters the drying unit to be dried and is output from the receiving unit. The feeding unit, the printing unit, the drying unit and the receiving unit are arranged in cooperation with the paper path, so that the paper path is approximately straight, and high-speed continuous printing of the paper can be guaranteed. The straight-paper-path flexo printing machine is suitable for small lists and middle and long lists.

Owner:广州互通气动机器工程有限公司

Bar code printer

The invention provides a bar code printer. The bar code printer comprises a base, a roller support is arranged on one side of the base, and a feed roller is arranged on the roller support; a roller support and a collection roller are arranged on the other side of the base; a lower auxiliary roller support is arranged on one side of the upper portion of the base close to the feed roller; a lower auxiliary roller is arranged on the upper portion of the lower auxiliary roller support; an upper auxiliary roller is arranged on the upper portion of the lower auxiliary roller; a drying platform is arranged on one side of the upper portion of the base close to the collection roller, dryers are arranged on the upper portion of the drying platform, an exhaust hood is arranged above the dryers, and ventilators are arranged on the upper portion of the exhaust hood. The bar code printer has the advantages that products can be continuously printed, ink can be dried in time after printing, and defective products can be reduced.

Owner:TIANJIN QIAOYANG PRINTING

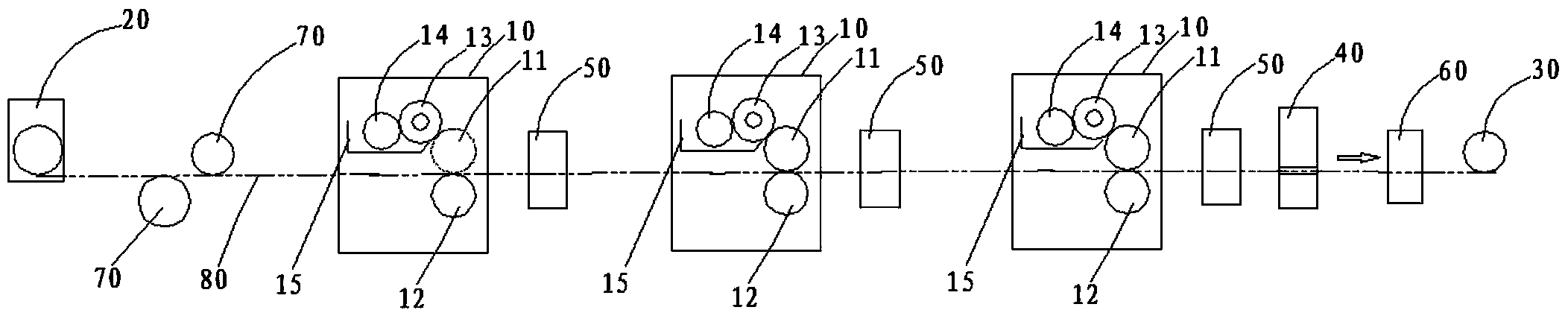

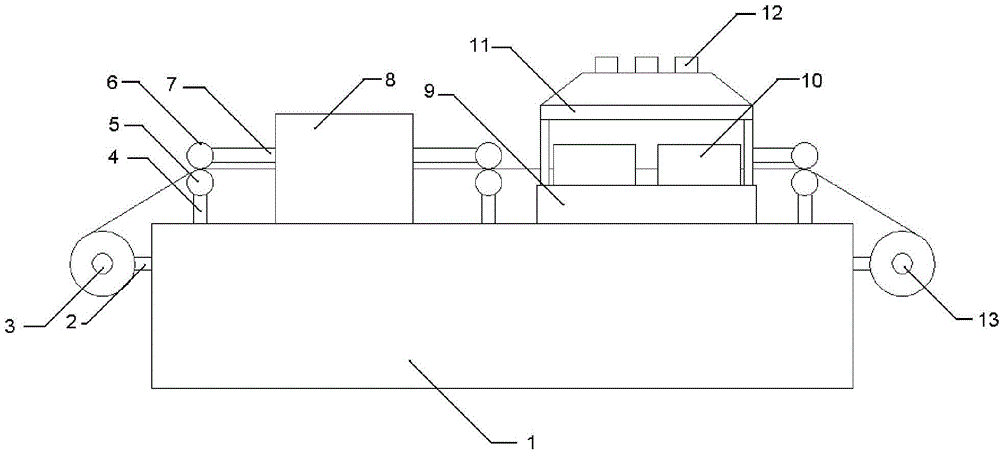

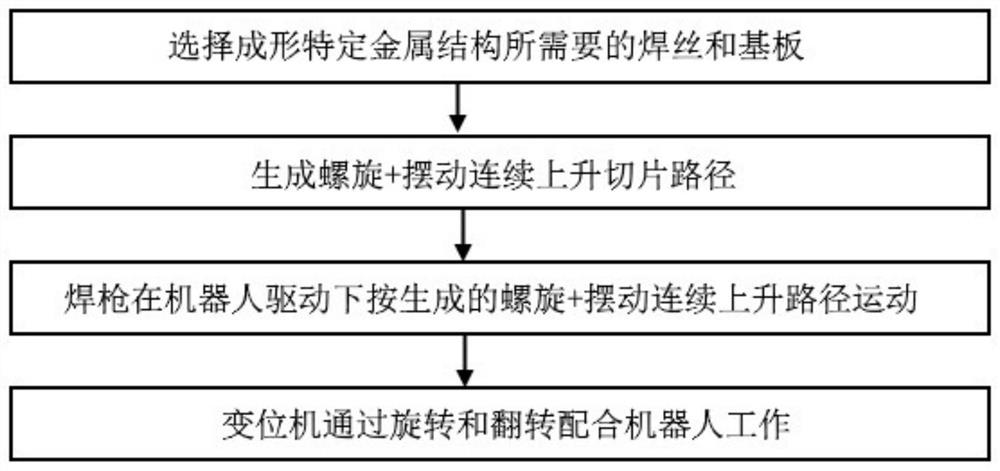

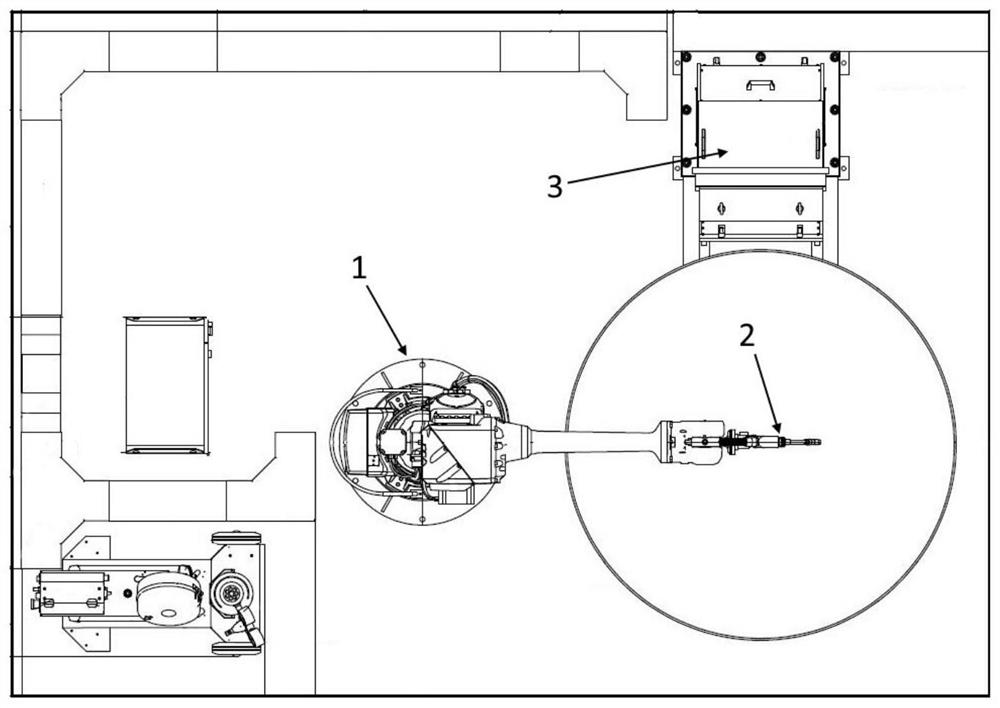

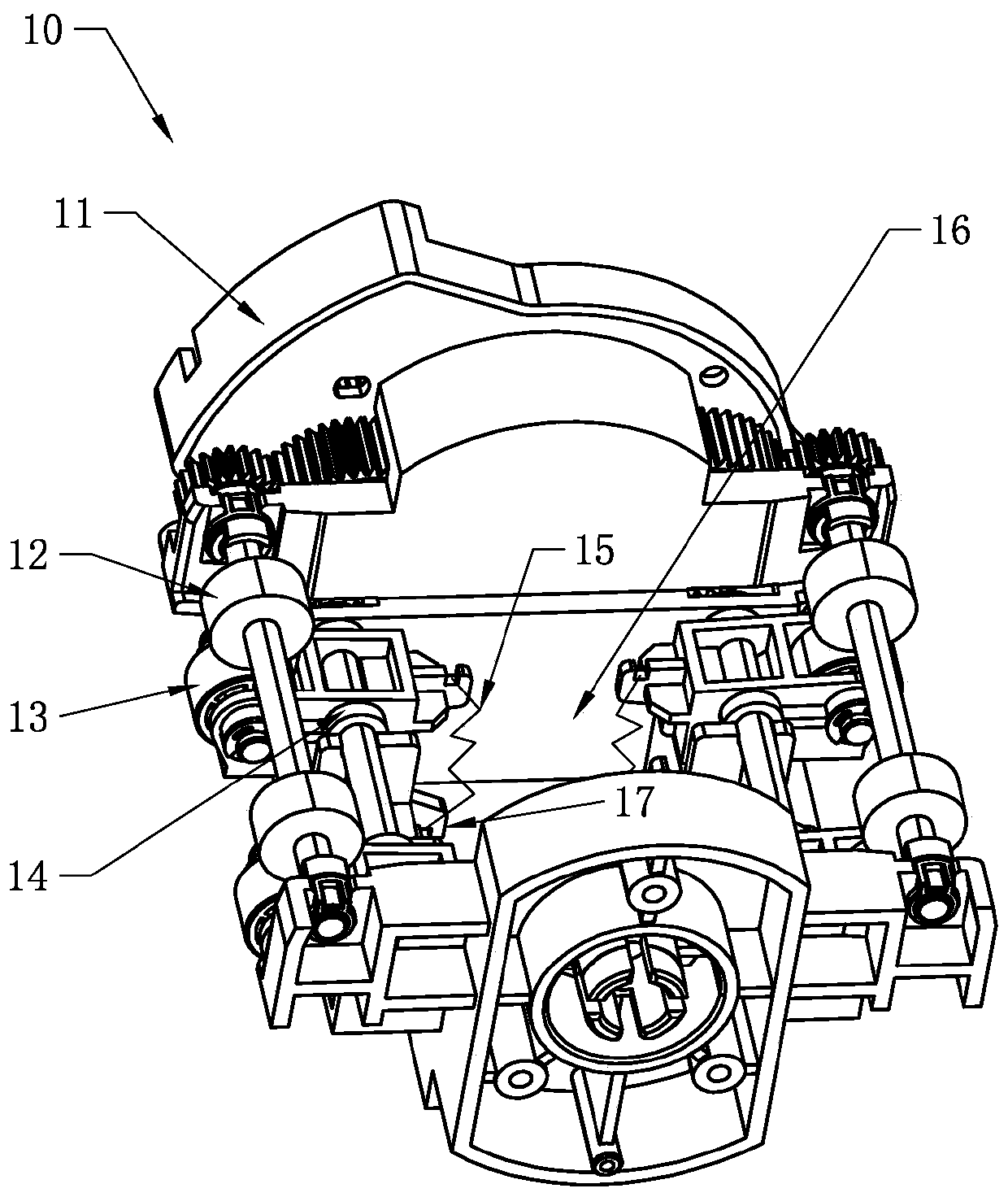

Wire arc additive manufacturing method, device and equipment for continuous growth of curved surface metal structure and computer storage medium

ActiveCN112846446ASolving the bottleneck of difficult continuous arc additive manufacturingContinuous ascending print pathAdditive manufacturing apparatusArc welding apparatusPath generationMechanical engineering

The invention provides a wire arc additive manufacturing method and system for continuous growth of a curved surface metal structure. The method comprises the following steps: selecting a welding wire and a base plate needed for forming a specific metal structure; generating a spiral and swinging continuous rising slice path; driving a welding gun by a robot to move according to the generated spiral and swinging continuous rising path; and enabling a positioner to cooperate with the robot to work through rotation and overturning. The system comprises a base assembly, a path generation module, an eight-axis linkage mechanism and a visual sensing module, wherein the base assembly is used for placing a specific metal structural member; the path generation module is used for generating the spiral and swinging continuous rising slice path; the eight-axis linkage mechanism (comprising a six-axis robot and a double-axis positioner) is used for tracking and printing according to the spiral and swinging continuous rising slice path generated by the path generation module; and the visual sensing module is used for monitoring a printed workpiece in real time. According to the method and system, the bottleneck that continuous wire arc additive manufacturing of an existing curved surface metal structural part is difficult is solved, the product development period is shortened, and the efficiency is improved.

Owner:NANJING ENIGMA IND AUTOMATION TECH CO LTD

Image forming apparatus and continuous printing method

InactiveUS20140355054A1Improve stabilityImprove printing efficiencyVisual presentation using printersDigital output to print unitsImage formationDatabase

Owner:RISO KAGAKU CORP

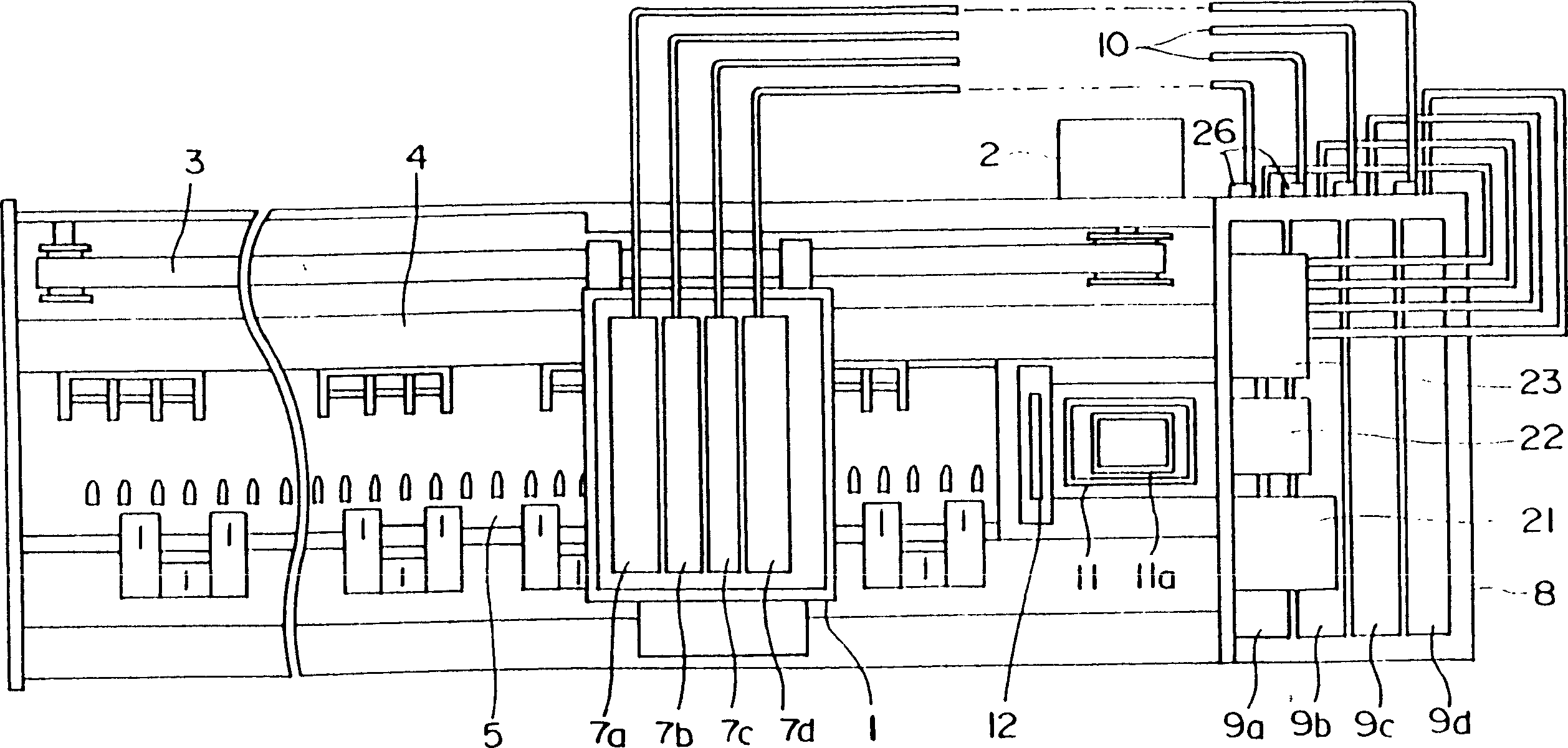

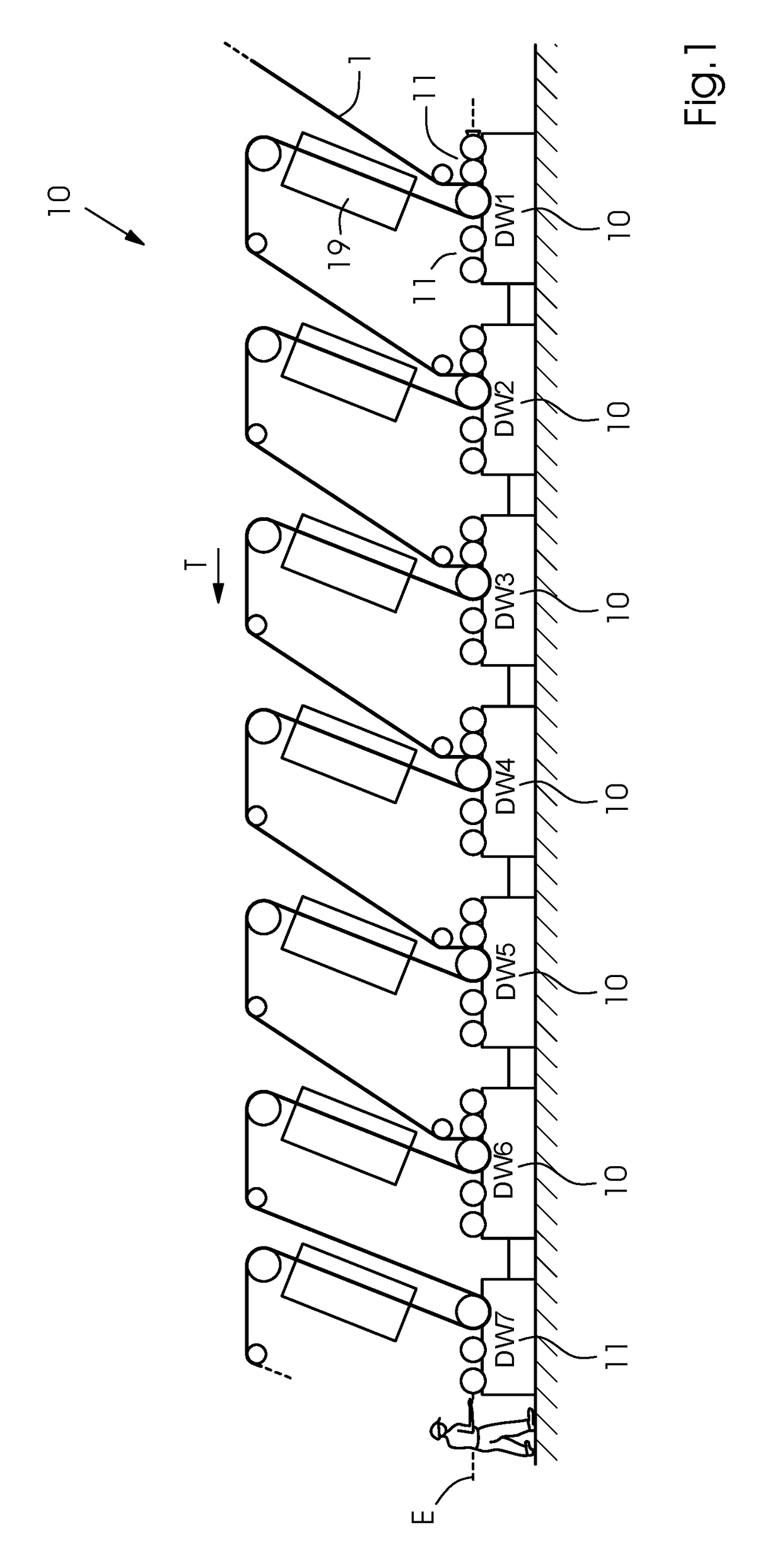

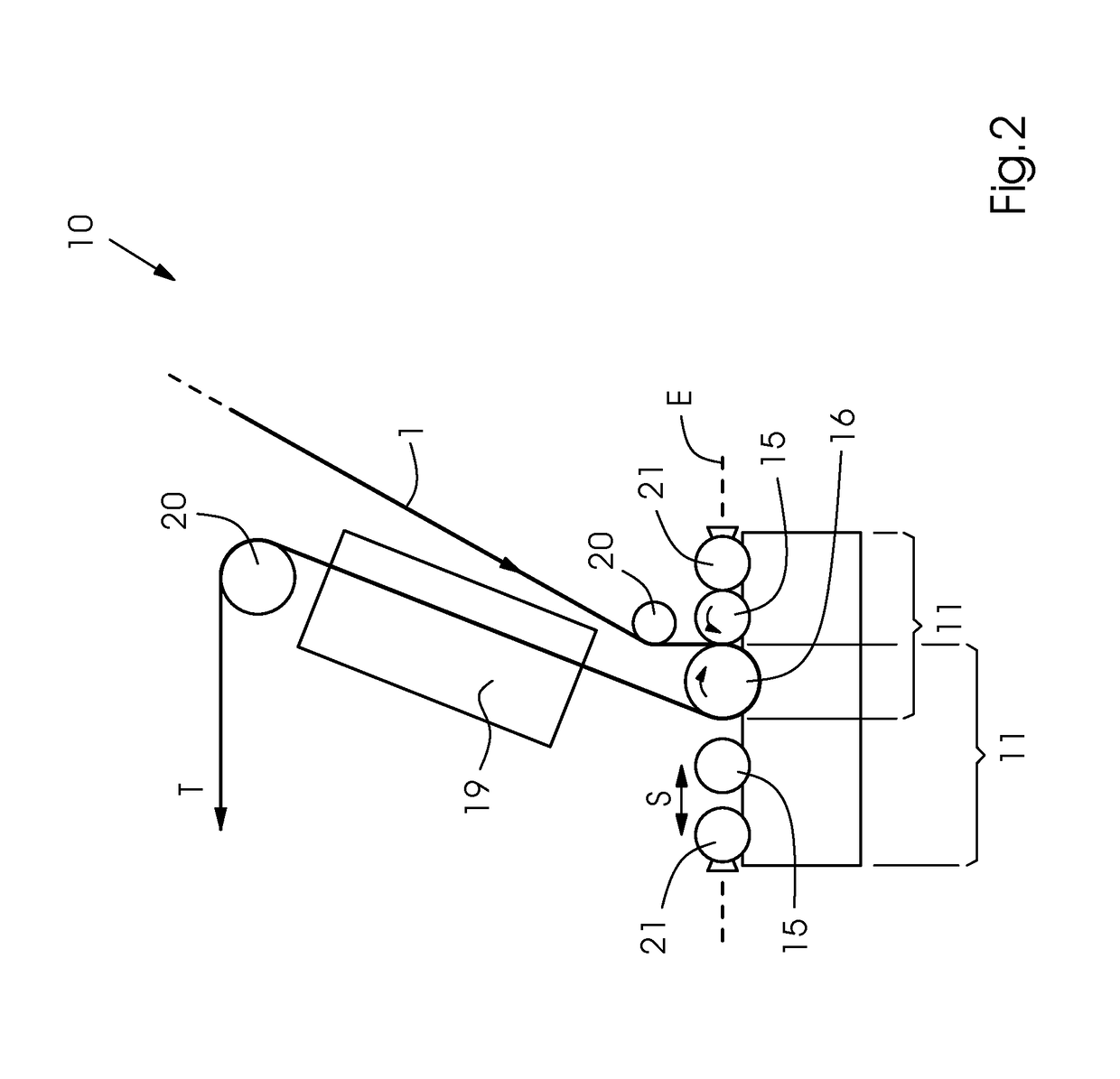

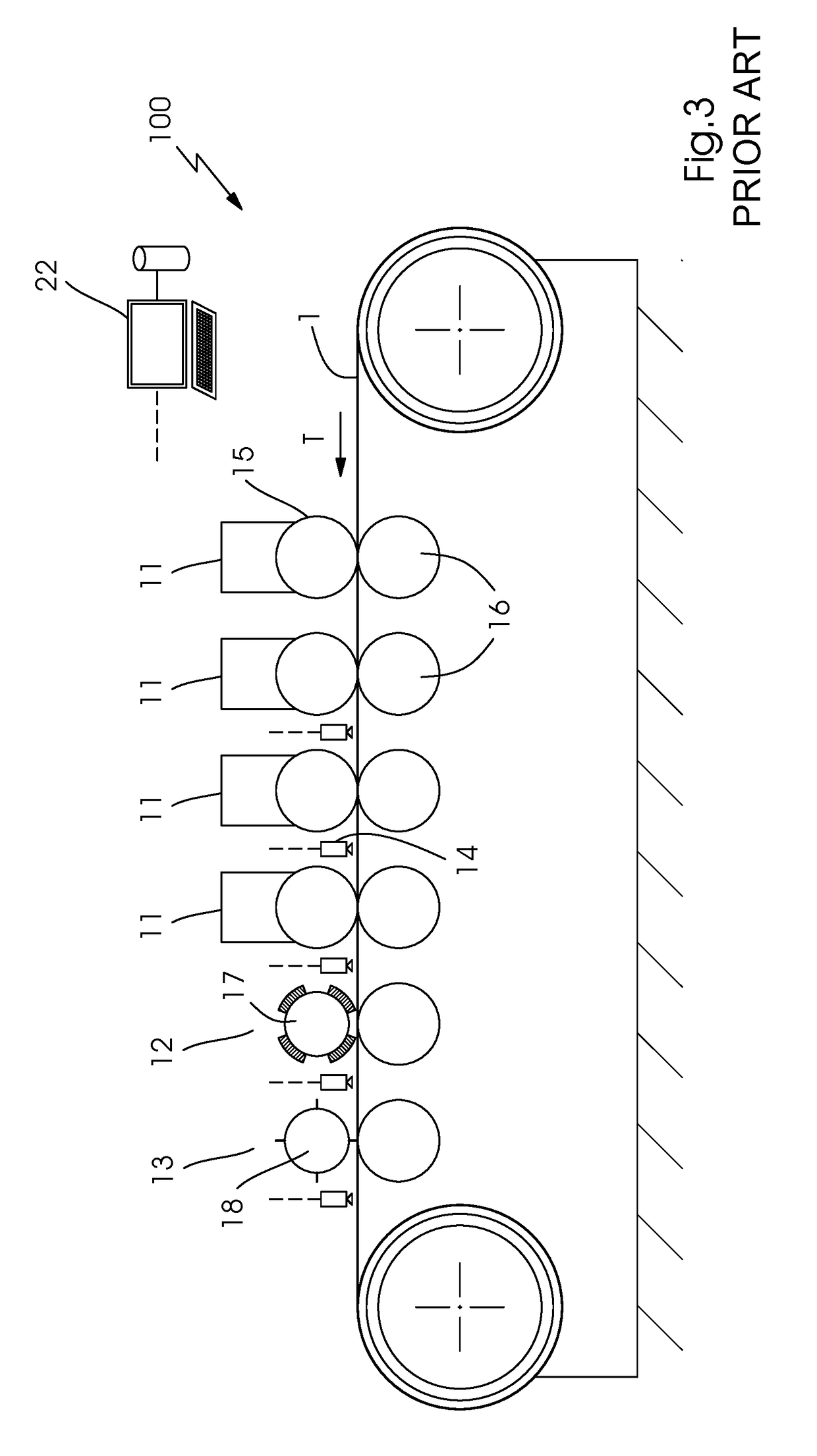

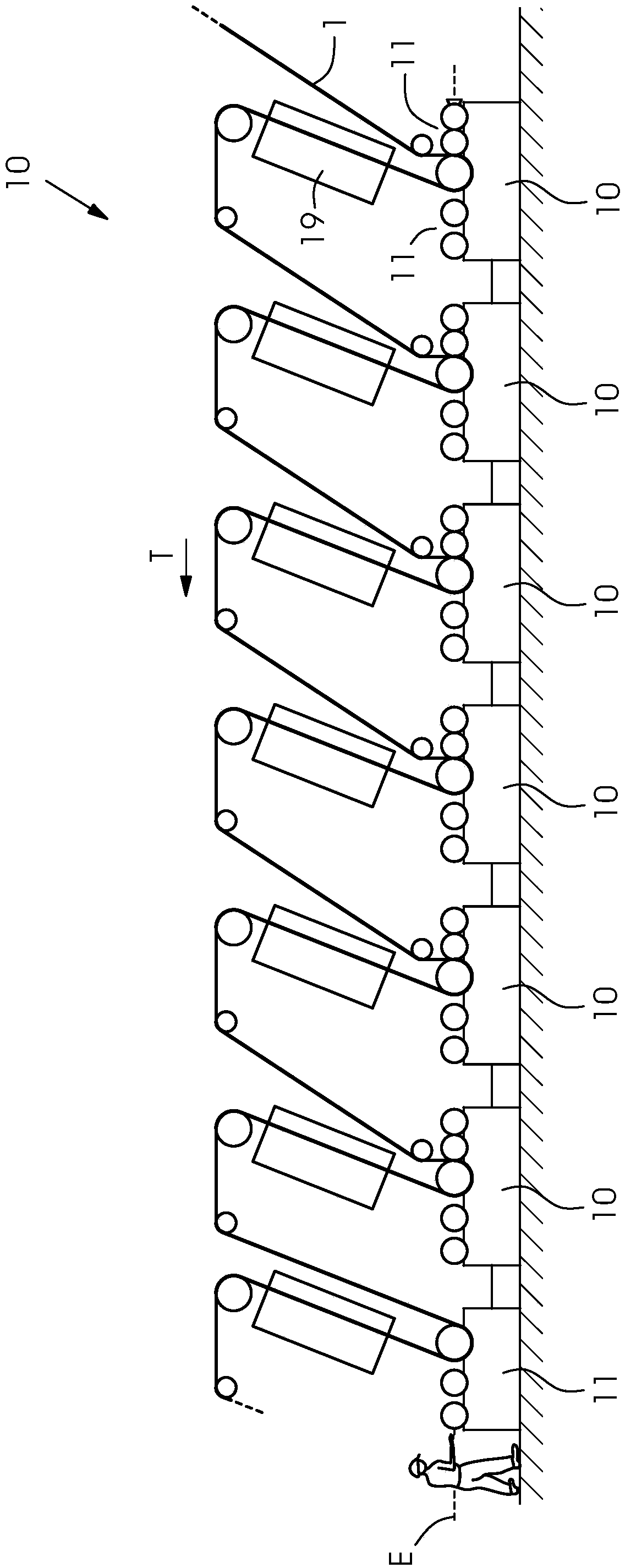

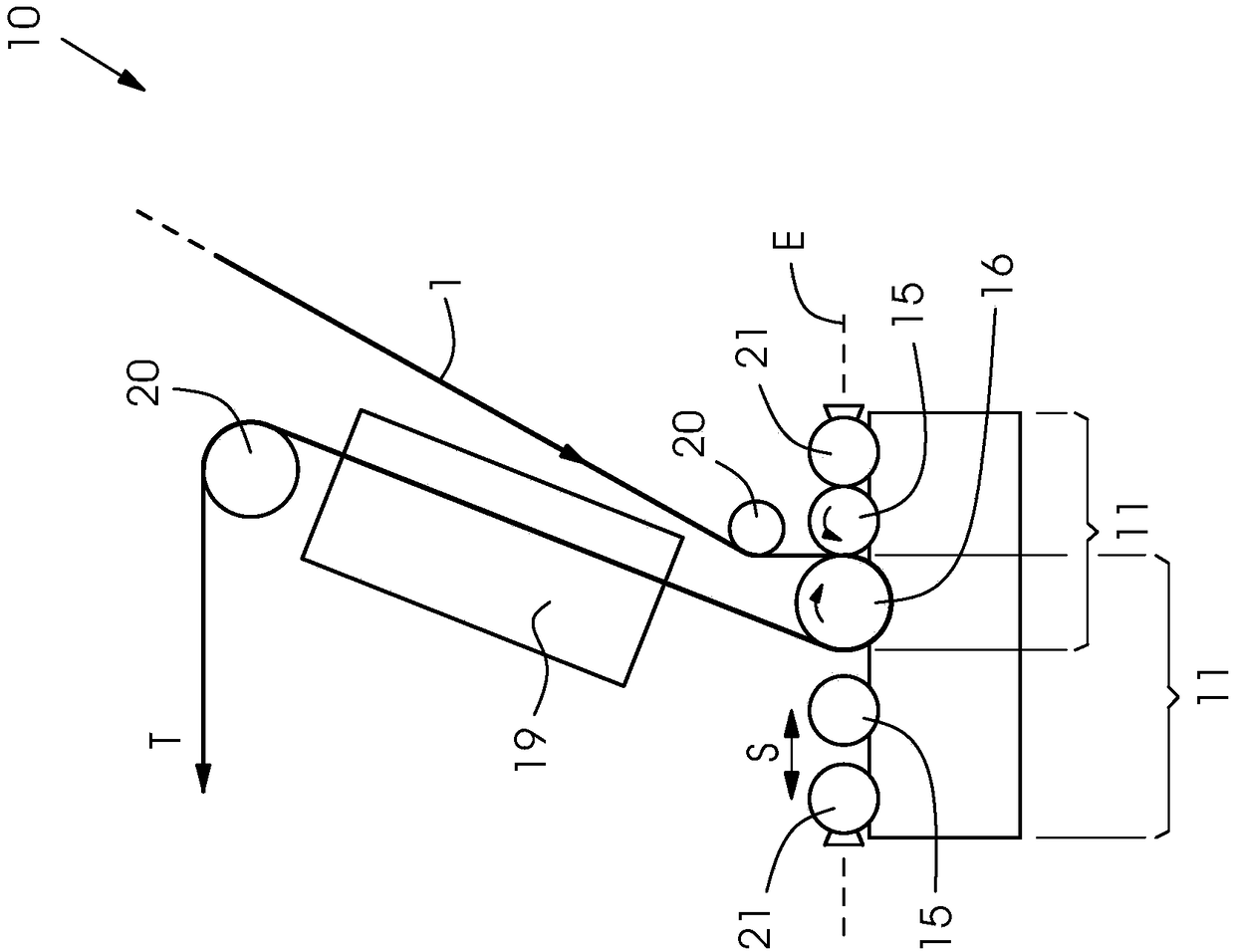

Printing machine with a twin printing unit and method for operating such a printing machine

ActiveUS20190016111A1Quick and easy job changeAvoid huge wasteCylinder pressesRotary letterpress machinesFlexographyEngineering

A printing machine for printing on a web of printing material includes a plurality of in-line flexographic printing units disposed in a plane that is accessible to a machine operator. Every two flexographic printing units of the plurality of flexographic printing units together form a double printing station and the two flexographic printing units of a respective double printing station have a common impression cylinder. A method of operating a printing machine is also provided.

Owner:HEIDELBERGER DRUCKMASHINEN AG

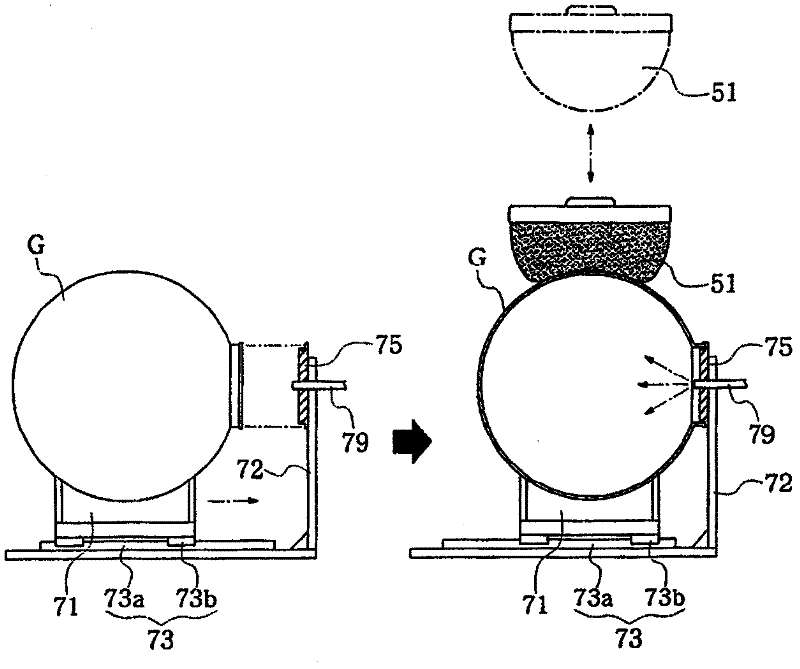

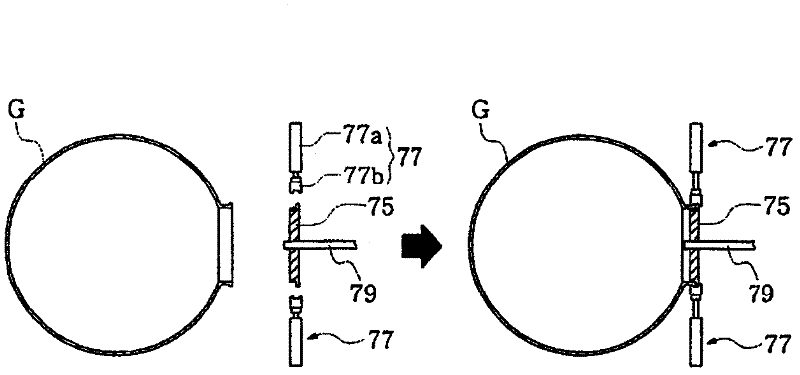

Printer for streetlight globe and globe using the same

InactiveCN102452218APrevent shrinkageAccurate printingMechanical apparatusOutdoor lightingCompression PumpEngineering

A printing device of a globe for a street light and a globe manufactured by the same are provided to enable consecutive printing in the shape of uniform image. A printing device of a globe for a street light comprises an image plate, an ink feeder, a printer, a fixing member, and a compression pump. A printing image is intagliated in the image plate. The ink feeder supplies ink to the image plate. The printer transfers the ink of an image type, with which the printing image is filled, to the surface of a globe, so image is printed on the globe. The image is printed on the globe. The fixing member fixes the globe to print the image on the outside of the globe.

Owner:罗俊河

Plant spraying decoration carpet and jet printing method thereof

The invention discloses a plant spraying decoration carpet on which various patterns are sprayed and printed on the front face and a method for spraying and printing the patterns on the plant spraying decoration carpet. The spray printing steps comprise that: patterns are designed, an environment friendly active dye is selected for mixing colors, and the active dye is mixed with the environment friendly addition agents such as penetrating agent, thickening agent, and the like, for forming a sizing agent with certain viscosity; the patterns are sprayed and printed; after fixation treatment, washing treatment is carried out; after the carpet after washing is dried, the carpet is rolled in bunches and is packaged to finished carpet; or the carpet is cut according to the size of the patterns,wrapped and packaged to the finished carpet.

Owner:张听飞

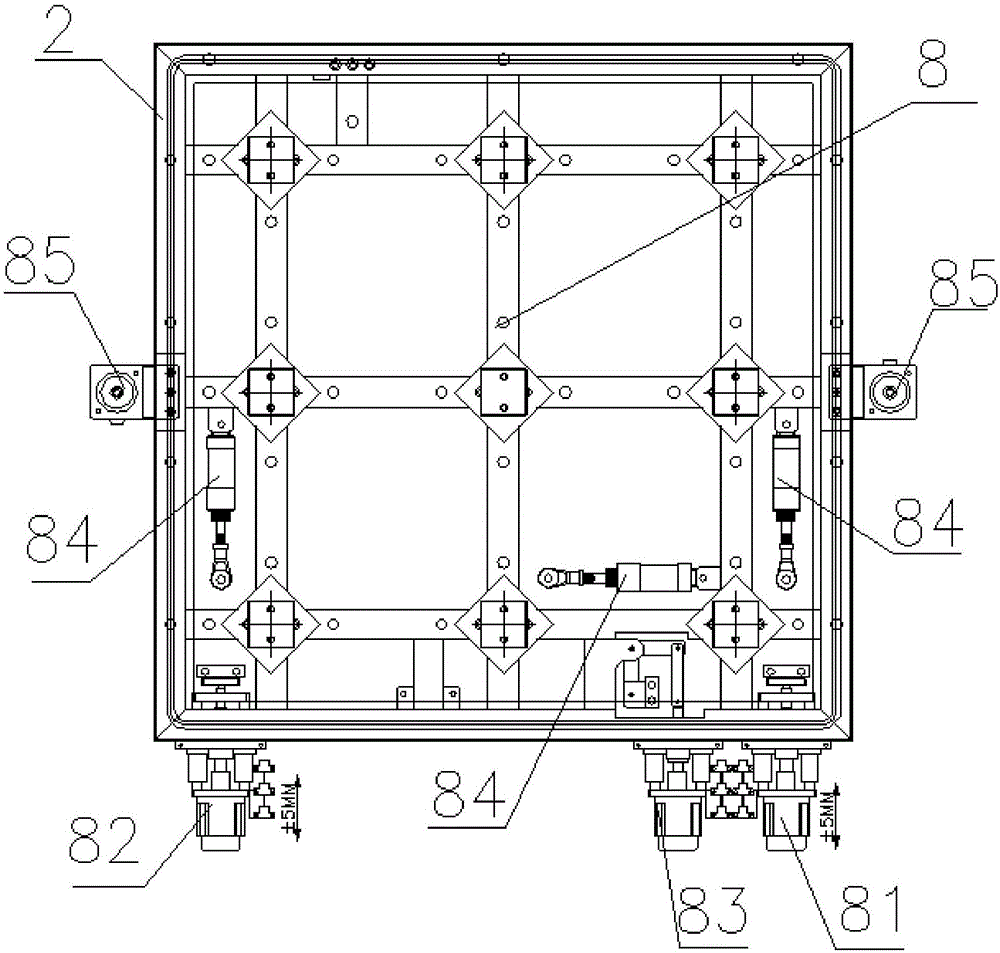

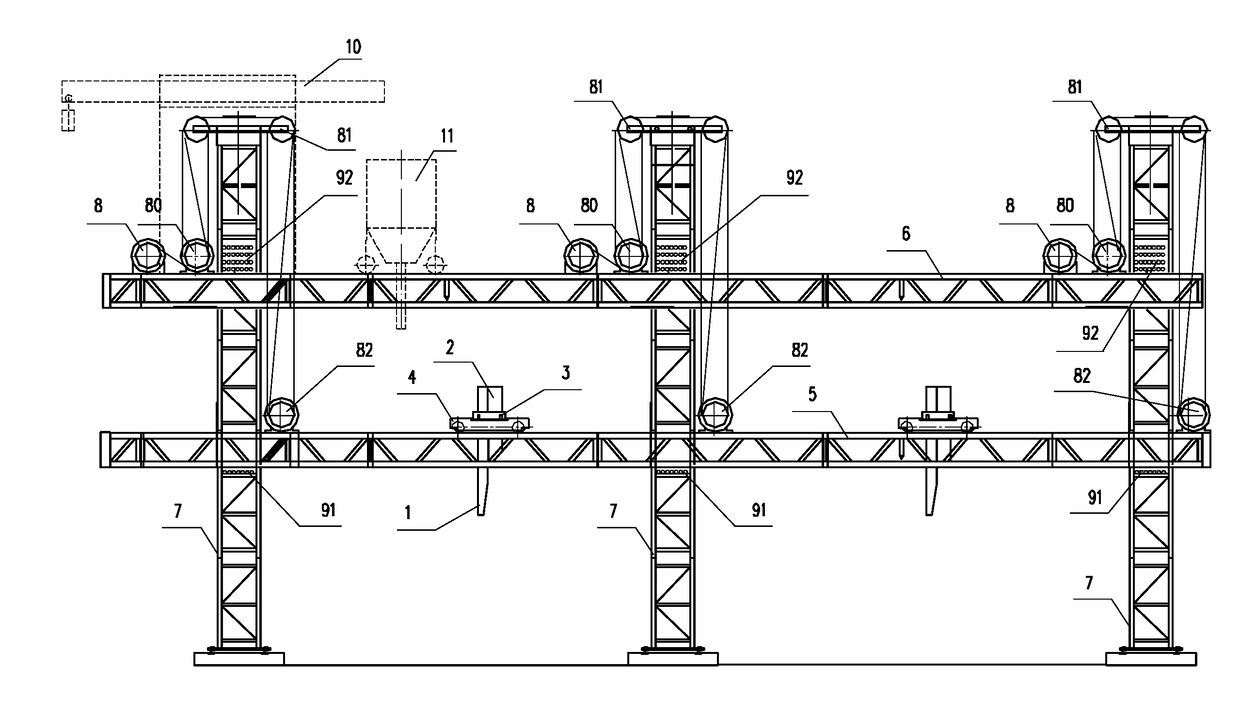

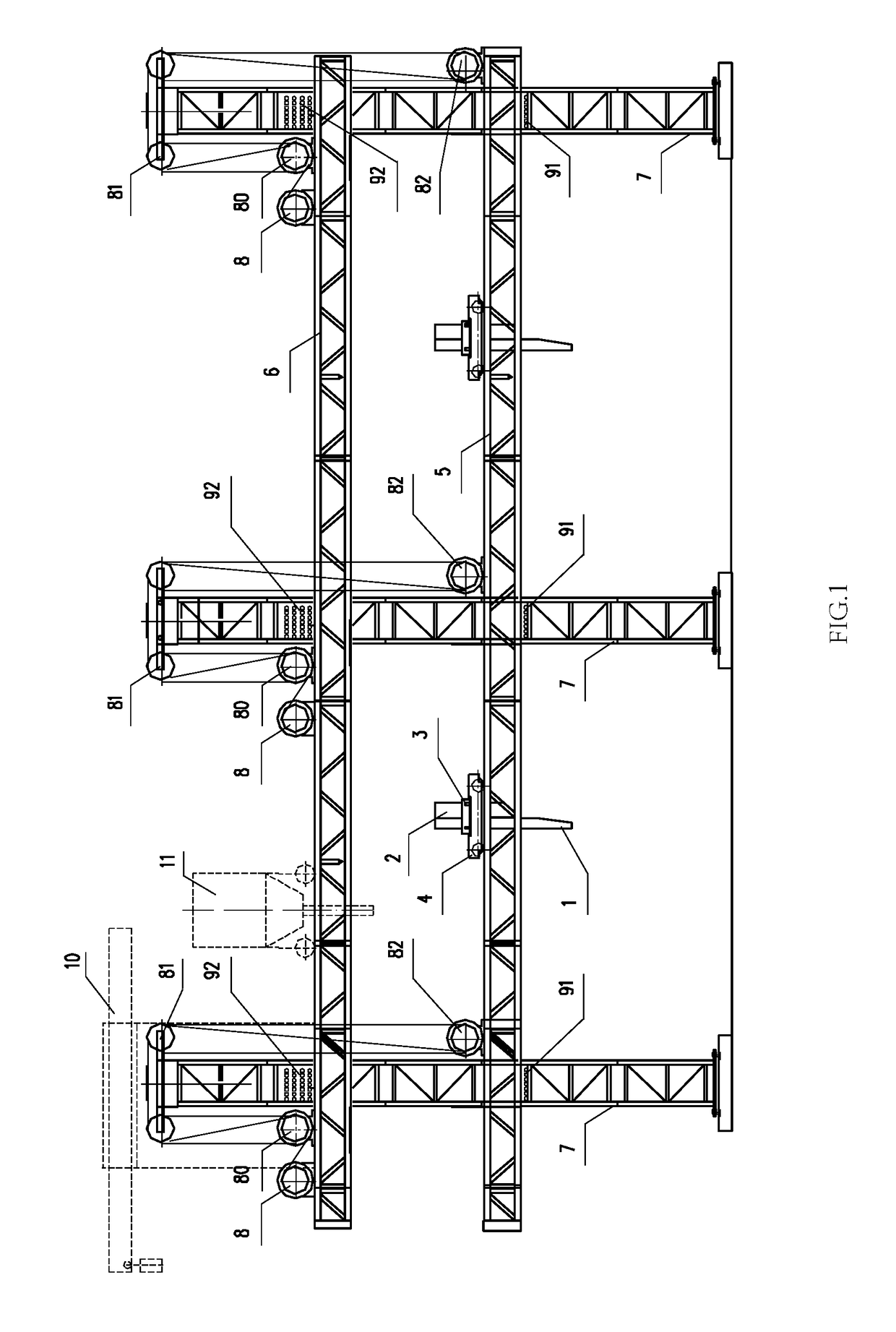

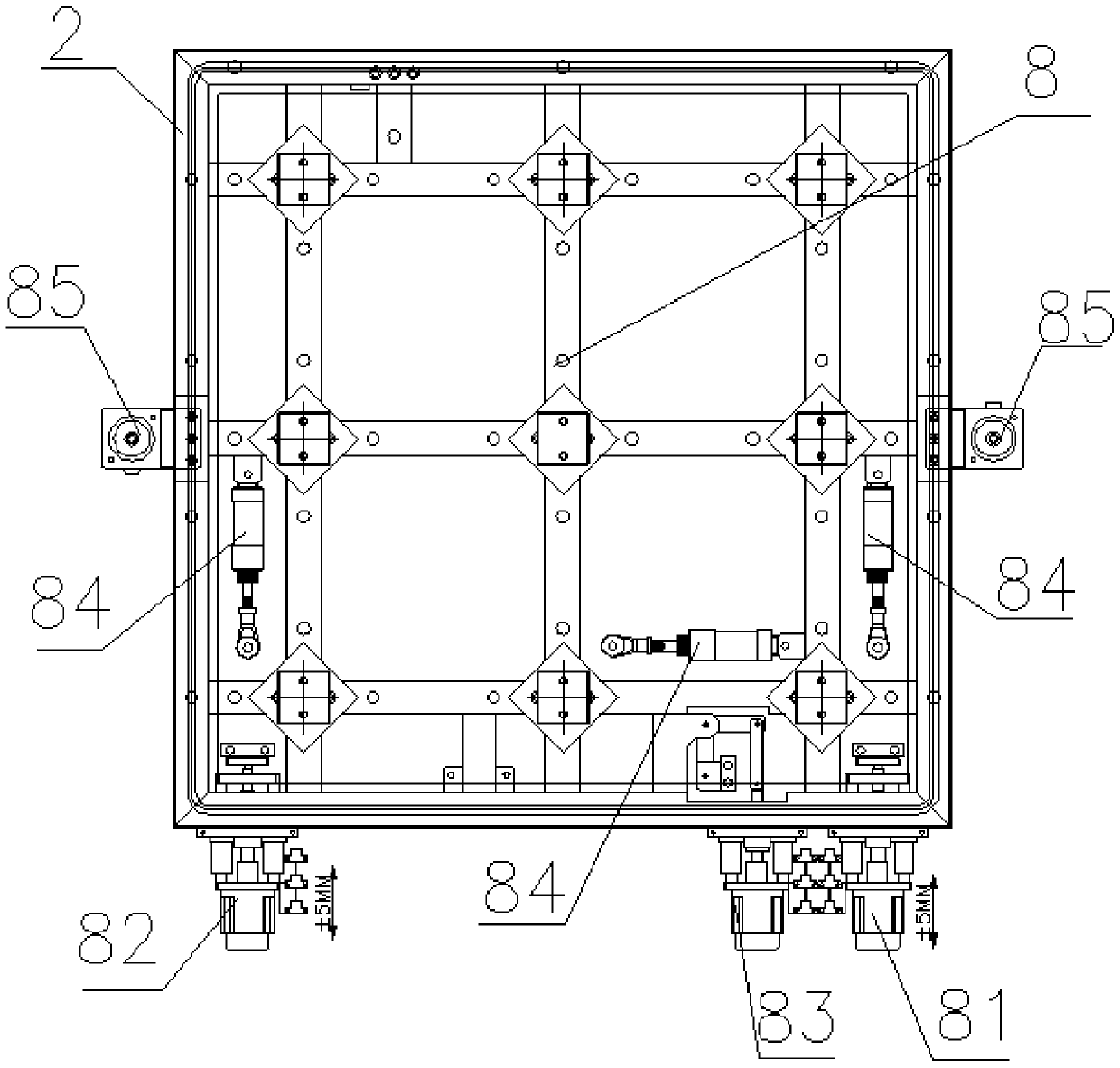

Rack structure for an in-field 3D construction printer

ActiveUS20180230703A1Reduce transport distanceIncrease build heightAdditive manufacturing apparatusCeramic shaping apparatusEngineeringWire rope

This invention discloses a rack structure for an in-field 3D construction printer, which comprises the vertical supporting posts consisting of connected standard vertical supporting post segments in two rows with symmetrical arrangement, a printing platform, a power and material storage platform, and lifting mechanism; said two rows of the vertical supporting posts are symmetrically arranged and fixed on the ground; the printing platform, and the power supply and material storage platform are fixed on the vertical supporting post through their respective cavities, and then the printing platform and the power and material storage platform are bolted on the vertical supporting post; the steel wire rope runs through a lifting drum, to a pulley block on the side of the power supply and material storage platform, and then from the intermediate pulley block to the pulley block on the side of the printing platform.

Owner:YINGCHUANG BUILDING TECH SHANGHAI CO LTD

A resin ink vacuum plug hole printing device and printing method thereof

Owner:昆山晟丰精密机械有限公司

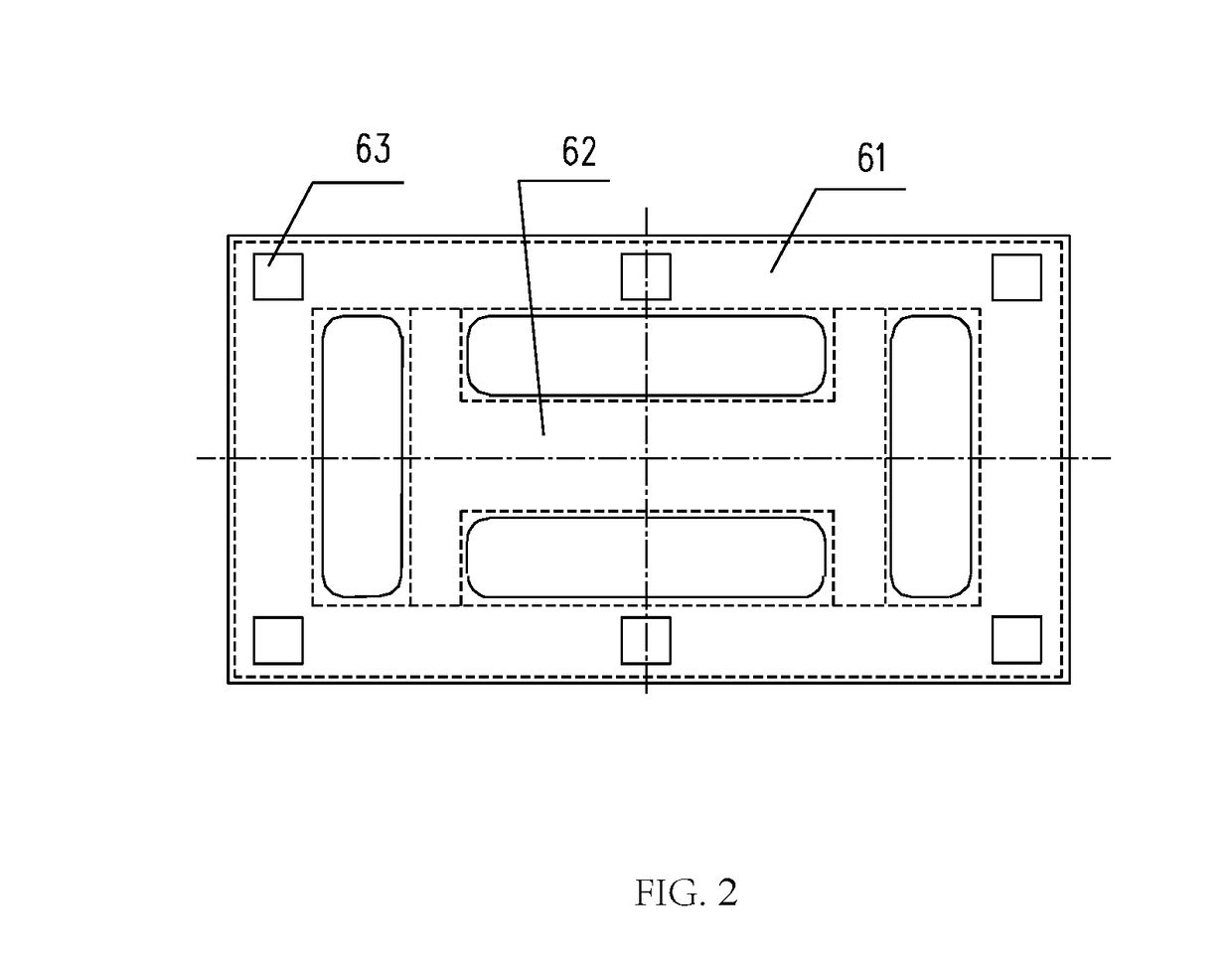

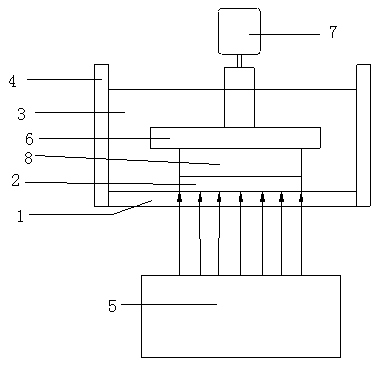

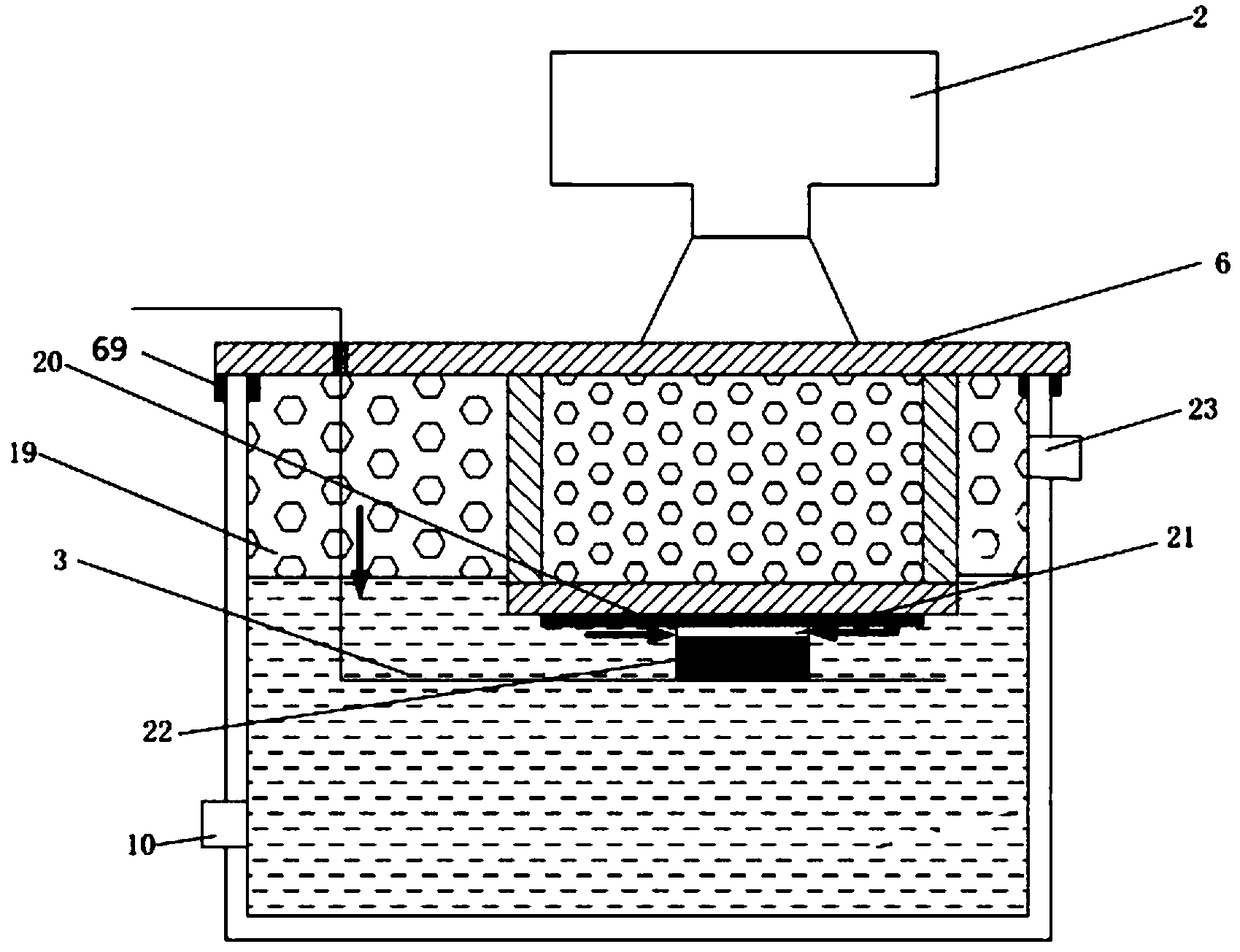

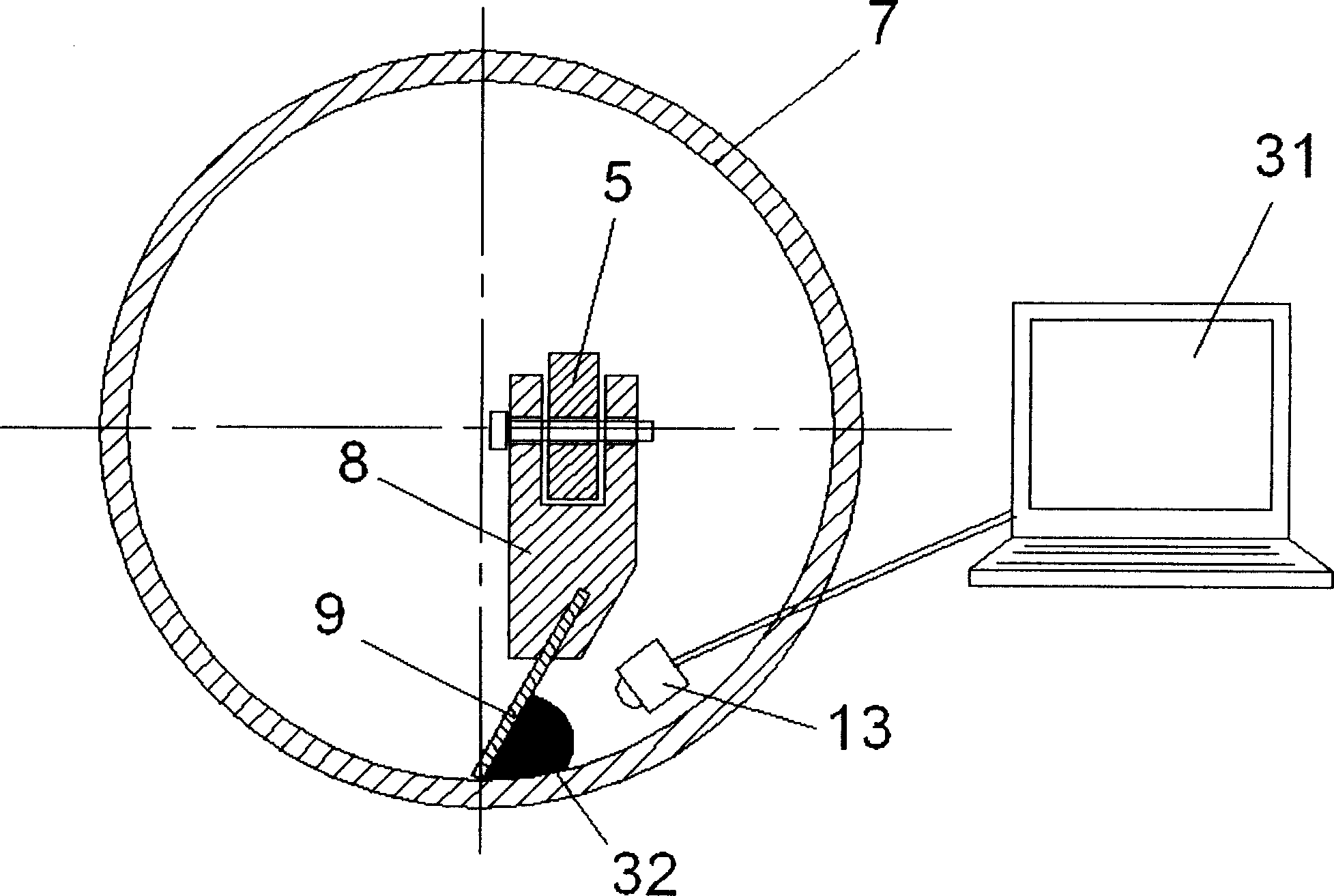

Continuous 3D (three-dimensional) printing system

ActiveCN109228315AAvoid stickingAvoid the refill stepAdditive manufacturing apparatus3D object support structuresEngineeringPhotocatalytic degradation

The invention provides a continuous 3D (three-dimensional) printing system. The continuous 3D printing system comprises a light transmission window (1), a non-curing layer (2), a photosensitive resin(3), a material tank (4), optical equipment (5), an object carrying stage (6), a motor (7) and a curing product (8), wherein the light transmission window (1) is positioned at the bottom part of the material tank (4); the photosensitive resin (3) is arranged in the material tank (4), and contains titanium dioxide nanoparticles and components which can be degraded into a blocking agent by visible light catalysis. The continuous 3D printing system has the beneficial effects that the non-curing layer is formed in the light transmission window in the printing process, the curing body mechanical stripping and photosensitive resin refilling process of the traditional 3D printing method can be effectively avoided, the continuous printing effect is realized, and the printing speed is higher than the printing speed of the traditional photosensitive resin 3D method, and is more than 20 times higher than the printing speed of the traditional 3D method; in the printing process, the thickness of the light transmission window is 3 to 50mm, the easiness in cracking and deformation in the printing process is avoided under the function of mold plugging force, the precision of the printed product ishigher, and the printing speed is comparable with the latest CLIP technique and reaches 500mm / h.

Owner:TAIZHOU POLYTECHNIC COLLEGE

Printing machine with twin printing unit and method for operating such a printing machine

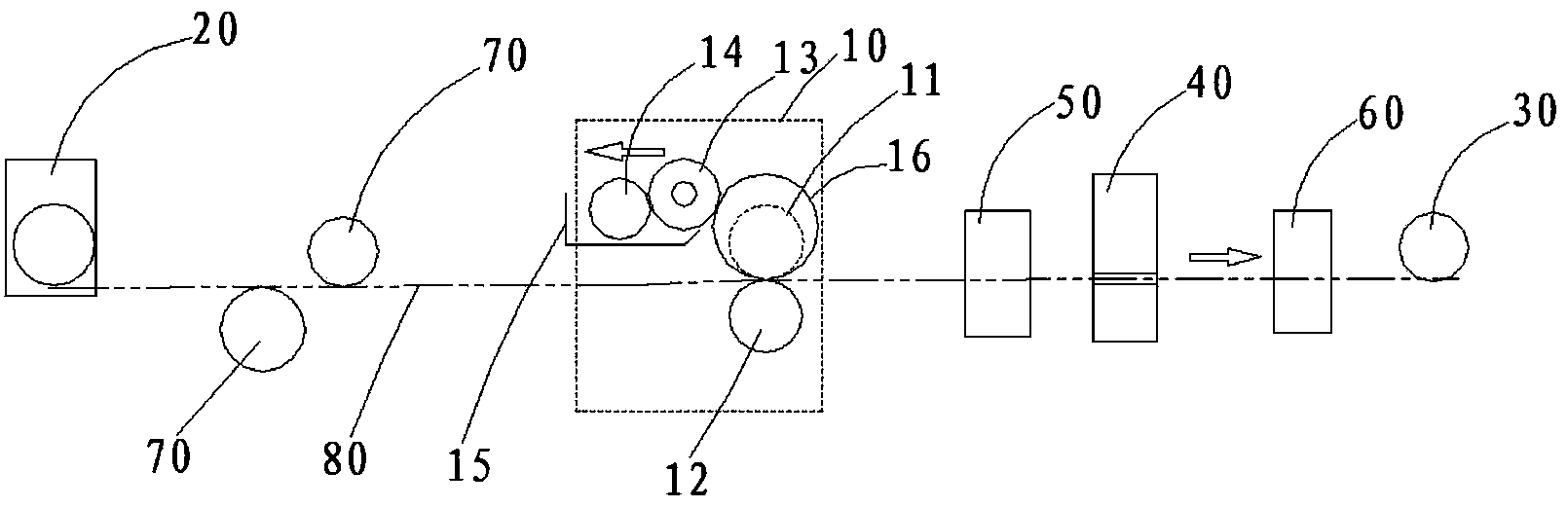

ActiveCN109263244AContinuous productionAchieve dryingCylinder pressesRotary letterpress machinesPrinting pressElectrical and Electronics engineering

The invention relates to a printing machine (100) for printing a web (1) of substrate material. The printing machine comprises a plurality of flexographic printing mechanisms (11) arranged in series,wherein the flexographic printing mechanism (11) is provided in a plane (E) accessible to a machine operator; the invention is characterized in that the two flexographic printing mechanisms (11, 11a,11b) of the plurality of flexographic printing mechanisms (11, 11a, 11b) always form a dual printing station (10) together, and that the two flexographic printing mechanisms (11, 11a, 11b) of the respective dual printing station (10) have a common pressing cylinder (16).

Owner:HEIDELBERGER DRUCKMASCHINEN AG

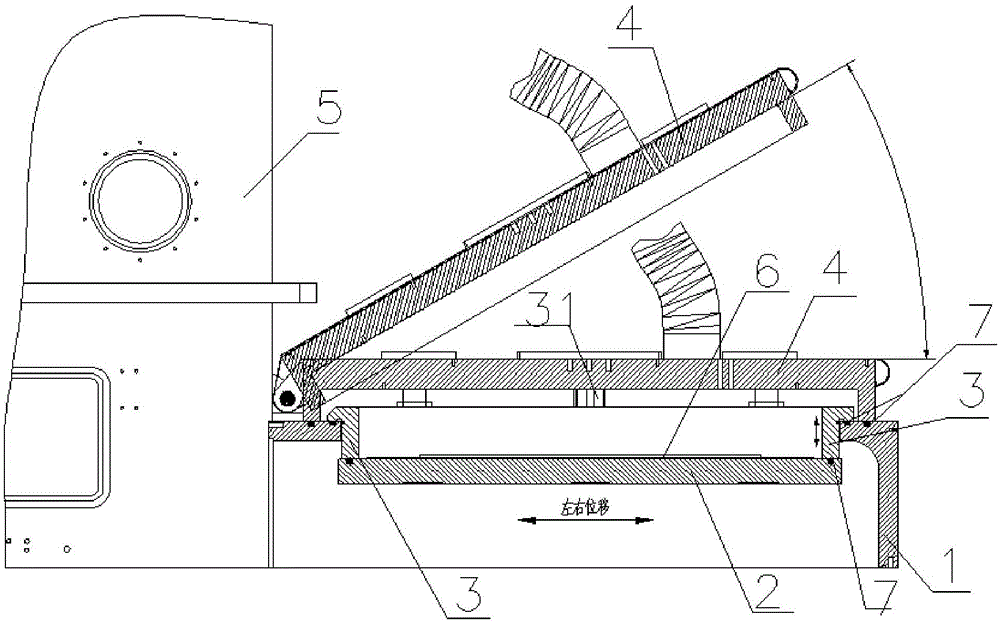

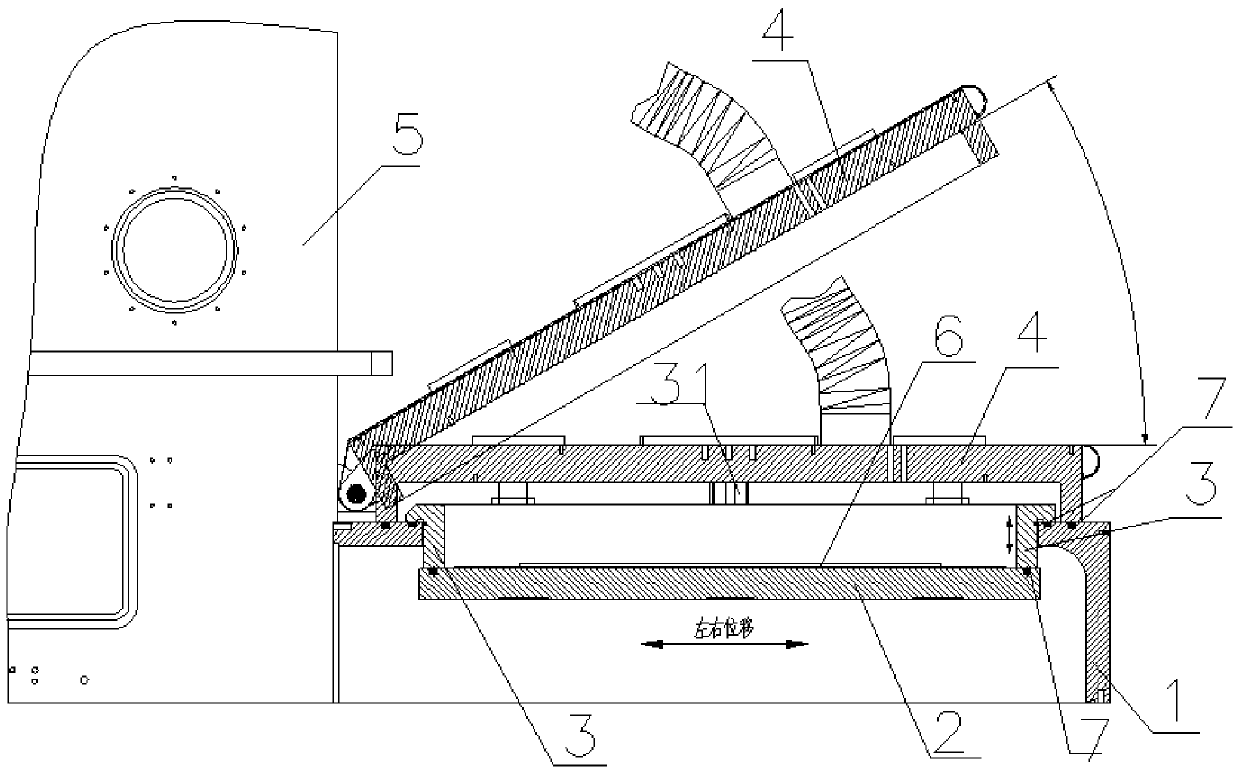

Continuous forming 3D printing equipment and operation method thereof

ActiveCN109016495AIncrease return speedTimely supplementManufacturing platforms/substratesManufacturing enclosuresEngineeringRapid prototyping

Disclosed are continuous forming 3D printing equipment and an operation method thereof. According to the continuous forming 3D printing equipment, the forming position is located in liquid photosensitive resin, when printing is started, a forming cylinder lifting device drives a forming cylinder to rise so as to form a sealed cavity with a sealing cabin, then gas is injected into the forming cylinder, through the pressure generated by the gas in the forming cylinder, the backflow speed of the liquid photosensitive resin is increased, it is ensured that the liquid photosensitive resin can be supplemented in time during high-speed sprinting, it is ensured that the whole process can be conducted continuously, and adaptability of the equipment to materials is improved; by adopting a lifting forming cylinder structure, the forming cylinder can be lowered to the initial position after parts are printed, thus taking out of the parts is facilitated; additionally, the lifting forming cylinder is further replaced conveniently, the types of the materials adapted by the equipment are increased; in addition, a continuous sinking type rapid forming method can meet 3D printing of large and complex structural parts; and the continuous forming 3D printing equipment has the advantages of simple structure, high forming speed and high precision.

Owner:XI AN JIAOTONG UNIV

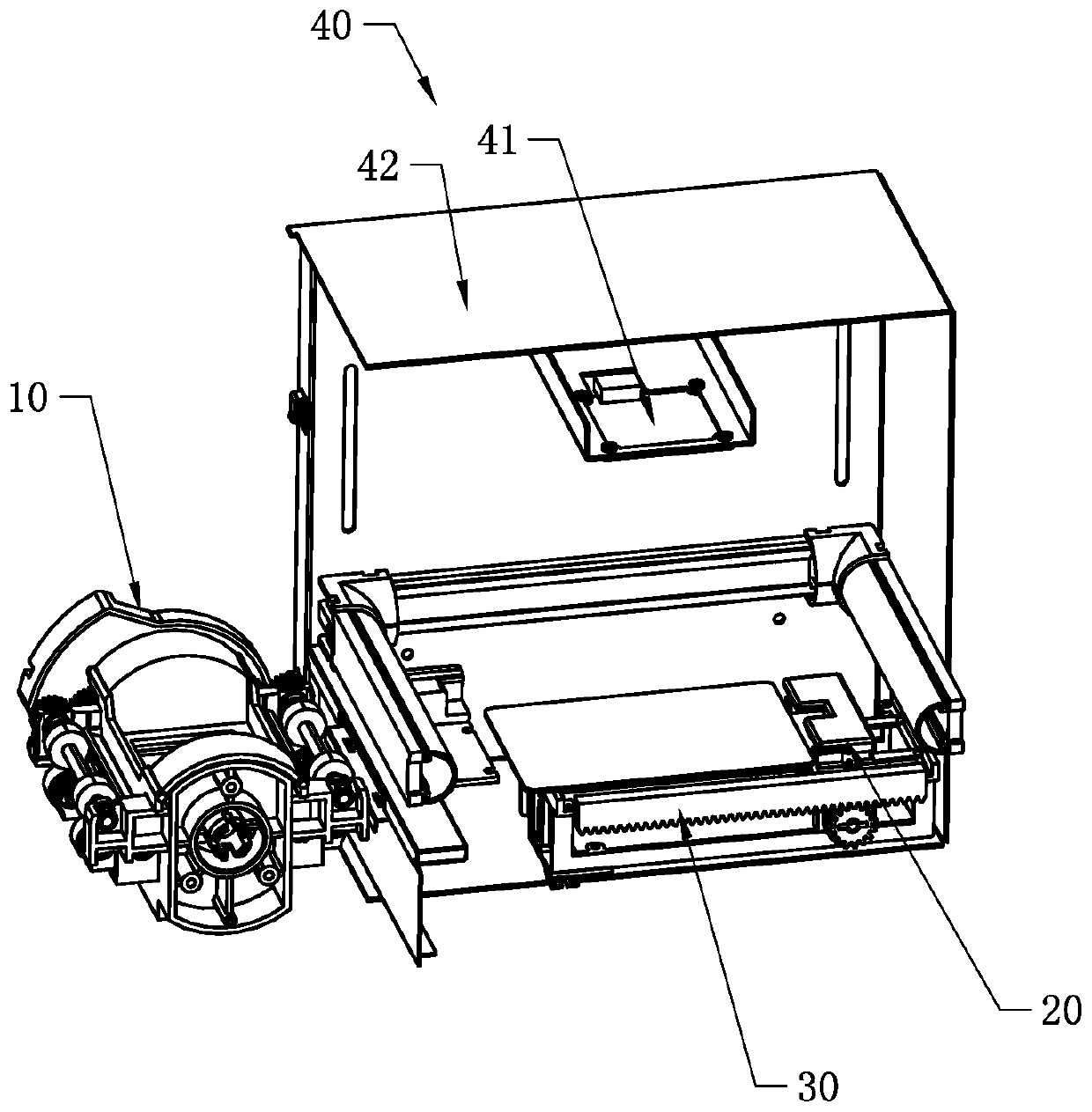

One-time imaging flatbed printer

InactiveCN108128041AContinuous printingIncrease productivityTypewritersOther printing apparatusEngineeringElectrical and Electronics engineering

The invention discloses a one-time imaging flatbed printer. The one-time imaging flatbed printer comprises a rack, a transmission device, a printing device and a moisturizing and cleaning device. Thetransmission device is arranged on the rack. The printing device is arranged on the rack and corresponds to the transmission device. The moisturizing and cleaning device is arranged on the rack and corresponds to the printing device. The printing device comprises a first printing mechanism, a second printing mechanism and a third printing mechanism. The first printing mechanism, the second printing mechanism and the third printing mechanism are arranged on the rack side by side and correspond to the transmission device. According to the one-time imaging flatbed printer, a novel printing form is adopted, a printing head is fixed, an object to be printed is driven by a conveyor belt to pass from the portion below the printing head, imaging can be achieved through one-time printing, continuous printing can be realized, and the production efficiency is improved.

Owner:GUANGZHOU NUOCAI DIGITAL PROD CO LTD

Preparation method of coarse cereal gel ink suitable for 3D printing and 3D printing snacks

InactiveCN110558356AImprove iron deficiency anemiaReduce brittlenessDough treatmentDough shapingFlavorPotato starch

The invention discloses a preparation method of coarse cereal gel ink suitable for 3D printing and 3D printing snacks. The preparation method of the coarse cereal gel ink comprises the steps: A, sieving one of black rice flour or oat flour or quinoa flour or a mixture of two or more of black rice flour or oat flour or quinoa flour with an 80-mesh sieve, placing butter, water, table salt and sugarin a stirrer, mechanically stirring and uniformly mixing to obtain an ingredient A; B, mixing whole wheat flour with potato starch, sieving the mixture with a 120-mesh sieve, sieving black bean flourwith a 80-mesh sieve, stirring and mixing, and adding a uniformly whipped egg liquid in three times during the period to obtain an ingredient B; and C, uniformly stirring and mixing the ingredient A and the ingredient B in a dough mixer, adding baking soda, and uniformly stirring. The health concept is followed, and the 3D printing technology is combined to design the coarse cereal gel ink with characteristics of smooth ink outgoing, continuous printing and good molding, and the coarse cereal snack product with characteristics of comprehensive nutrition, high printing precision, low sugar, high protein, unique flavor, good taste and easy chewing is prepared by using the coarse cereal gel ink as a base material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

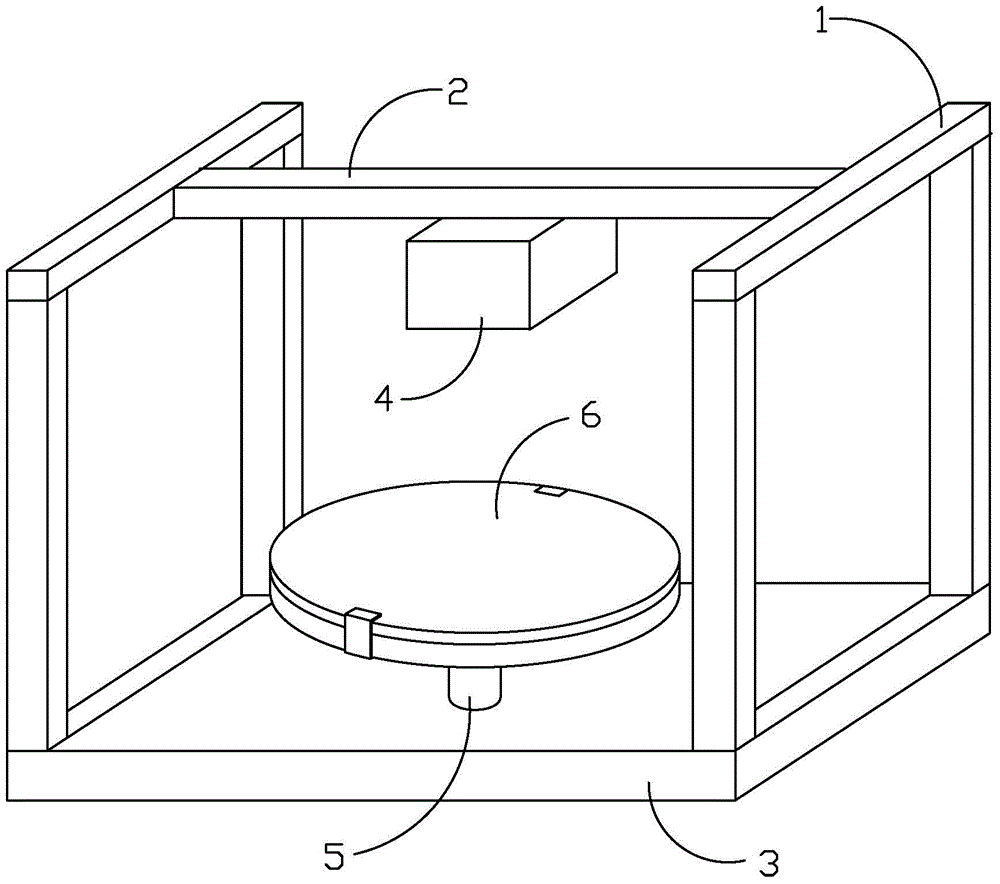

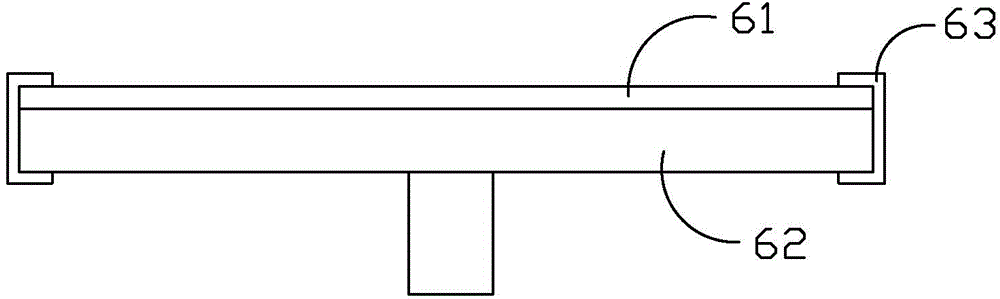

Cake 3D printing device

InactiveCN105685148AContinuous printingPrinting in rapid successionDough shapingEngineering3D printing

The invention discloses a cake 3D printing device. The cake 3D printing device comprises a support, a cross bar, a base, a printing assembly, a rotation and elevating unit and a worktable. The worktable comprises a base plate installed on the rotation and elevating unit, a printing panel overlapped above the base plate and fixing clamps uniformly installed on sides of the base plate and a printing panel. After cake printing, the fixing clamps are taken down so that cake and the printing panel can be taken down together and then a novel printing panel is installed and is fixed to the base plate through the fixing clamps so that fast and continuous printing of cake is realized. The printing panel can be prepared directly from a cystosepiment so that the printed cake does not need to be taken down from the printing panel and thus labor and time are saved.

Owner:CHENGDU MEILYU SCI & TECH CO LTD

Production method of gold stamping film

InactiveCN113135061ARealize continuous printing and hot stampingEasy to scale productionDecorative surface effectsHot stampingColor printing

The invention discloses a production method of a gold stamping film. The production method comprises the following steps that a substrate layer is coated with a release layer, the release layer is coated with a color printing layer, the color printing layer is coated with a mould pressing layer, and electroplating is carried out on the mould pressing layer to form an electroplated layer. A process of manufacturing the mould pressing layer comprises the following steps that a holographic embossment laser mould pressing plate is manufactured, graphic and text information is engraved on a nickel plate by using a laser holographic engraving technology, and the surface of the nickel plate is processed to manufacture a mould pressing metal plate; and positioning and mould pressing are carried out, an embossment laser transparent film is manufactured, and the set register precision is kept according to the used plate cylinder number. Color printing, the platinum embossment technology and the gold stamping technology are combined, the personalized 3D platinum embossment effect of container packaging is achieved through technological treatment of printing, mold pressing and electroplating, continuous printing and hot stamping are achieved, and large-scale production is facilitated. The method can be widely applied to the technical field of product packaging.

Owner:广州市丽宝包装有限公司

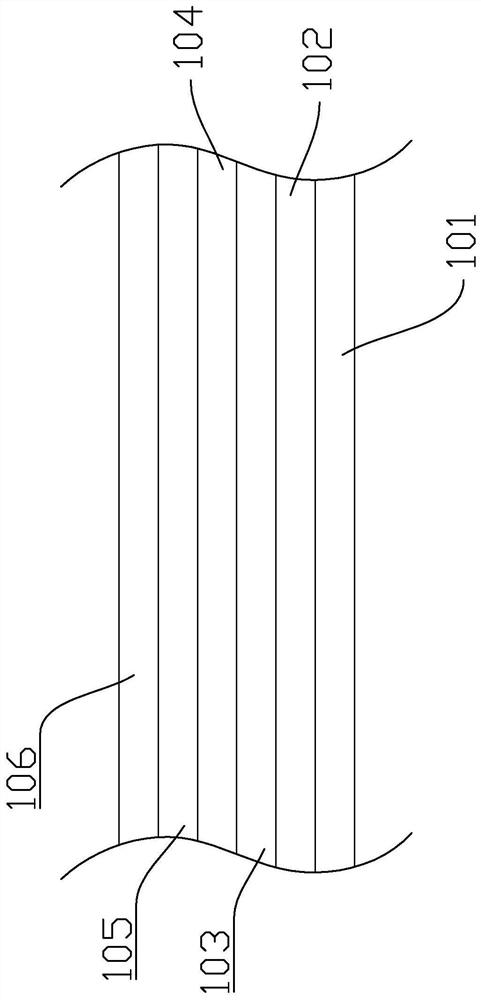

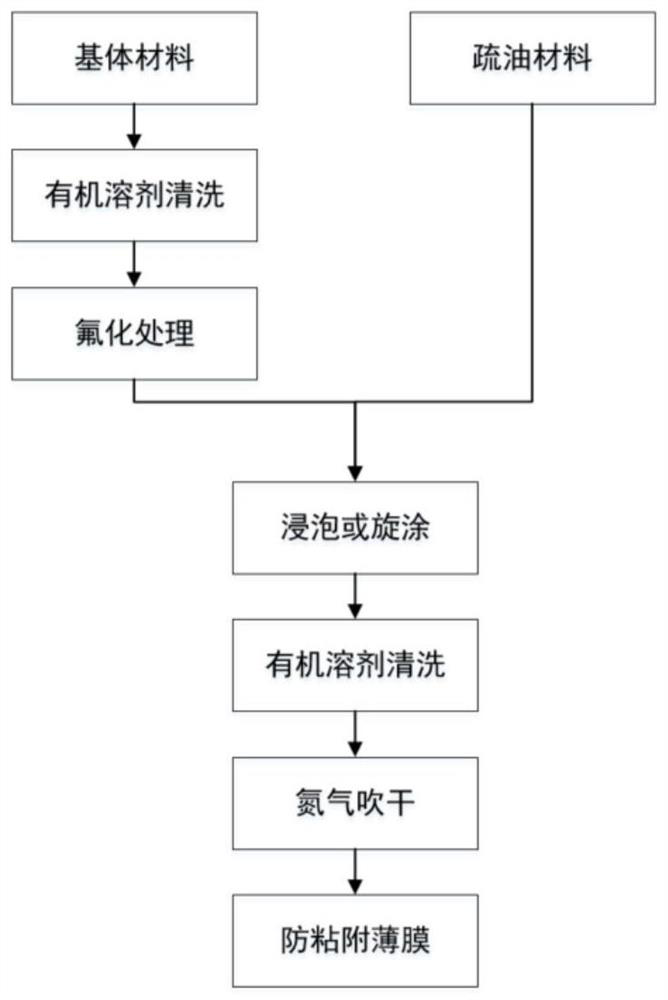

A method for preparing an anti-adhesion film for photocuring continuous surface molding 3D printing

ActiveCN110256724BReduce adhesionReduce usage requirementsAdditive manufacturing apparatusCoatingsThin membraneFilm material

A method for preparing an anti-adhesion film for photocuring continuous surface molding 3D printing. Soak the fluorinated porous material that is transparent to ultraviolet light in a fluorinated liquid or fluorine-containing nano-scale lubricating oil, and after a period of time, the fluorinated liquid or fluorine-containing nano-scale lubricating oil can fully infiltrate the interior of the porous material, and then Use organic solvents to remove excess fluorinated liquid or fluorine-containing nano-scale lubricating oil. Using the chemical compatibility of the porous material and the oleophobic phase and the capillary action of the porous material, a stable micron-sized liquid film is formed on the surface of the porous material, and the "solid bond" between the molded part and the light-transmitting porous film material "Transform into a "solid-liquid bond" between the molded part and the liquid oleophobic phase, separate the molded part from the porous material, reduce the adhesion between them, so that the printing process can be carried out continuously, the preparation method is low cost and simple fast.

Owner:XI AN JIAOTONG UNIV

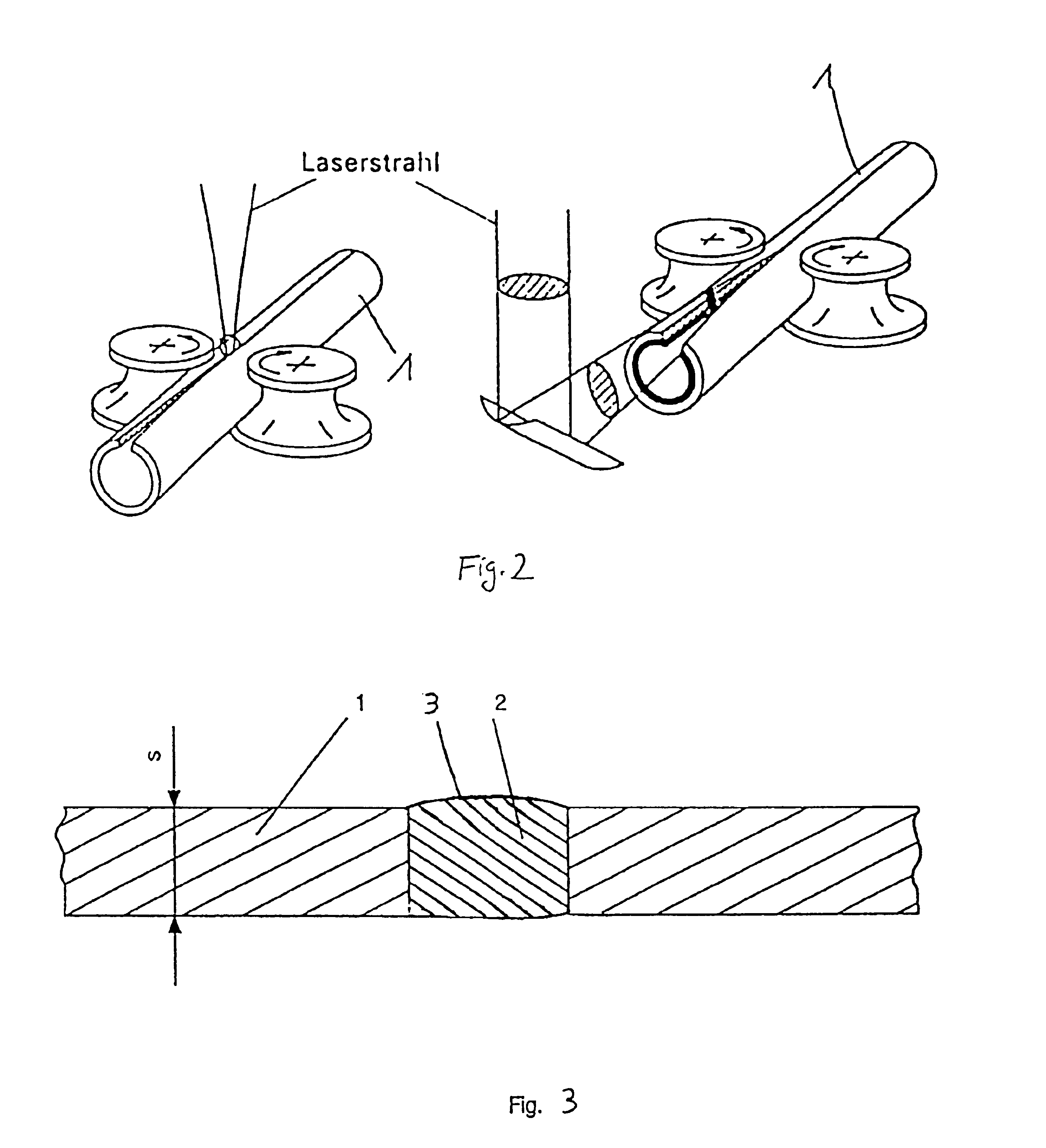

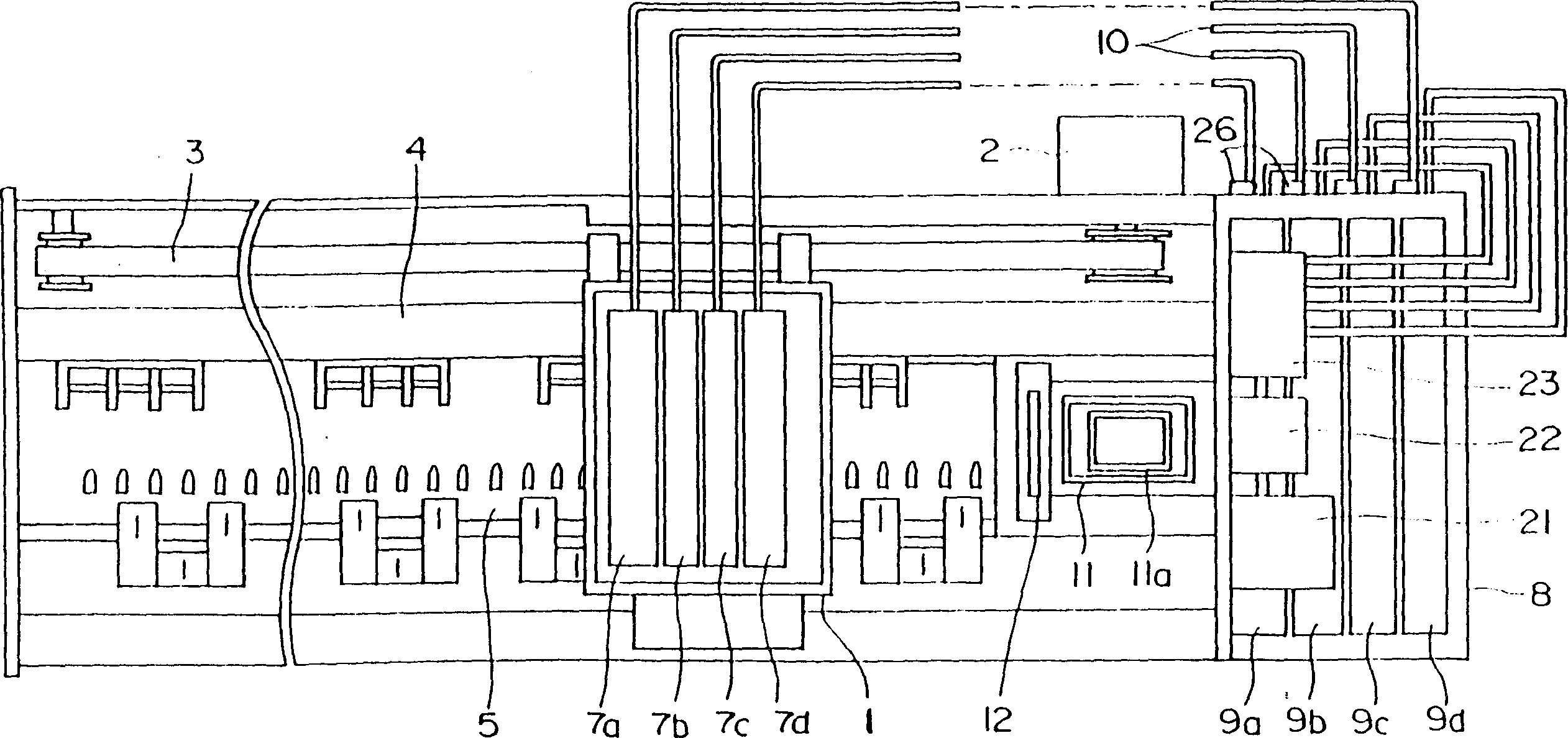

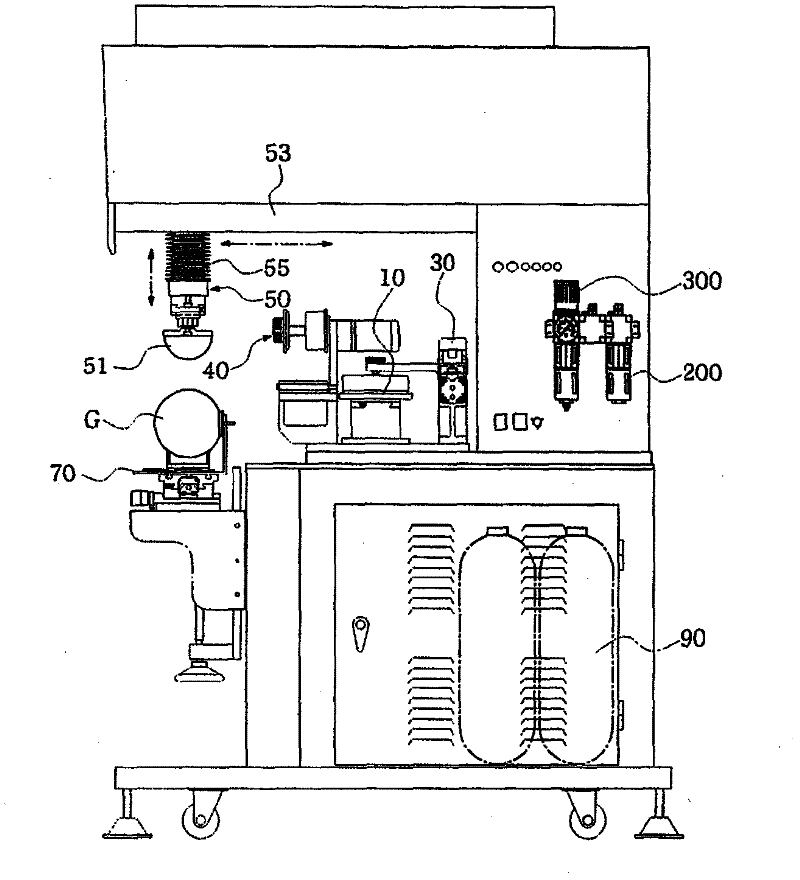

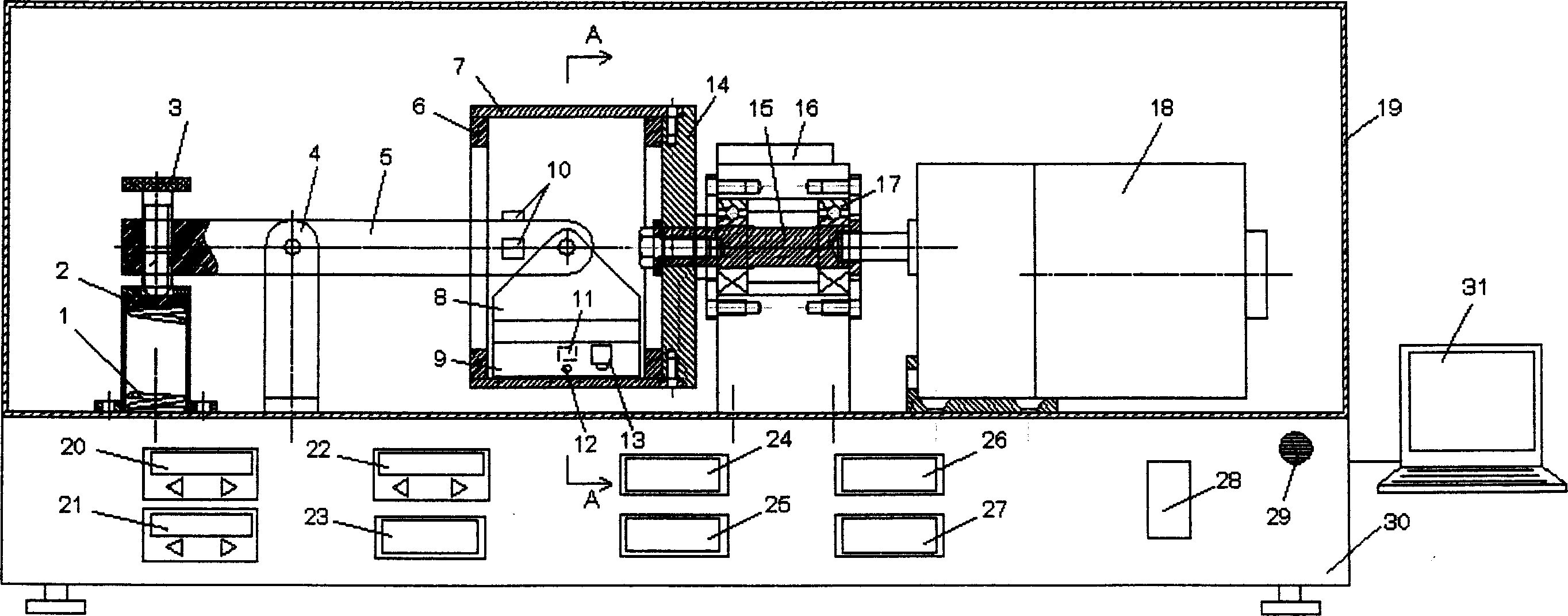

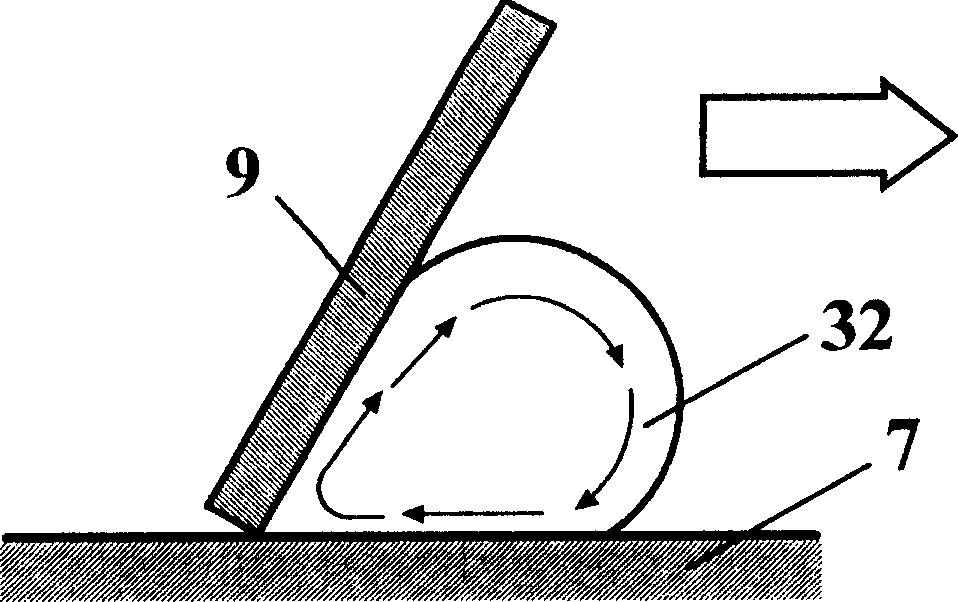

Testing apparatus and testing method for printable property of soldering paste

InactiveCN1673718AContinuous printingConsistent printing conditionsMaterial analysis by optical meansUsing mechanical meansProcess engineeringSolder paste

The present invention is soldering paste printability test apparatus and method. The test apparatus includes scraper loading part comprising spring, press rod rack, scraper holder, scraper, etc.; ring temperature rotating part comprising scraper blocking ring, ring template, turntable, spindle, DC reducing motor, etc; control and test part comprising atmosphere temperature and humidity controlling box, micro strain sheet, micro mechanical sensor, video camera, etc; and computer as the peripheral equipment. The test method includes using printing unit of scraper-ring structure in printing soldering paste continuously in different temperature and humidity, and monitoring soldering paste rolling state change with video camera, micro strain sheet and micro mechanical sensor to evaluate the printability of soldering paste.

Owner:吴懿平

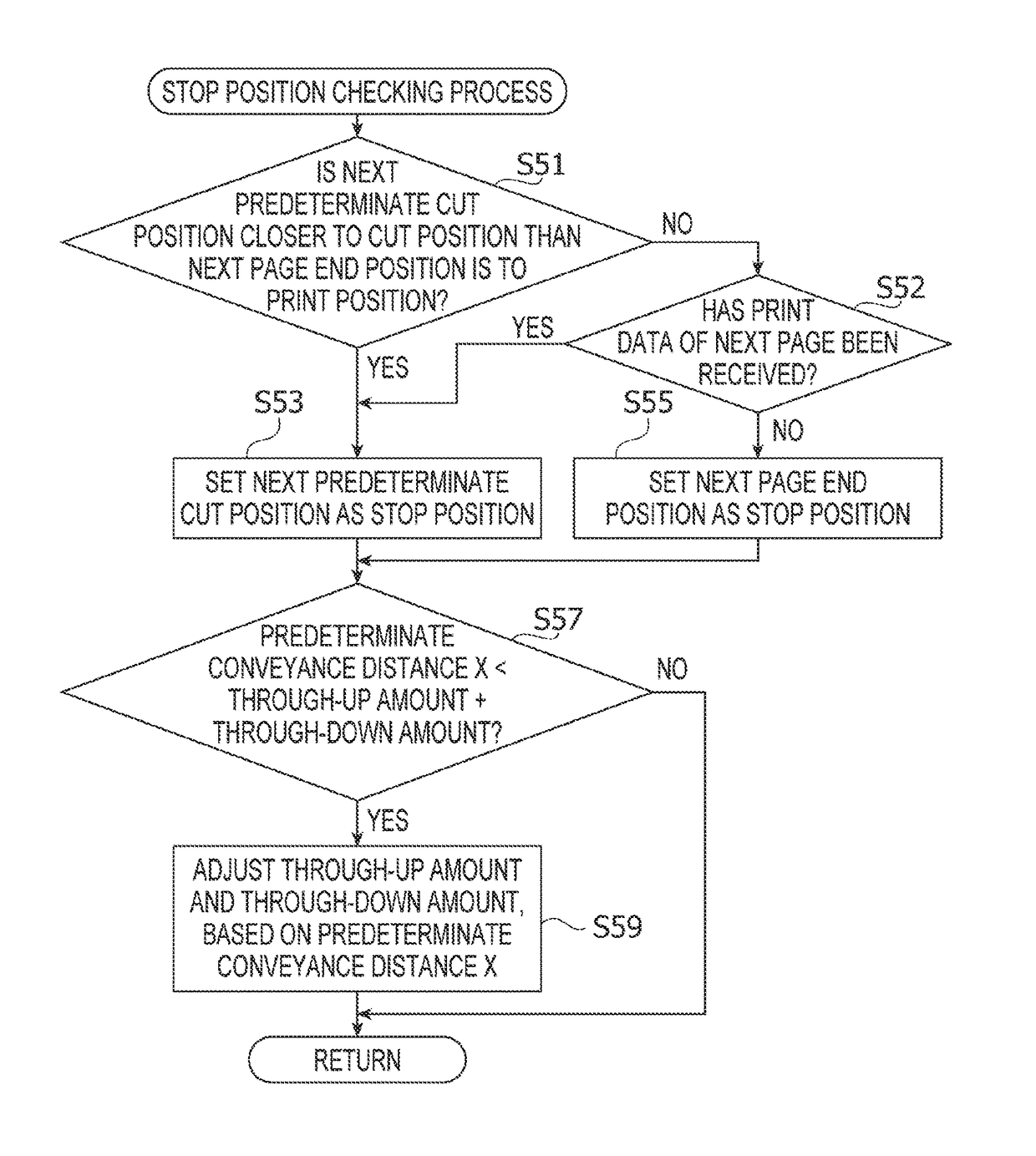

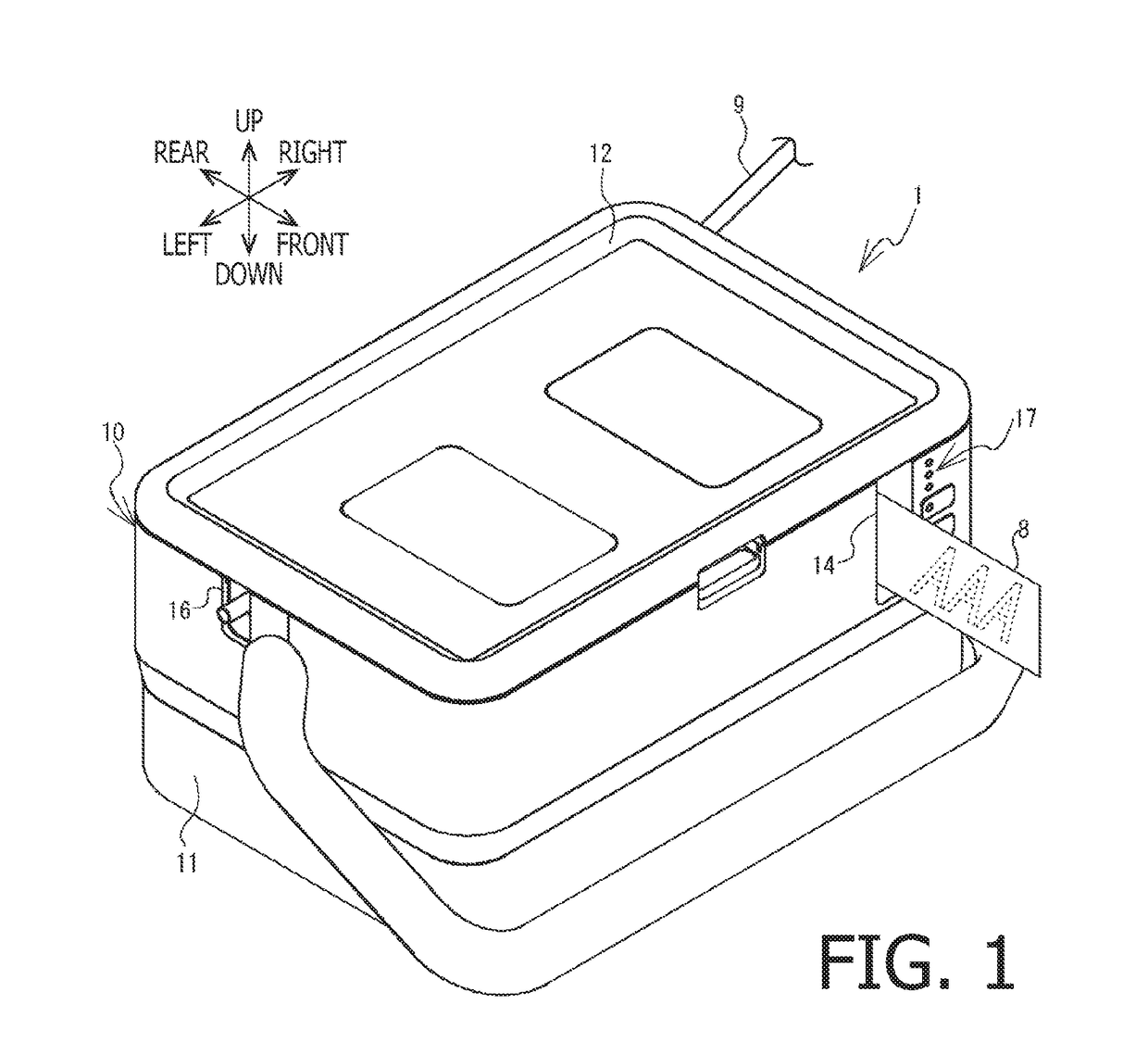

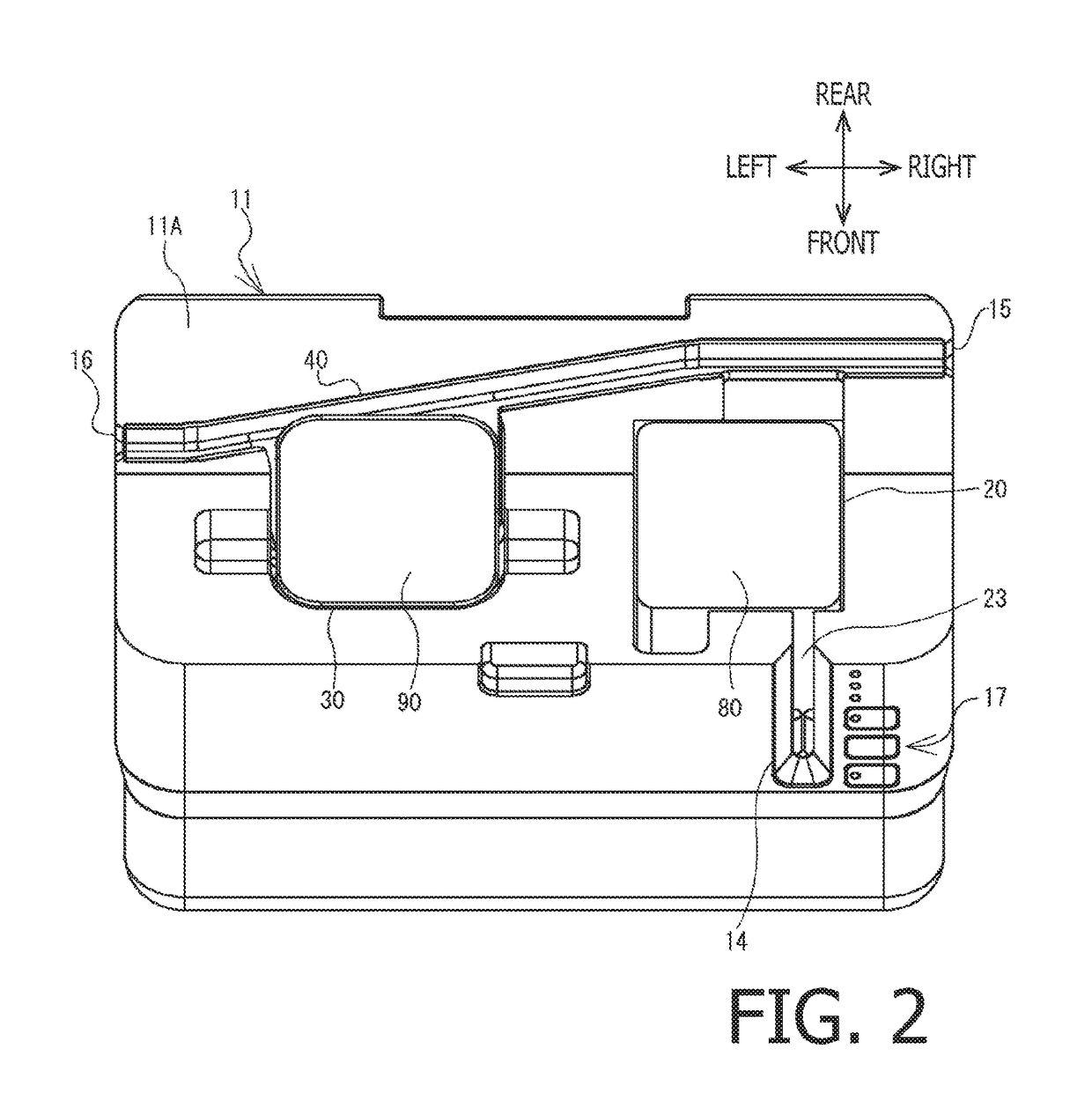

Printer, and method and computer-readable medium for the same

ActiveUS9718290B2Accurately cutting printed pagesContinuous printingTypewritersOther printing apparatusComputer engineeringConstant speed

A printer includes a controller configured to, when determining that print data of a next page is stored in a storage while a through-up printing process or a constant-speed printing process is in execution, perform a nonstop printing process, when a first distance between a cut position and a cut target portion closest to the cut position becomes coincident with a second distance over which a print medium is conveyed while a conveyance speed is decelerated at a particular deceleration from a current speed to zero, during the execution of the nonstop printing process, perform a through-down printing process until conveyance of the print medium is stopped, and when conveyance of the print medium is stopped, control a cutter to cut the cut target portion in the cut position.

Owner:BROTHER KOGYO KK

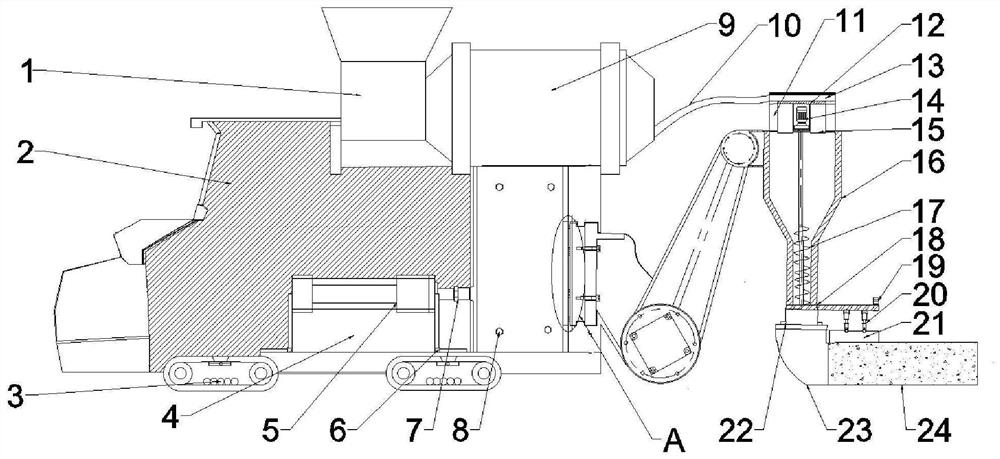

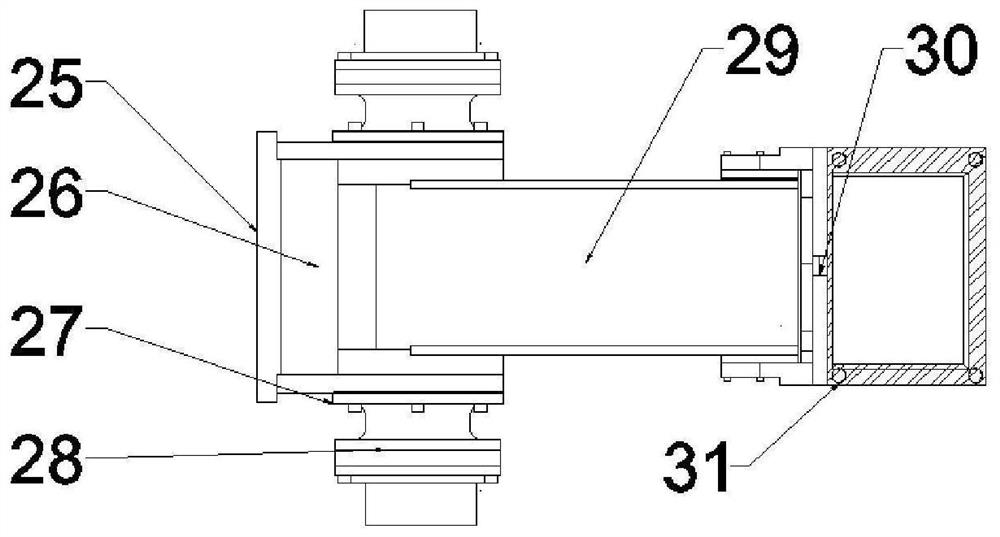

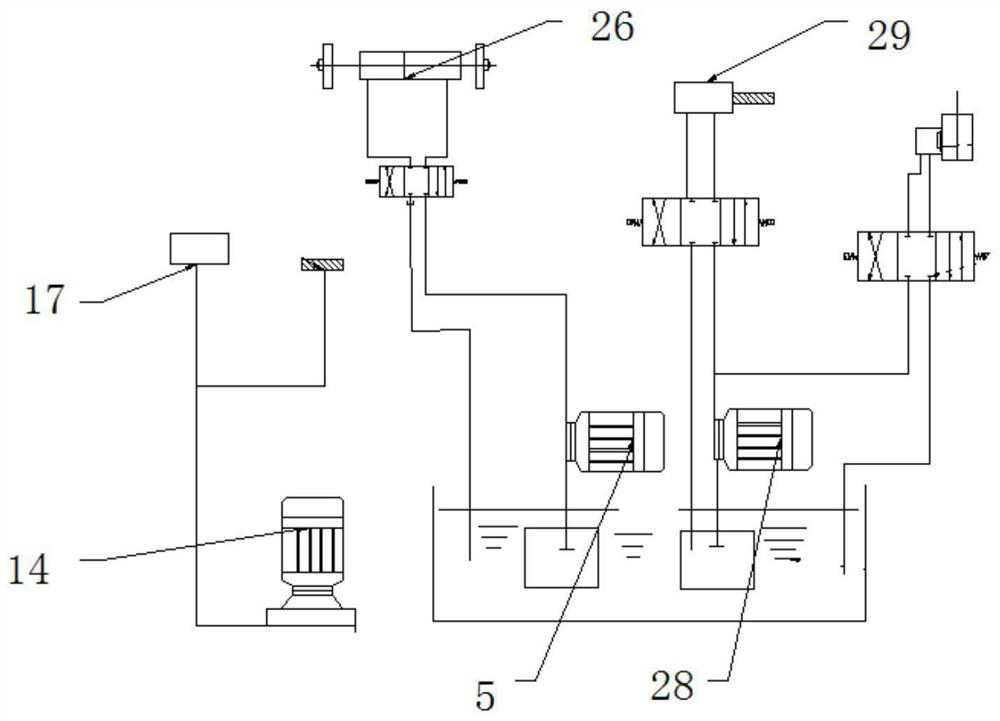

A 3D printing equipment and construction method for cement concrete pavement

ActiveCN113389112BAchieve large scaleRealize integrationRoads maintainenceRobotic armComputer printing

The invention relates to a cement concrete pavement 3D printing equipment and a construction method, belonging to the technical field of pavement paving. The equipment includes vehicle-mounted system, batching system, control system, printing system and leveling system. Among them, the batching system is set on the vehicle-mounted system, the batching system is connected to the printing system, and the printing system is equipped with a control system. Through the printing system and the control system, the Concrete is laid on the road surface, and the printing system is equipped with a leveling system, which can level the road surface paved with concrete. The invention combines 3D printing technology with concrete pavement technology, uses a mechanical arm to replace the portal steel frame used by traditional 3D printing machines, realizes the three-dimensional movement of the machine, and installs the mechanical arm on the vehicle-mounted system, so that the machine can Moving around makes the printing area unrestricted, realizing large-scale, integrated and fast printing construction on the road.

Owner:SHANDONG UNIV

Plant spraying decoration carpet and jet printing method thereof

The invention discloses a plant spraying decoration carpet on which various patterns are sprayed and printed on the front face and a method for spraying and printing the patterns on the plant spraying decoration carpet. The spray printing steps comprise that: patterns are designed, an environment friendly active dye is selected for mixing colors, and the active dye is mixed with the environment friendly addition agents such as penetrating agent, thickening agent, and the like, for forming a sizing agent with certain viscosity; the patterns are sprayed and printed; after fixation treatment, washing treatment is carried out; after the carpet after washing is dried, the carpet is rolled in bunches and is packaged to finished carpet; or the carpet is cut according to the size of the patterns, wrapped and packaged to the finished carpet.

Owner:张听飞

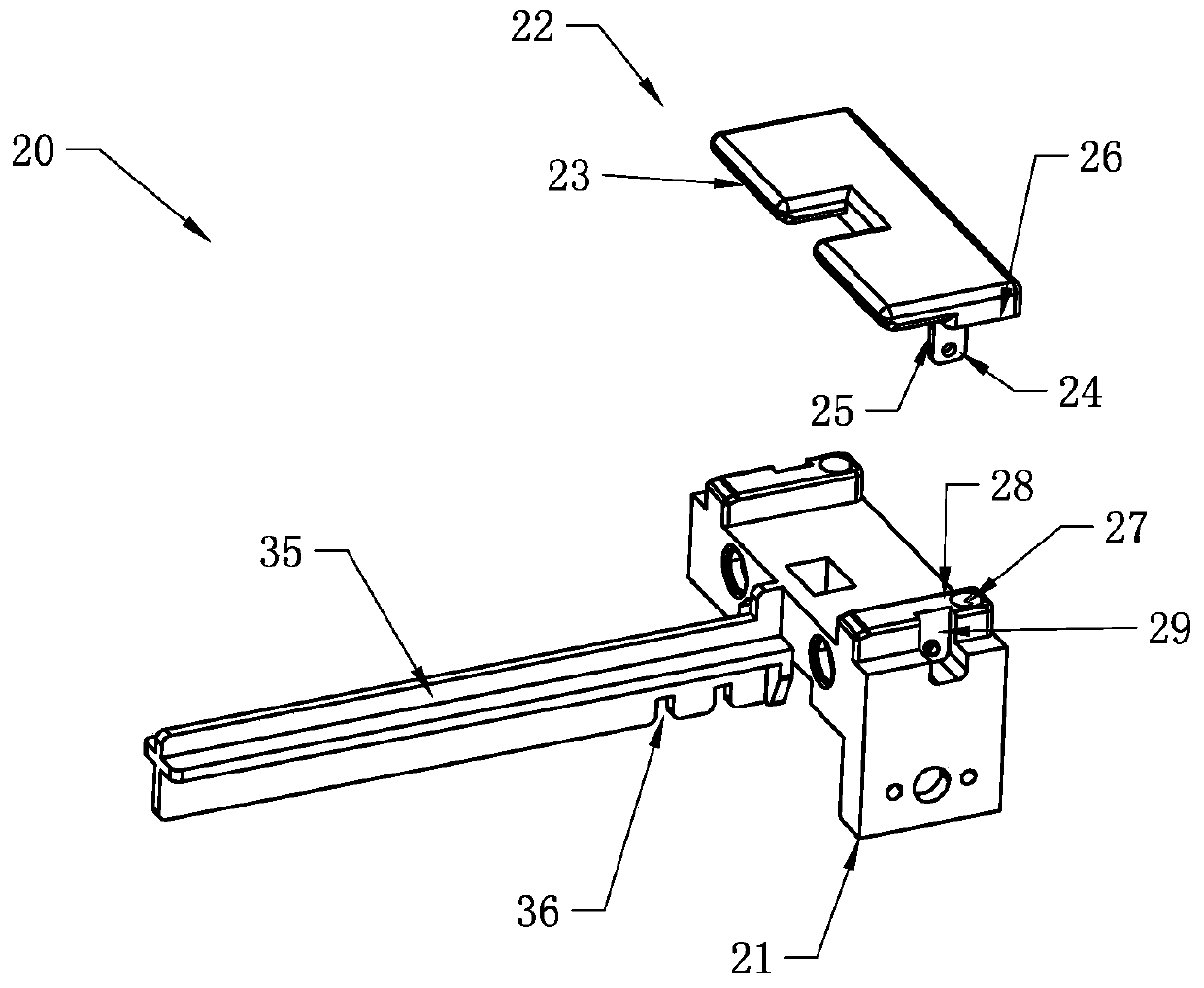

Transferring structure and printer

PendingCN110722882AEasy to take picturesEasy to printOther printing apparatusComputer printingEngineering

The invention discloses a transferring structure and a printer. The transferring structure comprises a turnover wheel, a conveying mechanism and a photographing system located above the conveying mechanism. The turnover wheel and the conveying mechanism sequentially convey cards. The conveying mechanism comprises a clamping assembly receiving the cards and a horizontal movement assembly driving the clamping assembly to get close to or away from the portion below the photographing system. According to the transferring structure, by arranging the horizontal movement assembly, manual transferringis replaced, the cards can be automatically moved to the photographing system to be photographed, and the photographing efficiency is improved. Furthermore, by arranging the clamping assembly, the cards can be fixed, it is ensured that the cards are accurately transferred, and it is avoided that the cards deviate and fall. Furthermore, by arranging the turnover wheel, the cards can be overturned,and therefore the other faces of the cards can be conveniently photographed, subsequent processing of the cards is also facilitated, printing and photographing of the cards can be automatically and continuously conducted, and the manufacture efficiency of the cards is improved.

Owner:JIANGMEN DASCOM COMP PERIPHERAL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com