Testing apparatus and testing method for printable property of soldering paste

A test device and printability technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of rough measurement methods, low precision, and reduced solder paste rolling ability, and achieve the effect of fast printability of solder paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

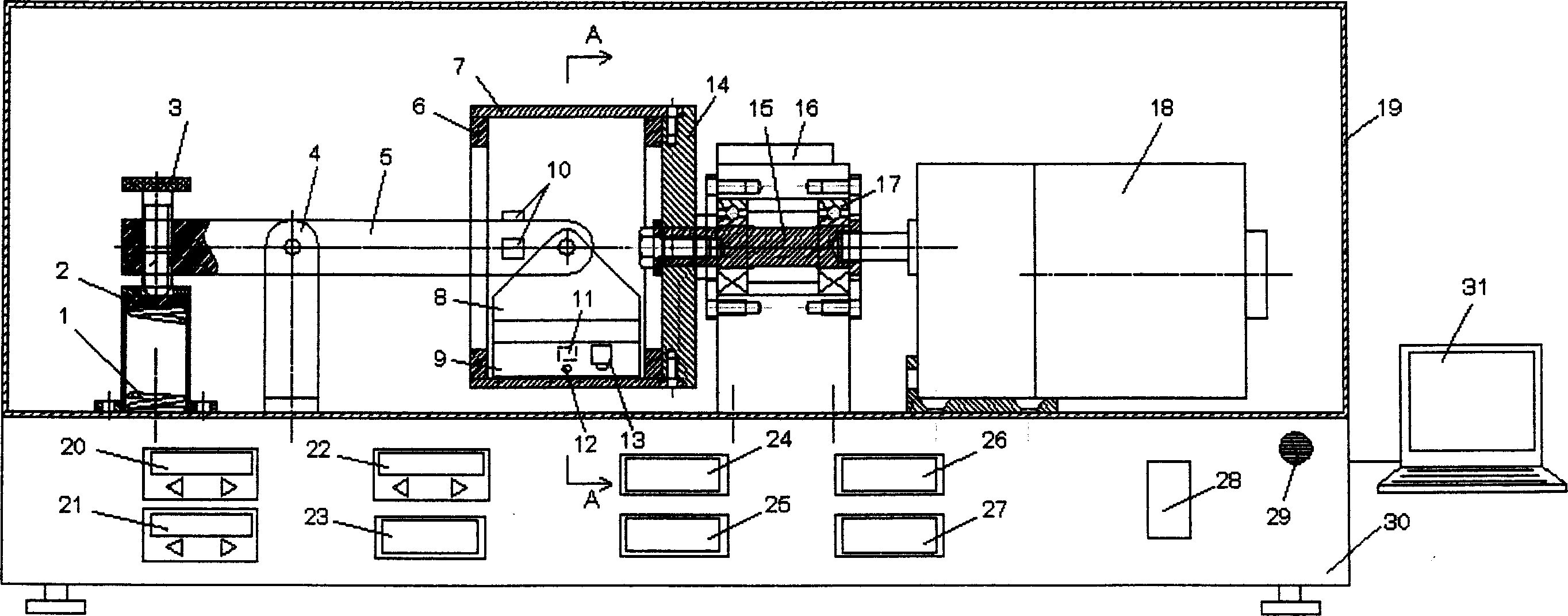

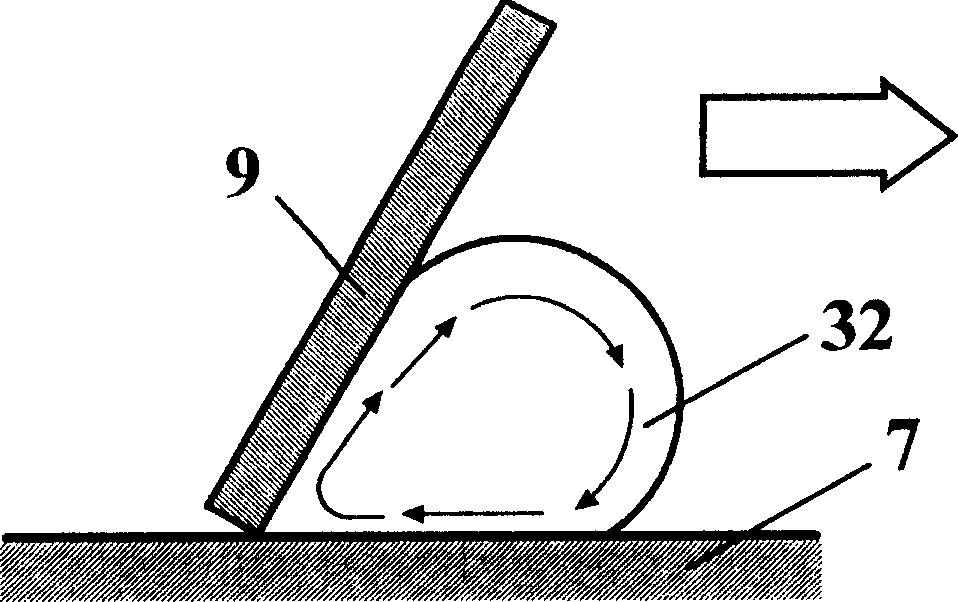

[0047] refer to figure 1 , all printing mechanisms are placed in the temperature and humidity atmosphere control box 19, by adjusting the temperature adjustment indicator 20 and the humidity adjustment indicator 21, the heater and the humidity regulator not shown in the temperature and humidity atmosphere control box 19 are controlled, Make the temperature and humidity in the temperature and humidity atmosphere control box 19 reach the set value, and can feed protective gas, such as nitrogen, into the temperature and humidity atmosphere control box 19 at the same time.

[0048] The output shaft of the decelerating DC motor 18 is rigidly connected with the mandrel 15 using a keyway, the mandrel 15 is rigidly connected with the turntable 14 with screws, the boss of the turntable 14 is embedded in the ring template 7, and the mandrel 15 is installed in the bearing 17 and can rotate. The turntable 14 and the ring template 7 are connected on the mandrel 15 to form a cantilever stru...

Embodiment 2

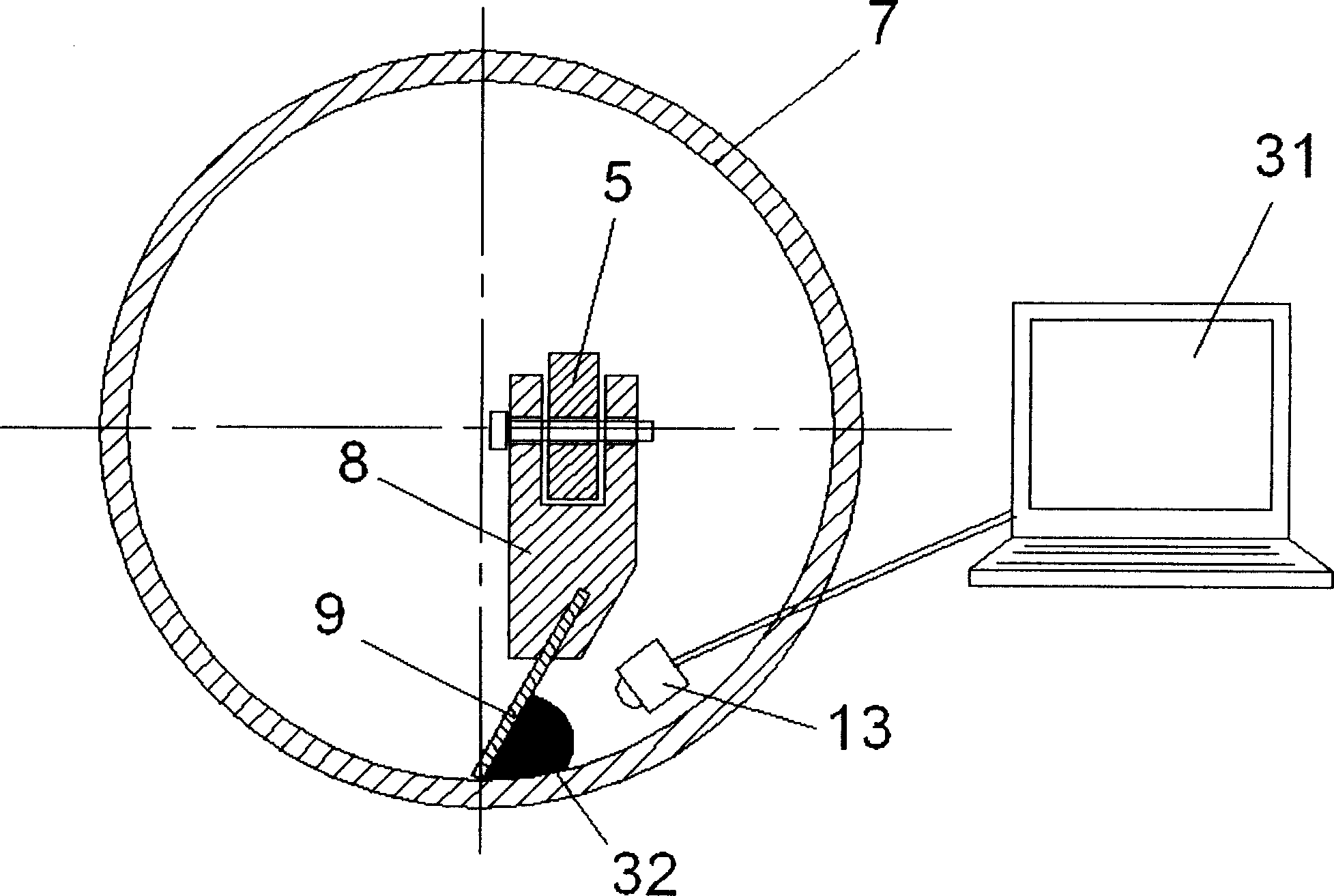

[0066] The rotating part of the ring template is as Figure 6 shown.

[0067] The device of embodiment 2 is different from the device of embodiment 1 except that the design of the rotating part of the ring formwork is different, and all the other functions and procedures are the same. figure 1 The positions of the console in the control box and other mechanisms and instruments in the temperature and humidity atmosphere control box are slightly changed. The rotating part of the ring formwork in this embodiment is a gear-toothed belt transmission structure. For the specific structure, see Figure 6 , the ring template outer band ring gear 33, the deceleration DC motor drives the ring template with the ring gear 33 through the mandrel 35, driving wheel 36, toothed transmission belt 34. The support wheel 37 is used to support the rotation of the ring template 33 . In addition to the advantages of Embodiment 1, this embodiment, since the ring template is not the rigid structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com