Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Affect output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

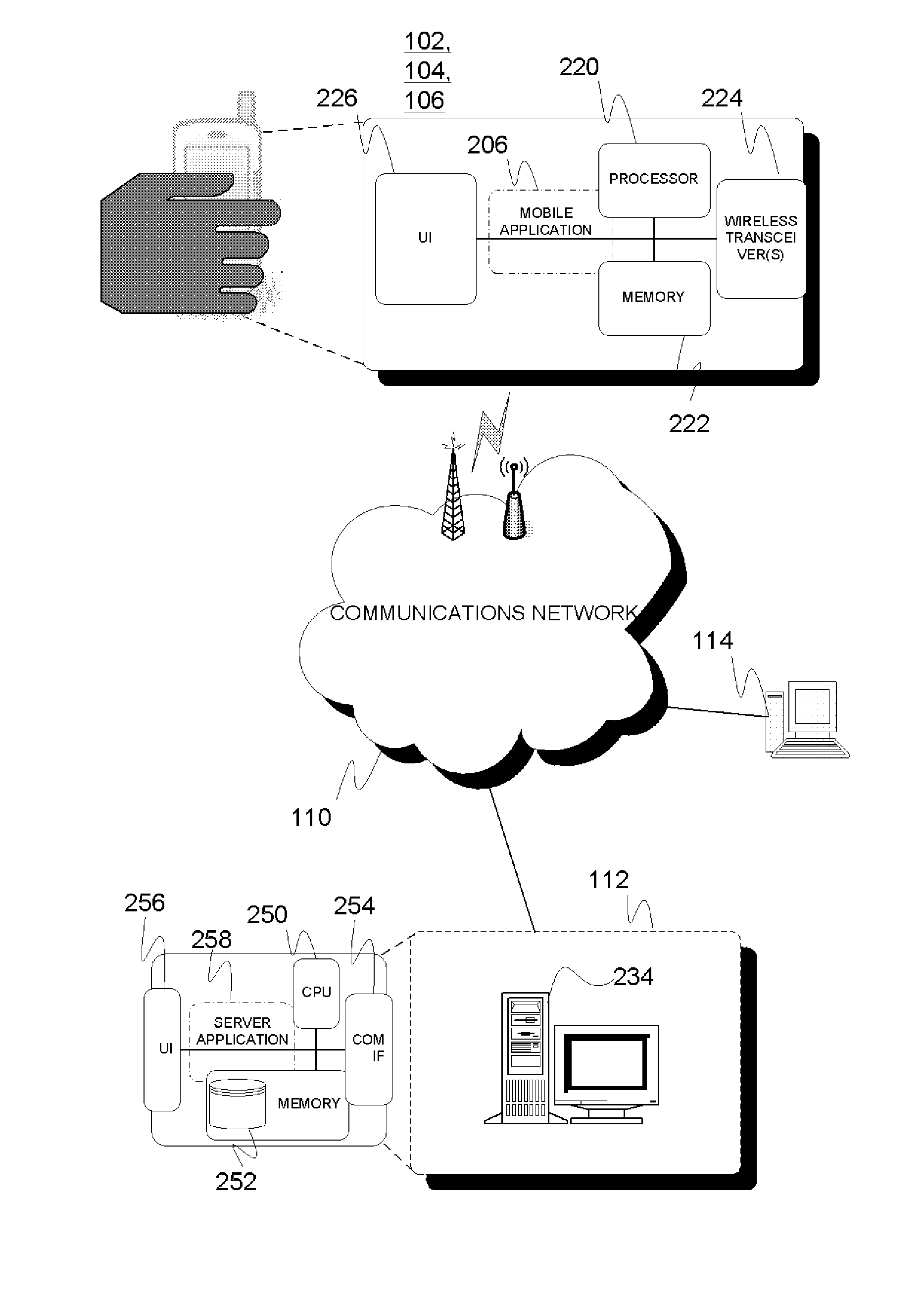

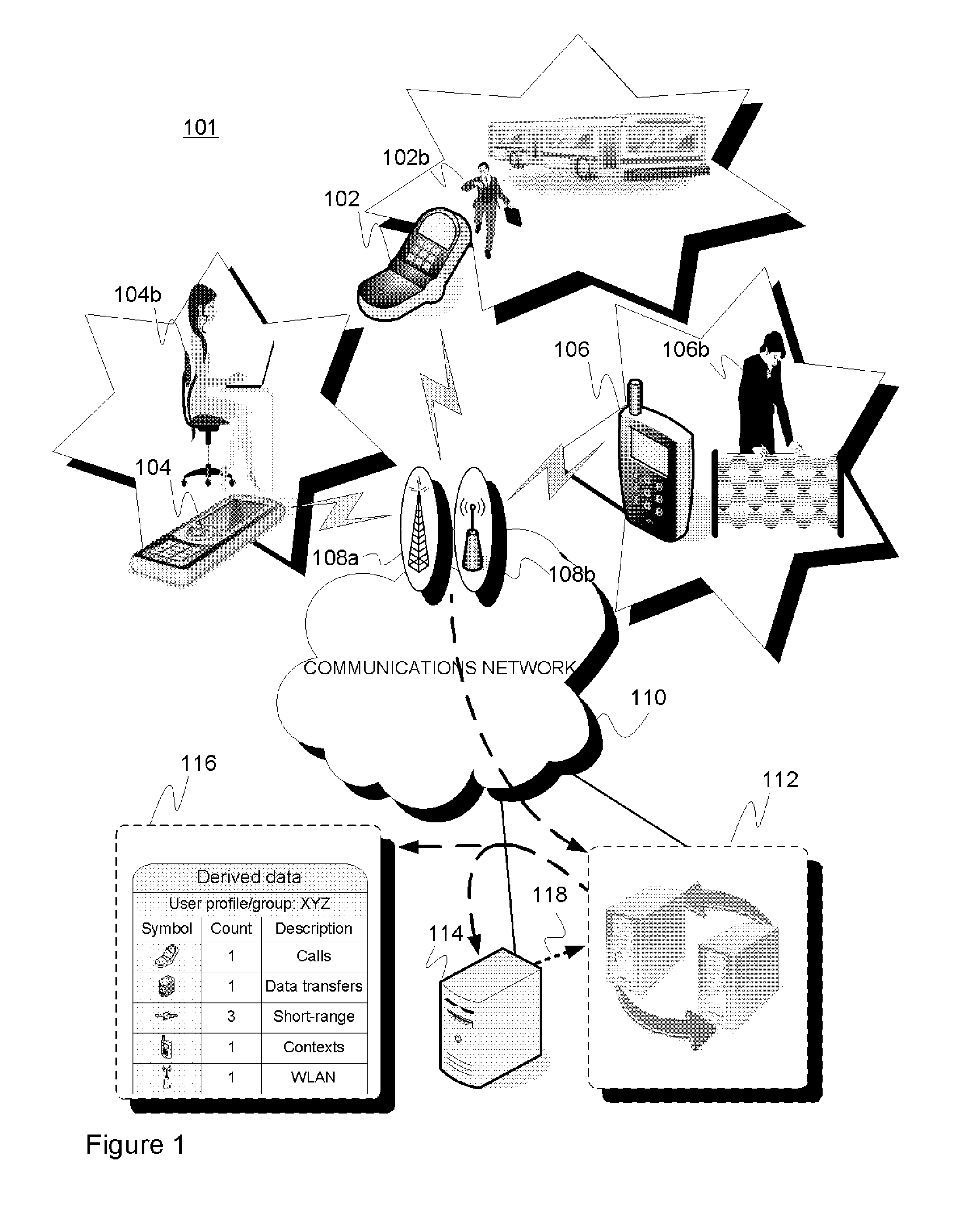

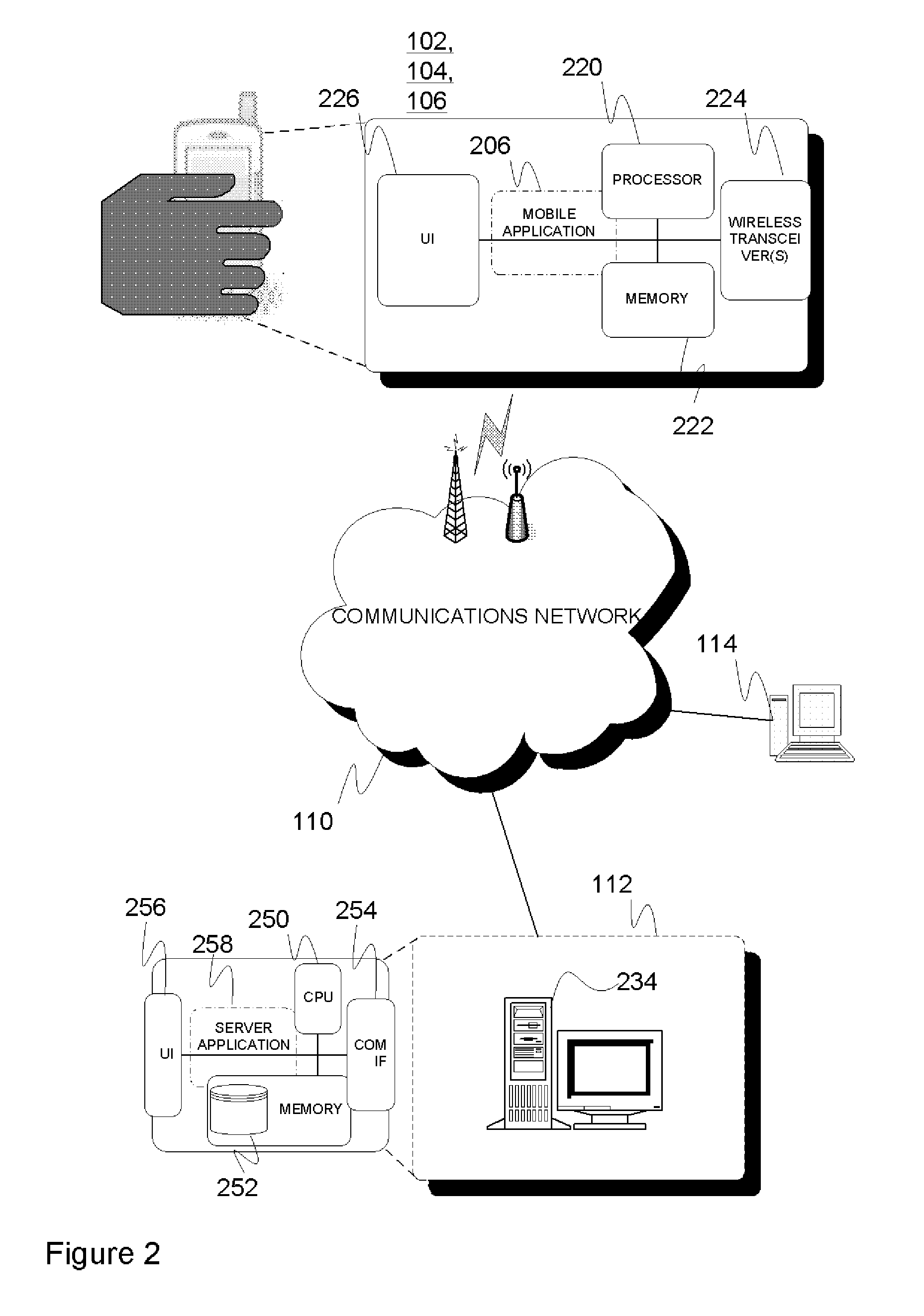

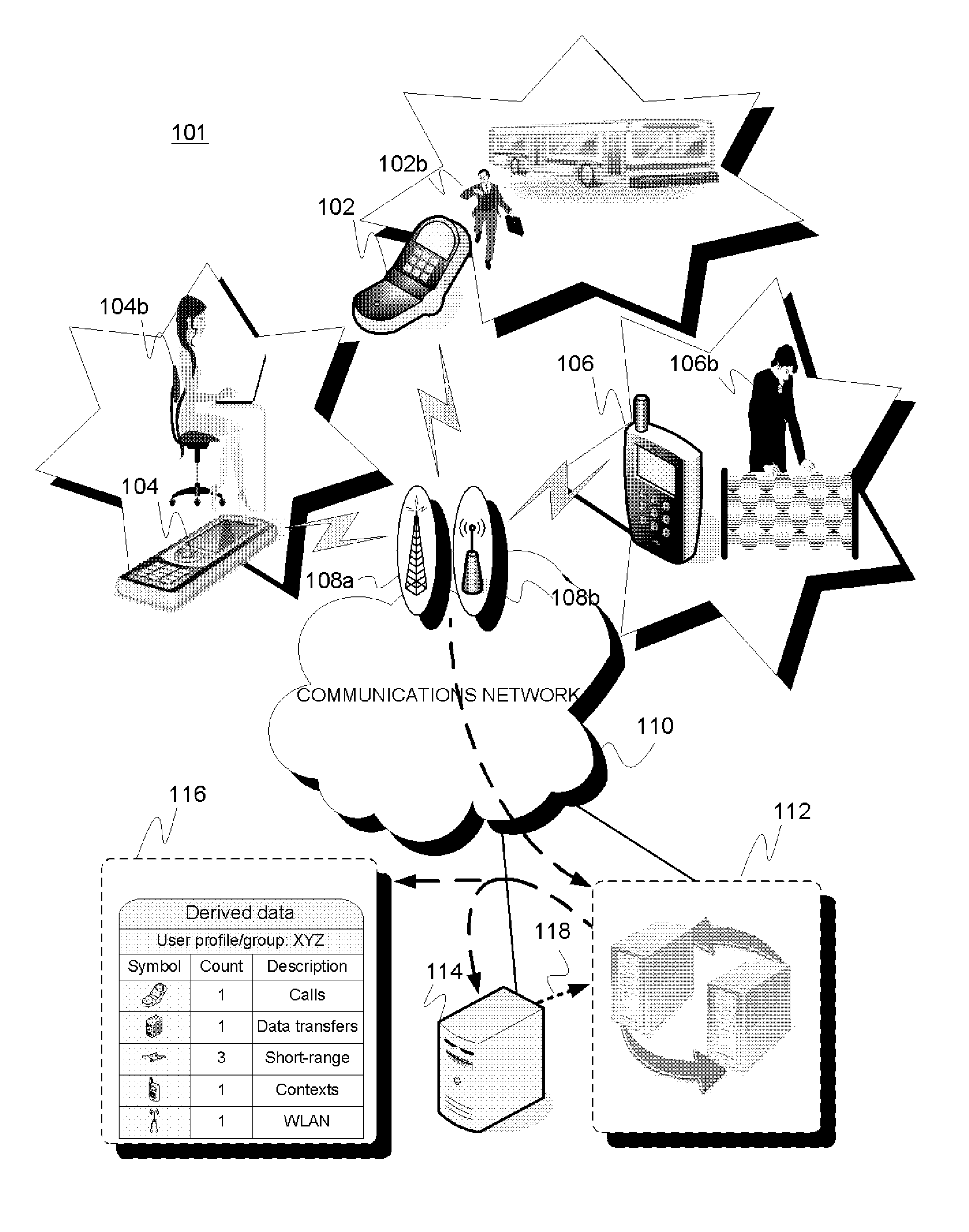

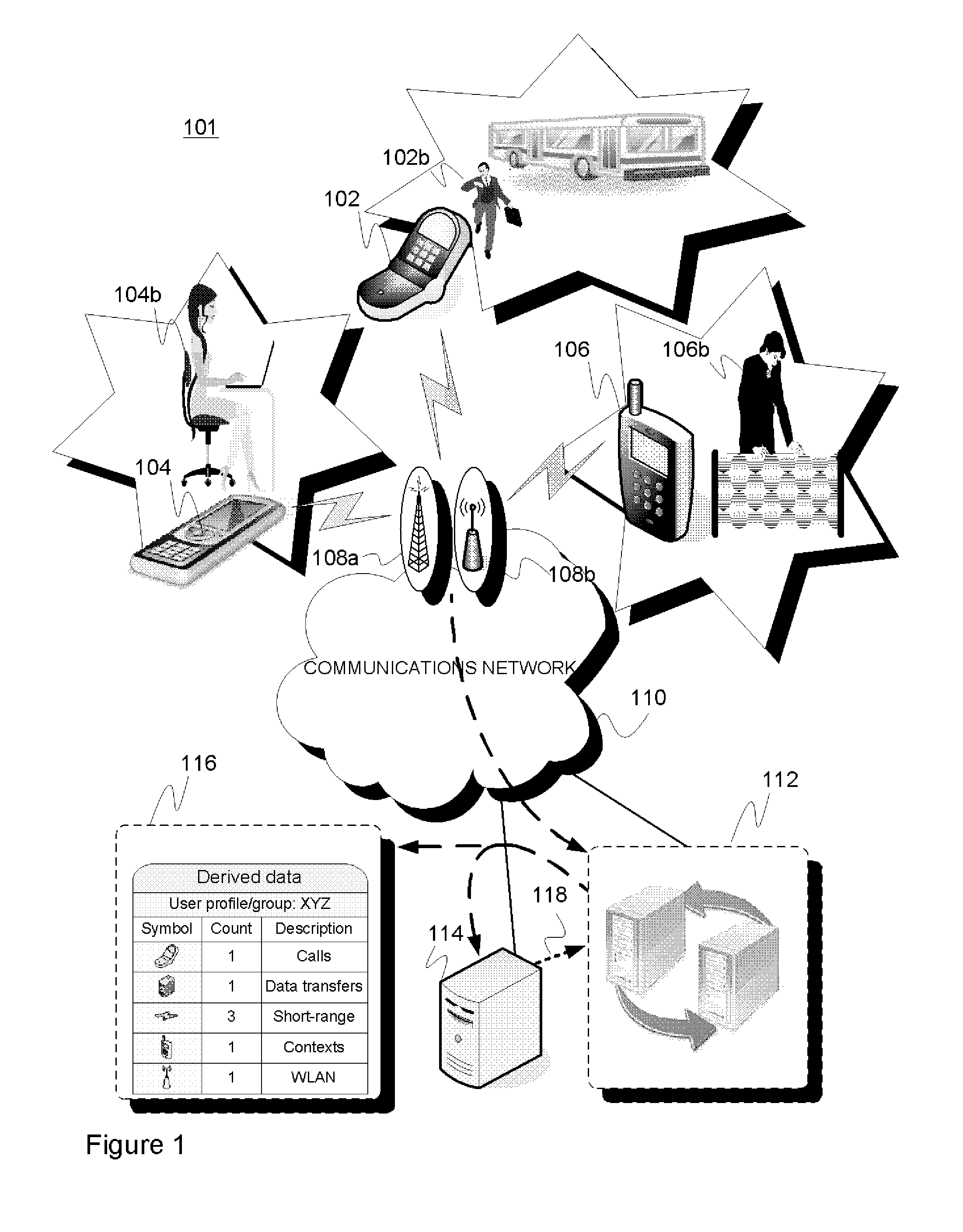

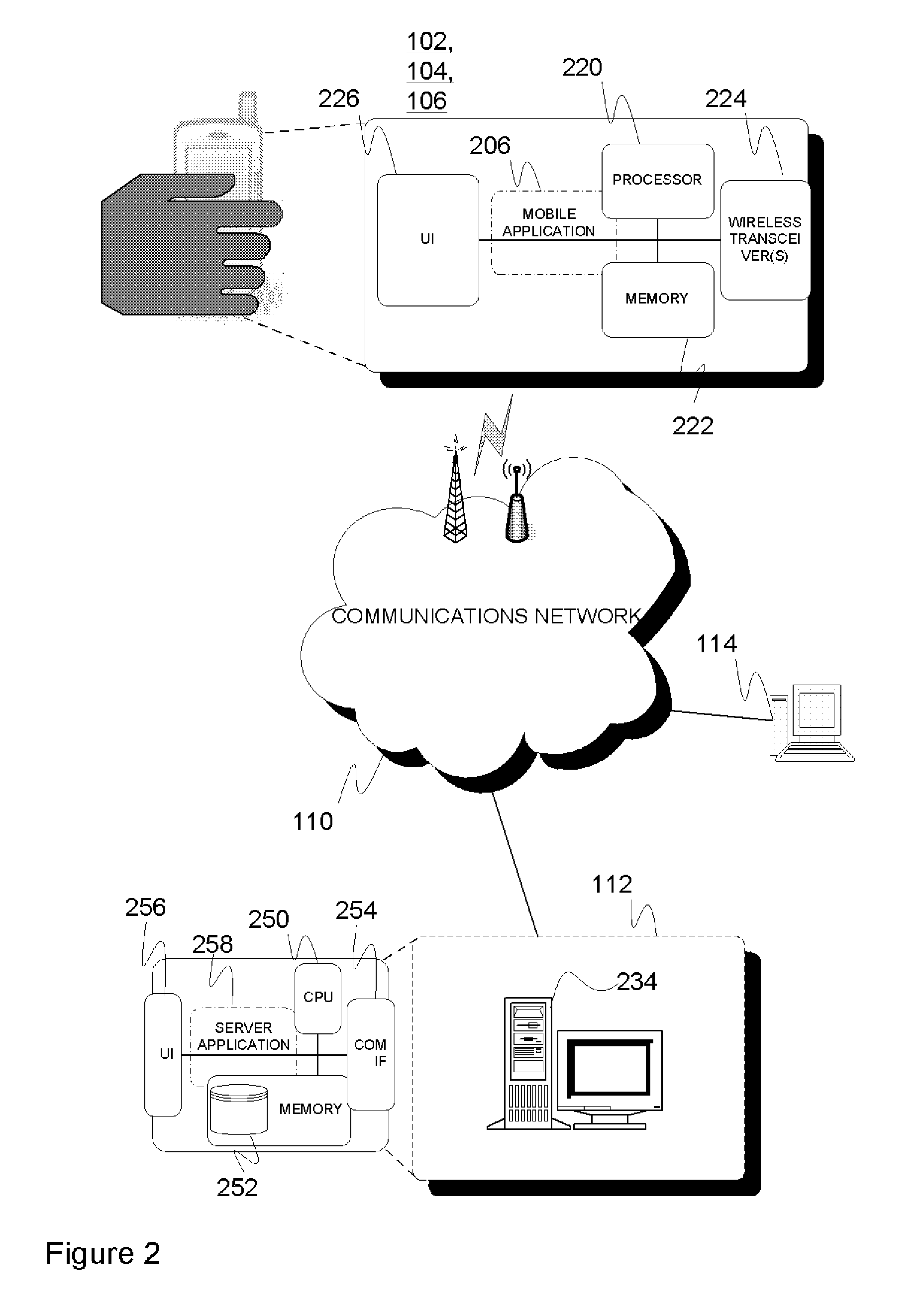

System and method for behavioural and contextual data analytics

ActiveUS20110264663A1Easy to customizeUseful for promotionDigital data processing detailsVisual data miningData packContext data

A server arrangement for managing observation data of wireless devices, including data input logic for obtaining observation data from wireless devices, the obtained data including behavioral and contextual raw data relative to the wireless devices, data mining logic for establishing a number of derived data elements, on the basis of processing and analyzing the obtained observation and optional supplementary data, the processing and analyzing incorporating aggregation procedures. At least one derived data element includes usage metrics with contextual dimension relative to applications or other features of wireless devices and users, data storage for storing the obtained data and the number of derived information elements, and a data distribution logic providing derived data. The distribution logic may serve a data query constructed by an external entity through provision of derived information from derived data elements according to the query parameters. A corresponding method for execution by the server arrangement is presented.

Owner:THE NIELSEN CO (US) LLC

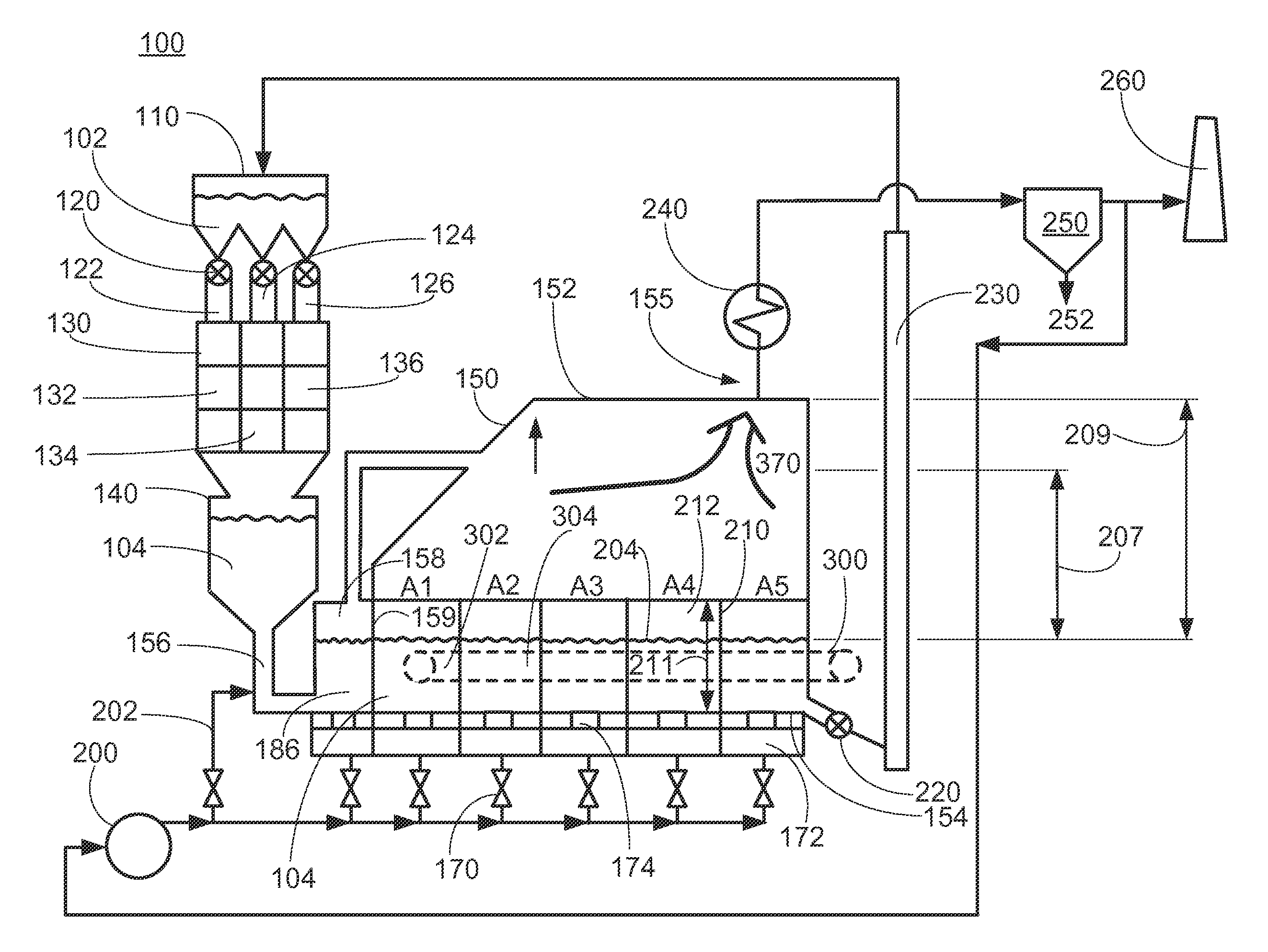

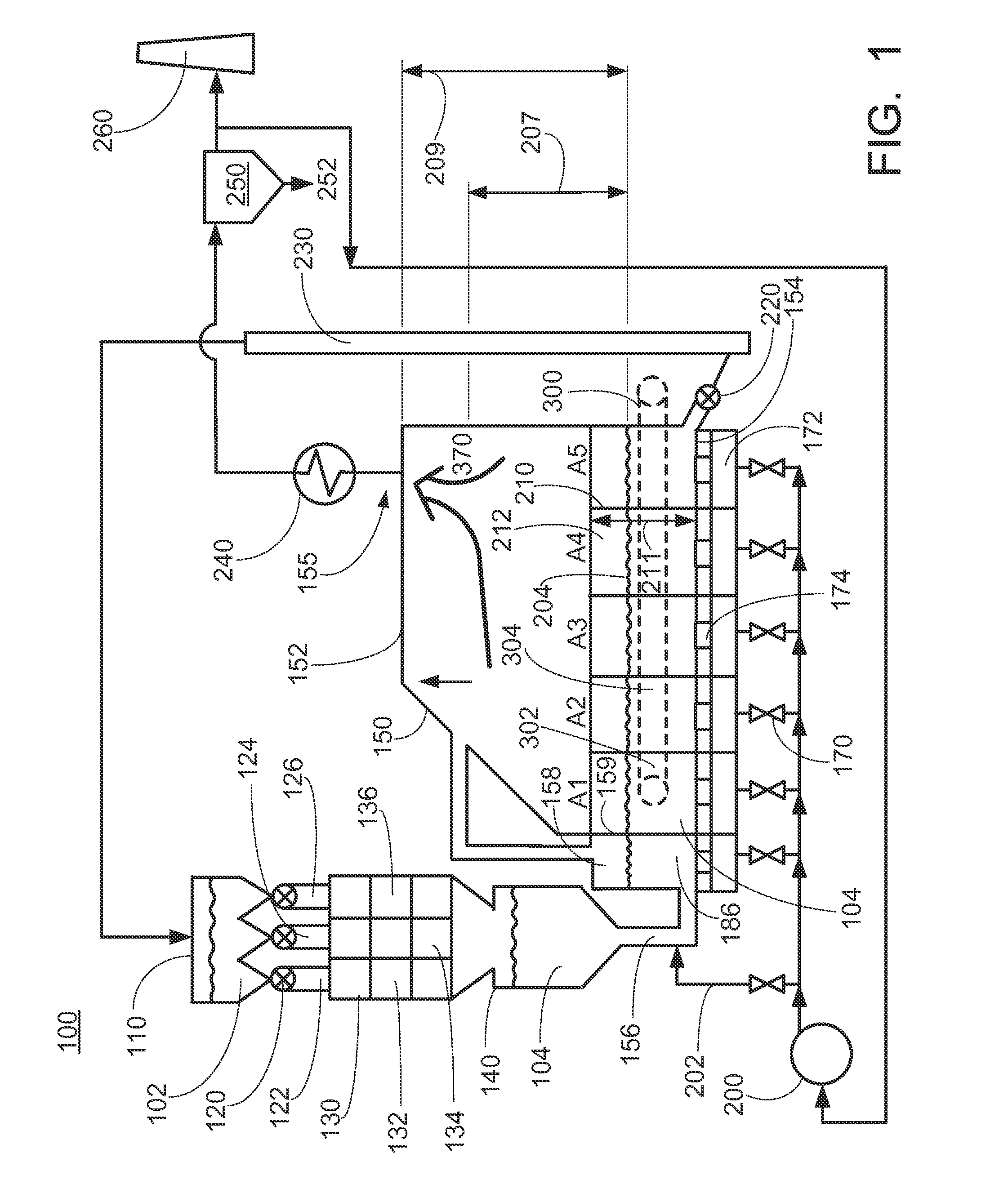

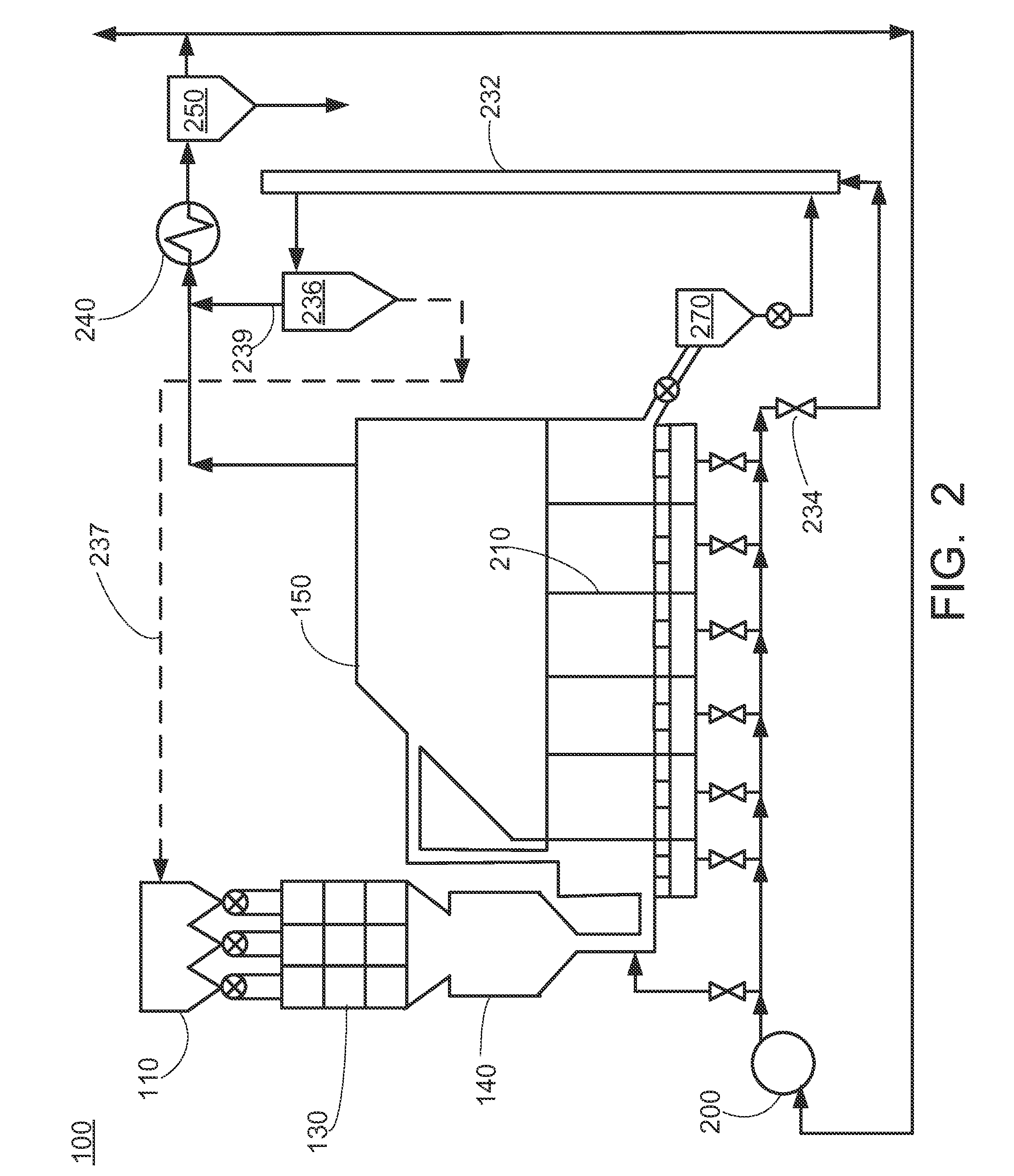

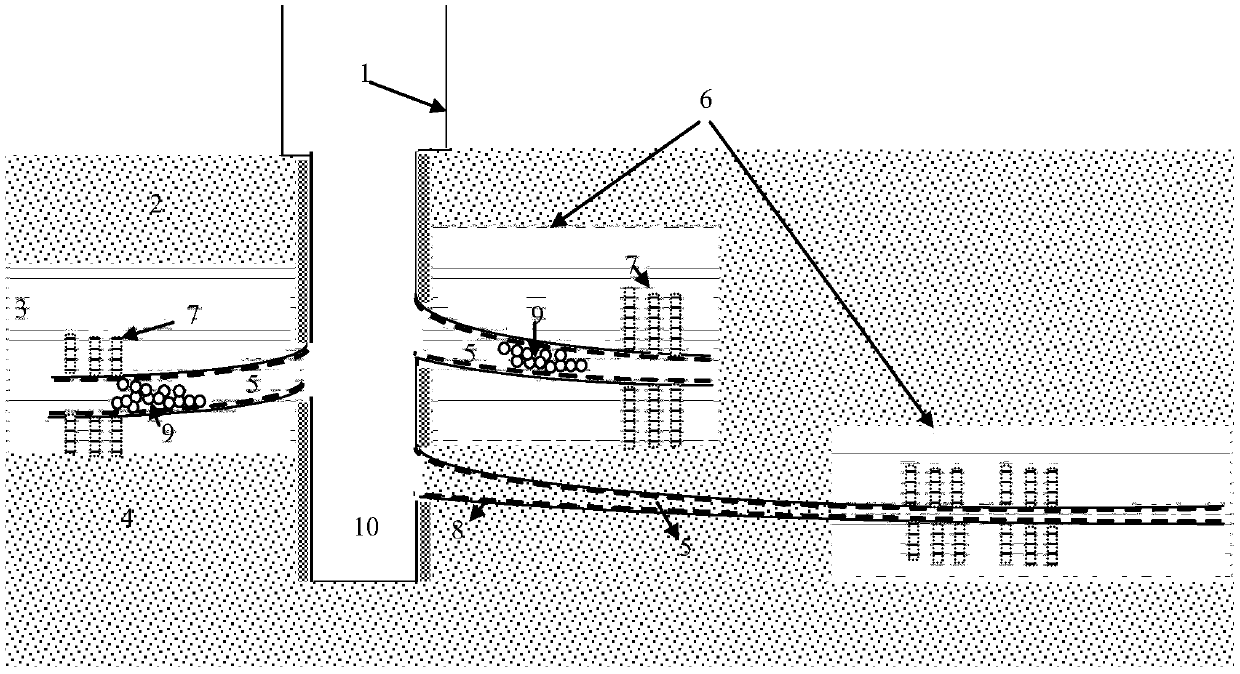

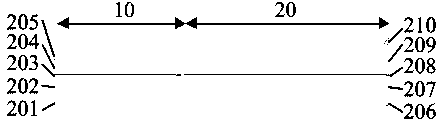

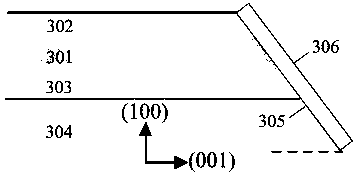

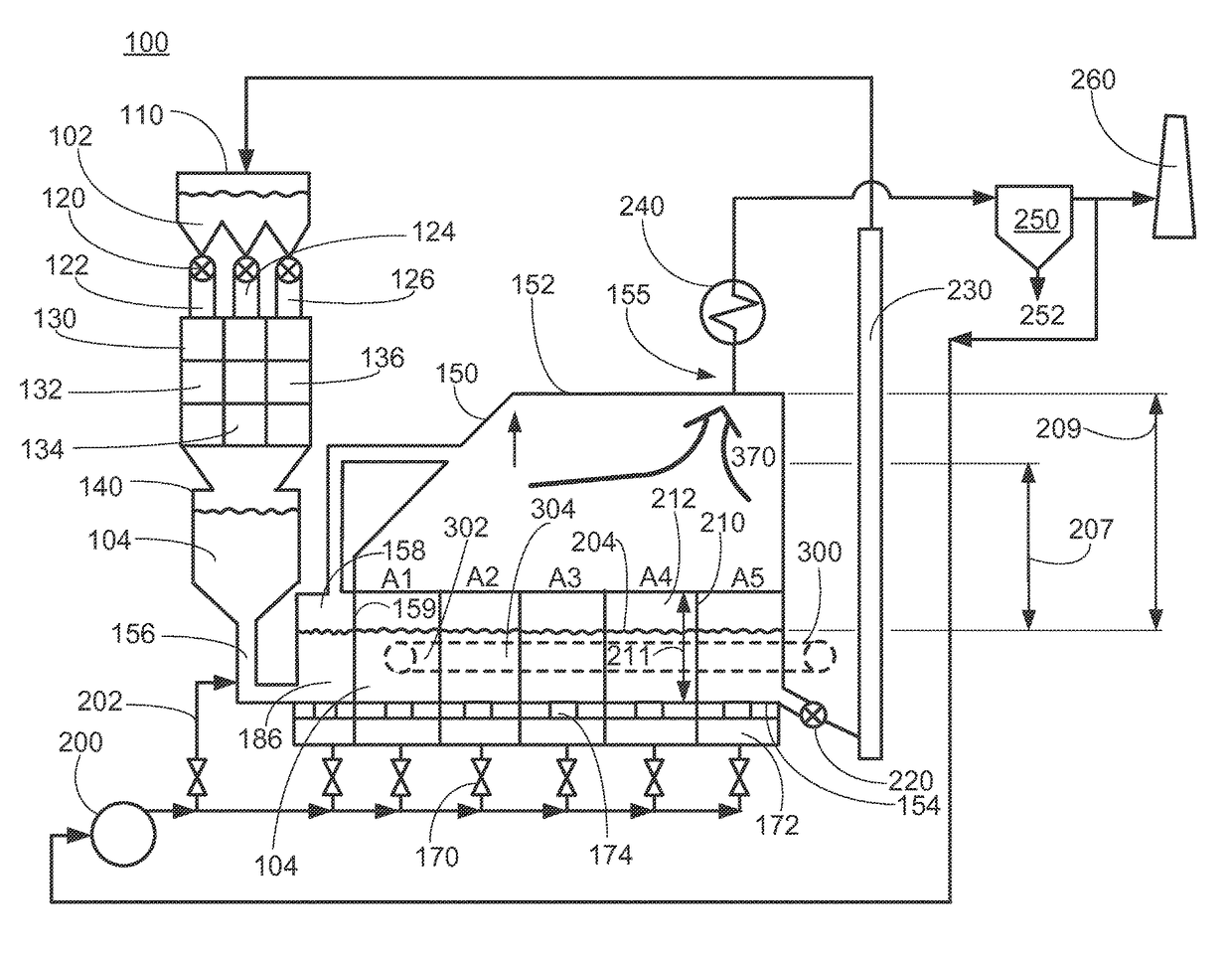

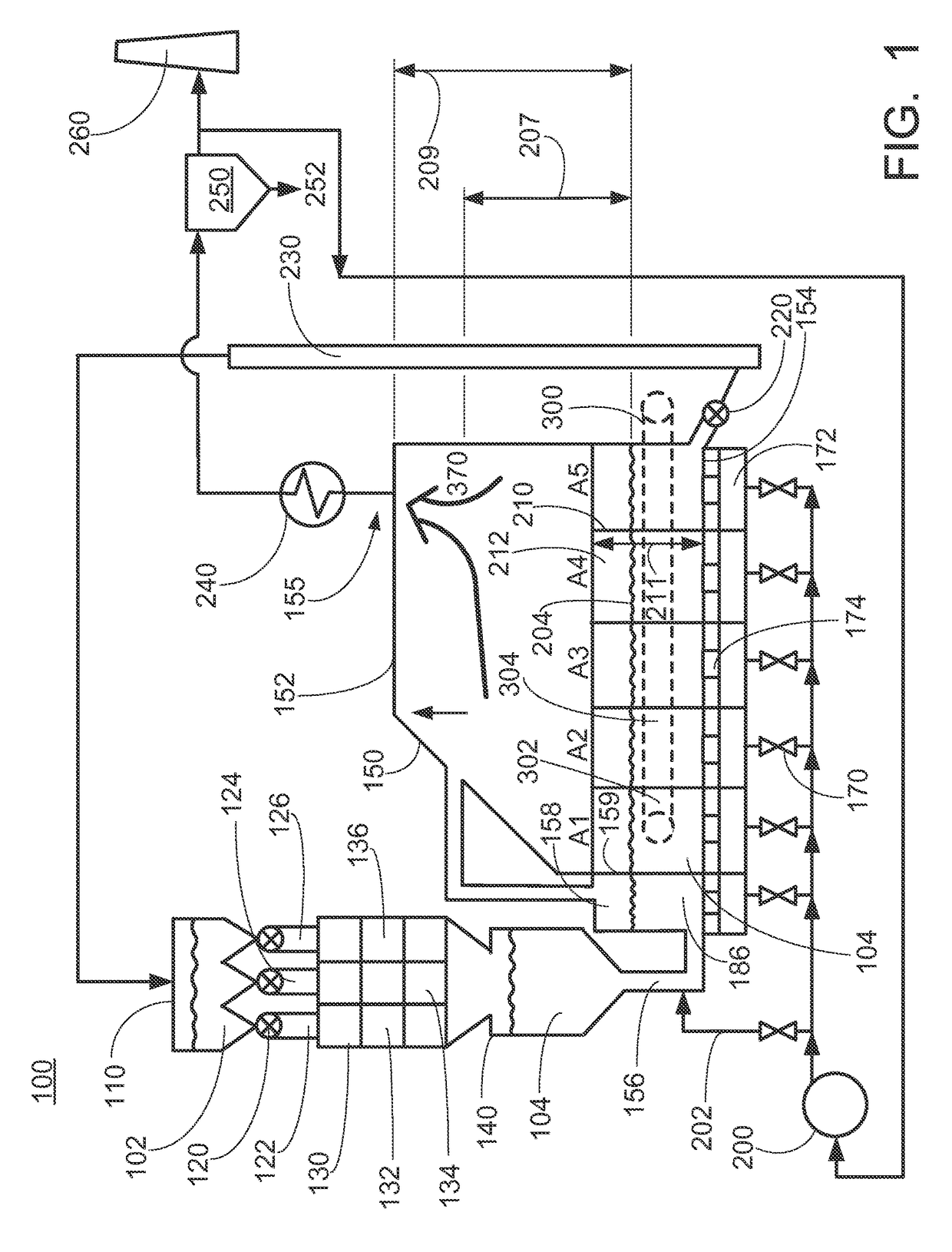

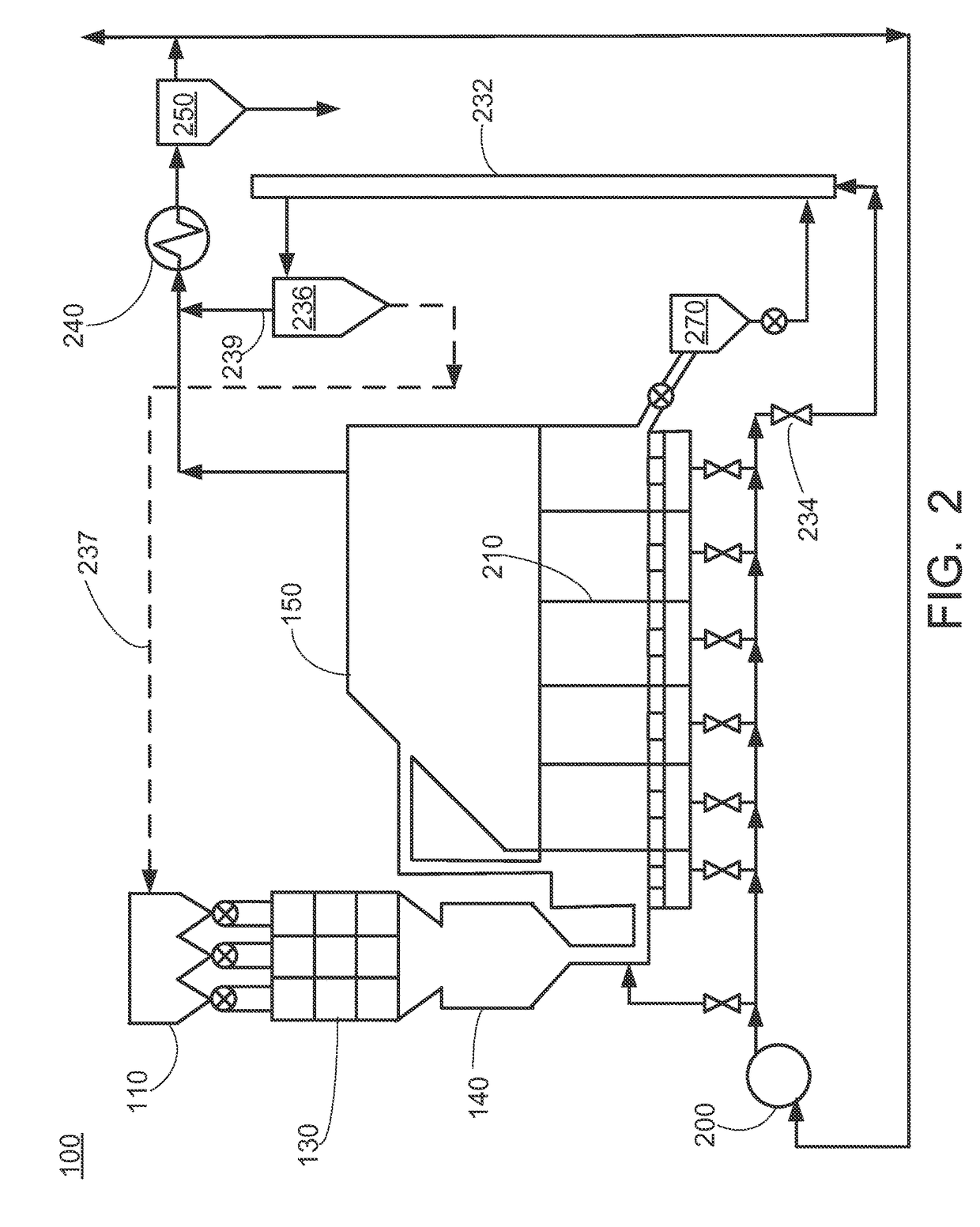

Concentrated solar power solids-based system

InactiveUS20140311479A1Increased system efficiency and flexibilityAffect outputSolar heating energyFrom solar energyConcentrated solar powerSolar power system

A solar power system comprises a solar receiver, a heated solids storage tank downstream of the solar receiver, a fluidized bed heat exchanger downstream of the heated solids storage tank, and means for transporting solid particles from the fluidized bed heat exchanger to a cold solids storage tank upstream of the solar receiver. The fluidized bed heat exchanger includes a first fluidized bed and a second fluidized bed. Solid particles flow through the fluidized bed heat exchanger and transfer heat energy to heating surfaces in the two fluidized beds. The system permits the solid particles to absorb more energy and permits a constant energy output from the fluidized bed heat exchanger.

Owner:THE BABCOCK & WILCOX CO

System and method for behavioural and contextual data analytics

ActiveUS9075883B2Useful for promotionEasy to integrateVisual data miningStructured data browsingObservation dataContext data

A server arrangement for managing observation data of wireless devices, including data input logic for obtaining observation data from wireless devices, the obtained data including behavioral and contextual raw data relative to the wireless devices, data mining logic for establishing a number of derived data elements, on the basis of processing and analyzing the obtained observation and optional supplementary data, the processing and analyzing incorporating aggregation procedures. At least one derived data element includes usage metrics with contextual dimension relative to applications or other features of wireless devices and users, data storage for storing the obtained data and the number of derived information elements, and a data distribution logic providing derived data. The distribution logic may serve a data query constructed by an external entity through provision of derived information from derived data elements according to the query parameters. A corresponding method for execution by the server arrangement is presented.

Owner:THE NIELSEN CO (US) LLC

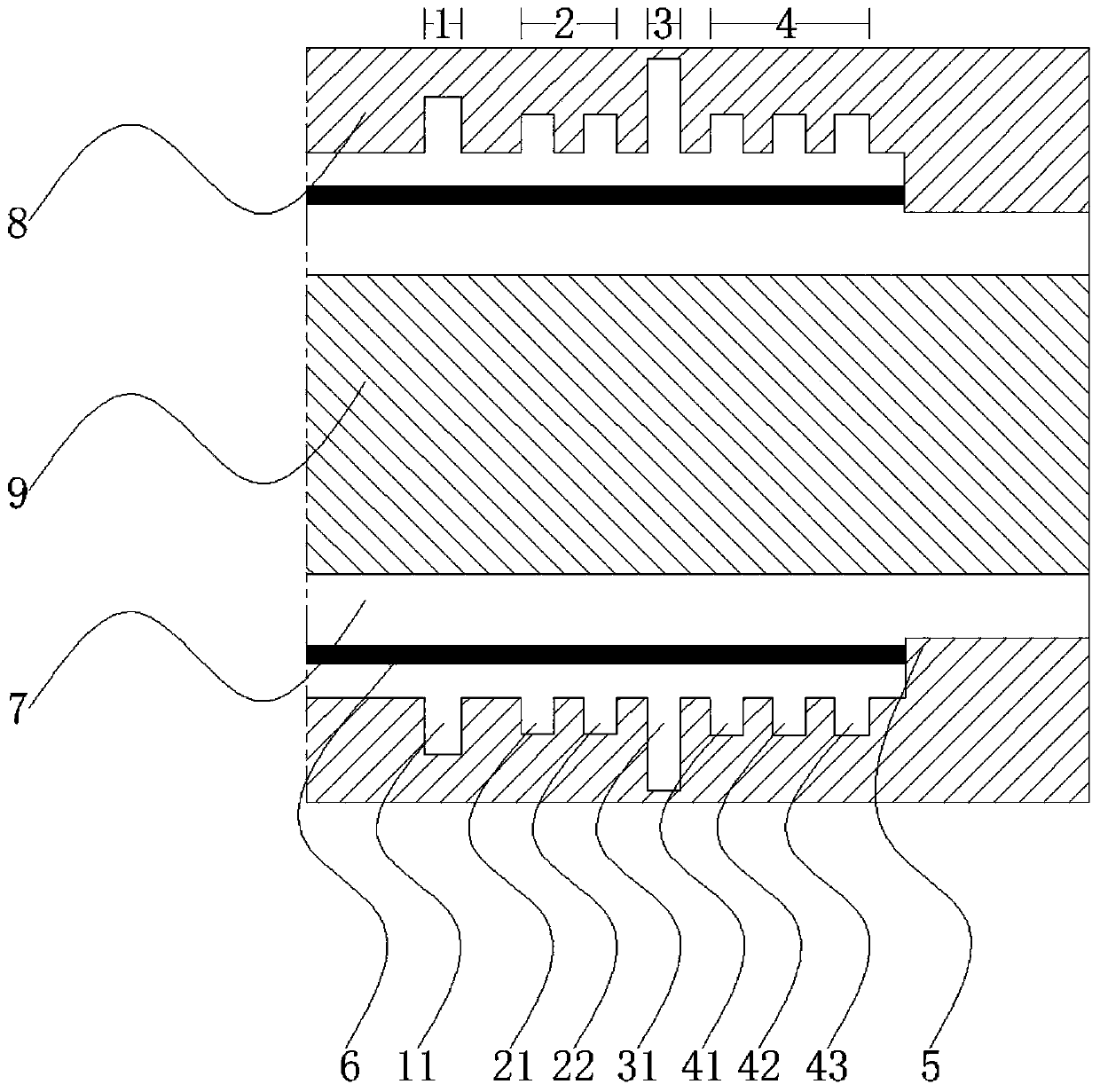

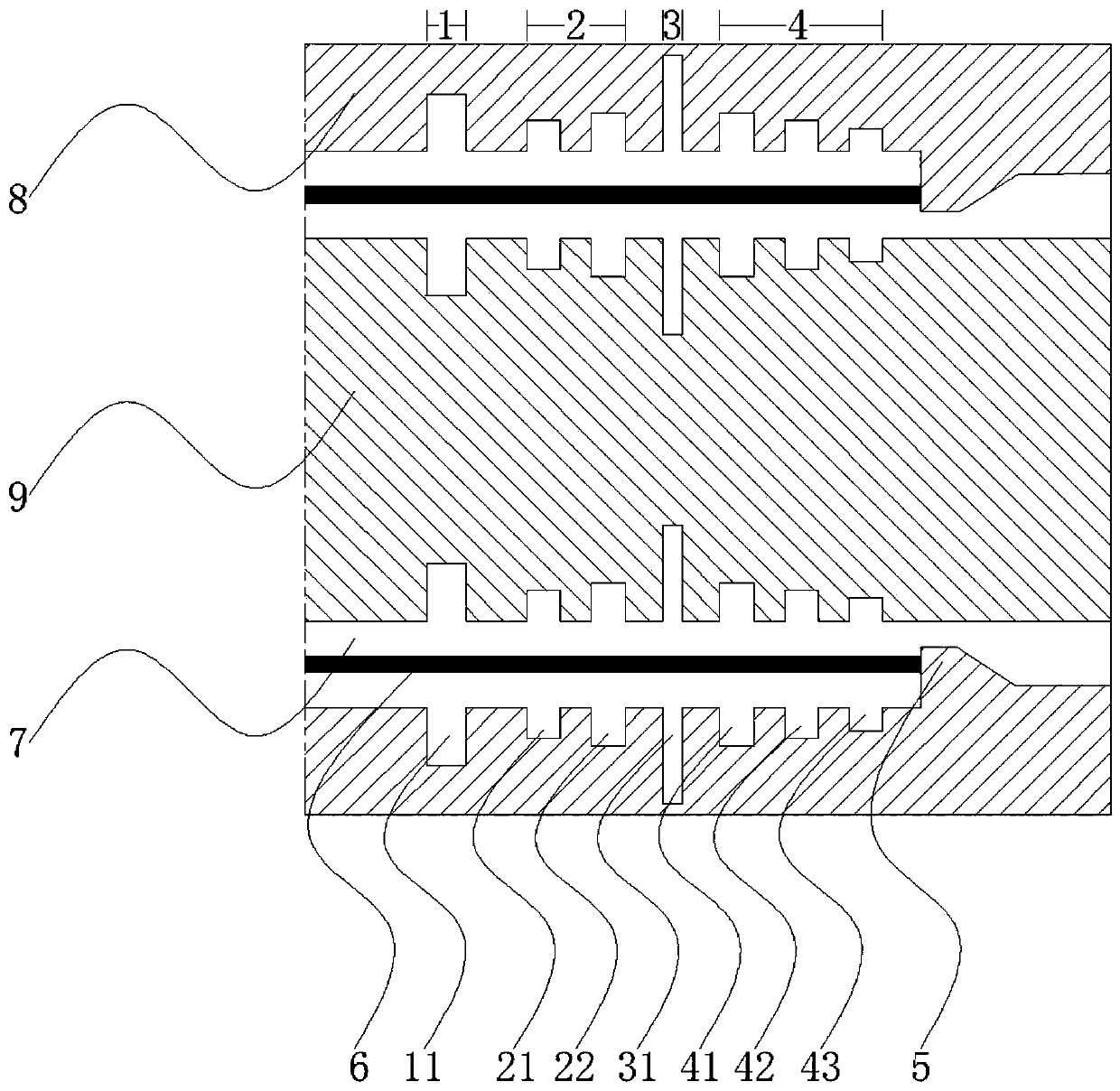

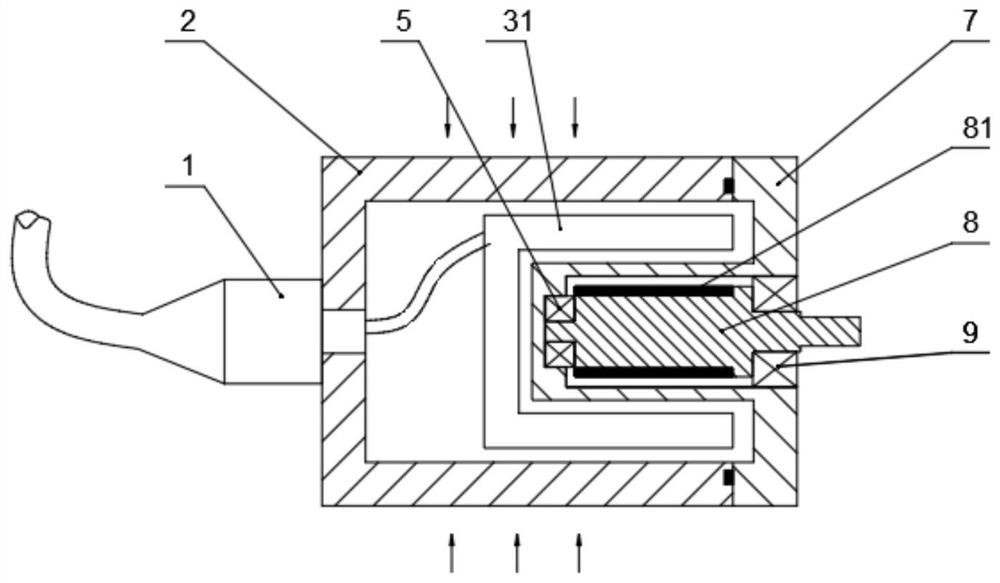

Electrolysis device for preparation of hypochlorous water

InactiveUS20100288626A1Improve productivityComplex structureCellsMachining electric circuitsProduction rateHypochlorous acid

An electrolysis device for preparation of hypochlorous water is provided, comprising an electrolytic cell, and cathodic and anodic electrolytic sheets arranged in the electrolytic cell, wherein the electrolytic cell is separated to form an inner tank for containing hydrochloric acid and an outer tank for circulating tap water, a central portion of the inner tank is sealed and separated relative to the outer tank, and a chlorine discharge outlet connected to the outer tank is provided at the upper end of the inner tank; the cathodic and anodic electrolytic sheets are located on both sides of the inner tank. The electrolysis device without a membrane utilizes tap water and hydrochloric acid as raw materials, having an inner tank for containing hydrochloric acid and an outer tank for circulating tap water. Chlorine generated through electrolysis of hydrochloric acid is discharged from the chlorine discharge outlet and combined with tap water in the outer tank to generate hypochlorous acid. This electrolysis device has simple structure, and can effectively improve productivity of hypochlorous water. Hypochlorous water produced by this electrolysis device has functions of sterilization and environmental protection.

Owner:KUAN YU WEN +1

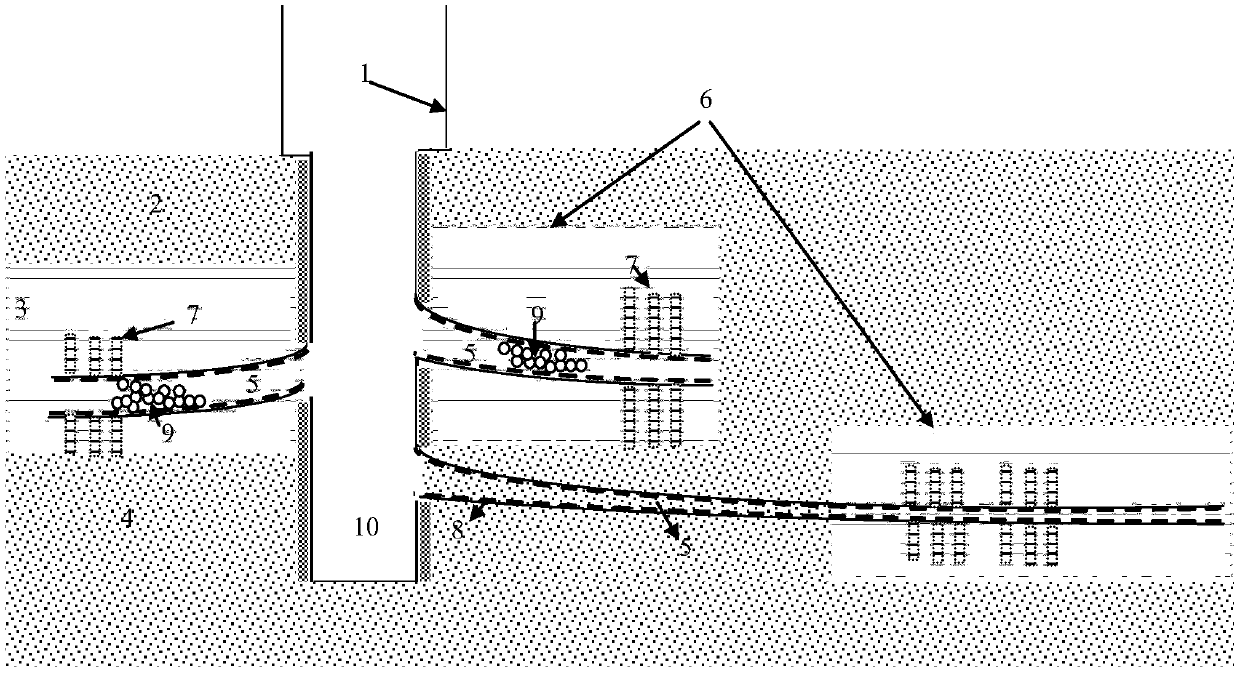

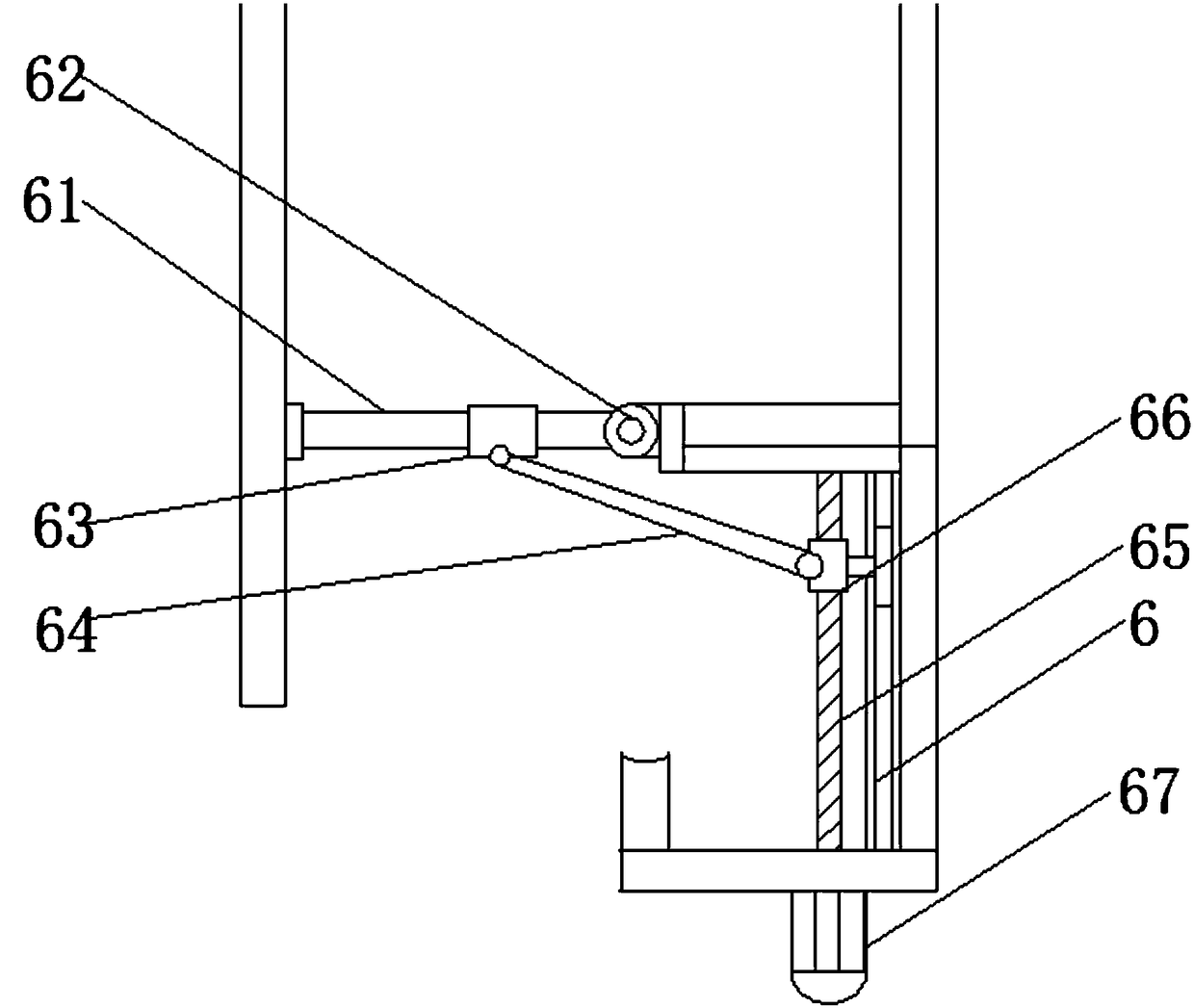

Combined mining method with decompression and heating in multi-branched horizontal wells for marine hydrate

ActiveCN109763794BEffective spreadIncrease the decomposition surfaceFluid removalUnderwater drillingMining engineeringHorizontal wells

Owner:QINGDAO INST OF MARINE GEOLOGY

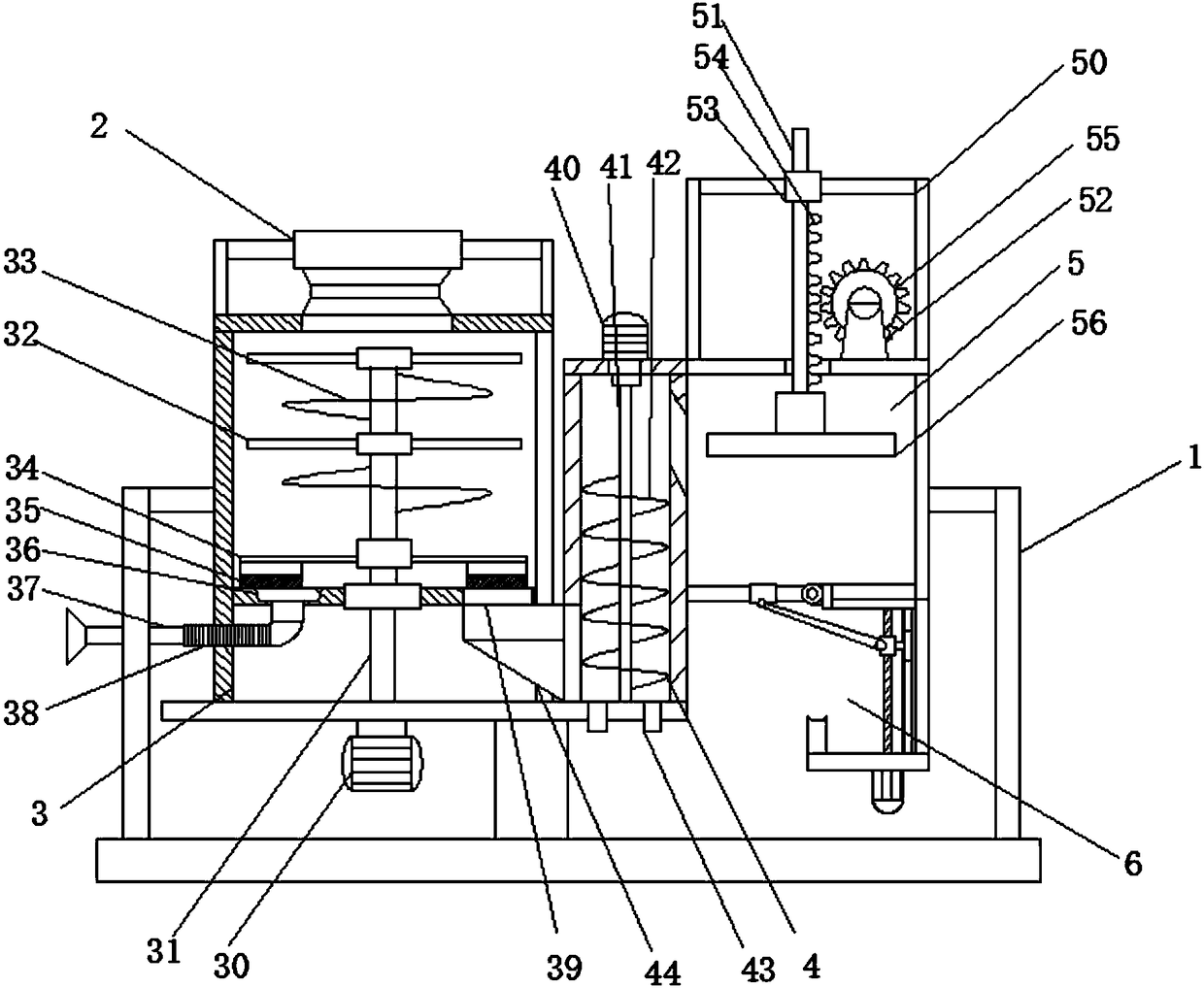

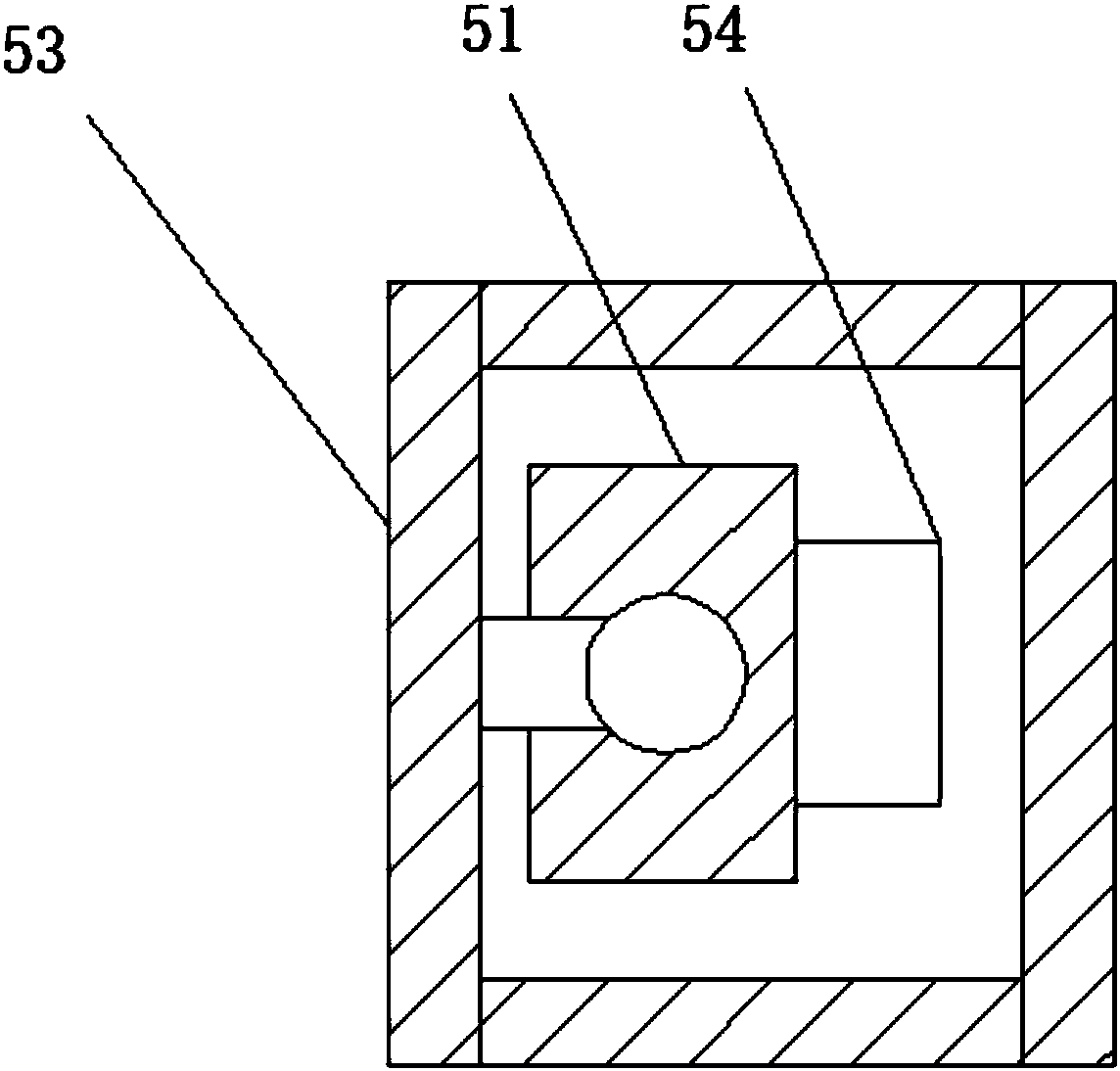

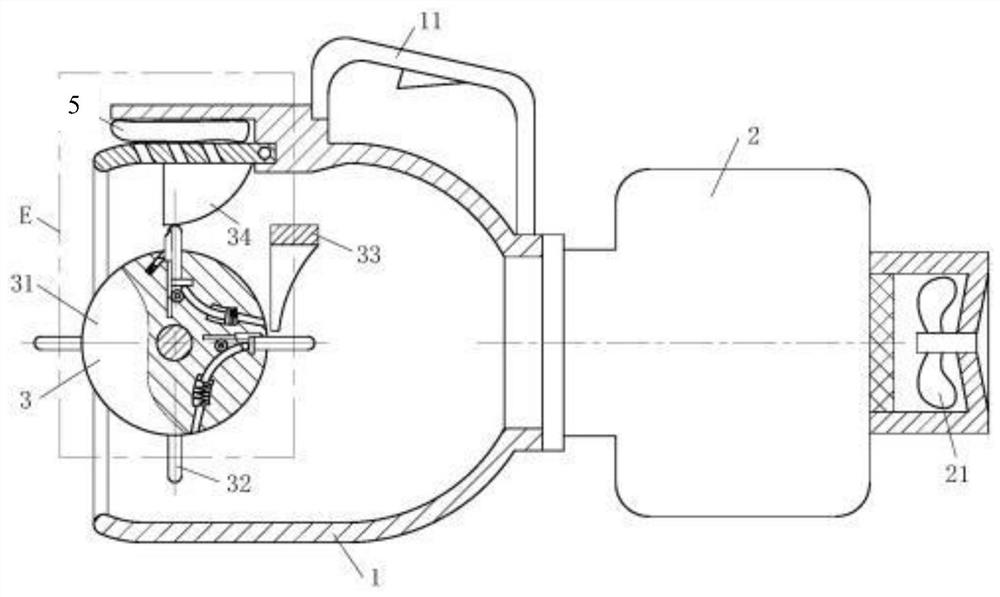

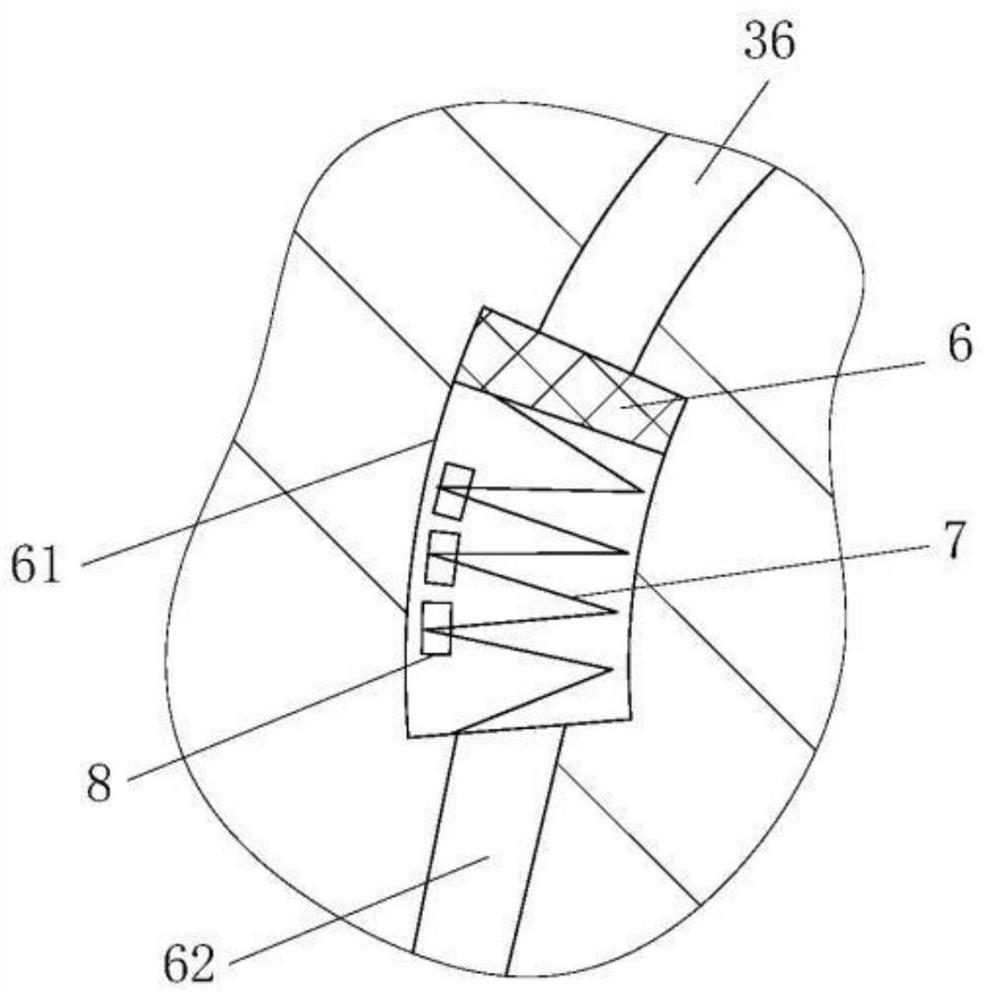

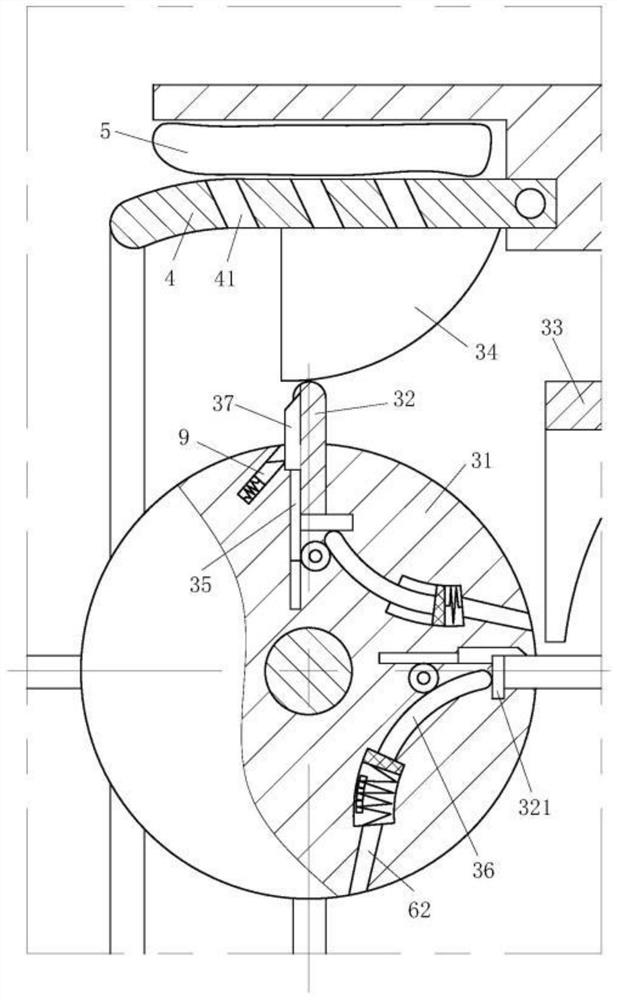

Disinfecting and crushing apparatus for plastics medical waste

InactiveCN108453120AImprove cutting effectAffect outputSolid waste disposalPlastic recyclingMedical wasteMechanical engineering

The invention discloses a disinfecting and crushing apparatus for plastics medical waste. The disinfecting and crushing apparatus comprises a stander, wherein a cutting box, a transport cavity, an extruding box and a discharging cavity are arranged in the stander, the cutting box is disposed on the front end of the stander, the top end of the cutting box is provided with a feeding frame, the feeding frame is provided with a feeding hopper communicated with the cutting box, the bottom end of the cutting box is provided with a cutting motor, the top end of the cutting motor is provided with a cutting rotating shaft, the cutting rotating shaft stretches into the cutting box and is provided with a plurality of pairs of cutting blades and spiral rods, the cutting blades and the spiral rods aredistributed in an staggered manner, the bottom end of the cutting rotating shaft is provided with a brush rod, the outer end of the brush rod is provided with a cleaning brush, the bottom end of the cutting box is provided with a water outlet and a transport port, the cleaning brush is disposed right above the water outlet and the transport port, and the water outlet is connected with a water discharging pipe. The cleaning brush is driven by a brush rod to rotate, so that the material can be prevented from being adhered onto a bottom plate and influencing the output of materials, and the blockage condition of the material can be prevented.

Owner:周佳裕

Multi-branch horizontal well depressurization and heating united mining method for marine hydrates

ActiveCN109763794AEffective spreadIncrease the decomposition surfaceFluid removalUnderwater drillingSoil scienceHorizontal wells

The invention discloses a multi-branch horizontal well depressurization and heating united mining method for marine hydrates. For the 'congenital' defects that the marine hydrates are distributed in ascattered manner and cannot self flow and get together, based on well type structure improvement of a 'main borehole + a multi-branch horizontal well', an ore body reservoir is hydraulically cut by avertical hydrate layer to improve the hydrate decomposition efficiency and achieve the design objectives of connecting three-dimensional scattered ore bodies and relieving the problems of a large amount of sand, instability of the reservoir and blockage formed by secondary hydrates. The united mining method comprises the following steps: (1) forming a well by a main borehole; (2) drilling a multi-branch horizontal well: forming a plurality of multi-branch horizontal wells, which form a certain included angle and are distributed in a fixed direction, around the main borehole, and arranging thehorizontal wells in the middle region of a hydrate reservoir, wherein joints between the multi-branch horizontal wells and between the multi-branch horizontal wells and the main borehole are all of sleeve and conventional sand control sieve tube structures; (3) performing limited sand control and reservoir supporting; (4) transforming the reservoir by hydraulic jetting; (5) performing heating toprevent blockage.

Owner:QINGDAO INST OF MARINE GEOLOGY

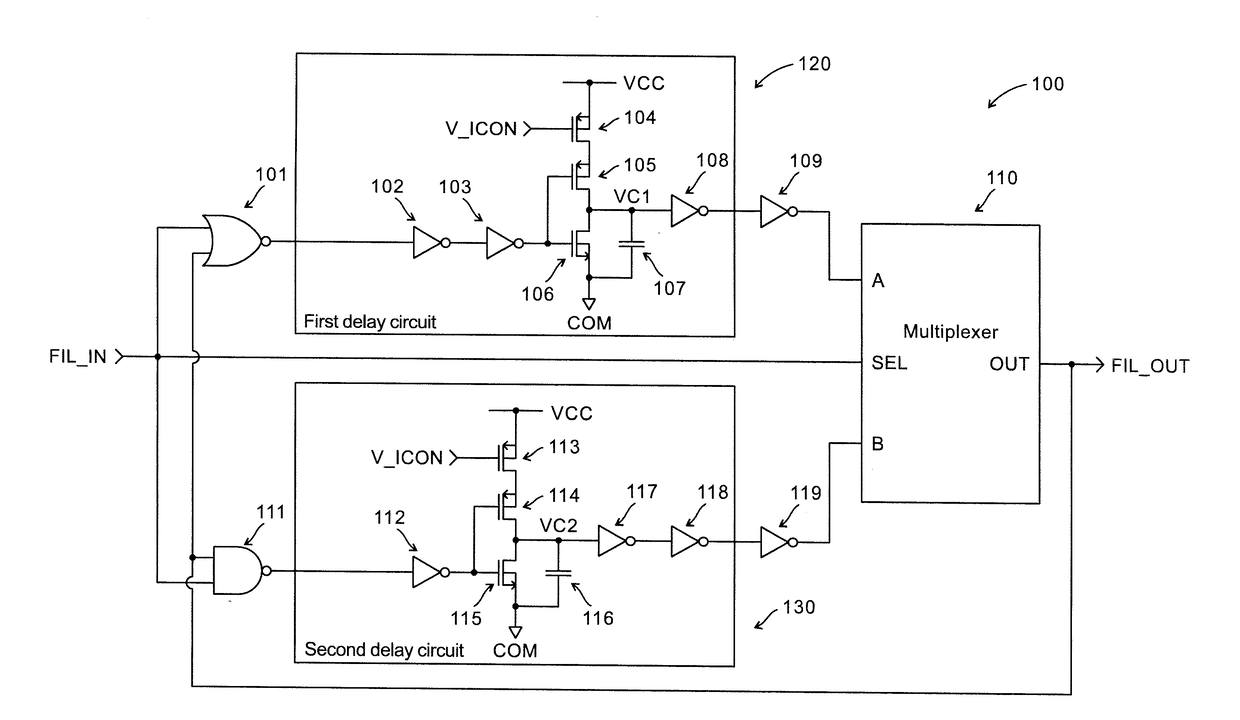

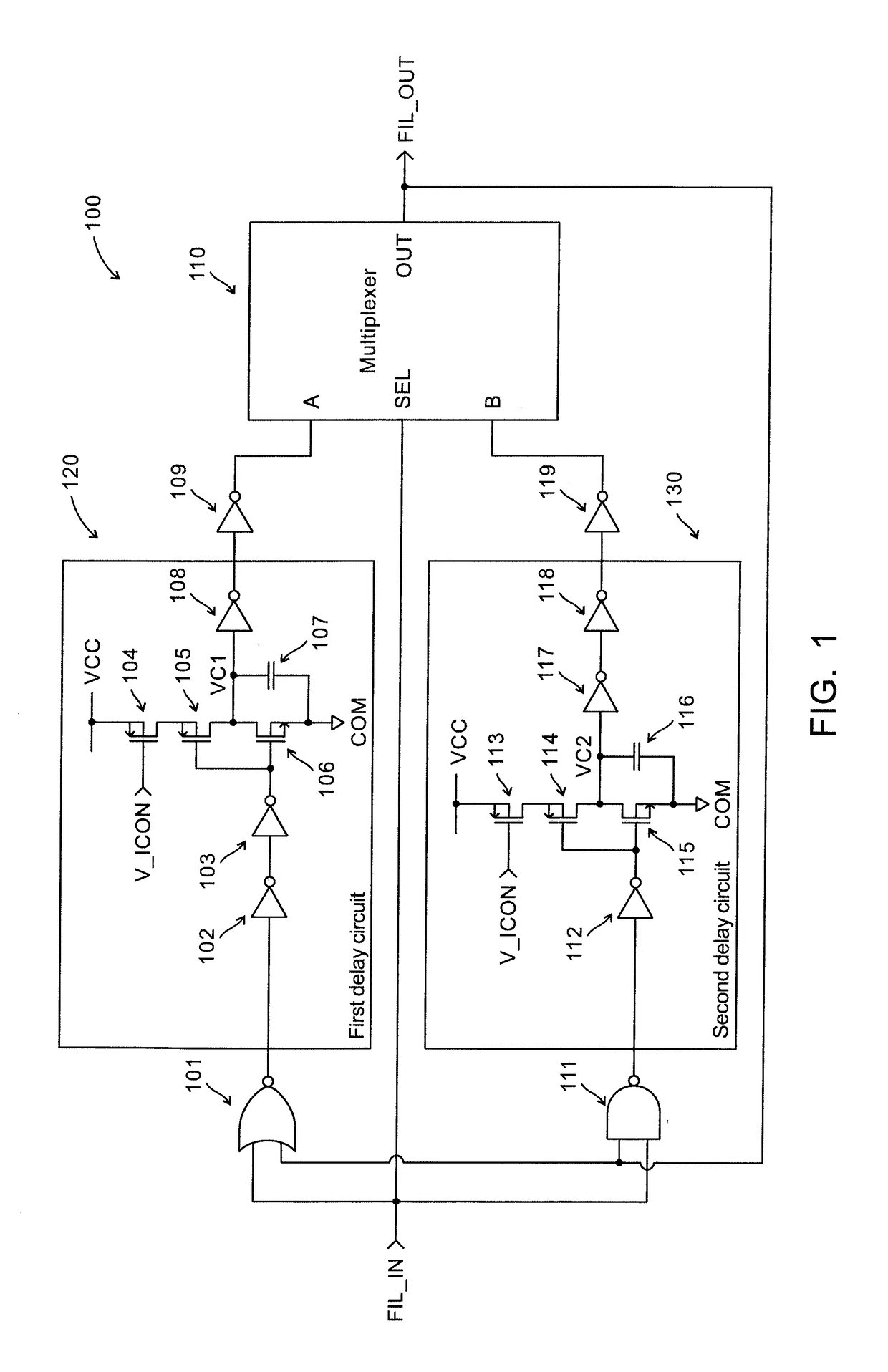

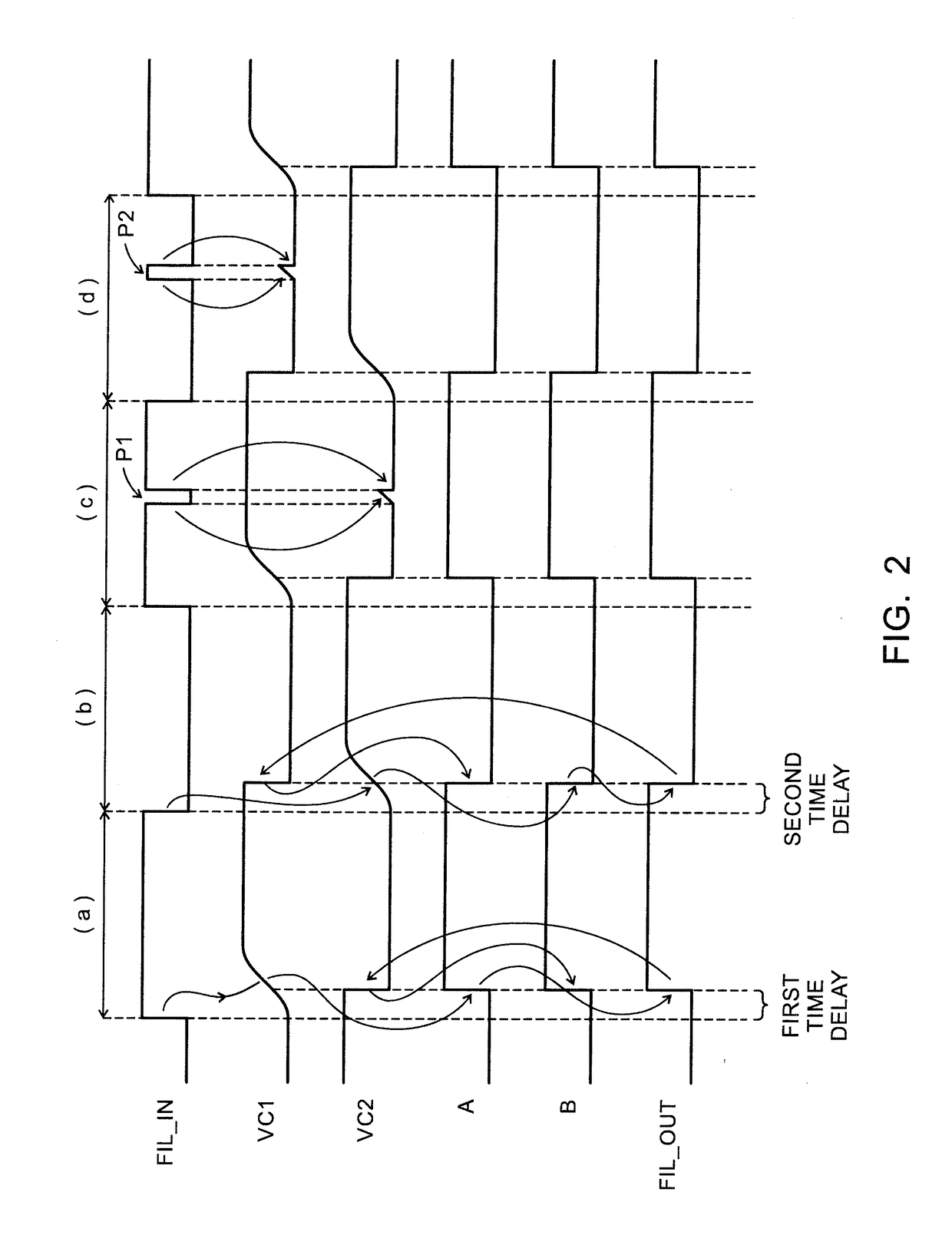

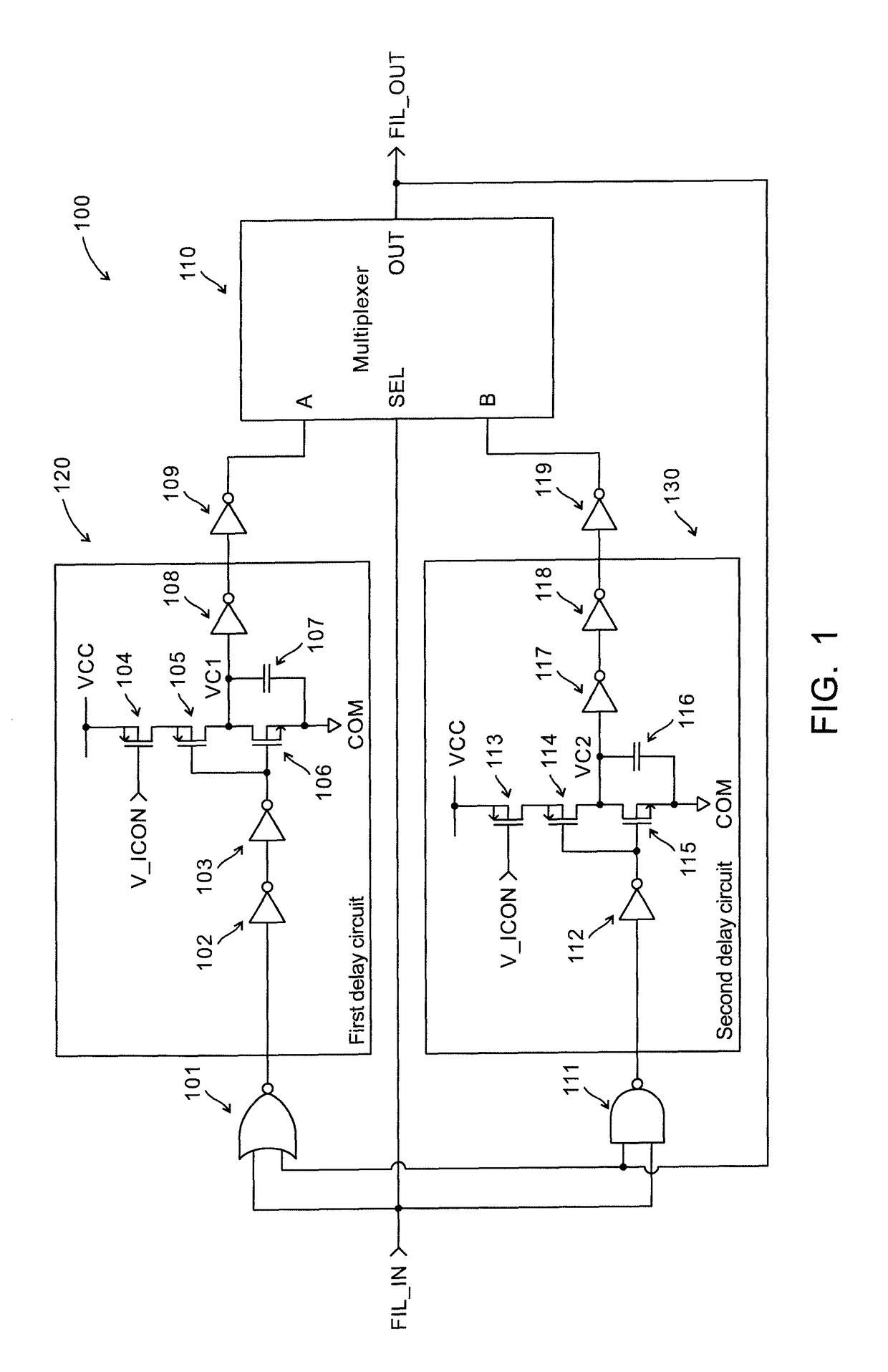

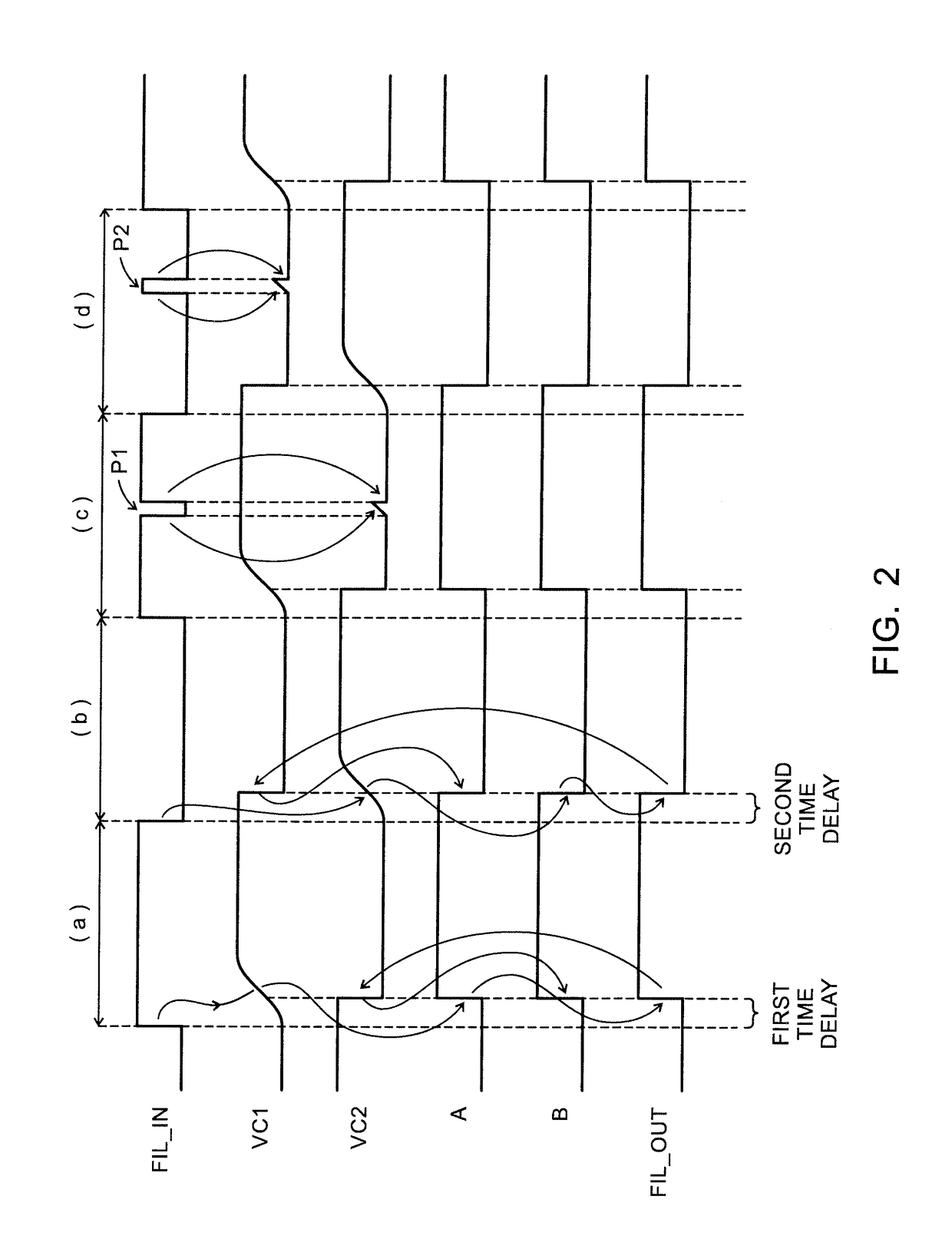

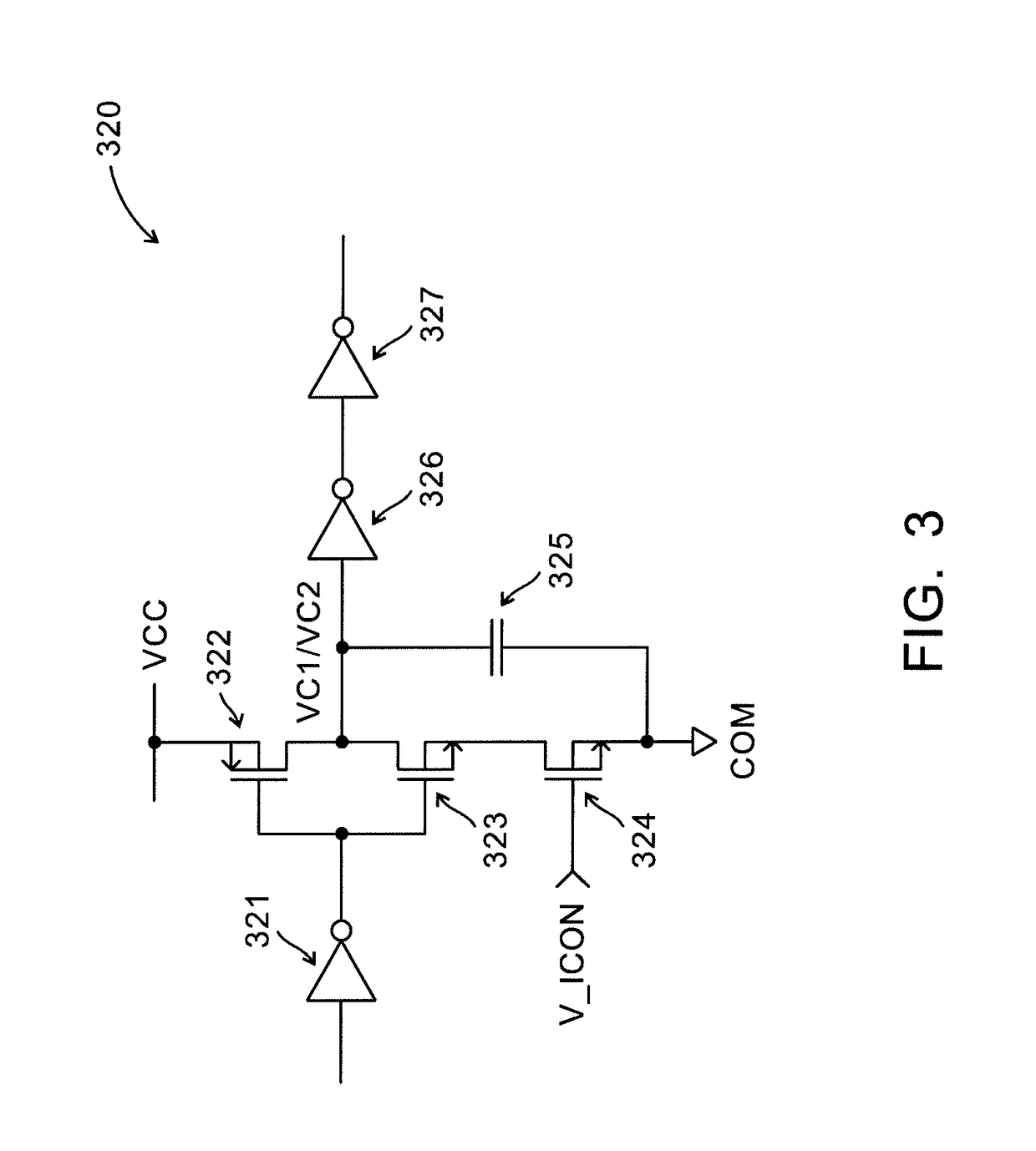

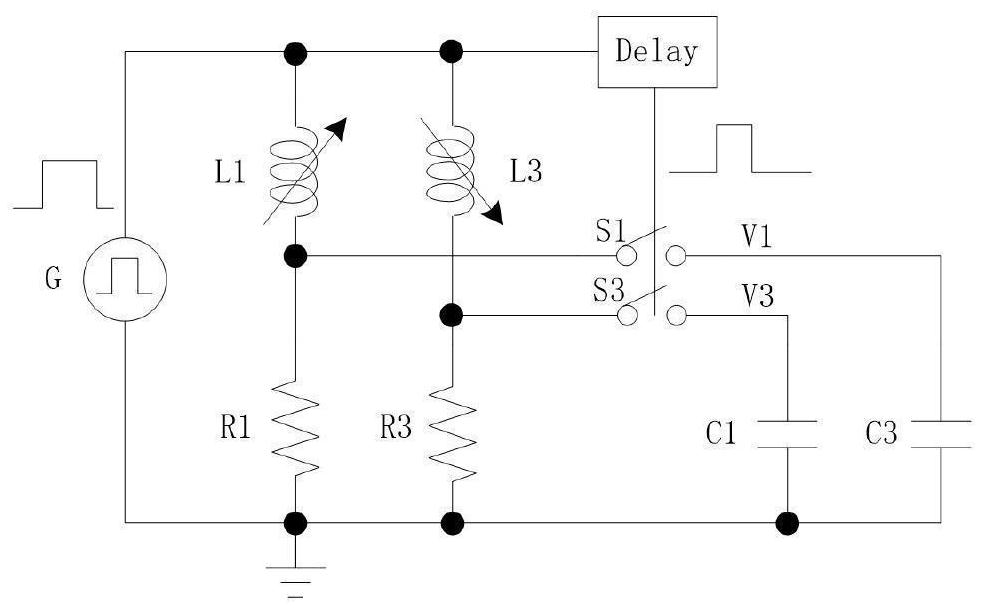

Pulse width filtering circuit

ActiveUS20180123576A1Improves circuit balanceImprove performanceLogic circuits characterised by logic functionContinuous to patterned pulse manipulationState variationEngineering

A pulse width filtering circuit for filtering pulse signals includes an input transition detection circuit detecting change of state of an input signal, including a first transition from a low signal to a high signal and a second transition from the high signal to the low signal; a first delay circuit determining whether the high signal from the first transition is maintained longer than a first period and, if so, generating a first output indicative of the first transition, after the first period; a second delay circuit determining whether the low signal from the second transition is maintained for longer than a second period and, if so, generating a second output indicative of the second transition, after the second period; and a switching circuit connected to the first and second delay circuits and selectively outputting the first output and the second output, based on the state of the input signal.

Owner:MOSWAY TECH LTD

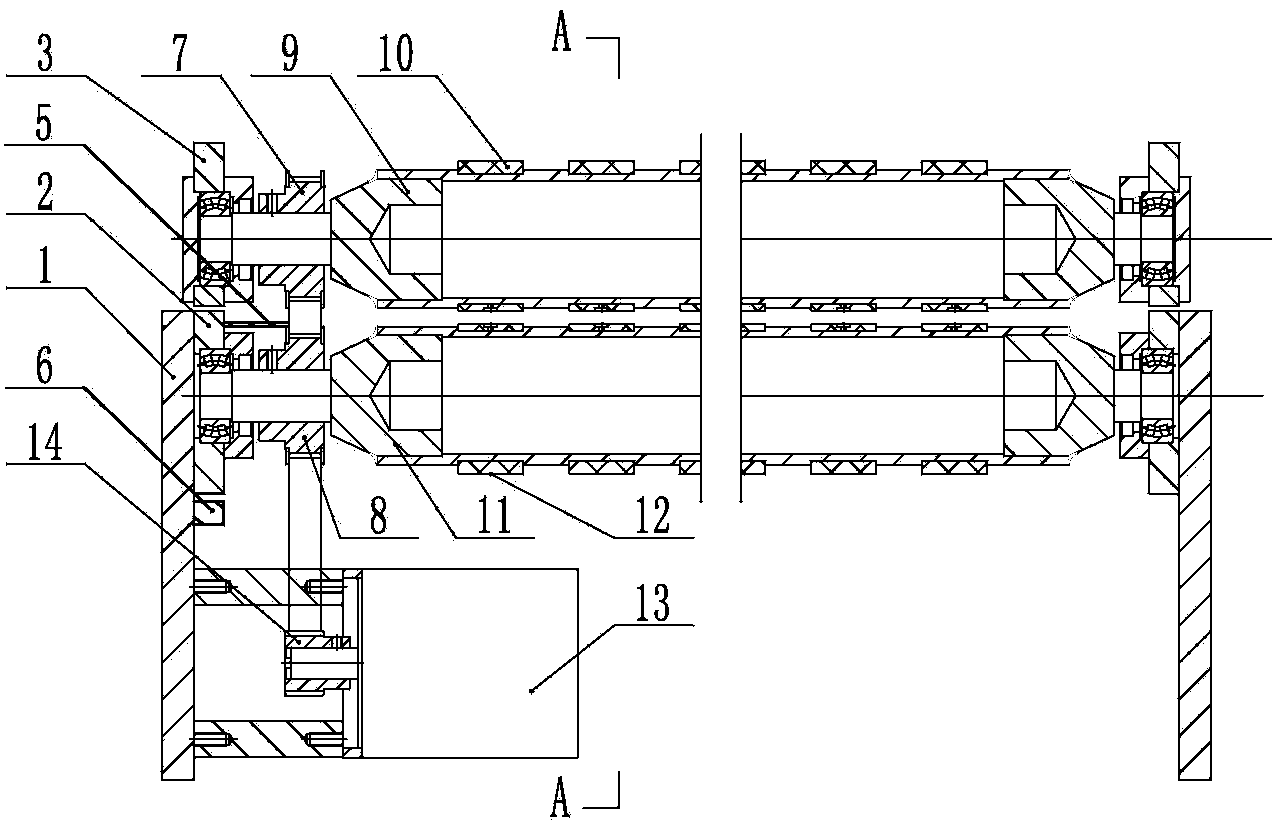

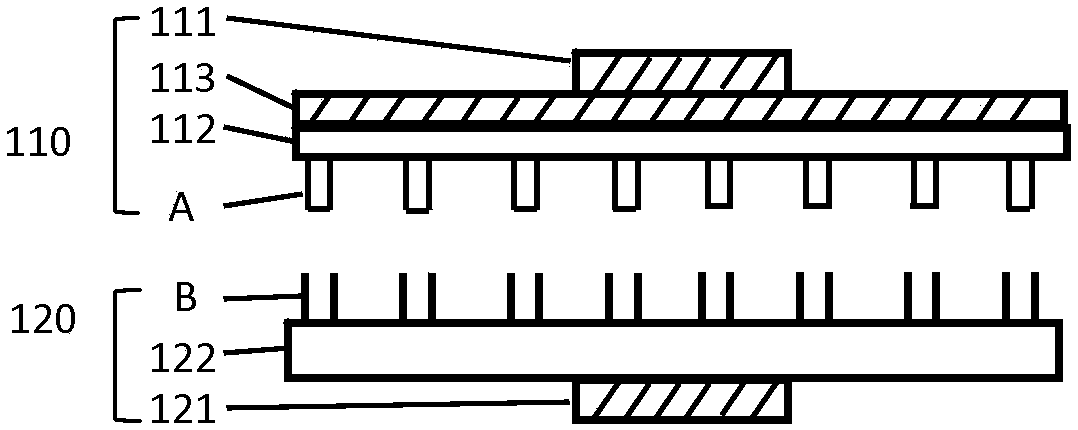

Discharging buffering device for paper products after high-speed cutting

ActiveCN103523581AReduce paper feed speedSmooth motionArticle deliveryPulp and paper industryContinuous production

The invention provides a discharging buffering device for paper products after high-speed cutting, and belongs to a speed regulating device in a high-speed output process for the paper products. The discharging buffering device is used for reducing the paper conveying speed after the paper products are cut through a cutting machine and enabling the paper conveying speed to be matched with low-speed paper conveying required by a subsequent procedure. According to the discharging buffering device, an upper shaft rubber sleeve and a lower shaft rubber sleeve are fixedly installed on an upper rotating shaft and a lower rotating shaft in a sleeved mode respectively, the upper shaft rubber sleeve and the lower shaft rubber sleeve are located above and below the cut paper products, and the upper rotating shaft and the lower rotating shaft rotate in the reverse direction. When an outer circular protrusion of the upper shaft rubber sleeve and an outer circular protrusion of the lower shaft rubber sleeve are oppositely overlapped, the cut paper products are clamped, the linear speed of the contact portions between the outer circular protrusions and the cut paper products is greatly less than the speed of the cut paper products, and the directions of the speeds are the same. According to the technical scheme, the technical problems that high-speed paper conveying of the paper products cut through the high-speed paper cutting machine cannot be matched with low-speed paper conveying required by the subsequent procedure, and continuous production is affected are solved.

Owner:QINGDAO JINYE PRECISION MACHINERY

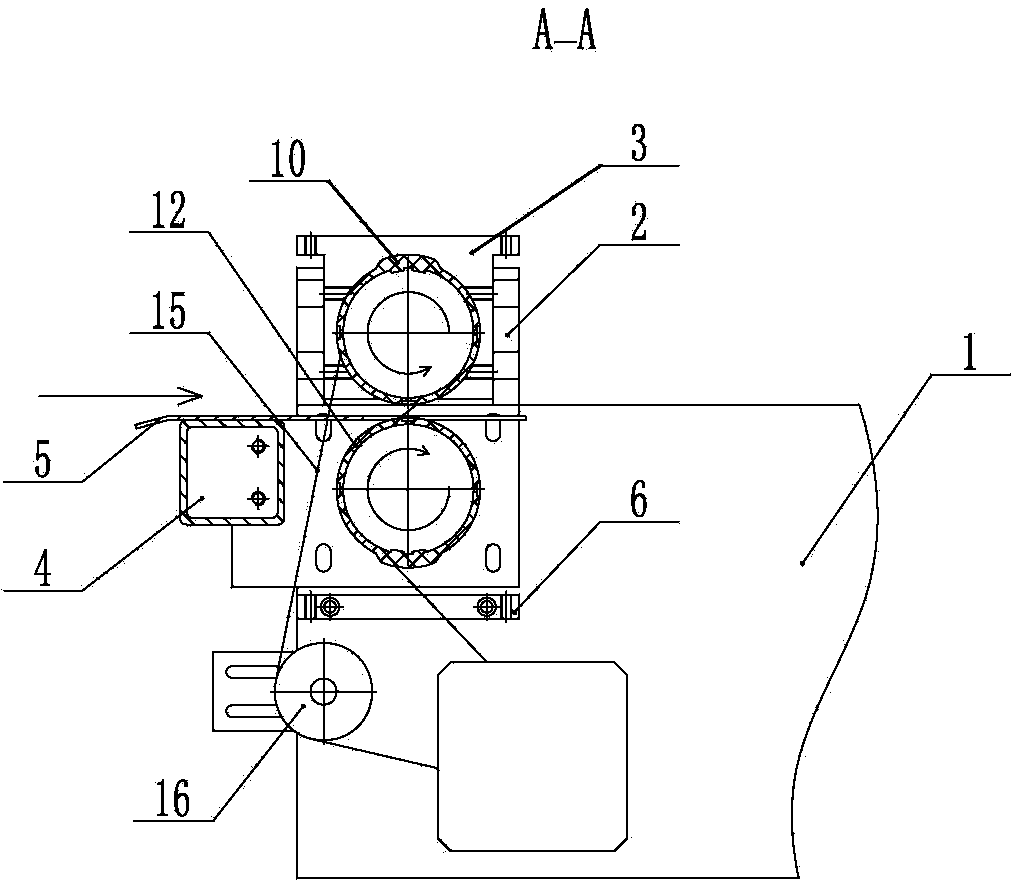

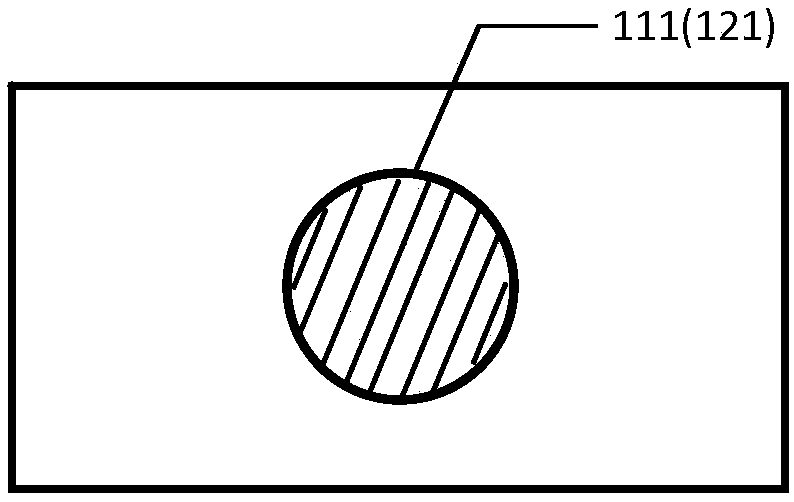

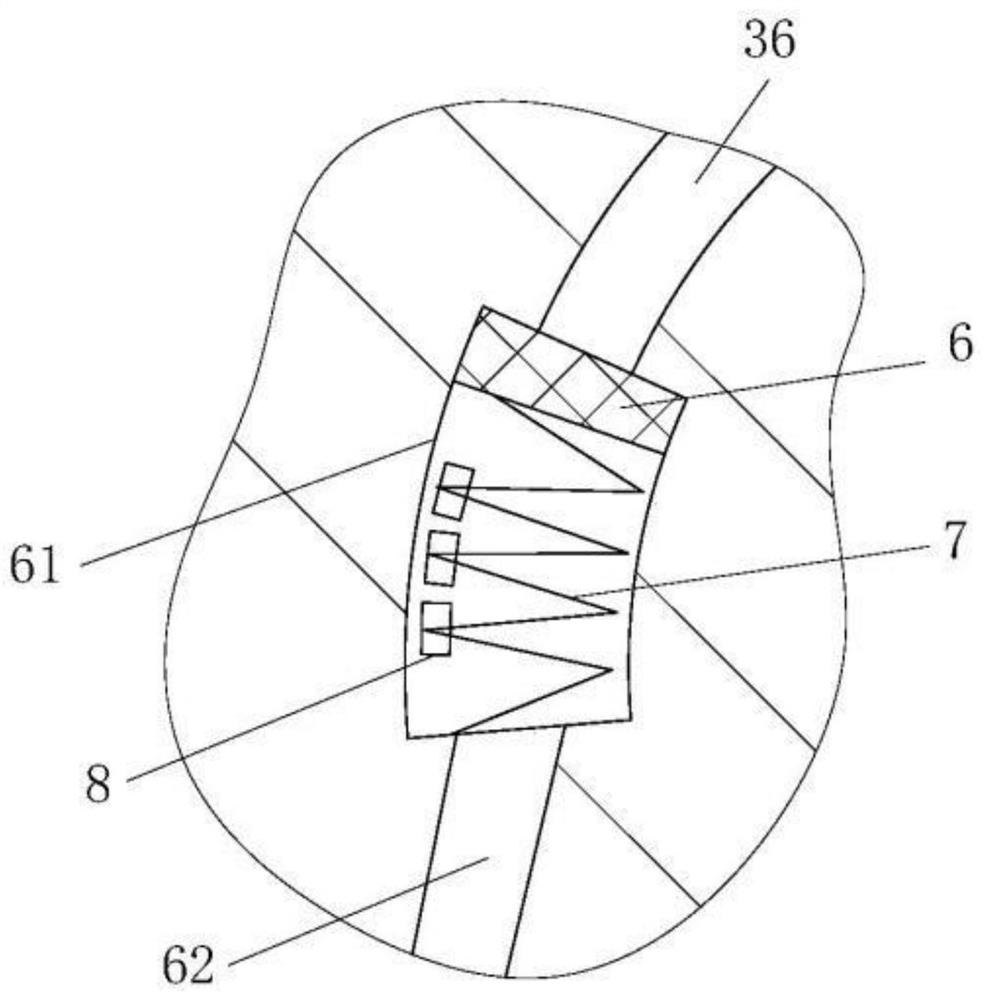

On-chip integrated cascade amplification semiconductor laser

ActiveCN109873295ARealize disseminationAchieving single-stage amplificationOptical wave guidanceLaser detailsGratingLuminous flux

The invention discloses an on-chip integrated cascade amplification semiconductor laser. The on-chip integrated cascade amplification semiconductor laser comprises a ridge type area, an on-chip DBR grating structure, a tapered type area and an epitaxial waveguide; the DBR grating structure is arranged on the ridge type area, the ridge type area is a ridge type waveguide structure, the tapered typearea is a gain waveguide structure; the epitaxial waveguide has a first-order ladder thickness; the ridge type area is arranged at a thin side of the epitaxial waveguide, the tapered type area is arranged at a thick side of the epitaxial waveguide, and the ridge type area and the tapered type area are cascaded. The laser of the design can more sufficiently utilize the tapered type area gain in comparison with a laser amplification way of traditionally utilizing the tapered gain structure; the base model feature is maintained when the mode volume is extended based on the iso-luminous flux principle, the optical quality of the near diffraction limit laser is guaranteed, and the brightness is greatly improved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Concentrated solar power solids-based system

A solar power system comprises a solar receiver, a heated solids storage tank downstream of the solar receiver, a fluidized bed heat exchanger downstream of the heated solids storage tank, and means for transporting solid particles from the fluidized bed heat exchanger to a cold solids storage tank upstream of the solar receiver. The fluidized bed heat exchanger includes a first fluidized bed and a second fluidized bed. Solid particles flow through the fluidized bed heat exchanger and transfer heat energy to heating surfaces in the two fluidized beds. The system permits the solid particles to absorb more energy and permits a constant energy output from the fluidized bed heat exchanger.

Owner:THE BABCOCK & WILCOX CO

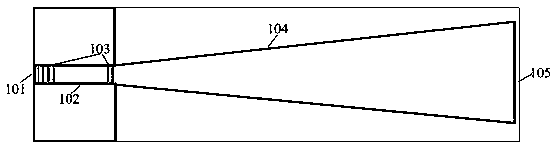

High-frequency high-power microwave device

ActiveCN110718426AAffect outputHigh energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a high-frequency high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. An electron beam transmission channel with an inner diameter of 8mm and an outer diameter of 14.6mm is formed between the inner conductor and the circular waveguide sleeve. A high-frequency structure is sequentially provided with a reflection region, a beam current pre-modulation region, a phase modulation region and a beam wave conversion region which are coaxial in the electron beam transmission direction. An annular collector protruding inwards in the radial direction is arranged behind the beam wave conversion region. An annular electron beam with the inner diameter of 12mm, the outer diameter of 12.6mm, thevoltage of 400kV and the beam intensity of 7.3kA is transmitted in the high-frequency structure under the guidance of an axial magnetic field with the magnetic field intensity of 1.5T, and high-frequency high-power microwaves with the frequency of 67.4GHz are generated. The high-frequency high-power microwave device is simple in structural size, and has the advantages of being small, light and easy to assemble.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

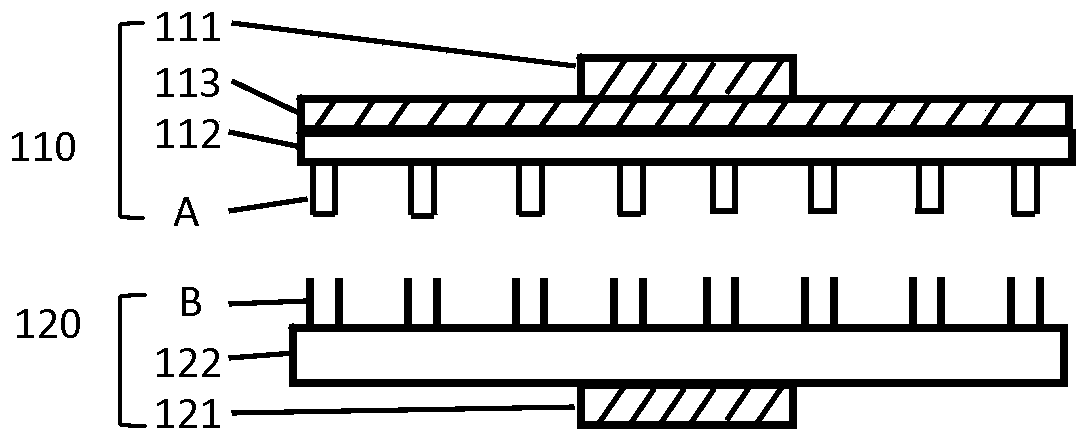

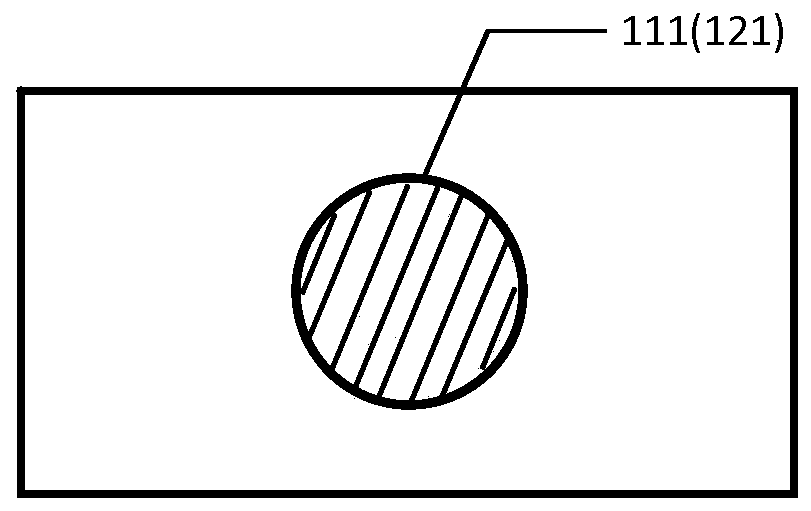

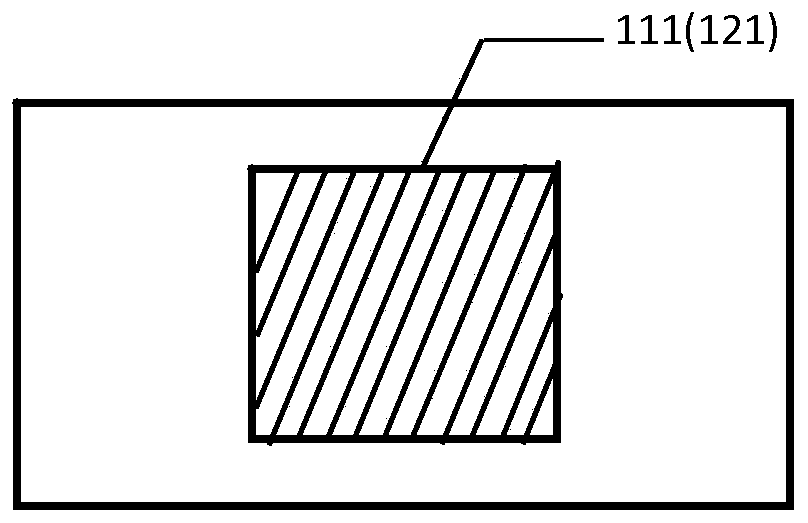

Friction nanogenerator and manufacturing method thereof

ActiveCN108123642AAffect outputSimple manufacturing processFriction generatorsNanogeneratorBiomedical engineering

The invention provides a friction nanogenerator and a manufacturing method thereof. The friction nanogenerator comprises a first friction unit and a second friction unit, wherein the first friction unit comprises a first magnetic part; the second friction unit is arranged oppositely to the first friction unit, the materials on the opposite surfaces of the two have different friction electrode orders, the second friction unit comprises a second magnetic part, the first magnetic part and the second magnetic part are arranged with the same poles corresponding; and relative movement between the first friction unit and the second friction unit is realized through same-pole repulsion. The friction nanogenerator provided in the invention has the advantages of stable output after long-time use, simple structure, safety and reliability, low cost, high output and simple manufacturing process.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

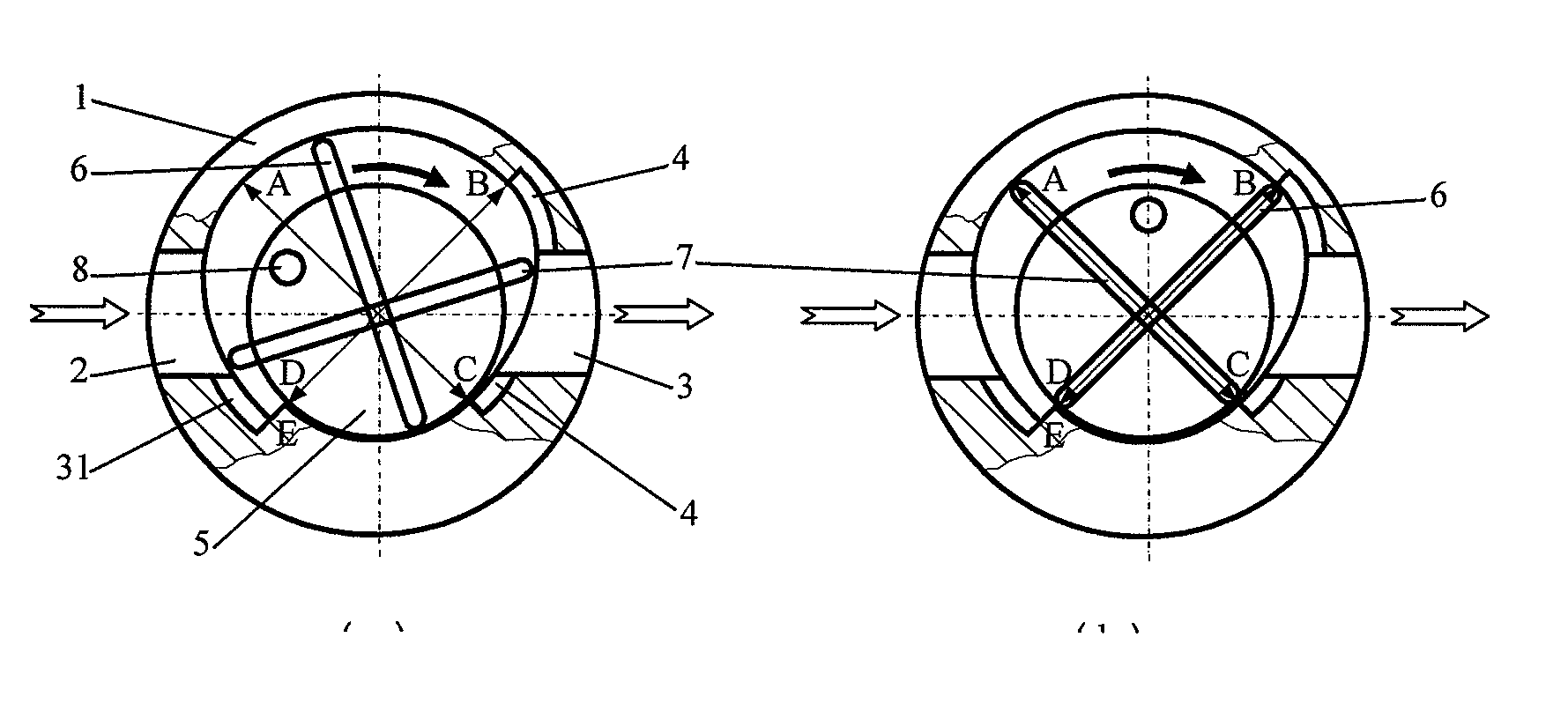

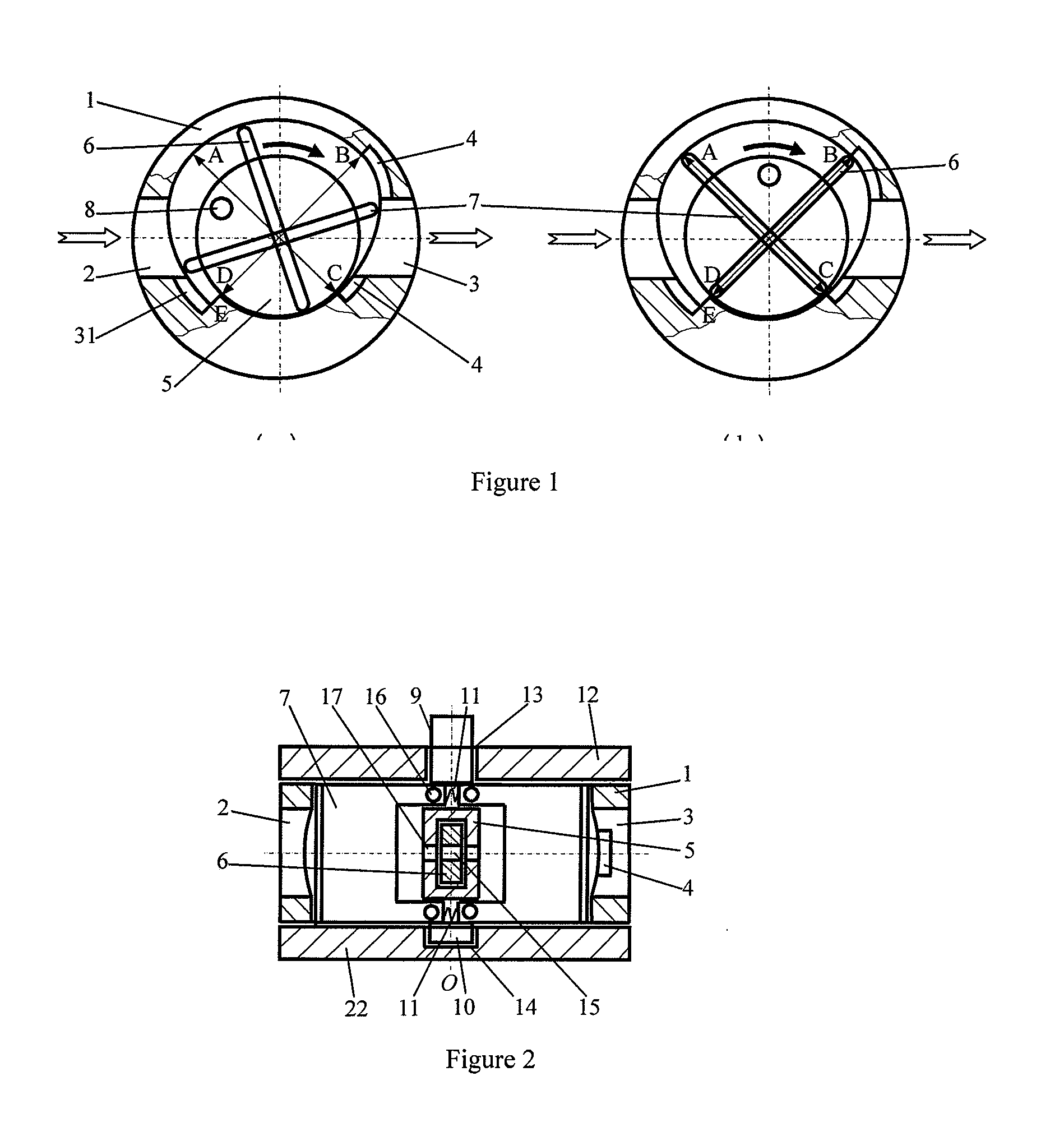

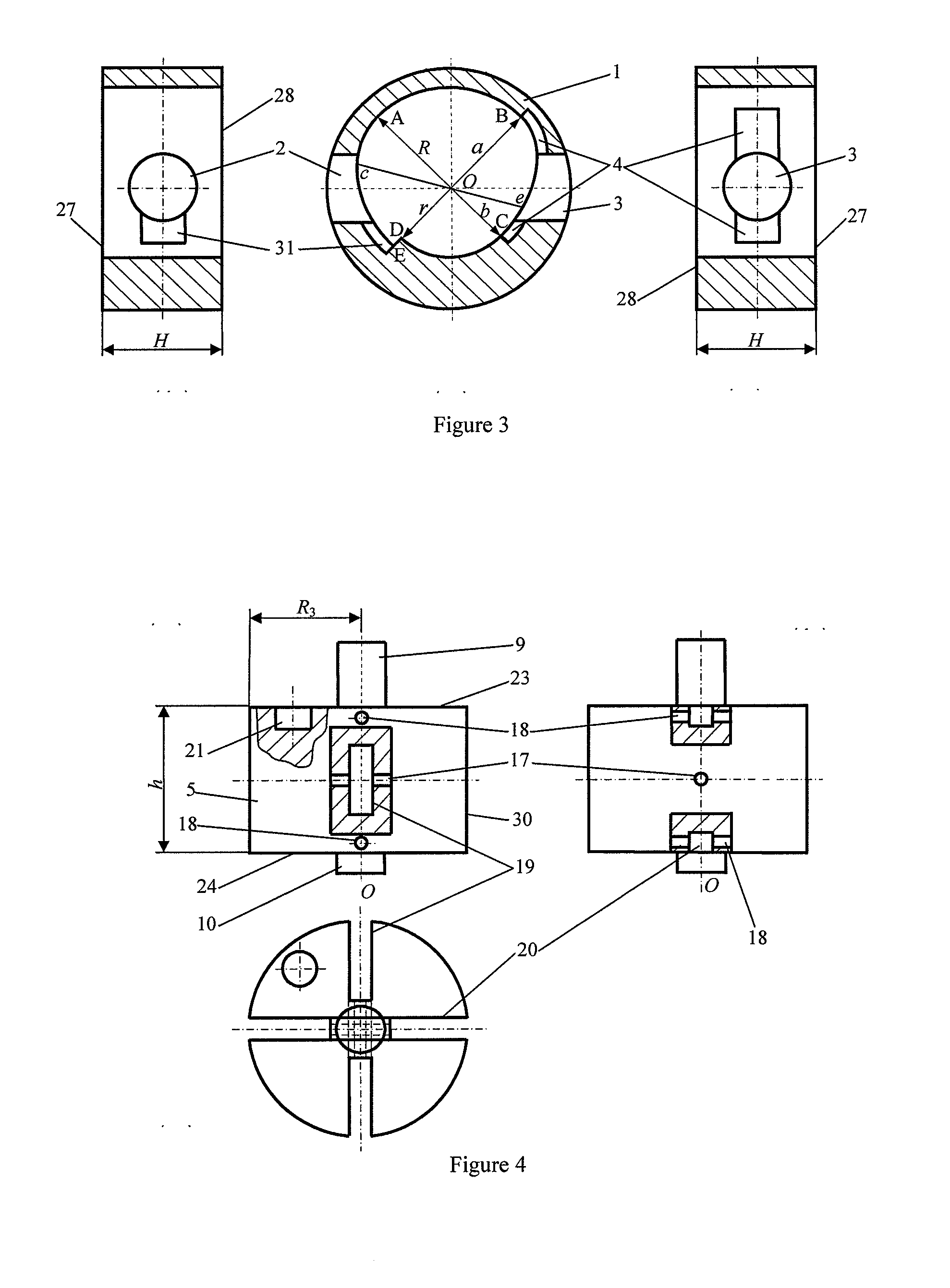

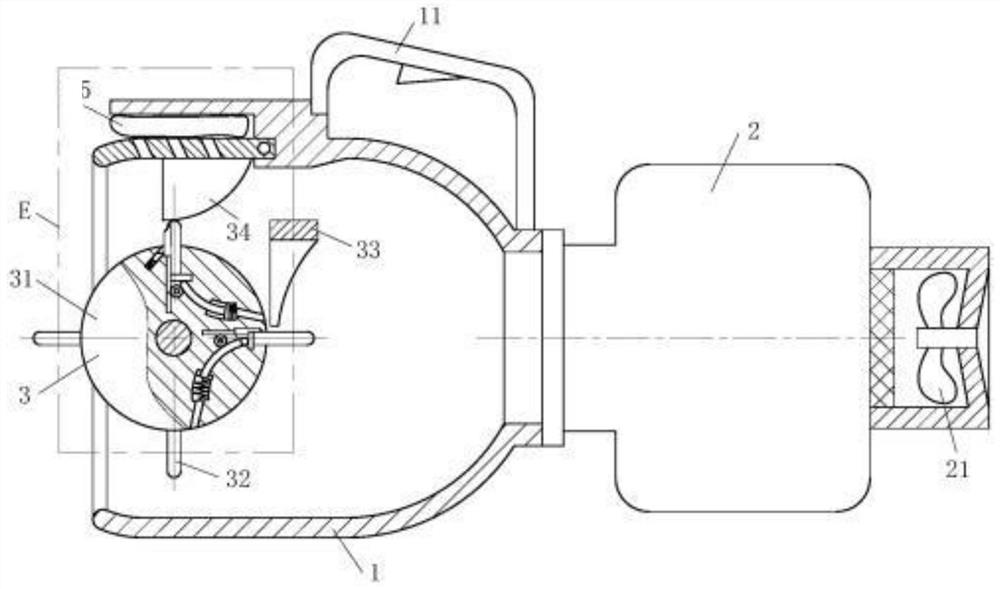

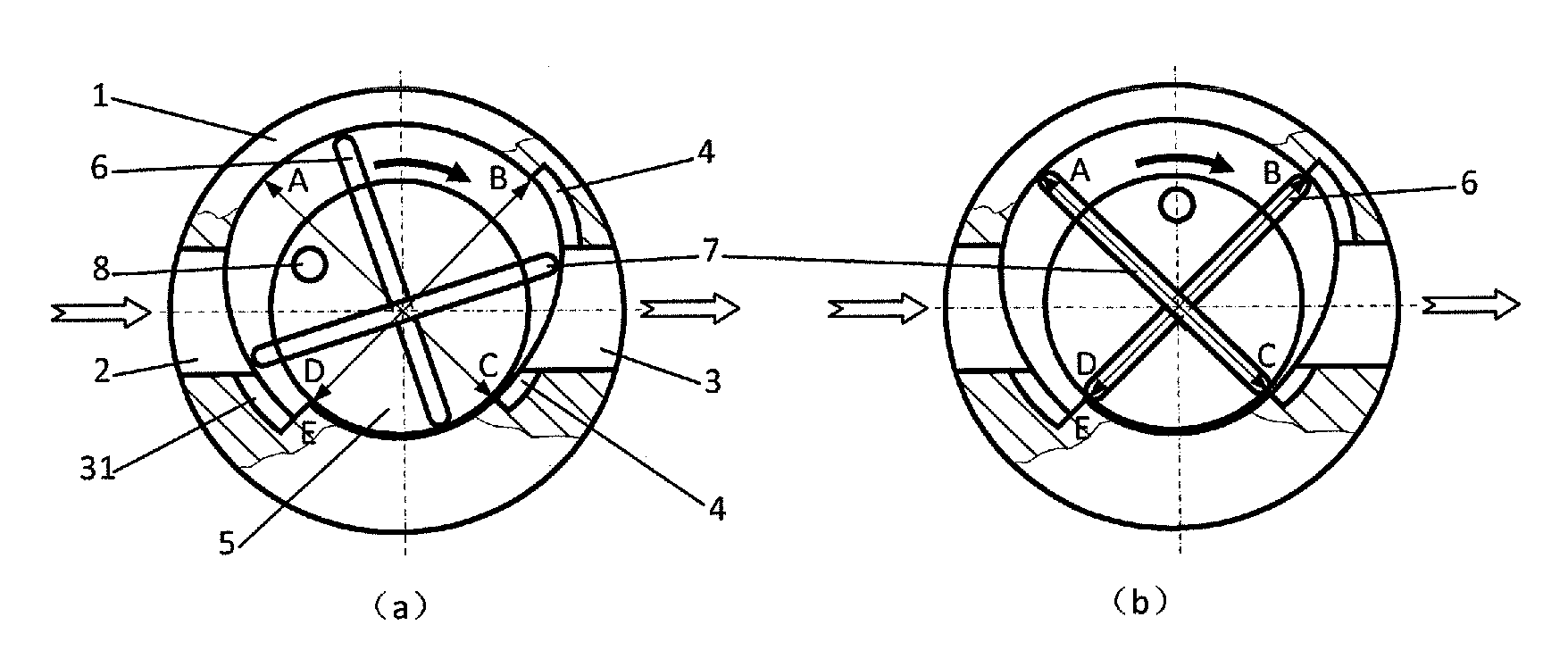

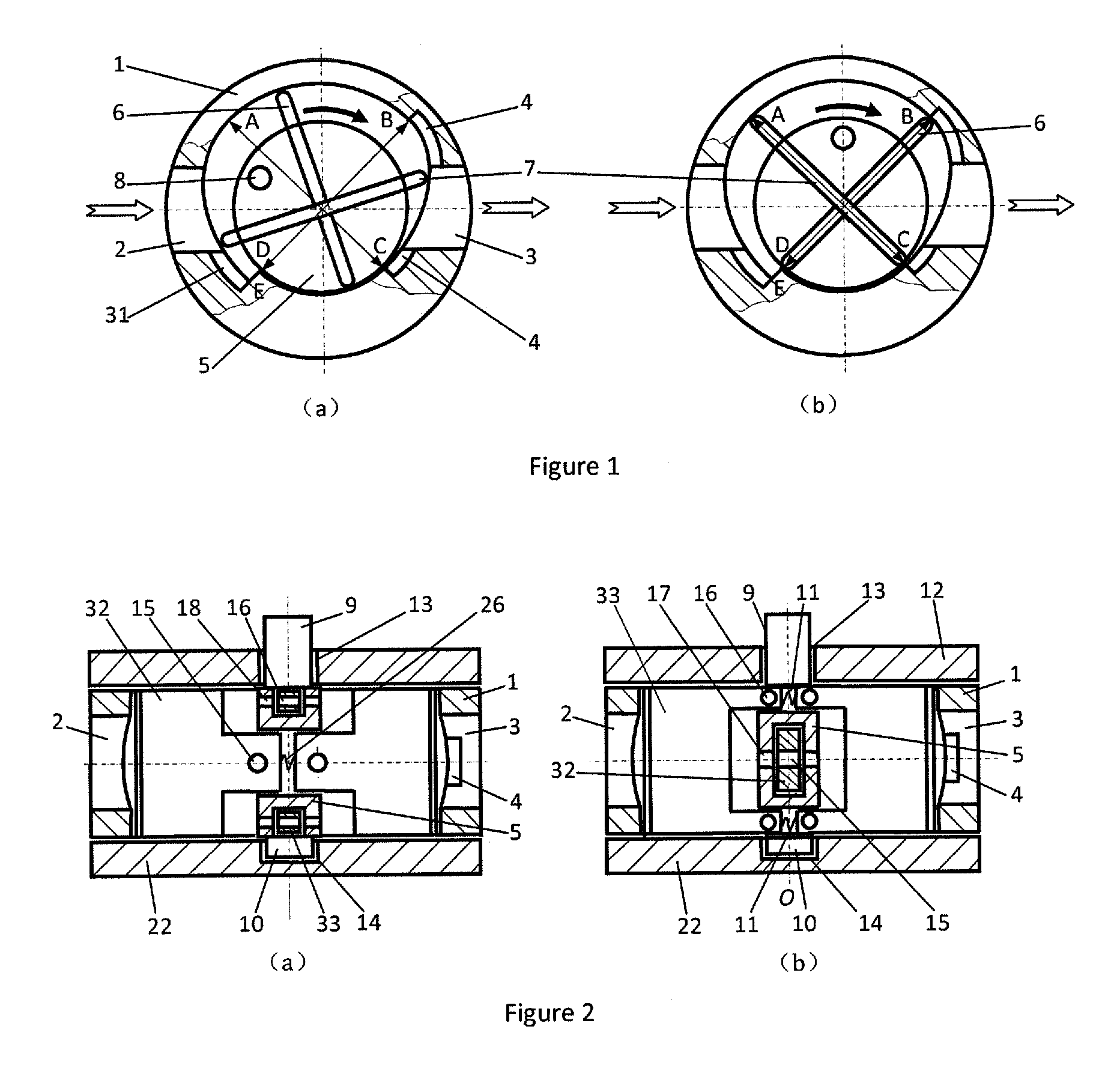

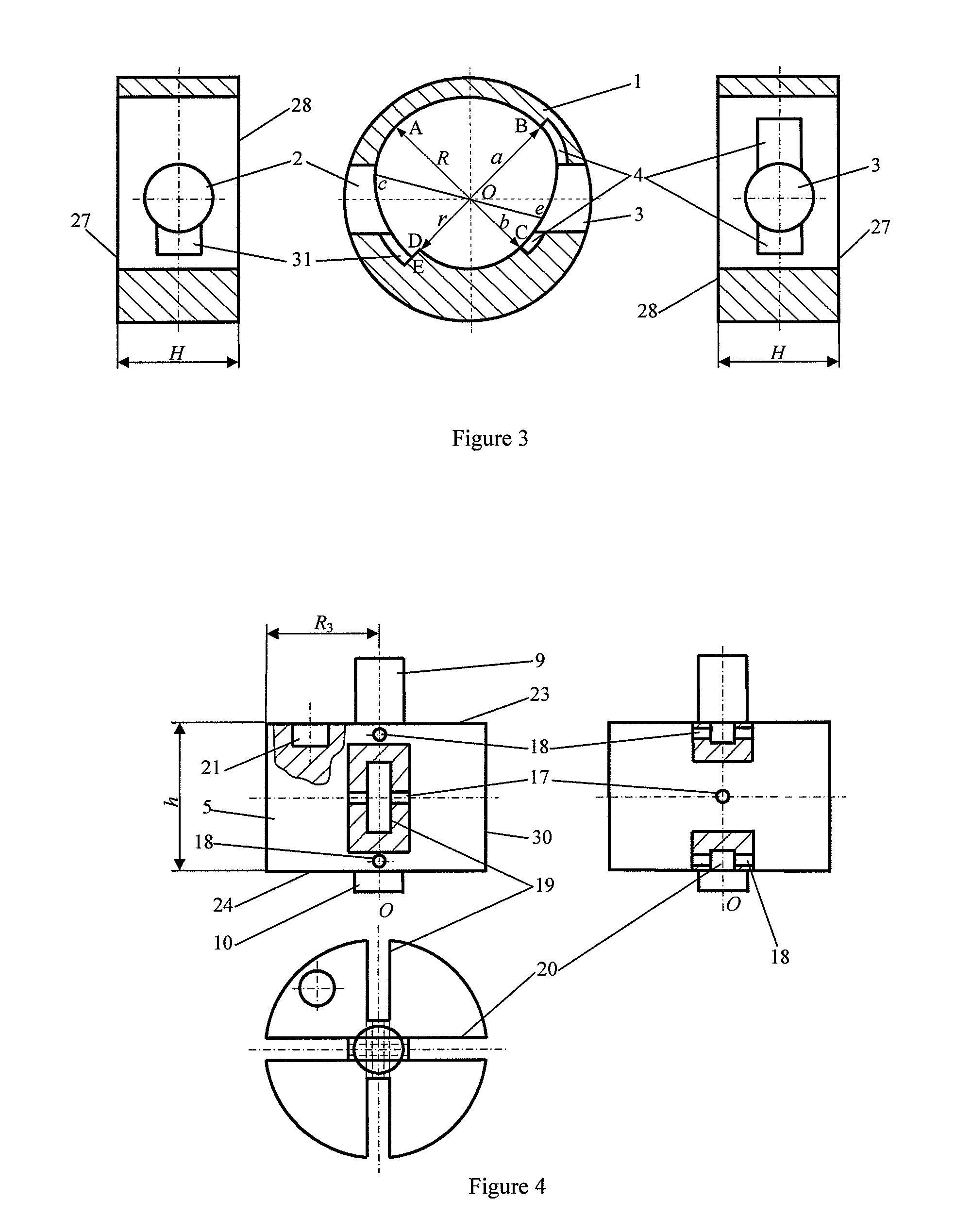

Metering pump with special-shaped cavity

InactiveUS20120164018A1Pressure increment is greatImprove pump efficiencyOscillating piston enginesRotary piston pumpsDrive shaftSlide plate

The invention discloses a metering pump with a special-shaped cavity, which comprises a housing, a rotor and two cover plates. The housing is a cylinder with a special-shaped surface inner cavity, an inlet and an outlet, and the special-shaped surface inner cavity is formed by combining a circular arc surface with a non-circular arc surface. The rotor comprises a rotor body and two pairs of combined sliding plates, wherein the rotor body is a column body processed with a transmission shaft, a centering shaft and crisscross guide grooves, and the combined sliding plates are mounted in the guide grooves. The cover plates are flat plates processed with bearing holes. The two end surfaces of the housing are matched with the cover plates for constituting a sealed cavity. In the sealed cavity, the rotor is matched with the bearing holes on the cover plates through the transmission shaft and the centering shaft. External driving force couple is acted on the transmission shaft so as to enable the rotor to rotate. When the rotor rotates, the non-circular arc surface of the special-shaped surface inner cavity can enable the two pairs of the combined sliding plates to slide in a cross manner so as to suck in fluid from the inlet and press out the fluid from the outlet. When the rotor rotates one cycle, four standard volumes are formed in a cavity body and the equal quantity of the fluid flows by the cavity body when the rotor rotates every one cycle. The flow rate of the fluid is metered by counting the number of rotation cycles of the rotor.

Owner:ZHEJIANG UNIV

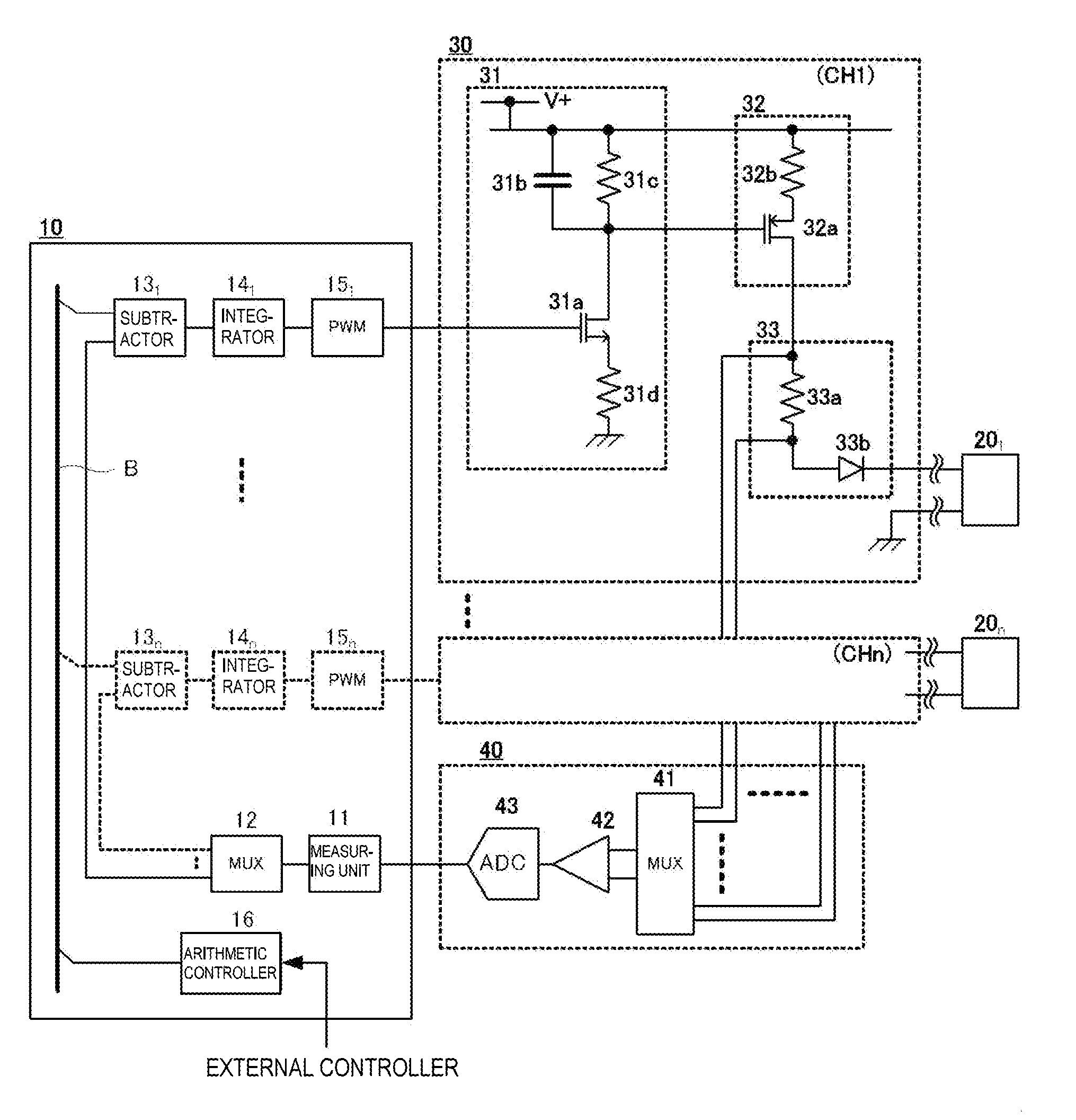

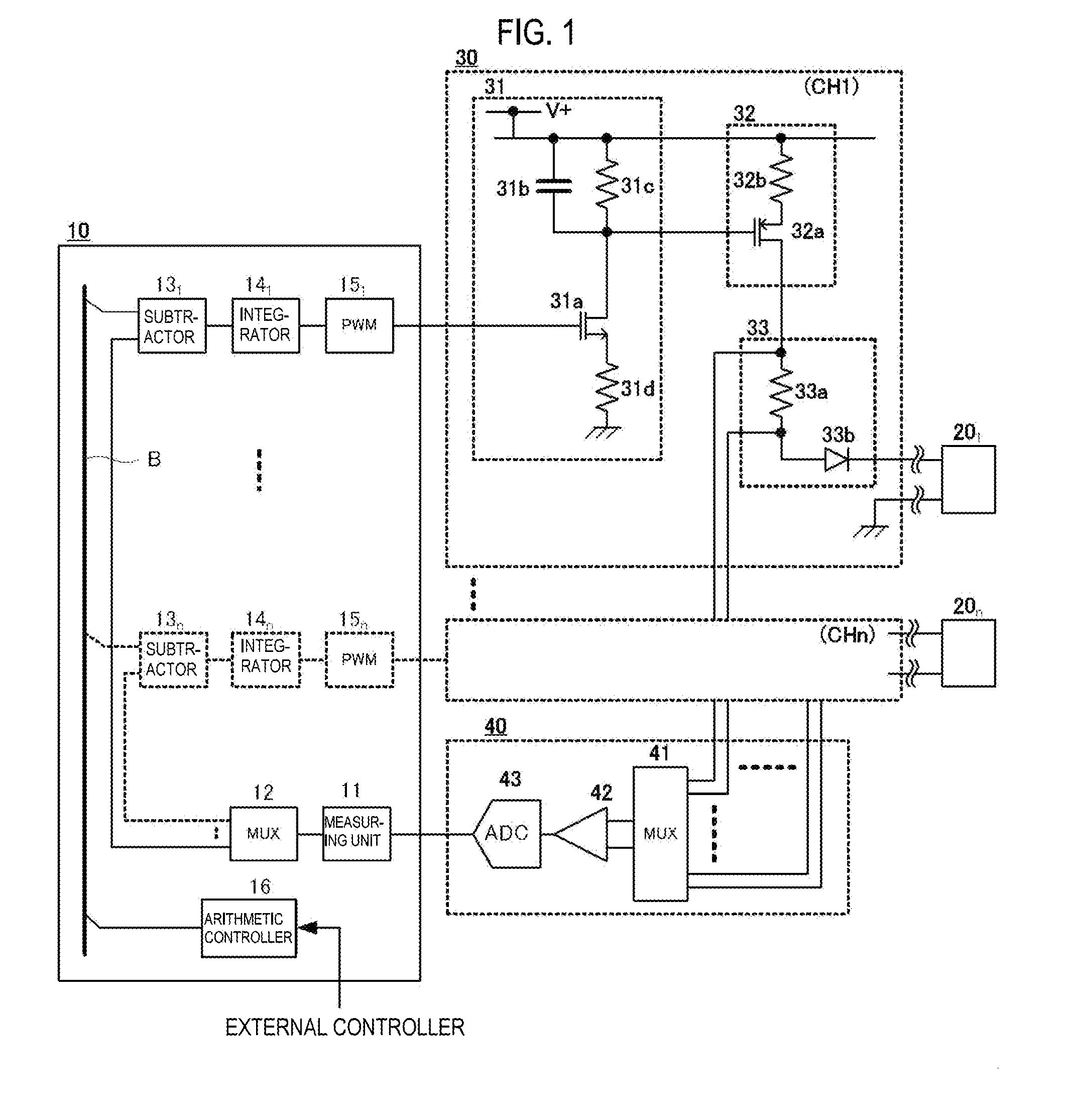

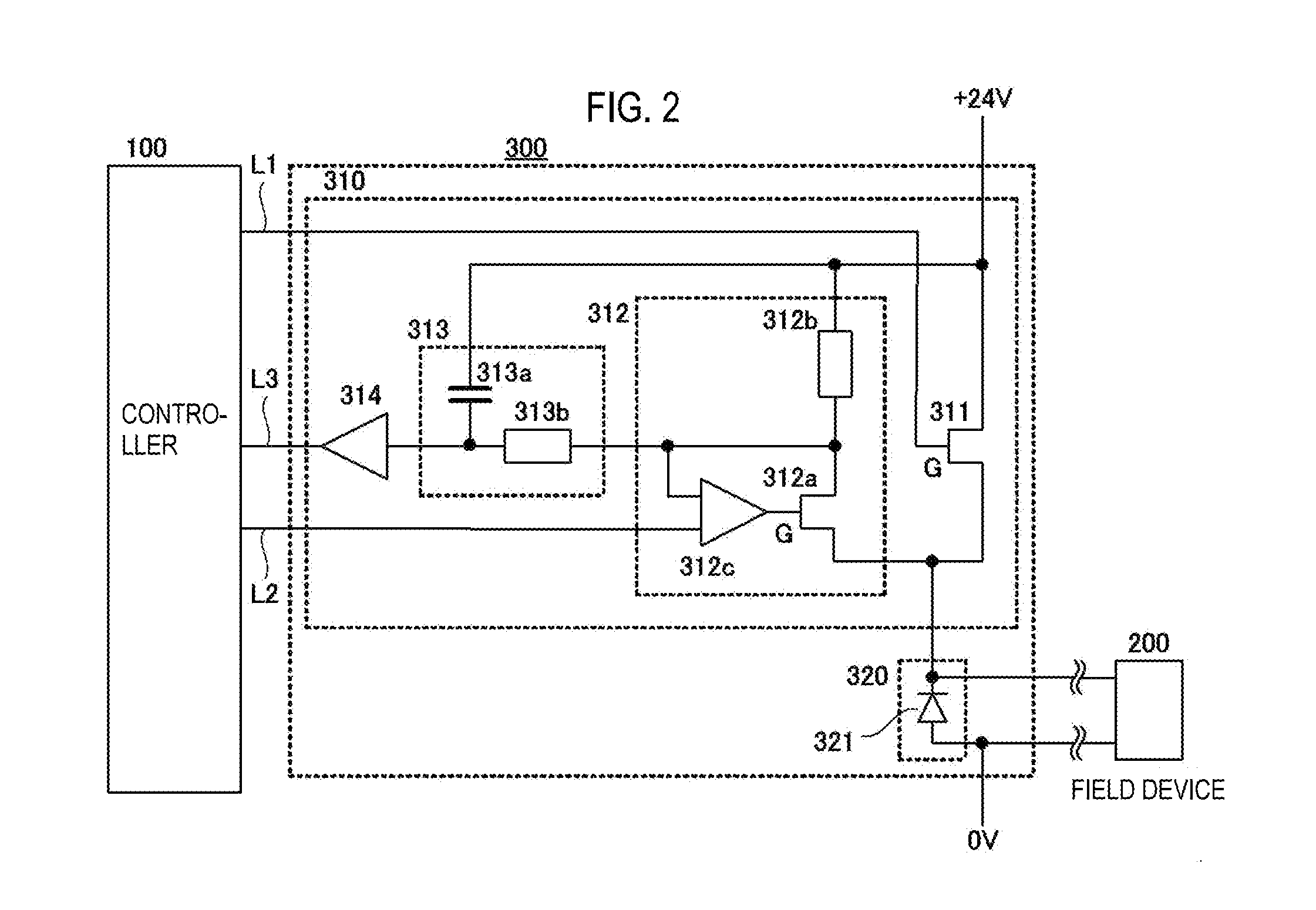

I/O module

ActiveUS20160134269A1Low costAffect outputProgramme controlDuration/width modulated pulse demodulationFeedback circuitsPwm signals

An input / output (I / O) module is configured to connect a controller and a field device. The I / O module includes a PWM (pulse width modulation) demodulator configured to demodulate a PWM signal that is input from the controller, a current source configured to output a current based on an output signal of the PWM demodulator to the field device, a resistance connected in line with the current source, and a feedback circuit configured to feed back an output current of the current source to the PWM demodulator via the controller.

Owner:YOKOGAWA ELECTRIC CORP

Coaxial high-frequency high-power microwave device

ActiveCN110718425AAffect outputIncrease beam energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a coaxial high-frequency high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. A high-frequency structure is arranged in the circular waveguide sleeve. The high-frequency structure is sequentially provided with a reflection region, a beam current pre-modulation region, a phase modulation region and a beam wave conversion region which are coaxial in the electron beam transmission direction. The reflection region, the beam pre-modulation region, the phase modulation region and the beam-wave conversion region are respectively provided with annular groove-shaped cavities at the corresponding positions of the sleeve wall of the circular waveguide sleeve and the inner conductor, and thecavities at the corresponding positions of the sleeve wall of the circular waveguide sleeve and the inner conductor form a reflection cavity, beam pre-modulation cavities a phase modulation cavity andbeam-wave conversion cavities. An annular collector protruding inwards in the radial direction is arranged behind the beam wave conversion region. An annular electron beam with the voltage of 400kV and the current of 9.0kA is transmitted in the microwave device under the guidance of an axial magnetic field with the magnetic field intensity of 1.2T, and 70GHz high-frequency high-power microwaves are generated. By adopting the coaxial high-frequency high-power microwave device, high-frequency high-power microwaves can be generated, and the microwave generation efficiency can be improved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

Pulse width filtering circuit

ActiveUS10236871B2Improve noise immunityAffect outputLogic circuits characterised by logic functionContinuous to patterned pulse manipulationEngineeringElectrical and Electronics engineering

A pulse width filtering circuit for filtering pulse signals includes an input transition detection circuit detecting change of state of an input signal, including a first transition from a low signal to a high signal and a second transition from the high signal to the low signal; a first delay circuit determining whether the high signal from the first transition is maintained longer than a first period and, if so, generating a first output indicative of the first transition, after the first period; a second delay circuit determining whether the low signal from the second transition is maintained for longer than a second period and, if so, generating a second output indicative of the second transition, after the second period; and a switching circuit connected to the first and second delay circuits and selectively outputting the first output and the second output, based on the state of the input signal.

Owner:MOSWAY TECH LTD

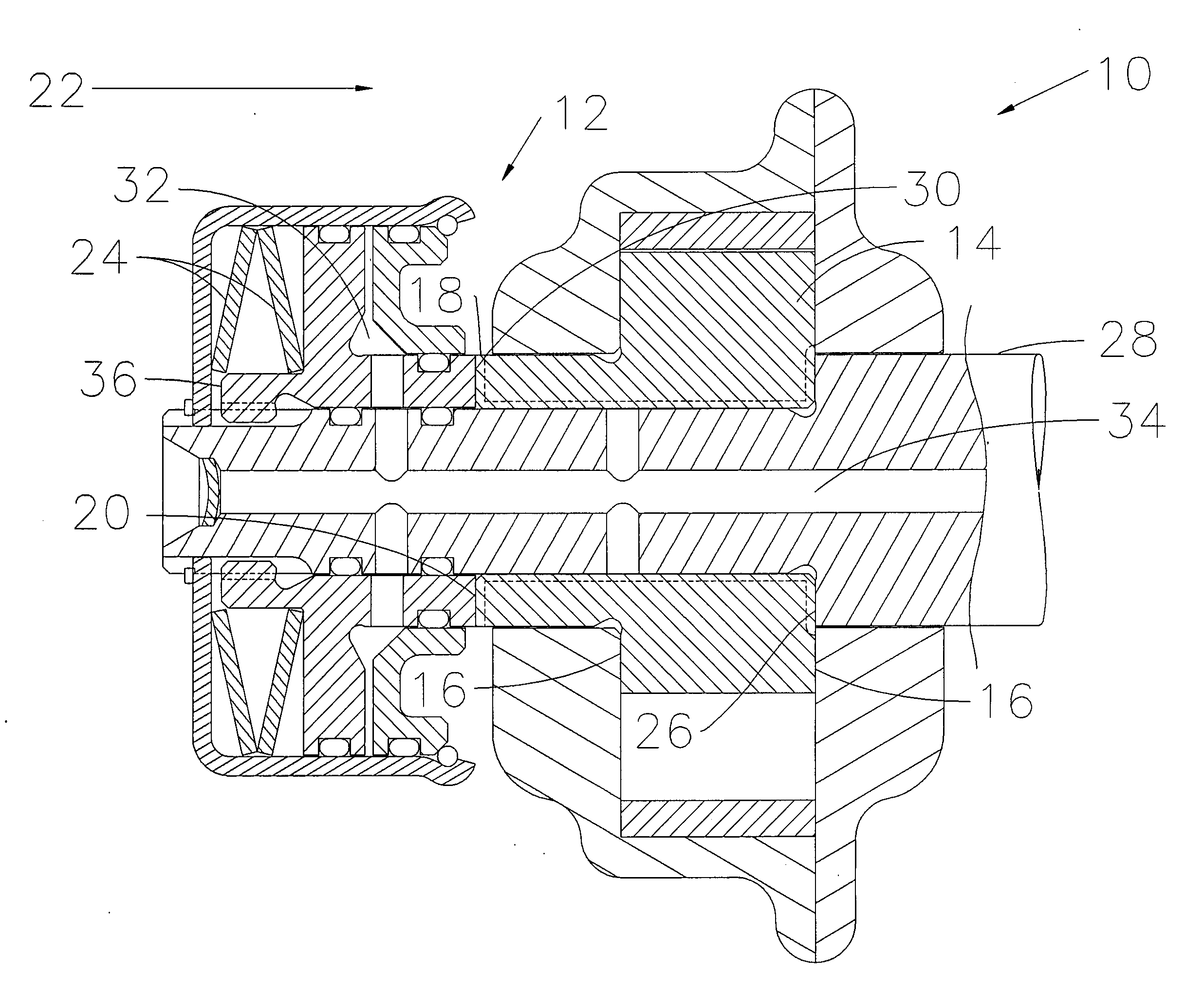

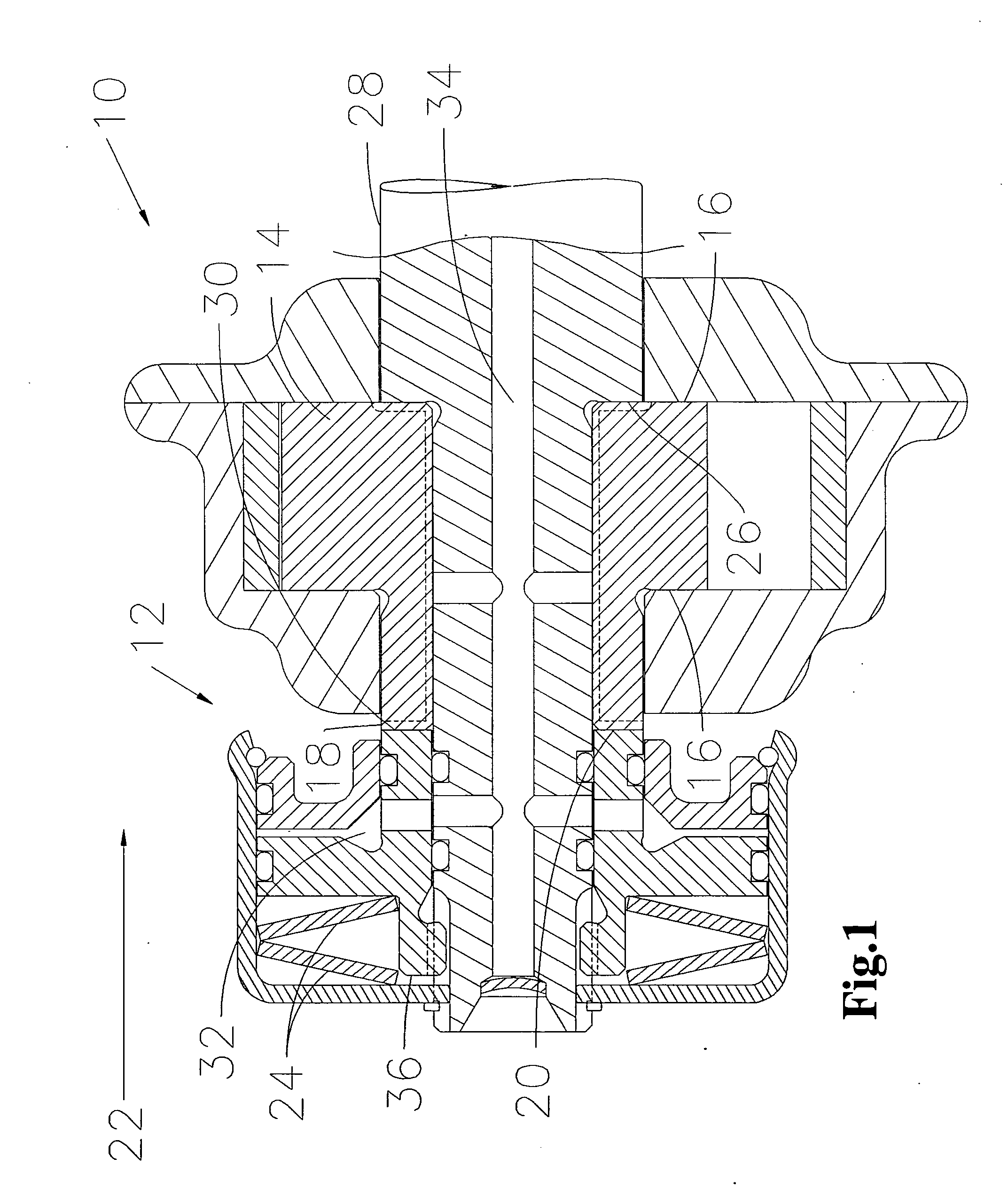

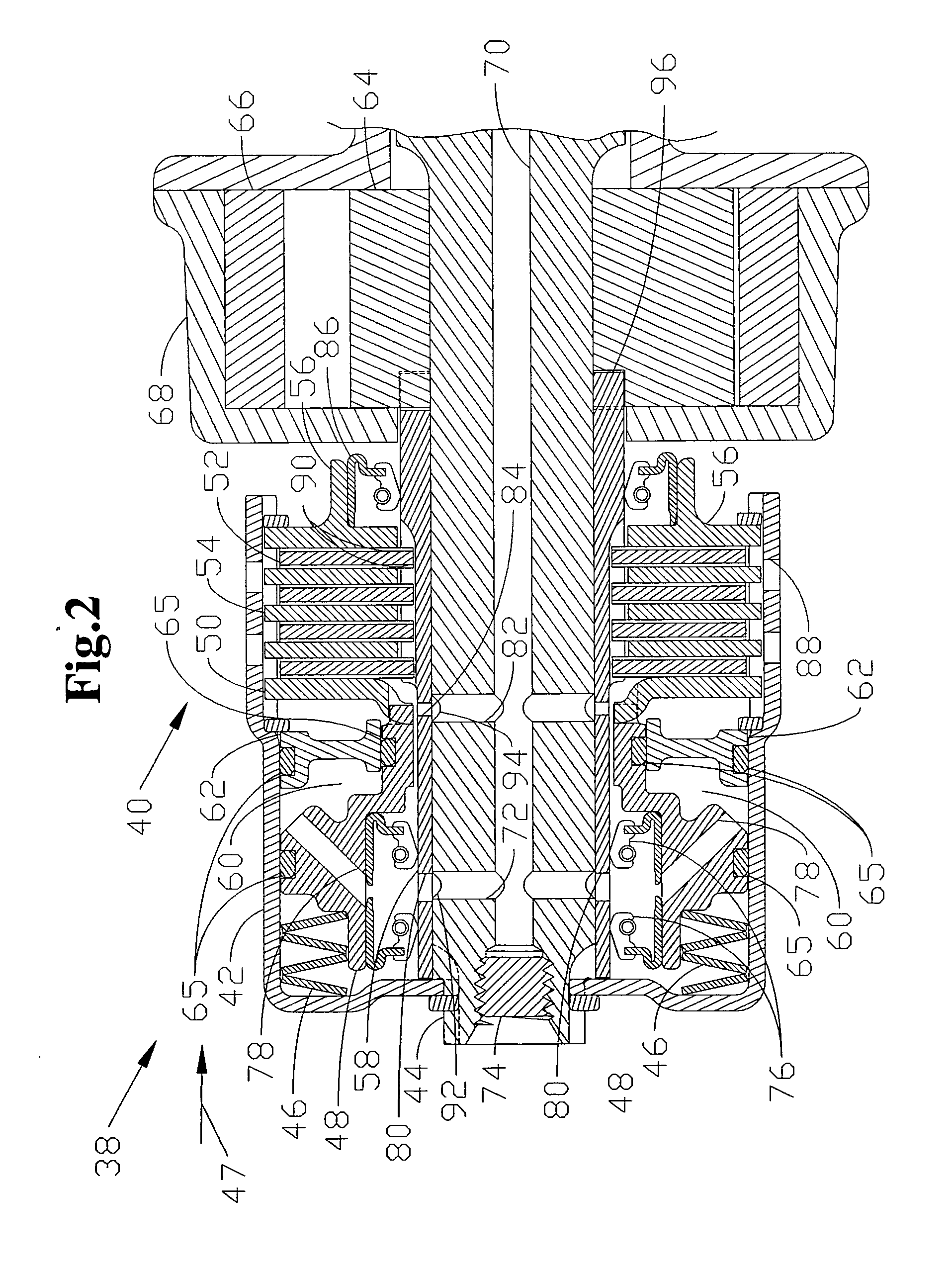

Variable output fluid pump system

InactiveUS20090297363A1Reduce amountAffect outputRotary piston pumpsRotary/oscillating piston combinationsHydraulic pumpPositive displacement pump

A variable output pump system is provided, the pump system having a first positive displacement pump; a pump drive operably coupled to the first positive displacement pump, wherein the pump drive operates the first positive displacement pump to have a first output profile during a first operating range and a second output profile during a second operating range, the pump drive having a hydraulic release being configured to decrease the second output profile as a hydraulic pressure increases.

Owner:METALDYNE LLC

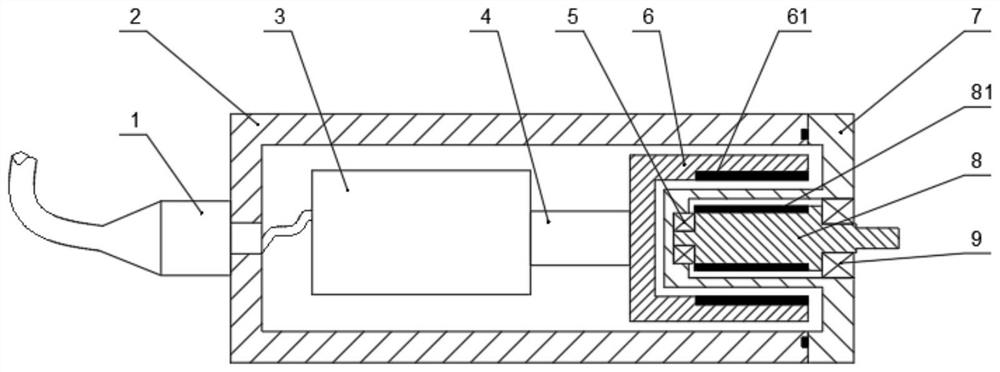

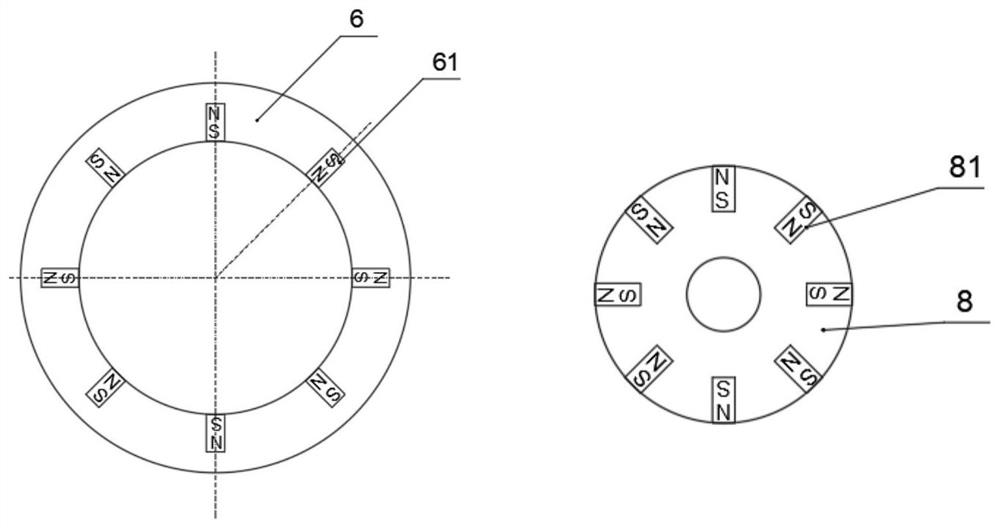

Deep-sea motor based on magnetic coupling transmission and transmission method

PendingCN113765330AReduced selection conditionsAvoid structural impactPermanent-magnet clutches/brakesCouplingElectric machinery

The invention discloses a deep-sea motor based on magnetic coupling transmission and a transmission method. The deep-sea motor based on magnetic coupling transmission comprises a non-magnetic pressure-resistant shell and a magnetic coupling motor; the pressure-resistant shell comprises a body and a cover body, and the magnetic coupling motor comprises a driving assembly and a magnetic coupling output rotor shaft; and a containing cavity is formed in the body, the cover body comprises a cover plate and an inner barrel part protruding towards the inner side face of the cover plate, the magnetic coupling output rotor shaft is installed in the inner barrel part through a bearing, the driving assembly is installed in the containing cavity, the body is covered with the cover plate in a sealed mode, and the magnetic coupling output rotor shaft is in transmission connection with the driving assembly in a magnetic coupling transmission mode. The deep-sea motor based on magnetic coupling transmission does not need a sealing element to carry out dynamic sealing on the output shaft, and the problems of oil leakage and dynamic sealing of the rotary output shaft are solved.

Owner:THIRD INST OF OCEANOGRAPHY MINIST OF NATURAL RESOURCES +1

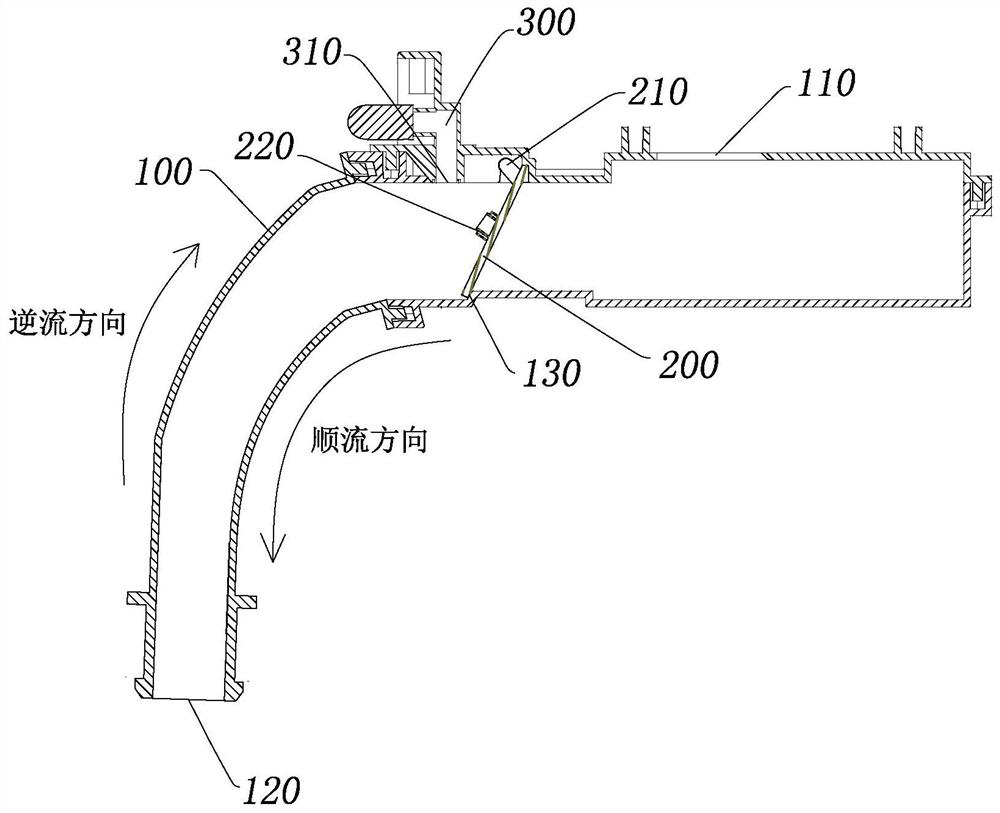

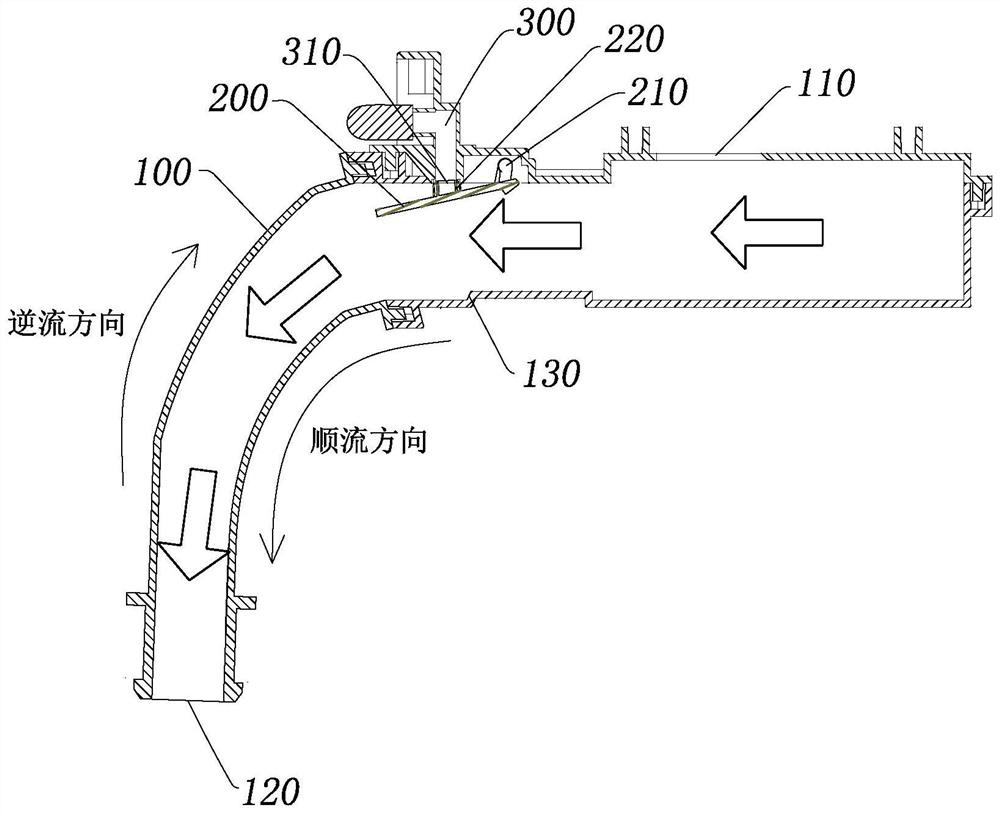

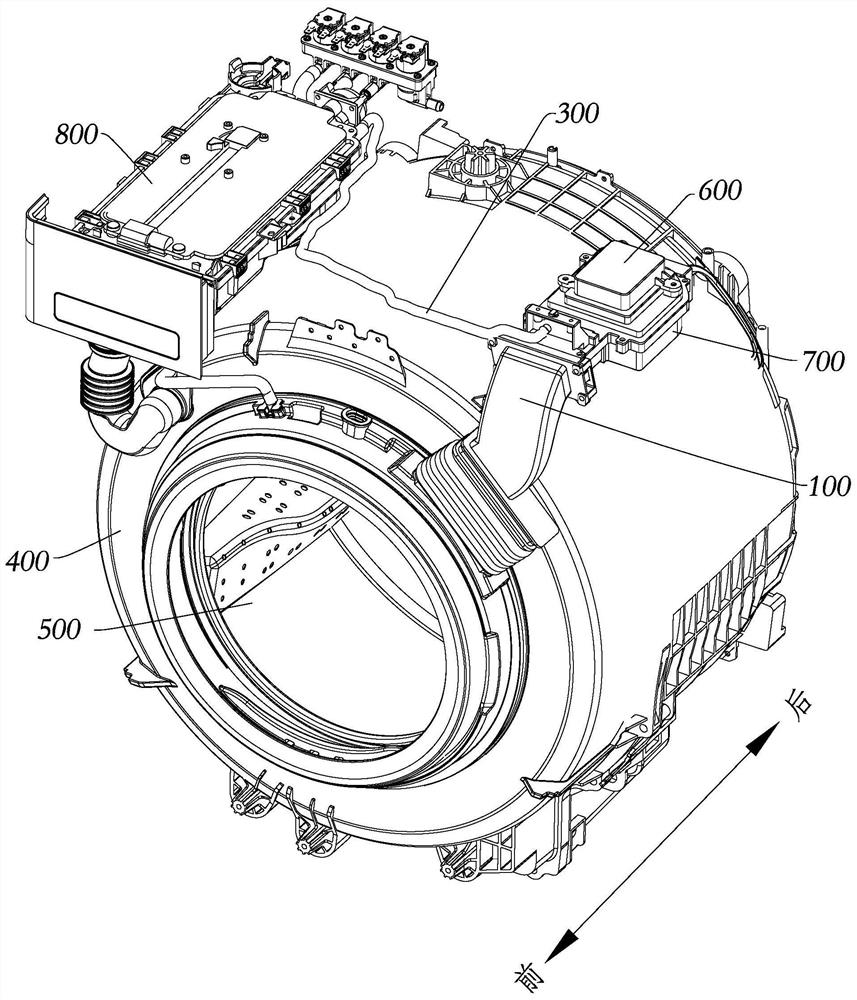

Non-return device of clothes treatment equipment and clothes treatment equipment

PendingCN113605056AReduce the burden onReduce the risk of penetration or even failureOther washing machinesTextiles and paperEngineeringMechanical engineering

The invention discloses a non-return device of clothes treatment equipment and the clothes treatment equipment, and belongs to the technical field of household appliances. The non-return device comprises a main channel for fluid to flow, a non-return piece and a bypass channel; the non-return piece is arranged in the main channel and has an opening state allowing downstream fluid in the main channel to pass through and a closing state preventing countercurrent fluid in the main channel from passing through; and the bypass channel is communicated with the main channel and is used for dredging countercurrent fluid in the main channel when the non-return piece is in the closed state. After the countercurrent fluid enters the main channel, the non-return piece is in the closed state to prevent the countercurrent fluid from passing through the non-return piece, and part of the countercurrent fluid blocked by the non-return piece is guided outwards from the bypass channel, so that the burden of the non-return piece is relieved, and the risk that the non-return piece is permeated by the countercurrent fluid and even fails is reduced.

Owner:PANASONIC APPLIANCES CHINA CO LTD +1

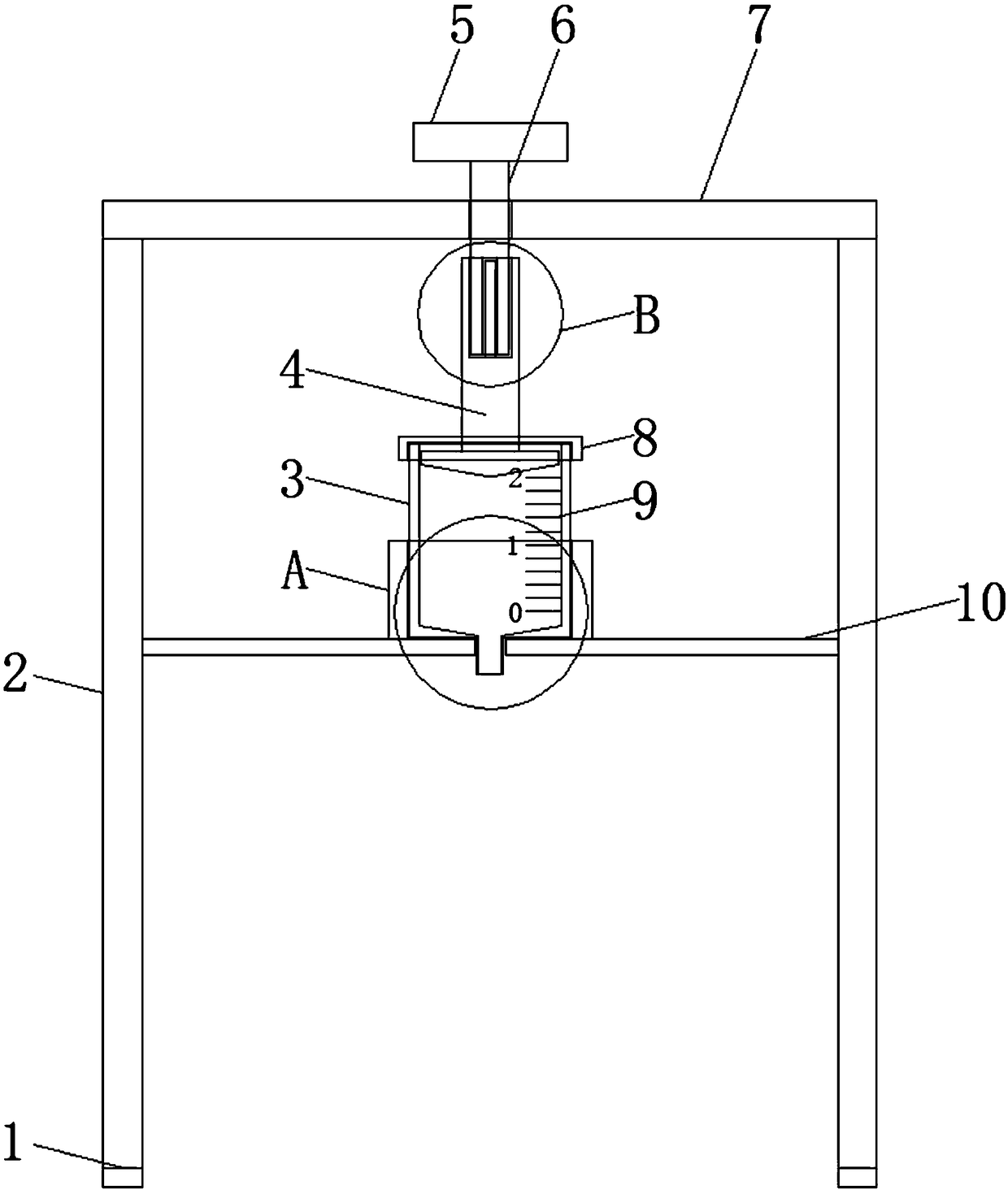

cotton picking equipment

ActiveCN109076782BAvoid the reduction of picking efficiencyAvoid reducing cleaning and maintenance workloadPicking devicesGear wheelAgricultural engineering

The invention belongs to the technical field of agricultural machinery, and particularly relates to cotton picking equipment. The equipment comprises a shell, a handle, a cotton collecting box, a fanand a picking module. The picking module is arranged in the shell and comprises a rotating roller, steel needles, a comb plate, an arc block, a straight rack, an arc rack and a cutter. A set of steelneedles are arranged evenly on an outer ring of the rotating roller. One side of the rotating roller is provided with the comb plate fixedly installed on the inner wall of the shell, and the comb plate is used for stripping cotton on the steel needles; the steel needles are slidably installed on the rotating roller; the inner wall of the shell above the rotating roller is provided with the arc block. The arc block is used for compressing the steel needles; the arc rack can be pushed to move through the movement of the steel needles; the arc rack pushes the straight rack to move through a gear.The straight rack pushes the cutter out of the rotating roller to cut cotton filaments wound around outer rings of the steel needles. Through the arrangement of the cutter, the cotton filaments woundaround the outer rings of the steel needles are cut off, and the situation that the picking efficiency is lowered when the cotton filaments are repeatedly wound is avoided; meanwhile, the workload for cleaning and maintaining the equipment is reduced.

Owner:浏阳市月亮岛农业科技开发有限公司

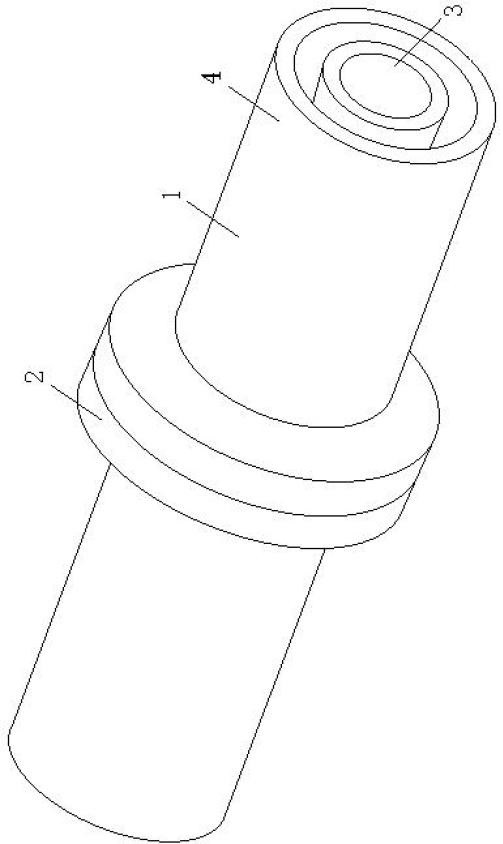

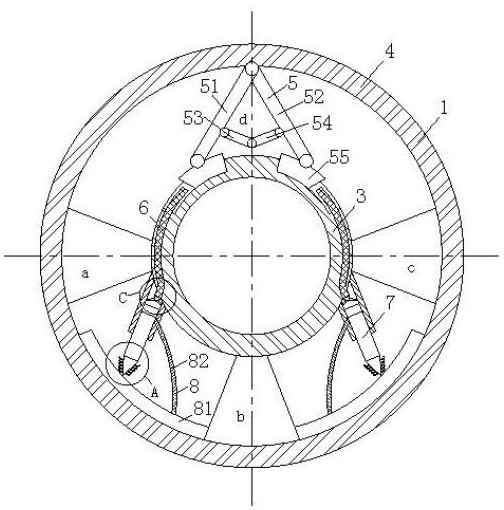

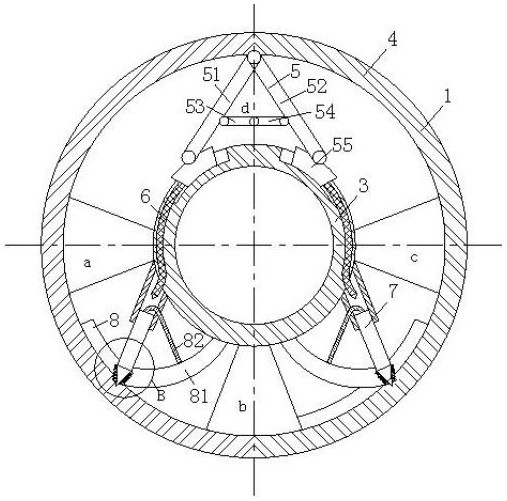

A pressure-resistant municipal drainage pipe

The invention belongs to the technical field of drainage pipes, in particular to a pressure-resistant municipal drainage pipe; it includes a drainage pipe body and a flange; the adjacent drainage pipe bodies are connected by a flange; the drainage pipe body includes an inner pipe and an outer pipe , and the positions a, b and c between the inner tube and the outer tube are connected by support columns, and the position d between the inner tube and the outer tube is provided with a decompression unit, and the decompression unit includes No. 1 pole, No. 2 pole and No. 3 pole , No. 4 rod and slider; by dividing the drain pipe body into an inner tube and an outer tube, and setting a decompression unit between the inner tube and the outer tube, when the outer tube is subjected to external pressure, the slider slides on the chute , reduce the pressure on the outer pipe, so that the pressure transmitted to the inner pipe is lower than the pressure that the inner pipe can withstand, and protect the inner pipe to avoid the rupture of the inner pipe and affect the transportation of water in the municipal area, thereby improving drainage tube life.

Owner:中冶华南建设工程有限公司

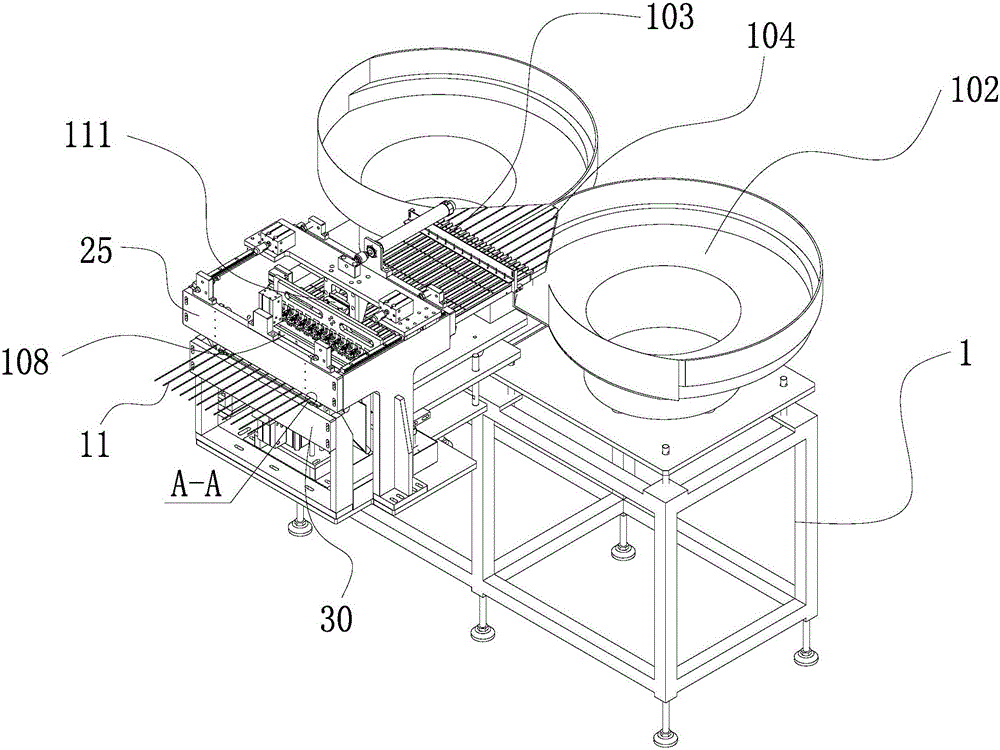

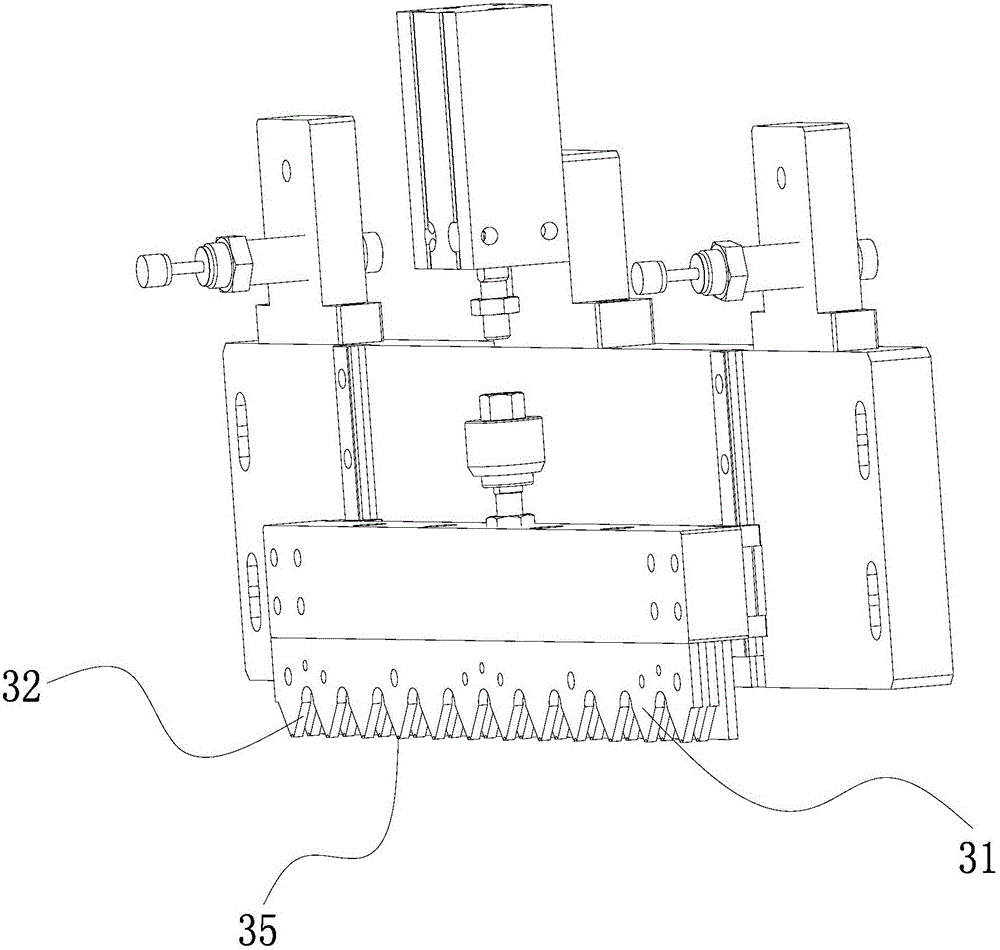

Assembly device for intravenous needle catheter and needle handle

PendingCN106042368AAccurate and reliable clampingAvoid the risk of falling looseIntravenous needlesGuide tube

The invention relates to an assembly device for an intravenous needle catheter and a needle handle. The assembly device comprises a rack, a catheter assembly device arranged on the rack, a needle handle discharge device and a material shifting mechanism, wherein the needle handle discharge device comprises a feeder and a conveying material path for conveying the needle handle; the feeder is provided with one or one group of output holes; the feeder is fixed to the rack, and can convey the needle handle to the conveying material path orderly along the output holes in a unified direction; the needle handle discharge device further comprises a limiting device and a positioning plate; and the positioning plate and the limiting device are sequentially distributed on the end part of the conveying material path, and are driven by a drive device to move up and down. According to the technical scheme adopted by the invention, the assembly device for the intravenous needle catheter and the needle handle can realize ordered output of the needle handle and positioning of the intravenous needle catheter, realizes automatic assembly for the needle handle and the intravenous needle catheter, is high in degree of automation, and improves working efficiency in comparison with a manual loading way.

Owner:梁启明

A high-frequency high-power microwave device

ActiveCN110718426BAffect outputHigh energyTransit-tube circuit elementsTransit-tube coupling devicesElectrical conductorMicrowave

The invention discloses a high-frequency and high-power microwave device, which comprises a circular waveguide sleeve and an inner conductor coaxial with the circular waveguide sleeve. An electronic device with an inner diameter of 8mm and an outer diameter of 14.6mm is formed between the inner conductor and the circular waveguide sleeve. Beam transmission channel; the high-frequency structure is provided with a coaxial reflection area, a beam pre-modulation area, a phase modulation area and a beam conversion area in sequence along the electron beam transmission direction; after the beam conversion area, a radially inwardly protruding annular collector is set ;Reflective area, beam pre-modulation area, phase modulation area and beam conversion area, respectively set annular groove-shaped reflection cavity, beam pre-modulation cavity, phase modulation cavity and beam conversion cavity on the circular waveguide sleeve; inner diameter 12mm , an outer diameter of 12.6mm, a voltage of 400kV, and a beam intensity of 7.3kA are transmitted in a high-frequency structure under the guidance of an axial magnetic field with a magnetic field strength of 1.5T, generating high-frequency and high-power microwaves with a frequency of 67.4GHz. The high-frequency and high-power microwave device of the present invention has the advantages of simple structure size, miniaturization, light weight and easy assembly.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

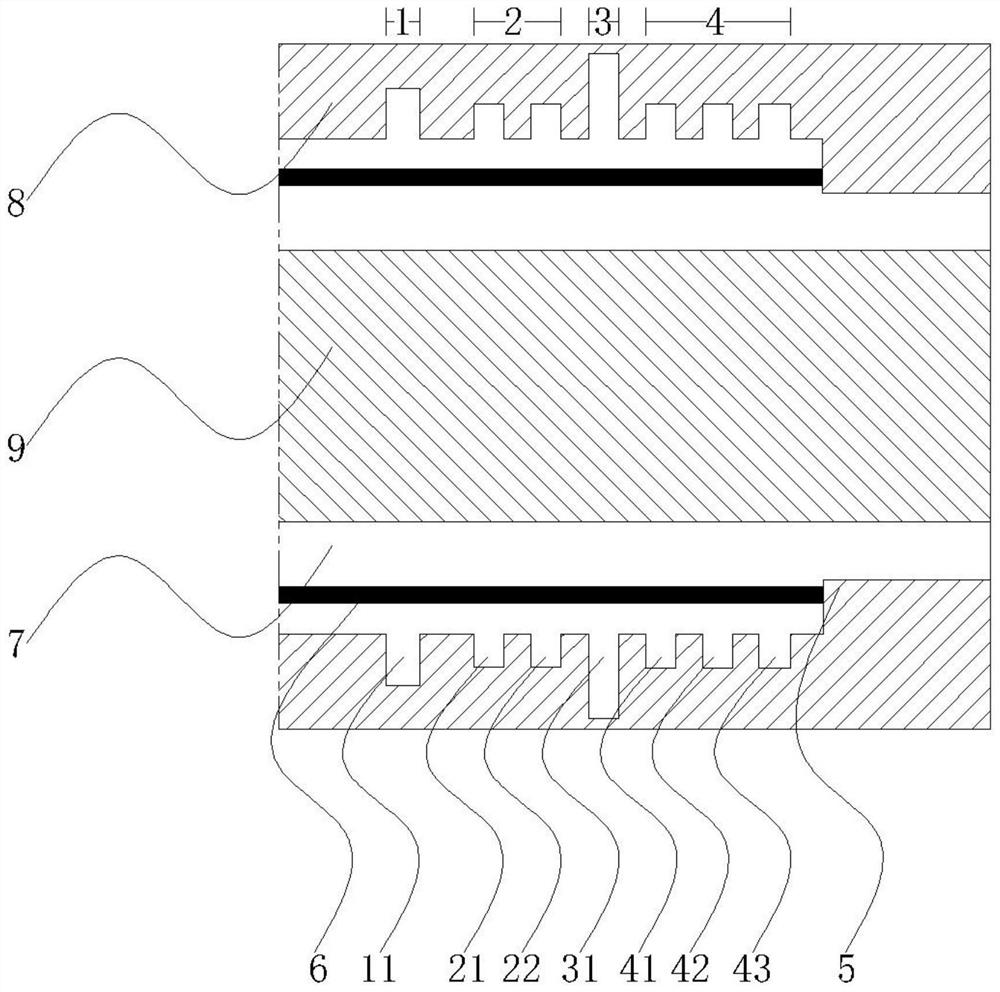

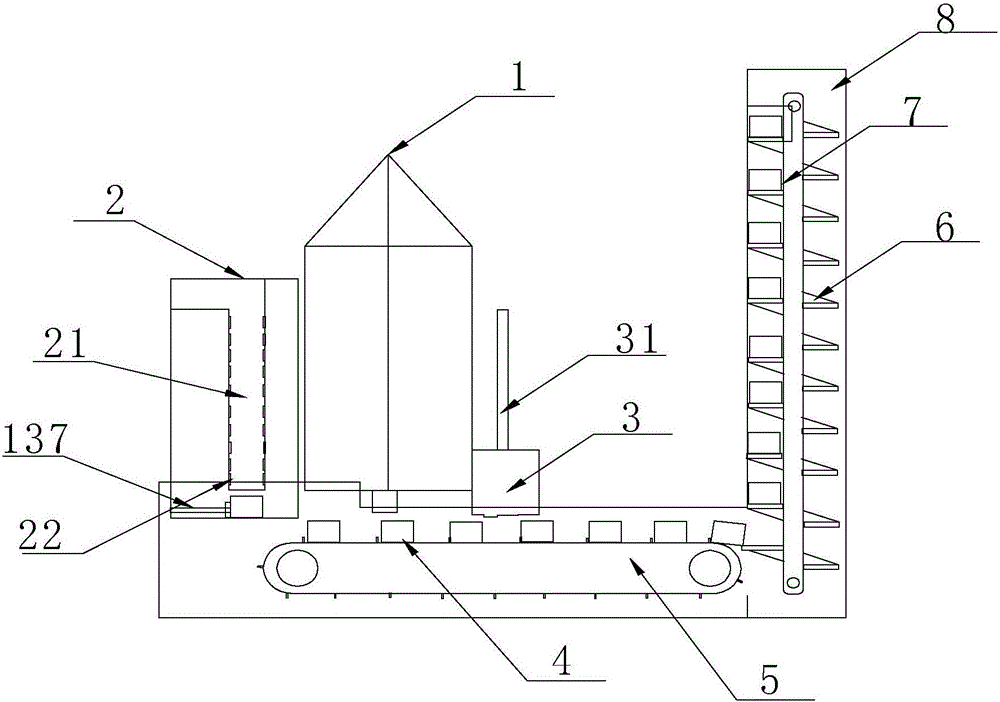

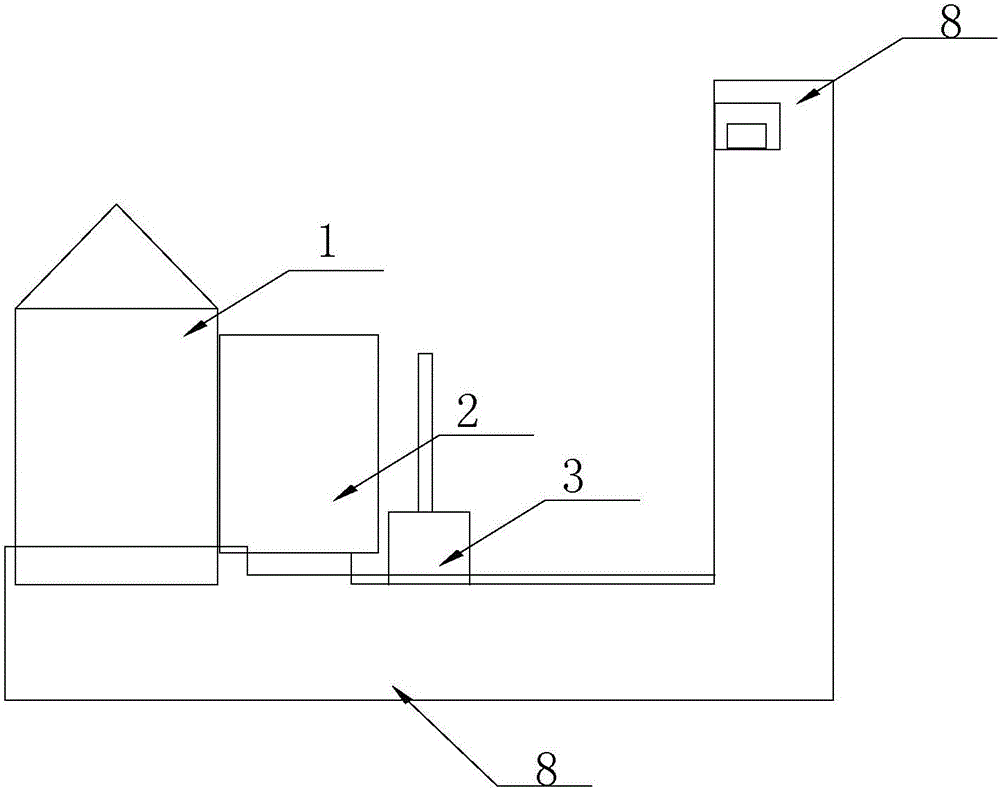

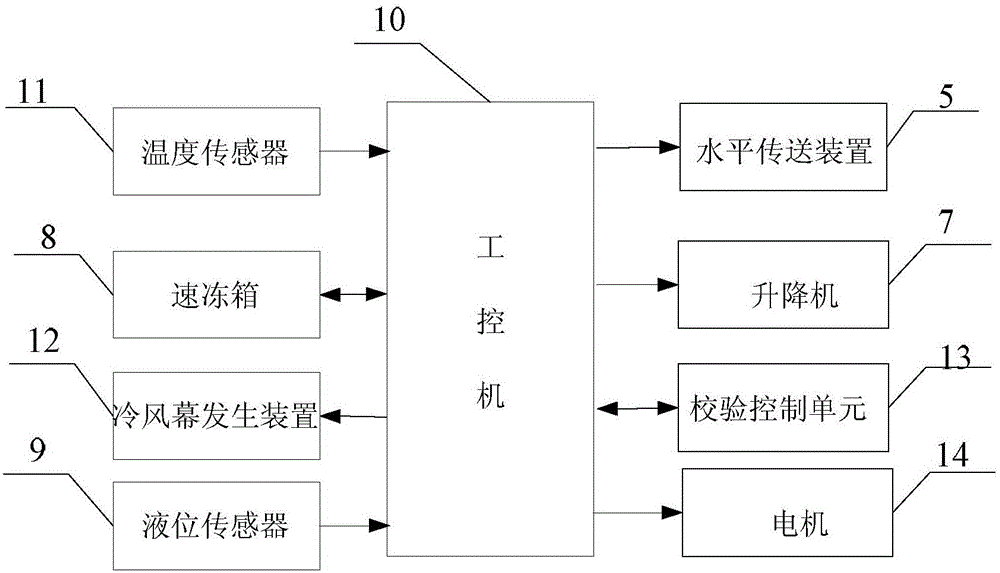

Livestock breading wastewater treatment device and method

ActiveCN106125580AAffect outputPromote growthProgramme control in sequence/logic controllersGrowth plantWastewater

A livestock breading wastewater treatment device and method are disclosed and relates to the technical field of livestock breading. The livestock breading wastewater treatment device and method can help solve a problem that currently livestock breading wastewater discharge causes environment pollution and leads to waste of organic fertilizer. According to the livestock breading wastewater treatment device and method, a wastewater collection tank is used for collecting livestock breading wastewater, a liquid level sensor is used for collecting height of liquid levels in the wastewater collection tank in real time, a stirring rod is used for stirring the wastewater in the wastewater collection tank in a timed manner, wastewater output can be prevented from being affected by deposition, a quick-freezing box is used for quickly freezing the wastewater held in a mould, a horizontal conveying device and an elevating machine are arranged in the wastewater collection tank, the horizontal conveying device is used for transversely conveying the mould, the elevating machine is used for upward transporting the mould, an auxiliary material spraying box is used for spraying plant growth facilitating microelements or matters that facilitate fast wastewater degradation in the wastewater in the mould in mould transporting processes, the mould is taken out and transported outward when the mould is transported to an opening of the quick-freezing box, and the livestock breading wastewater treatment device and method are suitable for treating livestock breading wastewater.

Owner:HEILONGJIANG ANIMAL HUSBANDRY RES INST

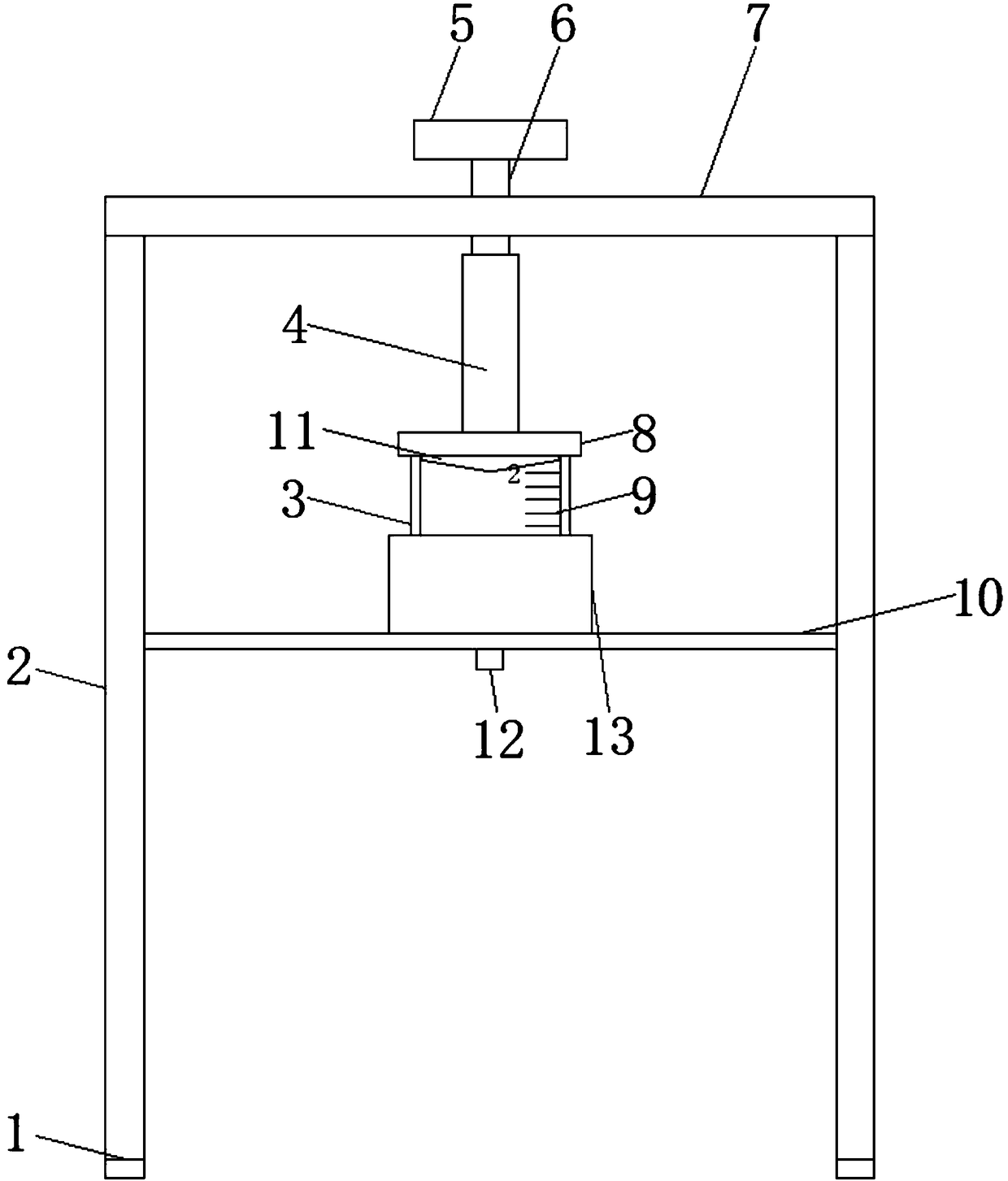

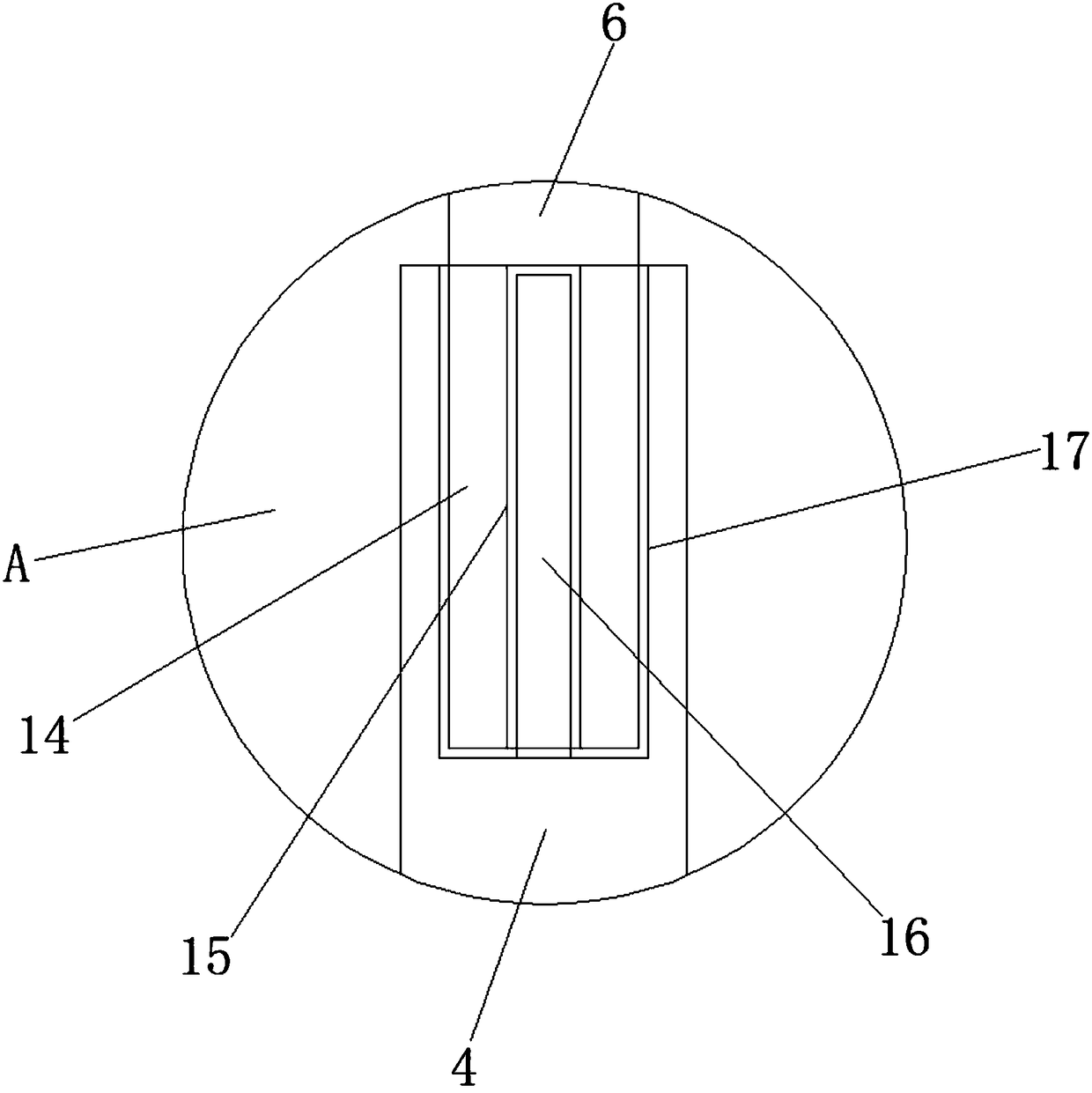

Spiral extrusion supplying device for biological product materials

The invention discloses a spiral extrusion supplying device for biological product materials. The spiral extrusion supplying device for the biological product materials comprises supporting posts, a burette, a top plate and a burette fixing plate. Antiskid blocks are installed at the bottom ends of the supporting posts, the top plate is welded to the top ends of the supporting posts, a threaded post is installed on the top plate in a penetrating mode, a rotary handle is welded to the top of the threaded post, a limiting block is arranged at the bottom end of the threaded post, and an insertinggroove is formed in the limiting block. A pushing rod is installed at the top end of a rubber plug, a limiting groove is formed in the top end face of the pushing rod, an inserting block is arrangedin the limiting groove, the threaded post and the pushing rod are fixed in an inserted mode through the inserting groove and the inserting block, a burette limiting block is welded to the top surfaceof the burette fixing plate, a titration port limiting hole is formed in the burette limiting block in a penetrating mode, the bottom end of the burette is provided with a titration port, and the burette and the burette fixing plate are installed in a limiting mode through the titration port and the titration port limiting hole. The spiral extrusion supplying device for the biological product materials has the advantage of being capable of controlling the dosage of titration supplying.

Owner:佛山市尚柏科技有限公司

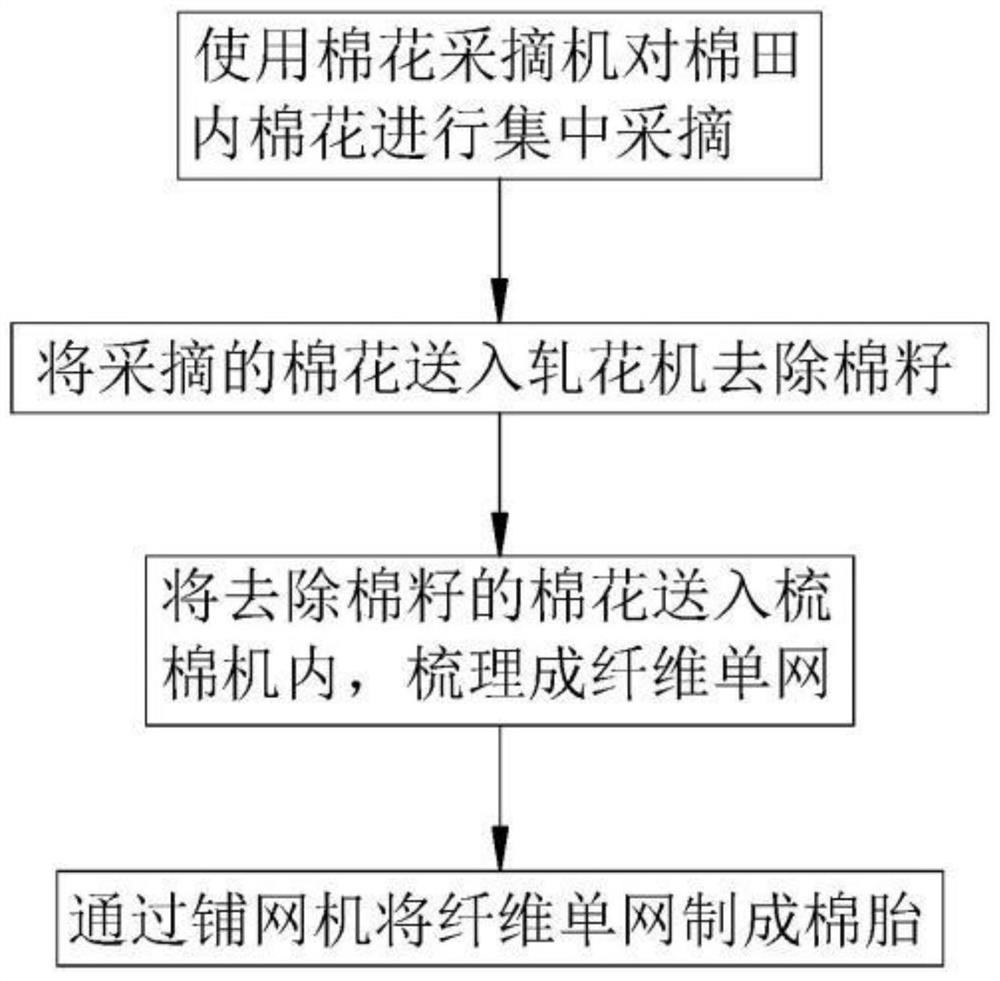

A kind of cotton batting production method

ActiveCN109197147BAvoid the reduction of picking efficiencyAvoid reducing cleaning and maintenance workloadNon-woven fabricsPicking devicesFiberStructural engineering

The invention belongs to the technical field of textile production, and specifically relates to a batting production method. The batting production method adopts a cotton picking machine. The cotton picking machine comprises a shell, a handle, a cotton collecting box, a fan and a picking module, wherein the shell is internally provided with the picking module; the picking module includes a rotating roller, steel needles, a comb plate, an arc-shaped block, a straight rack, an arc-shaped rack and a cutter; one side of the rotating roller is provided with the comb plate which is fixedly installedon the inner wall of the shell; the comb plate is used for stripping cotton on the steel needles; the steel needles are slidably installed on the rotating roller; the inner wall of the shell above the rotating shell is provided with the arc-shaped block; the arc-shaped block is used for compressing the steel needles; the movement of the steel needles can push the arc-shaped rack to move; the arc-shaped rack pushes the straight rack to move through a gear; and the straight rack pushes the cutter out of the rotating roller so as to cut cottons fibers around on the outer ring of each steel needle. The cotton fibers wound on the outer ring of each steel needle are cut through setting the cutter, thereby avoiding low picking efficiency caused by repeated winding of the cotton fibers, and reducing the cleaning and maintenance workload of the equipment at the same time.

Owner:绍兴纤逸纺织科技有限公司

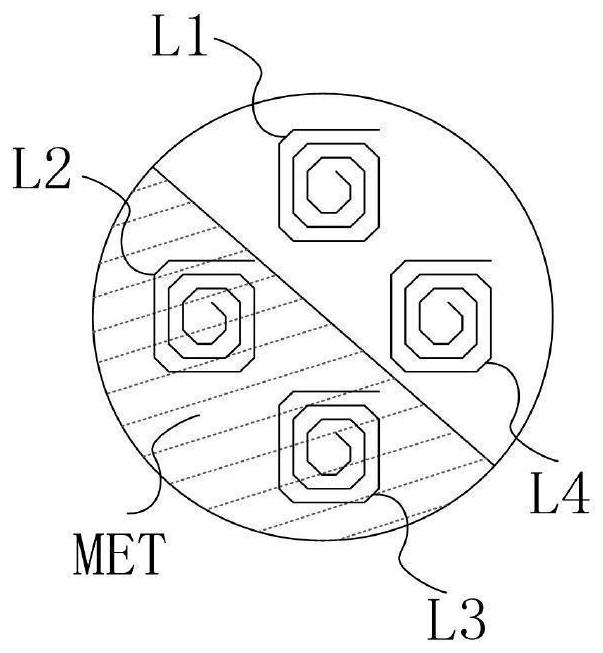

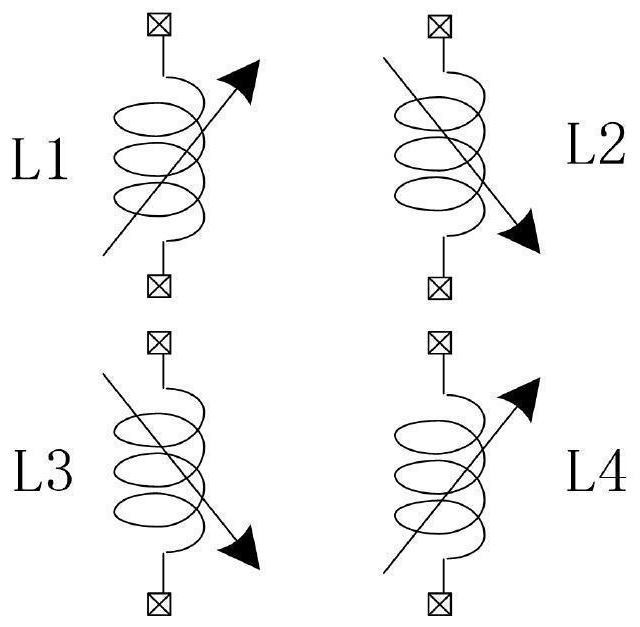

Self-excited coil induction angular position sensor and angular position detection method

PendingCN113932705ASmall sizeImprove detection distanceUsing electrical meansCoil inductanceEngineering

The invention discloses a self-excited coil induction angular position sensor and an angular position detection method. The angular position sensor comprises at least three induction coils, a coil inductance interference mechanism, at least one inductance detection circuit and an angular position acquisition circuit, wherein at least three induction coils form a coil group; the coil inductance interference mechanism is arranged on one side of the coil assembly, and when the induction coil is covered by the coil inductance interference mechanism, the inductance value corresponding to the induction coil changes; the inductance detection circuit is used for acquiring an inductance value of a set induction coil; and the angular position acquisition circuit is connected with the inductance detection circuit and is used for acquiring a rotation angle according to the change of the inductance value of each induction coil. According to the self-excited coil induction angular position sensor and the angular position detection method provided by the invention, a larger single induction coil size and an initial inductance value can be provided under the same area, so a higher detection distance can be provided.

Owner:深圳麦歌恩科技有限公司

Triboelectric nanogenerator and preparation method thereof

ActiveCN108123642BAffect outputSimple manufacturing processFriction generatorsNanogeneratorEngineering

The invention provides a friction nanogenerator and a manufacturing method thereof. The friction nanogenerator comprises a first friction unit and a second friction unit, wherein the first friction unit comprises a first magnetic part; the second friction unit is arranged oppositely to the first friction unit, the materials on the opposite surfaces of the two have different friction electrode orders, the second friction unit comprises a second magnetic part, the first magnetic part and the second magnetic part are arranged with the same poles corresponding; and relative movement between the first friction unit and the second friction unit is realized through same-pole repulsion. The friction nanogenerator provided in the invention has the advantages of stable output after long-time use, simple structure, safety and reliability, low cost, high output and simple manufacturing process.

Owner:BEIJING INST OF NANOENERGY & NANOSYST

Metering pump with special-shaped cavity

InactiveUS8974206B2Simple structureImprove reliabilityOscillating piston enginesSealing arrangement for pumpsSlide plateMetering pump

A metering pump with a special-shaped cavity comprising a housing, a rotor and two cover plates. The housing is a cylinder with a special-shaped surface inner cavity formed by combining two circular arc surfaces with two non-circular arc surfaces and a planar surface, an inlet and an outlet. The rotor comprises a rotor body and two pairs of combined sliding plates. The housing is matched with the cover plates for constituting a sealed cavity. When the rotor rotates, the non-circular arc surface of the special-shaped surface inner cavity can enable the two pairs of the combined sliding plates to slide in a cross manner so as to suck in fluid from the inlet and press out the fluid from the outlet. When the rotor rotates one cycle, four standard volumes are formed in a cavity body and the equal quantity of the fluid flows by the cavity body.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com