Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Avoid management chaos" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

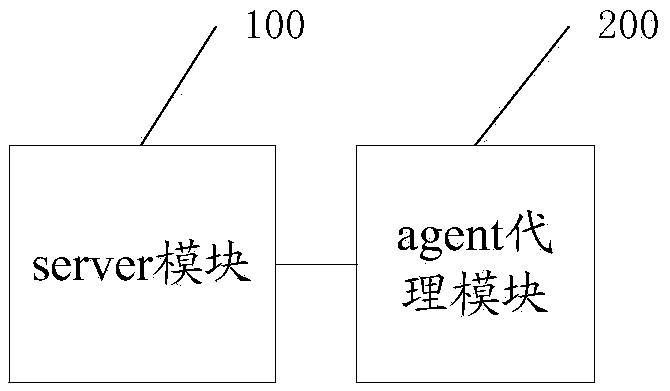

Safety critical system-oriented automatic testing resource management method and platform

InactiveCN102331970ASupport black box testingEasy to operateSoftware testing/debuggingEntity typeResource management

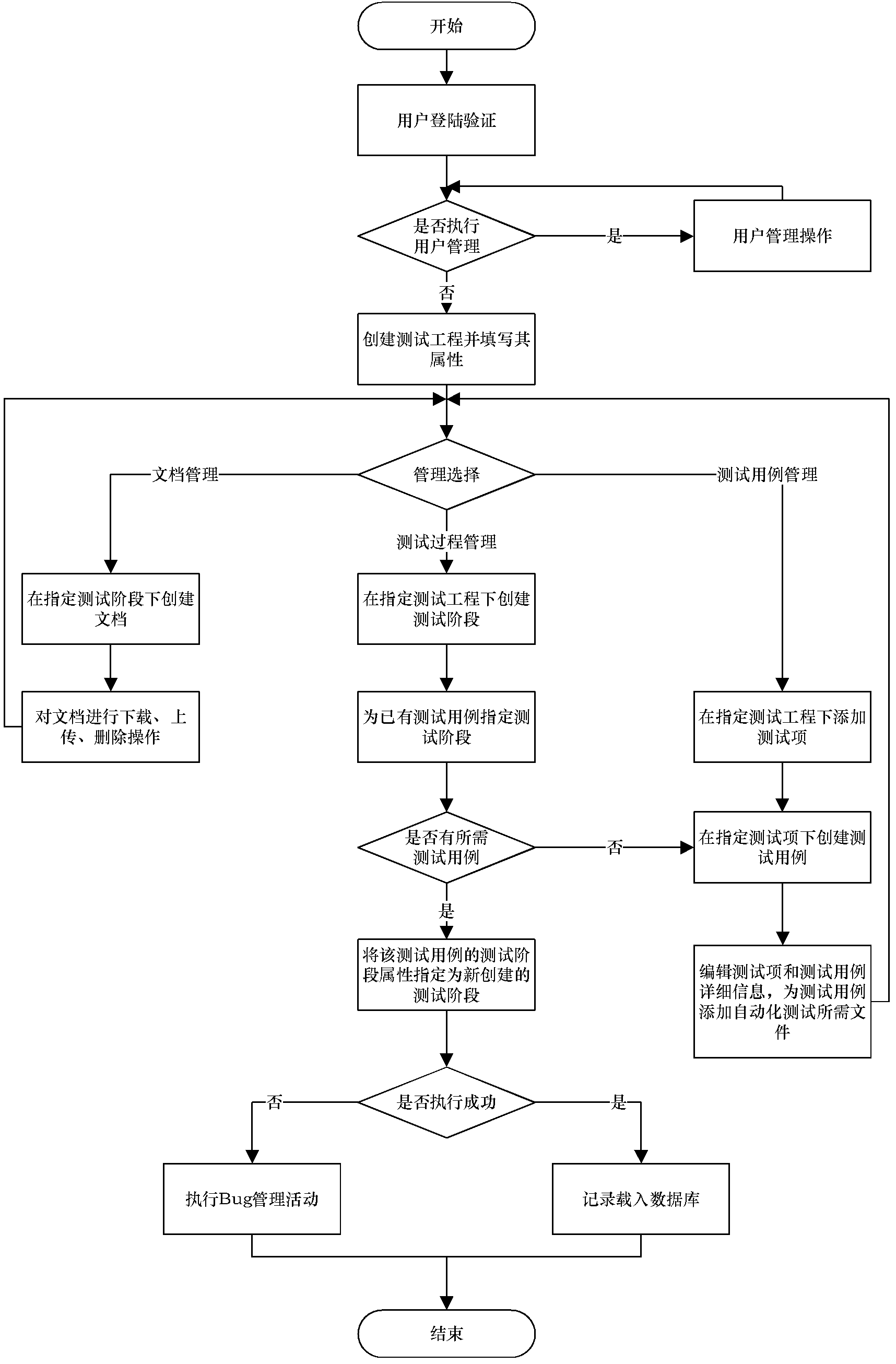

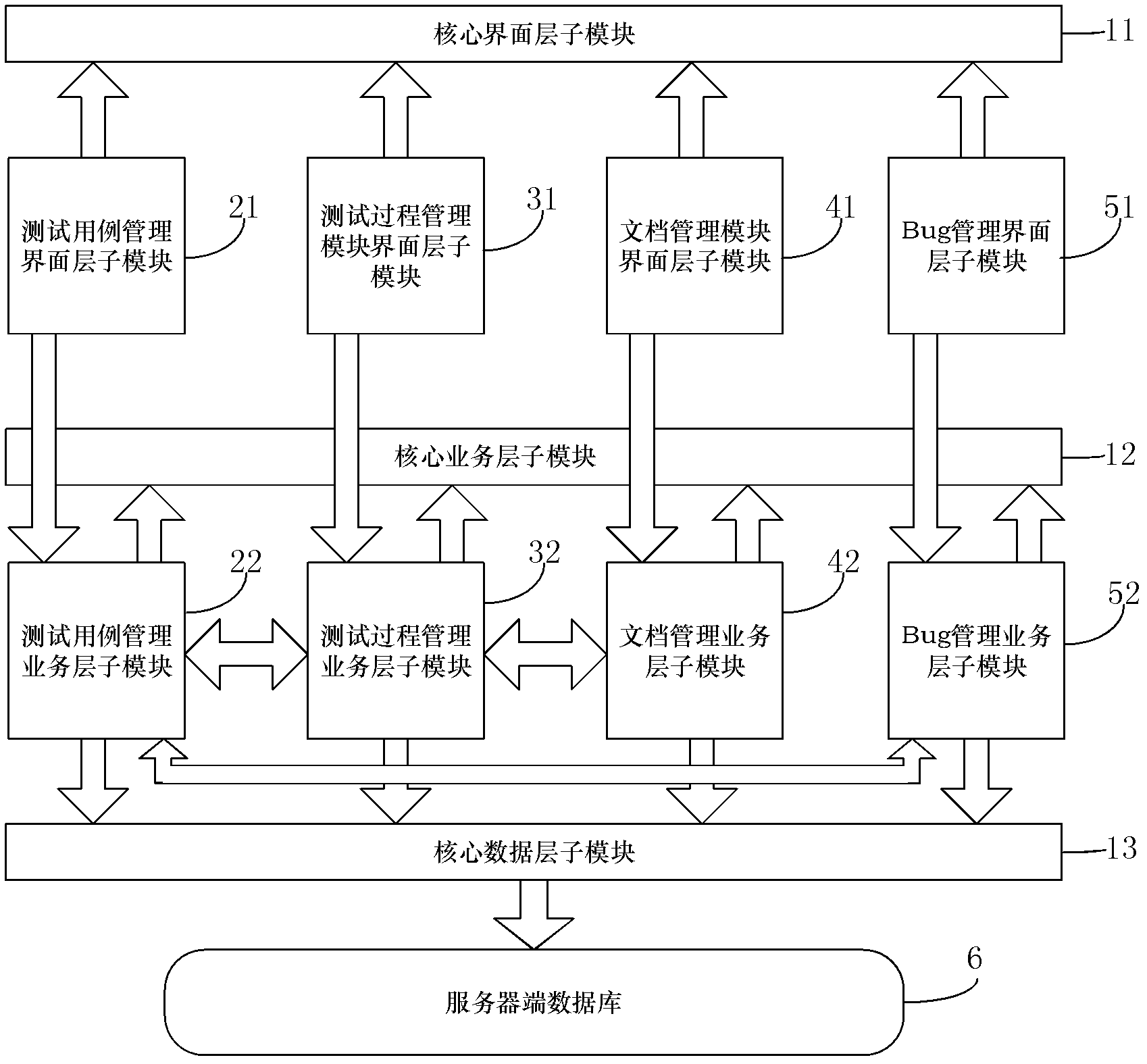

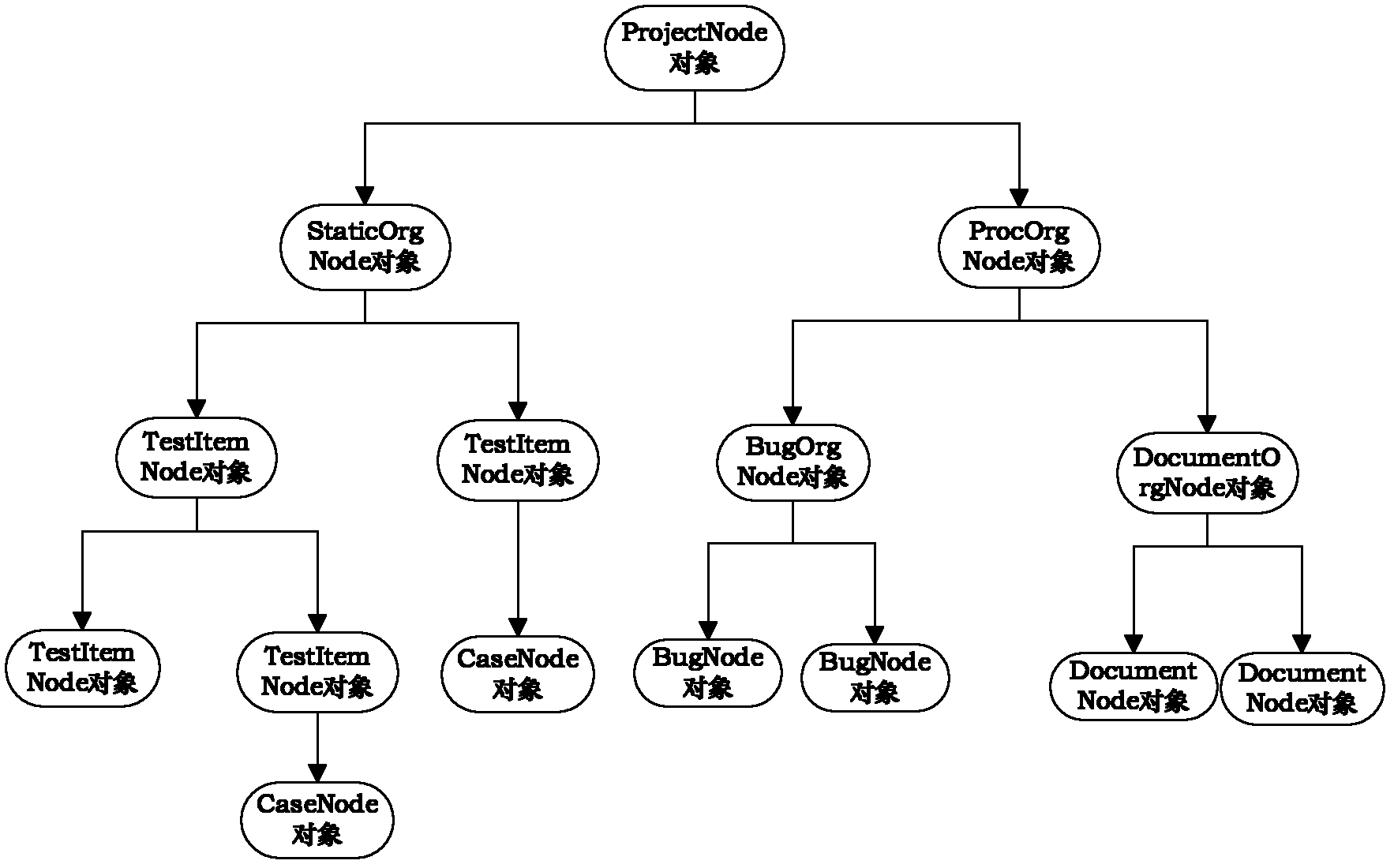

The invention relates to a safety critical system-oriented automatic testing resource management method and a safety critical system-oriented automatic testing resource management platform, which are applied to a huge safety critical system with a high requirement on safe reliability. In the method, a testing project is established after a user passes authentication, three management types, namely testing case management, testing process management and document management are set, and a user selects a corresponding management type to perform resource testing management. The platform has a qualification test (Qt) library-based client / server (C / S) framework on the basis of a management platform; a server is taken as a database; a client comprises a core module, a testing case management module, a testing process management module, a document management module and a Bug management module; and the tree structure and the entity type node data of testing resources and operation on the data are defined by the modules of the client. Uniform management on the automatic testing resources of the safety critical system is realized, and the resource management covers a testing stage from the time, so that the black box testing of the safety critical system is effectively supported.

Owner:BEIHANG UNIV

Common network management safety control system and method thereof

InactiveCN1889452ARealize centralized security managementImplement download cachingData switching networksCommunications systemSafety management systems

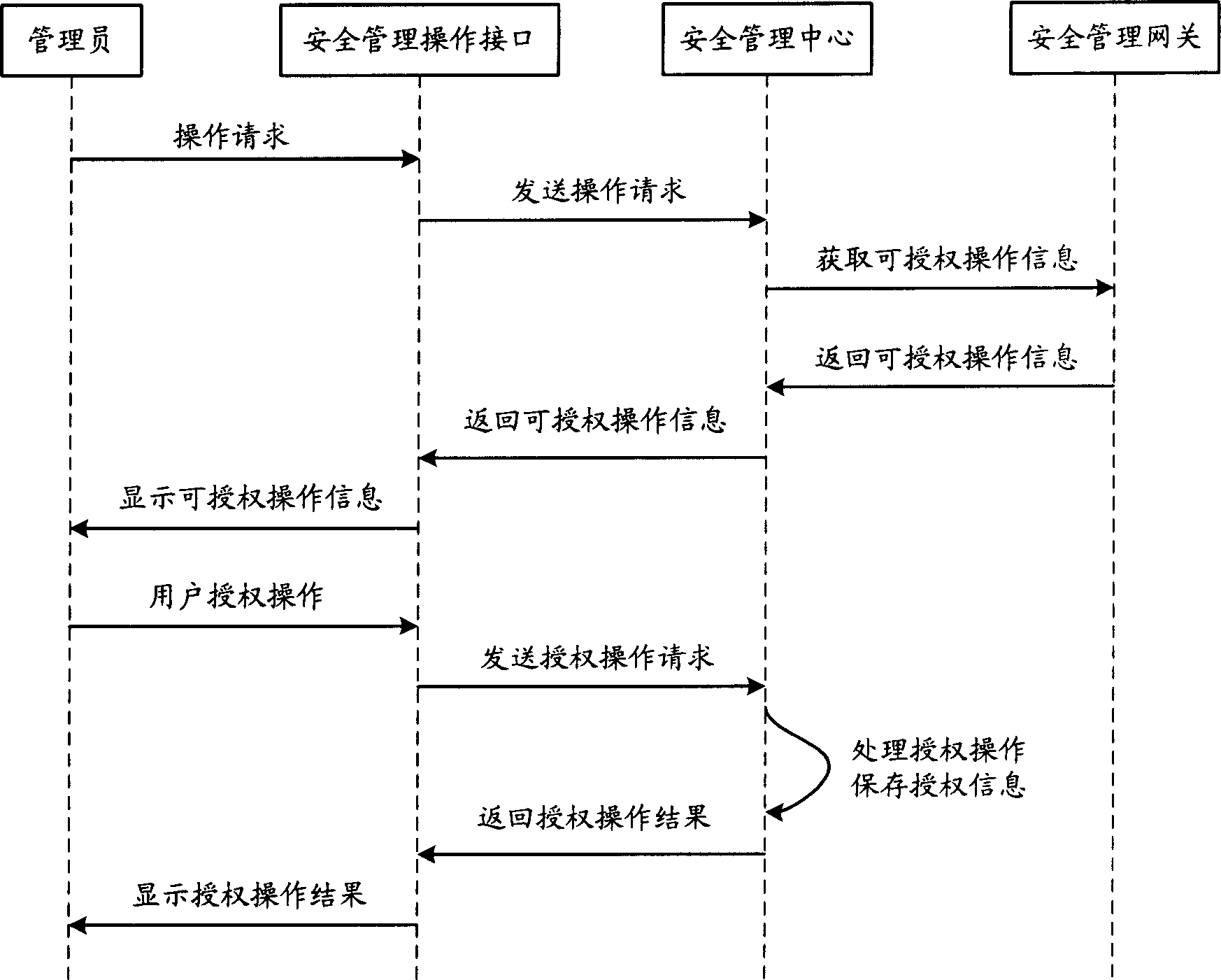

A network management technique of communication system includes dividing functional entities provided by different manufacture into different safety area and setting up a least one safety management gateway for each safety area to adapt safety management interface of safety area on universal safety management interface for realizing centralized safety management of all functional entities on network; additionally providing safety management-operation interface for supervisor to realize safety management system operation by utilizing user management, user authorization, user certification and user right identification.

Owner:HUAWEI TECH CO LTD

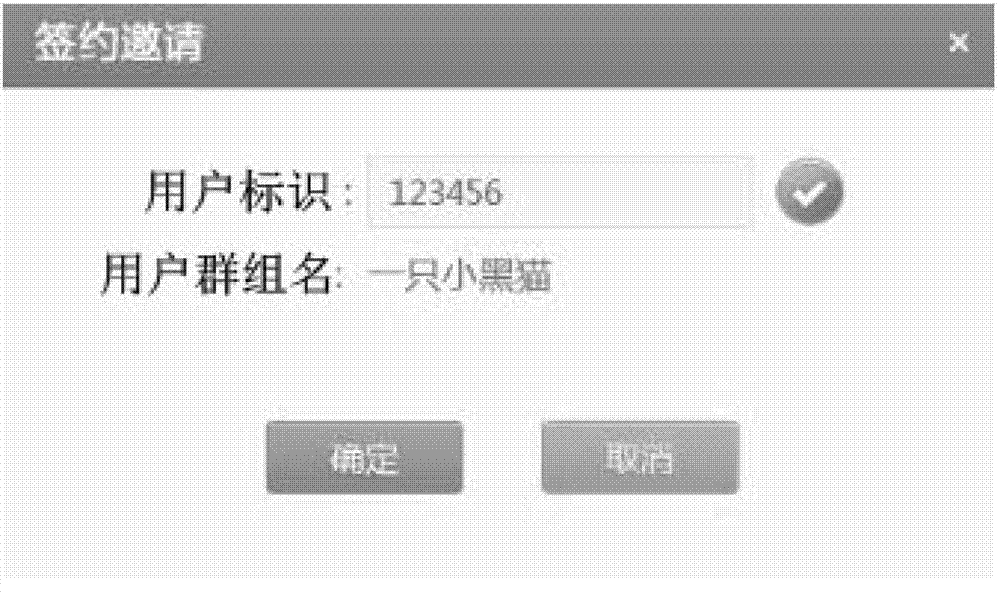

User group joining method and user group quitting method and device

ActiveCN103297280AEfficient managementAvoid management chaosSpecial service provision for substationSpecial data processing applicationsInternet communicationVoice communication

The invention discloses a user group joining method and a user group quitting method and device and belongs to the field of internet communication. The user group joining method comprises the steps of receiving a contract signing instruction input by an administrator and sent by a first terminal corresponding to the administrator of a user group and a user identification of a user to sign a contract, generating a contract signing invitation page including a prompt message for requesting the user to sign the contract to join the user group and an interface interaction element for inputting joining instruction acceptance, displaying the contract signing invitation page at a second terminal corresponding to the user to sign the contract and enabling the user to sign the contract to input a joining acceptance instruction through the interface interaction element, receiving the joining acceptance instruction sent by the second terminal and adding the user identification of the user to sign the contract to a user list corresponding to the user group. By means of the user group joining method and the user group quitting method and device, users can be effectively managed, and chaotic management of a voice communication platform is avoided.

Owner:TENCENT TECH (SHENZHEN) CO LTD

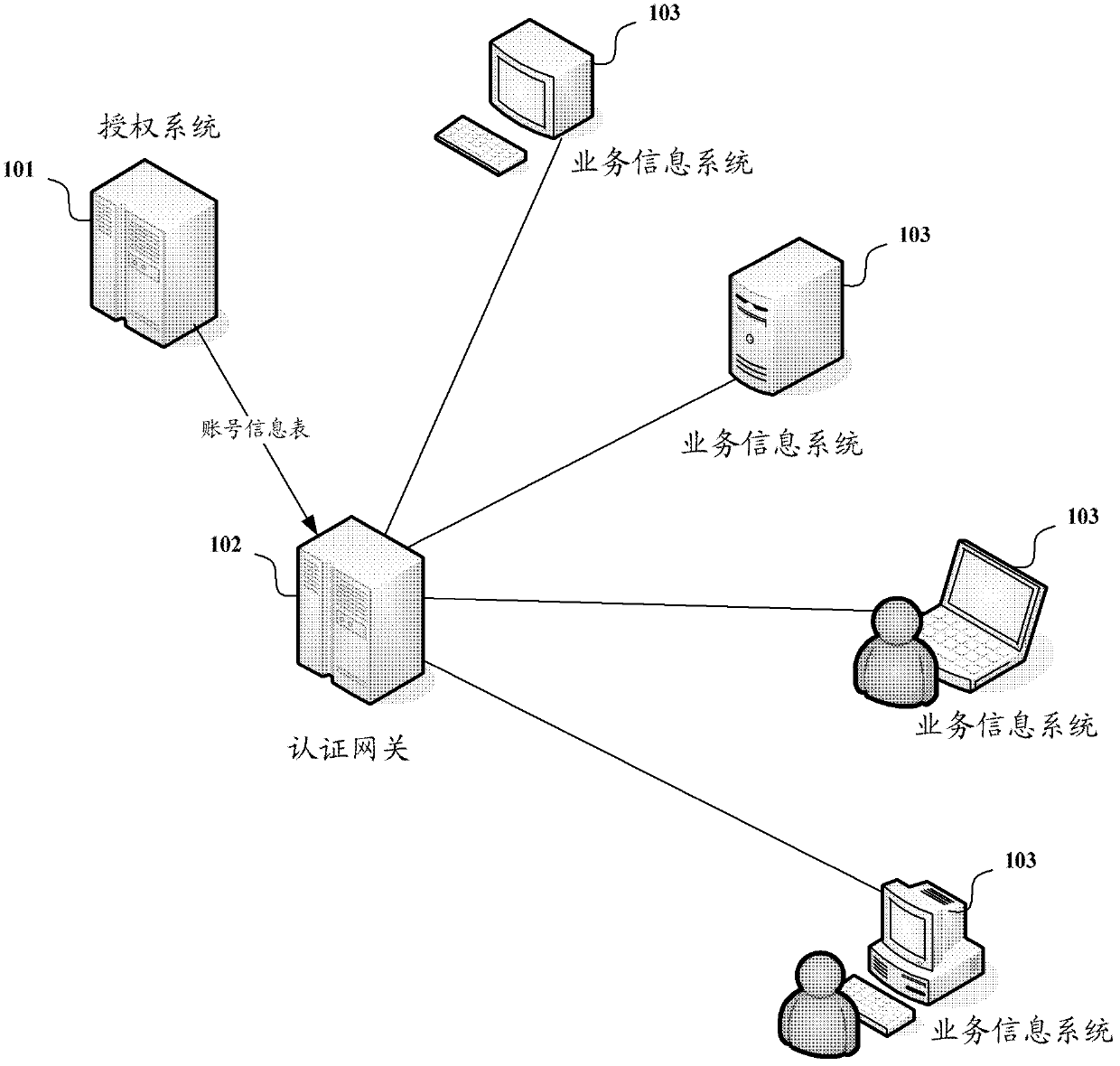

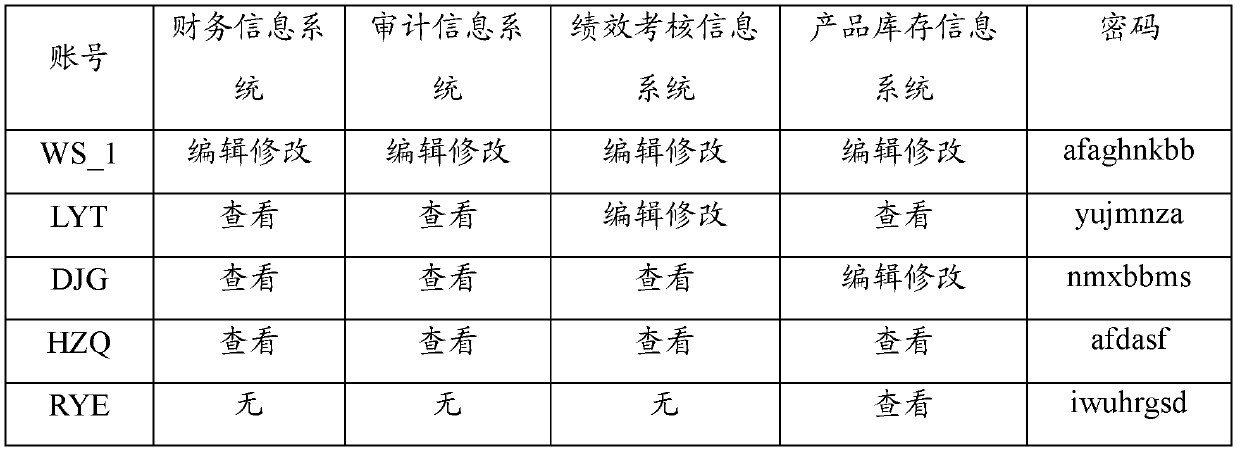

Business information system access authority control method and system thereof

InactiveCN102438019AAvoid management chaosImprove management efficiencyTransmissionUser needsUser input

The invention discloses a business information system access authority control system and a method thereof. The method comprises the following steps: a business information system obtains login information inputted by a user and sends the information to an authentication gateway; according to an account number in the received login information, the authentication gateway searches account number information of the account number in an account number information table, compares the received information with the searched information, obtains a verification result and returns the information to the business information system, and determines whether the user has access authority of the business information system, wherein, account number information of each account number recorded in the account number information table comprises a code of the account number and authority of the account number to access each business information system. Since the authentication gateway realizes unified centralize verification of authority, a problem that the user needs to use different account numbers and codes to carry out disperse management of verification on each business information system is avoided. Under the condition a plurality of information systems are used simultaneously, management efficiency of verifying account number authority is substantially raised.

Owner:NO 15 INST OF CHINA ELECTRONICS TECH GRP

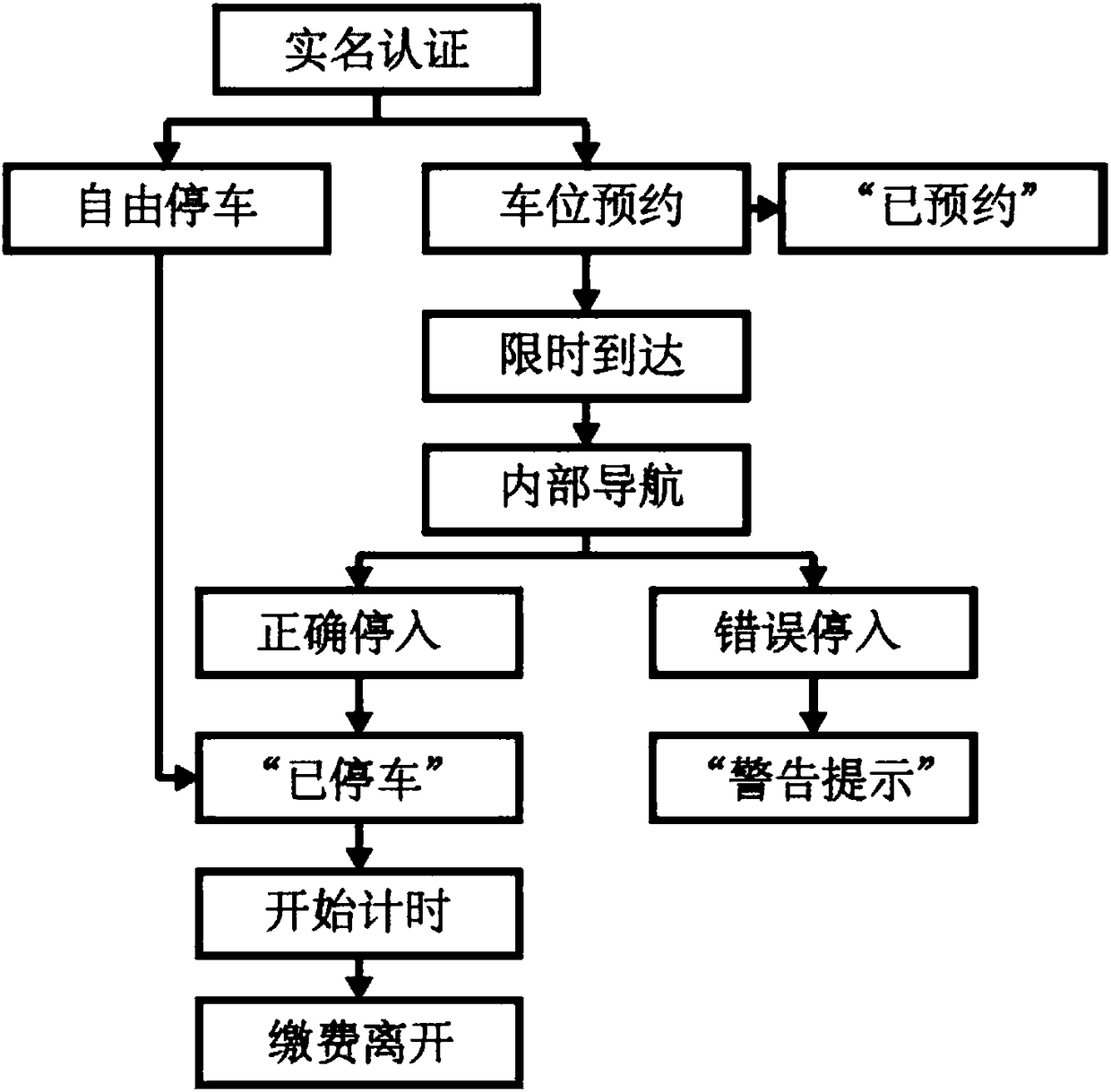

Internal navigation and parking space reservation system for parking lot and method

InactiveCN108230740AIn line with the operating logicAvoid cumbersomeInstruments for road network navigationTicket-issuing apparatusParking spaceEngineering

The invention discloses an internal navigation and parking space reservation system for a parking lot and a method. A parking space beside a destination can be reserved in advance by the reservation system, and a vehicle is guided to the reserved parking space in combination with a navigation system, a series of problems that a driver cannot find the parking space or gets lost in the parking lot after arriving at the parking lot are solved, and accordingly, the system is time-saving, safe and convenient, and facilitates management of the parking lot and maintenance of the internal order of theparking lot while providing convenience for the driver.

Owner:SHANDONG UNIV

Integrated container customs seal

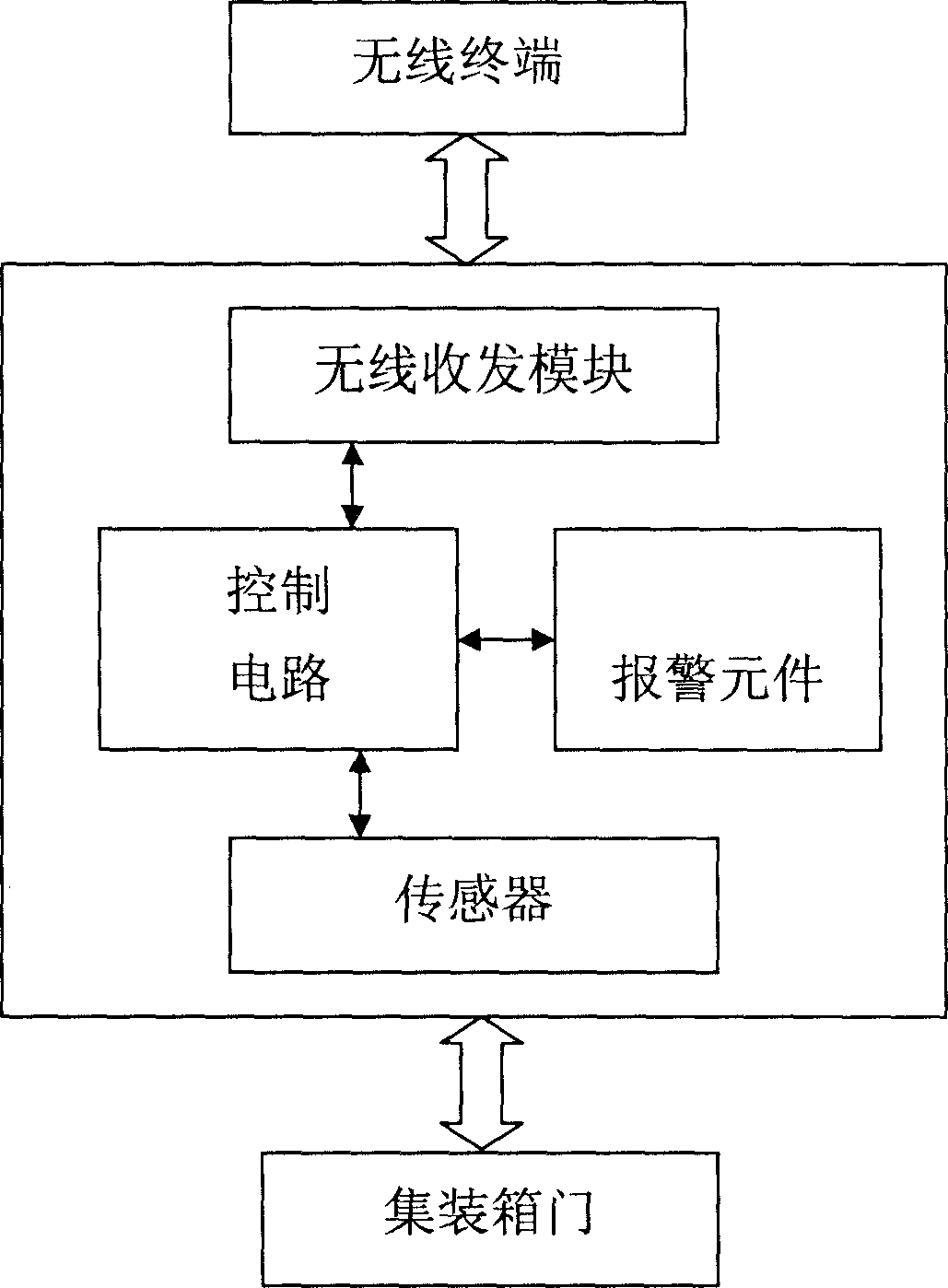

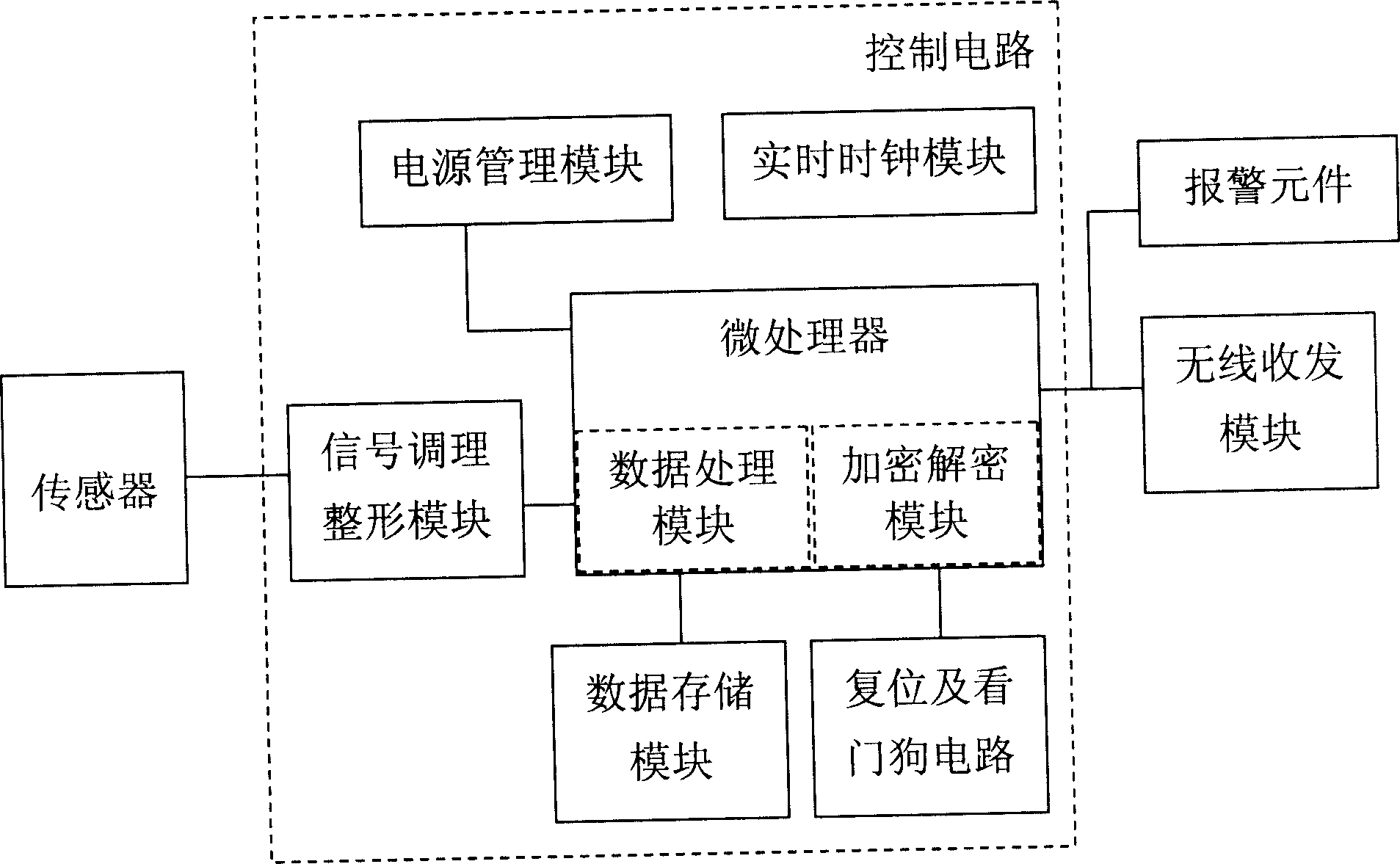

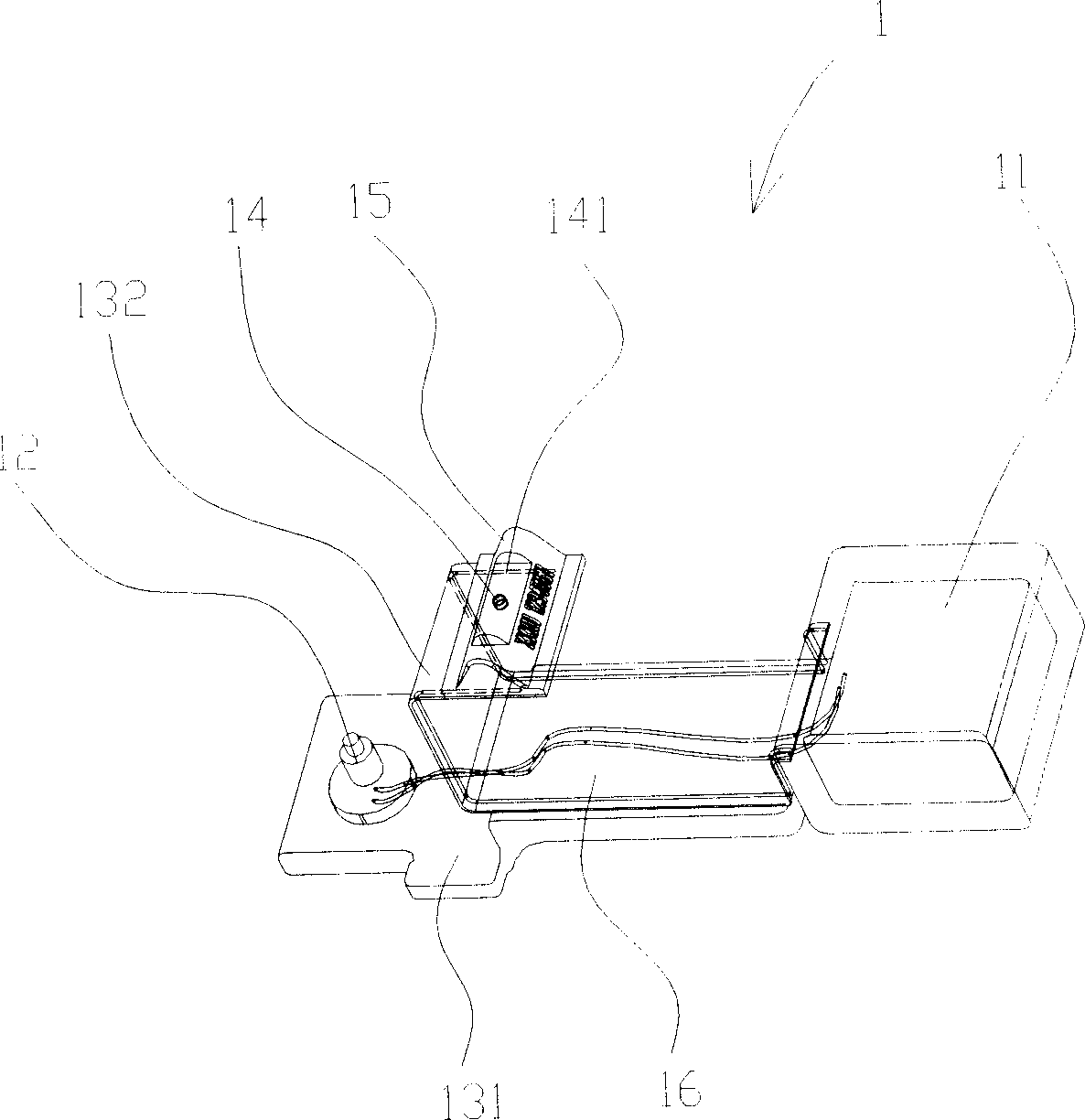

ActiveCN1884012APlay a role in direct response to freight safetyQuick checkBurglar alarm by openingLarge containersComputer moduleComputer terminal

An integrated container customs seal at least comprises: a sensor for sensing opening and closing states of the container door; a wireless transmitting and receiving module capable of communicating with a wireless terminal and realizing data transmission; an alarming element; and a control circuit respectively connecting with the sensor, the wireless transmitting and receiving module and the alarming element to receive and process signals of the sensor, control the wireless transmitting and receiving module to transmit and receive signals, control the alarming element to send alarm signals; the alarming element is an apparatus which is disposed on the external part of the container and can send naked eye recognizable signals under the control of the control circuit. The invention integrates the electronic customs seal and naked eye recognizable visualized customs seal to judge the illegal opening of the container door and alarm, so as to realize dual alarm and classified management of the container, and improve the container detection efficiency.

Owner:SHENZHEN CIMC SECURITY & SMART TECH

Method and system for intelligently managing laboratory EHS chemicals

The invention relates to the technical field of laboratory management, and relates to an intelligent management method and a system for laboratory EHS chemicals. Through the steps of self-help management of chemicals, the steps of intelligent management of chemical warehouse, the steps of chemical inquiry and the steps of user management; the chemical self-service management step comprises a chemical warehousing step, a self-service chemical safety collecting step, a returning step and a data management step; the intelligent management step of the chemical storehouse comprises a video monitoring step, a temperature and humidity real-time monitoring step and a chemical management step; a plurality of warehouse numbers are established in the chemical management step, and warehouse parametersincluding type, number, name, operation status, user login authentication mode, operation status and monitoring scope are set. A temperature and humidity device is arranged in a temperature and humidity real-time control step; in the video monitoring step, the number of video monitoring devices and the corresponding parameter setting can be selected, forming a complete chemical management systemlaboratory chemicals intelligent management methods and systems.

Owner:常州进出口工业及消费品安全检测中心

Power grid monitoring system and method based on streaming media

InactiveCN103327307AEnsure safetyAvoid data clutterClosed circuit television systemsSelective content distributionMonitoring systemPower grid

The invention relates to a power grid monitoring system based on streaming media. The power grid monitoring system based on the streaming media comprises client sides, a central server, a plurality of sub-servers and a monitoring device. One client side sends a request for obtaining a real-time video stream to the central server. The central server searches for the sub-server where the real-time video stream is located, sends the address of the sub-server to the client side, and meanwhile sends a command for connection establishment to the sub-server. The sub-server packages the video stream obtained from the monitoring device and then sends the video stream to the client side. When other client sides simultaneously send the requests for obtaining the real-time video steam, the sub-servers forward the real-time video stream to the other client sides. According to the power grid monitoring system based on the streaming media, the technical problem that due to hardware limitation, the monitoring device can not meet the requests which are simultaneously sent by the multiple client sides and used for obtaining the video stream is solved.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Method and system for virtual machine management in cloud computing

InactiveCN105373417AAvoid management chaosSoftware simulation/interpretation/emulationCloud computingVirtual machine

The invention discloses a method and a system for virtual machine management in cloud computing. The method comprises: receiving input name information of a virtual machine; storing the name information into a corresponding configuration script; after the virtual machine is started, analyzing the configuration script; and according to information of the analyzed configuration script, modifying a host name of the virtual machine. According to the method and the system, a host name of a new virtual machine can be dynamically injected from outside, so that when the scale of virtual machines in cloud is very large, domain control management disorder caused by host name conflict of the virtual machines is avoided.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

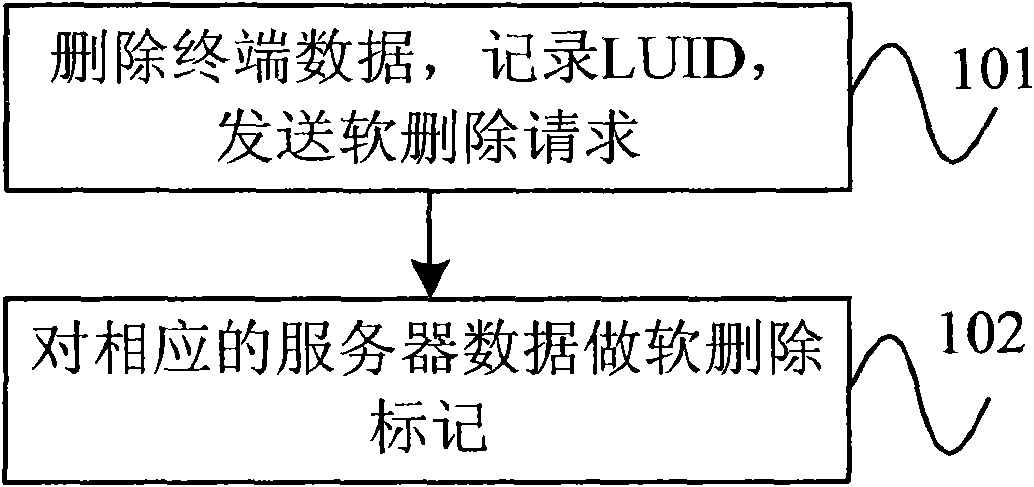

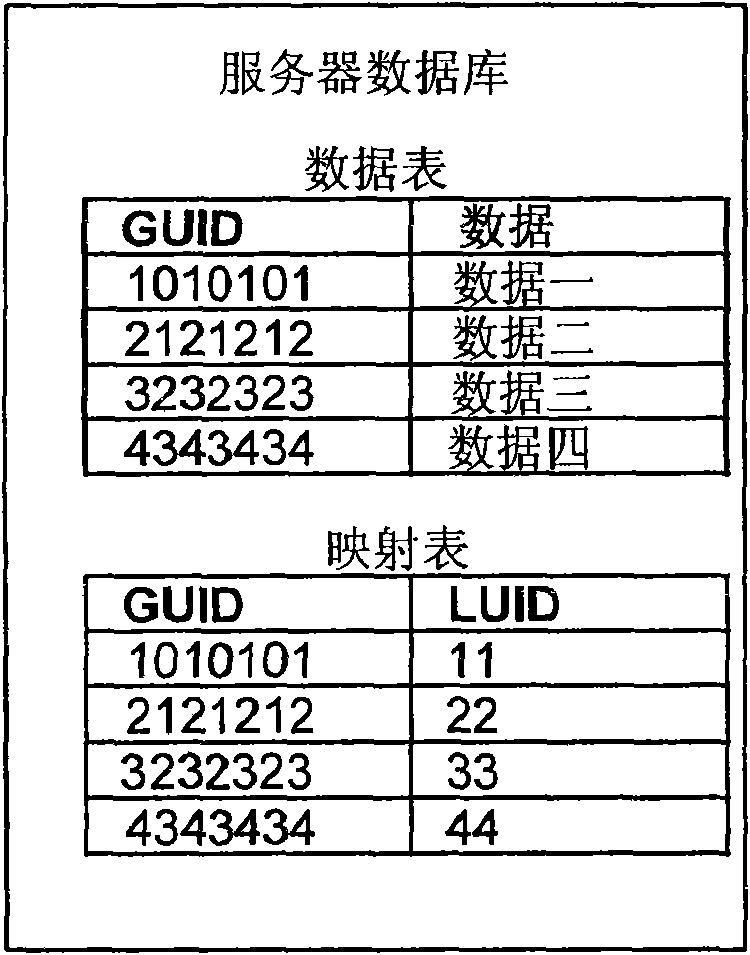

Methods for data soft deletion, data recovery and data synchronization, terminal and system

InactiveCN101610276AAvoid management chaosGuaranteed uptimeTransmissionData synchronizationData recovery

The invention relates to methods for data soft deletion, data recovery and data synchronization, a terminal and a system, wherein the method for the data synchronization comprises the step that a server and the terminal perform synchronization on server data without soft deletion markers in the process of data synchronization. The method for the data soft deletion comprises the following steps: receiving a soft deletion request from the terminal by the server; and acquiring the server data to be soft deleted according to the soft deletion request, and performing soft deletion mark on the data. Through the embodiment of the invention, because the server marks the server data to be soft deleted, the server data which is deleted soft can be known, thus in the process of normal synchronization or slow synchronization, the data which is deleted soft is not synchronized back to the terminal to avoid confused management of the data and further ensure the normal operation of the terminal.

Owner:HUAWEI TECH CO LTD

Hotel management system

InactiveCN109063874AImprove coordinationAchieve synthesisReservationsMarketingComputer moduleCustomer information

The invention discloses a hotel management system, comprising: a meal order management module is used for providing a meal order interface for a customer, which is used for receiving the meal order information and calculating the meal order cost; The room management module is used for recording and displaying the usage status of all rooms, and displaying the occupied time period of a room when theroom is reserved. Security module is used to monitor the room and corridor security and real-time early warning; The entrance guard module is used for verifying the identity information of the persons entering and leaving the hotel; The foreground module is used for collecting customer information and assigning room cards; The customer information management module is used for managing customer information; The fund management module is used to manage the funds paid by customers; The central control module is used for receiving the data sent by the order management module, the room managementmodule, the security module, the access control module, the foreground module, the customer information management module and the fund management module, and performing feedback control.

Owner:合肥德高信息科技有限公司

Automatic feeding system for producing optical cables

InactiveCN106113436AAvoid management chaosReduce irrelevant operationsFibre mechanical structuresProcess engineeringMaintenance Problem

The invention provides an automatic feeding system for producing optical cables. The automatic feeding system comprises a plurality of storage tanks and a plurality of storage buckets, wherein raw materials in a warehouse are sucked and conveyed to respective storage tanks by a first conveying mechanism by utilizing negative pressure; the raw materials in the storage tanks are sucked and conveyed to respective storage buckets by a second conveying mechanism by utilizing negative pressure; the raw materials in the storage buckets are extruded by virtue of screws and are conveyed to extrusion dies of optical cable production lines by a third conveying mechanism; one storage bucket is correspondingly arranged on one optical cable production line, one second feeding pipe is correspondingly arranged on one storage tank, all of the storage buckets communicate with all second feeding pipes by virtue of independent feeding branch pipes, regulating valves are respectively arranged on the feeding branch pipes, which storage tanks communicating with the storage buckets are respectively controlled by the regulating valves, and the feeding speed from the storage tanks to the storage buckets is regulated by virtue of the regulating valves. According to the automatic feeding system, full-automatic feeding for producing the optical cables is realized, the maintenance problem of production sites is solved, manpower and materials are saved, and the waste of the raw materials is avoided.

Owner:宏安集团有限公司

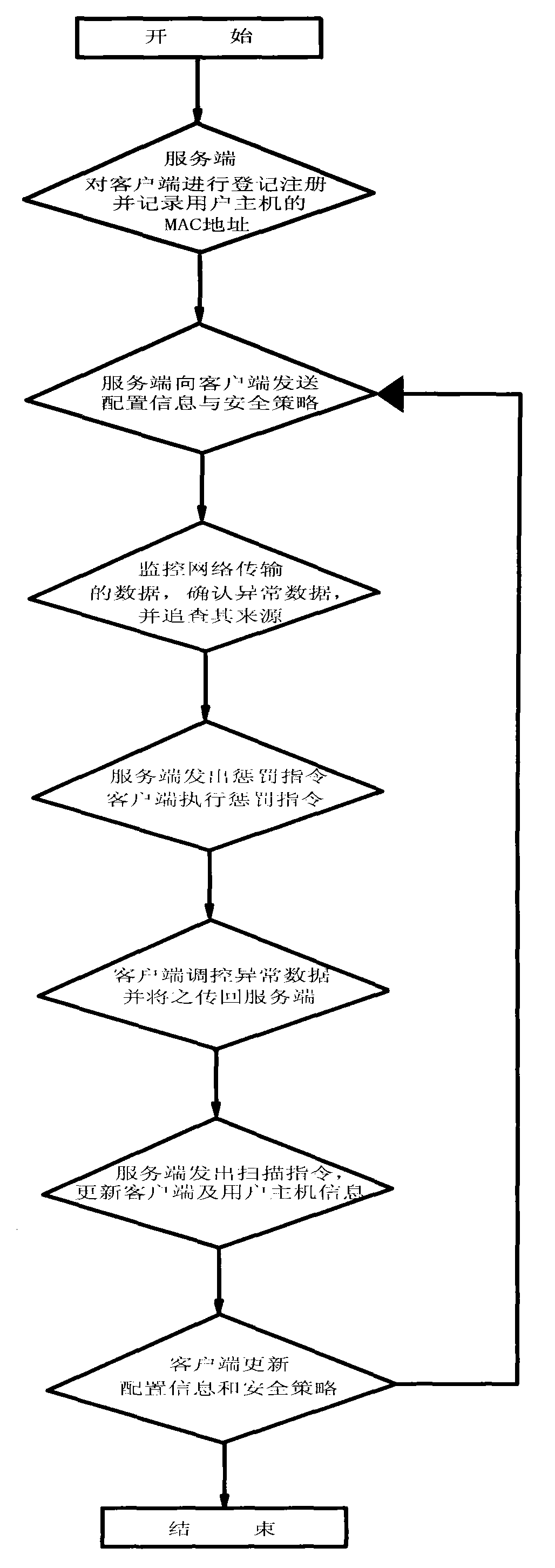

ASN (attack security interaction) and implementation method thereof

InactiveCN102088455ARealize direct unified managementSimplify administrative proceduresData switching networksProtocol processingSystems management

The invention discloses an ASN (attack security interaction), which belongs to the technical field of network communications and is used for solving the problem that the self-protection capacity of a network service end in the prior art is too weak. The ASN comprises a service end, a client-side and a user host machine, wherein the service end and the client-side are in a mapping relation; the client-side and the user host machine are in a mapping relation; a system management module, an exception handling module, a protocol processing module and a data storage are embedded in the service end; an instruction execution module is embedded in the client-side; the data storage, the exception handling module and the instruction execution module are directly connected with the system management module and controlled by the system management module; and the protocol management module is respectively connected with the exception handling module and the instruction execution module. The invention also provides an implementation method of the ASN. By using the implementation method of the ASN, the active defense and attack of the service end and the client-side is implemented, the network safety is improved, and the practical value is very high.

Owner:成都飞鱼星科技股份有限公司

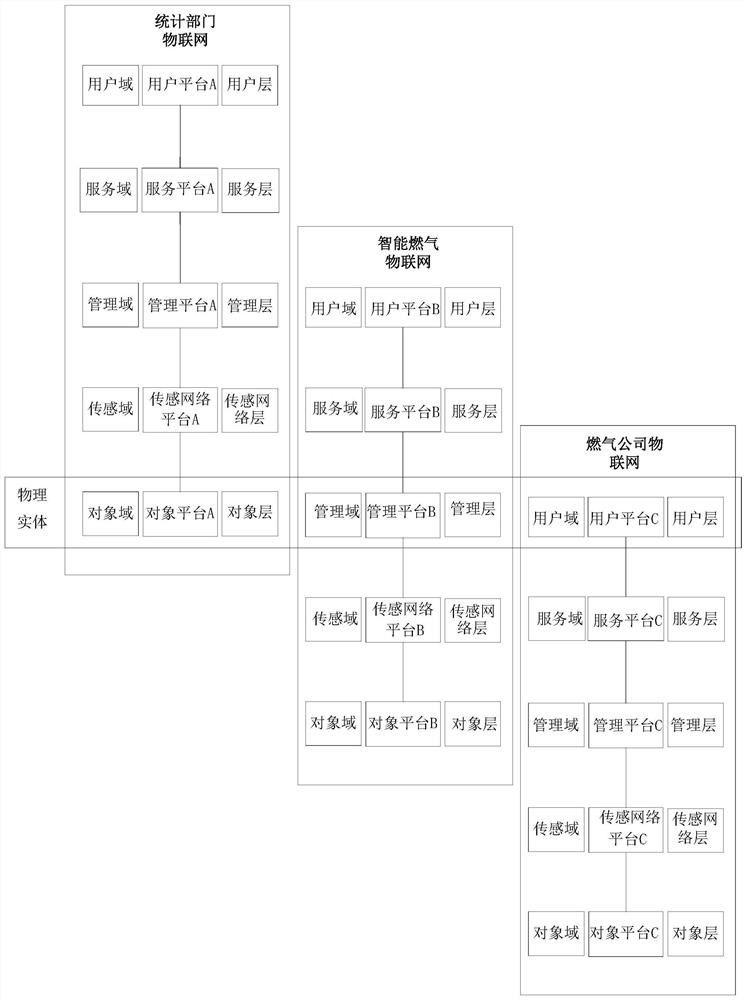

Smart city free network system based on smart gas meter and construction method

PendingCN112561726ARealize standardized managementAvoid management chaosData processing applicationsDatabase management systemsPaymentComputer network

The invention discloses a smart city free network system based on an intelligent gas meter. An intelligent gas internet of things provides gas consumption statistics and payment services for users ofthe intelligent gas internet of things; the gas company Internet of Things provides gas consumption data check and gas consumption unit price for the intelligent gas Internet of Things; when the gas company Internet of Things provides service for the intelligent gas Internet of Things, a node platform is established; the node platform is a management platform B in the intelligent gas Internet of Things, and the node platform is a user platform C in the gas company Internet of Things; and the Internet of Things of the gas company provides service for the management platform B of the intelligentgas Internet of Things by providing service for the node platform. The invention further discloses a smart city free network construction method based on the smart gas meter. According to the smart city free network system based on the smart gas meters and the construction method, standardized management of the free network is achieved, management disorder of the smart gas internet of things is avoided, networking efficiency is improved, supervision is facilitated, and meanwhile high adaptability is achieved.

Owner:CHENGDU QINCHUAN IOT TECH CO LTD

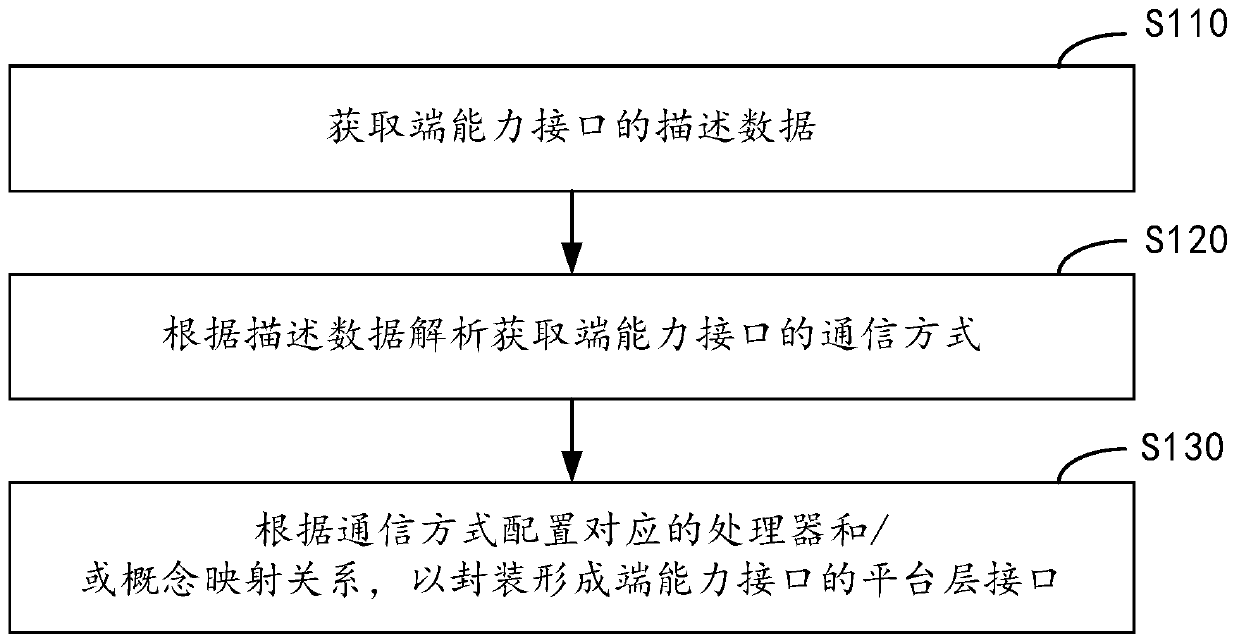

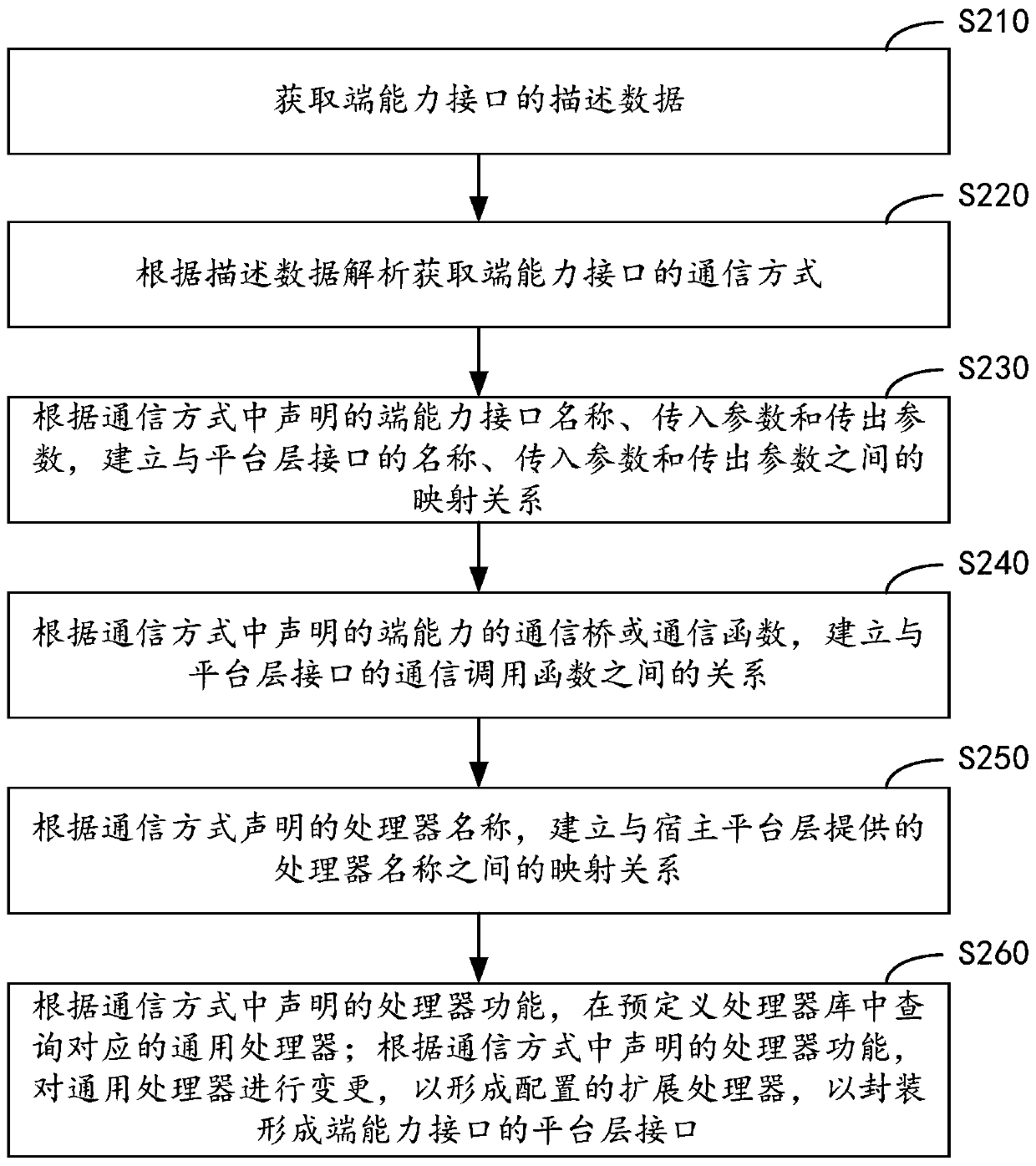

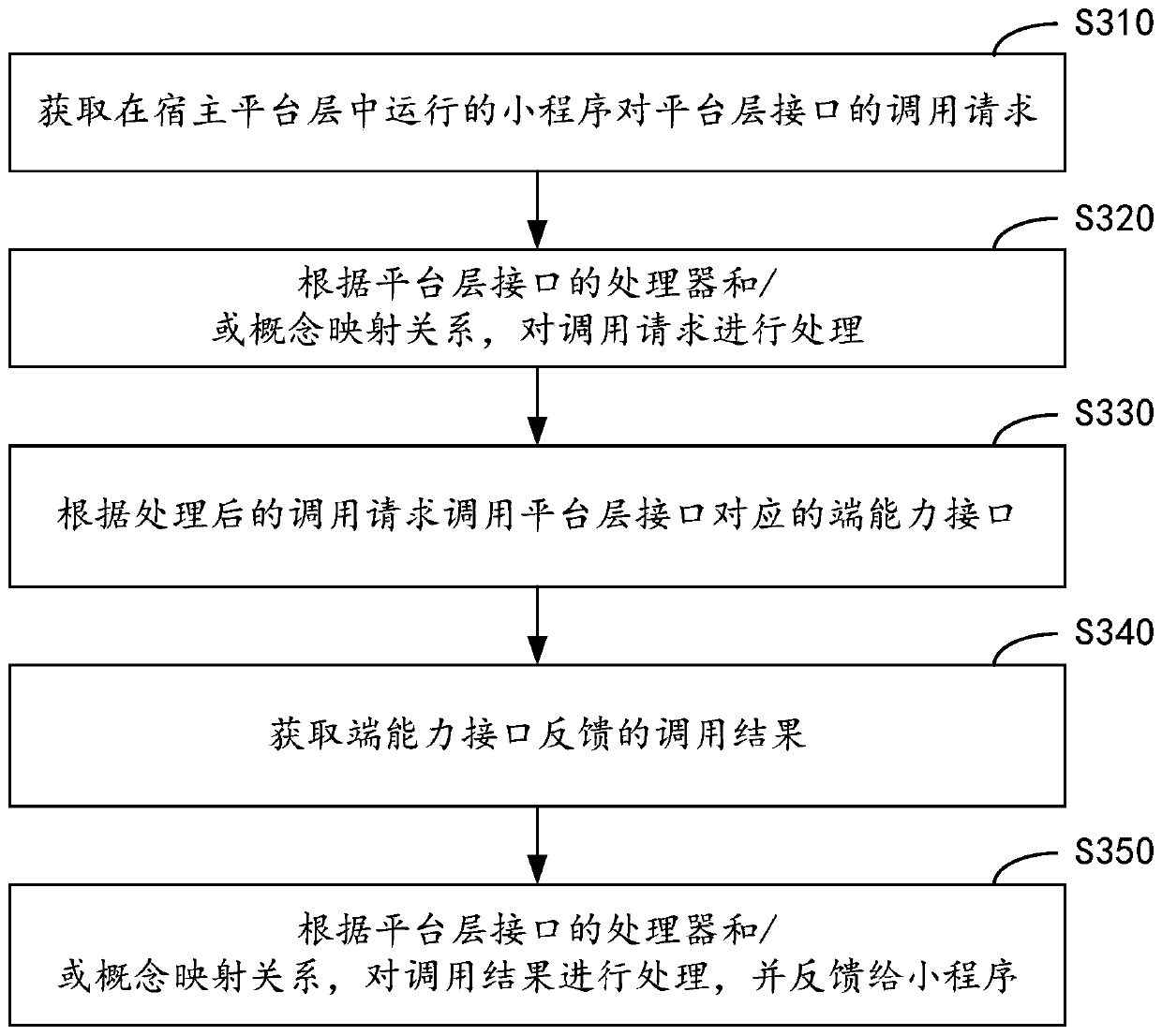

Application interface implementation method and device in host platform layer, equipment and medium

ActiveCN111367635AAvoid management chaosClear division of laborProgram initiation/switchingInterprogram communicationComputer hardwareOperational system

The embodiment of the invention discloses an application interface implementation method and device in a host platform layer, equipment and a storage medium, and relates to the technical field of computers. The specific implementation scheme is as follows: a host platform layer acquires description data of an end capability interface; analyzing the communication mode of the obtaining end capability interface according to the description data; and configuring a corresponding processor and / or concept mapping relationship according to the communication mode so as to package a platform layer interface for forming an end capability interface, the platform layer interface being used for processing communication interaction data in a process of calling the end capability interface by the applet through the host platform layer. Therefore, the host platform layer automatically generates the platform layer interface according to the description data of the end capability interface, a large amount of frequent host platform layer interface code maintenance caused by differences of terminal hardware, operating system versions and the like is avoided, and the manual maintenance cost of the hostplatform layer interface is reduced.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

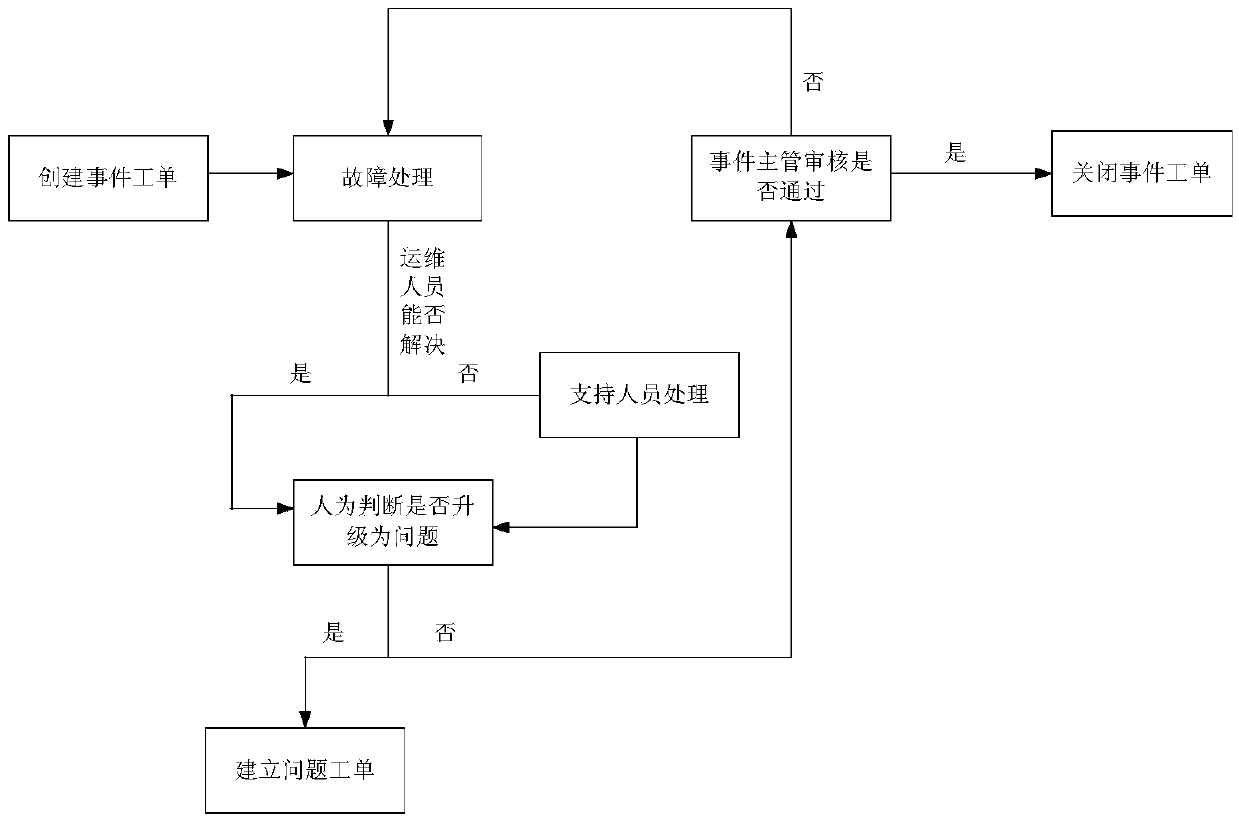

Event management method based on remote diagnosis environment

The invention discloses an event management method based on a remote diagnosis environment. The event management method comprises the following steps of collecting events or faults, which are discovered during user declaration, monitoring alarm and daily audit, through a service counter, establishing an event list, creating an event work order according to the event list, informing a worker to carry out fault processing according to the event work order, and better enabling an event supervisor to examine and verify an event work order processing result. The event management method has the following advantages that 1) visualization: through the method, the existing IT (Information Technology) resource information of a client is carded, operation and maintenance work can be normalized, and resource table visualization, working visualization and processing process visualization are implemented; 2) controllability: through the method, operation and maintenance work of the client can be normalized, normalization, standardization and institutionalization of daily work are implemented, processing and solution of faults and problems are intelligent and highly-efficient, and controllability and manageability of the whole operation and maintenance management working process are guaranteed.

Owner:CHINA NAT SOFTWARE & SERVICE

Vehicle parking lot reservation system

InactiveCN106682749AAvoid Malicious BookingGuaranteed economic benefitsReservationsIndication of parksing free spacesParking spaceEngineering

The invention provides a vehicle parking lot reservation system. The system comprises a parking lot subsystem which stores the use condition of the parking spaces in parking lots, parking status display lamps which are arranged right above the parking spaces in parking lots, a user input module which is used for inputting a destination where a reservation vehicle is heading, a controller which is used for acquiring candidate parking lots with unoccupied parking spaces near the destination and sending the information of the candidate parking lots to a selection module, and the selection module which is used for determining one parking lot as a reservation parking lot from the candidate parking lots, selecting a reservation parking space from the unoccupied parking spaces in the final parking lot and uploading the reservation parking lot and the reservation parking space to the controller. With the system, a parking lot near a destination can be booked in advance. When a vehicle runs to the destination, the vehicle can be parked directly in the booked parking lot. Thus, time is saved, and the trouble of looking for a parking space is avoided.

Owner:罗秋莲 +1

Ecological flow determination method considering lifting amount

ActiveCN111079085AService emphasisSolving Difficulties That Are Hard to QuantifyData processing applicationsGeneral water supply conservationSediment transportStream flow

Owner:XIAN UNIV OF TECH

Coding management system

InactiveCN107330666AAvoid management chaosMeet the needs of the settingFinanceOffice automationComputer architectureUser identifier

A coding management system disclosed by the present invention comprises a coding rule creation module used for presetting the coding rules, wherein the coding rules comprise the catalogue grade fields, the rule identifier fields and the rule description fields; an information inputting module used for inputting the field content corresponding to the coding rules to generate the coding rule information, wherein the coding rule information comprises the catalogue grades, the rule identifiers and the rule information; a coding node creation module used for creating the coding nodes according to the coding rule information to generate the coding node information, wherein the coding node information comprises the node catalogue grades and the node identifiers; a configuration database used for correlating the coding node information with a plurality of management sub-systems and generating the correlation information, so that the plurality of management sub-systems obtain the same coding node information according to the correlation information. The coding management system of the present invention can avoid the coding rule disorder and the coding information repetition effectively.

Owner:王剑

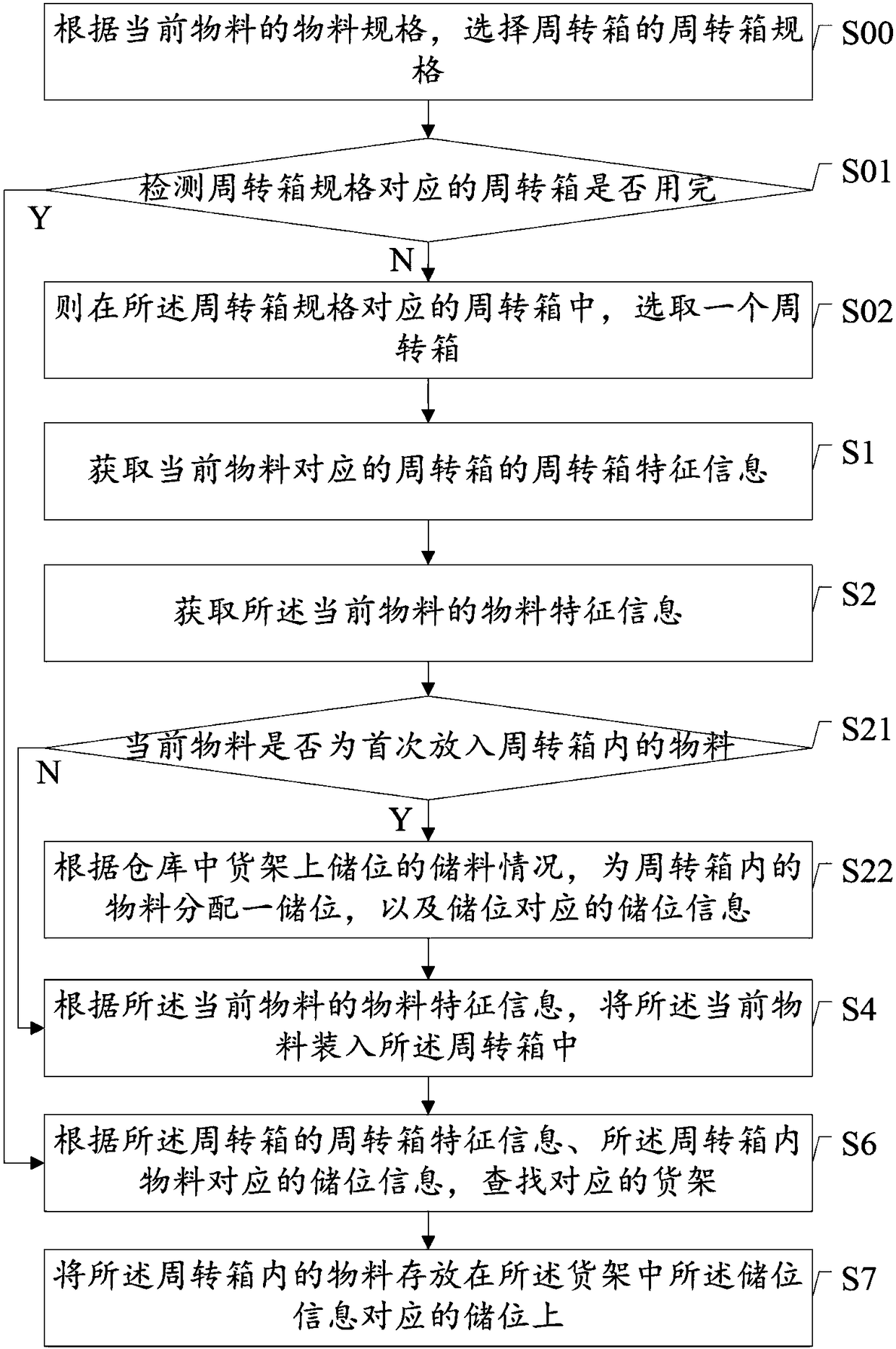

Warehouse management method and system

InactiveCN108502429AReduce operating proceduresIncrease the efficiency of sorting and warehousingCo-operative working arrangementsLogisticsComputer scienceMaterial storage

The invention provides a warehouse management method and system. The warehouse management method comprises the steps of S1 obtaining circulation case feature information of a circulation case corresponding to a current material; S2 obtaining material feature information of the current material; S4 placing the current material into the circulation case according to the material feature informationof the current material; S6 according to the circulation case feature information of the circulation box and storage location information corresponding to the material in the circulation case, searching for a corresponding goods shelf; and S7 storing the materials in the circulation case at the storage location, corresponding to the storage location information, in the goods shelf. According to the warehouse management method and system, through introduction of the circulation cases, the operation procedures are reduced for warehouse operation personnel, and the material storage efficiency isimproved.

Owner:SICHUAN FEIXUN INFORMATION TECH CO LTD

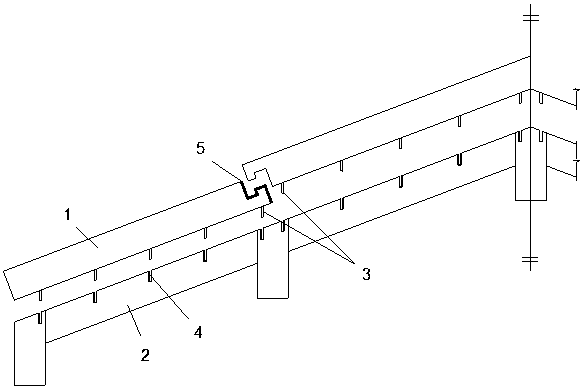

Fabricated sloping roof construction method

InactiveCN110295700APracticalEasy to assembleRoof covering using slabs/sheetsBuilding roofsEngineeringFixation stability

The invention relates to a fabricated sloping roof construction method. The method comprises the following steps that S1, according to the requirements of a design drawing, modeling is conducted through BIM software, a building is visualized, and the size and position of a beam are determined; S2, an overall sloping roof is divided and arranged according to the size and position of the beam, and the sloping roof is divided into a plurality of rectangular roof plates; S3, roof plates are prefabricated in a prefabricating field, a circle of bearing inserting anchoring rods are pre-buried in theperiphery of the lower surface of each roof plate, and the connection edge of every two adjacent roof plates is prefabricated with concave and convex groove structures for mutual buckling; S4, supporting seat sleeves are pre-buried in the beam according to the positions and quantity of the bearing inserting anchoring rods; and S5, all the roof plates are installed in the corresponding positions ofthe beam, the bearing inserting anchoring rods are inserted into the corresponding pre-buried supporting seat sleeves, and the adjacent roof plates are buckled and connected with one another throughthe concave and convex groove structures. The problems that when large-area large-gradient roof plate prefabricated members are installed through a traditional assembling mode, the jacking and liftingdifficulty is large, and the installing and fixing stability is poor are solved.

Owner:CHINA FIRST METALLURGICAL GROUP

Intelligent identification control cabinet

InactiveCN108419391AAvoid badAvoid management chaosCasings/cabinets/drawers detailsInformation transmissionComputer module

The invention belongs to the technical field of a control cabinet, and particularly relates to an intelligent identification control cabinet. The intelligent identification control cabinet comprises acabinet body and a cabinet door. One side of the cabinet door is hinged with the cabinet body, and the other side is connected with the cabinet body through an intelligent identification device. Theintelligent identification device comprises an electronic lock, an electronic lock control module, a comparator, a face identification device, a face information storage device and a remote information transmission device. The output end of the electronic lock control module is connected with the electronic lock. The face identification device and the output end of the face information storage device are connected with the receiving end of the electronic lock control module through the comparator. The face information storage device is connected with the remote information transmission device.The intelligent identification control cabinet overcomes defects in prior art. Information of an operator is identified by means of the identification device which is mounted on the cabinet door. Then the information of the operator is compared with a parameter in the information storage device, thereby realizing a purpose of intelligent unlocking, and preventing problems of low convenience and bad management of a carrying type key.

Owner:安徽沃屹智能装备有限公司

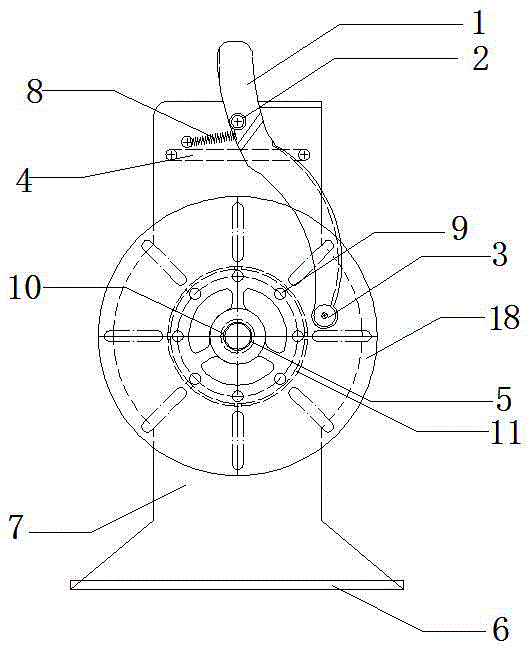

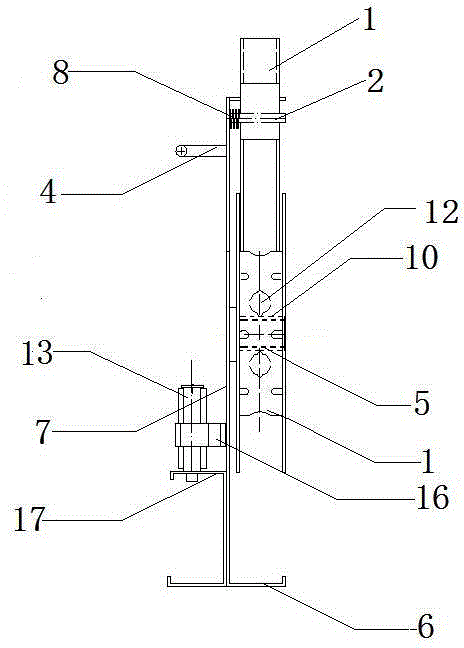

Portable coiling and storing device of tail fibers

InactiveCN104678523AWon't breakAvoid management chaosFibre mechanical structuresFiberMechanical engineering

The invention discloses a portable coiling and storing device of tail fibers. The portable coiling and storing device is characterized in that a main body part comprises a main body base (6), a main body supporting part (7), a fiber pressing device center shaft (2), a fiber pressing device (1), a fiber pressing device control spring (8), a fiber pressing wheel (3) and a main body center shaft (5) with a jack; a fiber storing tray part comprises a fiber coiling tray (11), a fiber storing tray axis (10), a tail fiber connector clamping groove (12), a fiber storing tray guard plate (18) and a handle clamping groove (9), wherein the fiber coiling tray (11) has a radius of at least 40 mm; the handle part comprises a hand lever (13), a handle body (19), a handle buckle (14) corresponding to the handle clamping groove (9) and a handle center shaft (15) corresponding to the main body center shaft (5). The portable coiling and storing device is simple and practical and easy to carry, and can achieve quick coiling and orderly storage of tail fibers.

Owner:STATE GRID CORP OF CHINA +1

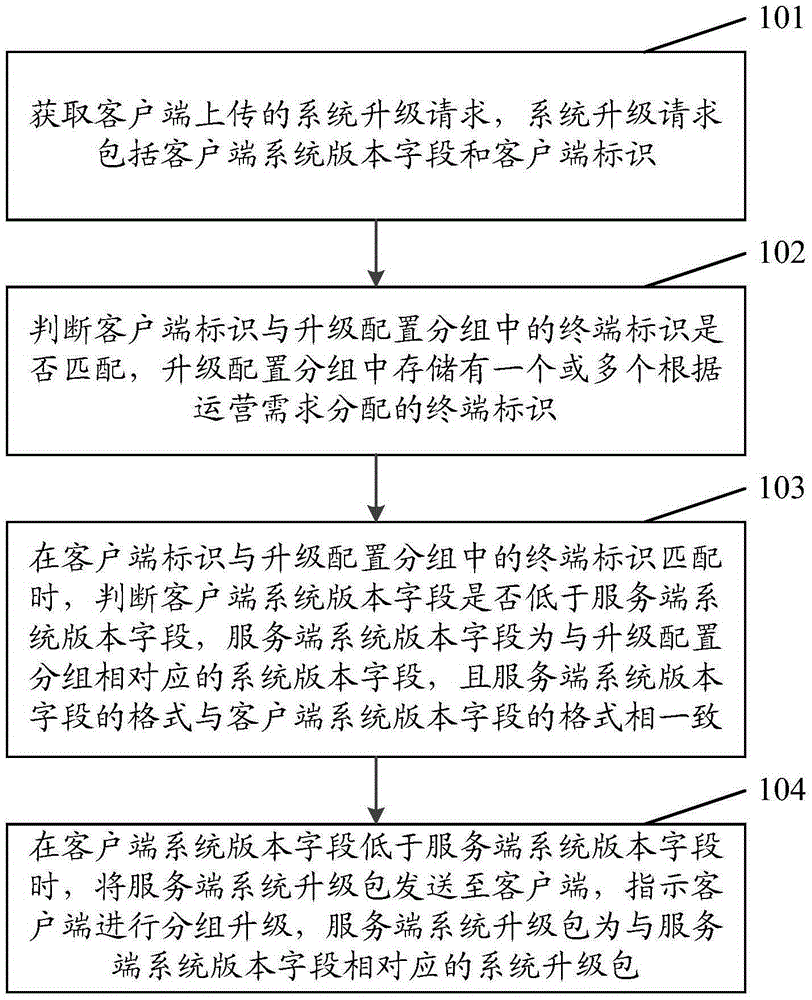

Group upgrading method and device

InactiveCN105915361AAvoid management chaosImprove scalabilityData switching networksComputer terminalClient-side

The invention discloses a group upgrading method and device. The method comprises the steps that a system upgrading request uploaded by a client side is acquired, wherein the system upgrading request includes a client side system version field and a client side identifier; whether the client side identifier is matched with the terminal identifier in an upgrading configuration group is judged; when the client side identifier is matched with the terminal identifier in the upgrading configuration group, whether the client side system version field is lower than a server side system version field is judged, and the format of the server side system version field is consistent with the format of the client side system version field; and when the client side system version field is lower than the server side system version field, a server side system upgrading package is transmitted to the client side to indicate the client side to perform group upgrading. According to the method, system upgrading can be performed according to the operation requirements through the upgrading configuration group with no requirement for the version number so that disordered management of the version number can be effectively avoided.

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

Account management method and device, computer device and computer readable storage medium

ActiveCN109670813AAvoid management chaosIntelligent managementPayment schemes/modelsLicenseComputer engineering

The invention is applicable to the field of electronic account management, and provides an account management method and device, a computer device and a computer readable storage medium. The method comprises the following steps of establishing a binding relationship between a license plate number and a main account; when a binding request sent by a first slave account is received, sending the binding request to the master account; And after the master account is confirmed, establishing a binding relationship between the license plate number and the first slave account. The embodiment of the invention provides the account management device. The binding relationship between the license plate number and the master account is established, and after the master account confirms that the bindingrequest is received, the binding relationship between the license plate number and the slave account is established, so that the master account can conveniently manage a plurality of slave accounts, the phenomenon of disordered account management is effectively avoided, and the user account management is more intelligent and standardized.

Owner:SHENZHEN WANHUA AUTO SERVICE INVESTMENT HLDG CO LTD

Patent on-line business processing system

InactiveCN105117846AAvoid the problem of low circulation efficiencyAvoid management chaosResourcesIntellectual propertyAgency structure

The invention provides a patent on-line business processing system. The patent on-line business processing system comprises a network module, a business requesting module, a business generation module, a business writing module, a business auditing module, a business confirmation module, an aid application module, a privilege management module, and a database module, and the business requesting module, the business generation module, the business writing module, the business auditing module, the business confirmation module, the aid application module, the privilege management module, and the database module are respectively connected with the network module. According to the patent on-line business processing system, a high-efficiency, convenient, and informational management network between clients, agencies, and the Intellectual Property Office is established, and the problem of low efficiency of paper pieces is solved.

Owner:CHANGSHA LUZHI INFORMATION TECH

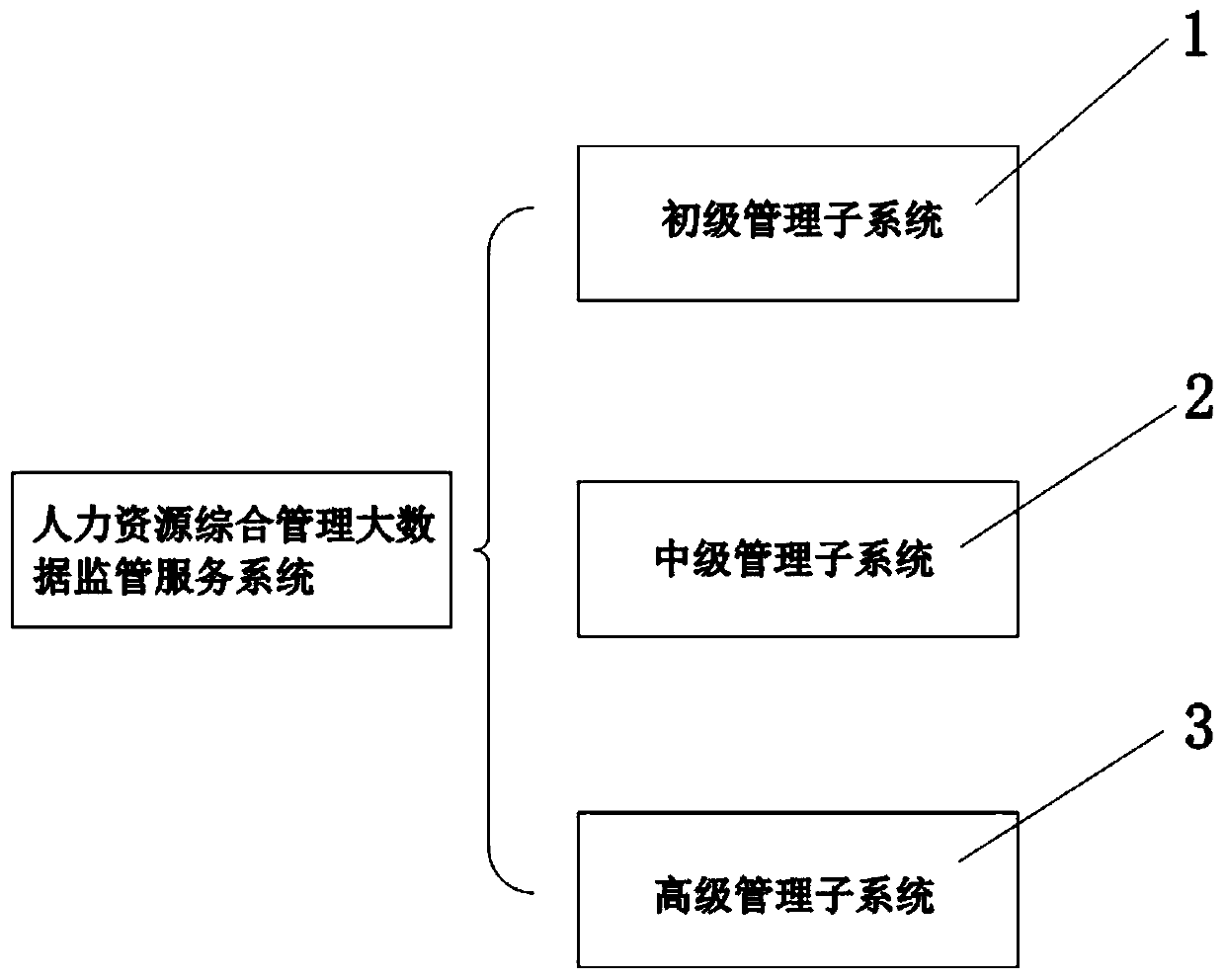

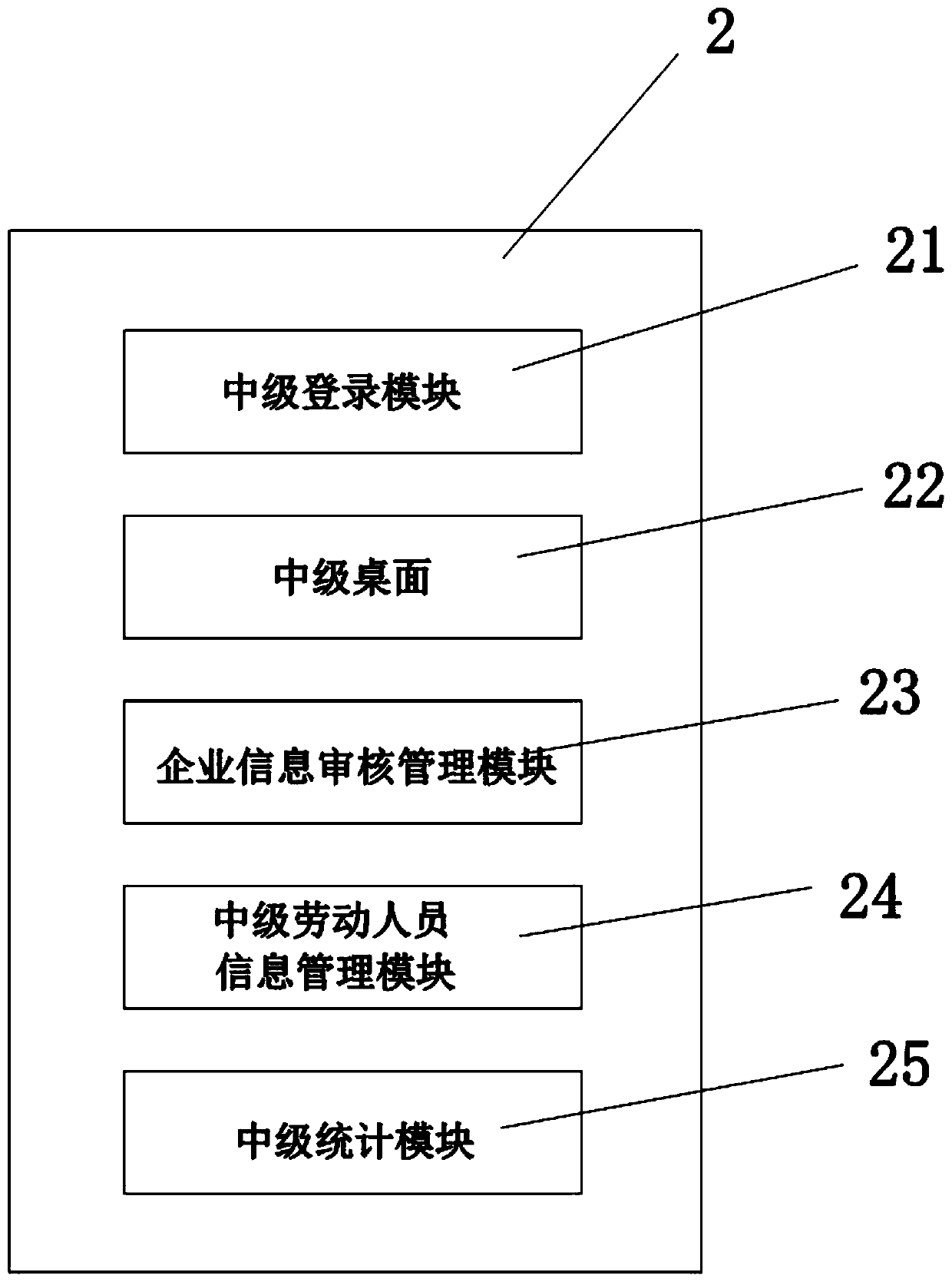

Human resource comprehensive management big data supervision service system

PendingCN110659882AEasy to manageQuick RecruitmentOffice automationResourcesBusiness enterpriseJob management

The invention provides a human resource comprehensive management big data supervision service system, which comprises three levels of management subsystems, namely a primary management subsystem, an intermediate management subsystem and an advanced management subsystem, wherein the three levels of management subsystem generate different management authorities according to management levels; the primary management subsystem comprises an enterprise user registration and login module, an enterprise basic information management module, an organization structure management module, an on-job management module, a departure management module and an enterprise data statistics module; each of the intermediate management subsystem and the advanced management subsystem comprises a login module, a desktop, a labor personnel information management module and a statistics module. According to the human resource comprehensive management big data supervision service system provided by the invention, management and statistics of enterprise personnel data can be realized, and entry and departure states of enterprise employees can be queried in real time; meanwhile, enterprises in one area can be conveniently counted and audited, and labor personnel information is managed.

Owner:重庆市重点产业人力资源集团有限公司

Method and device for manufacturing cable by using fine steel wires

ActiveCN112813712AStable pay-offLine optimizationRope making machinesUltimate tensile strengthMaterials science

The invention discloses a method and a device for manufacturing a cable by using micro steel wires. The method comprises the following steps: stacking and paying off, wire separating and combing, tension control, stranding, winding, clamping and pulling, cutting and taking up, wherein in the step of stacking and paying off, the diameter of the steel wire for paying off ranges from 0.03 mm to 3.0 mm, and spools are adopted for paying off and are arranged in a multi-layer and multi-column stacking mode; in the step of wire separating and combing, at least four wire separating and combing discs are adopted and evenly arranged between paying-off and stranding at intervals, and all the wire separating and combing discs sequentially deflect by an angle along the axis, so that the steel wires are adjusted step by step in the circumferential direction for multiple times, and thus a torsional angle is achieved through accumulation; wire holes are uniformly formed in the wire separating and combing discs, the wire holes are in fillet transition, and R is larger than 10 mm; and the wire separating and combing discs are made of a non-steel material. According to the method, the ultrahigh-strength fine steel wires are used for manufacturing the cable, under the same cable force requirement, the cable strand sectional area (diameter) is reduced, the porosity is reduced, the cable strand compactness is improved, meanwhile, the cable strand dead weight is reduced, and the spanning capacity of the cable is enhanced.

Owner:BAOSTEEL METAL

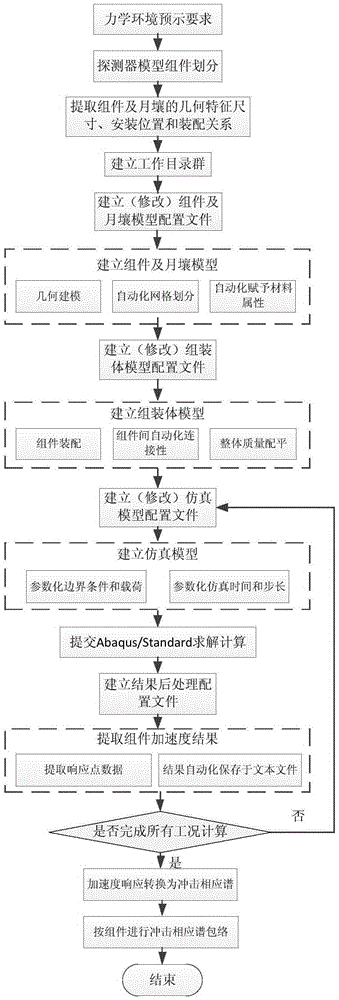

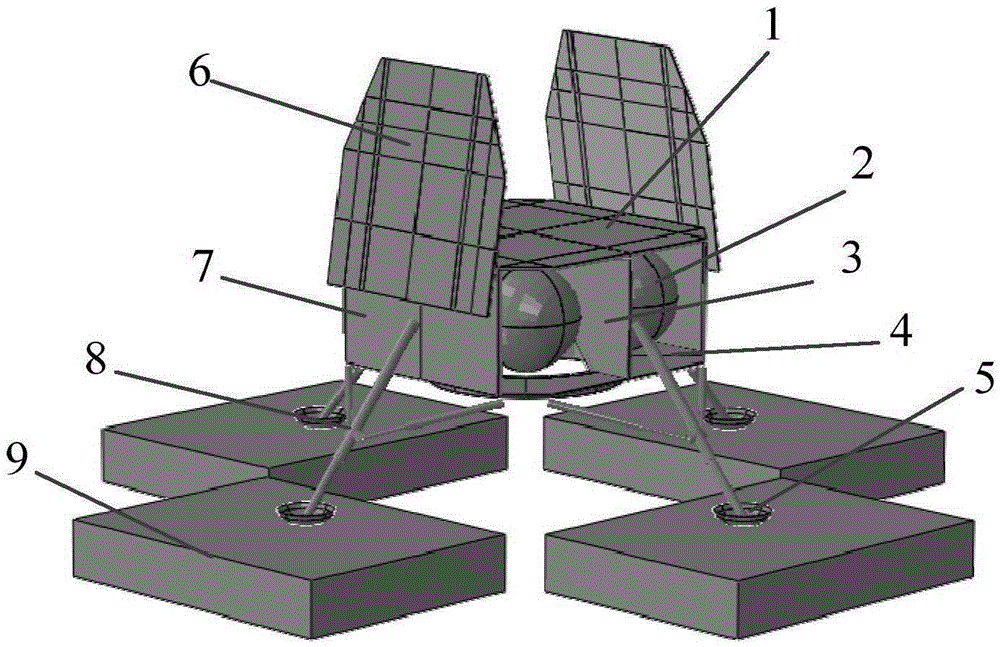

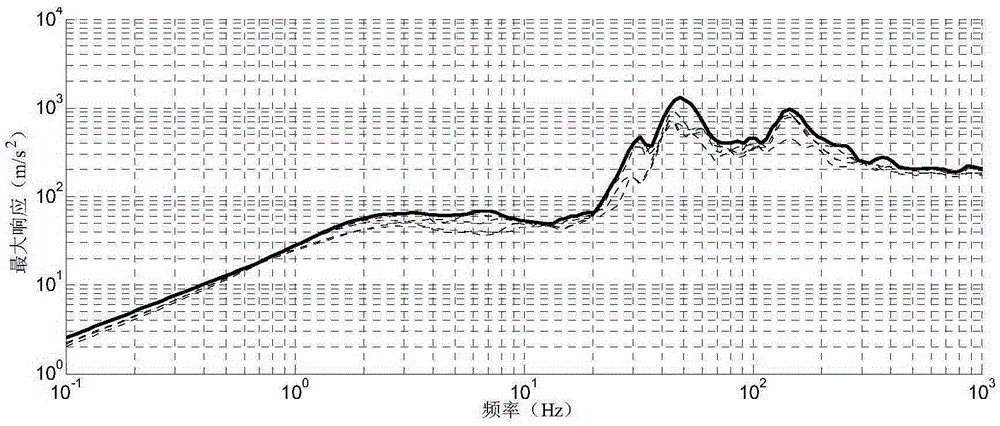

Component partitioning simulation method based on lunar probe landing mechanical environment prefiguration

ActiveCN105243247AAvoid management chaosImprove design and development efficiencySpecial data processing applicationsElement analysisDeep space exploration

The invention relates to a component partitioning simulation method based on lunar probe landing mechanical environment prefiguration, belonging to the technical field of deep space exploration. The invention provides a reasonable component partitioning simulation method based on the requirement of lunar probe landing mechanical environment prefiguration. The method can orderly and efficiently carry out the work of finite element analysis and provide convenience for the subsequent work of mechanical environment prefiguration, so that the defect that finite element modeling of a complex aerospace structure is tedious and fallible is avoided, and integrated analysis of component partitioning, finite element analysis and mechanical environment prefiguration is achieved. According to the component portioning simulation method, component partitioning can be carried out on a complex lunar probe according to the requirement of lunar probe landing mechanical environment prefiguration, so that the obtained result can be orderly stored; furthermore, modeling component partitioning keeps consistence with component partitioning required by mechanical environment prefiguration analysis, so that the problem of disordered result file management is avoided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Enterprise informatization management system

InactiveCN106651155AImprove operational efficiencyAvoid Management ChaosOffice automationResourcesInformatizationResource information

The invention discloses an enterprise informatization management system, which comprises a human management module, a project management module, a project scheduling module, an enterprise application server and a storage module, wherein the enterprise application server is independently connected with the human management module, the project management module, the project scheduling module and the storage module; the storage module is independently connected with the human management module, the project management module and the project scheduling module; the human management module comprises a human attendance recording unit, a purchasing human unit, a project design human unit, project implementation human unit and a project after service human unit; and the human attendance recording unit is used for recording the attendance situation of enterprise internal staff. By use of the system, the internal resources of an enterprise are subjected to informatization, job contents are reasonably distributed to enterprise staff, the internal operation efficiency of the enterprise is improved, a situation of the delaying and the loss of working time of a project link is avoided, an enterprise project schedule is improved, and enterprise benefits are improved.

Owner:GUANGDONG UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com