Line-dot recorder

A point-recording, line-based technology, used in power transmission devices, printing, transfer materials, etc., can solve problems such as difficult handling, complex mechanisms, and large spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

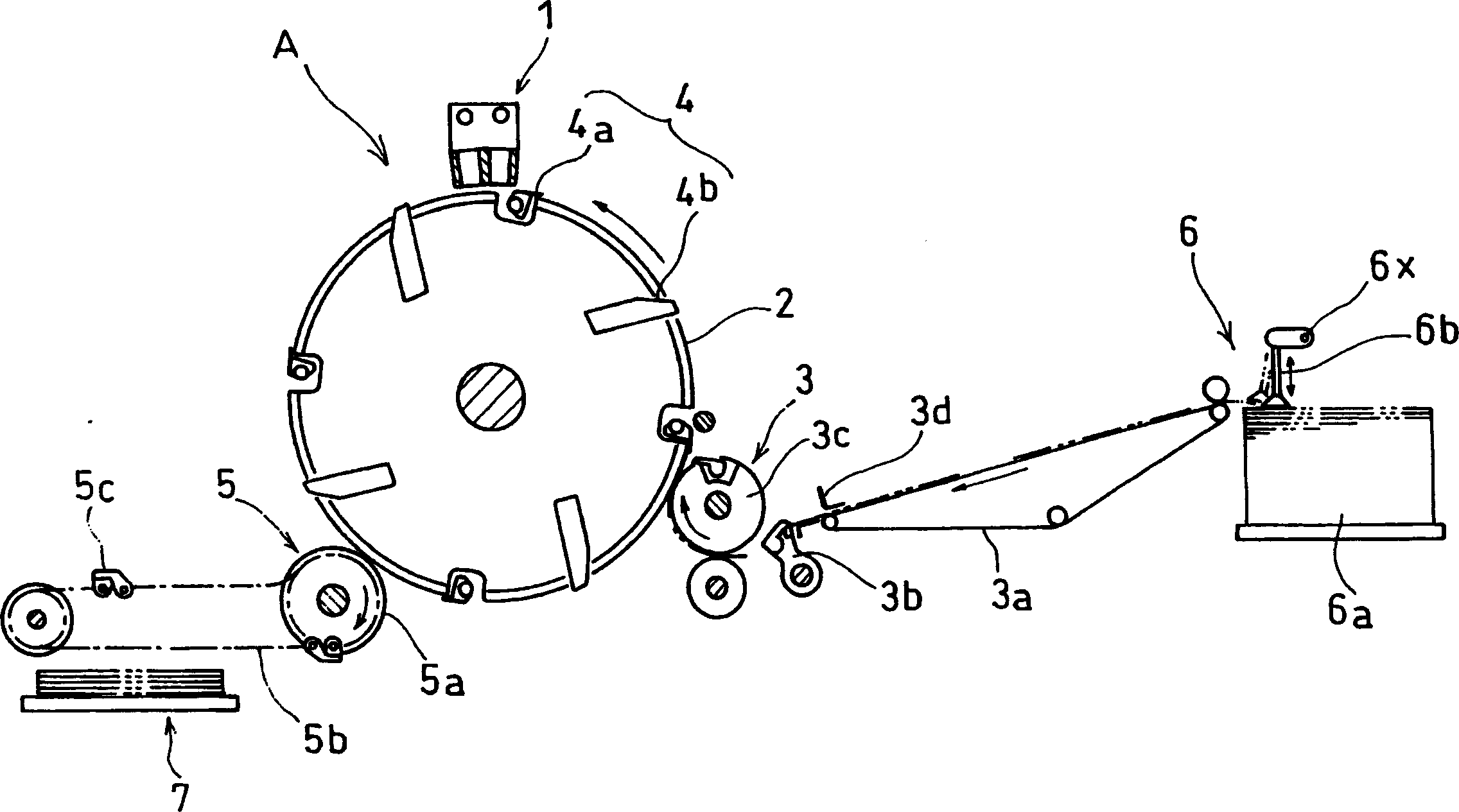

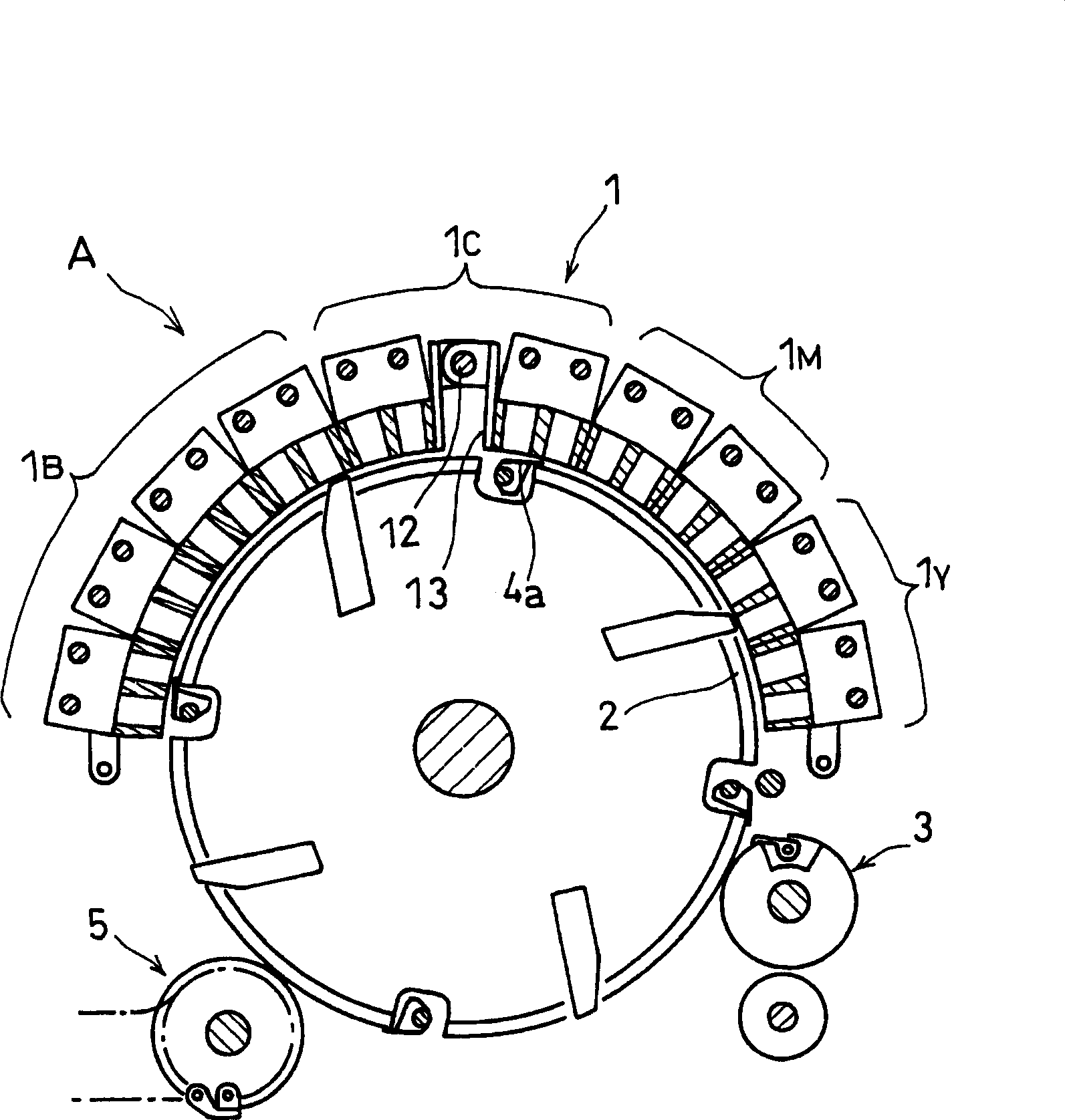

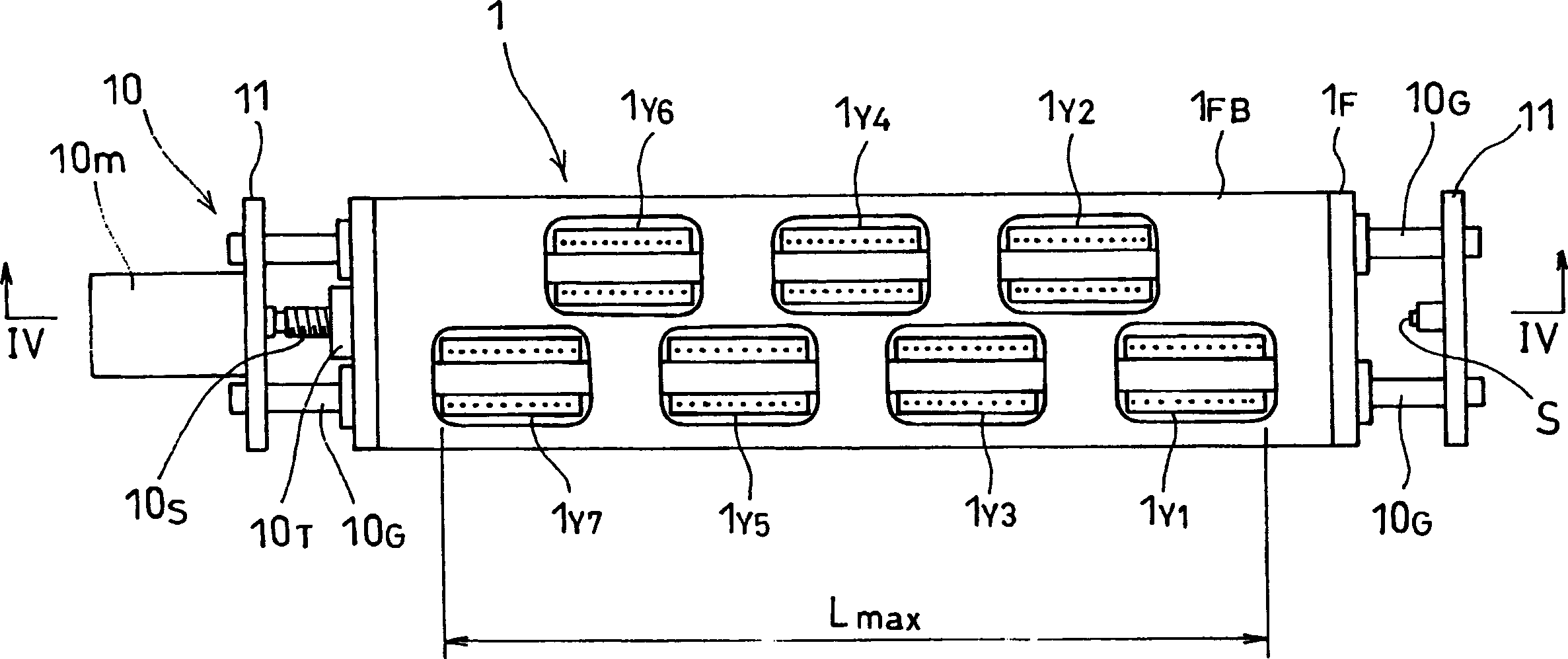

[0101] Hereinafter, embodiments for carrying out the present invention will be described with reference to the drawings. figure 1 It is a schematic diagram of the schematic structure of the dot recording apparatus of embodiment. As shown in the figure, the line dot recording apparatus A includes an inkjet head 1 having a plurality of discharge ports (nozzles), and a rotary drum 2 rotatably provided close to the head 1 .

[0102] For the rotary drum 2, a paper feed mechanism 3 is provided, which is composed of a paper feed roller 3c, etc., and the paper feed roller 3c supplies the paper of the printing medium sent by the conveyor belt 3a to the rotary drum 2 by swinging the grippers 3b; The mechanism 4 is provided on the rotary drum 2, and the tip of the supplied paper is attached to the peripheral surface of the drum with chuck claws 4a, and is mounted and held by the pressing plate 4b or the like in the middle of holding the paper. In addition, a paper discharge mechanism 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com