Printing machine with twin printing unit and method for operating such a printing machine

A printing press, double printing technology, applied in general parts of printing machinery, printing presses, rotary printing presses, etc., can solve problems such as long downtime, start waste pages, and reduce the efficiency of printing presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

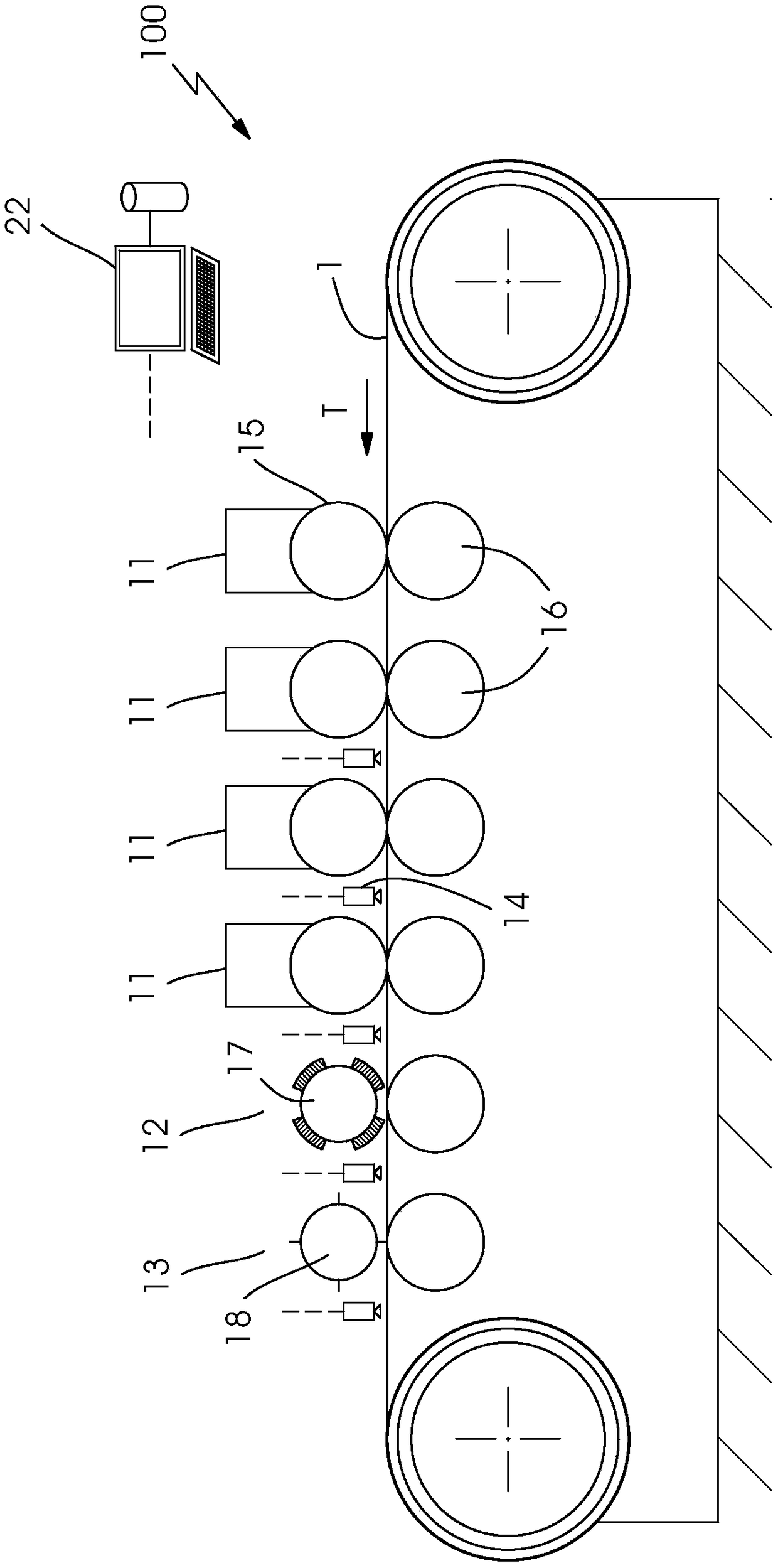

[0040] image 3 A rotary printing press 100 for printing a printing material web 1 according to the prior art is shown. The printing material web 1 is transported along the transport direction T through a plurality of processing units and processed there. These processing tools relate to a flexographic printing mechanism 11 , an embossing mechanism 12 and a die cutting and grooving mechanism 13 . Adjacent to the web run of the printing material web 1 , an inspection system 14 is provided, which is designed, for example, as a camera in order to continuously monitor the register accuracy of the processing of the printing material web 1 . In this case, in particular peripheral and lateral registers are monitored.

[0041] The inspection system 14 as well as the flexographic printing units 11 , embossing units 12 and die-cutting and notching units 13 are connected in terms of data transmission to a control unit 22 and can be controlled by this control unit 22 .

[0042] figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com