Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Avoid less efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

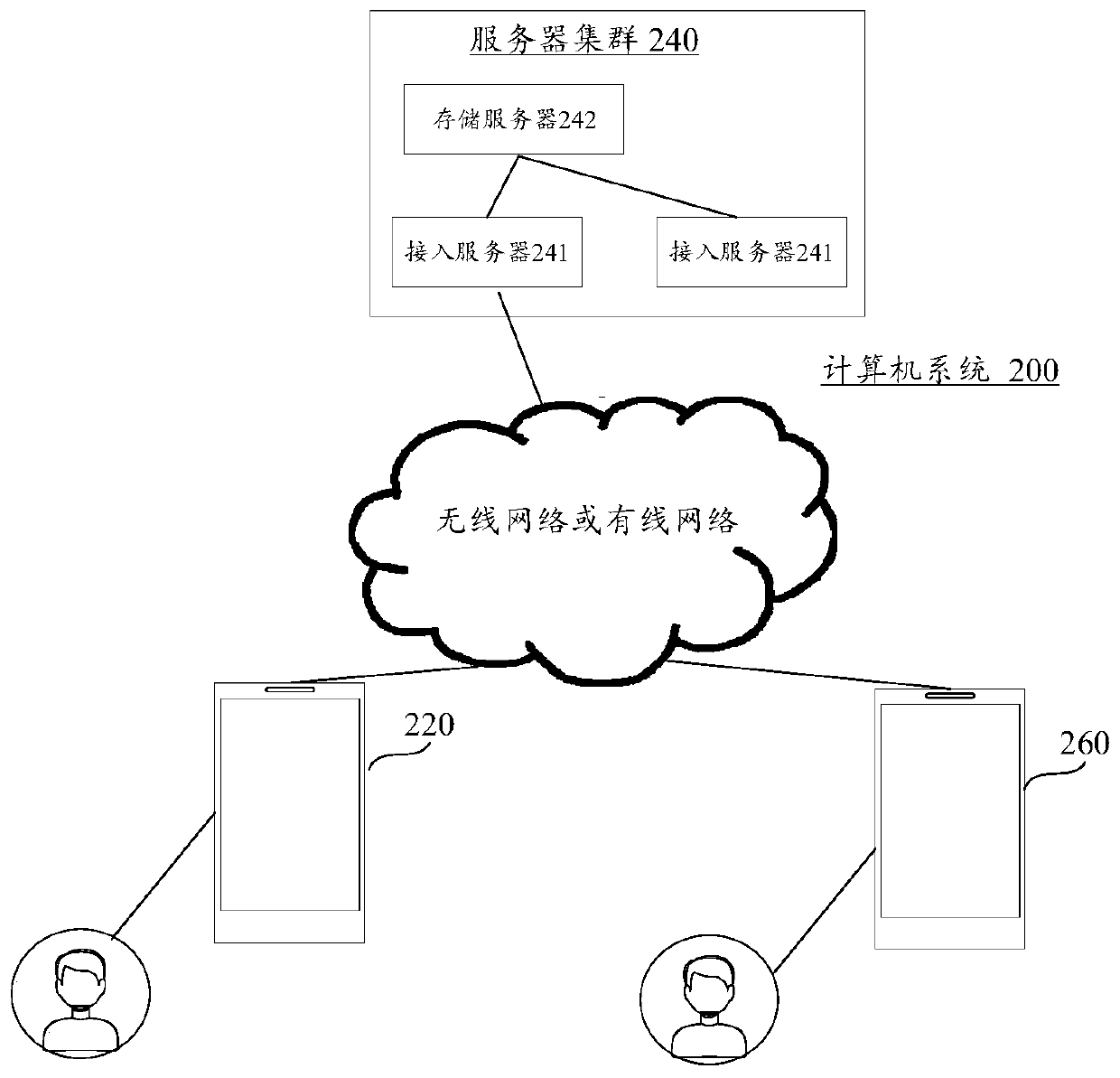

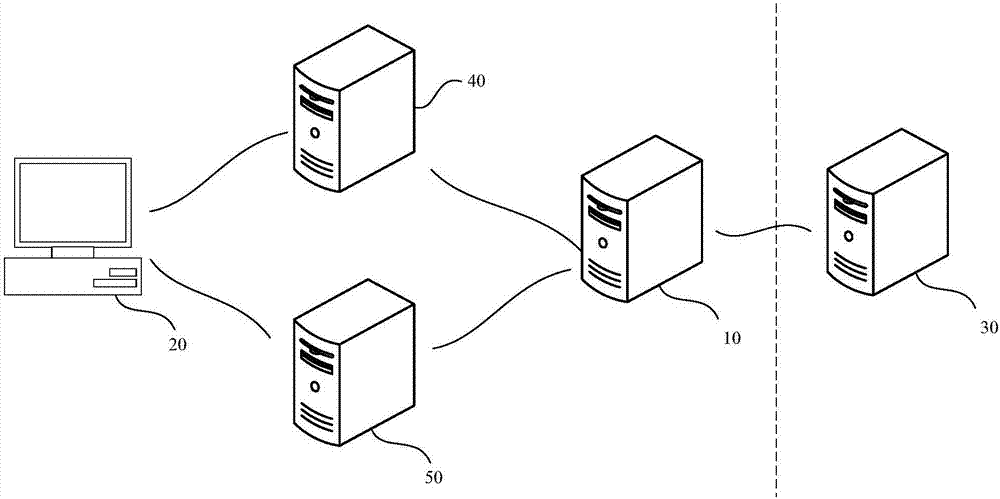

Database synchronization method and device

ActiveCN104809202AAvoid less efficientImprove efficiencySpecial data processing applicationsData informationData request

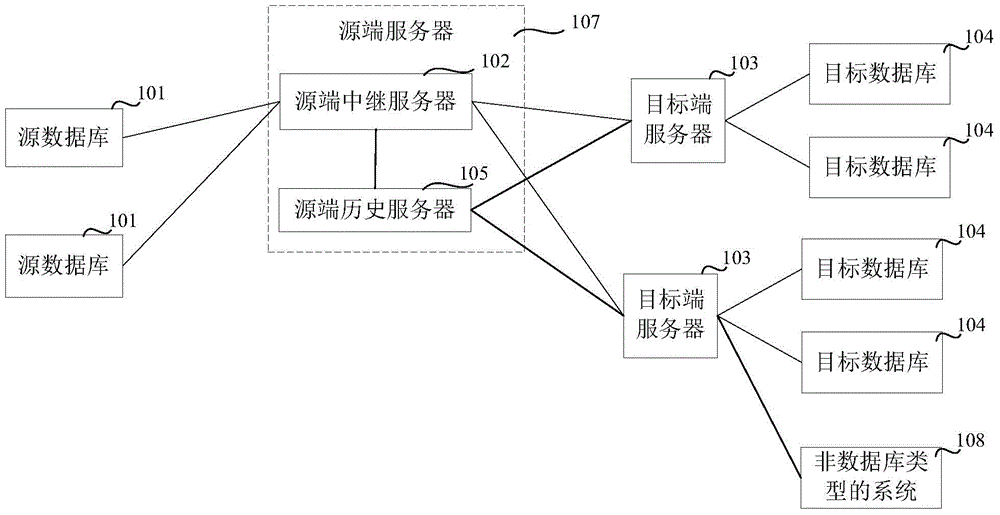

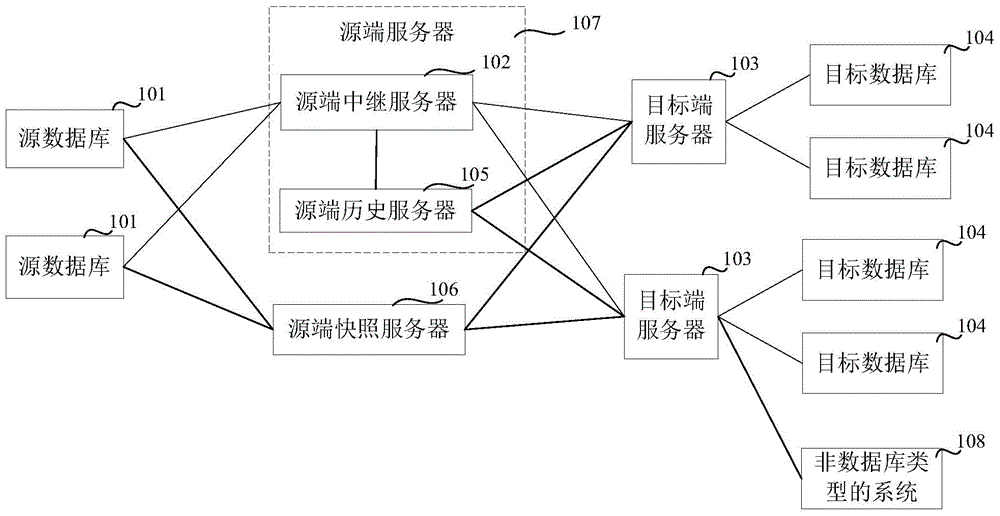

The embodiment of the invention relates to the technical field of databases, in particular to a database synchronization method and a database synchronization device, which are used for improving the initialization efficiency in a data synchronization process of a target database. According to the database synchronization method and the database synchronization device, a total data request message is sent to a source snapshotting server by a target server, determined total data information is sent to the target server by the source snapshotting server, so that a total data snapshotting document is obtained by the target server according to the total data information, and the total data snapshotting document is led into the target database, and thus, the initialization process of the target database is finished, thereby realizing automatic initialization control in the data synchronization process of the target database and improving the initialization efficiency in the data synchronization process of the target database.

Owner:UNION MOBILE PAY

Internet key management protocol re-negotiation authentication method and device

ActiveCN106169952AGuaranteed successEnsure safetyKey distribution for secure communicationThe InternetProtocol for Carrying Authentication for Network Access

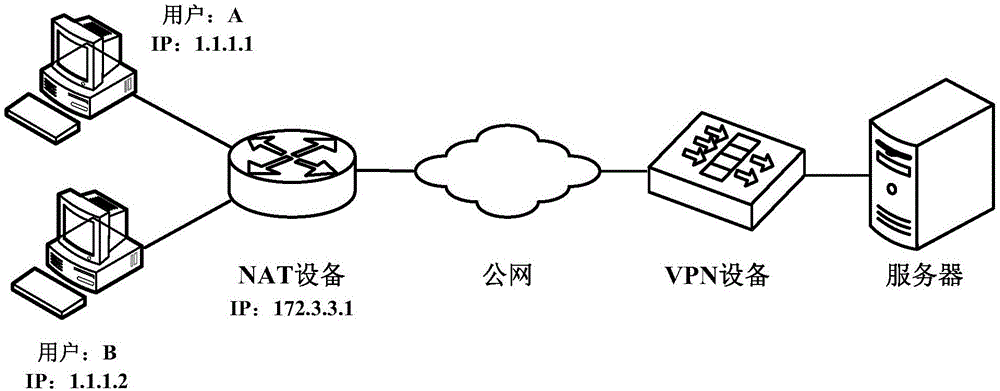

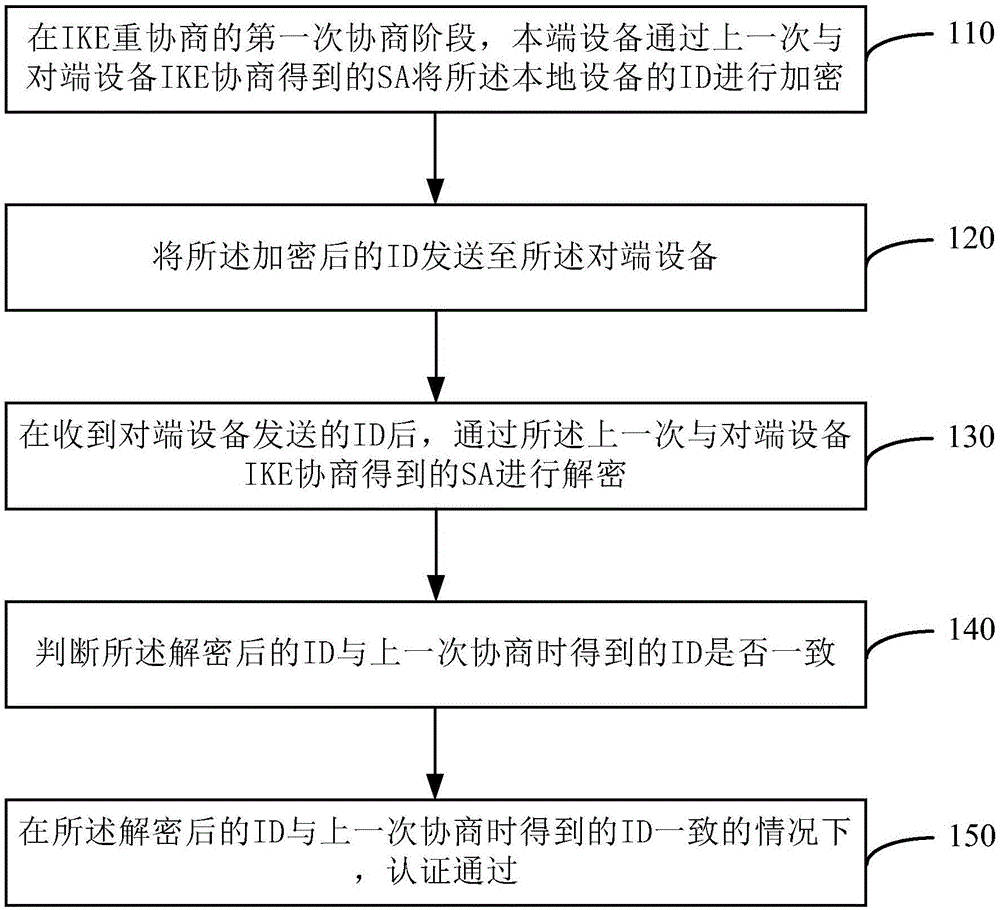

The present invention provides an internet key management protocol (IKE) re-negotiation authentication method and device. The method comprises: in the first negotiation stage of the IKE renegotiation, a device at one end performs encryption of the ID of a local device through the SA obtained by IKE renegotiation between the device at one end and the device at an opposite end at the last time; the encrypted ID is sent to the device at the opposite end; after the ID sent by the device at the opposite end is received, the decryption is performed through the SA obtained by the IKE renegotiation between the device at one end and the device at an opposite end at the last time; it is determined whether the decrypted ID is consistent to the obtained ID at the negotiation at the last time or not; and the authentication passes in the condition that the decrypted ID is consistent to the obtained ID at the negotiation at the last time. According to the embodiment of the invention, the safety can be ensured in the re-negotiation process of the internet key management protocol with no need for performing the EAP authentication.

Owner:HANGZHOU DPTECH TECH

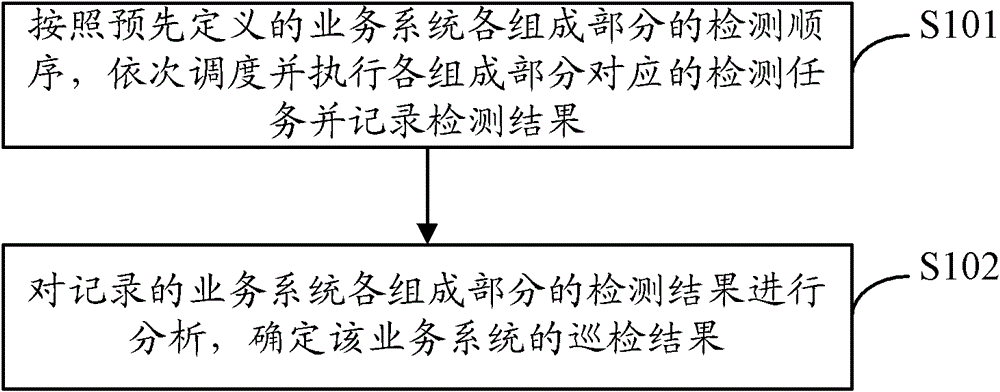

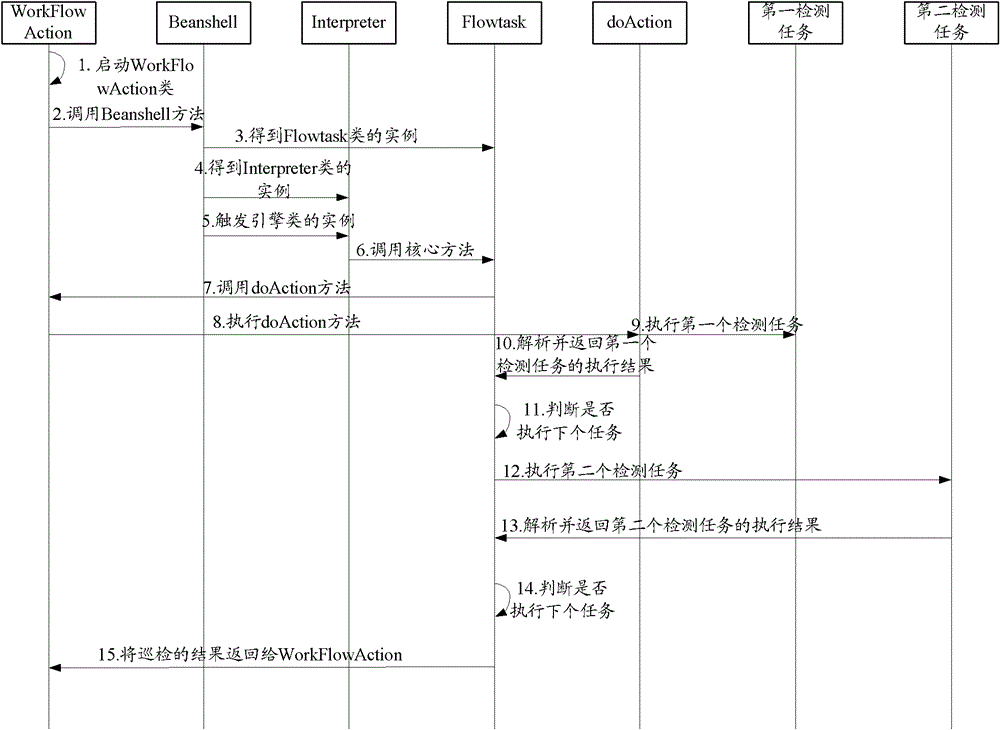

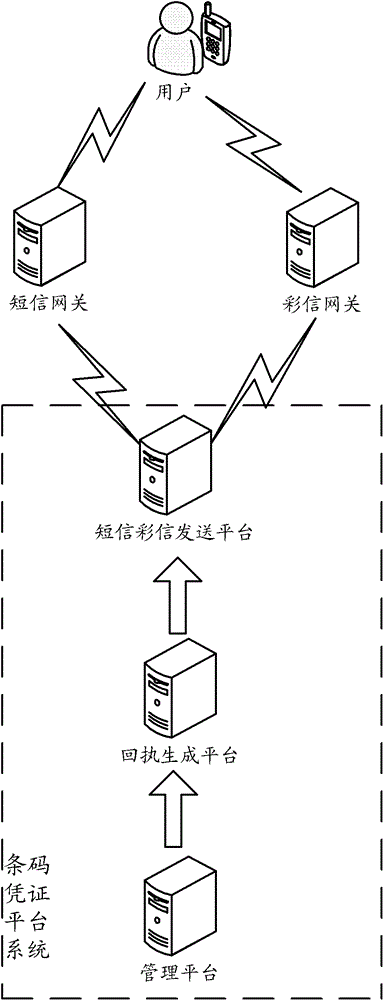

Method and device for polling service system

ActiveCN102752770ADetection intelligenceAvoid less efficientWireless communicationComputer scienceAutonomation

The invention discloses a method and a device for polling a service system. The method comprises the following steps of: scheduling and executing a detection task corresponding to each component in sequence and recording a detection result according to the predefined detection sequence of each component of the service system; and analyzing the recorded detection result of each component of the service system to determine the polling result of the service system. By using the method and the device, a multitask-scheduling automatic detection method is adopted; the detection of the different index parameters of each component of the service system can be realized; the intelligent and flow-way detection is realized; and the problem of lower efficiency brought about as a semi-artificial polling way of configuring a corresponding task script is respectively adopted for each part in the service system in the prior art is avoided.

Owner:CHINA MOBILE GRP BEIJING

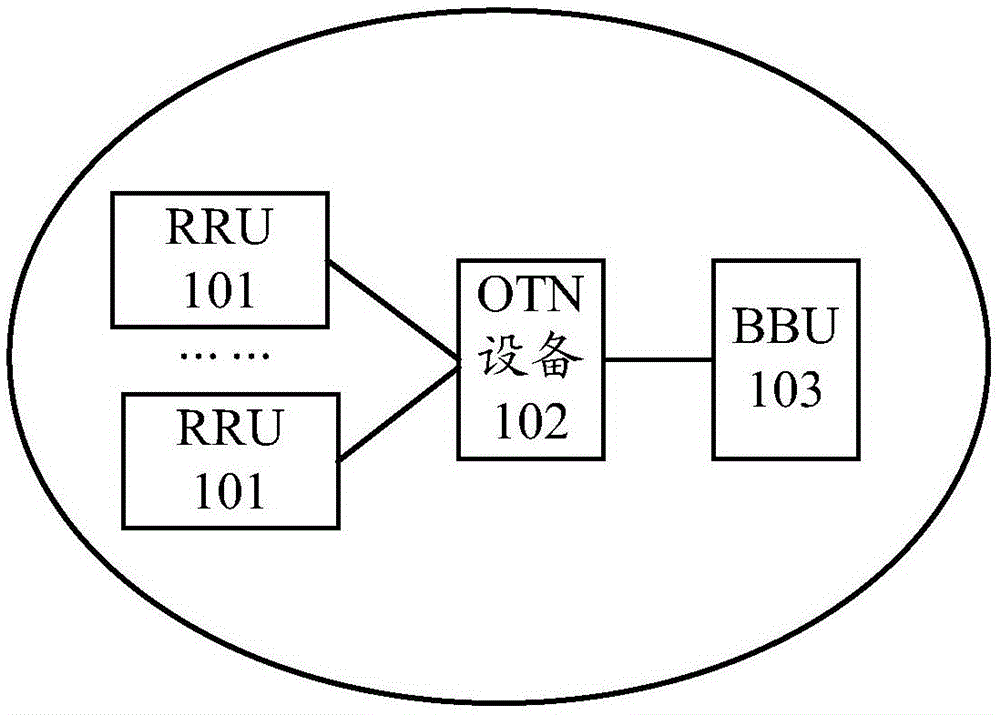

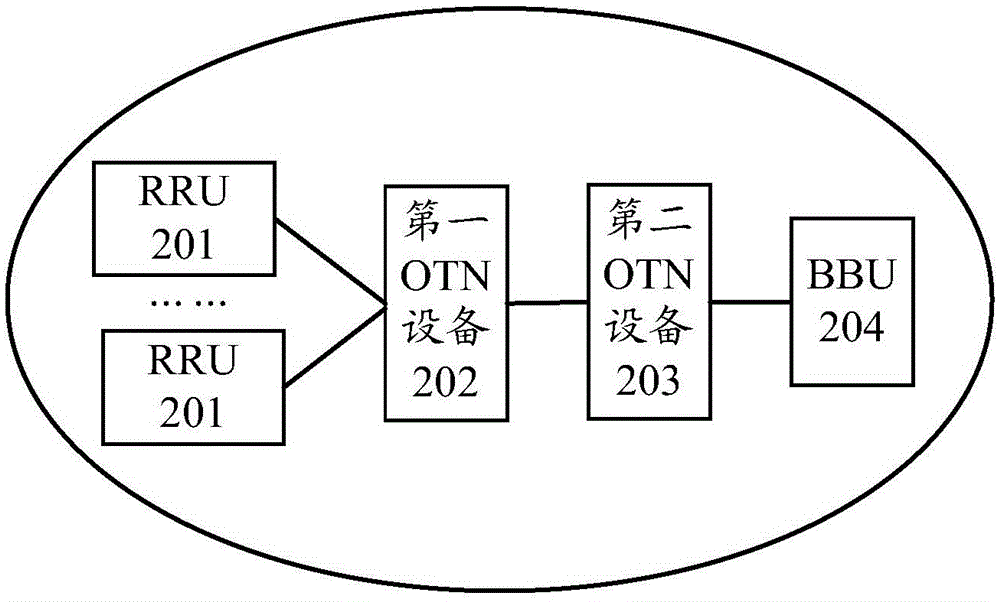

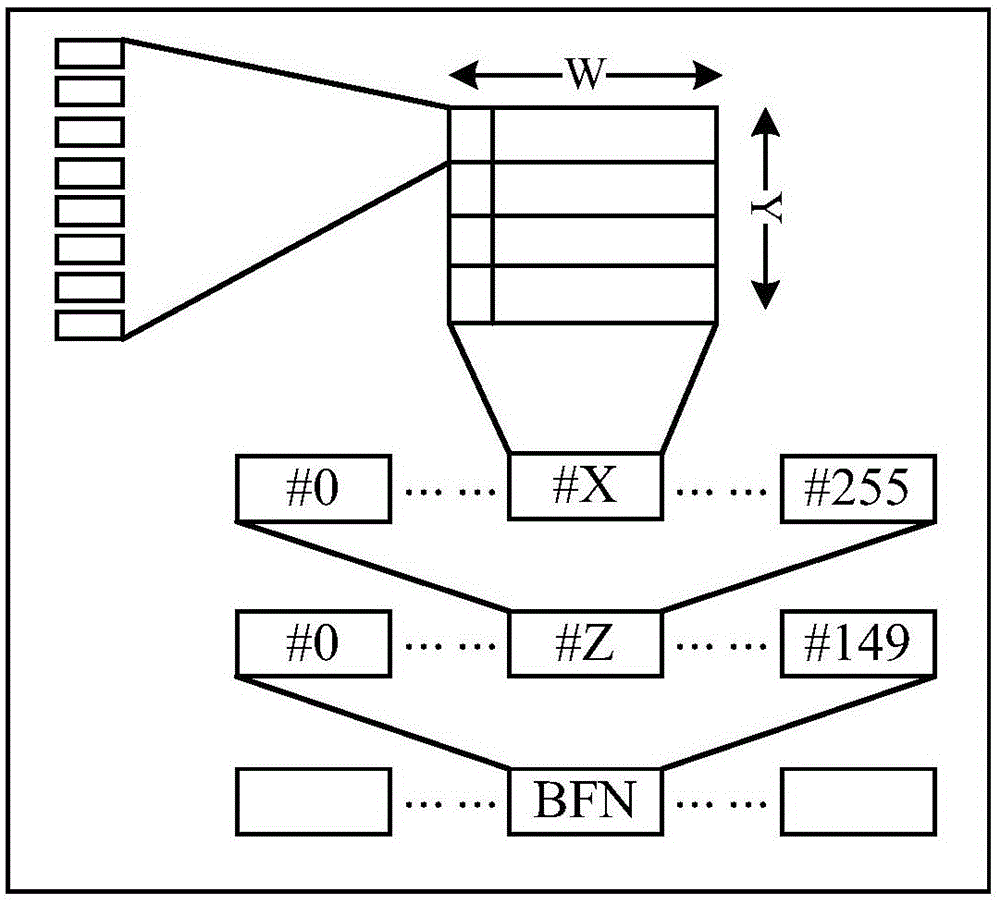

Method for data transmission and equipment

ActiveCN106712893AAvoid less efficientOmit transmission bandwidthError preventionSynchronisation by photonic/optical meansParallel computingCommon Public Radio Interface

The embodiment of the invention provides a method for data transmission and equipment. The method comprises: synchronization header indication information for indicating a frame header position of a first code stream is determined, wherein the first code stream is obtained by encoding on common public radio interface (CPRI) service data; decoding is carried out on the first code stream to obtain a second code stream, wherein the first code stream is a 10B code stream and the second code stream is an 8B code stream or the first code stream is a 66B code stream and the second code stream is a 64B code stream; frame header indicating information for indicating a frame header position of the second code stream is inserted in the second code stream according to the synchronization header indication information; and the second code stream and the frame header indicating information are mapped into an OPU of an ODU frame. According to the method provided by the invention, decoding is carried out on the 10B code stream / 66B code stream to obtain the 8B code stream / 64B code stream and the frame header indicating information for indicating the frame header position is inserted, so that a self-defined frame is formed. The self-defined is mapped to a playload region directly for transmission by peeling off costs, so that the transmission bandwidth can be saved and the data transmission efficiency can be improved.

Owner:HUAWEI TECH CO LTD

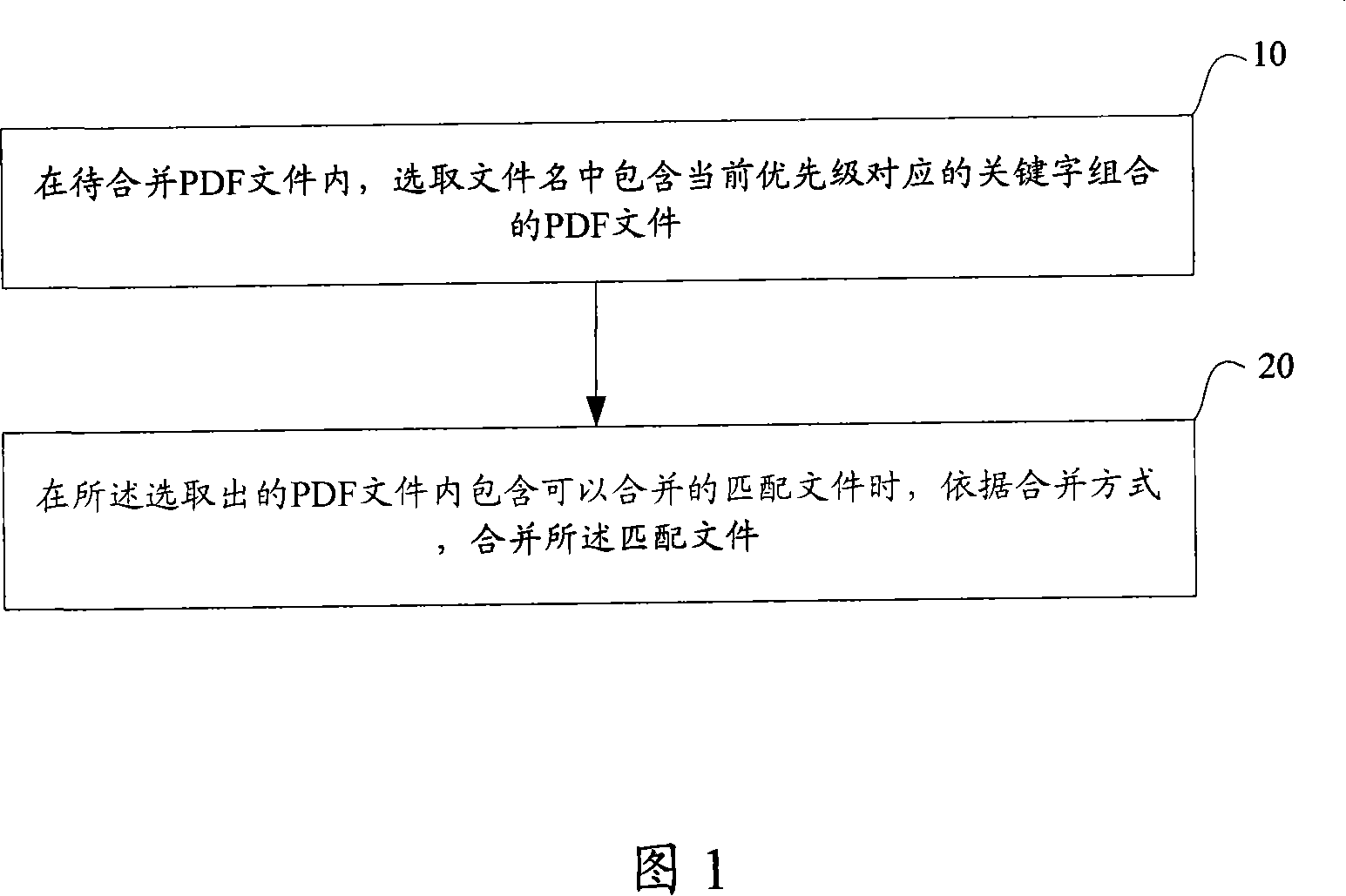

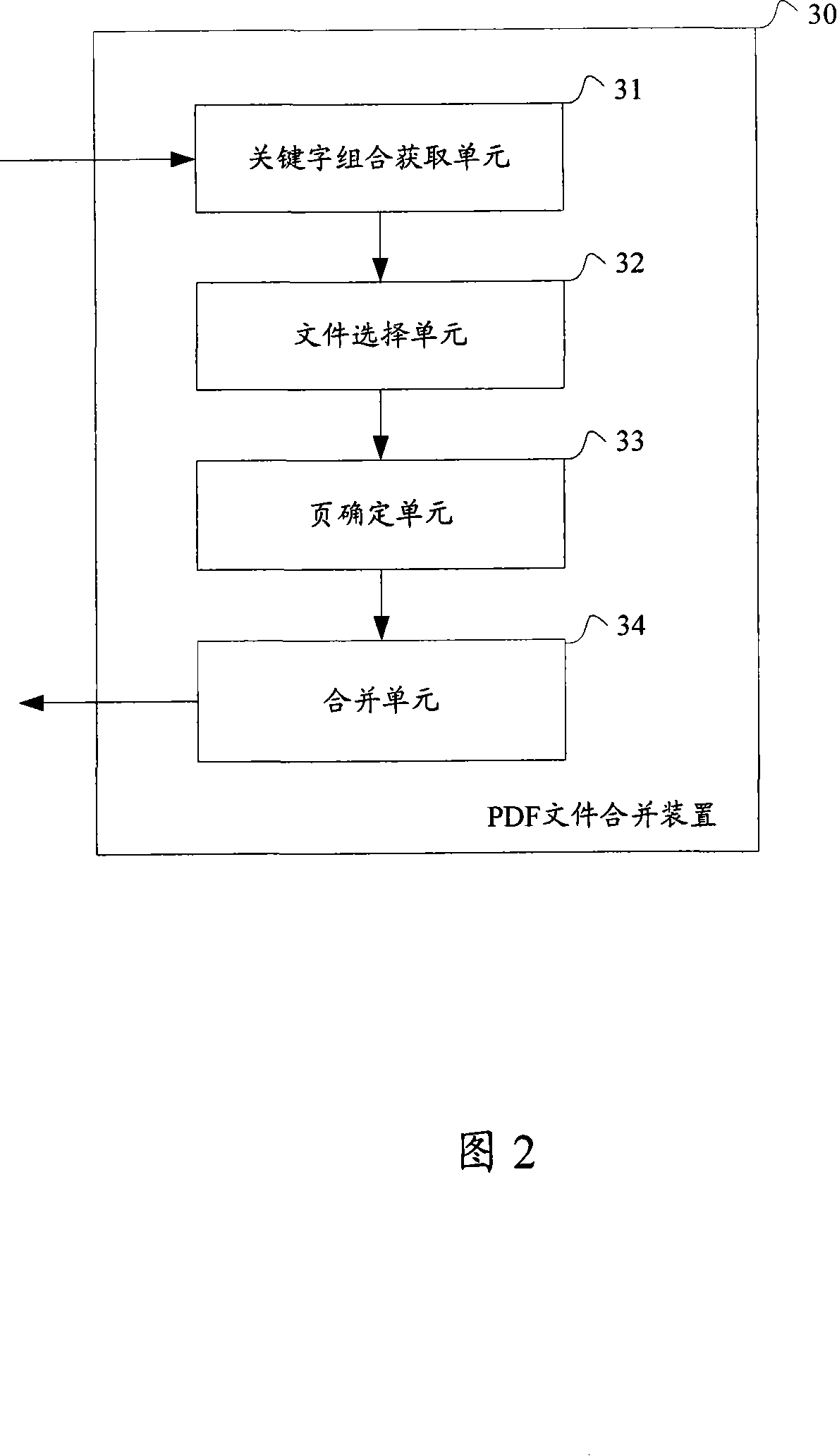

Combination method and apparatus capable of transplant document format file

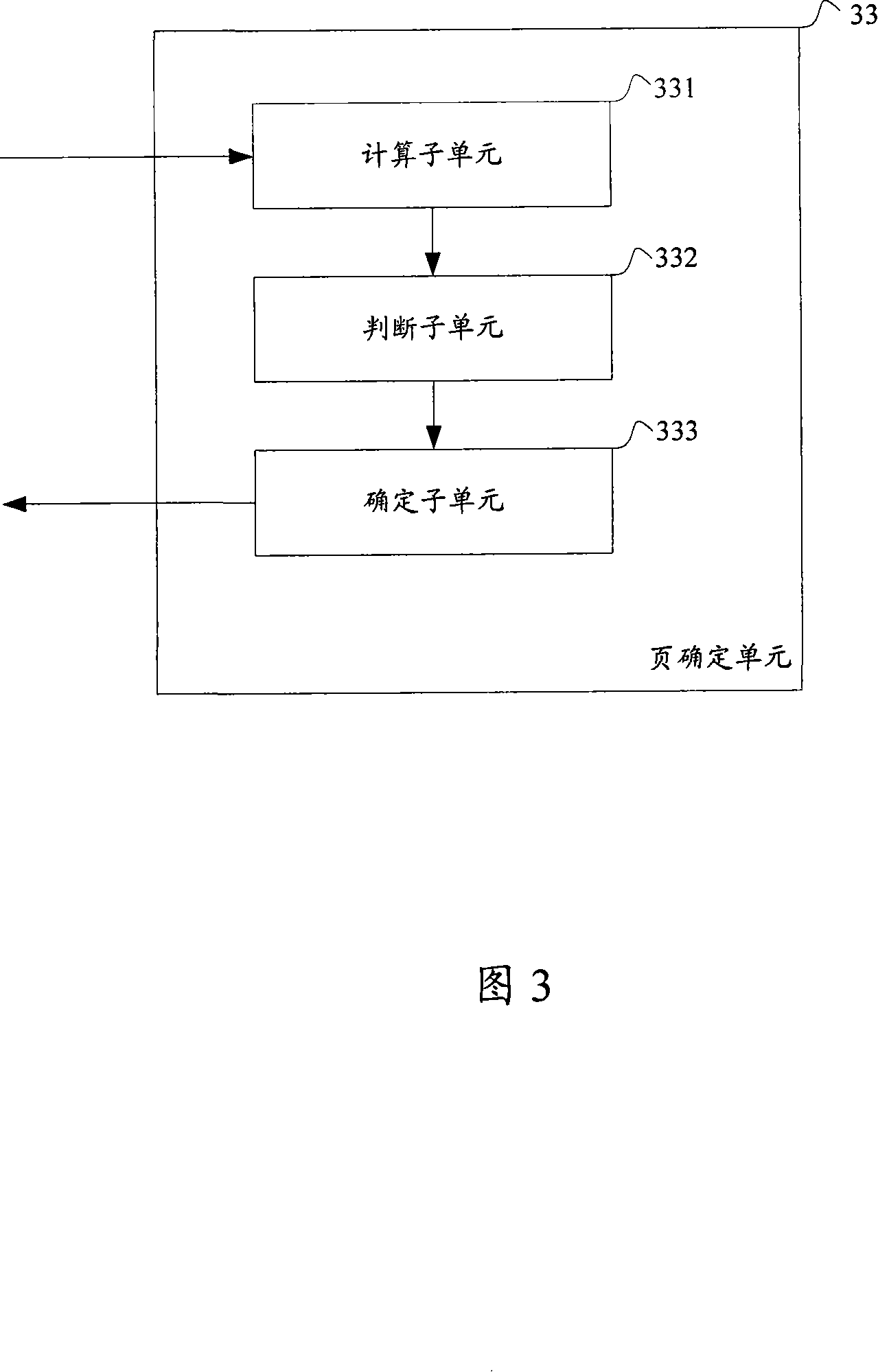

InactiveCN101140563AImplement automatic mergeAvoid less efficientSpecial data processing applicationsInput/output processes for data processingDocument formatDocumentation

The invention discloses a combination method for transportable document format files in the printing field, in order to increases combination efficiency of the transportable document format files; the invention comprises: Perform the following process to all priorities according to the sequence of high-to-low priority based on pre-determined priority in key word type combination, until all combining pages and combined pages of the files under combination are completely determined: According to the key word type combination in the current priority, acquire corresponding key word combination; execute the following process according to the each key word combination that is acquired, until all combining pages and combined pages in files under combination have been determined, or all key word combinations that are acquired are completed in treatment: In the remaining file under combination, file names that are selected includes current file under combination for key word combination; when it is identified that the selected files include combining files and combined files, determine the combining pages and combined pages; and perform combination on the determined combining pages and combined pages.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

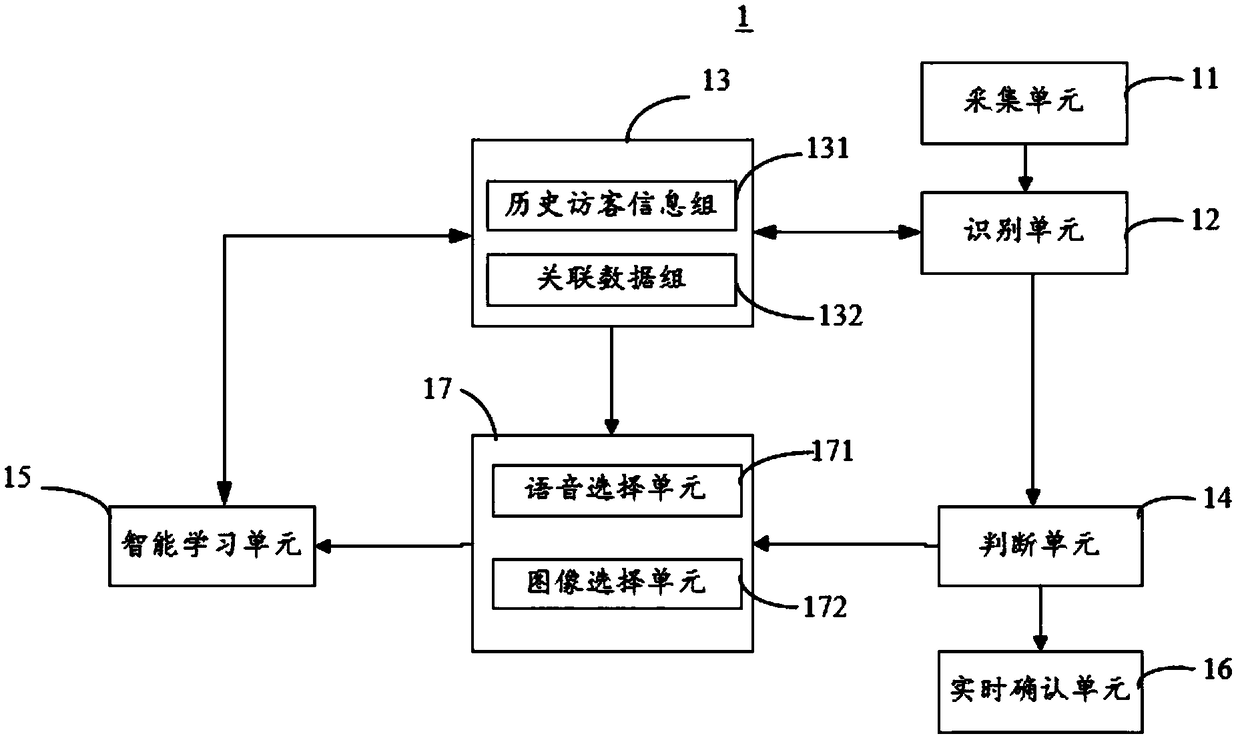

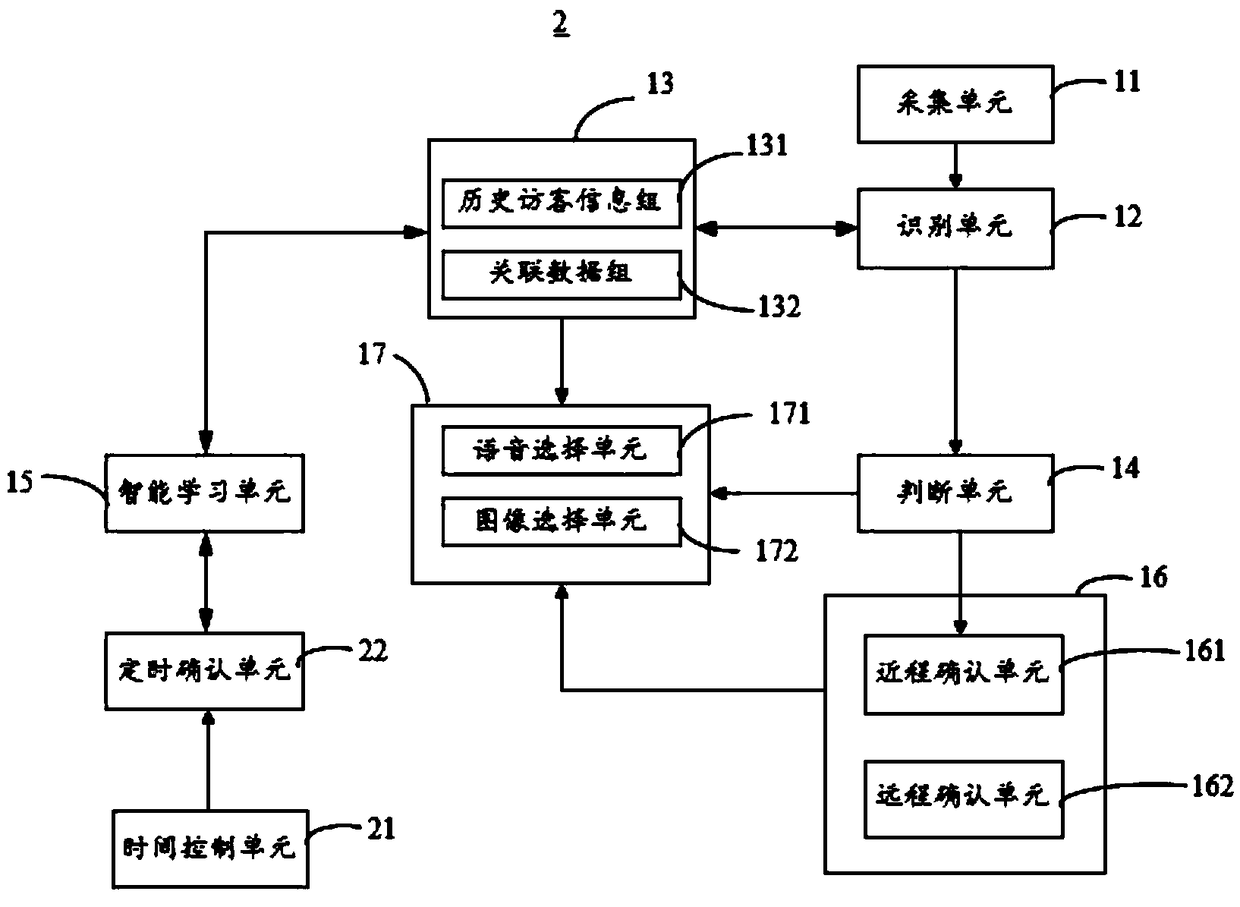

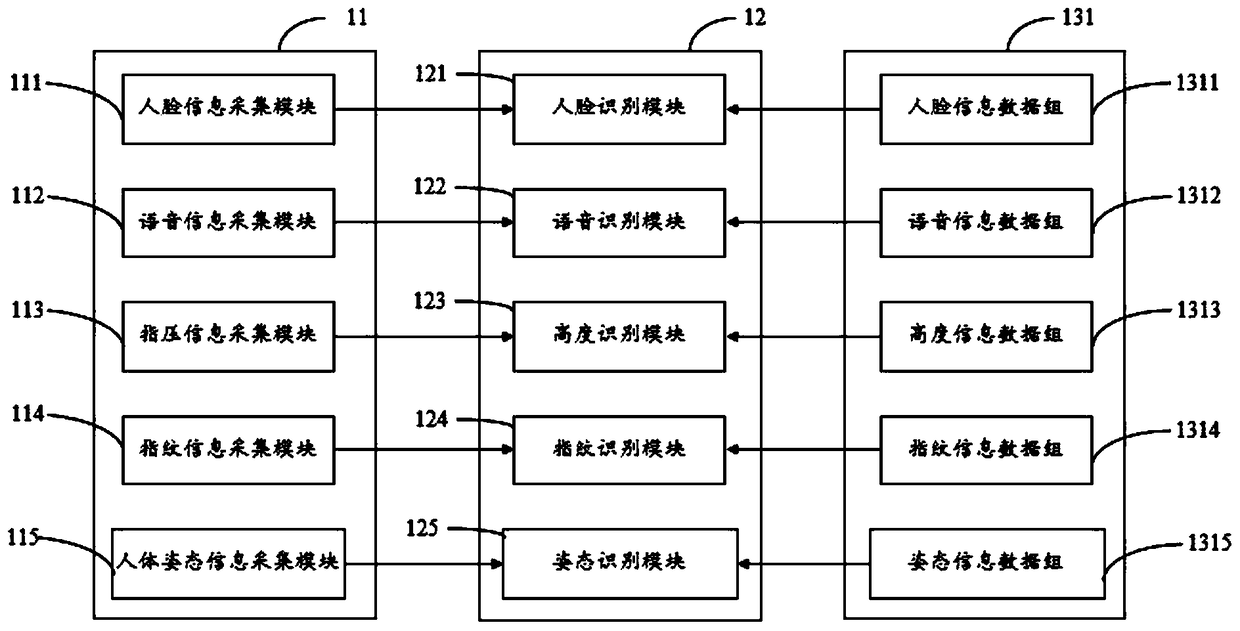

Control system for intelligent access control and control method thereof

The invention provides a control system for intelligent access control, comprising a collecting unit, an identification unit, a determination unit, a storage unit, an execution unit, an intelligent learning unit and a real-time confirmation unit. The determination unit determines whether to send the instruction information to the execution unit and whether to send the visitor information to the real-time confirmation unit. The real-time confirmation unit performs decision processing on the visitor information. The execution unit executes instructions from the determination unit and the real-time confirmation unit. The intelligent learning unit updates the historical visitor information group and the associated data group according to the visitor information and execution information of theexecution unit, performs recording and authority management on visitor information, and avoids the problem of the inefficiency in the existing technology due to frequent verification of visitors. Thecontrol system for intelligent access control and control method thereof also provides a control method of the control system.

Owner:上海学敬会展服务中心

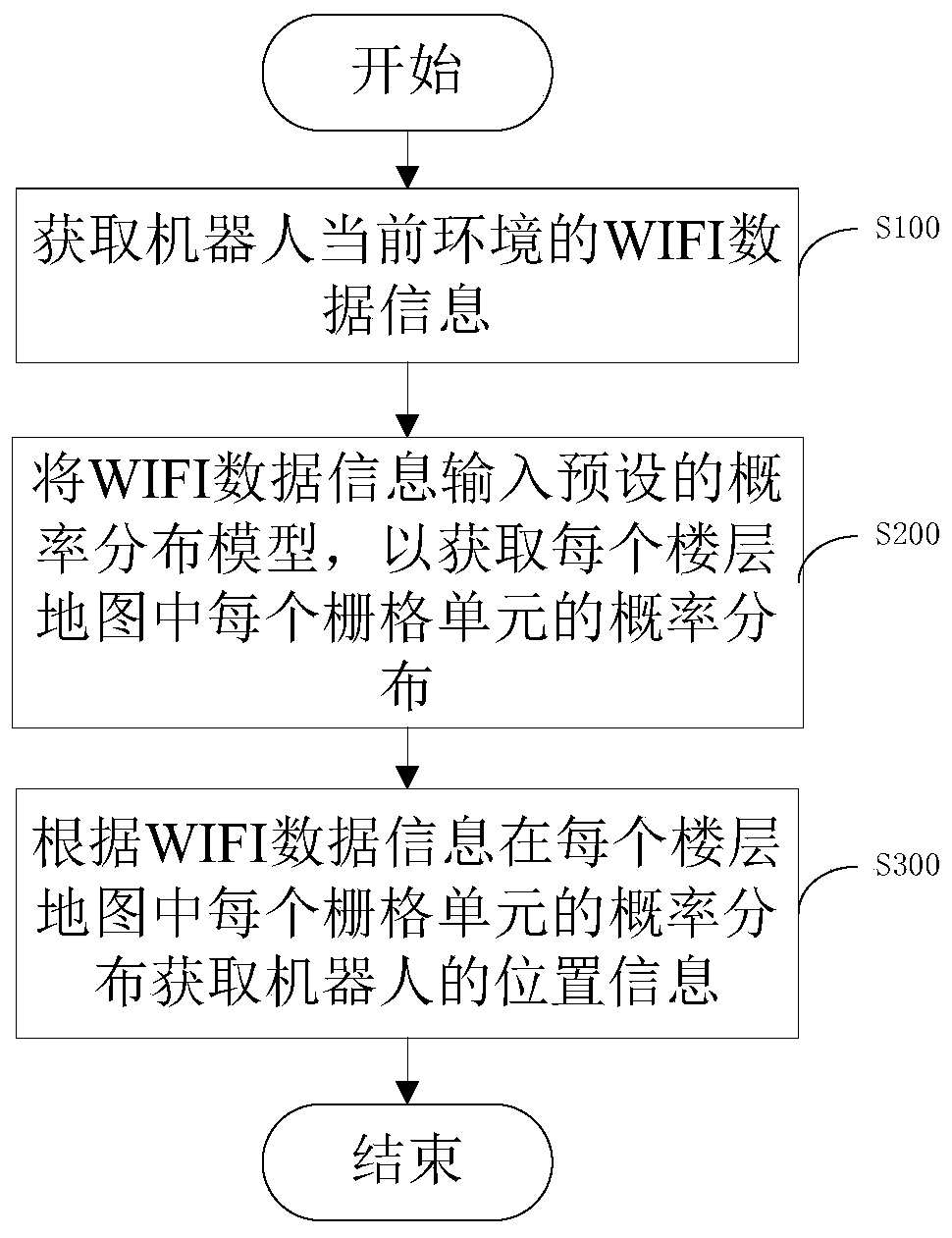

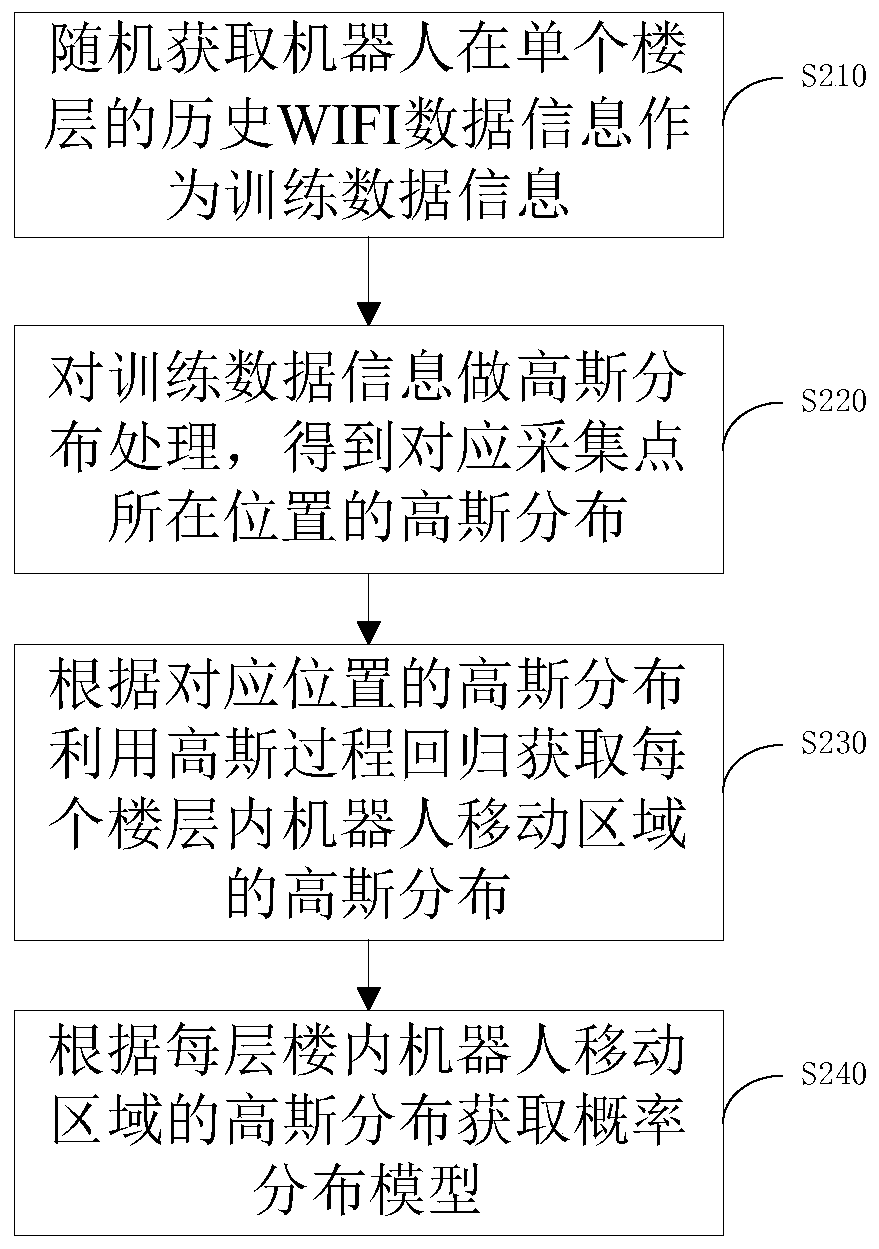

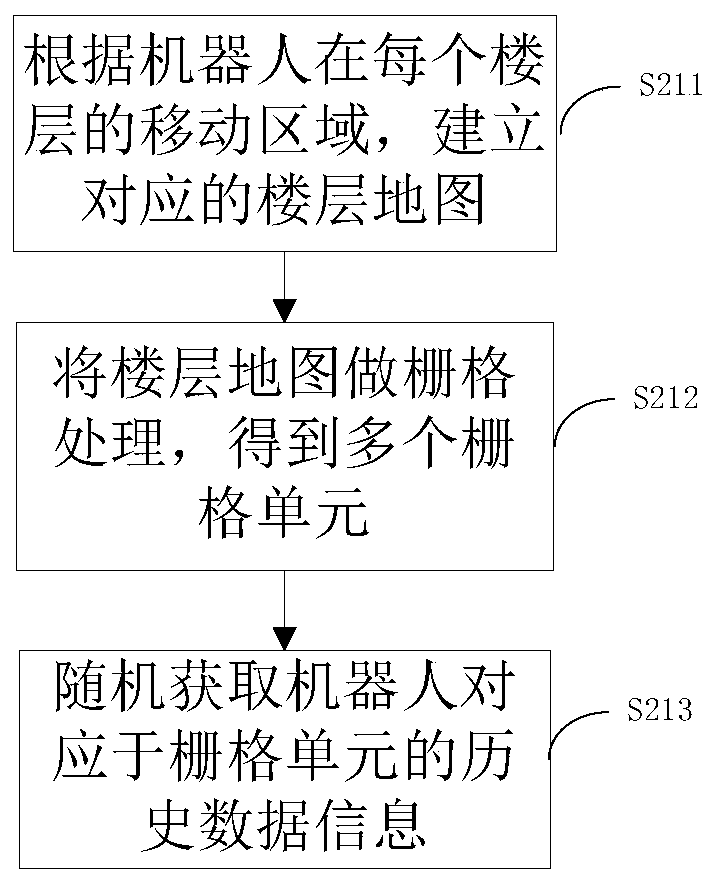

Multi-floor positioning method and system

InactiveCN110708674AImprove collection efficiencyAvoid less efficientParticular environment based servicesLocation information based serviceSimulationData source

The embodiment of the invention provides a multi-floor positioning method and system, and relates to the technical field of signal processing. The method comprises the steps of acquiring WIFI data information of the current environment of the robot; inputting the WIFI data information into a preset probability distribution model to obtain probability distribution of each grid unit in each floor map; acquiring position information of the robot according to probability distribution of the WIFI data information in each grid unit in each floor map. The problems that in an existing method, the WIFIpositioning effect is poor, WIFI data sources are manually collected, and consequently the collection efficiency of the WIFI data sources is low are solved.

Owner:北京云迹科技股份有限公司

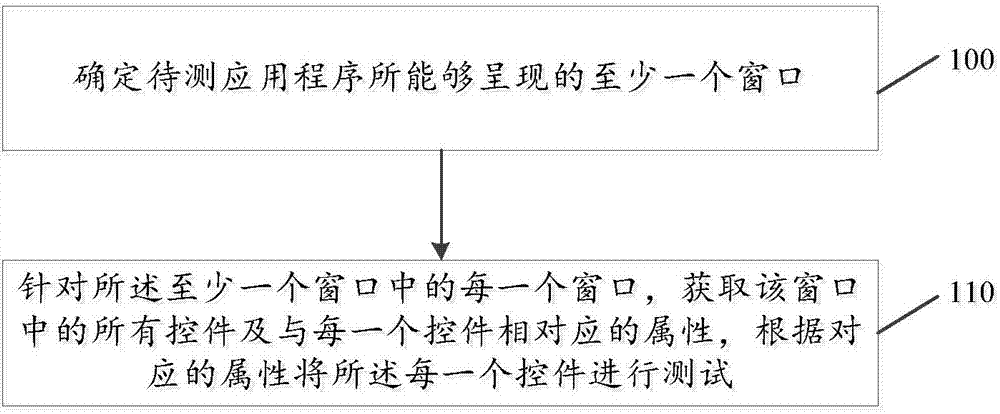

Method, device and medium for ergodic test

ActiveCN107368418AAvoid low accuracyAvoid less efficientSoftware testing/debuggingTest caseComputer engineering

The embodiment of the invention provides a method for an ergodic test. The method includes the steps of determining at least one window which can be presented by a to-be-tested application; for each window, acquiring all controls in the window and attributes corresponding to each control, and testing each control according to the corresponding attributes. According to the technical scheme, windows included in the to-be-tested application are determined firstly, the ergodic test is conducted by operating each control in each window, and since human involvement is not needed in the technical scheme, the defect of low accuracy in the prior art can be avoided; besides, a test case is not tested in the technical scheme, and therefore the defect of low efficiency in the prior art can be avoided.

Owner:网易有道信息技术(北京)有限公司

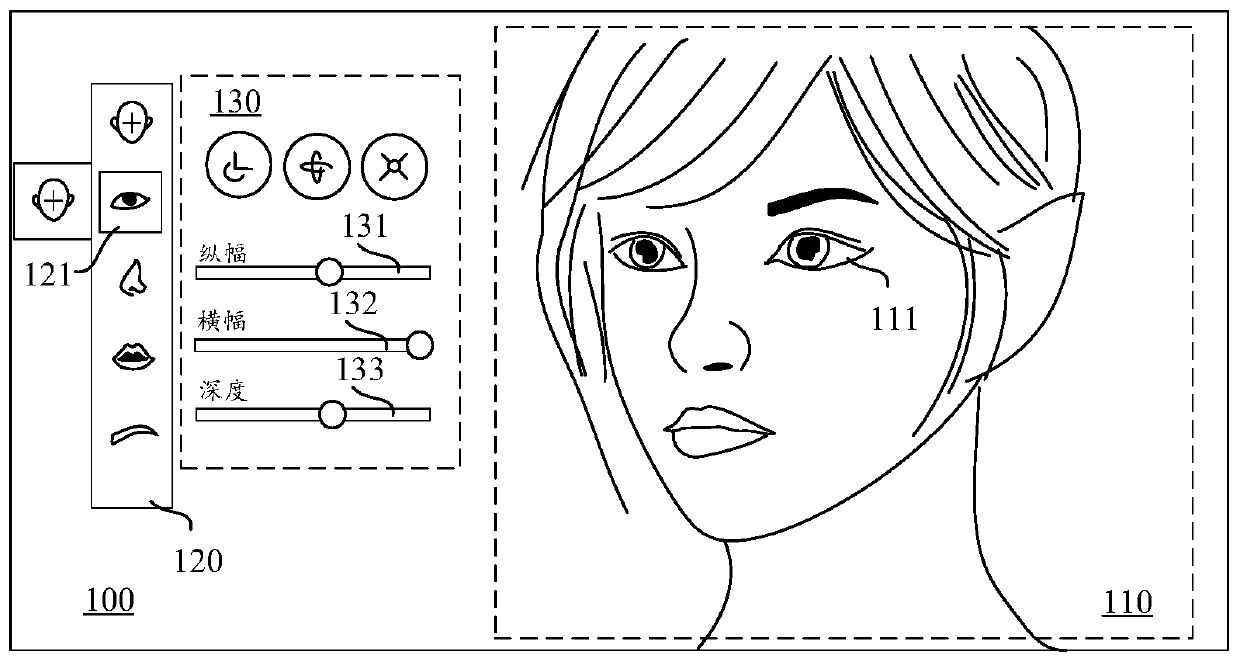

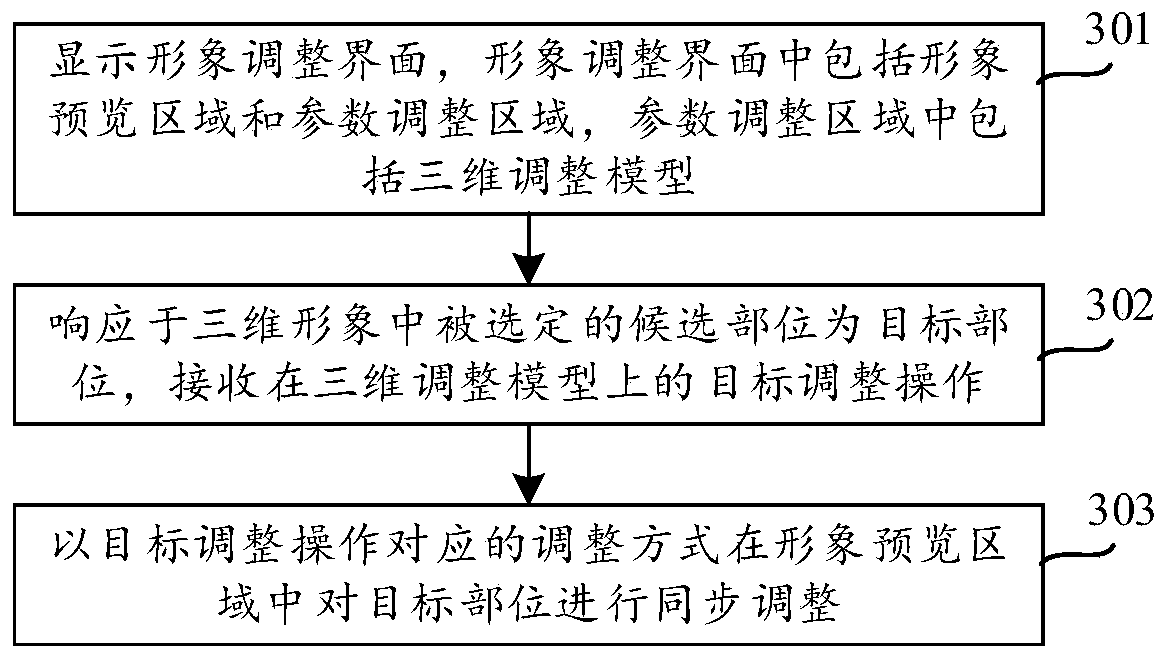

Three-dimensional image adjusting method, device and equipment and readable storage medium

ActiveCN111324250AImprove the efficiency of human-computer interactionAvoid less efficientInput/output processes for data processing3D modellingComputer graphics (images)Engineering

The invention discloses a three-dimensional image adjusting method, device and equipment and a readable storage medium, and relates to the field of three-dimensional modeling. The method comprises thesteps that an image adjustment interface is displayed, the image adjustment interface comprises an image preview area and a parameter adjustment area, and the parameter adjustment area comprises a three-dimensional adjustment model used for adjusting candidate parts in the three-dimensional direction; responding to a selected candidate part in the three-dimensional image as a target part, and receiving a target adjustment operation on the three-dimensional adjustment model; and synchronously adjusting the target part in the image preview area in an adjustment mode corresponding to the targetadjustment operation. A three-dimensional adjustment model is displayed in a parameter adjustment area; and the selected target part in the three-dimensional image is synchronously adjusted through the adjustment operation on the three-dimensional adjustment model, so that the problem of relatively low efficiency caused by accurate adjustment through multiple attempts in a mode of adjusting through a progress bar is avoided, and the human-computer interaction efficiency in the adjustment process of the three-dimensional image is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

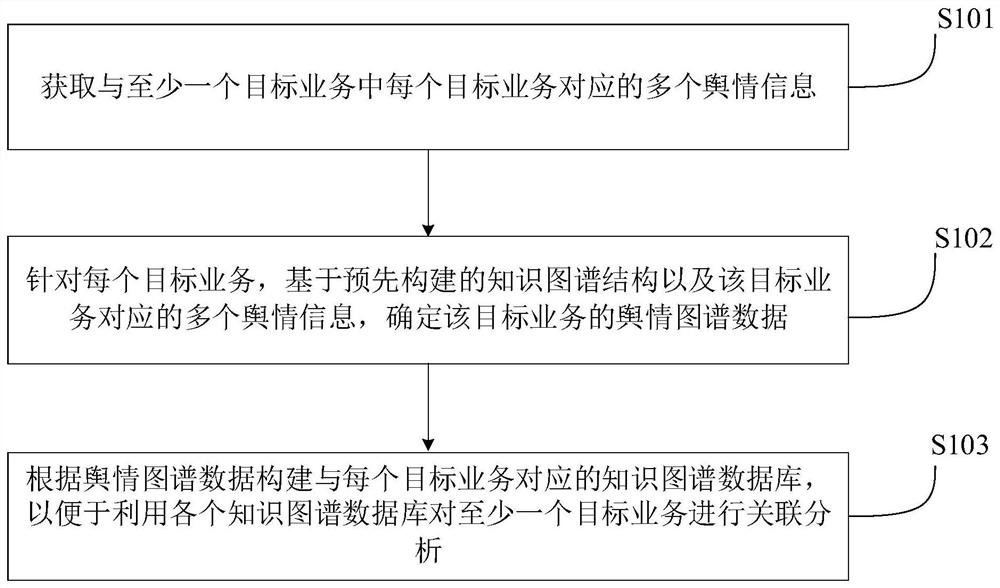

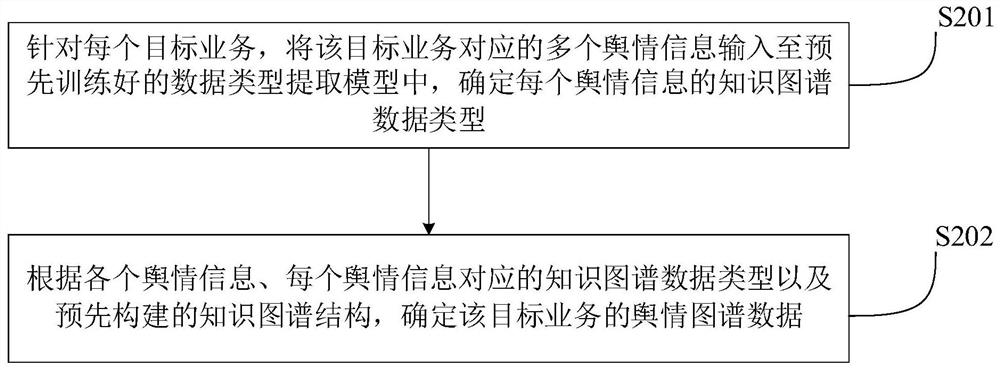

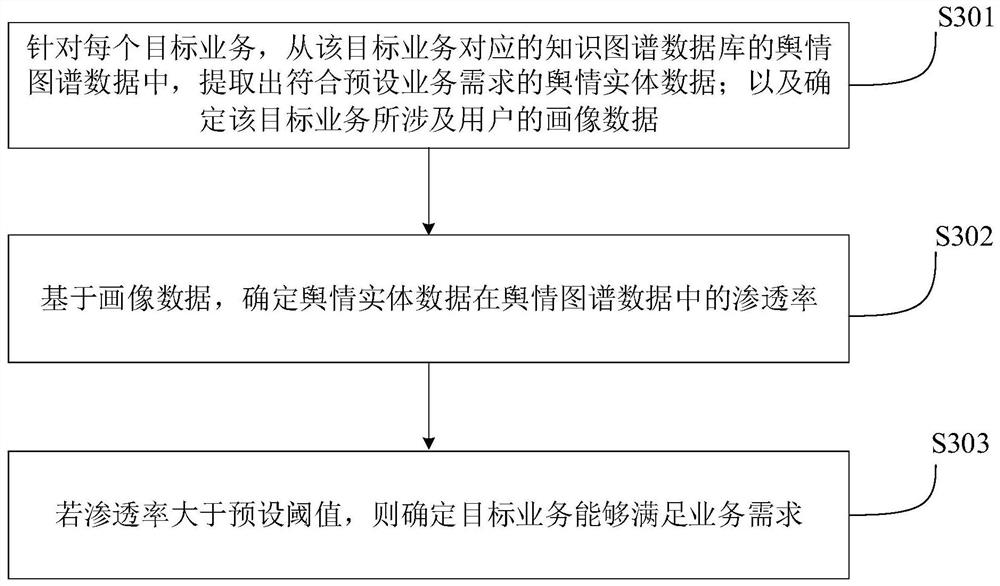

Public opinion analysis method and device, computer equipment and storage medium

PendingCN111611408ARealize automatic miningFacilitate correlation analysisSpecial data processing applicationsSemantic tool creationOpinion analysisEngineering

The invention provides a public opinion analysis method and device, computer equipment and a storage medium, and the method comprises the steps: obtaining a plurality of pieces of public opinion information corresponding to each target business in at least one target business; for each target business, determining public opinion graph data of the target business based on a pre-constructed knowledge graph structure and multiple pieces of public opinion information corresponding to the target business; and constructing a knowledge graph database corresponding to each target service according tothe public opinion graph data so as to perform association analysis on at least one target service by utilizing each knowledge graph database. By adopting the scheme, the public opinion graph data inthe public opinion information is extracted in combination with the knowledge graph structure, so that association analysis among the target services is realized through the constructed knowledge graph database, automatic mining of the public opinion information is realized, and the public opinion analysis efficiency is improved.

Owner:BEIJING MININGLAMP SOFTWARE SYST CO LTD

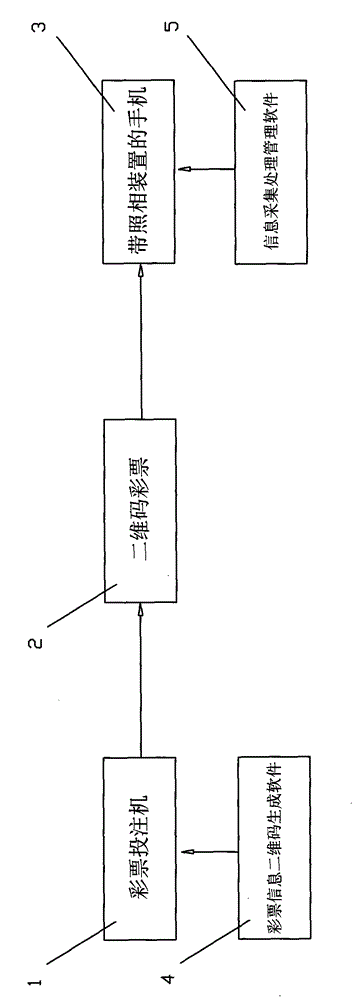

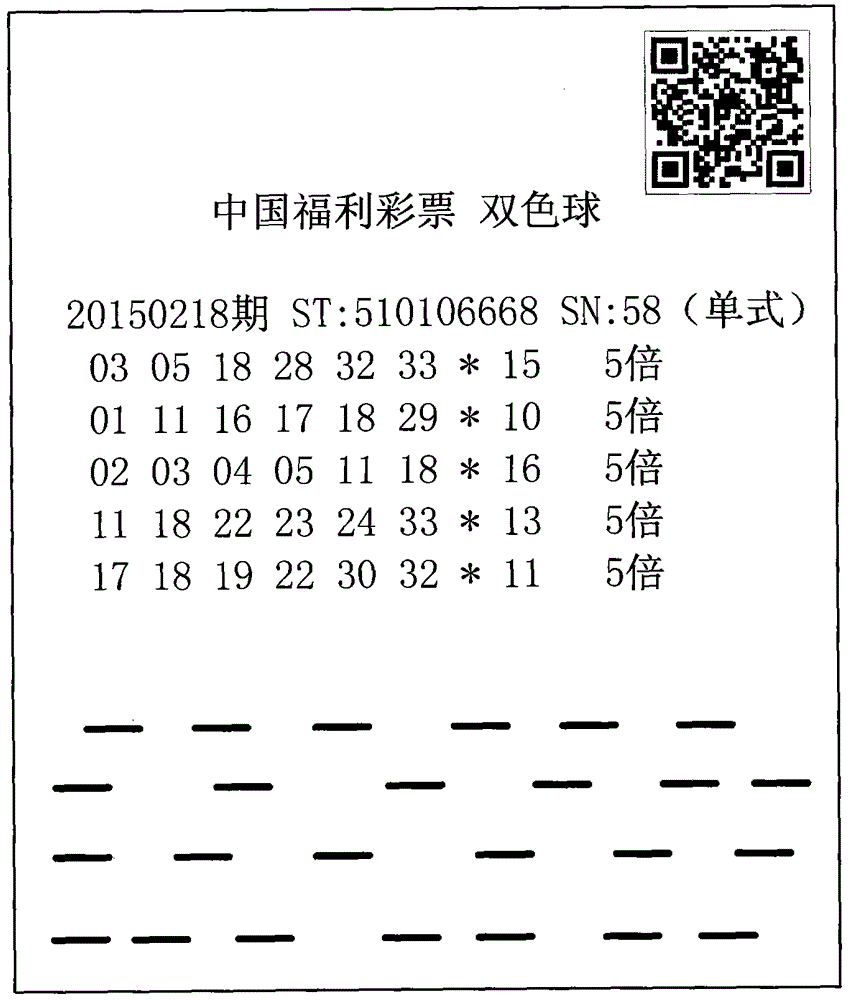

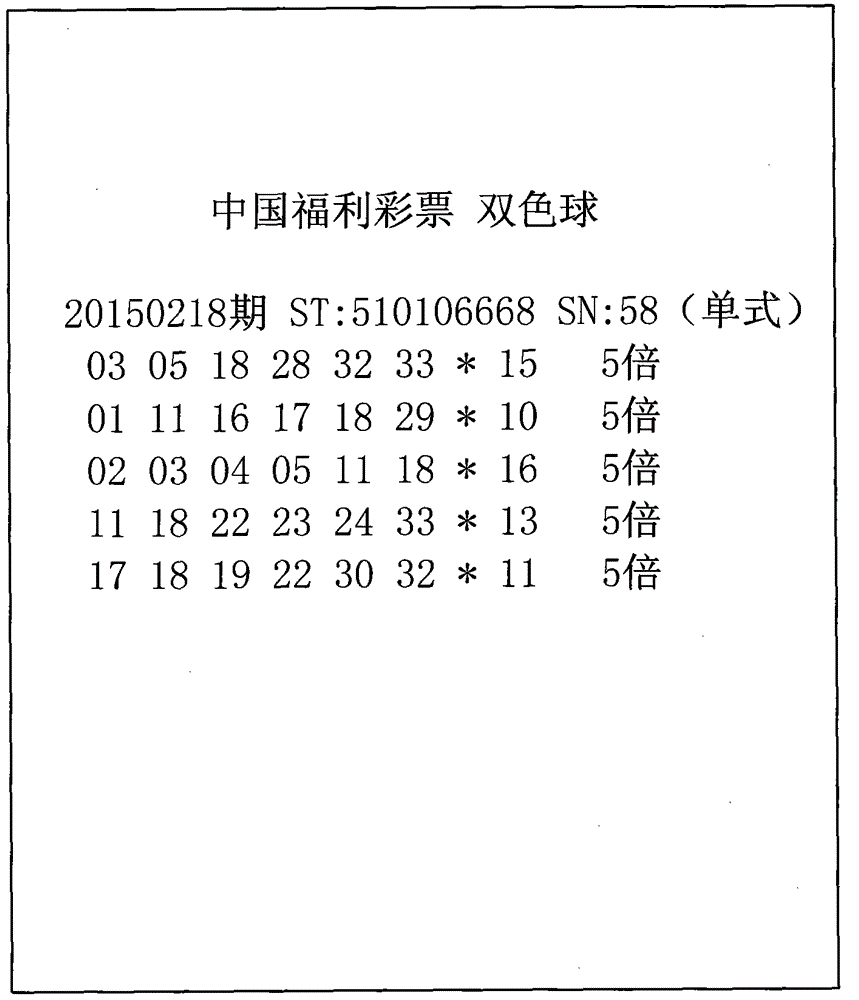

System and method of quickly obtaining lottery information

InactiveCN104835237AAvoid less efficientAvoid low recognition rateLottery apparatusSensing by electromagnetic radiationElectronic informationTheoretical computer science

The invention discloses a system and a method of quickly obtaining lottery information. The system is mainly composed of a lottery betting machine, two-dimension code lottery, a cell phone having a camera, lottery information two-dimension code generating software, and information acquisition and processing software. By means of the system, a lottery electronic information acquiring user can scanning the two-dimension code shape on a lottery by mobile phone photographing for obtaining editable lottery electronic text information. The system and the method can avoid a problem that manual re-inputting is low in efficiency, is high in labor intensity and is easy to cause mistake, and can avoid a problem that a method of photographing paper lottery text to acquire information is not high in recognition rate and is easy to cause mistake, thereby bringing convenience to the lottery electronic information acquiring user.

Owner:方文淋

Vehicle-mounted Lidar steel rail point cloud extraction method based on generalized neighborhood height difference

ActiveCN110189419AAvoid includingImprove responseImage enhancementImage analysisNeighborhood searchLidar point cloud

The invention discloses a vehicle-mounted Lidar steel rail point cloud extraction method based on generalized neighborhood height difference. The vehicle-mounted Lidar steel rail point cloud extraction method specifically comprises the following steps: 1, segmenting track bed point cloud according to a scanning angle or a track line of a vehicle-mounted Lidar point cloud; 2, adopting a statisticalfiltering algorithm to remove noise points caused by shielding factors of the steel rail in the ballast bed point cloud, and obtaining the ballast bed point cloud with the noise points removed; 3, carrying out columnar neighborhood search on one point in the ballast bed point cloud; 4, calculating the generalized neighborhood height difference of the point based on the columnar neighborhood; 5, repeating the step 3-4 until the generalized neighborhood height difference calculation of all points of the ballast bed area is completed, and a histogram is made; and 6, combining track knowledge anda generalized neighborhood height difference histogram to extract a steel rail vertex cloud. The vehicle-mounted Lidar steel rail point cloud extraction method can automatically extract the whole-line continuous steel rail vertex cloud, improves the extraction precision of the steel rail point cloud, is less in dependence on additional data, and is simple to implement.

Owner:SOUTHWEST JIAOTONG UNIV

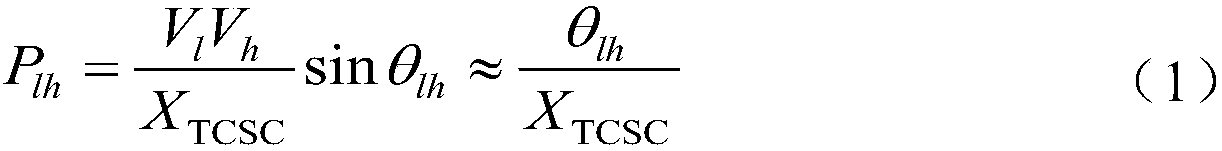

Active power steady-state security region construction method considering single TCSC (thyristor-controlled series compensation) equivalent reactance parameters

ActiveCN107732904AAvoid less efficientFlexible AC transmissionAc network circuit arrangementsSteady state securitySeries compensation

The present invention relates to an active power steady-state security region construction method considering single TCSC (thyristor-controlled series compensation) equivalent reactance parameters. According to the method, thyristor-controlled series compensation equivalent reactance parameters and node active power are combined creatively; according to a problem that an existing active power steady-state security region construction method does not consider TCSC equivalent parameters, a method of correcting the injection power of nodes is adopted to replace a method of changing the structuralparameters of a power grid to influence the distribution of power flow, so as to analyze TCSC; the display expression of an injection power space active power steady-state security region consideringsingle TCSC equivalent reactance parameters is theoretically inferred; and a problem that a traditional method needs to traverse TCSC equivalent reactance values and generate a series of active powersteady-state security regions one by one can be solved. Combined with engineering practices, the method of the invention has high analysis efficiency and can satisfy on-line steady-state security assessment.

Owner:WUHAN UNIV

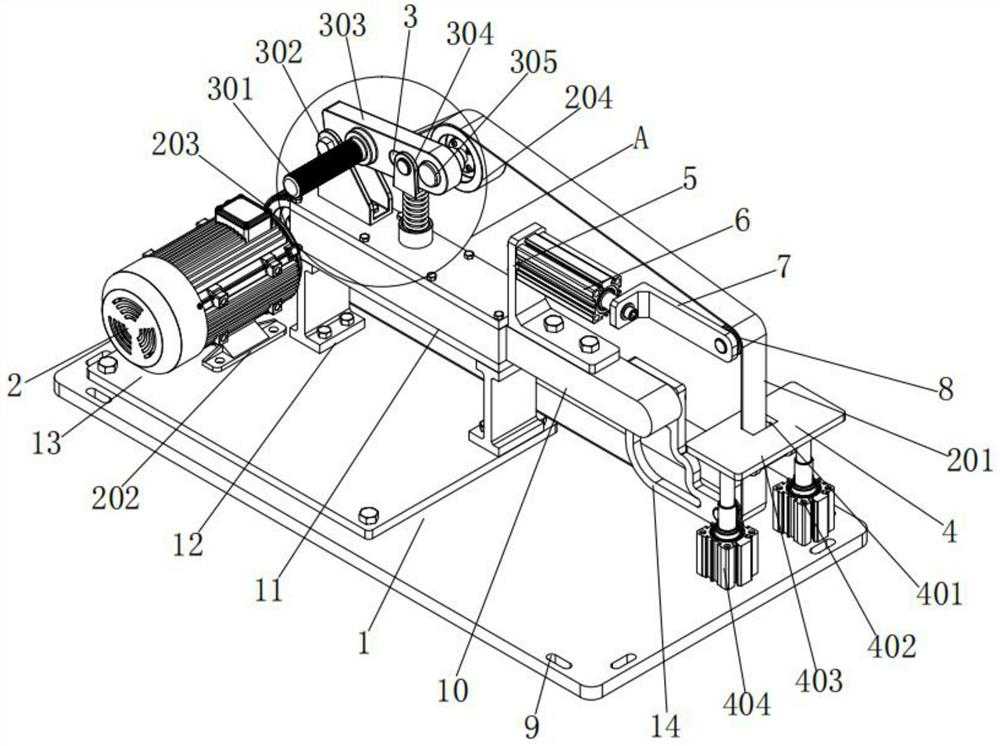

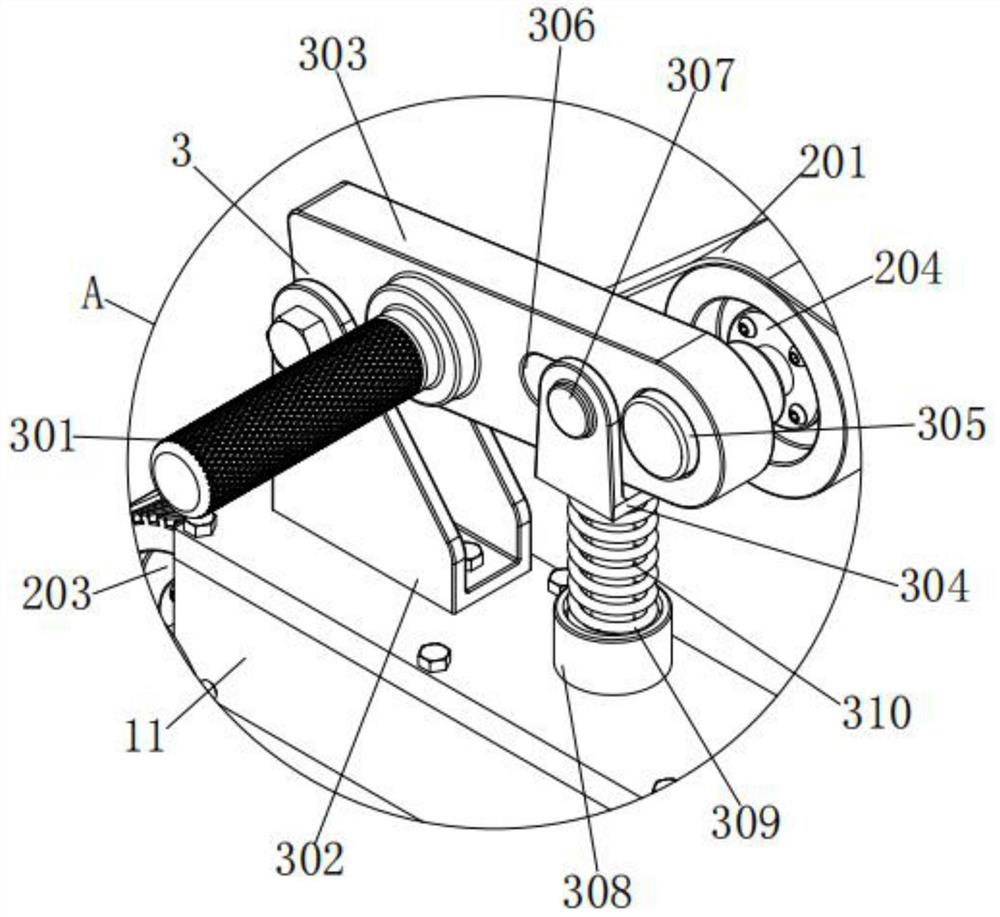

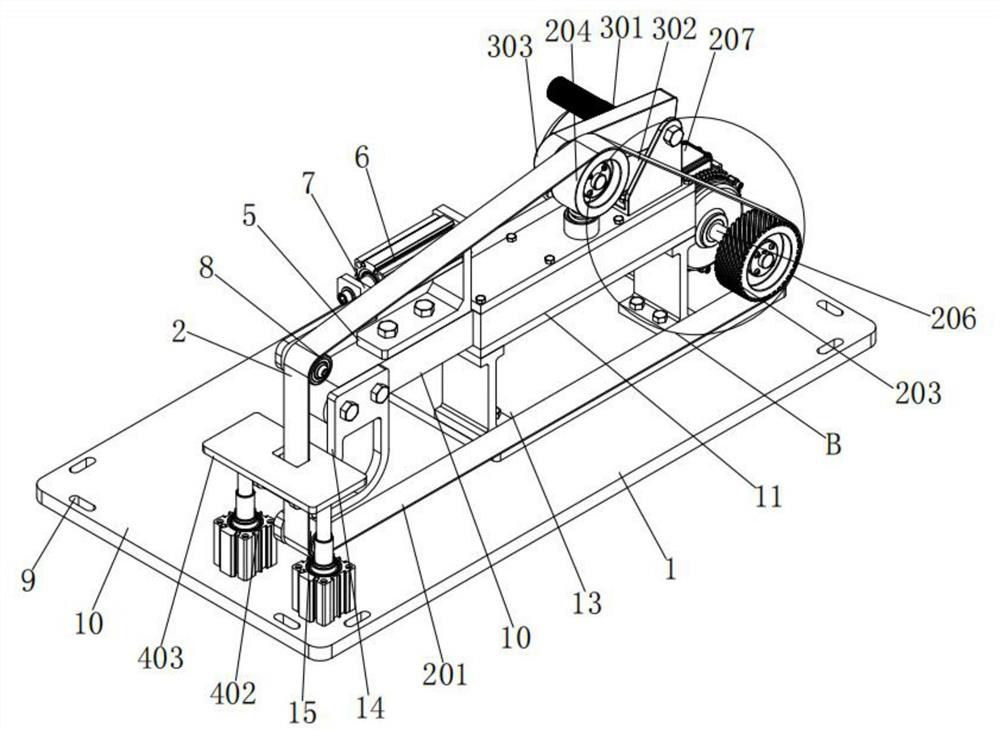

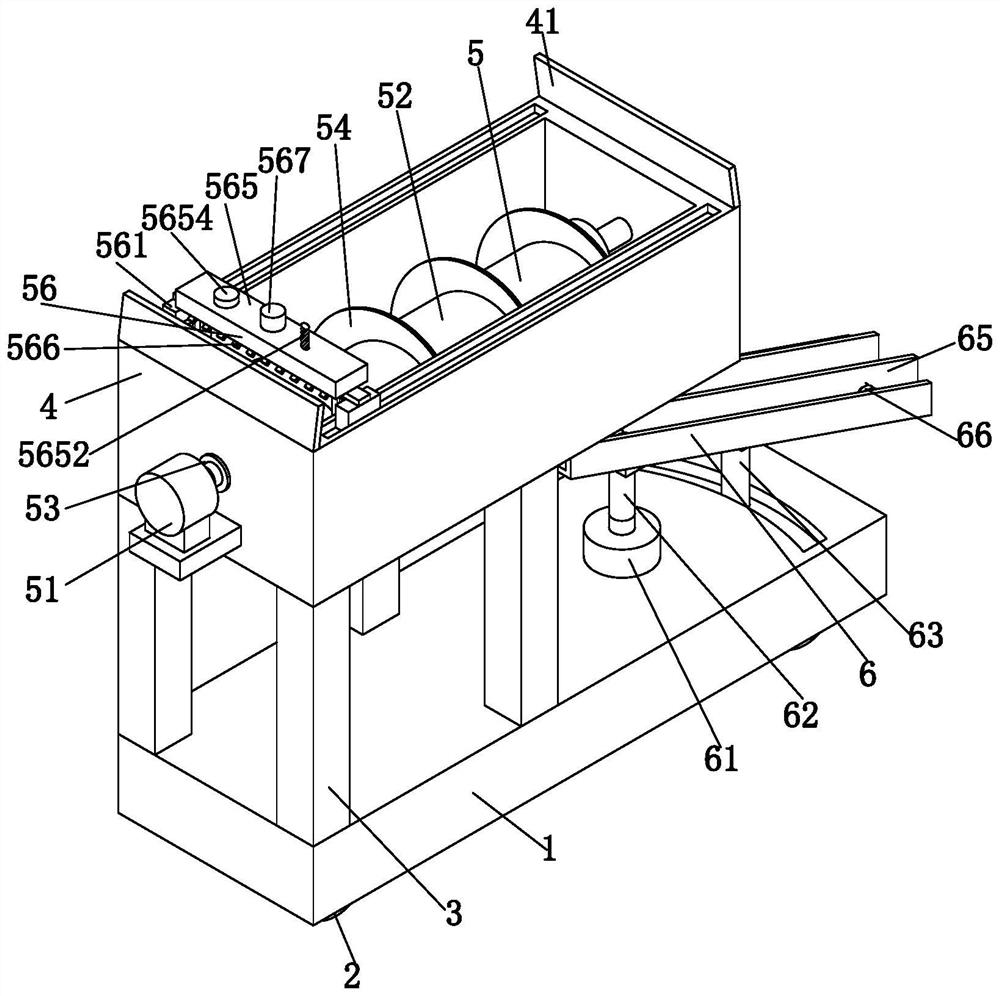

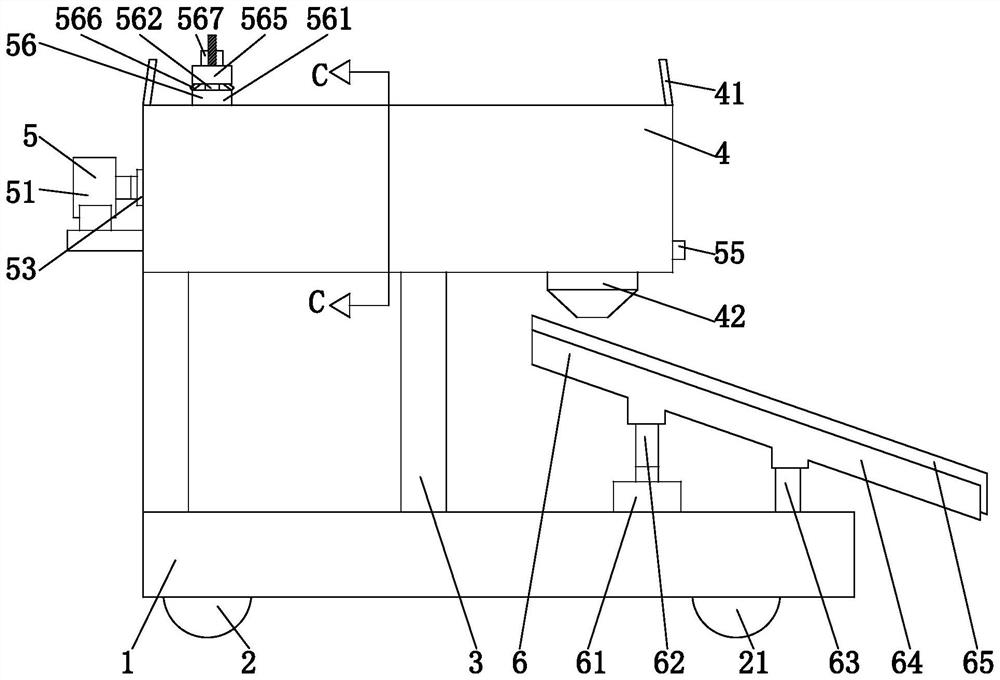

Belt sander with polishing angle adjusting function and using method thereof

PendingCN113319705AMeet different needsAvoid damageGrinding carriagesBelt grinding machinesSanderEngineering

The invention discloses a belt sander with a polishing angle adjusting function and a using method thereof, and relates to the technical field of abrasive belt sanding. The belt sander with the polishing angle adjusting function comprises a bottom plate and a base plate, and the base plate is fixedly connected to the left side of the upper end of the bottom plate; the two sides of the rear portion of the upper end of the base plate are fixedly connected with a sleeve plate through supports, and a transmission mechanism and an adjusting mechanism are installed on the two sides of the upper end of the bottom plate correspondingly. According to the belt sander with the polishing angle adjusting function and the using method thereof, through cooperation of a telescopic air cylinder, a movable round roller, an abrasive belt, a platform, a blocking roller and a fixed round roller, an output shaft of the telescopic air cylinder can stretch out to drive the movable round roller to move; compare with the prior art, an upper cylinder and a lower cylinder rotate synchronously to achieve inclination of the abrasive belt is adopted, according to the scheme, the blocking roller is matched with the movable round roller, and therefore the problem that efficiency is poor in the mode that the existing upper cylinder and the lower cylinder rotate synchronously to achieve inclination of the abrasive belt is solved.

Owner:陈国安

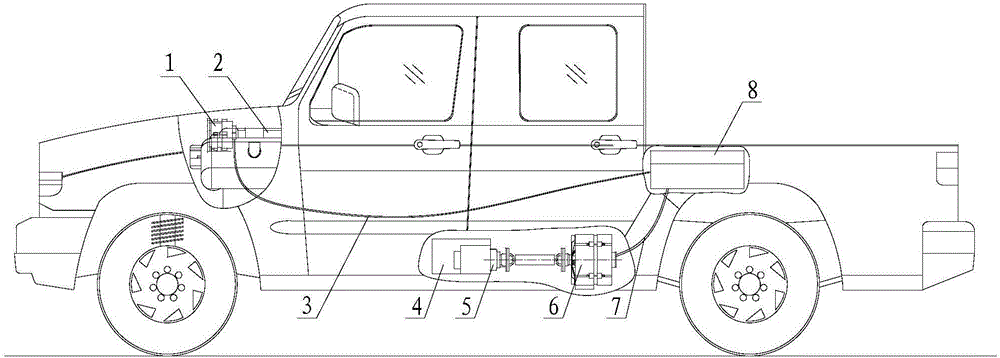

Vehicle-mounted double-motor power take-off power supply system and method

The invention provides a vehicle-mounted double-motor power take-off power supply system and method. The system comprises a first generator, a second generator and a control unit, wherein the first generator is installed in an engine bin, connected with a vehicle engine and driven by the vehicle engine to run and generate electricity; the second generator is installed on a vehicle power take-off opening, connected with a vehicle gearbox and driven by the vehicle gearbox to run and generate electricity; and the control unit is connected with the first generator and the second generator through a cable and controls output power of the first generator and the second generator. According to the vehicle-mounted double-motor power take-off power supply system, the power take-off generators of different power are installed in the vehicle engine bin and on the power take-off opening respectively and controlled simultaneously by the same control unit, so that the working requirements of vehicles on different power utilization working conditions are met, the power of the whole system is improved, the efficiency is improved, the loss is reduced, and the high-power power utilization requirements of light or small vehicles are met.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

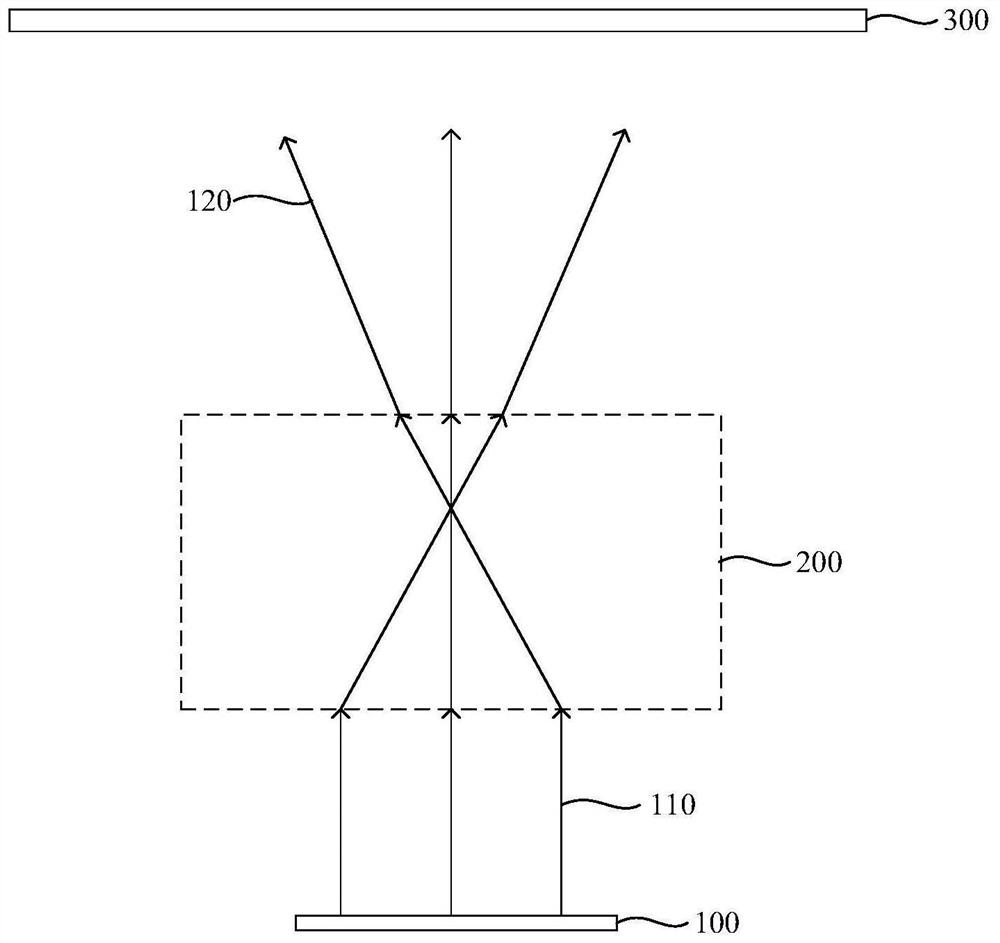

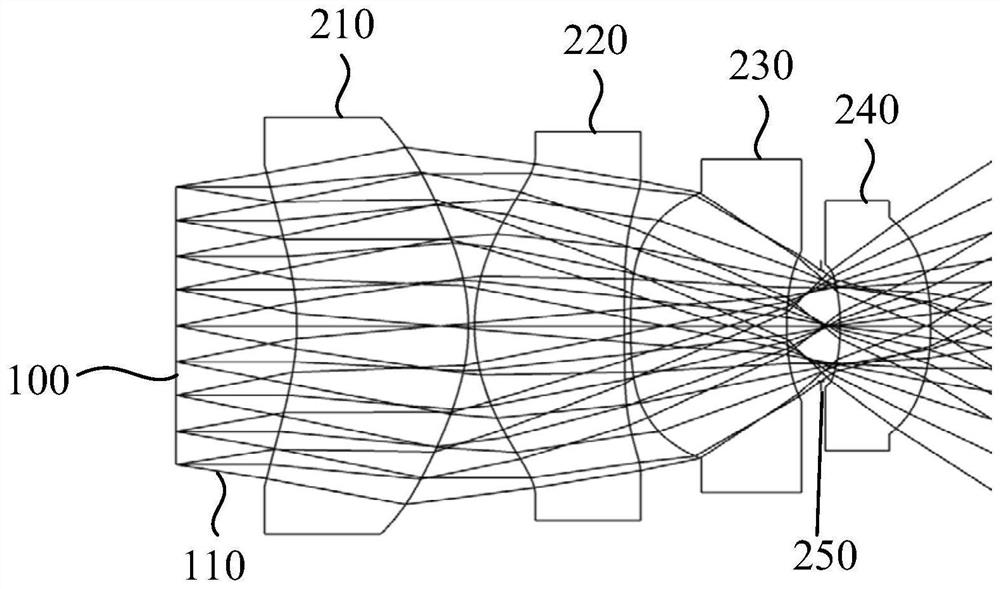

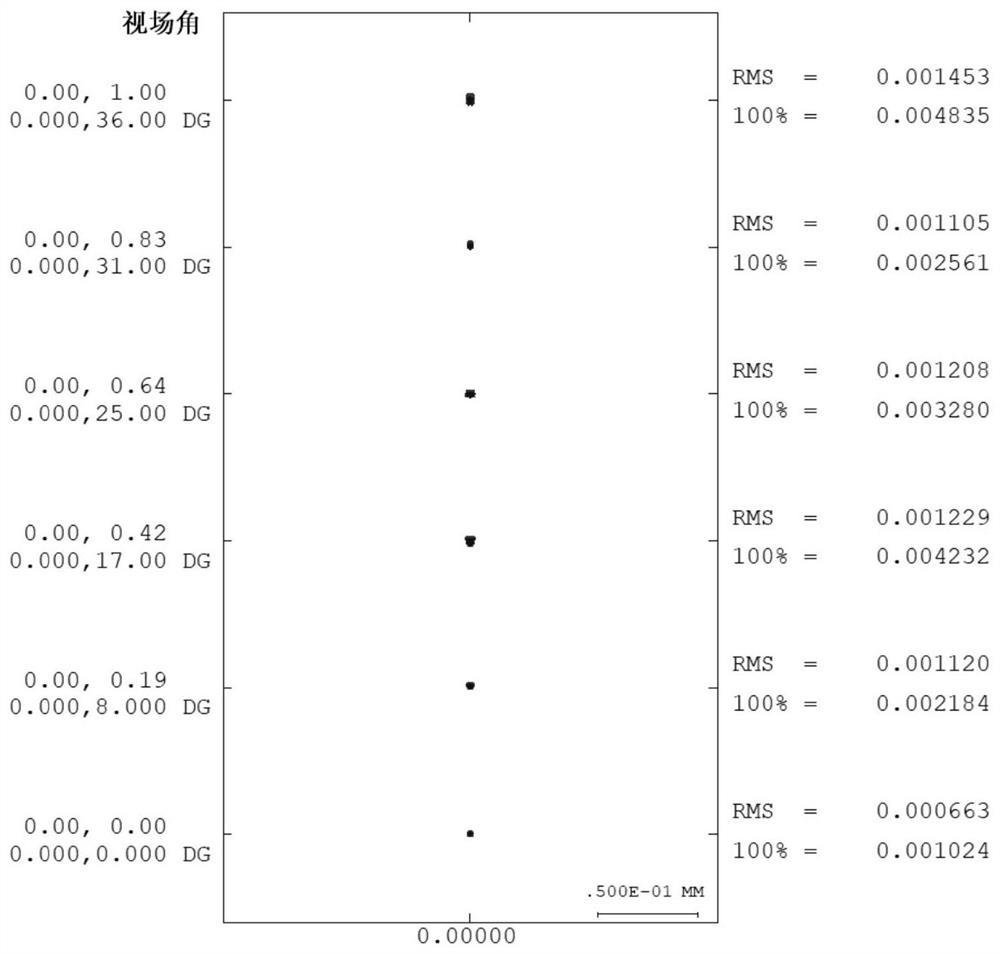

Lens and structured light projection module

The invention provides a lens and a structured light projection module, and relates to the technical field of optical devices. The lens comprises a first convergent lens, a second convergent lens, a third convergent lens and a fourth convergent lens which are sequentially arranged along a light emitting direction, wherein the first convergent lens, the second convergent lens, the third convergentlens and the fourth convergent lens are all aspheric lenses. Under the action of the converging lens, the divergent light beams are finally intersected on the main optical axis to form a certain included angle to be projected into a target area in the form of parallel light beams, so that a light spot group is formed, and the depth information of an object in the target area is measured. When depth information is measured in some scenes, the requirement for the number of light spots is not high, therefore a diffractive optical element can be prevented from being used, the manufacturing cost ofthe lens is effectively reduced, the structure of the lens is simplified, and the assembling difficulty is also reduced. Through the lens, the distance between adjacent light spots can be increased,and therefore a larger field angle is formed.

Owner:DONGGUAN VISIONX-TECH CO LTD

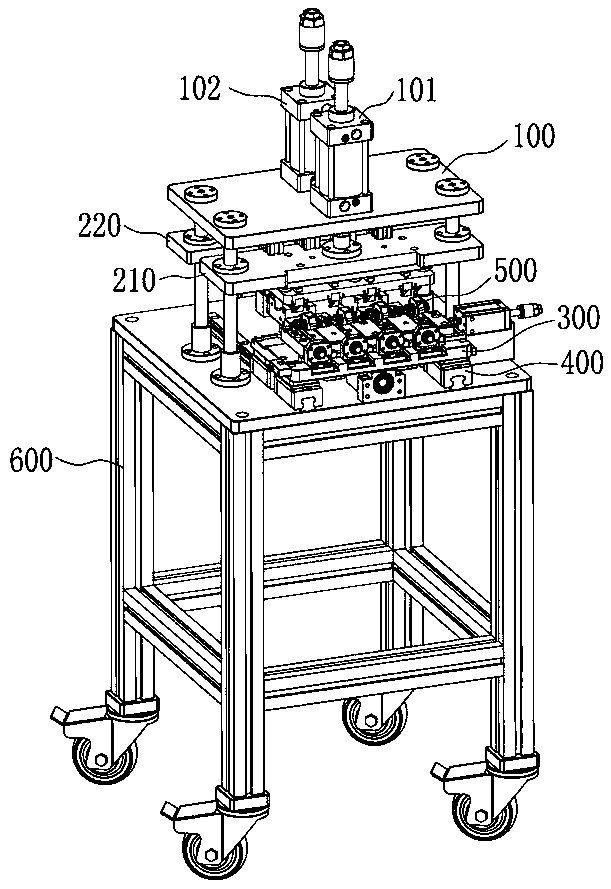

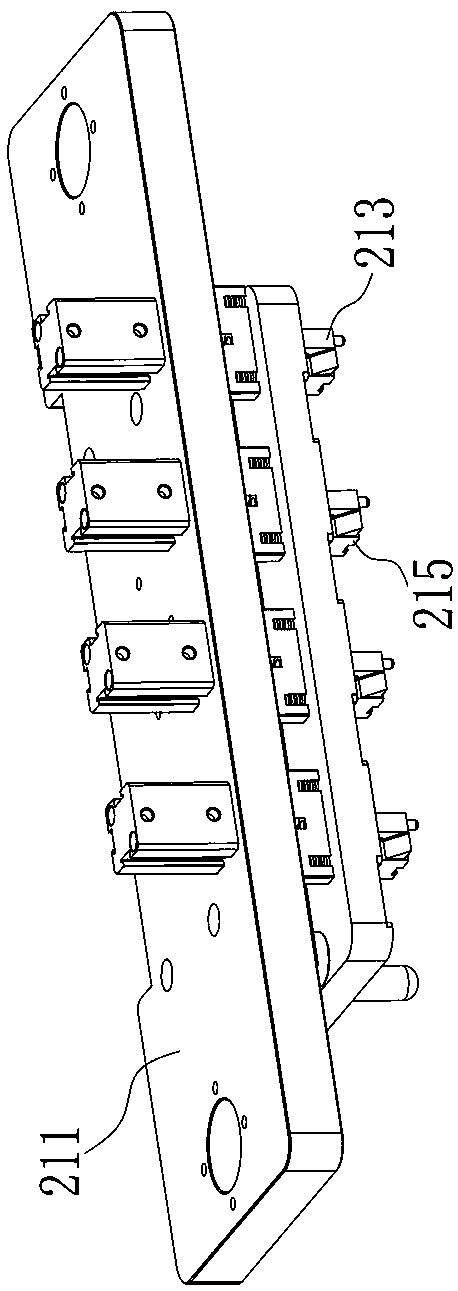

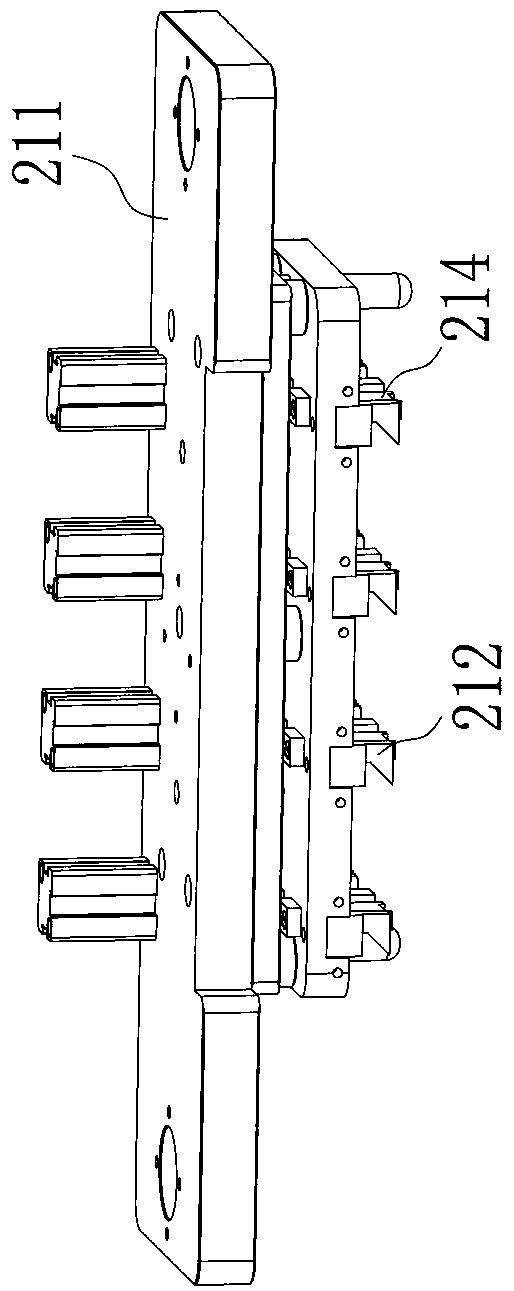

Rotary bending formation equipment

The invention discloses rotary bending formation equipment. The rotary bending formation equipment comprises a top plate cylinder mechanism, an upper die mechanism, a lower die mechanism, a guide railmechanism, a rack and pinion mechanism and a frame; the upper die mechanism is of a separated structure and comprises a first upper die mechanism and a second upper die mechanism; the first upper diemechanism and the second upper die mechanism can move between the top plate cylinder mechanism and the lower die mechanism by virtue of a guide column and guide sleeve component; the rack and pinionmechanism is arranged on the lower die mechanism; the lower die mechanism is arranged on the guide rail mechanism; and the guide rail mechanism is fixedly arranged on the frame. The rotary bending formation equipment disclosed by the invention can be used for carrying out press-bending and rotational bending on a product and effectively improves the production efficiency and the formation qualityof the product.

Owner:SHENZHEN TONGTAIYING ELECTRONICS TECH CO LTD

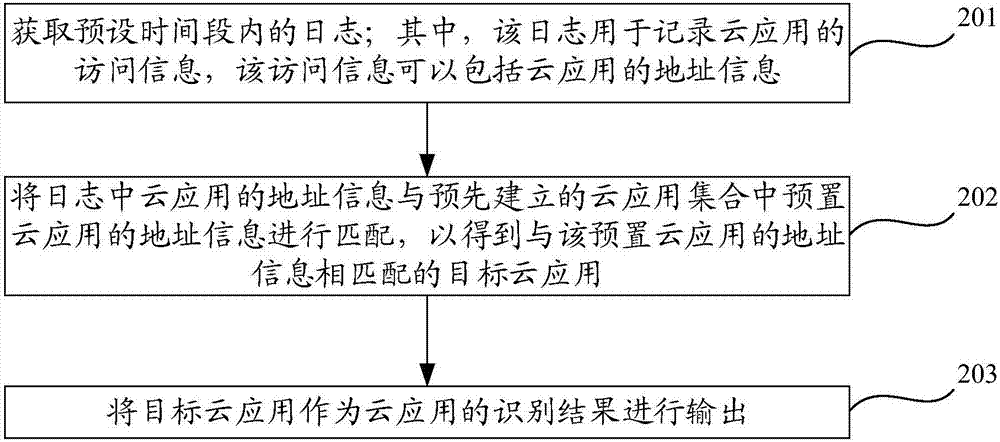

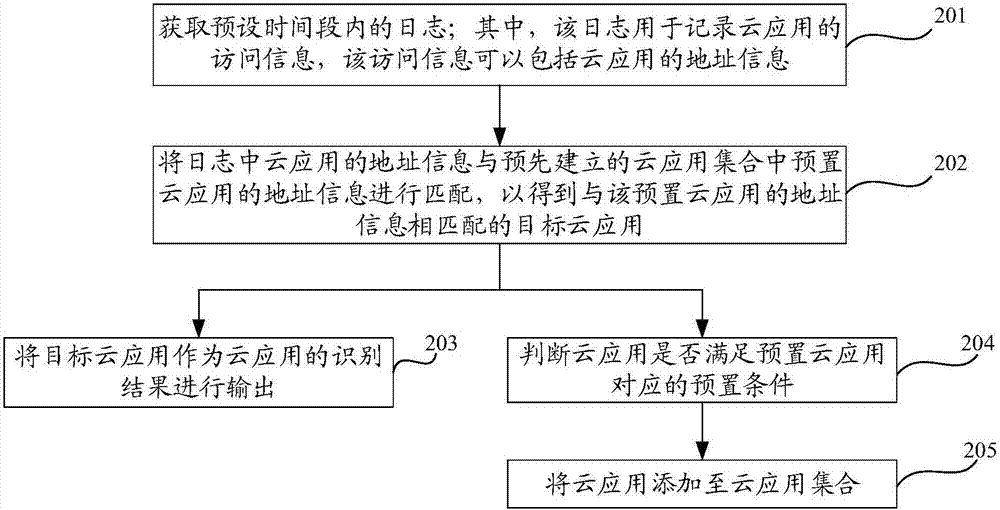

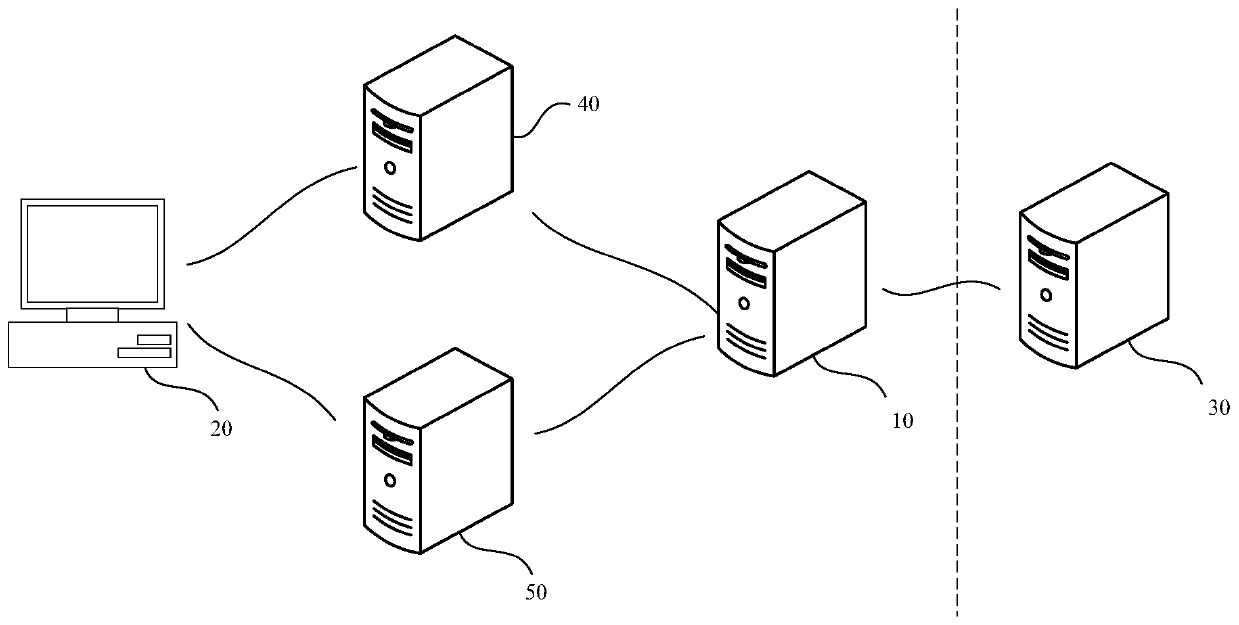

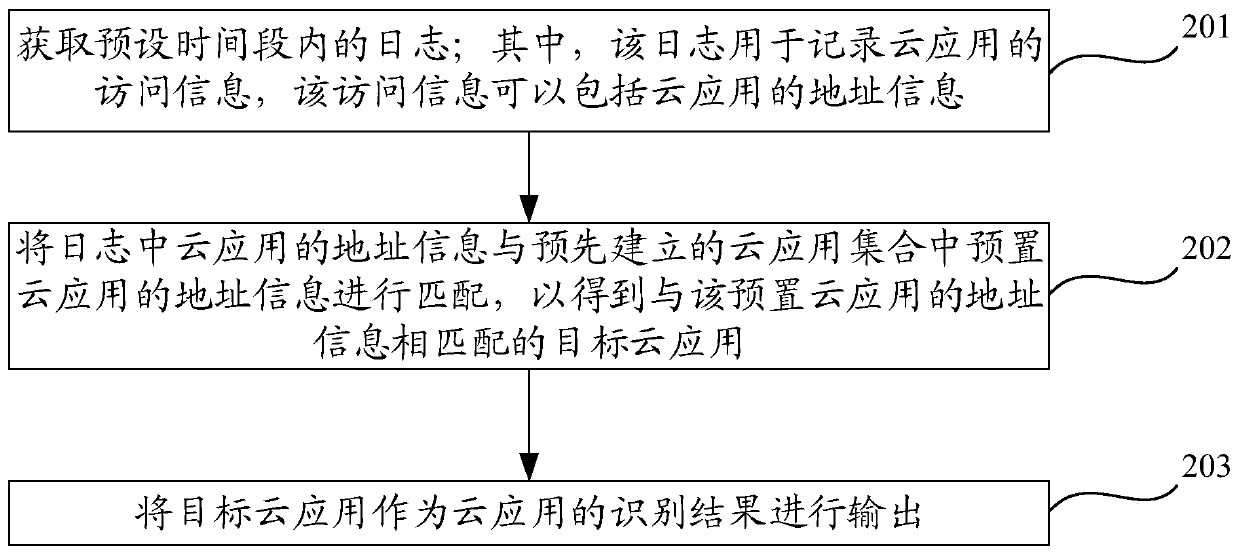

Identification method and device for cloud application

ActiveCN107332824AImprove forwarding efficiencyAvoid less efficientData switching networksTime segmentOperating system

The embodiment of the invention provides an identification method and device for a cloud application. Specifically, the method comprises the steps of obtaining logs in a preset time period, wherein the logs are used for recording access information of the cloud application, and the access information comprises address information; matching the address information of the cloud application in the logs with the address information of preset cloud applications in a pre-established cloud application set, thereby obtaining a target cloud application matching the address information of the preset cloud application; and outputting the target cloud application as an identification result of the cloud application. According to the method and the device, the cloud application can be identified without intercepting a message, the problem that the message forwarding efficiency is relatively low resulting from intercepting the message is avoided, and the message forwarding efficiency is improved.

Owner:BEIJING QIANXIN TECH

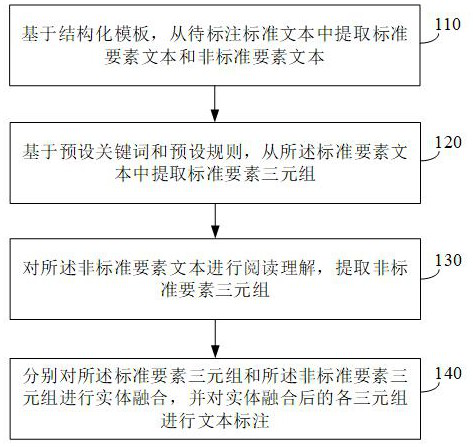

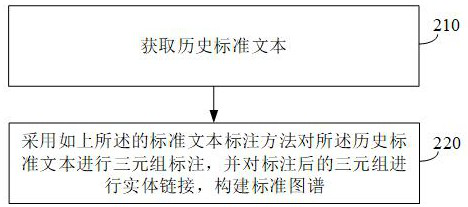

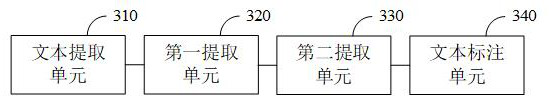

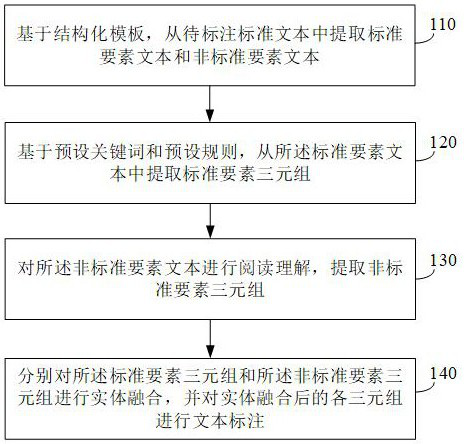

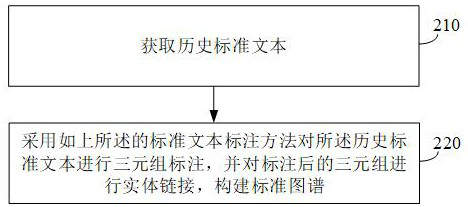

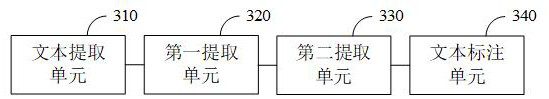

Standard text labeling and standard atlas construction method and device

ActiveCN112733508AAvoid less efficientQuick and accurate extractionNatural language data processingEngineeringData mining

The invention provides a standard text labeling and standard atlas construction method and device. The method comprises the following steps: extracting a standard element text and a non-standard element text from a to-be-labeled standard text based on a structured template; extracting a standard element triple from the standard element text based on a preset keyword and a preset rule; reading and understanding the non-standard element text, and extracting a non-standard element triple; and respectively carrying out entity fusion on the standard element triples and the non-standard element triples, and carrying out text labeling on the triples after entity fusion. The standard element triples are extracted on the basis of the preset keyword and the preset rule, and the non-standard element triples are extracted on the basis of reading comprehension, so that the triples used for constructing the standard atlas can be rapidly and accurately extracted, and the problem that the efficiency of constructing the standard atlas is low due to the fact that texts are manually labeled in a traditional method is solved.

Owner:CHINA ELECTRONICS STANDARDIZATION INST +1

Polycarboxylate superplasticizer and preparation method thereof

The invention discloses a polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is prepared from raw materials: by weight, 340-360 parts of methoxypolyethylene glycol, 20-40 parts of methacrylic acid, 2-10 parts of hydroxyalkyl acrylic ester, 2-6 parts of catalyst, 2-6 parts of polymerization inhibitor, 2-6 parts of oxidizing agent, 1-5 parts of reducing agent, 1-5 parts of tartaric acid and 640 parts of water. The preparation method of the polycarboxylate superplasticizer is carried out at the temperature ranging from 5 DEG C to 40 DEG C. According to the preparation method, the problem of low efficiency at temperature during use of one type of reducing agent can be avoided, dropwise adding time can be shortened, production cycle can be shortened, energy consumption can be lowered, and production cost can be decreased.

Owner:安徽森普新型材料发展有限公司

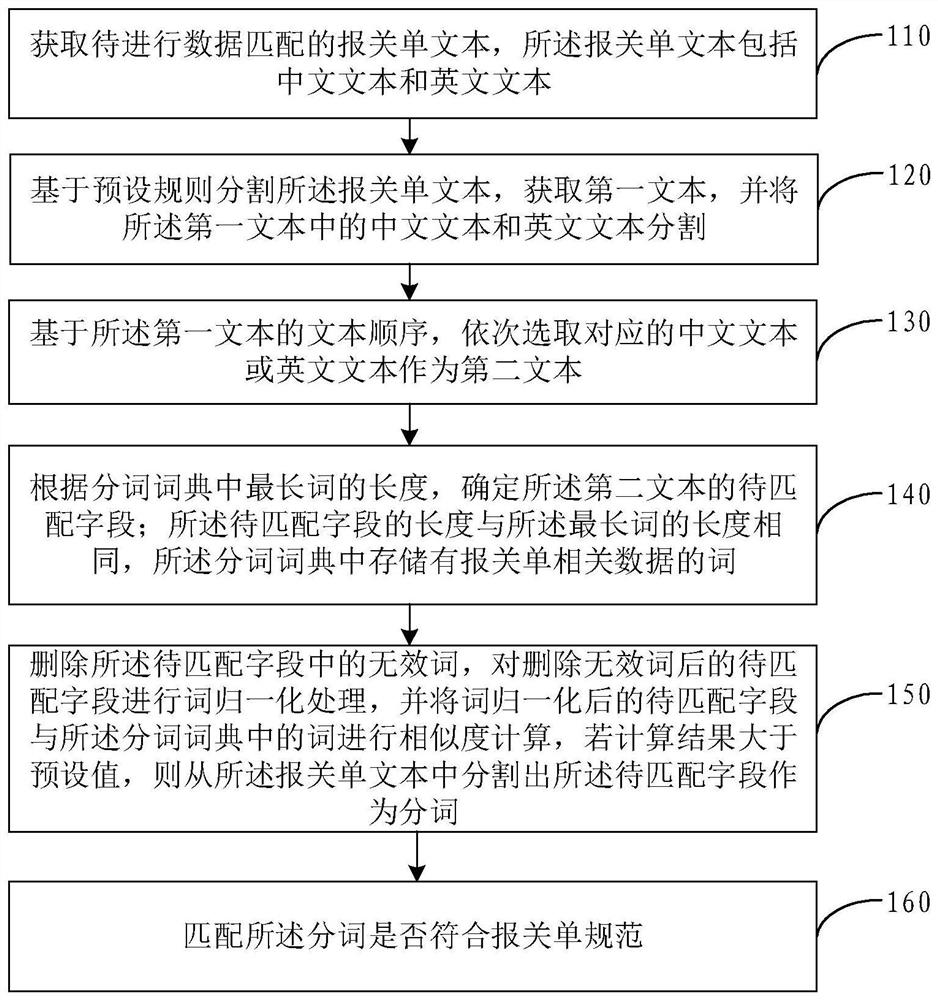

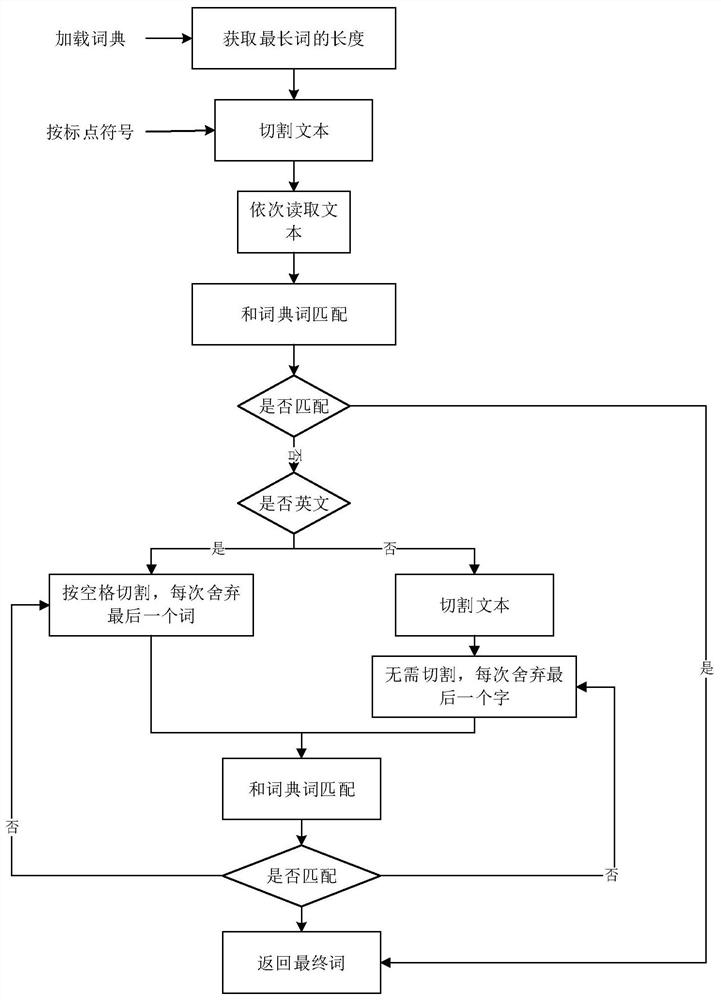

Customs declaration data matching method and device

PendingCN112395866AAvoid low calibration accuracyAvoid the problem of low calibration accuracyNatural language data processingText database queryingData matchingEngineering

The embodiment of the invention provides a customs declaration data matching method and device, and the method comprises the steps: segmenting a customs declaration text based on a preset rule, obtaining a first text, segmenting a Chinese text and an English text in the first text, and sequentially selecting the corresponding Chinese text or English text as a second text based on the text sequenceof the first text, and determining a to-be-matched field of the second text according to the length of the longest word in the word segmentation dictionary, deleting invalid words in the to-be-matched field, performing word normalization processing on the invalid words, performing similarity calculation on the invalid words and words in the word segmentation dictionary, and if a calculation result is greater than a preset value, segmenting the to-be-matched field from the customs declaration text to serve as segmented words, and matching whether the segmented words conform to customs declaration specifications. According to the method of the invention, data matching verification can be carried out on the Chinese text and the English text respectively, the to-be-matched field is determinedaccording to the length of the longest word in the word segmentation dictionary, the influence of similar words is considered, and the verification efficiency and accuracy are improved.

Owner:SINOTRANS

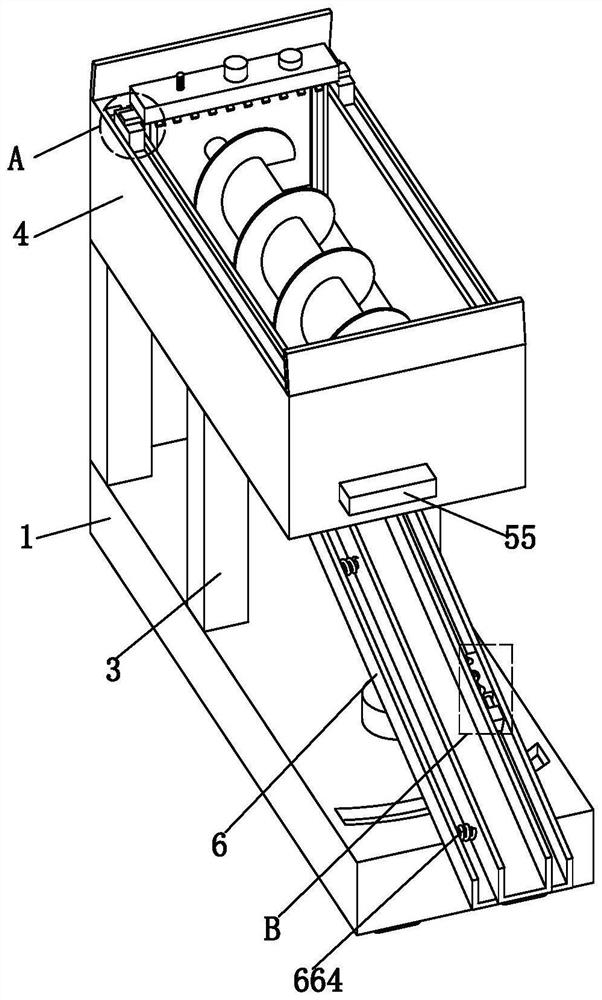

Horizontal concrete transportation device for roof construction

ActiveCN113863676AAffect the use effectImprove pouring efficiencyRoof toolsBuilding material handlingArchitectural engineeringSlurry

The invention relates to the technical field of concrete transportation, and particularly relates to a horizontal concrete transportation device for roof construction. The horizontal concrete transportation device comprises a moving frame, rollers, supporting columns, a transportation frame, a stirring mechanism and a guide frame. In the stirring mechanism, concrete is stirred through stirring blades in the rotating process of a stirring shaft, and the situation that stones and slurry are distributed unevenly due to sinking of the stones in the concrete in the transportation process, and the subsequent use effect of the concrete is affected is avoided; and in the guide frame, a first supporting frame rotates and is matched with a second supporting frame to drive a material guide frame to rotate, then the material guide frame can be driven to rotate to different positions of a roof, thus pouring of the concrete at the corners of the roof can be achieved, and the pouring efficiency of the concrete is improved.

Owner:中建五局第二建设有限公司

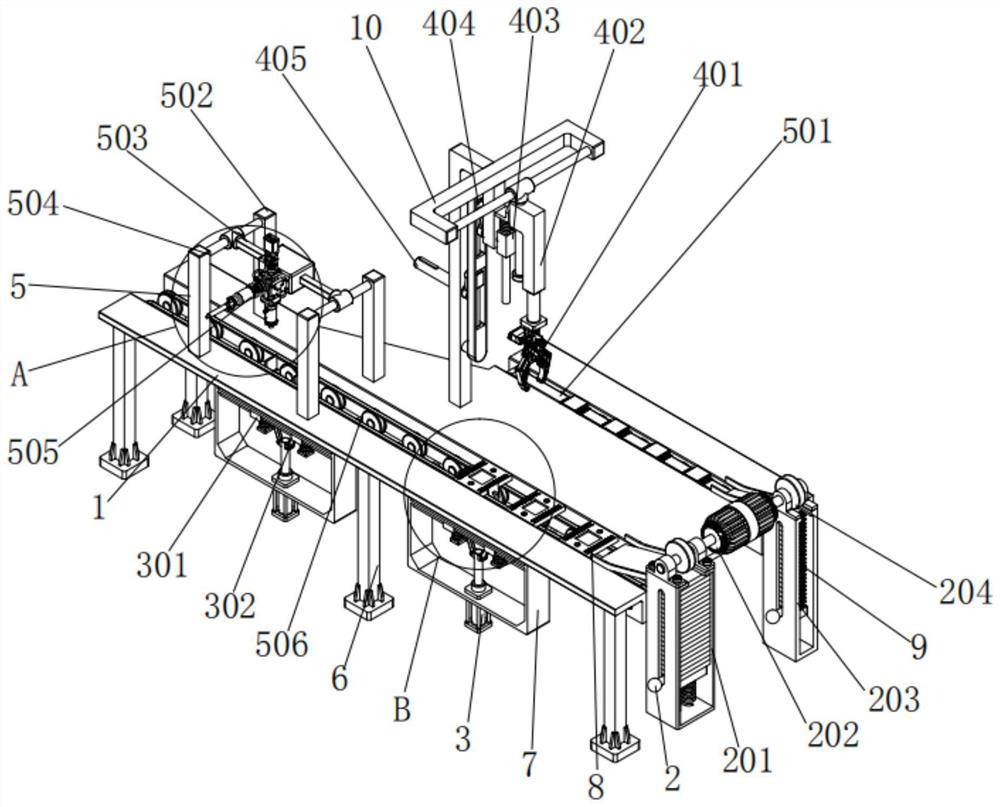

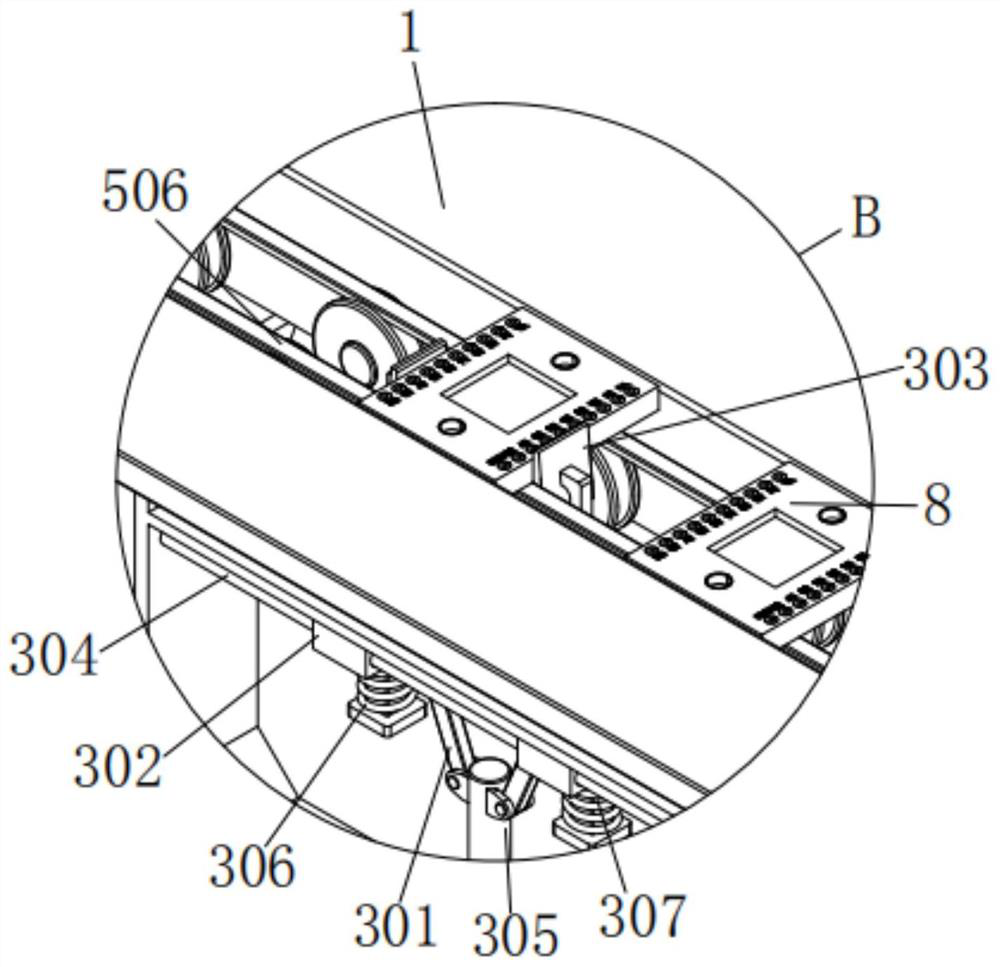

Automatic packaging device for producing and packaging digital-to-analog converter

ActiveCN113066743AScientific and reasonable structureEasy to useSemiconductor/solid-state device manufacturingConveyor partsConvertersHydraulic cylinder

The invention discloses an automatic packaging device for producing and packaging a digital-to-analog converter. The automatic packaging device comprises a platform and frames, the frames are fixedly connected to the left end and the right end of the front side of the lower end of the platform, and a positioning mechanism is arranged above the frames; the positioning mechanism comprises a first sliding block, an inclined rod, a clamping plate, a first transverse rod, a hydraulic cylinder, a second spring, a supporting rod, a rolling wheel, a base plate and a bottom plate, the bottom plate is fixedly connected to the lower portion of the supporting rod, and the two sides of the second spring are fixedly connected with the bottom plate and the first sliding block correspondingly. The automatic packaging device for production and packaging of the digital-to-analog converter is scientific and reasonable in structure and safe and convenient to use, the circuit board cannot move through cooperation of a hydraulic cylinder, a first sliding block, an inclined rod, a clamping plate, a second conveying belt, a rolling wheel base plate, the digital-to-analog converter and the circuit board, and center positioning of the circuit board is guaranteed through left-right synchronous movement. The problem that position fixation cannot be accurately ensured when packaging and welding between the digital-to-analog converter and the circuit board are carried out is avoided.

Owner:北京盈创力和电子科技有限公司

A method and device for identifying cloud applications

ActiveCN107332824BImprove forwarding efficiencyAvoid less efficientData switching networksDistributed computingComputer engineering

Embodiments of the present invention provide a cloud application identification method and device, wherein the method specifically includes: obtaining a log within a preset time period; the log is used to record the access information of the cloud application; the access information includes: address Information; match the address information of the cloud application in the log with the address information of the preset cloud application in the pre-established cloud application set, so as to obtain the target cloud application that matches the address information of the preset cloud application; The target cloud application is output as a recognition result of the cloud application. The present invention can realize cloud application identification without intercepting messages, avoids the problem of low message forwarding efficiency caused by message interception, and improves message forwarding efficiency.

Owner:BEIJING QIANXIN TECH

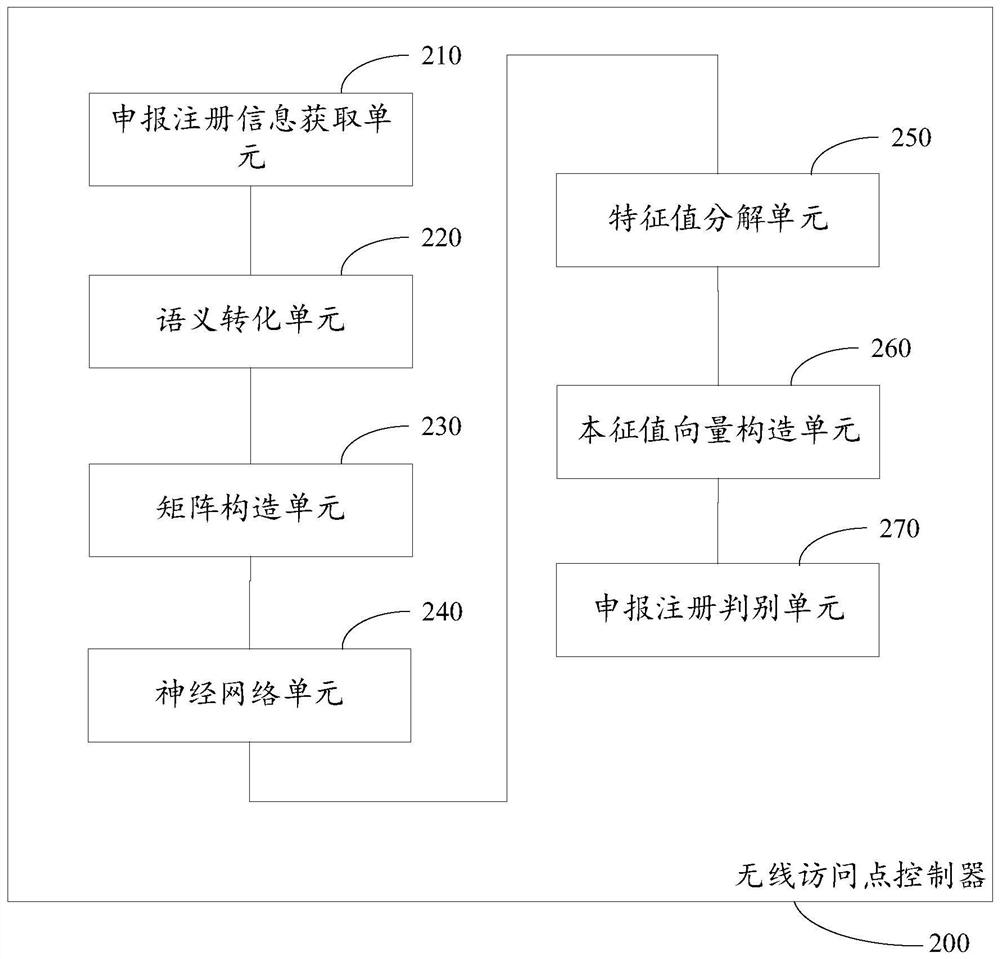

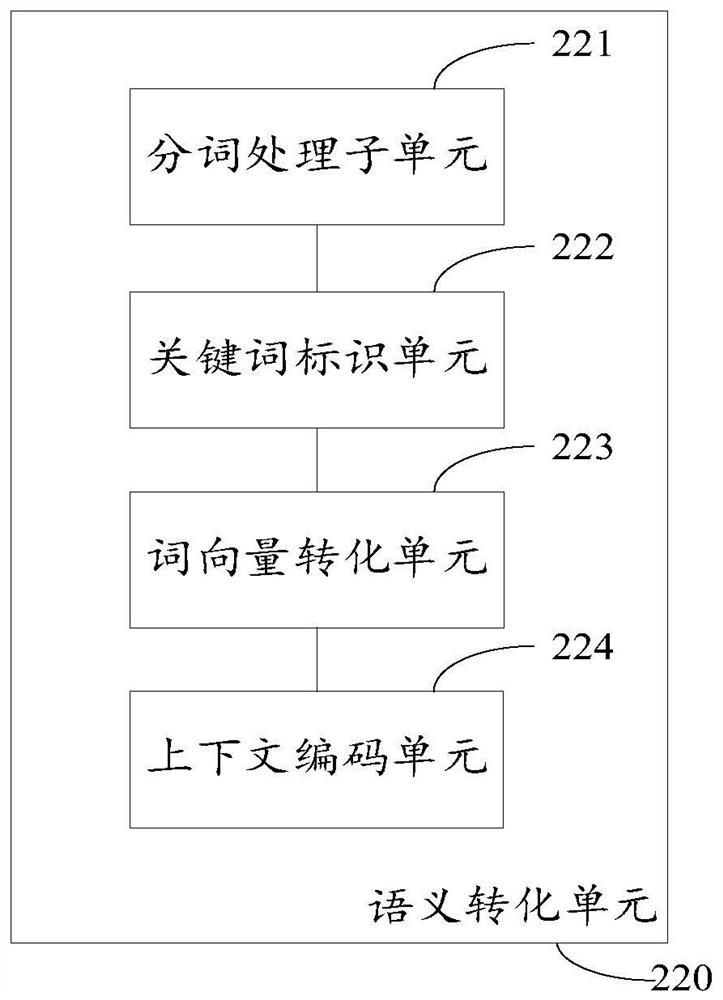

Wireless access point controller, wireless access point controller operation method, and electronic equipment

InactiveCN113821640AImprove accuracyAvoid less efficientSemantic analysisNeural architecturesComputer networkReal-time computing

The invention relates to the field of AP declaration registration, and particularly discloses a wireless access point controller. The wireless access point controller adopts a semantic understanding model based on a deep learning technology to perform centralized processing on declaration and registration information of a plurality of APs on the premise of ensuring accuracy and efficiency so as to determine whether declaration and registration of each AP are correct or not, and therefore, simultaneous declaration and registration of the plurality of APs can be realized. In this way, on one hand, the accuracy of AP declaration and registration can be improved, and on the other hand, the condition of relatively low efficiency during AP declaration and registration can be avoided.

Owner:黎川县梦颖科技有限公司

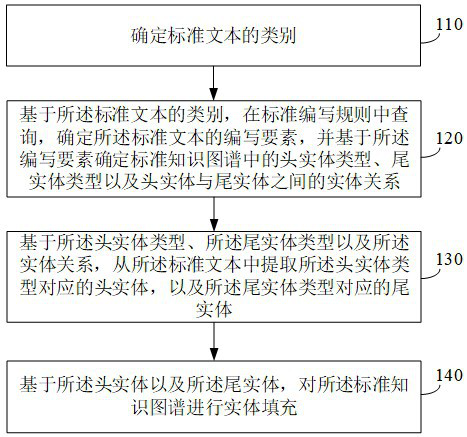

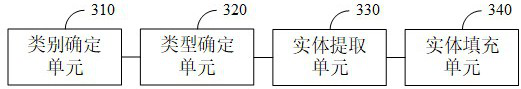

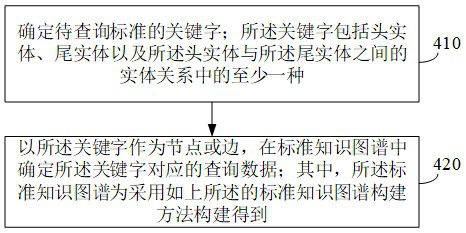

Standard knowledge map construction, standard query method and device

ActiveCN113177125BAccurate representationQuick and accurate querySemantic analysisText database indexingEntity typeTheoretical computer science

The present invention provides a standard knowledge map construction, standard query method and device. The method includes: based on the category of the standard text, querying in the standard writing rules, determining the writing elements of the standard text, and determining the content of the standard knowledge map based on the writing elements. The head entity type, tail entity type, and entity relationship between the head entity and the tail entity; based on the head entity type, tail entity type, and entity relationship, extract the head entity corresponding to the head entity type and the corresponding tail entity type from the standard text The tail entity; based on the head entity and tail entity, the standard knowledge map is filled with entities. The present invention can construct a standard knowledge map according to different types of standard texts, so that the constructed standard knowledge map can accurately represent the content information of different types of standard texts, and then can quickly and accurately query the corresponding standard data information from the standard knowledge map , higher efficiency.

Owner:CHINA ELECTRONICS STANDARDIZATION INST +1

Method and device for standard text labeling and standard map construction

ActiveCN112733508BAvoid less efficientQuick and accurate extractionNatural language data processingText annotationEngineering

The invention provides a method and device for standard text labeling and standard map construction. Based on a structured template, standard element texts and non-standard element texts are extracted from standard texts to be marked; based on preset keywords and preset rules, standard elements are extracted from Extract standard element triples from the text; read and understand non-standard element texts, extract non-standard element triples; perform entity fusion on standard element triples and non-standard element triples respectively, and merge entity fusion Each triplet is text labeled. The invention extracts triplets of standard elements based on preset keywords and preset rules, and extracts triplets of non-standard elements based on reading comprehension, so that triplets used to construct standard maps can be quickly and accurately extracted, avoiding traditional methods The problem of low efficiency in constructing standard maps based on manual labeling text in the paper.

Owner:CHINA ELECTRONICS STANDARDIZATION INST +1

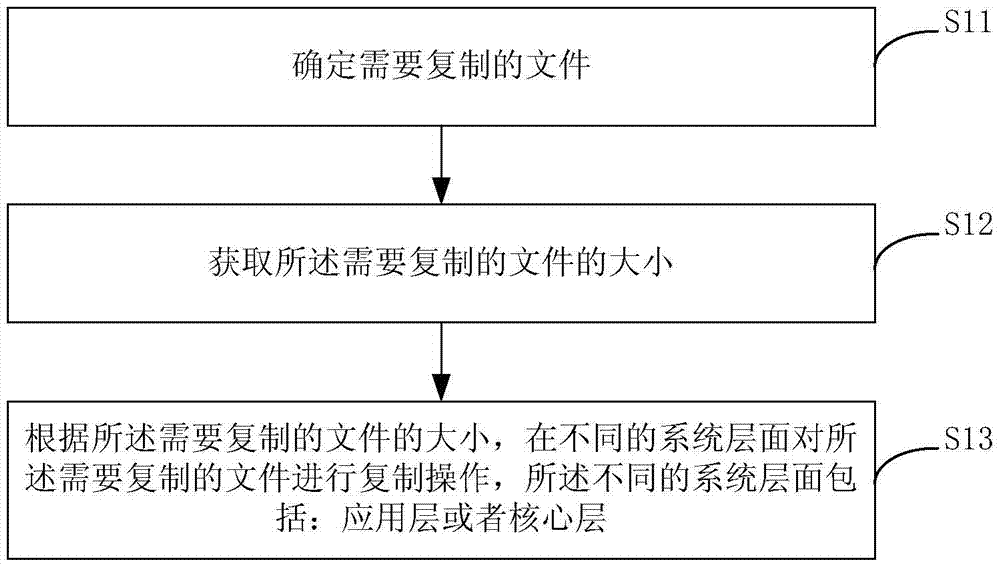

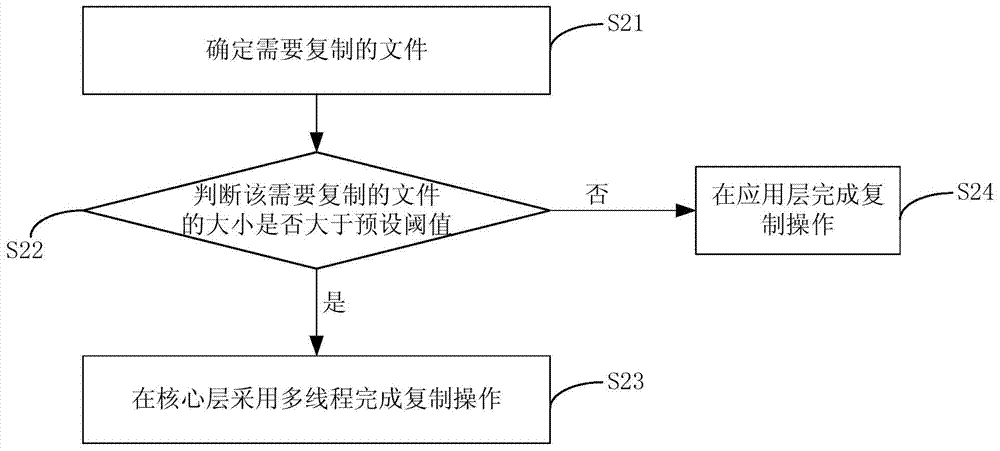

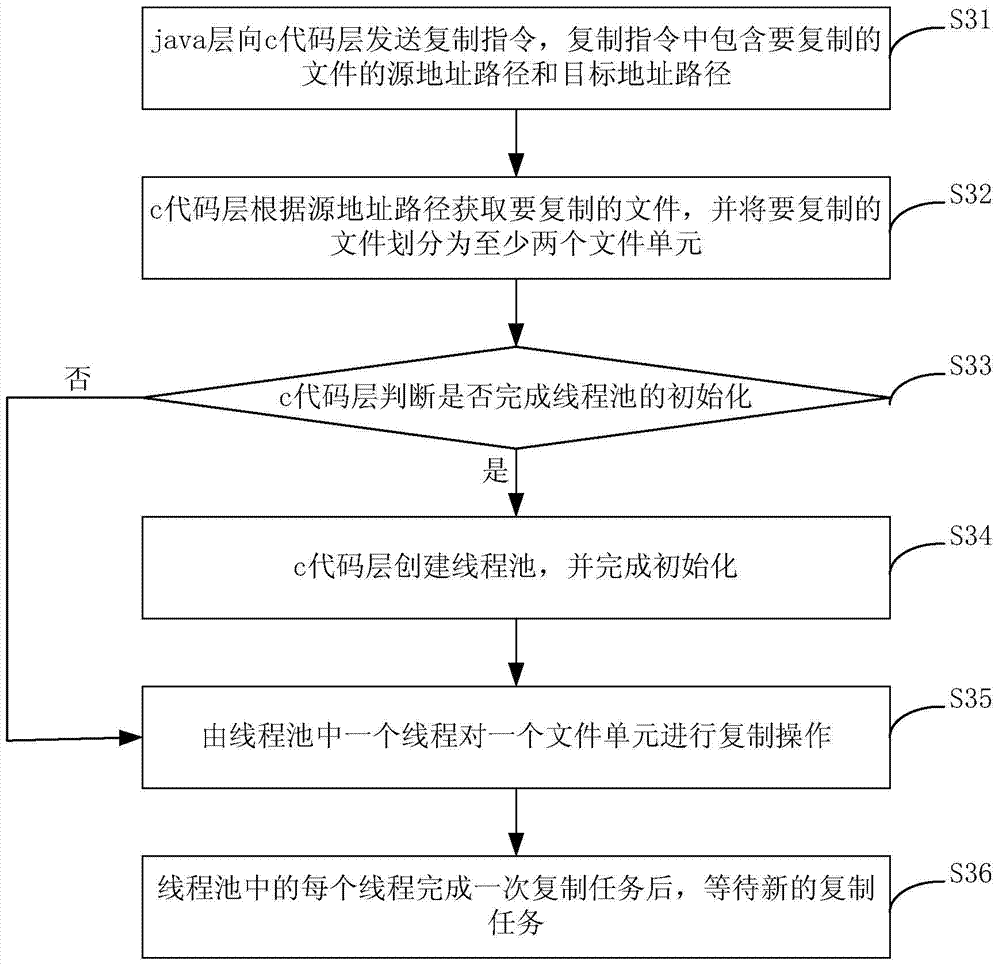

File copying method and device

ActiveCN104133846BAvoid less efficientImprove efficiencyFile/folder operationsSpecial data processing applicationsComputer scienceFile copying

The invention provides a file copying method and a file copying device. The file copying method comprises the following steps that: a file to be copied is determined; the size of the file to be copied is obtained; and the file to be copied is subjected to copying operation in different system levels according to the size of the file to be copied, and the different system levels comprise application levels or core levels. The file copying method has the advantage that the file copying efficiency can be improved.

Owner:ZHUHAI BAOQU TECH CO LTD

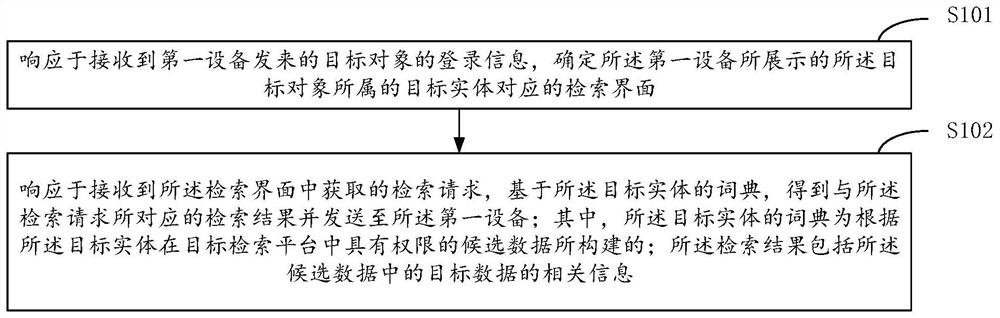

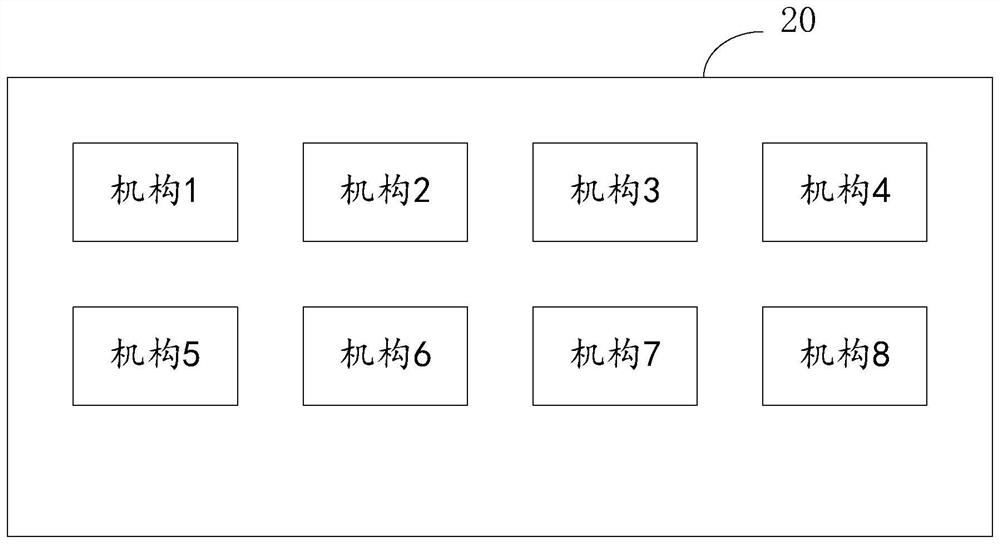

Retrieval method, device and system, electronic equipment and storage medium

PendingCN114297469AEasy to understandAvoid less efficientDigital data information retrievalDigital data protectionEngineeringDatabase

The invention provides a retrieval method, device and system, electronic equipment and a storage medium, and relates to the field of big data processing and the like. According to the specific implementation scheme, in response to received login information, sent by first equipment, of a target object, a retrieval interface corresponding to a target entity, to which the target object belongs, displayed by the first equipment is determined; in response to a received retrieval request obtained in the retrieval interface, based on the dictionary of the target entity, obtaining a retrieval result corresponding to the retrieval request, and sending the retrieval result to the first device; wherein the dictionary of the target entity is constructed according to candidate data, having permission, of the target entity in a target retrieval platform; the retrieval result comprises related information of target data in the candidate data. According to the embodiment of the invention, the retrieval processing efficiency can be improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

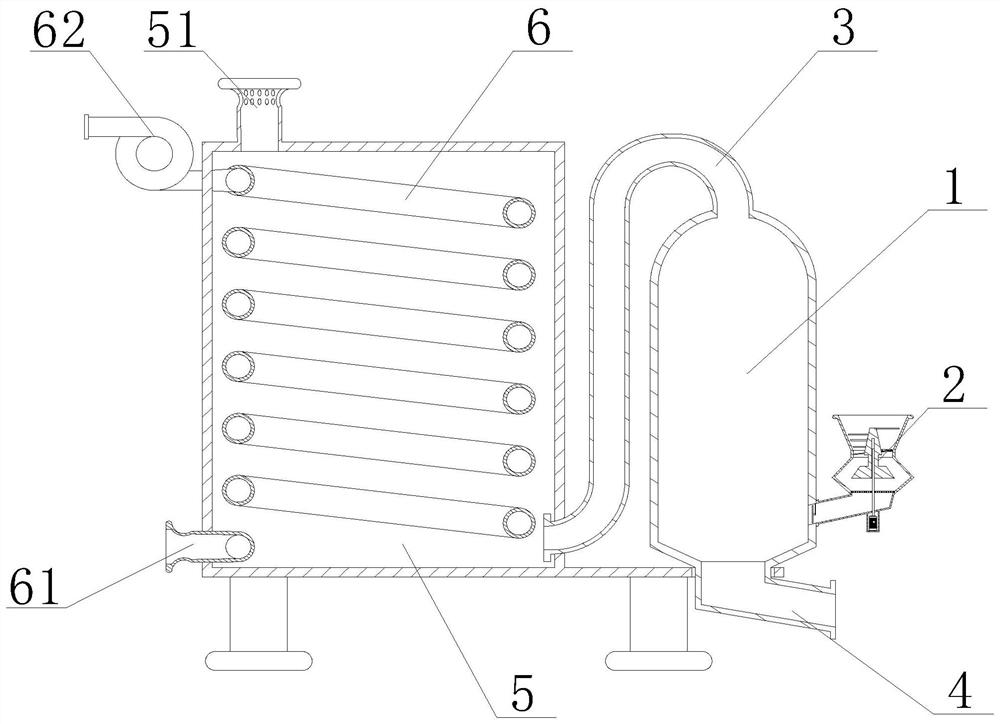

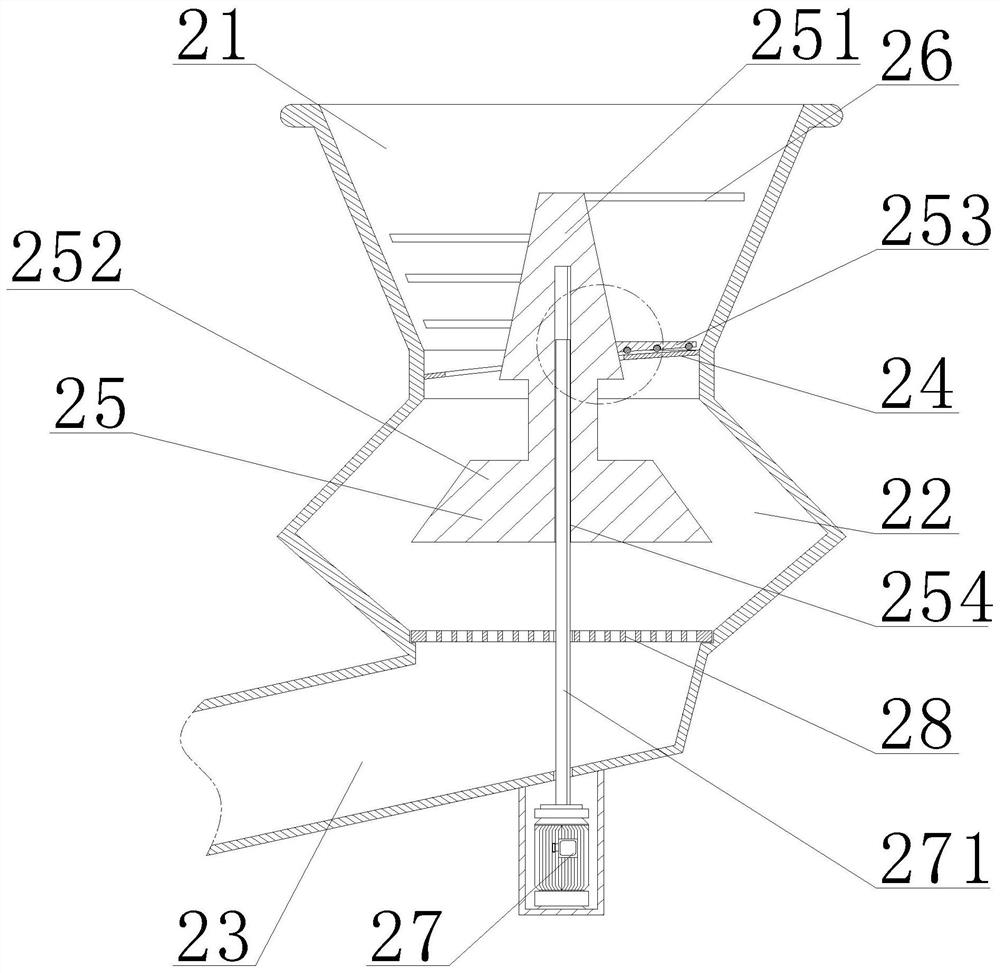

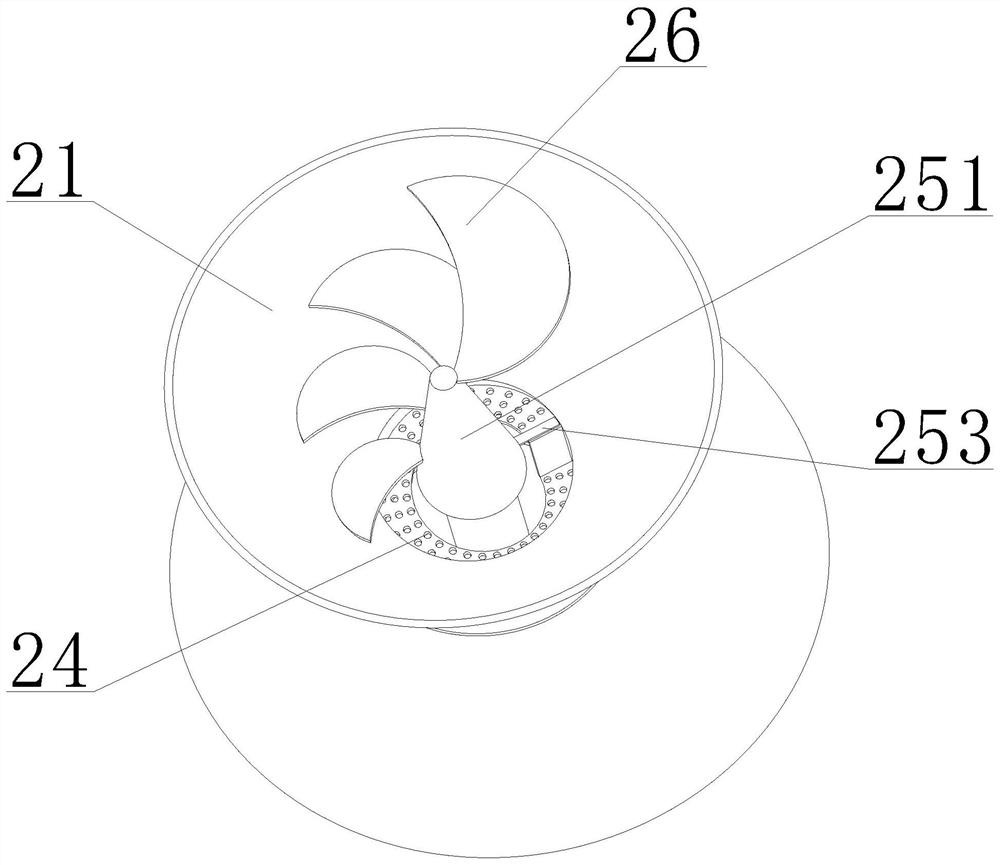

Coal-fired hot-blast stove capable of improving combustion rate

PendingCN112013415AAvoid lossIncrease burn rateAir heatersCombustion technology mitigationCoal briquetteCold air

The invention relates to a coal-fired hot-blast stove capable of improving the combustion rate. The coal-fired hot-blast stove comprises a stove body, wherein the upper portion of the stove body is connected with a heat exchange bin arranged on one side through a smoke exhaust pipe, and used for conducting heat exchange on cold air in a heat exchange pipe in the heat exchange bin; and the outer wall of the stove body is fixedly connected with a feeding hopper used for crushing coal briquettes into coal particles or pulverized coal. According to the coal-fired hot-blast stove, a crusher in thefeeding hopper rotates, rises and falls along a single-circle spiral net, a conical column at the upper half part of the crusher drives a blade to primarily process coal briquettes to cut the coal briquettes into coal briquettes of smaller sizes, and then heavy pressing is carried out on a leaking net by a pressing table at the lower half part of the crusher to press the coal briquettes into pulverized coal or coal particles meeting the specification, so that combustion is facilitated. An original feeding hopper of the coal-fired hot-blast stove is changed into a device for processing the coalbriquettes into the pulverized coal, so that the loss during pulverized coal transportation is avoided, the problem that the efficiency of directly burning the coal briquettes is low is solved, and the combustion rate of the hot-blast stove is improved.

Owner:无为皖江粮食机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com