A resin ink vacuum plug hole printing device and printing method thereof

A resin ink and printing device technology, applied in printing, printing presses, rotary printing presses, etc., can solve problems such as work vacuum damage, and achieve the effect of improving efficiency, high efficiency and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

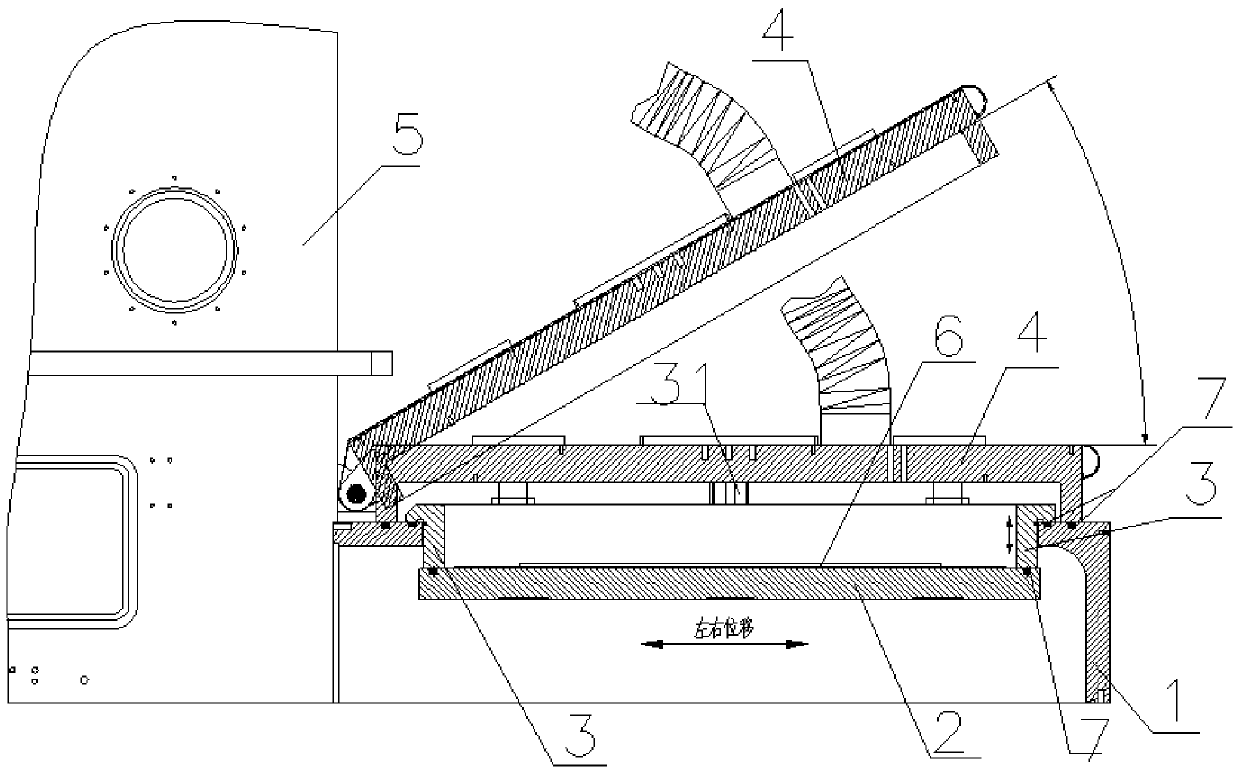

[0029] Such as figure 1 As shown, a resin ink vacuum plug hole printing device is disclosed in this embodiment, which includes a printing main chamber 5, and the above-mentioned printing main chamber 5 is the main working environment for the device to print a circuit board 6, so the above-mentioned printing main chamber 5 It is a vacuum printing environment during printing. After printing is completed in the above-mentioned main printing chamber 5, take out the printed circuit board or replace the circuit board to be printed. In order not to destroy the vacuum degree in the above-mentioned printing main chamber One side of 5 is provided with a transfer bin, and the above-mentioned printing main bin 5 and the transfer bin are connected, so printed circuit boards can be transferred between the above-mentioned printing main bin 5 and the transfer bin.

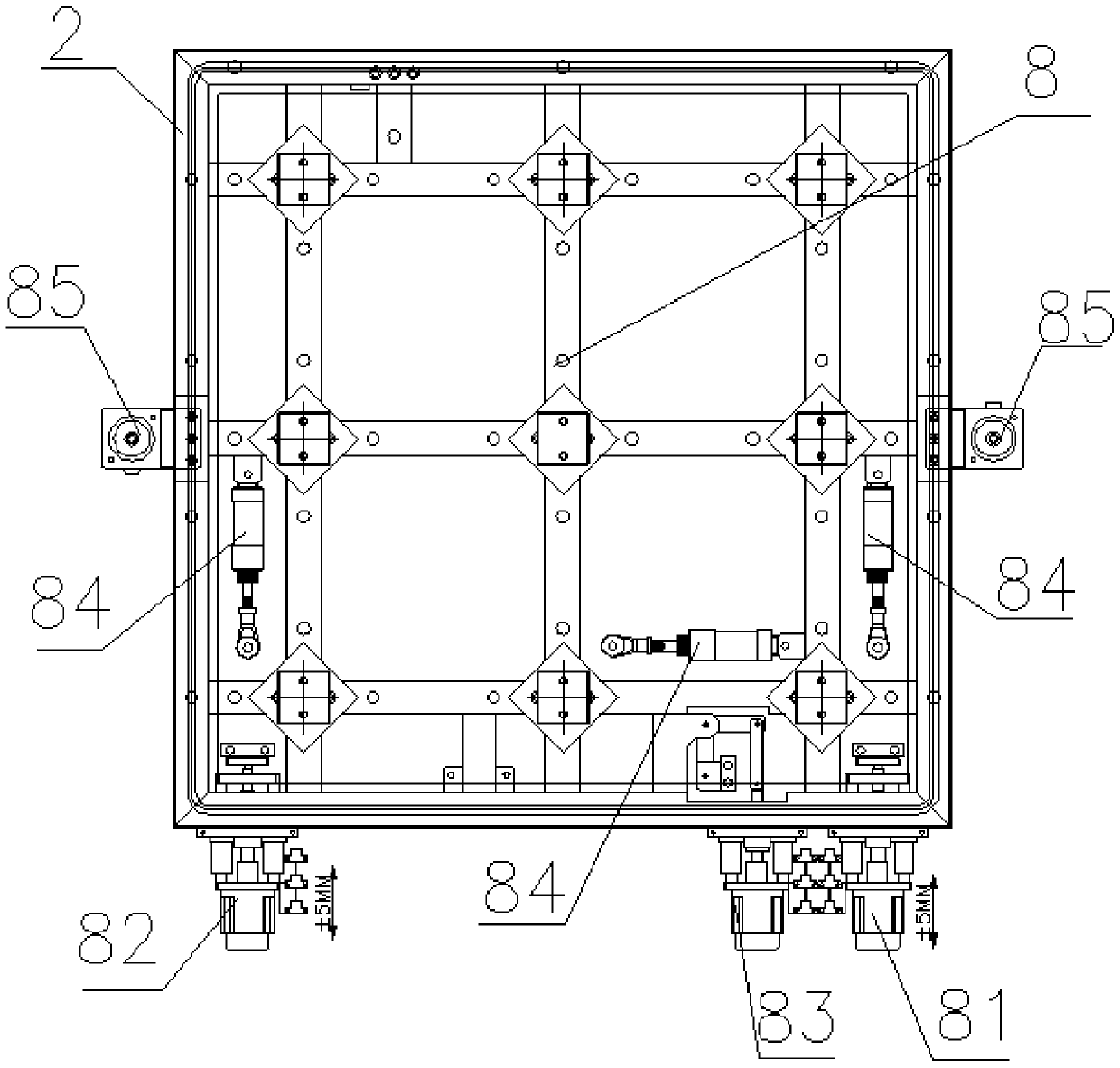

[0030] The above-mentioned transfer warehouse includes a warehouse body 1 and a warehouse cover plate 4 for sealing the warehous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com