Continuous forming 3D printing equipment and operation method thereof

A 3D printing and equipment technology, applied in metal processing equipment, 3D object support structure, additive manufacturing, etc., can solve the problems of large parts printing difficulty, slow reflow speed, difficult to take out parts, etc., to improve equipment adaptability to material types, The effect of fast forming speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with accompanying drawing:

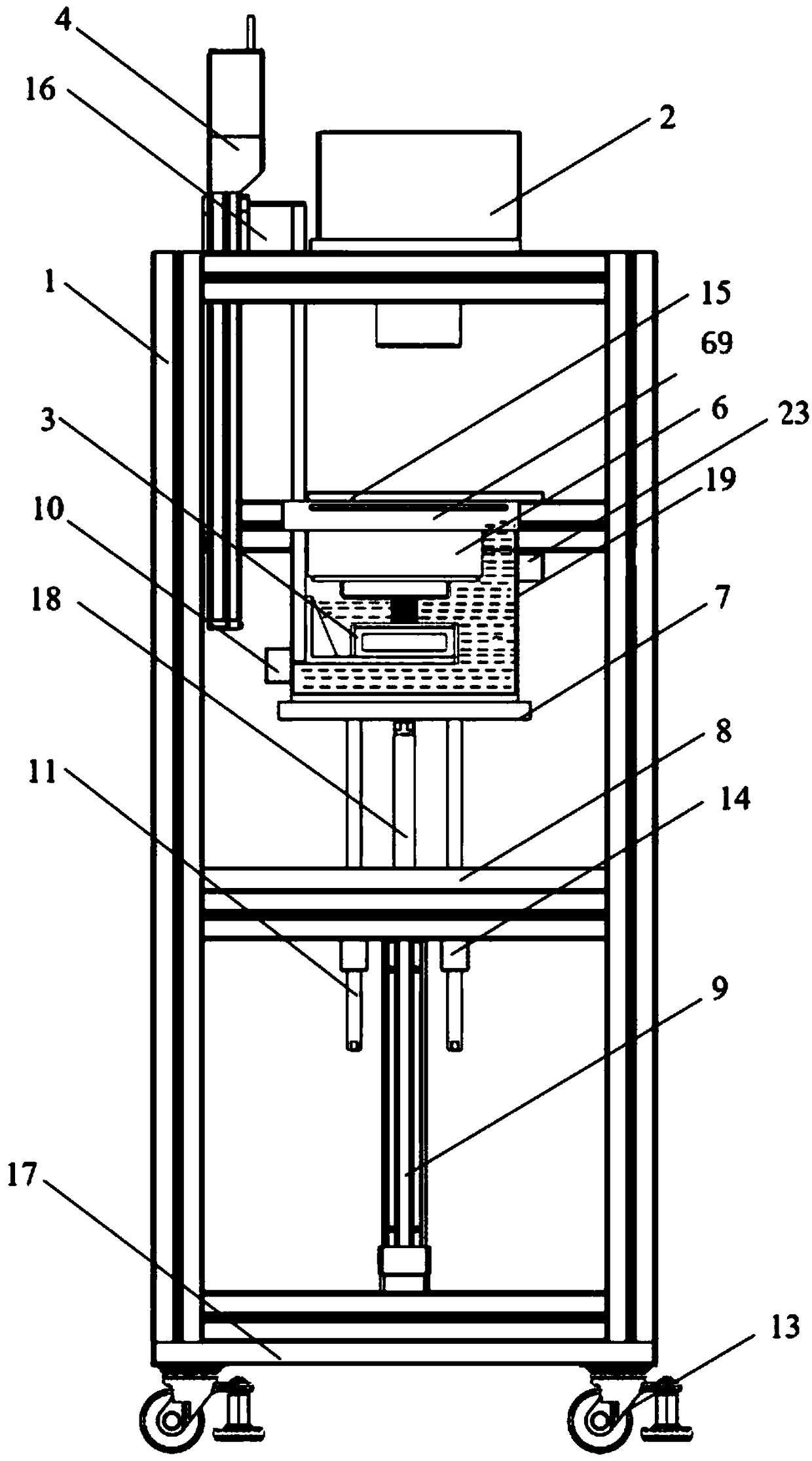

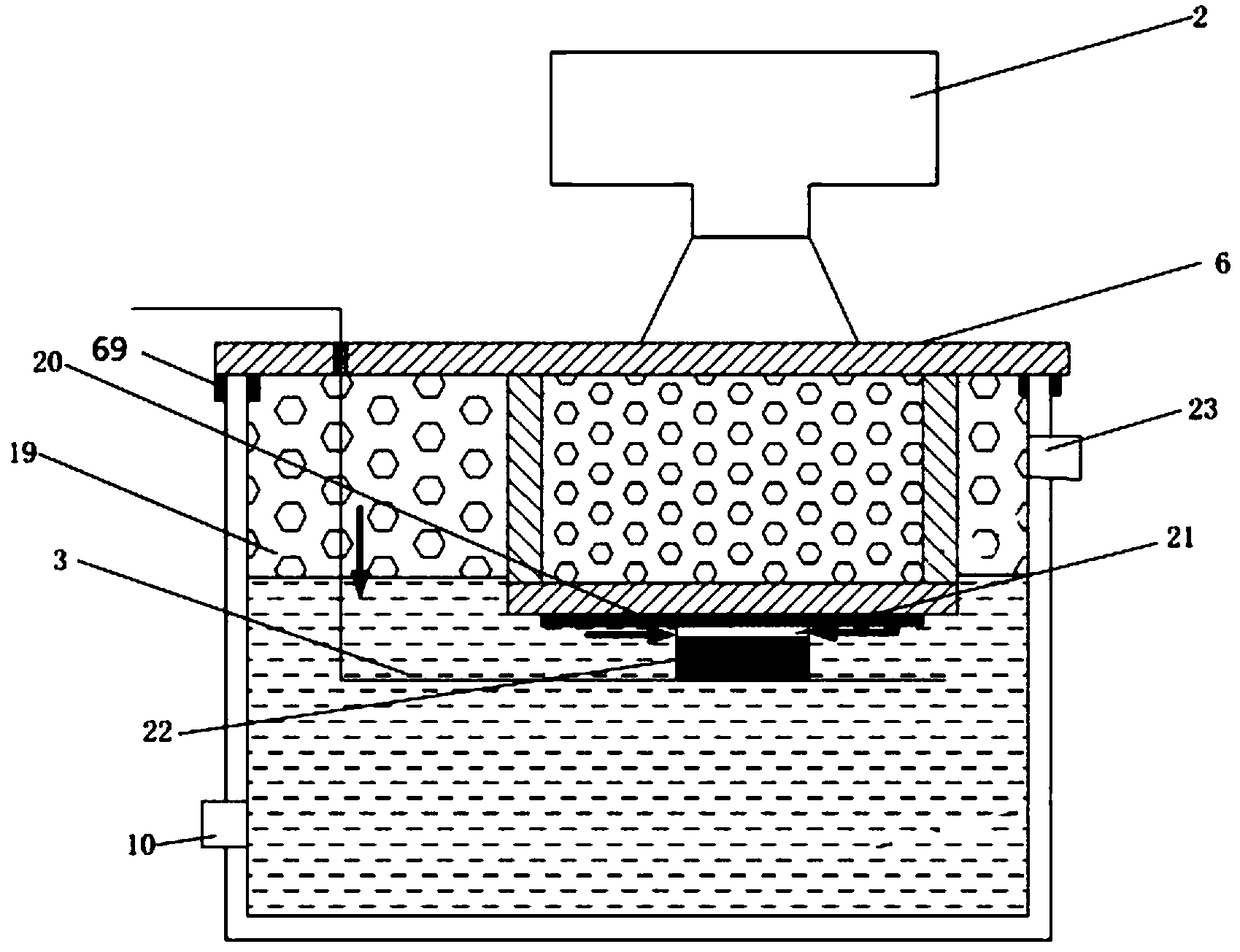

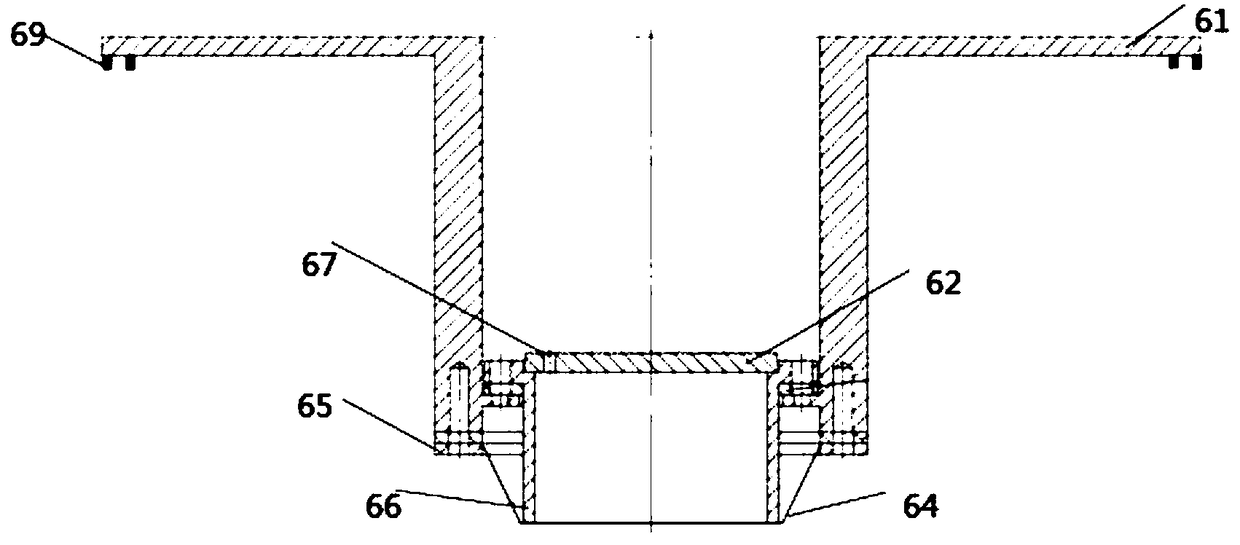

[0028] see Figure 1 to Figure 5 b, a continuous molding 3D printing equipment, including a frame 1, a molding cylinder 19, a molding cylinder lifting device, a light source 2, a molding platform 3, a molding platform lifting device, and a sealed cabin 6; the inside of the frame 1 is installed sequentially from top to bottom There are sealing cabin 6, molding cylinder 19 and molding cylinder lifting device, the molding cylinder lifting device drives the molding cylinder 19 to move up and down, when the molding cylinder 19 rises, the sealing cabin 6 is located inside the molding cylinder 19; the bottom of the sealing cabin 6 is provided with a molding platform 3. A forming platform lifting device is provided on the inner side of the frame 1, and the forming platform 3 is connected to the forming platform lifting device; the light source 2 is set on the top of the frame 1, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com