Ink cartridge for ink-jet printer

A technology for printers and ink cartridges, applied in printing and other directions, can solve the problems of residual pressurized air, occupying a large volume, increasing the amount of synthetic resin, etc., and achieve the effects of convenient assembly operation, simple assembly process, and improved productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

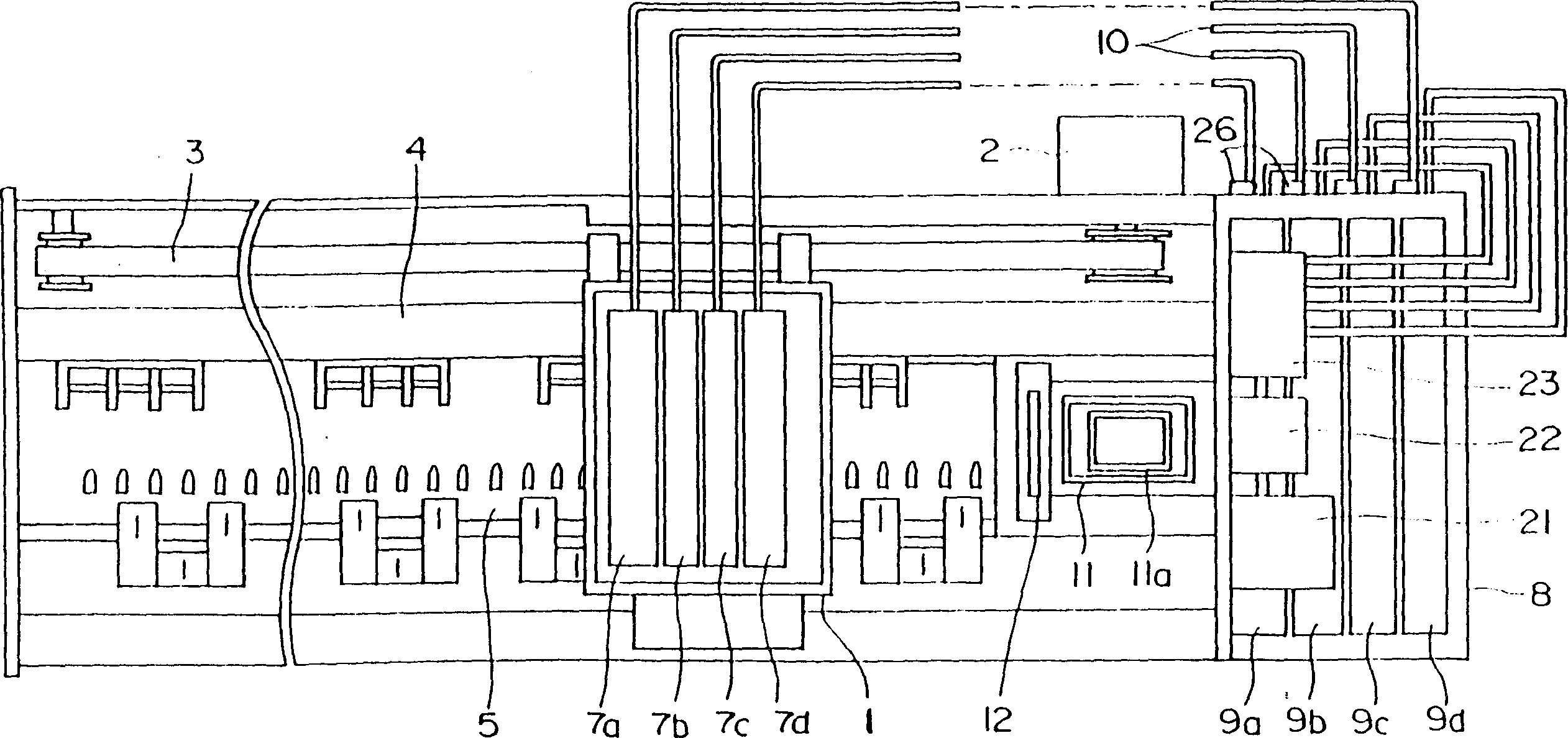

[0154] Next, ink cartridges according to embodiments of the present invention and ink jet printers using the ink cartridges will be described with reference to the embodiments shown in the drawings. first, figure 1 An example of an inkjet printer to which the ink cartridge according to each embodiment of the present invention can be used is shown in plan view.

[0155] exist figure 1 Among them, symbol 1 represents a carriage, and the carriage 1 is guided by the scanning guide part 4 through the toothed belt 3 driven by the carriage motor 2, and is in the length direction of the paper feeding part 5, that is, the width direction of the recording paper, that is, the main The scan direction reciprocates.

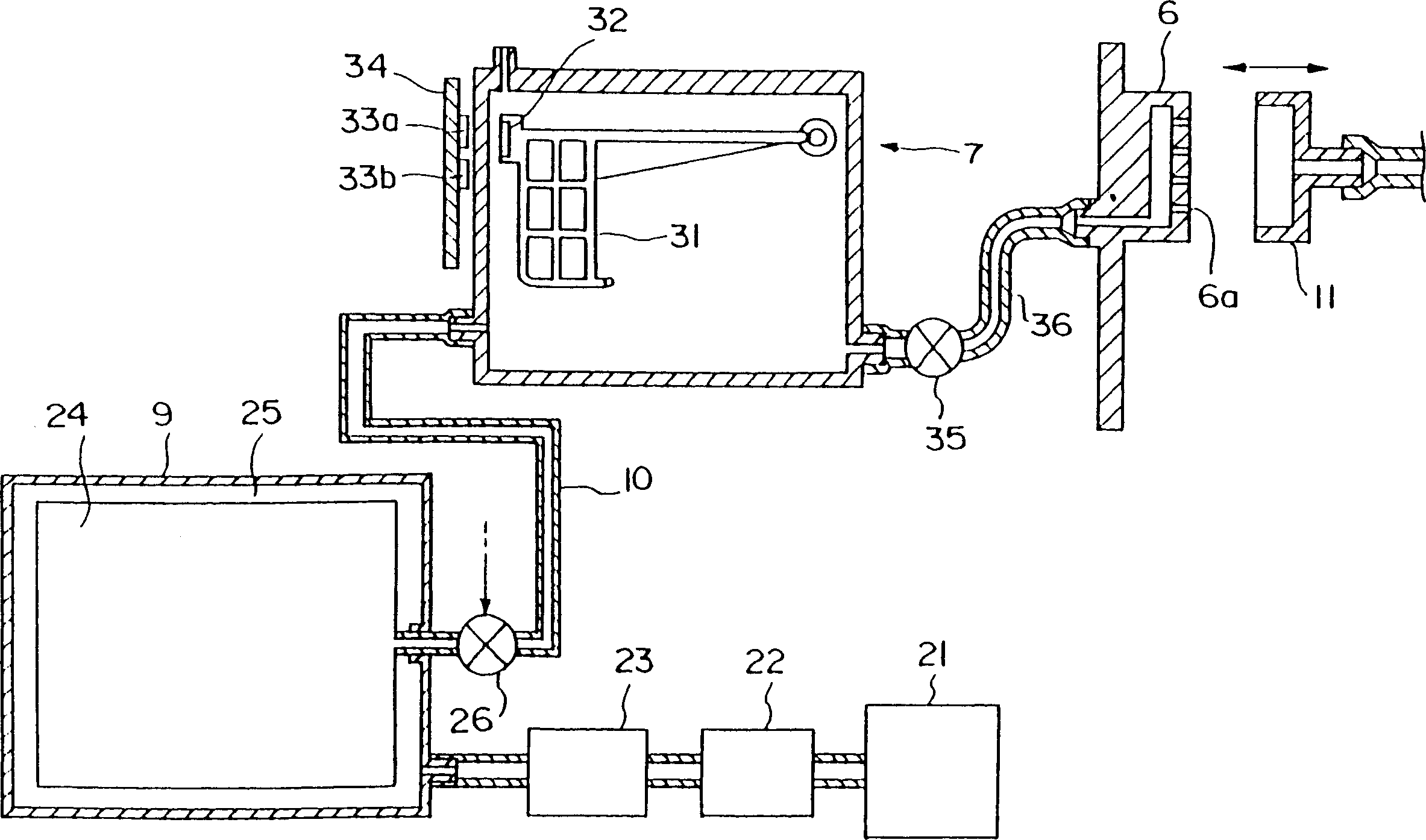

[0156] Although figure 1 Not shown in the figure, on the surface of the carriage 1 opposite to the paper feeding member 5, an ink jet print head 6 to be described later is mounted. On the carriage 1 are mounted sub-tanks 7a to 7d for supplying ink to the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com