A method for preparing an anti-adhesion film for photocuring continuous surface molding 3D printing

A 3D printing and anti-adhesion technology, applied in the field of 3D printing, can solve the problems of high price, high equipment requirements, and oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

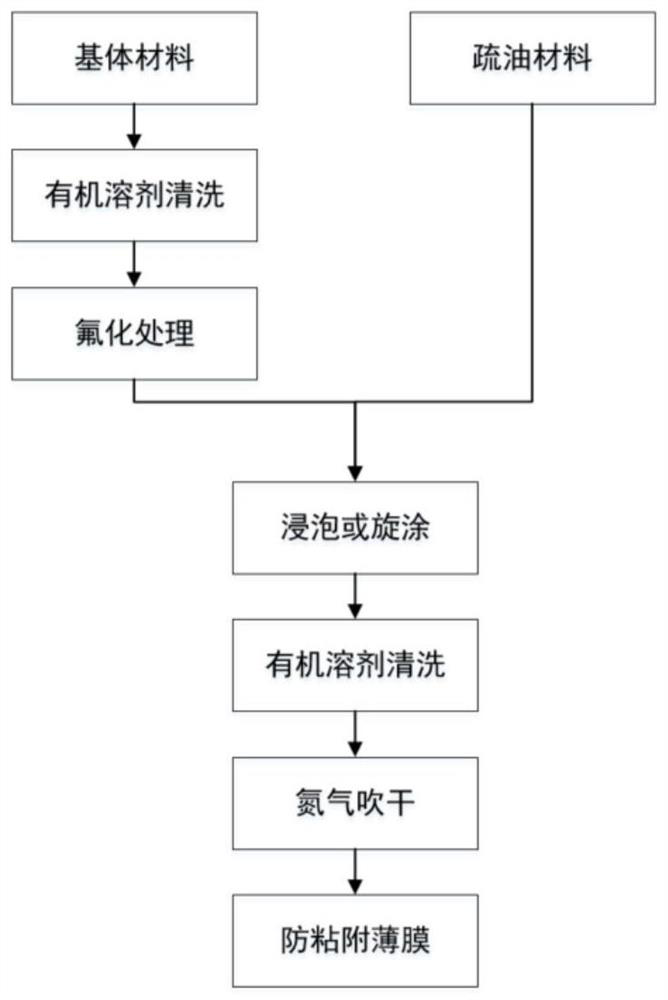

[0027] A method for preparing an anti-adhesion film for photocuring continuous surface forming 3D printing, characterized in that it comprises the following steps:

[0028] Step 1: Use fluorosilane coupling agent to fluorinate the base material, soak the base material in liquid oleophobic material, and soak for 0-2400 hours with the help of ultrasonic vibration, heating or microwave treatment, or by Coating method, so that the oleophobic material adheres to the base material;

[0029] Step 2, using an organic solvent to remove excess liquid oleophobic material to obtain an adhesive film material.

[0030] The matrix material is a light-transmitting porous organic polymer film material, a low-density organic polymer film material or an organic polymer film material with a microstructure.

[0031] The matrix material is porous polyperfluoroethylene film, polytetrafluoroethylene nuclear hole film, ultra-low density polyethylene film, medium density polyethylene film, linear low ...

Embodiment 1

[0041] The polyperfluoroethylene porous film with a backing layer is used as the substrate 1, and the perfluoropolyether lubricating oil is used as the oleophobic phase 2. The surface of the film is cleaned with acetone and deionized water respectively, and then the surface is blown dry with nitrogen. Soak the film in perfluoropolyether lubricating oil and let it stand for 24 hours. Then the film is taken out, excess perfluoropolyether lubricating oil is washed away with acetone, and the surface of the film is blown dry with nitrogen to obtain an anti-adhesion film material. Such as Figure 4 As shown, when printing, the anti-adhesion film material is pasted on the bottom of the resin tank 5, and the photosensitive resin 7 is cured under the action of UV light and bonded to the molding board 3. Since there is a gap between the molding part 6 and the base material 1 layer of liquid oleophobic phase 2, the solid-solid bond between the molded part 6 and the substrate 1 is transf...

Embodiment 2

[0043] combine figure 2, with a microstructured PDMS film as the substrate 1, perfluoropolyether lubricating oil as the oleophobic phase 2, and per(heptadecane) fluorodecyltrimethoxysilane as the silane coupling agent. The surface of the PDMS film was cleaned with acetone and deionized water, respectively, and the surface was blown dry with nitrogen, and then the surface of the PDMS film was treated with oxygen plasma. Then the PDMS film was soaked in per(heptadecane)fluorodecyltrimethoxysilane, and left to stand in a vacuum environment for 8 hours to perform fluorination treatment. The excess per(17)fluorodecyltrimethoxysilane on the PDMS film was removed with acetone, washed with deionized water, and dried with nitrogen. Then, by immersion coating method, the PDMS film was soaked in perfluoropolyether lubricating oil, and placed in a vacuum environment for 24 hours. Then take out the film, wash off excess perfluoropolyether lubricating oil with acetone, then clean with de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com