Horizontal concrete transportation device for roof construction

A technology for horizontal transportation of concrete, applied in cement mixing devices, clay preparation devices, roofing tools, etc. It can solve the problems of concrete stones sinking, affecting the efficiency of roof sealing, and increasing the workload of workers. Fluency, avoiding clogging, and improving pouring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

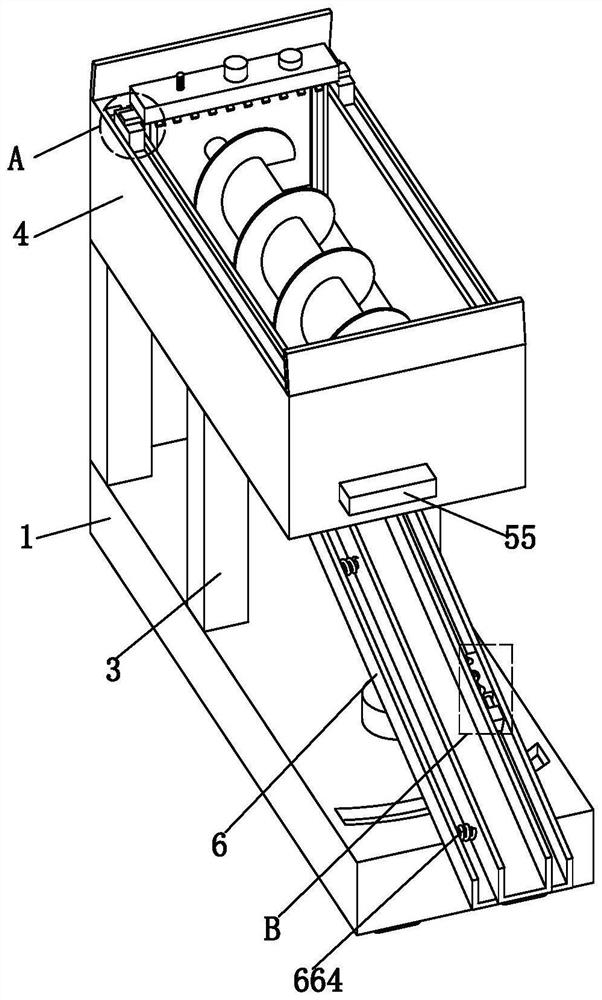

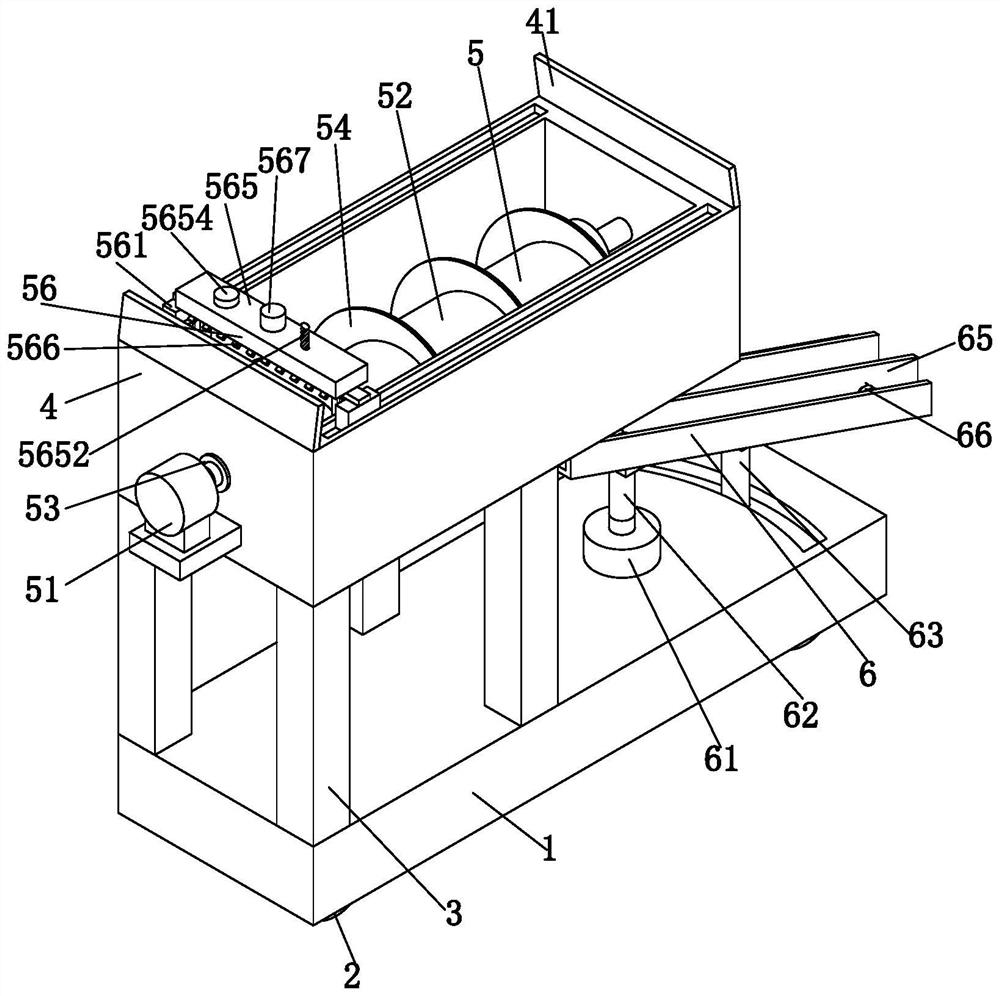

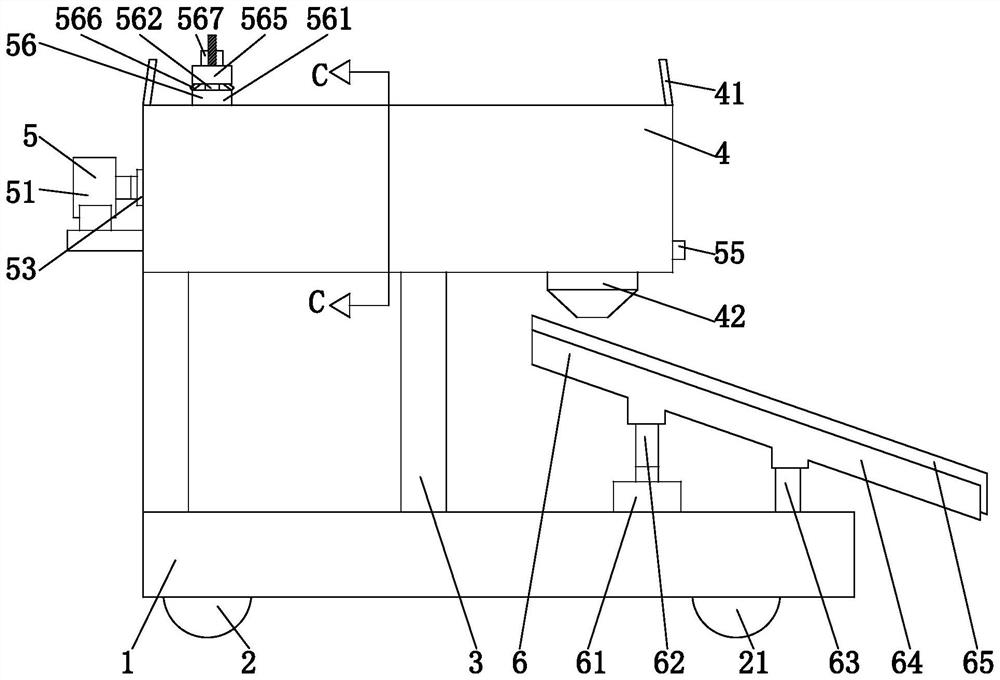

[0026] refer to figure 1 as well as figure 2 , a concrete horizontal transport device for roof construction, comprising a mobile frame 1, rollers 2, support columns 3, a transport frame 4, a stirring mechanism 5 and a guide frame 6, four corners of the lower end surface of the mobile frame 1 are provided with moving Groove, rollers 2 are installed inside the moving groove, and two sets of support columns 3 are arranged on the upper end surface of the mobile frame 1, and each set of support columns 3 is symmetrically installed on the upper end surface of the mobile frame 1, and the upper end surfaces of the support columns 3 are jointly installed with a transport frame 4. A stirring mechanism 5 is installed inside the transport frame 4, a discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com